Abstract

Hybrid organic–inorganic nanocomposites are great candidates for display and illumination systems due to improved optoelectronic properties and photostability. This work endeavours towards the scientific study of the influence of defect-induced zinc oxide nanoparticles (ZnO) on the optical characteristics of poly[2-methoxy-5-(2′-ethylhexyloxy)-1,4-phenylenevinylene] (MEH-PPV). ZnO nanoparticles consist of many vacancies which facilitate light emission across the visible region. The green defective emission occurring due to the presence of oxygen vacancies in ZnO was used to re-excite MEH-PPV and hence, improve the luminescence quantum efficiency. The photostability of the nanocomposite was enhanced through charge transfer (prevents the formation of superoxides) and energy transfer (reduces the non-radiative decay) mechanisms.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymer light-emitting diodes (PLEDs) have opened new potential applications in flexible displays and various lighting designs because of their high-luminescence efficiency, wide-viewing angle, full colour/large-area display, lightweight nature, transparency and low power consumption [1, 2]. Thus, PLEDs have excellent features and versatile applications particularly because of the solution processability and interesting photophysical properties of light-emitting polymers (LEPs) used as the emissive layer in the device. In general, LEPs are highly unstable and undergo rapid degradation when exposed to an ambient environment due to attack of moisture, oxygen and light [3]. Despite the substantial progress, improvement in the lifetime remains a challenge. Additionally, the majority of LEPs are p-type materials which hinder the charge carrier balance in the device [2]. Efficient charge transport, electron–hole balance and recombination of excitons in the emissive layer are significant for improving the efficiency of PLEDs [4]. The charge carrier transport and electron–hole balance can be obtained by introducing n-type nanoparticles into the polymer matrix [5] which is also reported to enhance the device lifetime [6]. When the ratio of the charge carriers in the emissive zone is appropriately balanced, the luminescence efficiency and device stability can be considerably improved. Hence, for these reasons, nanocomposite materials consisting of LEPs and inorganic nanoparticles have gained great interest in various optoelectronic applications [7,8,9]& [10].

The most applicable nanoparticle used in various optoelectronic devices is zinc oxide (ZnO), which is a II–VI semiconductor metal oxide [11]. ZnO is a direct bandgap (3.37 eV) material with a large exciton binding energy (60 meV) and high thermal stability [12]. Generally, ZnO nanoparticles consist of a large number of intrinsic and extrinsic defects which facilitate light emission across the visible region [13]. The renewed interest in utilizing the defective levels of ZnO nanoparticles in improving the photoluminescence efficiency and photostability of the LEP, poly[2-methoxy-5-(2′-ethylhexyloxy)-1,4-phenylenevinylene] (MEH-PPV) is the main focus of this article.

Nanocomposite based on MEH-PPV and ZnO nanoparticles is widely studied for their intriguing optoelectronic properties. This type II heterostructure nanocomposite has gained enormous attention due to its low cost, wet chemical processing on the flexible substrate and strong absorption properties [14, 15]. Hence, MEH-PPV/ZnO nanocomposite finds application in device fabrication of organic light-emitting diodes (OLEDs) [16], organic photovoltaics (OPVs) [17], sensors and transistors. Skoda et al. investigated the effect of colloidal ZnO nanocrystals of varied sizes on the properties and efficiency of PLEDs with MEH-PPV/ZnO as an emissive layer [18]. Aleshin examined the concentration effect of ZnO nanoparticles on optoelectronic properties of MEH-PPV/ZnO and PFO/ZnO nanocomposites [14]. Yahya and Rusop studied the optical and morphological properties of MEH-PPV containing different wt% of ZnO nanoparticles [19]. Jetson et al. investigated the influence of surface-modified ZnO on the fluorescence properties of MEH-PPV/ZnO nanocomposite [15]. Periyayya et al. reported an improvement in luminescence properties of conjugated polymers (Alq3, Flu and PCB) with the incorporation of higher carrier property ZnO nanoparticles where radiative recombination was enabled by singly ionized oxygen vacancies [20]. Musa et al. also reported improvement in the luminescence efficiency of MEH-PPV/ZnO nanocomposite at low wt% of ZnO due to energy transfer from defective levels of ZnO to MEH-PPV [21]. Hence, it is understood that morphology and defective states of ZnO have influenced the photophysical properties of conjugated polymers to a large extent at various concentrations. Among them, there is very scarce work reported on the influence of defective electronic bands of ZnO nanoparticles on the properties of the conjugated polymer. Till date, there is not much detailed work reported on the role of oxygen vacancies in ZnO nanoparticles in affecting the photophysical properties and photostability of MEH-PPV. Henceforth, this article examines the effect of defective states of ZnO nanoparticles on the optoelectronic properties of MEH-PPV/ZnO nanocomposite. It presents the properties of MEH-PPV/ZnO hybrid nanocomposite obtained by incorporating defective and relatively defect-free ZnO nanoparticles. The nanocomposite prepared using defective ZnO displayed six times improvement in luminescence quantum efficiency in comparison with nanocomposites prepared using defect-controlled ZnO. Additionally, the stability of MEH-PPV was also improved with the incorporation of defective ZnO nanoparticles. Thus, this work reports that the vacancies in ZnO nanoparticles facilitate the enhancement of luminescence intensity, conductivity and photostability of MEH-PPV using defective ZnO nanoparticles which act as good electron transport material and light stabilizer.

Experimental section

ZnO nanoparticles were prepared through the sol–gel technique as explained elsewhere [13]. The preparation scheme of defect-controlled and defective ZnO is given in supplement S1. The structural, morphological and photophysical characterization of prepared ZnO nanoparticles is provided in supplement S2, S3 and S4, respectively. MEH-PPV polymer was synthesized through the Gilch route process [22, 23]. The reaction scheme is given in our previous work [24]. Initially, the hybrid nanocomposites were prepared through in situ polymerization scheme by incorporating 3 wt% ZnO nanoparticles (defective/defect-controlled). The process of in situ polymerization is detailed in our previous work [25]. The pictorial representation of the in situ polymerization process is given in Fig. 1.

Characterization techniques

Fourier transformed infrared (FTIR) spectra of hybrid nanocomposites were acquired using IRAffinity-I (Shimadzu) with the wavenumber ranging from 400 to 4000 cm−1. The absorbance spectra of the polymeric solutions with 10–4 mg mL−1 concentration were acquired using a u-2900 spectrophotometer (Hitachi). The steady-state emission spectra and kinetics of fluorescence decay were obtained through a Fluorolog FL3-11 spectrofluorometer (Horiba Instruments) with a 450-Watt xenon lamp as the excitation source. Time-resolved photoluminescence (TRPL) was measured with a double grating excitation and emission monochromator using the TCSPC method. PMT (R928P) (Hamamatsu Photonics, Japan) was used as the detector. The liquid samples (10–4 mg mL−1 concentration) were analysed using a 460 nm Nano LED source. Quantum yield was estimated through relative quantum yield measurements with fluorescein dye as reference. The contact angle was measured using a HO-IAD-CAM-01B contact angle meter (holmarc). Cyclic voltammetry (CV) curves were recorded using an electrochemical workstation (CHI 660E Electrochemical workstation—CH Instruments—USA) with three-electrode systems consisting of a polymer-coated glassy carbon working electrode, platinum counter electrode and Ag/AgCl as reference electrode. 0.1 M of tetrabutylammonium hexafluorophosphate in acetonitrile was employed as the supporting electrolyte.

Results and discussion

Functional group analysis of MEH-PPV/ZnO hybrid nanocomposites

In order to examine any chemical bonding between the polymer and the incorporated nanoparticles, the functional group of pristine MEH-PPV and hybrid nanocomposites was analysed through FTIR spectroscopy. The FTIR spectra of MEH-PPV and nanocomposite samples are shown in Fig. 2. There were no significant structural changes in the polymer nanocomposites compared to pristine MEH-PPV [22]. In addition to the IR bands of MEH-PPV, the appearance of a weak band at 435 cm−1 (Zn–O) indicates the successful incorporation of ZnO into MEH-PPV [13]. Additionally, the C–H wag at 863 cm−1 in pristine MEH-PPV saw a slight shift to 853 cm−1 in both the hybrid nanocomposites due to the removal or transfer of H+ ions (protons) due to O2− in ZnO (deprotonation effect) [26]. The trivial changes in the FTIR spectrum with no evidence of a new functional group indicate the existence of a physical interaction between MEH-PPV and nanoparticles, i.e. the mere dispersion of ZnO in the polymer matrix [25].

Photophysical characterization of MEH-PPV/ZnO hybrid nanocomposites

Absorbance spectra shown in Fig. 3a were recorded for 10–4 g ml−1 concentrated polymeric solutions. The absorbance spectra of hybrid nanocomposites were similar to that of pristine MEH-PPV indicating the absence of a ground-state complex [27]. However, the addition of ZnO nanoparticles increased the absorption intensity of MEH-PPV and shifted the absorbance maxima towards a lower wavelength. The formation of MEH-PPV/ZnO heterojunctions within the polymer is mainly attributed to enhanced absorption [28]. The hypsochromic shift in λmax of absorbance spectra of MEH-PPV/ZnO nanocomposites indicated the shortening of the polymer chain length due to an in situ polymerization process [25]. This implies the reduction in aggregate formation in the nanocomposites which is another possible reason for increased adsorption since the molar absorbance of aggregates is lower than in isolated chains. Among the nanocomposites, samples prepared using defective ZnO displayed stronger absorption compared to nanocomposite with defect-controlled ZnO. The capacity to strongly absorb visible light by oxygen vacancies in ZnO due to bandgap narrowing accounted for improved absorbance in the case of MEH-PPV/defective ZnO hybrid nanocomposite [29].

The steady-state PL spectra given in Fig. 3b were obtained by exciting the polymer solutions (10–4 mg mL−1 concentration) at 490 nm. The emission spectra of hybrid nanocomposites were similar to pristine MEH-PPV with an intrachain excitonic emission (~ 550 nm) and interchain excitonic emission (~ 600 nm) [30]. Similar to the absorbance spectra, the emission maxima of hybrid nanocomposites exhibited a hypsochromic shift due to the shortening of polymer chain length. The ratio of interchain and intrachain emission intensity (I600 nm/I550 nm) of pristine MEH-PPV, MEH-PPV/defect-controlled ZnO and MEH-PPV/defective ZnO was estimated as 0.5, 0.45 and 0.4, respectively. The least ratio in the case of MEH-PPV/defective ZnO nanocomposite signifies the highest reduction in aggregate formation. In comparison with emission spectra of pristine MEH-PPV, both the hybrid nanocomposites exhibited PL quenching. The significant reduction in emission intensity was due to the charge transfer process from MEH-PPV to ZnO nanoparticles. Generally, ZnO possesses high electron affinity (~ 4.2 eV) which extracts the electrons from the Lowest Unoccupied Molecular Orbital (LUMO) of MEH-PPV. As a result, the transfer of electrons from MEH-PPV to ZnO nanoparticles is energetically favoured. Henceforth, the excitons dissociation at the polymer nanoparticle interface has led to PL quenching. [27].

However, the emission spectra of nanocomposite with defective ZnO displayed increased emission intensity compared to nanocomposite with defect-controlled ZnO nanoparticles. Hence, for further understanding of the quenching behaviour, the wt% of both defective and defect-controlled ZnO nanoparticles (3, 5 and 10 wt %) incorporation was varied and the corresponding Stern–Volmer plots were examined. The corresponding steady-state PL spectra of the nanocomposites with different wt% of ZnO are given in supplement S5.

The Stern–Volmer plot in Fig. 4 displays the difference between defective ZnO and defect-controlled ZnO nanoparticles incorporated nanocomposites in terms of quenching efficiency. In the plot, F0 represents the integrated spectral area (500–800 nm) of pure MEH-PPV, and F represents the integrated spectral area of MEH-PPV/ZnO nanocomposites with different ZnO wt%. The F0/F provides the quenching efficiency of defective and defect-controlled ZnO nanoparticles. From the Stern–Volmer plot, defective ZnO is determined to quench the luminescence of MEH-PPV at a lower rate than defect-controlled ZnO nanoparticles. This is because, after photoexcitation, the defect centres are filled with extracted electrons that can relax through (1) non-radiative decay via surface states or (2) tunnel into the nanoparticle and relax radiatively or non-radiatively based on the nature of the final state [27]. Thus, the higher possibility of a non-radiative mechanism provides a route for the separation of excitons, resulting in the quenching of the nanocomposite’s emission compared to pristine MEH-PPV in the case of MEH-PPV/defect-controlled ZnO nanocomposite, and this probability increases rapidly with an increase in the wt% of defect-controlled ZnO due to enhanced nanoparticle network formation. However, the probability of radiative decay mechanism in defective sites of ZnO accounted for enhancement in PL intensity for MEH-PPV/defective ZnO nanocomposite compared to defect-controlled ZnO incorporated nanocomposite. Additionally, there is no drastic quenching witnessed with the increase in wt% of defective ZnO, because with an increase in defective ZnO content the probability of radiative recombination also increases.

The quenching efficiency was further analysed in detail by examining the luminescence quantum efficiency through relative quantum yield measurements. Fluorescence quantum efficiency is the ratio of the number of photons emitted to the number of photons absorbed. The relative fluorescence quantum yield measurement technique as described in our previous work [25] was adopted by taking fluorescein dissolved in 0.1 M NaOH solution as the reference. Quantum efficiency (Φf) was calculated using Eq. 1 [31]:

Here, η is the refractive index of the sample’s solvent (1.496 for toluene) and ηref is the refractive index of the reference’s solvent (1.33 for 0.1 M NaOH solution). Φref is the quantum yield of fluorescein (0.79), and I and Iref are the integrated fluorescence area of the sample and fluorescein, respectively. A and Aref are the corresponding absorbance maxima of the sample and fluorescein. The emission spectra of MEH-PPV/ZnO hybrid nanocomposites and their corresponding reference at different optical densities are shown in Fig. 5 from which the integrated area was calculated. The emission spectra of pristine MEH-PPV and its corresponding reference at different optical densities are given in the supplement S6. The luminescence quantum efficiency of pristine MEH-PPV, MEH-PPV/defect-controlled ZnO and MEH-PPV/defective ZnO nanocomposites was estimated as 24% [standard deviation (SD) of 0.02], 16% (SD of 0.02) and 22% (SD of 0.01). The decrease in quantum efficiency of both hybrid nanocomposites compared to pristine MEH-PPV was due to charge transfer. The sixfold improvement in the luminescence efficiency with the incorporation of defective ZnO nanoparticles compared to defect-controlled ZnO nanoparticles is explained using the energy band diagram shown in Fig. 6.

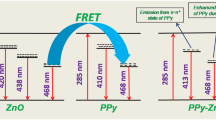

The two energy levels of V0+ and V0++ denote the defective levels due to oxygen vacancies in Fig. 6a. The excited electron harvested from the LUMO of MEH-PPV has the possibilities of approaching V0+ and V0++ from the conduction band of ZnO. During the transit of electron from the conduction band to V0++, radiation of 605 nm (orange emission) is reported to be emitted [32]. Additionally, the electron transit from the conduction band can be transferred to V0+. This transition is unstable, and hence, further the electron radiatively decays from V0+ to the valance band of ZnO. This radiative decay results in the emission of green light (~ 510 nm) which is also witnessed in the PL spectra of ZnO nanoparticles (Figure. S4.2). Since the green emission is the excitation wavelength for MEH-PPV (~ 500 nm), it re-excites the MEH-PPV molecules. Consequently, it is possible to induce energy transfer from ZnO to MEH-PPV by exciting the “green” defective band in ZnO [21]. Thus, the presence of defective levels due to oxygen vacancies in ZnO has proven to improve the quantum efficiency of MEH-PPV in comparison with the incorporation of defect-controlled ZnO in MEH-PPV. Rather defect-controlled ZnO can only result in mere charge transfer and exciton dissociation at the MEH-PPV/ZnO interface as represented in Fig. 6b which is particularly suitable for photovoltaics.

The incorporation of ZnO nanoparticles via in situ polymerization decreases the formation of polymer defects and suppresses the aggregation caused by quenching of MEH-PPV molecules [20]. However, in MEH-PPV/defect-controlled ZnO, the electrons harvested from MEH-PPV decay non-radiatively at the polymer/nanoparticle interface or via the surface of nanoparticles. During the charge transfer process, the excited electron–hole pairs dissociate at MEH-PPV and ZnO interfaces, which led to luminescence quenching and lower quantum efficiency. The absence of defective levels in ZnO nanoparticles eliminates the possibility of the re-excitation process. Therefore, the quenching process due to defect-controlled ZnO nanoparticles suggests that the ZnO nanoparticles provide an alternative pathway for excited electrons and reduce the radiative emission of the excitons [15]. Rather in MEH-PPV/ZnO hybrid nanocomposites, the introduction of defective levels in ZnO nanoparticles was found to enhance the luminescence properties through the re-excitation process. Therefore, the nanocomposite prepared using defective ZnO nanoparticles is suggested to be a suitable candidate for PLEDs.

Emission kinetics of MEH-PPV/ defective ZnO hybrid nanocomposites

The emission lifetime of MEH-PPV and MEH-PPV/defective ZnO nanocomposite was examined using time-resolved PL (TRPL) spectroscopy. The TRPL spectra of MEH-PPV and defective ZnO nanocomposite are shown in Fig. 7. The fluorescence of the solution decays almost exponentially with the time constant of ~ 0.4 ns.

The decay rate constants were determined by fitting the fluorescence decay curves with a biexponential function as given in equation 2 [33]:

Here, luminescence intensity is represented using I, pre-exponential factors are A1 and A2, time is represented as t, and the fast and slow lifetime components are denoted as τ1 and τ2, respectively. The radiative recombination rate (kr) and non-radiative recombination rate (knr) are obtained from Eqs. 3 and 4, respectively.

where ϕ is the quantum efficiency and τavg is the average lifetime which is obtained from equation 5

Table 1 represents the emission kinetics of MEH-PPV and nanocomposite at 555–552 nm emission wavelength, respectively.

It can be inferred from Table 1 that there is an overall increment in the τavg of the nanocomposite by 0.02 ns due to the hopping of excitons in the MEH-PPV matrix in the presence of ZnO nanoparticles [24]. Additionally, the longer exciton lifetime can be related to reduced exciton mobility, indicating that excitons do not quench completely (i.e. excitons cannot reach the quenching centres) which signifies that harvested electrons from MEH-PPV by ZnO nanoparticles do not relax non-radiatively via tunnelling through nanoparticles. The long exciton lifetime in the case of the nanocomposite (0.14 ns) can be attributed to interchain excitons as reported by Yan et al. [34]. However, it is already discussed that interchain excitons do not appear when polymers are formed in the pores of nanoparticles during an in situ polymerization process. Hence, the change in the behaviour of the long radiative lifetime component can be attributed to polymer chain conformation where polymer chains in pores might have a strong torsional distortion in pores and twisting points, thus probably forming charge separation centres and therefore, creating the long-lived charge transfer states and reducing the radiative recombination rate [35]. However, the reduction in quantum yield and radiative recombination rate indicates only the dissociation of excitons at the polymer/nanoparticle interface. This is because the non-radiative recombination rate of nanocomposite has been reduced by 0.05 ns−1 which signifies the reduction in polymer chain defects [33]. Thus, reduced knr value denotes that luminescence quenching in nanocomposites (0.22) compared to MEH-PPV (0.24) was purely due to charge transfer and not associated with polymeric chain defects. Henceforth, the incorporation of ZnO nanoparticles via in situ polymerization was successful in eliminating the kinks in the MEH-PPV polymer chain thereby reducing the non-radiative recombination.

Electrochemical analysis for MEH-PPV/defective ZnO hybrid nanocomposites

Furthermore, the electron transfer process from MEH-PPV to ZnO nanoparticles was also examined through electrochemical analysis. The cyclic voltammetry (CV) graphs of MEH-PPV and MEH-PPV/defective ZnO nanocomposite are shown in Fig. 8.

It can be witnessed from the CV analysis that with the incorporation of defective ZnO nanoparticles the reduction current was increased from − 0.026 mA to − 0.069 mA which denoted the increased conductivity. This is proof of the transfer of electrons from MEH-PPV to ZnO nanoparticles. The increase in reduction current density indicates the gain of electrons in the electrochemical system of the nanocomposite. Abbaszadeh et al. reported that MEH-PPV has three orders increased hole mobility compared to electron mobility [36]. Thus, the p-type nature of MEH-PPV might result in improper charge balance in PLEDs shifting the emission zone near the cathode resulting in heating and deterioration of device efficiency and lifetime. However, in MEH-PPV/ defective ZnO nanocomposite, the increment in reduction current due to the gain of the electron in the system indicates the improvement in n-type characteristics of the nanocomposite facilitating charge balance.

In addition to improvement in the luminescence properties and electrochemical properties, it is also desirable to enhance the photostability of the nanocomposites for the optimum device lifetime. Our previous work on MEH-PPV/MgO nanocomposites elaborates on the role of oxygen vacancies in preventing the degradation of the polymer [25]. Hence, the same is expected with MEH-PPV/ defective ZnO nanocomposite also.

Photostability analysis and degradation studies

The stability of MEH-PPV in the ambient environment is the bottleneck in using them as an emissive layer in PLEDs. Hence, it is significant to examine the degradation of the pristine MEH-PPV and MEH-PPV/defective ZnO nanocomposite exposed to an ambient environment. Polymer solution with 6 mg mL-1 concentration was drop cast on a cleaned glass substrate. The thickness of polymer coating for each sample drop cast on the glass substrate was approximately 700–850 nm. The compactness and hydrophobicity of the polymeric films on the glass substrate were estimated using contact angle measurements. Figure 9 denotes the contact angle of MEH-PPV and MEH-PPV/defective ZnO nanocomposite film.

Figure 9 demonstrates that defective ZnO incorporated MEH-PPV exhibited a slightly higher CA of 91° compared to pristine MEH-PPV films with a CA of 88°. The higher contact angle for MEH-PPV/defective ZnO nanocomposite indicated the improved hydrophobic nature of these samples. Additionally, the higher contact angle of nanocomposite also indicates a compact structure with rigid morphology and a dense film with lesser porosity, whereas the lower contact angle of MEH-PPV films signifies the hydrophilic nature, porosity associated problems and voids. These pores can eventually create stress/strain which leads to defects aiding non-radiative recombination and poor charge transport [37]. This was witnessed with an increased non-radiative rate and lower current density for MEH-PPV compared to nanocomposite. Ultimately, the defective ZnO incorporated MEH-PPV produced films with lower stress, lesser defects and increased hydrophobicity.

These prepared films were exposed to an ambient environment with no effective protection to examine their photostability. These samples were subjected to PL and FTIR spectroscopy in an equal time interval to analyse the change in luminescence intensity and structure of the polymer. Figure 10a, b denotes the change in PL spectra of MEH-PPV and the nanocomposite w.r.t to time.

It is observed that MEH-PPV/ZnO nanocomposite degrades at a slower rate, unlike pristine MEH-PPV. In the case of MEH-PPV, the rate of degradation was 125,000 units per day, while for nanocomposites it was only 52,900 units per day. MEH-PPV/ZnO nanocomposite displayed a 60% improvement in photostability in comparison with pristine MEH-PPV. Generally, MEH-PPV tends to degrade rapidly when exposed to an ambient environment because of moisture intervention and attack of oxygen. Thus, the plausible reasons behind the superior photostability of the MEH-PPV/ZnO sample are (1) reduction in polymer chain defects, (2) prevention of superoxide formation and (3) increased hydrophobicity.

Generally, pristine MEH-PPV possesses excessive polymeric defects compared to MEH-PPV/ZnO nanocomposite paving way for easier degradation of the fluorescent moiety and resulting in photobleaching. However, the in situ polymerization process has drawn the polymer onto the surface of the nanoparticles, thereby reducing the probability of defective polymer chains and enhancing the photostability. [38]. Secondly, the photoexcited electrons from MEH-PPV readily combine with singlet oxygen forming superoxide anions O2−. These superoxides have the ability to cleave the polymer chain resulting in polymer chain scission which no longer displays fluorescence [39]. Rather ZnO incorporation prevents the attack of oxygen in MEH-PPV/ZnO nanocomposite. The photoexcited electrons are extracted from the LUMO of MEH-PPV to the conduction band of ZnO nanoparticles and trapped by the defective sites of ZnO cuts-off the channel for the formation of superoxide anion hence avoiding degradation by the attack of oxygen. Similar results were observed in MEH-PPV/r-GO [39] and MEH-PPV/MgO [25] nanocomposites also. The extraction of the electron from the polymer was confirmed through electrochemical analysis. In addition to the attack of oxygen, another important factor of degradation was moisture intervention. The hydrophobic nature of the nanocomposite has the capacity to prevent the moisture intrusion. Moreover, the reduction in the formation of polymer aggregates with the incorporation of ZnO nanoparticles attributes to enhancement in stability as reported by Quites et al. [40].

Furthermore, it can be observed from Fig. 11 that both pristine MEH-PPV and MEH-PPV/ZnO nanocomposites exhibited a hypsochromic shift of 10–22 nm after the 5th and 7th week of weathering, respectively. The hypsochromic shift in wavelength indicates the breakage of conjugated segments of the polymer chain [41]. Generally, the degradation of MEH-PPV exposed to an ambient environment is a two-step process: (1) oxidation of MEH-PPV to aromatic aldehydes leading to luminescence quenching due to carbonyl formation [42] and (2) photochemical reactions generate new molecules which show increasing PL intensity at a shorter wavelength during degradation [43]. Later these small fluorescent moieties photodegraded and become non-luminescent molecules. Hence, the change in the chemical structure of the conjugated polymer segments was examined through FTIR analysis.

Figure 11a, b denotes the structural disintegration of MEH-PPV and MEH-PPV/ZnO nanocomposite films exposed to outdoor weathering. Both MEH-PPV and MEH-PPV/ZnO nanocomposite exhibited similar degradation mechanisms with carbonyl formation at 1700 cm−1 due to attack of oxygen [42], OH bond formation due to moisture attack and distortion of phenyl group denoting the disintegration of the conjugated segments due to the combined effect of light and oxygen [41] [44]. However, the phenomenal changes in the FTIR spectrum of MEH-PPV/ZnO nanocomposites occurred only after three weeks of exposure, whereas pristine MEH-PPV films started to degrade rapidly within one week of exposure. Eventually, the introduction of ZnO nanoparticles was successful in reducing the polymeric defects and preventing the moisture and oxygen intervention, thereby improving the photostability of MEH-PPV in the nanocomposite.

Conclusion

In summary, this article examined the effect of vacancies (defective levels) in ZnO nanoparticles on the photophysical properties of MEH-PPV/ZnO hybrid nanocomposite for light-emitting applications. Hybrid nanocomposites were successfully synthesized via in situ polymerization using ZnO nanoparticles with and without defective sites. The typical polymerization process resulted only in physical interaction between ZnO and MEH-PPV (dispersion of nanoparticles in MEH-PPV). The absence of chemical interaction was confirmed with no structural changes in the FTIR spectra of nanocomposites compared to pristine MEH-PPV. The photophysical properties of MEH-PPV/ZnO nanocomposites display no significant shift in λmax compared to pristine MEH-PPV indicating the absence of ground-state charge complex formation. The introduction of ZnO nanoparticles enhanced absorbance and quenched the luminescence of MEH-PPV due to interfacial interactions and the charge transfer process, respectively. Luminescence quantum efficiency of MEH-PPV was improved sixfold with the incorporation of defective ZnO nanoparticles compared to the introduction of defect-controlled ZnO nanoparticles. This was due to energy transfer from defective levels of ZnO to MEH-PPV. The energy transfer was possible by exciting the “green” defective band (defect level created due to the presence of oxygen vacancies) in ZnO nanoparticles. In addition to photoluminescence enhancement, the introduction of defective ZnO nanoparticles also lowers the non-radiative recombination rate, increases the conductivity and improves the hydrophobicity of nanocomposites. Further, MEH-PPV/defective ZnO nanocomposites exhibit superior photostability because of reduced polymeric defects due to in situ polymerization, prevention of superoxide formation that prohibits the attack of oxygen which was due to the charge transfer process and finally the hydrophobic nature which inhibited moisture intervention. Conclusively, it can be inferred that the nanocomposite with defective ZnO nanoparticles is a suitable candidate for PLEDs mainly due to (1) improved luminescence quantum efficiency (22%) which supports superior device performance, (2) enhanced photostability that aids in better device stability and 3 increased conductivity that facilitates charge balance.

References

Forrest SR (2004) The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 428:911–918

Sevcik J, Urbanek P, Skoda D, Jamatia T, Nadazdy V, Urbanek M, Antos J, Munster L, Kuritka I (2021) Energy resolved-electrochemical impedance spectroscopy investigation of the role of Al-doped ZnO nanoparticles in electronic structure modification of polymer nanocomposite LEDs. Mater Des 205:109738

Burroughes JH, Bradley DDC, Brown AR, Marks RN, Mackay K, Friend RH, Burns PL, Holmes AB (1990) Light-emitting diodes based on conjugated polymers. Nature 347:539–541. https://doi.org/10.1038/347539a0

Kumar SA, Shankar JS, Periyasamy BK, Nayak SK (2019) Device engineering aspects of organic light- emitting diodes (OLEDs). Polym Technol Mater 58:1–28. https://doi.org/10.1080/25740881.2018.1563133

Zou JP, Le Rendu P, Musa I, Yang SH, Dan Y, That CT, Nguyen TP (2011) Investigation of the optical properties of polyfluorene / ZnO nanocomposites. Thin Solid Films 519:3997–4003. https://doi.org/10.1016/j.tsf.2011.01.205

Zhang J, Zhang X, Feng H, Yu Z, Zhang J, Liu S, Zhang L, Xie W (2019) Efficient and stable hybrid organic light-emitting device based on inorganic metal oxide hole transport layer and electron transport layer. J Mater Chem C 7:1991–1998. https://doi.org/10.1039/C8TC06135A

Tang A, Teng F, Jin H, Gao Y, Hou Y, Liang C, Wang Y (2007) Investigation on photoconductive properties of MEH-PPV / CdSe-nanocrystal nanocomposites. Mater Lett 61:2178–2181. https://doi.org/10.1016/j.matlet.2006.08.042

Sabah FA, Abdul I, Kabaa EA, Zaini MF, Omar AF (2020) Characterization of hybrid organic / inorganic semiconductor materials for potential light emitting applications. Opt Mater (Amst) 107:110117

Habelhames F, Nessark B, Bouhafs D, Cheriet A (2010) Synthesis and characterisation of polypyrrole – indium phosphide composite film. Ionics (Kiel) 16:177–184. https://doi.org/10.1007/s11581-009-0338-0

Online VA, Yuan J, Sun Y (2014) High-efficiency polymer–PbS hybrid solar cells viamolecular engineering. J Mater Chem A 3:2572–2579. https://doi.org/10.1039/c4ta03995e

Elhames FH, Nessark B, Boumaza N, Bahloul A, Bouhafs D, Cheriet A (2009) Electrochemical and photoelectrochemical study of gallium arsenide – polybithiophene composite. Synth Met 159:1349–1352. https://doi.org/10.1016/j.synthmet.2009.03.009

Klingshirn C (2007) ZnO: material, physics and applications. ChemPhysChem 8:782–803. https://doi.org/10.1002/cphc.200700002

Sangeetha A, Seeli SJ, Bhuvana KP, Kader MA, Nayak SK (2019) Correlation between calcination temperature and optical parameter of zinc oxide (ZnO) nanoparticles. J Sol-Gel Sci Technol 91:261–272. https://doi.org/10.1007/s10971-019-05000-8

Aleshin AN (2013) Organic optoelectronics based on polymer – inorganic nanoparticle composite materials. Phys Usp 56(6):627–632. https://doi.org/10.3367/UFNe.0183.201306i.0657

Jetson R, Yin K, Donovan K, Zhu Z (2010) Effects of surface modification on the fluorescence properties of conjugated polymer / ZnO nanocomposites. Mater Chem Phys 124:417–421. https://doi.org/10.1016/j.matchemphys.2010.06.058

Aleshin AN, Alexandrova EL, Shcherbakov IP (2009) Hybrid active layers from a conjugated polymer and inorganic nanoparticles for organic light emitting devices with emission colour tuned by electric field. J Phys D Appl Phys 42(10):105108. https://doi.org/10.1088/0022-3727/42/10/105108

Choi Y, Park H, Golledge S, Johnson DC (2012) A study on the incorporation of ZnO nanoparticles into MEH-PPV based organic – inorganic hybrid solar cells. Ceram Int 38:525–528. https://doi.org/10.1016/j.ceramint.2011.05.068

Skoda D, Urbanek P, Sevcik J, Munster L, Antos J, Kuritka I (2018) Microwave-assisted synthesis of colloidal ZnO nanocrystals and their utilization in improving polymer light emitting diodes efficiency. Mater Sci Eng B 232–235:22–32

Yahya NZ, Rusop M (2012) Investigation on the optical and surface morphology of conjugated polymer MEH-PPV: ZnO nanocomposite thin films. J Nanomater. https://doi.org/10.1155/2012/793679

Periyayya U, Hye J, Hyoung J, Hong C (2011) Synthesis and improved luminescence properties of OLED / ZnO hybrid materials. Vaccum 86:254–260. https://doi.org/10.1016/j.vacuum.2011.06.016

Musa I, Massuyeau F, Faulques E, Nguyen T (2012) Investigations of optical properties of MEH-PPV / ZnO nanocomposites by photoluminescence spectroscopy. Synth Met 162:1756–1761. https://doi.org/10.1016/j.synthmet.2012.01.011

Pan J, Chen Z, Xiao Y, Huang W (2000) Synthesis and characterization of fully soluble polyphenylenevinylene, Chinese. J Polym Sci 18:541–549

Neef CJ, Ferraris JP (2000) MEH-PPV: improved synthetic procedure and molecular weight control. Macromolecules 33:2311–2314

Kumar S, Gouthaman S, Shankar JS, Periyasamy BK, Nayak SK (2021) Stable and color tunable MEH-PPV/PMMA polymer blends for light-emitting applications. Chem Phys Lett 770:138462. https://doi.org/10.1016/j.cplett.2021.138462

Kumar SA, Shankar JS, Periyasamy BK, Nayak SK (2021) Role of defective states in MgO nanoparticles on the photophysical properties and photostability of MEH-PPV/MgO nanocomposite. Phys Chem Chem Phys 23:22804–22816

Shankar JS, Kumar SA, Periyasamy BK, Nayak SK (2018) Studies on optical characteristics of multicolor emitting MEH-PPV / ZnO hybrid nanocomposite. Polym Technol Mater 58:148–157. https://doi.org/10.1080/03602559.2018.1466171

Ton-that C, Phillips MR, Nguyen T (2008) Blue shift in the luminescence spectra of MEH-PPV films containing ZnO nanoparticles. J Lumin 128:2031–2034. https://doi.org/10.1016/j.jlumin.2008.07.004

Al-asbahi BA, Qaid SMH, Ghaithan HM, Farooq WA (2021) Enhancing the optical and optoelectronic properties of MEH-PPV-based light-emitting diodes by adding SiO2/TiO2 nanocomposites. J Non Cryst Solids 552:120429

Wang J, Wang Z, Huang B, Liu Y, Qin X, Zhang X, Dai Y (2012) Oxygen vacancy induced band-gap narrowing and enhanced visible light photocatalytic activity of ZnO. ACS Appl Mater Interfaces 4:4024–4030

Cossiello RF, Susman MD, Aramendı PF, Atvars TDZ (2010) Study of solvent-conjugated polymer interactions by polarized spectroscopy. J Lumin 130:415–423. https://doi.org/10.1016/j.jlumin.2009.10.006

Nimith KM, Satyanarayan MN, Umesh G (2018) Enhancement in fluorescence quantum yield of MEH-PPV: BT blends for polymer light emitting diode applications. Opt Mater (Amst) 80:143–148

Bandopadhyay K, Mitra J (2015) Zn interstitials and O vacancies responsible for n- type ZnO: what do the emission spectra reveal? RSC Adv 5:23540–23547. https://doi.org/10.1039/c5ra00355e

Kumar SA, Shankar JS, Periyasamy BK, Nayak SK (2021) Role of defective states in MgO nanoparticles on the photophysical properties and photostability of. Phys Chem Chem Phys 23:22804–22816. https://doi.org/10.1039/d1cp03035c

Yan M, Rothberg LJ, Kwock EW, Miller TM (1995) Interchain excitations in conjugated polymers. Phys Rev Lett 75:1992–1995. https://doi.org/10.1103/PhysRevLett.75.1992

Telbiz GM, Yu O, Dementjev A, Kiskis J, Gulbinas V, Valkunas L, Extensive I (2010) Effect of nanoscale confinement on fluorescence of MEH-PPV/MCM-41 composite. Phys Status Solidi A 207:2174–2179. https://doi.org/10.1002/pssa.201026151

Abbaszadeh D, Kunz A, Kotadiya NB, Mondal A, Andrienko D, Michels JJ, Wetzelaer GAH, Blom PWM (2019) Electron trapping in conjugated polymers. Chem Mater 31:6380–6386. https://doi.org/10.1021/acs.chemmater.9b01211

Mittal T, Tiwari S, Mehta A, Tiwari SK, Sharma SN (2017) Comparison of polymeric stabilization of organic / inorganic ( MEH-PPV / TiO2) hybrid composites synthesized via different routes. Colloid Polym Sci 295:1097–1107. https://doi.org/10.1007/s00396-017-4094-9

Carter SA, Scott JC, Brock PJ (2013) Enhanced luminance in polymer composite light emitting devices enhanced luminance in polymer composite light emitting devices. Appl Phys Lett. https://doi.org/10.1063/1.119848

Ran C, Wang M, Gao W, Ding J, Shi Y, Song X, Chen H, Ren Z (2012) Study on photoluminescence quenching and photostability enhancement of MEH-PPV by reduced graphene oxide. J Phys Chem C 116:23053–23060

Quites FJ, Germino JC, da Silva Azevedo CK, Moreto JA, Faleiros MM, Atvars TDZ (2017) Exfoliation of zinc-layered hydroxide by luminescent conjugate polyelectrolyte: synthesis and photophysical aspects. J Sol-Gel Sci Technol 83:457–466. https://doi.org/10.1007/s10971-017-4432-x

Louis B, Caubergh S, Larsson P-O, Tian Y, Scheblykin IG (2017) Light and oxygen induce chain scission of conjugated polymers in solution. Phys Chem Chem Phys 20:1829–1837. https://doi.org/10.1039/C7CP07347J

Scott JC, Kaufman JH, Salem J, Goitia JA, Brock PJ, Dipietro R (1996) MEH-PPV light-emitting diodes: mechanisms of failure. Mol Cryst Liq Cryst Sci Technol Sect A Mol Cryst Liq Cryst 283:57–62. https://doi.org/10.1080/10587259608037864

Galey C, Park H (2019) Intermediate states during photodegradation in MEH-PPV solutions and thin films Intermediate states during photodegradation in MEH-PPV solutions and thin films. AIP Adv 9:105010. https://doi.org/10.1063/1.5099382

Khillan RK, Su Y, Varahramyan K (2004) Degradation of MEH-PPV due to oxygen/moisture traps through C-v analysis and attenuated total reflection IR spectroscopy. Mat Res Soc Sump Proc 814:1–7

Acknowledgements

The authors are thankful to the Department of Science and Technology (DST) for providing financial support under the scheme DST—Innovation in Science Pursuit for Inspired Research (INSPIRE), Government of India, to carry out this research [DST/INSPIRE Fellowship/2017/IF170799 dated 30.08.2018]. The authors are also grateful to Council of Scientific and Industrial Research (CSIR), Government of India, for providing funding to carry out this research [03(1376)/16/EMR-II dated at 26.10.2017].

Author information

Authors and Affiliations

Contributions

SAK (Corresponding author) contributed to conceptualization, data curation (worked on defect-induced ZnO nanocomposites), formal analysis, funding acquisition from DST, investigation, methodology, software, validation, visualization and writing—original draft. JSS contributed to data curation (worked on defect-controlled ZnO nanocomposites), formal analysis and visualization. BKP contributed to resources, investigation, writing—review and editing, funding acquisition from CSIR, supervision and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Andrea de Camargo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ashok Kumar, S., Shankar, J.S. & Periyasamy, B.K. ZnO energy transfer and enhanced photoluminescence in MEH-PPV/ZnO hybrid nanocomposite. J Mater Sci 57, 12449–12462 (2022). https://doi.org/10.1007/s10853-022-07412-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07412-4