Abstract

Electrode materials structures hold the key to enhance the performance. Based on the time-dependent growth process of niobium precursor, single-crystal Na2Nb2O6·nH2O nanowires and NaNbO3 nanocubes were successfully synthesized through a facile and friendly hydrothermal route at 180 °C under different reaction times. NaNbO3 nanowires were derived by calcination treatment of Na2Nb2O6·nH2O nanowires which was employed as self-sacrificing templates. By comparing the electrochemical behavior of these niobium-based anodes, NaNbO3 nanocubes show a discharge capacity of about 115 mA h g−1 over 1000 cycles at 1000 mA g−1, exhibiting higher reversible capacity and superior rate performance than NaNbO3 nanowires. The superior cell performance could be interpreted in terms of the different morphologies of NaNbO3, which results in the better Li-ion diffusion abilities and higher pseudo-capacitance of the as-fabricated NaNbO3 nanocubes electrode. This work provides fundamental insights into the morphology–property relationship of both NaNbO3 nanowires and NaNbO3 nanocubes, providing a solid guide for developing anode materials for Li-ion battery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, lithium-ion batteries (LIBs) are the most widely used energy storage devices for powering portable devices and electrical vehicles [1,2,3]. However, due to their high-rate poor security and deteriorated cycling performance limited by the rate performance of commercial graphite anodes, traditional lithium-ion batteries cannot achieve the rapidly increasing high power energy storage requirements [4, 5]. Exploring safe and high-performance anode materials for LIB has been the focus of much research. Niobium-based materials are demonstrated to be promising anode candidates for high-rate energy storage applications, because they have fast kinetics of the electrochemical ion insertion and extraction. To date, a number of niobium-based materials, especially niobium-based oxides with multiple redox couples (Nb5+/Nb4+ and Nb4+/Nb3+), have attracted much attention because of their high specific capacities. As the most studied molecule of the niobium-based oxides, Nb2O5 featured with high working voltage and a large practical capacity have drawn ever-increasing attention as anode materials for LIBs. But its poor electronic conductivity and capacity retention that resulting in insufficient rate capability and shortened cycling life greatly restrict its applicability [6,7,8,9,10]. To obtain more outstanding niobium-based oxide anodes, various strategies, such as introducing other metal elements into Nb2O5, have been adopted [11, 12]. As a result, intercalation-type M-Nb–O anode materials have been studied worldwide due to their safe operating potentials, high specific capacities, high cycling stability, and significant intercalation pseudocapacitive behavior.

M–Nb–O compounds based on transition metals and alkaline earth metal including Ti–Nb–O [13,14,15], Fe–Nb–O [16,17,18], Ga–Nb–O [19, 20], Cr–Nb–O [21], Zr–Nb–O [22, 23], W–Nb–O [24, 25], Mg–Nb–O [26], Ba–Nb–O [27] are reported to be fabricated and used as anode materials for LIBs. However, the synthetic route of the above M–Nb–O materials always involves complicated processes and high calcination temperatures. NaNbO3, as a new member of M–Nb–O materials based on alkali metal, has attracted particular research attention in recent years due to its simple green synthesis route and excellent photophysical and chemical properties. While NaNbO3 has been widely used as piezoelectric materials, ferroelectric materials, biological detection reagents and photocatalytic materials, the application of NaNbO3 for LIBs has not been explored until Yan et al. reported NaNbO3 micro-/nano-crystals as anode for Li-ion storage, and then revealing its pseudocapacitive intercalation mechanism [28]. It is well known that the performance of an electrochemical performance of an electrode material greatly depends on its morphology and microstructure because different structures can afford different effective surface areas and electroactive sites as well as conductive networks [29,30,31,32,33,34,35,36]. However, to date, comparative investigating the effect of morphologies of NaNbO3 on the performance for LIBs is still lacking.

Herein, the electrochemical performances of controllable NaNbO3 nanowires and NaNbO3 nanocubes were explored for LIB. NaNbO3 with tunable morphology was prepared combined a facile and friendly hydrothermal route. The NaNbO3 nanowires were obtained after hydrothermal time of 2 h and a heat-treat at 500 °C for 12 h, while NaNbO3 nanocubes were easy prepared by the hydrothermal treatment time of 3 h. Their electrochemical performances as anodes for LIBs were investigated. Meanwhile, the effects of NaNbO3 morphology on Li-ion diffusion abilities and storage were intensively studied. Morphological control can result in the increase of Li-ion diffusion kinetics and Li storage of NaNbO3 nanocubes, which deliver a higher discharge capacity of about 115 mA h g−1 over 1000 cycles at 1000 mA g−1 and exhibit higher rate capability than those of NaNbO3 nanowires prepared in this work.

Materials and methods

Materials synthesis

All materials were analytical reagents, which were used without any purification. Nb2O5 (purity, 99.5%) and sodium hydroxide (purity, 99%) were obtained from Sinopharm Chemical Reagent Co., Ltd. NaNbO3 nanowires were synthesized though the combination of a hydrothermal method and calcination following a time-dependent growth process. In a typical synthetic process, Nb2O5 (1.00 g, 3.76 mmol) was added into a solution of NaOH (10 M, 60 mL) and then transferred into Teflon-lined stainless-steel autoclave. The autoclave was held at 180 °C for 2 h. After the reaction, the autoclave was naturally cooled to room temperature. The obtained white solids were washed with ethanol and deionized water several times to remove the impurities. Then, the as-prepared products were placed in a vacuum drying oven at 100 °C for 24 h, and niobium precursors of Na2Nb2O6·nH2O nanowires were obtained. Subsequently, Na2Nb2O6·nH2O nanowires were calcined at 500 °C for 12 h in a muffle and converted into NaNbO3 nanowires. NaNbO3 nanocubes were synthesized through the same hydrothermal procedure with a reaction time increasing to 3 h.

Material characterizations

XRD characterization was performed on a Bruker D8 Focus X-ray diffractometer using Cu Kα radiation (λ = 1.5406 Å) in the 2θ range from10 to 60°. SEM characterization was performed on a Hitachi SU-70 SEM instrument. TEM characterization was performed on a JEOL JEM-2100 TEM instrument.

Electrochemical measurements

The electrochemical performance was evaluated by using CR2016-type coin cells that were assembled in a glove box filled with highly pure Ar gas (< 1 ppm of oxygen and water). The working electrodes were prepared by using N-methylpyrrolidone (NMP)-based slurry containing active materials (NaNbO3 nanowires or nanocubes), conductive carbon black (Super P), and binder (PVDF) in a mass ratio of 65:25:10. The loading mass of active materials in the final working electrode is around 1 ~ 1.5 mg cm−2. Metallic Li plates were used as counter electrodes. The electrolyte was made up of 1 M LiPF6 in the mixture of ethylene carbonate (EC), diethylene carbonate (DEC) and dimethyl carbonate (DMC) (EC/DEC/DMC = 1:1:1, volume ratio). Galvanostatic charge/discharge performances were carried out using a CT2001 automatic battery tester (LAND, China). Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) tests were performed on a VMP-3 electrochemical workstation (Bio-Logic, France).

Results and discussion

A typical schematic illustration for the synthesis of NaNbO3 nanowires and NaNbO3 nanocubes is illustrated in Scheme 1. The niobium and sodium sources were provided by niobium pentoxide and sodium hydroxide, respectively. Using a hydrothermal reaction, we first fabricated white solid precursor of Na2Nb2O6·nH2O nanowires from niobium pentoxide and sodium hydroxide at 180 °C for 2 h. Subsequently, niobium precursor of Na2Nb2O6·nH2O nanowires was calcined at 500 °C for 12 h affording NaNbO3 nanowires, which essentially retained the corresponding morphologies of niobium precursor. Considering the higher thermodynamic stability of NaNbO3 nanocubes and the characteristics of Na2Nb2O6·nH2O nanowires’ metastable phase, it is anticipated that the longer hydrothermal reaction time will promote the transformation of Na2Nb2O6·nH2O nanowires to NaNbO3 nanocubes. Upon prolong the hydrothermal reaction time to 3 h, the precursor of Na2Nb2O6·nH2O nanowires was converted gradually into single-crystal NaNbO3 nanocubes. It is noted that this synthetic route is able to provide a low-cost, facile and potential scale-up technology for obtaining high-quality NaNbO3 nanocubes and nanowires in high yield, easily in the gram scale for one batch experiment.

The X-ray diffraction (XRD) patterns of the as-prepared NaNbO3 nanocubes and nanowires are presented in Fig. 1a, in which the sharp diffraction peaks imply the good crystalline of the products. Similarly, to previously reported ones, the single-crystal NaNbO3 obtained in this work exhibits the characteristic XRD peaks, which are in good agreement with the values given in the standard card of the orthorhombic phase (JCPDS 33–1270). The positions of the main diffraction peaks for NaNbO3 appear at around 22.7, 22.9, 32.1, and 32.5° , which correspond to the (101), (040), (200), (002), (141) crystal faces, respectively. No peaks of impurity are observed in the XRD pattern, indicating the high purity of obtained NaNbO3 samples. The crystal structure of orthorhombic NaNbO3 is shown in Fig. 1b and is similar to a typical perovskite structure, in which NbO6 octahedron as an elementary component and all NbO6 octahedrons are connected at the corners forming the 3D framework with Na+ ions incorporated in between the sheets. Such stable interconnected microchannel structure is significantly in favor of the rapid Li+ ion transportation and high cycling stability. The lattice parameters and unit-cell volumes calculated from the XRD data show that for NaNbO3 nanocubes, these values become larger compared to that of NaNbO3 nanowires (Table S1). It is well known that the increased unit volume can expand the transmission path of Li+ in its lattice [37], which is beneficial to significantly improve the ionic conductivity and electrochemistry of NaNbO3 nanocubes as anode material for Li-ion battery [38, 39].

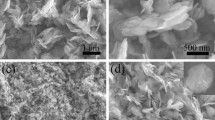

The morphology and structure of NaNbO3 products were examined by scanning electron microscope (SEM) and transmission electron microscope (TEM). Figure 2a and e depicts the SEM images of the NaNbO3 nanowires and nanocubes, respectively. It could be seen that 1D wire-like crystals with average dimensions of 200 nm in diameter and tens of micrometers in length were successfully synthesized by the feasible hydrothermal synthesis, which consistent with the results of the TEM images (Fig. 2a and b). While NaNbO3 nanocubes were prepared with size ranges from 0.5 to 1.5 μm (Fig. 2e and f). The high-resolution TEM (HRTEM) images demonstrated the NaNbO3 nanowires and nanocubes were well crystallized, as evidenced by the clear and orderly lattice fringes (Fig. 2c and g). Meanwhile, the lattice spacing in the HRTEM images is 0.27 nm and 0.41 nm (Fig. 2c and g), matching to the (200) and (101) crystallographic planes of NaNbO3. Additionally, the SAED patterns perfectly match with the orthorhombic structure (P2/m space group), indicating its single-crystalline character. These HRTEM and SAED results are in good agreement with the XRD analyses. The X-ray energy-dispersive spectra (EDS) elemental mapping images (Fig. 2d and h) show the presence of O, Na and Nb elements and uniform distribution of these elements in the NaNbO3 products.

The electrochemical performances of as-obtained NaNbO3 nanocubes and nanowires as anode for LIB were then evaluated using 2016-type coin cell. Cyclic voltammetry (CV) profiles in Fig. 3a and b show the first five CV curves of the NaNbO3 anode for the Li/ NaNbO3 cell, which was measured between 0.005 and 3 V (vs. Li/Li+) at a scan rate of 0.2 mV s−1. Clearly, the current density was noticeably reduced after the first cycle in the low voltage range due to the capacity loss and then remained almost unchanged for the following cycles. This is a typical behavior of niobium-based anode materials due to irreversible electrochemical reaction and formation of solid electrolyte interface. The cathodic peaks at 1.32 and 0.75 V can be attributed to Li+ intercalate into crystalline NaNbO3 to form LixNaNb5-xO3, and these redox peaks correspond to the valence variations of Nb5+/Nb4+ and Nb4+/Nb3+. Notably, as shown in Fig. 3c and its inset, the NaNbO3 nanocubes electrode showed narrower potential hysteresis (0.017 V) and higher peak currents and area, representing higher Li storage ability [15, 27]. This could be attributed to improved electronic conductivity of NaNbO3 nanocubes due to its unique morphology. Figure 3d and Figure S1a showed the discharge/charge voltage profiles of the Li/ NaNbO3 nanocubes and nanowires cell at different current densities (50, 100, 200, 300, 400, 500, 600, 700, 800, 900 and 1000 mA g−1) in the potential range of 0.005–3.0 V. The discharge profiles of all current densities were characterized by featureless plateaus of a typical dominated surface-controlled kinetics (i.e., pseudocapacitive properties), which were in good agreement with the small redox peaks in the CV plots.

a,b Cyclic voltammograms for the first 5 cycles at a scan rate of 0.2 mV s−1, c comparison of cyclic voltammograms, d initial charge/discharge curves, e rate performances of NaNbO3 nanocubes and NaNbO3 nanowires. f The long-term cycling performance of NaNbO3 nanocubes and NaNbO3 nanowires tested at a high current density of 1000 mA g−1

Next, NaNbO3 nanocubes were evaluated by galvanostatic discharge/charge at various current rates. As shown in Fig. 3e and Figure S1b, NaNbO3 nanocubes exhibited excellent rate performance. The initial specific capacity of NaNbO3 nanocubes was ∼161.8 mAh g−1 at a current density of 100 mA g−1. When the current density was changed to 1000 mA g−1, a specific capacity of ∼124.7 mAh g−1 was retained and finally recovered to ∼178.7 mAh g−1 at a current density of 100 mA g−1. In contrast, NaNbO3 nanowires showed obviously lower specific capacity at each rate stages that only 104.3 mAh g−1 at a current density of 100 mA g−1 and 64.8 mAh g−1 at a current density of 1000 mA g−1, indicating the cube morphology advantage of Li storage during charge/discharge.

In addition, good capacity retention over long cycles is crucial for the practical implementation of an electrode material. Therefore, long-term cycling performances of the NaNbO3 nanocubes and nanowires were investigated. As shown in Fig. 3f, NaNbO3 nanocubes displayed a higher reversible capacity retention than NaNbO3 nanowires. At a current density of 1000 mA g−1, an initial specific capacity of 69.5 mAh g−1 was achieved. After 1000 cycles, the capacity increased above 114.8 mAh g−1, corresponding to a capacity retention of 165%. The excellent long-term cycling stability and the 100% coulombic efficiency indicated the high electrochemical stability and reversibility of NaNbO3 nanocubes. The characteristic of gradually increased specific capacity of the NaNbO3 nanocubes may be due to the persistent activation process during cycling indicating a new anode candidate bearing superior kinetics and stability for Li-ion storage.

In order to quantitatively analyze the pseudo-capacitance behavior in NaNbO3 nanocubes and NaNbO3 nanowires, the CV experiments were further implemented at a scan rate of 0.2 to 1 mv s−1 (Figs. 4a and d). The electrodes used for comparison were selected with the same quality of active material. Similar peak shapes could be observed during the anode and cathode processes, in which the redox peak current increased with the increasing scan rate. Obviously, the peak current of the NaNbO3 nanocubes at each scan rate was greater than that of the NaNbO3 nanowires, indicating that the NaNbO3 nanocubes had the electrochemical activity of Li storage. The pseudocapacitive contributions behavior can be calculated according to Eq. (1) [40]:

a, d The cyclic voltammograms of NaNbO3 nanocubes and NaNbO3 nanowires recorded at different scan rates. Percentages of pseudocapacitive contributions at different sweep rates, and CV curves with detailed pseudocapacitive contributions at 1.0 mV s−1 for b, e NaNbO3 nanocubes and c, f NaNbO3 nanowires

where I and v refer to the current response at a given potential and scanning speed, a and b are adjustable parameters, and av and bv0.5 represent the pseudo-capacitance contribution and the diffusion control contribution, respectively. At 0.2, 0.4, 0.6, 0.8 and 1.0 mV s−1, the pseudo-capacitance contributions of NaNbO3 nanocubes could be reached to 57.3, 64.4, 69.8, 74.9 and 79.5%, respectively (Fig. 4b), demonstrating its significant pseudo-capacitance behavior between the slow and fast electrochemical reactions. Meanwhile, by contrast with NaNbO3 nanocubes, the corresponding percentages of NaNbO3 nanowires were decreased to 49.5, 59.9, 67.5, 72.7 and 76.3%, respectively (Fig. 4e). For a better understanding, the detailed pseudo-capacitance contribution in the potential range of 0.2 to 1.0 mv s−1 was shown in the CV curve of 1.0 mV s−1 (Fig. 4c, f and Figure S2). Therefore, it is confirmed that the NaNbO3 nanocubes exhibited a more significant pseudo-capacitance effect at all scanning speeds.

The diffusion behaviors of lithium ions in NaNbO3 nanocubes and NaNbO3 nanowires were obtained through the CVs collected at different scanning rates of 0.2 ~ 1 mV s−1. The linear relationship between the redox peak current (Ip) and the square root of the scan rate (V0.5) is shown in Fig. 5a and b [41]. By deriving the classic Randles–Sevcik equation (Eq. (2)), the apparent Li diffusion coefficient D of NaNbO3 nanocubes and NaNbO3 nanowires for lithiation and delithiation can be calculated [42, 43]:

where n, C and S are the number of charge transfers (Eq. (2)), the molar concentration of Li+ in the electrolyte (0.001 mol cm−3), and the geometric area of the electrode (1.54 cm2). It could be found that the DLi+ values of NaNbO3 nanocubes were 4.78 × 10–13 cm2 s−1 for anode process and 4.09 × 10–13 cm2 s−1 for cathode process. For comparison, the DLi+ values of NaNbO3 nanowires were 4.03 × 10–13 cm2 s−1 for anode process and 3.38 × 10–13 cm2 s−1 for cathode process. Apparently, the DLi+ value of NaNbO3 nanocubes was greatly larger than NaNbO3 nanowires, which could be explained by the larger unit volume of NaNbO3 nanocubes (confirmed by the results of XRD) [37,38,39].

The potential electrochemical impedance spectroscopy (PEIS) diagram of NaNbO3 nanocubes and NaNbO3 nanowires is shown in Fig. 5c. Each plot consists of two recessed semicircles and a slope [44]. According to previous studies, the semicircle observed in the high-frequency region refers to the desolubilization, electron transfer and adsorption of Li+ ions, which is represented as R2/Q2 pairs in the equivalent circuit (Fig. 5c inset). The slope observed in the low-frequency region corresponds to the Warburg resistance (Q3), which represents the diffusion of Li+ ions in the lattice of NaNbO3 nanocubes and NaNbO3 nanowires. R1 in the equivalent circuit reflects the ohmic resistance of the battery, which is mainly due to the electrolyte. The fitting R2 values of the NaNbO3 nanocubes and NaNbO3 nanowires were 180.7 and 223.3 Ω, respectively. Therefore, the NaNbO3 nanocubes showed faster Li+ ion desolubilization, electron transfer, adsorption and Li+ ion insertion on the surface of active particles than NaNbO3 nanowires, indicating its better electrochemical kinetics.

In addition, based on the EIS results, the Warburg factor and apparent Li+ ion diffusion coefficient of NaNbO3 nanocubes and NaNbO3 nanowires can be calculated using Eq. (3) [45]:

where D refers to the Li+ ion diffusion coefficient, R is the gas constant, T is the absolute temperature, C is the molar concentration of Li in the electrolyte, F is the Faraday constant, and S is the geometric area of the electrode, and σ embodies the Warburg factor that can be obtained through Fig. 5d and Eq. (4) [46,47,48]:

where \(Z^{\prime}\) and \(\omega\) represent the real impedance and the angular frequency, respectively. The calculated Li+ ion diffusion coefficients of NaNbO3 nanocubes and NaNbO3 nanowires were 4.88 × 10–13 cm2 s−1 and 2.91 × 10–13 cm2 s−1, respectively. It further proved that NaNbO3 nanocubes have the ability to quickly migrate lithium ions, which was beneficial to the maintenance of charge and discharge under high current density.

Based on the aforementioned discussions, the optimal rate capability of NaNbO3 nanocubes could be ascribed to several factors: (i) the better thermodynamic stability of NaNbO3 nanocubes facilitated Li+ transportation and higher cycling stability; (ii) the superior electrochemical kinetics of NaNbO3 nanocubes was beneficial for electron transfer, adsorption and Li+ insertion on the surface of active sites; (iii) NaNbO3 nanocubes exhibited larger Li+ ion diffusion coefficient and significant pseudo-capacitance behavior. The combined effects of these three factors have significantly improved the rate capability.

Conclusions

In summary, NaNbO3 nanocubes and NaNbO3 nanowires were made by a simple hydrothermal reaction and were used as anode materials for M–NbV–O embedded with Li-ion batteries. Comparative studies were explored to figure out the influence of morphology on the performance of Li-ion batteries. Experimental proves that NaNbO3 nanocubes and NaNbO3 nanowires have shared angle of NbO6 octahedron forms a three-dimensional framework crystal structure, which leads to their large Li+ ion diffusion coefficient. The unpaired 4d electrons in the Nb4+ ion led to its conductor characteristics and high conductivity. In particular, a significant pseudo-capacitance contribution is achieved in both slow and fast electrochemical reactions. Therefore, NaNbO3 nanocubes and NaNbO3 nanowires show excellent electrochemical performance. At 100 mA g−1, NaNbO3 nanocubes and NaNbO3 nanowires can provide a high reversible capacity of 161.8/104.3 mAh g−1. At 1000 mA g−1, NaNbO3 nanocubes and NaNbO3 nanowires can still provide a high capacity of 124.7/64.8 mAh g−1. Obviously, NaNbO3 nanocubes exhibit better electrochemical performance than NaNbO3 nanowires, which can be attributed to the better Li-ion diffusion abilities and higher pseudo-capacitance of NaNbO3 nanocubes. Hence, this work provided a guide for the design of practical anode materials in the research community of high-performance Li-ion batteries.

References

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Goodenough JB, Kim Y (2010) Challenges for rechargeable Li batteries. Chem Mater 22(3):587–603

Dunn B, Kamath H, Tarascon JM (2011) Electrical energy storage for the grid: a battery of choices. Science 334:928–935

Zhang SS (2006) The effect of the charging protocol on the cycle life of a Li-ion battery. J Power Sour 161(2):1385–1391

Arico AS, Bruce P, Scrosati B, Tarascon JM, Van Schalkwijk W (2005) Nanostructured materials for advanced energy conversion and storage devices. Nat Mater 4(5):366–377

Song MY, Kim NR, Yoon HJ, Cho SY, Jin HJ, Yun YS (2017) Long-lasting Nb2O5-based nanocomposite materials for Li-ion storage. ACS Appl Mater Inter 9(3):2267–2274

Yan L, Chen G, Sarker S, Richins S, Wang H, Xu W, Rui X, Luo H (2016) Ultrafine Nb2O5 nanocrystal coating on reduced graphene oxide as anode material for high performance sodium ion battery. ACS Appl Mater Inter 8(34):22213–22219

Liu G, Jin B, Bao K, Xie H, Guo J, Ji X, Zhang R, Jiang Q (2017) Facile synthesis of porous Nb2O5 microspheres as anodes for lithium-ion batteries. Int J Hydrogen Energ 42(9):6065–6071

Wei M, Wei K, Ichihara M, Zhou H (2008) Nb2O5 nanobelts: a lithium intercalation host with large capacity and high rate capability. Electrochem Commun 10:980–983

Wei M, Wei K, Ichihara M, Zhou H (2008) Nb2O5 nanobelts: a lithium intercalation host with large capacity and high rate capability. Electrochem Commun 10(7):980–983

Kodama R, Terada Y, Nakai I, Komaba S, Kumagai N (2006) Electrochemical and in situ XAFS-XRD investigation of Nb2O5 for rechargeable lithium batteries. J Electrochem Soc 153(3):A583–A588

Liu Q, Zhang Q, Liu B, Dai WL (2020) Facile one-step hydrothermal synthesis of single-crystalline SnNb2O6 nanosheets with greatly extended visible-light response for enhanced photocatalytic performance and mechanism insight. Nanotechnology 32(6):065705

Liu Q, Zhang Q, Zhang L, Dai WL (2020) Highly efficient single-crystalline NaNb1-XTaXO3 (X=0.125) wires: the synergistic effect of tantalum-doping and morphology on photocatalytic hydrogen evolution. J Mater Sci Technol 54:20–30

Takashima T, Tojo T, Inada R, Sakurai Y (2015) Characterization of mixed titanium-niobium oxide Ti2Nb10O29 annealed in vacuum as anode material for lithium-ion battery. J Power Sour 276:113–119

Tang K, Mu X, van Aken PA, Yu Y, Maier J (2013) Nano-earl-tring TiNb2O7 as anodes for rechargeable lithium batteries. Adv Energy Mater 3(1):49–53

Liu X, Wang H, Zhang S, Liu G, Xie H, Ma J (2018) Design of well-defined porous Ti2Nb10O29/C microspheres assembled from nanoparticles as anode materials for high-rate lithium ion batteries. Electrochim Acta 292:759–768

Wang T, Shi S, Kong F, Yang G, Qian B, Yin F (2016) The role of stable interface in nano-sized FeNbO4 as anode electrode for lithium-ion batteries. Electrochim Acta 203:206–212

Wang T, Ge T, Shi S, Wu M, Yang G (2018) Synthesis of wolframite FeNbO4 nanorods as a novel anode material for improved lithium storage capability. J Alloy Compd 740:7–15

Kumari TSD, Gandhi RV, Rahul G, Kamalanathan G, Kumar TP, Jeyakumar D, Lakshminarasimhan N (2014) Electrochemical lithium insertion behavior of FeNbO4: structural relations and in situ conversion into FeNb2O6 during carbon coating. Mater Chem Phys 145(3):425–433

Lou X, Fu Q, Xu J, Liu X, Lin C, Han J, Luo Y, Chen Y, Fan X, Li J (2017) GaNb11O29 nanowebs as high-performance anode materials for lithium-ion batteries. ACS Appl Nano Mater 1(1):183–190

Wang Z, Zheng R, Li Y, Yu H, Zhang J, Zhang X, Bi W, Shui M, Shu J (2020) Synthesis and characterization of GaNb11O29@C for high-performance lithium-ion battery. Ceram Int 46(5):5913–5919

Kong F, Jiao G, Wang J, Tao S, Han Z, Fang Y, Yang G, Zhang L, Qian B (2017) Co-precipitation synthesis and electrochemical properties of CrNbO4 anode materials for lithium-ion batteries. Mater Lett 196:335–338

Li Y, Zheng R, Yu H, Cheng X, Liu T, Peng N, Zhang J, Shui M, Shu J (2019) Observation of ZrNb14O37 nanowires as a lithium container via in situ and ex situ techniques for high-performance lithium-ion batteries. ACS Appl Mater Inter 11(25):22429–22438

Yang C, Zhang Y, Lv F, Lin C, Liu Y, Wang K, Feng J, Wang X, Chen Y, Li J, Guo S (2017) Porous ZrNb24O62 nanowires with pseudocapacitive behavior achieve high-performance lithium-ion storage. J Mater Chem A 5(42):22297–22304

Yan L, Lan H, Yu H, Qian S, Cheng X, Long N, Zhang R, Shui M, Shu J (2017) Electrospun WNb12O33 nanowires: superior lithium storage capability and their working mechanism. J Mater Chem A 5(19):8972–8980

Yan L, Shu J, Li C, Cheng X, Zhu H, Yu H, Zhang C, Zheng Y, Xie Y, Guo Z (2019) W3Nb14O44 nanowires: ultrastable lithium storage anode materials for advanced rechargeable batteries. Energy Storage Mater 16:535–544

Zhu X, Fu Q, Tang L, Lin C, Xu J, Liang G, Li R, Luo L, Chen Y (2018) Mg2Nb34O87 porous microspheres for use in high-energy safe fast-charging and stable lithium-ion batteries. ACS Appl Mater Inter 10(28):23711–23720

Cheng X, Qian S, Yu H, Zhu H, Xie Y, Zheng R, Liu T, Shui M, Shu J (2019) BaNb3.6O10 nanowires with superior electrochemical performance towards ultrafast and highly stable lithium storage. Energy Storage Mater 16:400–410

Yan T, Ding R, Ying D, Huang Y, Huang Y, Tan C, Sun X, Gao P, Liu E (2019) An intercalation pseudocapacitance-driven perovskite NaNbO3 anode with superior kinetics and stability for advanced lithium-based dual-ion batteries. J Mater Chem A 7(40):22884–22888

Park S, Sung J, Chae S, Hong J, Lee T, Lee Y, Cha H, Kim SY, Cho J (2020) Scalable synthesis of hollow β-SiC/Si anodes via selective thermal oxidation for lithium-ion batteries. ACS Nano 14(9):11548–11557

Li H, Ren Y, Yang P, Jian Z, Wang W, Xing Y, Zhang S (2019) Morphology and size controlled synthesis of the hierarchical structured Li1.2Mn0.54Ni0.13Co0.13O2 cathode materials for lithium ion batteries. Electrochim Acta 297:406–416

Wang C, Higgins D, Wang F, Li D, Liu R, Xia G, Li N, Li Q, Xu H, Wu G (2014) Controlled synthesis of micro/nanostructured CuO anodes for lithium-ion batteries. Nano Energy 9:334–344

Augustyn V, Come J, Lowe MA, Kim JW, Taberna PL, Tolbert SH, Abruña HD, Simon P, Dunn B (2013) High-rate electrochemical energy storage through Li+ intercalation pseudocapacitance. Nat Mater 12(6):518–522

Liu H, Liang G, Gao C, Bi S, Chen Q, Xie Y, Fan S, Cao L, Pang WK, Guo Z (2019) Insight into the improved cycling stability of sphere-nanorod-like micro-nanostructured high voltage spinel cathode for lithium-ion batteries. Nano Energy 66:104100

Zhang K, Li Y, Wang Y, Zhao J, Chen X, Dai Y, Yao Y (2020) Enhanced electrochemical properties of iron oxalate with more stable Li+ ions diffusion channels by controlling polymorphic structure. Chem Eng J 384:123281

Guo Y, Zhang L, Wang J, Liang J, Xi L (2019) Facile method for adjustable preparation of nano-Fe7S8 supported by carbon as the anode for enhanced lithium/sodium storage properties in Li/Na-ion batteries. Electrochim Acta 322:134763

Li J, Yao W, Zhang F, Rao X, Zhang Q, Zhong S, Cheng H, Yan Z (2021) Porous SnO2 microsphere and its carbon nanotube hybrids: Controllable preparation, structures and electrochemical performances as anode materials. Electrochim Acta 388:138582

Song K, Seo DH, Jo MR, Kim YI, Kang K, Kang YM (2014) Tailored oxygen framework of Li4Ti5O12 nanorods for high-power Li ion battery. J Phys Chem Lett 5(8):1368–1373

Kang K, Ceder G (2006) Factors that affect Li mobility in layered lithium transition metal oxides. Phys Rev B 74(9):094105

Kang K, Meng YS, Breger J, Grey CP, Ceder G (2006) Electrodes with high power and high capacity for rechargeable lithium batteries. Science 311(5763):977–980

Lu X, Wu G, Xiong Q, Qin H, Ji Z, Pan H (2017) Laser in-situ synthesis of SnO2/N-doped graphene nanocomposite with enhanced lithium storage properties based on both alloying and insertion reactions. Appl Surf Sci 422:645–653

Mao W, Liu K, Guo G, Liu G, Bao K, Guo J, Hu M, Wang W, Li B, Zhang K, Qian Y (2017) Preparation and electrochemical performance of Ti2Nb10O29/Ag composite as anode materials for lithium ion batteries. Electrochim Acta 253:396–402

Hu R, Chen D, Waller G, Ouyang Y, Chen Y, Zhao B, Rainwater B, Yang C, Zhu M, Liu M (2016) Dramatically enhanced reversibility of Li2O in SnO2-based electrodes: the effect of nanostructure on high initial reversible capacity. Energ Environ Sci 9(2):595–603

Augustyn V, Simon P, Dunn B (2014) Pseudocapacitive oxide materials for high-rate electrochemical energy storage. Energ Environ Sci 7(5):1597–1614

Liu H, Hu R, Sun W, Zeng M, Liu J, Yang L, Zhu M (2013) Sn@SnOx/C nanocomposites prepared by oxygen plasma-assisted milling as cyclic durable anodes for lithium ion batteries. J Power Sources 242:14–121

Yi T, Xie Y, Wu Q, Liu H, Jiang L, Ye M, Zhu R (2012) High rate cycling performance of lanthanum-modified Li4Ti5O12 anode materials for lithium-ion batteries. J Power Sources 214:220–226

Churikov AV, Ivanishchev AV, Ivanishcheva IA, Sycheva VO, Khasanova NR, Antipov EV (2010) Determination of lithium diffusion coefficient in LiFePO4 electrode by galvanostatic and potentiostatic intermittent titration techniques. Electrochim Acta 55(8):2939–2950

Nakayama M, Ikuta H, Uchimoto Y, Wakihara M (2003) Study on the ac impedance spectroscopy for the Li insertion reaction of LixLa1/3NbO3 at the electrode-electrolyte interface. J Phys Chem B 107(38):10603–10607

Cheng M, Xia J, Hu J, Liu Q, Wei T, Ling Y, Li W, Liu B (2021) Nitrogen and oxygen codoped carbon anode fabricated facilely from polyaniline coated cellulose nanocrystals for high-performance Li-ion batteries. ACS Appl Energy Mater 4(9):9902–9912

Acknowledgements

We acknowledge the financial supports from National Natural Science Foundation of China (22002102, 21773291, 61904118), Natural Science Foundation of Jiangsu (BK20190935, BK20190947), Natural Science Foundation of the Jiangsu Higher Education Institutions of China (19KJA210005), Inner Mongolia Autonomous Region Key Laboratory of Nanocarbon Materials (No. MDK2019008), Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX20_2588), Jiangsu Key Laboratory for Environment Functional Materials.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

Handling Editor: Mark Bissett.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Du, Z., Liu, Q., Cheng, M. et al. Facile construction of single-crystalline sodium niobate anode materials: insight into the relationship of the morphology and excellent performance for lithium-ion batteries. J Mater Sci 57, 5987–5997 (2022). https://doi.org/10.1007/s10853-022-07048-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07048-4