Abstract

The fabrication of advanced oil/water separation materials with integrated properties of mechanical robust, high efficiency, and low cost is a long-standing challenge. O-SM/ALG (octadecylamine modified silk microfibers/calcium alginate) sponges were synthesized in this paper through a facile process. The as-fabricated O-SM/ALG sponges possess interconnected porous structure, high mechanical durability, hydrophobicity, and lipophilicity that favored for oil/water separation. As oil absorbents, the O-SM/ALG sponges displayed excellent water repellence, exhibited high absorption capacity for various oils and organic solvents (the saturated absorption capacity was 13.1–24.6 times of its own weight), and showed good recyclability (reused > 20 cycles with remained high absorption efficiency). Furthermore, the O-SM/ALG sponges could also be applied as a filter to effectively and selectively separate oils from the oil/water mixture, being a promising candidate for the treatment of oily wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid development of modern industry continuously demands oil, thus accompanies the production of massive oily wastewater and oil-spill accidents. These oil spills cause severe damage to the environment and ecosystems. Therefore, it is essential to develop biocompatible materials-based adsorbents to eliminate oil pollutants and realize oil/water separation [1,2,3].

Biomaterials (e.g., silk fibroin, gelatin, cellulose, alginate, chitosan, and wool) derived sponges have been extensively explored in various fields including wound healing, tissue engineering, drug delivery, cellular behaviors directing, oil/water separation, wastewater treatment, catalysis, and energy storage, due to their incredible advantages such as controllable pore size, three-dimensional porous structure, high absorption capability, wide resource, biocompatibility, biodegradability, non-toxicity, chemical reactivity, and biological properties [4,5,6,7,8]. Especially for the application of oil/water separation, aside from the above advantages, biomaterials derived sponges usually exhibit good environmental friendliness, convenient preparation process, structural stability, recyclability, and high absorption capability, being ideal substrates for efficient oil/water separation [4, 9]. For example, biomimetic superelastic sodium alginate-based sponges are suitable for the separation of oil/water mixture and simultaneous removal of water-miscible contaminant with high efficiency [10]; nanocellulose sponges own high absorption capacity for various kinds of oils and nonpolar liquids, and exhibited good separation selectivity for oil/water mixture [11]. Among these, a sustainable biomaterial, silk fibroin that isolated from Bombyx mori, attracted attention. Silk fibroin has multiple functional groups that favor chemical modification, the robust mechanical property also promises silk fibroin possibilities both as substrates and reinforcements to fabricate various material formats [12]. For example, surface modified silk cocoon-derived sponges exhibit high cleaning ability for oil contaminate through selective absorption and filtration [13].

To realize the selective separation of oil from water, the sponges should be hydrophobic and oleophilic. However, plenty of the biomaterials derived sponges show intrinsic hydrophilic property, barely applicable in oil/water separation. Facile methods (e.g., dip coating, chemical vapor deposition, in situ chemical reaction, and carbonization) for the surface modification of the biomaterials derived sponges are developed to tune the hydrophilic sponges surface into hydrophobic [14]. Wet chemical reaction is a relatively convenient method for hydrophobic modification, because most of the biomaterials present multiple functional groups on their skeletons that preferable to execute chemical reaction. Additionally, the chemically modified sponges own high structure uniformity, hardly suffer from the change of chemical properties during multiple cycles of usage. Silylation grafting, incorporation of inorganics, and alkanes grafting are generally used to increase the hydrophobicity of biomaterials derived sponges [15]. For example, silk fibroin fibers were surface modified by octadecylamine to realize a superhydrophobic character (static water contact angle of 150°), and showed both excellent selectivity and high oil sorption ability [16]; homogeneous interpenetrated superhydrophobic/oleophilic polymethylsilsesquioxane-silk fibroin hybrid aerogels exhibited high performance for continuous water/oil separation through filtration [17]; silylated wood sponges showed excellent oil/water absorption capacity with high selectivity, an oil-collecting device was successfully designed to continuously separate contaminants from water [18].

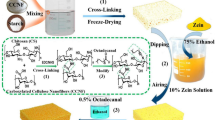

Based on these, to fabricate efficient and environmentally friendly oil/water separation sponges that derived from biomaterials, herein, silk microfibers (SM), and calcium alginate (ALG) were conjunct together and surface modified to fabricate a composite sponge. SM was dipped into sodium alginate solution, and ALG deposited on SM to fabricate SM/ALG sponges by cross-linking reaction between sodium alginate and Ca2+. ALG usually suffers from weak mechanical properties [3], thus SM was introduced to provide mechanical support to the composite sponges. After the hydrophobic modification of SM/ALG to form O-SM/ALG sponges, the morphology, physicochemical properties, as well as the oil absorption and separation capacity of the O-SM/ALG sponges were systematically studied to evaluate their possibility as oil absorbents.

Experimental

Materials

Bombyx mori cocoon was bought from Ankang City (Shanxi, China). Sodium alginate was bought from Shanghai Macklin Biochemical Co., Ltd. Dipentaerythritol penta-/hexa-acrylate (DTA) was bought from Shanghai Macklin Biochemical Co., Ltd. Octadecylamine was acquired from Shanghai Aladdin Biochemical Technology Co., Ltd. Polydimethylsiloxane was purchased from Tianjin Dingshengxin Chemical Co., Ltd. Toluene was purchased from Yantai Yuandong Fine Chemical Co., Ltd. Vacuum pump oil was obtained from Ningbo Jiangbei Lianya Lubricating Oil Co., Ltd. Olive oil was obtained from Beijing Pinli Food Co., Ltd. Peanut oil was obtained from COFCO Fulinmen Food Marketing Co., Ltd. Other reagents such as NaHCO3, cyclohexane, dichloromethane, Sudan III, methylene blue, and methyl blue were obtained from Sinopharm Chemical Reagent Co. Ltd., China.

Preparation of SM/ALG sponges

Bombyx mori cocoon was degummed twice in the boiling NaHCO3 (0.5 wt.%) solution for 30 min, thoroughly washed in deionized water, and dried at 50 °C to get the silk microfibers (SM). Fixed amount of SM (30, 60, 90, and 120 mg) was packed in a cylindrical plastic mold and compressed to a volume of 1 cm3. 1 mL of sodium alginate solution (0.5, 1, 2, 5, and 10 mg/mL) was then added, and the mixture was sprayed with 2 M of CaCl2 solution to form sponges. The as-synthesized sponges were taken out, immersed and washed in H2O to get the SM/ALG sponges. The SM/ALG sponges were denoted as SMx/ALGy according to the mass of SM (x, mg) and the concentration of sodium alginate (y, mg/mL) used to fabricate the sponges. The sample name of SMx/ALGy sponges as well as the mass ratio of SM and sodium alginate were listed in Table 1.

Surface modification of SMx/ALGy sponges

The SMx/ALGy sponges were solvent replaced to ethanol, vibrated in DTA solution (dissolved in ethanol, 133 mg/mL) for 24 h, and thoroughly washed by ethanol. Then the as-gained sponges were solvent replaced into tetrahydrofuran, vibrated in octadecylamine solution (dissolved in tetrahydrofuran, 5 mg/mL) for 24 h, thoroughly washed by tetrahydrofuran, and dried at room temperature to get the octadecylamine modified SMx/ALGy sponges (denoted as O-SMx/ALGy).

Characterization

The morphology was characterized by a scanning electron microscopy (SEM, JEOL 7401, Japan) at an acceleration voltage of 10 kV, the sponges were Pt-sputtered before measurement. FTIR analyses were performed on a Nicolet iS50 Fourier transform infrared spectrometer (Thermo Electron, USA). Contact angle was measured on a CA100D contact angle measurement instrument (Shanghai Innuo Precision Instruments Co., Ltd), at least three regions of each sample were measured to calculate an average value.

Absorption Capacity of the O-SMx/ALGy sponges

The absorption capacity of the O-SMx/ALGy sponges was measured in various organic solvents including peanut oil (0.9279 g/cm3), olive oil (0.9176 g/cm3), vacuum pump oil (0.9074 g/cm3), toluene (0.865–0.869 g/cm3), polydimethylsiloxane (0.966–0.974 g/cm3), cyclohexane (0.778–0.779 g/cm3), dichloromethane (1.320–1.330 g/cm3), and chloroform (1.471–1.484 g/cm3). O-SMx/ALGy sponges with the same volume size (weighed m0) were immersed in 30 mL of organic solvents for 5 min to reach absorption equilibrium, then the O-SMx/ALGy sponges were taken out, drained for 30 s until no redundant organic solvent dripped off, and weighted (m). The absorption capacity was calculated as: capacity = (m − m0)/m0 × 100%. Cyclic absorption capacities were measured by squeezing the sponges manually to remove the organic solvents.

Oil/water separation by absorption

1 mL of dichloromethane was mixed with 15 mL of H2O. The O-SMx/ALGy sponges were placed at the dichloromethane/water interface to absorb the dichloromethane, after which the sponges were squeezed manually to re-collect the dichloromethane. The separation of cyclohexane/water was conducted in a similar way. The oils were dyed with Sudan III for better visual observation.

Oil/water separation by filtration

The O-SMx/ALGy sponges were served as filter layers (thickness: ~ 3.5 mm) to separate oil/water mixtures by gravity. A piece of O-SMx/ALGy sponge was fixed in a simple oil/water separation device reformed from a syringe, then the mixture of oil and water (15 mL of oil and 5 mL of water) was poured into the device and permeated through the sponge. Dichloromethane/water and cyclohexane/water were tested. The water was dyed with methylene blue and oil was dyed with Sudan III for better visual observation.

Results and discussion

The scheme for the fabrication process of the hydrophobic sponges is described in Fig. 1a. Through a frequently-used method, silk microfibers (SM) were obtained by degumming the silkworm cocoon in 0.5% NaHCO3. SM own advantages including low cost, good mechanical strength, easy modification, and excellent environmental friendliness, perfect as skeleton matrix for composite sponges. The SM/ALG sponges were then fabricated by immersing the SM into the aqueous solution of sodium alginate, following by the ionically cross-linking by Ca2+ to form calcium alginate (ALG). Then, octadecylamine was decorated onto the surface of the SM/ALG sponges with the assistance of dipentaerythritol penta-/hexa-acrylate (DTA) to form the hydrophobic O-SM/ALG sponges. SEM images exhibited that the pristine SM owned smooth surfaces, the incorporation of ALG led to nanosheets attached on the surface of SM (Fig. 1b, c). The cross-linking of DTA and the following decoration of octadecylamine resulted in much rougher surfaces due to the uniformly location of octadecylamine on the skeleton of the sponges, which counted for the hydrophobic property of the composites (Fig. 1d, e). Besides, all the samples had inter-connective three-dimensional porous network structures that favor for oil absorption.

The O-SM/ALG sponges exhibited good mechanical strength. As shown in Fig. 2a, the sponges with different shapes can be directly formed in different molds. Additionally, the drying process did not cause adverse impact on the mechanical strength of the O-SM/ALG sponges, the sponges remained their structural integrity after drying at room temperature (Fig. S1). The O-SM/ALG sponges also displayed excellent flexibility and compressibility (Fig. 2b, c), they can be bended without showing any visible damage, and can be almost completely recovered (> 93% of its initial height) after sustaining a large compression deformation. Octadecylamine was bind to SM/ALG with the help of DTA, thus would not fall off from the sponges during mechanical deformation, promising good durability for oil absorption. FTIR spectrum of the O-SM/ALG sponge exhibited enhanced characteristic peak intensities of C=O stretching vibration at 1741 cm−1 and peaks of C–H stretching vibrations at 2916 and 2853 cm−1, which confirmed the successful decoration of DTA and octadecylamine on the surface (Fig. 2d).

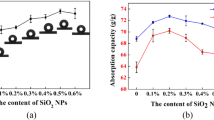

Next, the hydrophobicity of the O-SM/ALG composite sponges was evaluated by measuring the water contact angle (Fig. 3). All the samples exhibited contact angles in the range of 131°–140°, varied very gently by the difference of the ratio of SM and ALG, indicating that all the O-SM/ALG composite sponges were hydrophobic and the hydrophobicity was mainly determined by the surface decoration of octadecylamine.

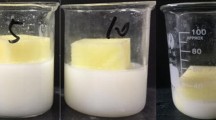

The hydrophobicity of the O-SM/ALG sponges promised their good oil/water separation ability. Before the surface decoration of octadecylamine, as shown in Fig. 4a, the unmodified SM/ALG sponges absorbed both water (methylene blue staining) and oil (Sudan III staining) with no differential. In contrast, water droplets can hold their spherical shape and stand steadily on the surface of a hydrophobic O-SM/ALG sponge (Fig. 4b), while oil droplets were completely absorbed into the sponge, confirming that the sponge was dramatically transformed from amphiphilic to hydrophobic after surface modification. Additionally, octadecylamine was well-distributed in the structure of O-SM/ALG sponges, the inner sides (cross-sectional surface) of the composite sponges exhibited water repellency hardly different from the outer surface (Fig. 4c).

a Droplets of peanut oil (dyed with Sudan III) and water (dyed with methylene blue) on the surface of a SM60/ALG0.5 sponge. b Droplets of peanut oil (dyed with Sudan III) and water (dyed with methylene blue) on the surface of a O-SM60/ALG0.5 sponge. c Photograph of the cross-sectional surfaces of O-SM60/ALG0.5 sponge to examine the water-repellent property in the bulk of the sponge. d A SM60/ALG0.5 sponge and a O-SM60/ALG0.5 sponge in H2O. e A O-SM60/ALG0.5 sponge was immersed into H2O by external force. f A O-SM60/ALG0.5 sponge was immersed into cyclohexane by external force. g Photographs of a manual compression-decompression process of a O-SM60/ALG0.5 sponge, with a water droplet (dyed using methyl blue) on the surface

Due to the light weight and hydrophobicity, the O-SM/ALG sponges can float at the water–air interface (Fig. 4d), while the unmodified SM/ALG sponges sank below the water surface. When the O-SM/ALG sponges were forced into the water by an external force, lots of air bubbles can be seen on the surface of the sponge because of its hydrophobicity (Fig. 4e) [19, 20], in sharp contrast to their sinking in the cyclohexane (Fig. 4f). Meanwhile, the hydrophobicity of the O-SM/ALG sponges was not affected by the mechanical deformation, a water droplet can keep its spherical shape on the surface during the compression (Fig. 4g), indicating the ability of sponges to bear mechanical forces while retaining water repellency. As a result, the O-SM/ALG sponges showed good mechanical properties, lipophilicity, and hydrophobic properties, demonstrating potential applications in oil/water separation.

The oil absorption capability of the O-SM/ALG sponges was first evaluated using olive oil as a model oil. The absorption capability was greatly affected by the components of the composites. As shown in Fig. 5, the absorption capacity decreased accompanied by the increase in the sponge density, higher addition amount of both SM and ALG would lead to lower oil absorption capability, which may because higher concentration of raw materials increased the unit weight of sponges while decreased their pore size, thus left insufficient space for oil transmission. For example, a O-SM30/ALG0.5 sponge had the highest absorption capacity and showed an absorption capacity of 2680% for olive oil, the O-SM60/ALG2 sponge had an absorption capacity of 978%, while the O-SM120/ALG10 sponge had a low absorption capacity of 358%.

The O-SM/ALG sponges exhibited high absorption capacities for various oils and solvents, and can absorb oils 13.1–24.6 times of its own weight depending on the density of the oils (Fig. 6a). As shown in Table S1, the absorption capacity was comparable to some of the previously reported materials. For example, the maximum absorption amount of O-SM60/ALG0.5 sponges for chloroform, dichloromethane, and peanut oil was 24.6, 21.9, and 17.3 times of its own weight, respectively, confirmed their good absorption ability. Nevertheless, the O-SM/ALG sponges possessed excellent reusability (Fig. 6b). After 20 times of consecutive squeezing-absorption, the absorption capacity of the hydrophobic sponges did not decrease, the absorption capacities of O-SM60/ALG0.5 sponges for vacuum pump oil and dichloromethane can still remain 2118% and 2186%, respectively, beneficial for reducing the absorbent cost in practical applications. Additionally, after 20 times of squeezing-absorption, the O-SM60/ALG0.5 sponges maintained its skeleton structure without visible morphology change, as shown in Fig. S2, there was neither crack nor fragment appeared, proving their good durability for oil/water separation.

The O-SM/ALG sponges were able to quickly absorb low-density cyclohexane and high-density dichloromethane in water (Fig. 7). When the O-SM/ALG sponges were placed in oil/water mixtures, both oils can be selectively and completely collected. The O-SM/ALG sponge floated on the water surface after the absorption of cyclohexane because of the low density, and can be directly reused by taking out and squeezing. Similarly, when the sponge was forced into water to contact with the dichloromethane at the bottom, dichloromethane was quickly and completely absorbed, while no water is absorbed, and no dichloromethane was left in the water after the sponge was taken out, exhibiting good oil absorption and oil/water separation ability.

Moreover, the O-SM/ALG sponges could be applied for the continuous separation of oil/water mixture (Fig. 8). Both light oil/water and heavy oil/water mixture can be completely and efficiently separated though a filtration process using a thin layer of O-SM/ALG sponges as filter membrane. Although the sponges had inter-connective porous structure, due to the excellent water proof performance of the sponges, water would not pass through the sponges after the oil was separated.

Conclusion

In summary, O-SM/ALG sponges were fabricated with attractive features including interconnected porous structure, mechanical durability, hydrophobicity (water contact angle of 131°–140°), and lipophilicity. The O-SM/ALG sponges exhibited high absorption capacity for various oils and organic solvents (the saturated absorption capacity was 13.1–24.6 times of its own weight), good stability, and recyclability (the absorption capacity remained basically unchanged after 20 cycles) as biomass-derived oil-absorbing materials. The O-SM/ALG sponges can selectively remove oils from oil/water mixtures, demonstrates great potential for effective separation of oils in practical applications.

References

Gore PM, Naebe M, Wang X, Kandasubramanian B (2022) J Hazard Mater 426:127822. https://doi.org/10.1016/j.jhazmat.2021.127822

Zhou J, Zhang Y, Yang Y, Chen Z, Jia G, Zhang L (2019) Appl Surf Sci 497:143762. https://doi.org/10.1016/j.apsusc.2019.143762

Liu Q, Liu Y, Feng Q, Chen C, Xu Z (2023) J Hazard Mater 441:129965. https://doi.org/10.1016/j.jhazmat.2022.129965

Sam EK, Liu J, Lv XM (2021) Ind Eng Chem Res 60:2353–2364. https://doi.org/10.1021/acs.iecr.0c05906

Zhang HQ, Jin Y, Chi C et al (2021) Biomaterials 273:120824. https://doi.org/10.1016/j.biomaterials.2021.120824

Guo B, Dong R, Liang Y, Li M (2021) Nat Rev Chem 5:773–791. https://doi.org/10.1038/s41570-021-00323-z

Lerdchai K, Kitsongsermthon J, Ratanavaraporn J, Kanokpanont S, Damrongsakkul S (2016) J Pharm Sci 105:221. https://doi.org/10.1002/jps.24701

Patil PP, Reagan MR, Bohara RA (2020) Int J Biol Macromol 164:4613–4627. https://doi.org/10.1016/j.ijbiomac.2020.08.041

Hadji EM, Fu B, Abebe A, Bilal HM, Wang J (2020) Front Chem Sci Eng 14:749. https://doi.org/10.1007/s11705-019-1890-4

Yang J, Chen Y, Gao K et al (2021) Carbohydr Polym 272:118527. https://doi.org/10.1016/j.carbpol.2021.118527

Phanthong P, Reubroycharoen P, Kongparakul S et al (2018) Carbohydr Polym 190:184–189. https://doi.org/10.1016/j.carbpol.2018.02.066

Gore PM, Naebe M, Wang X, Kandasubramanian B (2019) Chem Eng J 374:437–470. https://doi.org/10.1016/j.cej.2019.05.163

Shome A, Moses JC, Rather AM, Mandal BB, Manna U (2021) ACS Appl Mater Interfaces 13:24258–24271. https://doi.org/10.1021/acsami.1c03150

Peng M, Zhu Y, Li H et al (2019) Chem Eng J 373:213–226. https://doi.org/10.1016/j.cej.2019.05.013

Fürtauer S, Hassan M, Elsherbiny A, Gabal SA, Mehanny S, Abushammala H (2021) Polymers 13:2739

Patowary M, Pathak K, Ananthakrishnan R (2016) RSC Adv 6:73660–73667. https://doi.org/10.1039/c6ra14723b

Maleki H, Whitmore L, Hüsing N (2018) J Mater Chem A 6:12598–12612. https://doi.org/10.1039/c8ta02821d

Guan H, Cheng ZY, Wang XQ (2018) ACS Nano 12:10365–10373. https://doi.org/10.1021/acsnano.8b05763

Guo Z, Long B, Gao S et al (2021) J Hazard Mater 402:123838. https://doi.org/10.1016/j.jhazmat.2020.123838

Wu X, Lei Y, Li S et al (2021) J Hazard Mater 403:124090. https://doi.org/10.1016/j.jhazmat.2020.124090

Acknowledgments

This work was supported by Talent Foundation funded by Province and Ministry Co-construction Collaborative Innovation Center of Eco-chemical Engineering (No. STHGYX2206).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, S., Liu, K. & Wu, X. Composite sponges fabricated by silk fibers and alginate for efficient oil/water separation. J Mater Sci 58, 457–465 (2023). https://doi.org/10.1007/s10853-022-08030-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08030-w