Abstract

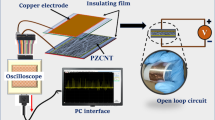

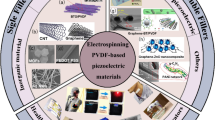

High-temperature stable eco-friendly energy-harvesting technologies are in high demand for industrial applications wherein piezoelectric energy harvesting is gaining interest. The present work describes a high-temperature stable electrospun nanofiber-based flexible piezoelectric nanogenerator (PENG). A lead-free piezoelectric filler potassium sodium niobate (KNN) is incorporated in polyetherimide (PEI) matrix through an electrospinning process. A polymeric solution of PEI in 1-methyl-2-pyrrolidone (NMP) solvent is prepared at a fixed concentration of 25 wt% and filler loading varied from 1 to 3%. Among the various percentages of KNN NRs, 2% KNN NRs @ PEI nanocomposite demonstrates the most promising results (voltage of 6.3 V and current of 0.60 μA). In addition, the flexible nanogenerator holds its piezoelectric performance even at very high temperatures (studied up to 250 ºC) without any significant deterioration in properties. Finally, the optimized piezoelectric nanogenerator (PENG) is used to charge capacitor and glow LED. Therefore, the flexible nanogenerator prepared with 2% KNN NRs @PEI has huge potential to be explored as piezoelectric sensors or energy harvesters in high-temperature stable applications wherein the conventional piezoelectric polymers like PVDF and other thermoplastics fail to sustain their piezoelectric response.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Surmenev RA, Orlova T, Chernozem RV et al (2019) Hybrid lead-free polymer-based nanocomposites with improved piezoelectric response for biomedical energy-harvesting applications: a review. Nano Energy 62:475–506. https://doi.org/10.1016/j.nanoen.2019.04.090

Meng Y, Chen G, Huang M (2022) Piezoelectric materials: properties, advancements, and design strategies for high-temperature applications. Nanomater 12:1171. https://doi.org/10.3390/NANO12071171

Palatnikov MN, Sandler VA, Sidorov NV et al (2020) Conditions of application of LiNbO3 based piezoelectric resonators at high temperatures. Phys Lett A 384:126289. https://doi.org/10.1016/J.PHYSLETA.2020.126289

Zhang S, Yu F (2011) Piezoelectric materials for high temperature sensors. J Am Ceram Soc 94:3153–3170. https://doi.org/10.1111/J.1551-2916.2011.04792.X

Boller C (2000) Next generation structural health monitoring and its integration into aircraft design. Int J Syst Sci 31:1333–1349. https://doi.org/10.1080/00207720050197730

Sheiretov Y, Grundy D, Zilberstein V et al (2009) MWM-array sensors for in situ monitoring of high-temperature components in power plants. IEEE Sens J 9:1527–1536. https://doi.org/10.1109/JSEN.2009.2019335

Bae JH, Chang SH (2019) PVDF-based ferroelectric polymers and dielectric elastomers for sensor and actuator applications: a review. Funct Compos Struct 1:012003. https://doi.org/10.1088/2631-6331/AB0F48

Mokhtari F, Cheng Z, Raad R et al (2020) Piezofibers to smart textiles: a review on recent advances and future outlook for wearable technology. J Mater Chem A 8:9496–9522. https://doi.org/10.1039/d0ta00227e

Bairagi S, Ali SW (2020) Poly (vinylidine fluoride) (PVDF)/Potassium Sodium Niobate (KNN) nanorods based flexible nanocomposite film: Influence of KNN concentration in the performance of nanogenerator. Org Electron 78:105547. https://doi.org/10.1016/j.orgel.2019.105547

Yu F, Lu Q, Zhang S et al (2014) High-performance, high-temperature piezoelectric BiB3O6 crystals. J Mater Chem C 3:329–338. https://doi.org/10.1039/C4TC02112F

Damjanovic D (1998) Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Reports Prog Phys 61:1267. https://doi.org/10.1088/0034-4885/61/9/002

Khanbareh H, Van Der Zwaag S, Groen WA (2014) Effect of dielectrophoretic structuring on piezoelectric and pyroelectric properties of lead titanate-epoxy composites. Smart Mater Struct 23:105030. https://doi.org/10.1088/0964-1726/23/10/105030

Khanbareh H, van der Zwaag S, Groen WA (2017) In-situ poling and structurization of piezoelectric particulate composites. J Intell Mater Syst Struct 28:2467–2472. https://doi.org/10.1177/1045389X17689928/ASSET/IMAGES/LARGE/10.1177_1045389X17689928-FIG6.JPEG

Khanbareh H, Hegde M, Bijleveld JC et al (2017) Functionally graded ferroelectric polyetherimide composites for high temperature sensing. J Mater Chem C 5:9389–9397. https://doi.org/10.1039/c7tc02649h

Jain A, Prashanth KJ, Sharma AK et al (2015) Dielectric and piezoelectric properties of PVDF/PZT composites: a review. Polym Eng Sci 55:1589–1616. https://doi.org/10.1002/PEN.24088

Egerton L, DILLON DM, (2018) Piezoelectric and dielectric properties of ceramics in the system potassium—sodium niobate. J Am Ceram Soc 42:438–442. https://doi.org/10.1111/j.1151-2916.1959.tb12971.x

Park C, Ounaies Z, Wise KE, Harrison JS (2004) In situ poling and imidization of amorphous piezoelectric polyimides. Polymer (Guildf) 45:5417–5425. https://doi.org/10.1016/j.polymer.2004.05.057

Tzounis L, Hegde M, Liebscher M et al (2018) All-aromatic SWCNT-Polyetherimide nanocomposites for thermal energy harvesting applications. Compos Sci Technol 156:158–165. https://doi.org/10.1016/j.compscitech.2017.12.030

Hegde M, Lafont U, Norder B et al (2013) SWCNT induced crystallization in an amorphous all-aromatic poly(ether imide). Macromolecules 46:1492–1503. https://doi.org/10.1021/ma302456h

Teka A, Bairagi S, Shahadat M et al (2018) Poly(vinylidene fluoride) (PVDF)/potassium sodium niobate (KNN)–based nanofibrous web: a unique nanogenerator for renewable energy harvesting and investigating the role of KNN nanostructures. Polym Adv Technol 29:2537–2544. https://doi.org/10.1002/pat.4365

Bairagi S, Ali SW (2019) Effects of surface modification on electrical properties of KNN nanorod-incorporated PVDF composites. J Mater Sci 54:11462–11484. https://doi.org/10.1007/s10853-019-03719-x

Bairagi S, Ali SW (2019) A unique piezoelectric nanogenerator composed of melt-spun PVDF/KNN nanorod-based nanocomposite fibre. Eur Polym J 116:554–561. https://doi.org/10.1016/j.eurpolymj.2019.04.043

Li X, Wang N, Fan G et al (2015) Electreted polyetherimide–silica fibrous membranes for enhanced filtration of fine particles. J Colloid Interface Sci 439:12–20. https://doi.org/10.1016/J.JCIS.2014.10.014

Han SO, Son WK, Cho D et al (2004) Preparation of porous ultra-fine fibres via selective thermal degradation of electrospun polyetherimide/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) fibres. Polym Degrad Stab 86:257–262. https://doi.org/10.1016/j.polymdegradstab.2004.04.015

Sato DM, Guerrini LM, De Oliveira MP et al (2018) Production and characterization of polyetherimide mats by an electrospinning process. Mater Res Express 5:115302. https://doi.org/10.1088/2053-1591/aadd85

Thakur Y, Zhang T, Iacob C et al (2017) Enhancement of the dielectric response in polymer nanocomposites with low dielectric constant fillers. Nanoscale 9:10992–10997. https://doi.org/10.1039/C7NR01932G

Thakur P, Kool A, Bagchi B et al (2015) In situ synthesis of Ni(OH)2 nanobelt modified electroactive poly(vinylidene fluoride) thin films: remarkable improvement in dielectric properties. Phys Chem Chem Phys 17:13082–13091. https://doi.org/10.1039/C5CP01207D

Gonçalves R, Martins PM, Caparrós C et al (2013) Nucleation of the electroactive β-phase, dielectric and magnetic response of poly(vinylidene fluoride) composites with Fe2O3 nanoparticles. J Non Cryst Solids 361:93–99. https://doi.org/10.1016/J.JNONCRYSOL.2012.11.003

Yang H, Zhang J, Lin Y, Wang T (2017) High Curie temperature and enhanced magnetoelectric properties of the laminated Li0058(Na0535K048)0942NbO3/Co06 Zn04Fe17Mn03O4 composites. Sci Rep 71(7):1–10. https://doi.org/10.1038/srep44855

Banerjee S, Bairagi S, Ali SW (2022) A lead-free flexible piezoelectric-triboelectric hybrid nanogenerator composed of uniquely designed PVDF/KNN-ZS nanofibrous web. Energy 244:123102. https://doi.org/10.1016/J.ENERGY.2022.123102

Selvarajan S, Alluri NR, Chandrasekhar A, Kim SJ (2016) BaTiO3 nanoparticles as biomaterial film for self-powered glucose sensor application. Sensors Actuators, B Chem 234:395–403. https://doi.org/10.1016/j.snb.2016.05.004

Karasawa J, Takaku H, Fukami T (1996) Localized polarization in strontium titanate crystal. Jpn J Appl Physics Part 1 Regul Pap Short Notes Rev Pap 35:5129–5131. https://doi.org/10.1143/jjap.35.5129

Dong K, Peng X, Wang ZL (2020) Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv Mater 32:1–43. https://doi.org/10.1002/adma.201902549

Hyeon DY, Lee GJ, Lee SH et al (2022) High-temperature workable flexible piezoelectric energy harvester comprising thermally stable (K, Na)NbO3-based ceramic and polyimide composites. Compos Part B Eng. https://doi.org/10.1016/j.compositesb.2022.109671

Dharmasena RDIG, Jayawardena KDGI, Mills CA et al (2017) Triboelectric nanogenerators: providing a fundamental framework. Energy Environ Sci 10:1801–1811. https://doi.org/10.1039/C7EE01139C

Kumar C, Perris J, Bairagi S et al (2023) Multiscale in-situ quantification of the role of surface roughness and contact area using a novel Mica-PVS triboelectric nanogenerator. Nano Energy 107:108122. https://doi.org/10.1016/J.NANOEN.2022.108122

Huan Y, Zhang X, Song J et al (2018) High-performance piezoelectric composite nanogenerator based on Ag/(K, Na)NbO3 heterostructure. Nano Energy 50:62–69. https://doi.org/10.1016/j.nanoen.2018.05.012

Acknowledgements

The authors are grateful to the Department of Science and Technology (DST), Government of India, for funding (Sanction Letter: DST/TDT/DDP-05/2018 (G) under Device Development Program) this research work. Finally, the authors would like to thank Central Research Facility (CRF), IIT Delhi, for different characterization facilities.

Author information

Authors and Affiliations

Contributions

SR contributed to formal analysis, data curation, writing original draft, and editing. AC contributed to formal data analysis. MJ contributed to reviewing and editing. WA contributed to conceptualization, project administration, review, and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

No experiments involving human tissue are conducted in the current study.

Additional information

Handling Editor: Jean-Francois Gohy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Roy, S., Chowdhury, A., Joshi, M. et al. Flexible and high-temperature stable nanofiber composite made of PEI/KNN for energy harvesting. J Mater Sci 59, 171–187 (2024). https://doi.org/10.1007/s10853-023-09156-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09156-1