Abstract

Thermal stabilization of polyacrylonitrile (PAN) multifilaments was performed using a multi-step annealing approach in an air environment. Ammonium persulfate (APS) pretreatment of PAN multifilaments was performed prior to the thermal stabilization process. APS pretreatment of PAN resulted in the sulfation of polymer chains. The results suggest that APS pretreatment accelerated the thermal stabilization reactions of the PAN multifilaments. Thermal treatment of APS-treated PAN multifilaments resulted in enhanced thermal stability. It seems that APS promoted the oxidative cross-linking of polymer chains. The structure and properties of thermally stabilized samples were determined employing a set of measurements, such as fiber thickness, linear density, volume density, flame test, mechanical properties, X-ray diffraction (XRD), thermogravimetric analysis (TGA), infrared (IR) spectroscopy, and scanning electron microscopy (SEM). Analysis of the X-ray diffraction and FT-IR spectroscopy results suggested rapid aromatization reactions with increasing stabilization times. Detailed analysis of X-ray diffraction curves obtained after a curve-fitting procedure suggested the rapid transformation of the original structure to a totally disordered amorphous phase containing pre-graphitic domains as shown by the gradual reduction in the degree of apparent crystallinity of the original PAN multifilament. The experimental results suggest that ammonium persulfate was very effective and efficient in promoting stabilization reactions. The use of APS is expected to reduce the overall manufacturing cost of the final carbon fiber processing by reducing the time needed for the thermal stabilization step.

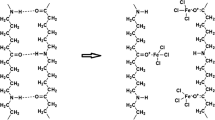

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At present, carbon fibers are considered worldwide as one of the strongest and most lightweight reinforcement materials for constructing advanced composite supplies [1, 2]. Carbon fibers contain anisotropic carbon with a value from 92 to 100 wt% carbon. This fiber has some outstanding properties such as high chemical and thermal stability in the absence of an oxidizing agent, decent electrical and thermal conductivity, tensile strength and tensile modulus, low-density value, and exceptional creep resistance properties. [3,4,5]. Carbon fiber in the form of a composite offers itself as an attention-grabbing ingredient for various advanced and high-volume applications due to having excellent tensile properties and low-density value. The number of carbon fiber manufacturing industries is constantly increasing with a target in aerospace industries, construction industries, military, medical and sports materials production [3, 4, 6, 7]. The application of carbon fiber reinforced polymeric (CFRP) composites helps to reduce weight significantly in these sectors.

Now, the maximum carbon fiber manufacturers use polyacrylonitrile precursors due to better tensile properties and high yield. However, the most practical method of manufacturing carbon fiber is the carbonization of organic fibers. Cellulosic fibers and mesophase pitch are also considered as other reasonable precursors for this case [8]. The oxidative stabilization of the precursor fiber is one of the most important stages to make the precursor fiber infusible in the high-temperature carbonization stage in carbon fiber manufacturing [9,10,11]. This stage keeps a greater influence on the tensile properties and final structure formation of the carbon fiber. About 69% of the overall energy cost is spent in the stabilization and carbonization stages of carbon fiber manufacturing. However, about 48% of energy is required only for fiber stabilization. Therefore, the maximum amount of energy and time required goes to perform the stabilization stage properly [12,13,14]. This is why this stage is considered the stage to have the most potential for optimization, as well as to reduce the environmental influence. Increasing production quantity for worldwide carbon fiber demand and even incremental perfections in processing parameters would have a massive adverse effect on the ecology [15]. Consumption of reduced fuel may be considered as an initial direct benefit during the manufacturing process. Accordingly, the succeeding cost optimization permits using carbon fiber and its composites in diverse high-volume automotive and industrial applications for decreasing weight, which lowers carbon dioxide emissions from mass transport [16, 17].

In the stabilization process, PAN fiber is heated up to 300 °C for 1 h or more to convert it into an infusible, non-flammable fiber. After finishing this stage, the samples are heated in an inert environment to carbonize at 1000 to 2500 °C, called the carbonization temperature [18,19,20,21]. In stabilization, the white PAN fibers first turned into golden yellow, afterward light and dark brown, and black. In the stabilization process, heating is applied gradually, which is called an exothermic process. It avoids any sudden release of extra heat, which may result in extreme weight loss, chain scission, or even fusion and burning of the fibers [22, 23]. Before the carbonization stage, the oxidized polyacrylonitrile fiber achieves infusible and non-burning properties [24]. The principal objective of the oxidation stage is not to lose the molecular and fibrillar orientation by forming cross-linking in the spun structure during carbonization. Polyacrylonitrile molecules need to be tied together, or the innate stiffness of the molecules needs to be improved to avoid or limit the chain scission and chain relaxation in the carbonization stage [25, 26]. In most commercial manufacturing, stabilization is done in an air atmosphere between 230 and 280 °C for the polyacrylonitrile precursor fiber. During the stabilization stage, generally, cyclization and dehydrogenation reactions occur. Cyclization is greatly exothermic; however, the exotherm is lessened when employing polyacrylonitrile copolymer precursors. In the oxidation reaction, the comonomer works as an initiator [27]. Different investigations [28, 29] have revealed that the oxidative stabilization rate of the polyacrylonitrile precursor is influenced by copolymer composition, applied temperature, and imposed tension during the process.

The stabilization process alters the chemical structure of the PAN and makes it thermally stable [30]. This process also has a significant influence in transforming the polyacrylonitrile fiber into an infusible stable ladder polymer. Thermal stabilization transforms the nitrile bond (C≡N) into nitrilo bonding (C=N). It develops cross-linking within the polyacrylonitrile molecules, which allows functioning at elevated temperatures with the least volatilization of carbonaceous substances [31, 32]. It is also experimental [33] that the C=C, C=N, and =C–H groups are created as a result of cyclization, aromatization, and elimination reactions, whereas the CH2 and CN groups are vanished entirely. The creation of the ladder ring structure is supposed for the black color of the stabilized PAN fiber [34, 35]. In the entire stabilization process, the applied temperature, the heating and cooling rate, and the stabilization period play important roles in affecting the overall heating treatment result of the PAN fiber [30, 36,37,38,39]. When the stabilization temperature goes beyond 180 °C, the molecular chains of polyacrylonitrile start to unfold and move around. It is experimentally true that higher modulus carbon fiber can be manufactured from polyacrylonitrile precursor fibers by applying optimal stabilization conditions rather than un-stabilized fibers or the fibers stabilized at high temperature [40,41,42].

Different chemical treatments on polyacrylonitrile fibers have been reported in obtaining a modified-stabilized fiber structure and increasing the stabilization rate. Application of sodium, potassium, and ammonium persulfate [43], hydrazine hydrate [44], copper chloride (I) [45], hydrogen peroxide [46], potassium permanganate [47,48,49], dibutyltin dimethoxide [50], and guanidine carbonate [51] on precursor fibers accelerate the stabilization speed significantly. However, this process reduces the activation energy of the stabilization reaction. Ammonium persulfate is one of the inexpensive oxidants, which have low long-term toxicity [52]. H2SO4 and ammonium sulfate are generated as two principal by-products in oxidation, accounting for 60% of the total sulfate ions in the solution [53]. Ammonium persulfate is a strong oxidant, generally used in polymer chemistry as a strong oxidizer [54] and in different manufacturing processes as a bleaching and cleaning agent [55]. APS is highly water-soluble and inexpensive with low long-term toxicity. Due to having reduced density, viscosity, and pH values with high solubility, APS is typically preferred to sodium–potassium persulfate. Persulfate decomposes in aqueous solutions by applying heat through concurrently occurring two independent chemical reactions as follows [56, 57]:

-

1.

Symmetrical break of the O–O bond leads by the un-catalyzed reaction and forms two sulfate-free radicals, which disappear when reacting with H2O to produce atomic oxygen and anion bisulfate;

$${\text{S}}_{2} {\text{O}}_{8}^{ = } \to 2{\text{SO}}_{4}^{ - }$$$$2{\text{SO}}_{4}^{ - } + 2{\text{H}}_{2} {\text{O}} \to 2{\text{HSO}}_{4}^{ - } + 2{\text{HO}}$$$$2{\text{HO}} \to {\text{H}}_{2} {\text{O }} + \frac{1}{2}{\text{O}}_{2}$$ -

2.

Unsymmetrical break of the O–O bond leads by the acid-catalyzed reaction, which forms sulfur tetra-oxide and bisulfate.

$${\text{S}}_{2} {\text{O}}_{8}^{ = } + {\text{H}}^{ + } \to {\text{HS}}_{2} {\text{O}}_{8}^{ - }$$$${\text{HS}}_{2} {\text{O}}_{8}^{ - } \to {\text{SO}}_{4} + {\text{HSO}}_{4}^{ - }$$$${\text{SO}}_{4} \to {\text{SO}}_{3} + \frac{1}{2}{\text{O}}_{2}$$

The literature survey showed that except for the work patented by Riggs [43], no other studies seem to have been published related to the impacts of ammonium persulfate in accelerating the stabilization rate of PAN fiber by stimulating the oxidative cross-linking within adjacent polymer chains. Hence, an exhaustive inquiry was essential to perform a further investigation on the application of ammonium persulfate as a possible chemical post-treatment for improving the stabilization process. This work aimed to explore the outcomes of ammonium persulfate pretreatment on the molecular structure of thermally stabilized polyacrylonitrile fiber before performing the carbonization process. Through a combination of tests, structural characterization was performed. Burning test, volume density, linear density, tensile properties, thermogravimetric analysis (TGA), infrared spectroscopy (IR) measurements, and X-ray diffraction (XRD) were accomplished to monitor and follow the chemical and structural transformations for different stabilization periods applied to samples.

Experimental details

Thermally stabilized sample preparation

The polyacrylonitrile precursor multifilament used in this experiment has a linear density of 539 denier per 180 filaments, with 3 dpf each. No less than 90% of acrylonitrile and 10% of vinyl acetate is believed to be present in the PAN precursor fiber as its chemical composition [58]. Prior to the stabilization stage of polyacrylonitrile fiber, ammonium persulfate [(NH4)2S2O8] was used for pretreatment in aqueous condition. Ammonium persulfate has the characteristics to accelerate the stabilization step while applied in the appropriate experimental circumstances. Because of the presence of free radical ions, SO4− and H2O2, ammonium persulfate is believed to show this acceleration activity during thermal stabilization [56, 59].

Surface impurities of the original PAN multifilament yarn were removed by immersing in isopropyl alcohol-perchloroethylene solution for 60 min at room temperature to remove the spin-finish oil. The PAN sample was subsequently washed under running water for about 30 min and air-dried to finalize the surface cleaning process. Chemical pretreatment of the precursor PAN fiber was performed in a 15% aqueous ammonium persulfate solution by immersing the samples at room temperature for 24 h. The pH value of the solution was 2.5 at 20 °C. The pretreated PAN contained 10.68% (w/w) ammonium persulfate on a dry basis. Following the removal of surface impurities and chemical impregnation, the samples were subjected to the multi-step stabilization process. The thermal stabilization process was performed in an air circulation oven. To restrict the length of the samples and to preserve physical contraction and molecular orientation, the APS pretreated yarns were initially wound onto square-shaped stainless steel frames [58, 60].

During the heating experiments, the heating rate was kept constant at 2 °C/min to reach 200 °C from room temperature, and then 1 °C/min in each stage to reach 250 °C, while the cooling rate was programmed as 2 °C/min. In the heating experiments, applied stabilizing times were 5 min, 15 min, 30 min, 45 min, and 60 min. The APS pretreated PAN multifilament was stabilized in the air atmosphere by employing a multi-step stabilization approach, as illustrated in Fig. 1.

Experimental data collection

Thermogravimetric (TGA) analysis

A Perkin Elmer diamond thermogravimetric analyzer system was used to obtain thermograms of the raw and thermally stabilized samples. Throughout the TGA experiments, the maximum temperature was 1000 °C, the heating rate was 10 °C/min, and the sample weight was around 5–6 mg. By using the melting point standards of indium (156.6 °C), tin (231.9 °C), zinc (419.5 °C), aluminum (660.1 °C), and gold (1064.2 °C), temperature calibration of TGA was performed. In both systems, 20 mg as the standard weight was used at room temperature to perform weight balance calibration. A continuous flow of nitrogen gas (200 ml/min) was kept constant during the experiments. By using the TGA data set, carbon yield (%) and weight loss (%) were evaluated for the original and ammonium persulfate impregnated thermally stabilized polyacrylonitrile multifilament.

Fourier transform infrared (IR) measurements

By using a Perkin Elmer® FT-IR spectrometer, infrared analysis was performed in absorbance mode. By means of a Norton–Beer apodization function, 50 interferograms were used to get an average value. Compared to a conforming number of background scans, every single sample spectrum was ratioed by maintaining unchanged device adjustments. In the end, by utilizing curve fitting procedures and the SPECTRUM® software, all the spectra were investigated where applicable.

X-ray diffraction (XRD) analysis

By utilizing a Bruker® AXS D8 model X-ray diffractometer, X-ray traces were acquired by employing nickel filtered CuKα radiation (λ = 0.154056 nm). At 10 steps per degree, counting was carried out. In the range of 5–35° 2θ in reflection mode, X-ray scattering data was obtained for both pure and thermally stabilized samples, and corrected for polarization, Lorentz, and incoherent scatter factors [61].

Scanning electron microscopy

LEO 440 Scanning Electron Microscope was employed to examine the surface morphology of the polyacrylonitrile samples. The distance from the detector to specimens was kept at 8 to 12 mm, and for most specimens, a 10 kV operating voltage was used. To avoid electrostatic charging impacts and improve the conductivity, a gold coating was applied on the surface of the specimens.

Assessment of burning behavior and color change

On exposure to fire with a match flame, thermally stabilized polyacrylonitrile fibers were tested to observe whether the samples were burnt or not. Depending on the burning behavior of the samples in ordinary match flame, the observed results were mentioned here as pass or fail.

Assessment of fiber thickness

Utilizing a polarizing microscope (Model: Nikon ME600L), fiber thickness was measured for the untreated and stabilized PAN samples. For the measurement of fiber thickness, 20 marks were taken widthwise from five different filaments, and the average value was used.

Assessment of linear density

Through the assessment of weight (g) per unit length (m), the linear density was obtained for the PAN multifilament sample. For linear density measurement, Tex, which is the evaluated value of the weight of yarn in grams for each 1000 m length, was used as a common unit. Stabilization yield was also assessed from the linear density values, which can be described as the ratio of linear density values of pure samples to stabilized samples under investigation.

Assessment of volume density

Using a density gradient column operated at 23 ± 1 °C, volume density values for the samples were obtained. Isopropyl alcohol (ρ = 0.796 g/cm3) and perchloroethylene (ρ = 1.62 g/cm3) were used to prepare the column for measuring the density of untreated and thermally stabilized PAN samples. To achieve the stable position, the samples were allowed to stay in the solution for about 24 h. By introducing certain floats of recognized density and by plotting the float density values on a graph against the float height in the column, which settled in 24 h, the density gradient column was calibrated. The calibration graph is expected to be a straight line, and the floats need to fit along the straight line, which would be the determinant of density values for different unknown samples.

Assessment of mechanical properties

A PROWHITE tensile testing machine was used to measure the mechanical properties of the untreated and thermally stabilized PAN samples at room temperature. Tensile experiments were performed by keeping the gauge length at 20 mm and the crosshead speed at 5 mm/min. During testing, proper care was taken to avoid any unwanted yarn slippage. At the breaking point of the sample, the tensile strength was assessed, and the average values were reported for 20 breaks in each case. Tensile strength of the samples was first obtained in N/Tex, and then multiplied by the density value in g/cm3 to convert it into MPa. Similarly, from the tensile strength curve, the initial slope was considered to measure tensile modulus values in GPa.

Data analysis

Assessment of IR-conversion index

For evaluating the total amount of cross-linked ladder polymer in the thermally stabilized PAN in the stabilization stage, the IR-conversion-index is generally used, and was determined by Eq. (1) [62].

where I0 indicates conjugated band intensity at approximately − 1590 cm−1, while IN indicates nitrile band intensity at about − 2242 cm−1, each above the baseline.

X-ray data-curve fitting

For the separation of overlapped peaks, all the traces of X-ray diffraction for the raw and stabilized polyacrylonitrile multifilament were fitted by the curve-fitting technique established by Hindeleh et al. [61]. Mutually, the Gaussian and Cauchy functions are considered present in each profile. Computer programing gives some precise values for peaks as profile function (f), peak position (2θ), peak height in electron unit, and peak breadth at half height, when the traces of experimental and the calculated intensity congregate in the most satisfactory parameters.

Assessment of X-ray stabilization index

To determine the values of the X-ray stabilization index, Eq. (2) [63] was applied in this work.

where Io indicates the (100) reflection intensity at 2θ = 17° of the original polyacrylonitrile multifilament, while I indicates the (100) reflection intensity at 2θ = 17° of stabilized polyacrylonitrile multifilament, correspondingly. After the curve fitting process, the intensity values were collected.

Assessment of apparent X-ray crystallinity

Apparent X-ray crystallinity (χc) is defined as the ratio of integrated intensity under the resolved peaks to the integrated intensity of the total scatter under the experimental trace [64]. Generally, it is articulated as follows in Eq. (3). In the present study, the assessment was performed in range 2θ between 5 and 35°.

Assessment of apparent lateral crystallite size

By using Stoke’s deconvolution method, the peak widths at half height were corrected [65]. The apparent lateral crystallite size was evaluated for stabilized polyacrylonitrile fiber by applying Scherrer Eq. (4) for the particular reflection concerned.

where L(hkl) indicates the average crystallite length vertical to the hkl planes, λ indicates the radiation wavelength (λ = 0.154 nm), K is a Scherrer parameter, β indicates breadth at half-maximum intensity, and θ indicates the Bragg’s angle for the reflection concerned.

Results and discussion

In carbon fiber manufacturing, thermal stabilization is a compulsory stage done normally in an air atmosphere that enables tolerance to a high temperature by the precursor fiber during the carbonization process. Different structural alterations occur in the pendant nitrile (C≡N) groups in the structure of the polymer because of the chemical reactions in the stabilization process and a ladder-like structure forms. Dehydrogenation also occurs in the additional transformation process, which forms conjugated structures with C=C double bonding with the elimination of carboxylic acid groups from a vinyl acetate comonomer. In the polymer chain, a carbon atom from the nitrile groups creates bonding with a nitrogen atom from the neighboring nitrile groups. It forms a nitrilo (C=N) conjugation, which ultimately leads to the production of a six-membered ring. A heterocyclic structure is formed basically by structural transformations. This structure contains carbonyl (C=O), C=C double bonds, nitrilo (C=N) groups, and remaining –C–H groups. Conjugated double bonds are produced with a cross-linked structure by combining the dehydrogenation and oxidation process.

Assessment of physical properties

In a circulated air environment, the thermal stabilization process was performed for the ammonium persulfate ((NH4)2S2O8) pretreated PAN multifilaments. This process was done by a multi-step annealing approach at 250 °C for different treatment times ranging from 5 to 60 min (Fig. 1). The color of the precursor fiber is altered during the thermal stabilization process from the white color of raw PAN through shades of brown and dark brown in the initial phases to a blackish and black color in the last phases (Table 1). The PAN is thought to have a highly cross-linked aromatized structure in the thermally stabilized PAN filament, indicated by the color changes. In the advanced stages, transforming into deep colors confirms the thermally stabilized structure of the PAN filament.

The flame test results are presented in Table 1. After 45 min of the multi-step stabilization process, the ammonium persulfate pretreated PAN samples passed the critical flame test by showing non-burning properties when placed into an ordinary match flame. Therefore, the sample with a stabilization time of 45 min in the multi-step approach is expected as completely stabilized to resist high carbonization temperatures (Table 1). The outer layer of the precursor fiber is subjected to a prompt oxidation reaction that causes the inhibition of elemental oxygen diffusion into the inner zone during thermal stabilization. Consequently, the outer and inner zones of the stabilized fibers have some differentiations that cause the color differences between these two layers. An equivalent degree of thermal stabilization is required for both the outer and inner zone of the sample to obtain a properly stabilized structure. By selecting proper precursor properties, including cross-sectional shape and filament fineness, and by maintaining proper temperature [66] and time in the stabilization process [67, 68], the heterogeneity of the outer-inner zone [69] might be avoided. It has been reported that with the escalation of stabilization temperature and time, the outer-inner zone heterogeneity is progressively vanished [70]. The outer-inner zone heterogeneity causes the color difference through the cross section of the PAN sample. Adequate stabilization and accumulation of the oxygen-based functional groups, like carbonyl, hydroxyl, and carboxylic groups on the polymer chain backbone is supposed for the dark color in the outer zone. However, insufficient stabilization is considered for the light color of the inner zone of precursor fiber that may not tolerate higher temperature in the carbonization step [71].

Table 1 and Fig. 2 present the volume density values for the untreated (pristine) and thermally stabilized PAN multifilaments impregnated with 15% APS solution. A continuous increase in volume density is shown between 5 and 60 min stabilization time. Volume density values start from 1.179 g/cm3 for the pristine PAN and go to 1.395 g/cm3 for the 60 min thermally stabilized PAN. The development of a ladder-like structure in the polymer is attributed to the escalation of volume density values, which are incorporated by the close packing of the polymer chains because of the cyclization of the nitrile groups [72].

In the present experiment, volume density values demonstrate a constant upsurge with the increase in the stabilization period. Takaku et al. [73] mentioned increased density values for a higher stabilization temperature. They described that to reach a certain volume density; a shorter stabilization time is sufficient at high temperatures. They also revealed that in the extended stabilization period, the precursor fiber reached a fixed density of 1.58 g/cm3, regardless of the stabilization temperature. In published works, results present that the increase in the volume density of stabilized precursor fiber decreases the volume density value of the carbon fiber [73]. These indicate the significant number of micro-void formations in the carbon fiber structure obtained from high density thermally stabilized fiber but eventually shows reduced tensile strength of carbon fibers. It also suggests that the thermally stabilized fiber with an optimum density must obtain desired tensile properties in carbon fiber. It has been noticed that to produce high strength carbon fiber, the volume density values of the stabilized fiber should be in the range of 1.34 to 1.39 g/cm3 and the oxygen content between 5 and 9% [73]. The increased volume density values for higher stabilization periods endorse the growth of extensive cross-linking in the stabilized fiber that causes lateral compaction of the whole fiber structure.

Prior to the thermal stabilization, the linear density value of the pristine polyacrylonitrile was increased by 10.68% following the impregnation of the 15% APS, and reached 66.35 tex. In Table 1 and Fig. 3, linear density values of the thermally stabilized PAN multifilaments are presented for different stabilization periods. After 5 min of stabilization, the linear density value reduces by 1.6% compared to the APS impregnated PAN multifilaments and shows a constant fall with increasing the stabilization period. The decrease in linear density was continuous up to the stabilization time of the 60 min multi-step annealing for the sample. A linear density loss of 6.38% was noticed for the 60 min stabilized samples compared to the APS impregnated PAN sample. Stabilization yield was evaluated and found to drop to 95.02% in the 60 min annealed sample because of the weight loss in the thermal treatment (Table 1). The decrease in linear density values by the increase in stabilization period is caused by the probable elimination of the elementary hydrogen, nitrogen, oxygen, and carbon containing functional groups.

Variation of fiber thickness of the stabilized PAN multifilaments is shown in Table 1 for different stabilization periods. Fiber thickness of the stabilized PAN decreased from 19.68 µm to 17.22 µm with a stabilization period of 60 min in the multi-step annealing. The fiber thickness declined swiftly after 15 min treatment time to 6.2%, and further decreases continued with the succeeding stabilization period. A maximum amount of decrease in fiber thickness was identified after 60 min multi-step annealing with approximately 12.5% loss in fiber thickness in comparison to the thermally untreated PAN sample. The weight loss of the sample in the thermal stabilization is supposed to be the main cause for decreasing fiber thickness.

Assessment of mechanical properties

The shifting of tensile strength values of untreated and APS impregnated-stabilized polyacrylonitrile multifilaments are presented in Table 2 and Fig. 4. Tensile strength of 5 min thermally stabilized PAN shows a sudden fall of about 40.7% and reaches 162.2 MPa from 273.5 MPa of raw PAN sample. Afterward, it exhibits a gradual decrease until 45 min thermal stabilization and reaches 152.4 MPa. The tensile strength values show a sharp fall by approximately 52.1% of the PAN samples for 60 min thermal stabilization. In the TOS process performed in the air atmosphere, nitrile (C≡N) bonds are transformed into nitrilo (C=N) bonds by an intermolecular cross-linking reaction. This transformation causes cohesive energy loss significantly within the polymer chains, and it is the main reason working behind reducing tensile strength. The extent of nitrile bond transformation into nitrilo bonds determines the amount of tensile strength loss in the TOS process [24].

Untreated PAN multifilament shows the highest elongation at break of about 9.08%. Throughout the stabilization periods, there is a trend of decreasing values. The tendency starts with a sudden fall in the 5 min multi-step annealing by 3.77%, and finally reaches 1.44% for the 60 min treatment time.

Tensile modulus values are presented in Fig. 5 for the untreated and thermally stabilized PAN multifilaments. The tensile modulus of the raw PAN was 12.99 GPa, which declines swiftly to about 32% just after the 5 min multi-step annealing of the APS-treated sample. The latter case shows a steady rise up to the 60 min stabilization time and reaches 12.78 GPa.

Assessment of thermal analysis (TGA)

TGA thermogram analysis is generally used to obtain carbon yield percentage, which is considered an essential measure for thermally stabilized samples. In the carbonization stage, thermally stabilized polyacrylonitrile samples lose their weight by eliminating the organic constituents as pyrolysis by-products. Typically, the carbonization phase is in the temperature range between 200 °C and 600 °C and beyond, and elements apart from carbon are likely removed from the PAN sample in this stage. In the dehydrogenation reaction, hydrogen is generally removed as part of water vapor. However, nitrogen is removed as nitrogen (N2) gas or hydrogen cyanide (HCN), and oxygen is eliminated in the form of carbon dioxide (CO2), carbon monoxide (CO), water (H2O) vapor, or simple oxygen (O2) gas.

In Fig. 6, TGA thermograms are plotted for untreated and thermally stabilized PAN samples. TGA thermograms present the diminution of weight loss with the rise of treatment time, which indicates the increase in carbon yield due to intensifying the cross-linking density. Because of the formation of a higher number of cross-linking related ladder structures, thermally stabilized PAN loses weight over a broader temperature range. However, the untreated PAN loses weight over a more narrow temperature range. An extreme thermal decomposition is observed in 5 min (multi-step annealed) in thermally stabilized samples between 300 and 450 °C with a weight loss of 63.5% at 500 °C and 56.6% at 1000 °C. With the increase in the stabilization period, the weight loss drops gradually between 50 and 450 °C (Fig. 6). For the 60 min, thermally stabilized PAN multifilament, weight loss becomes 75.9% at 500ºC and 69.2% at 1000 °C.

A comparison of the carbon yields for the untreated and ammonium persulfate impregnated thermally stabilized PAN multifilament samples at temperatures of 500 °C and 1000 °C is presented in Fig. 7. From the TGA analysis, it is noticed that the occurrence of oxidation-based cross-linking reactions caused the thermally stabilized PAN to obtain higher thermal stability. The outcomes demonstrate that the carbon yield value escalates with the increase in the stabilization period. The carbon yield value for the 5 min stabilized PAN sample was 63.7% and 55% at 500 °C and 1000 °C, respectively. In the experiment, APS pretreated, and 60 min stabilized PAN multifilament presents a maximum carbon yield value of 75.9% at 500 °C and 69.1% at 1000 °C. A constant rise of carbon yield is observed at 500 °C and 1000 °C for different stabilization periods from 5 to 60 min (Fig. 7).

Differential TGA (dTGA) curves of TGA thermograms are presented in Fig. 8. The dTGA curve of the original PAN multifilament sample shows exothermic peaks located at 300 and 467 °C. Following the thermal stabilization reactions, the dTGA peak for the stabilized samples shifts to 406 °C, and a new peak appears at 300 °C. These peaks are believed to be due to the cyclization and aromatization reactions of polyacrylonitrile fiber with the release of various gaseous materials, including acetonitrile, acrylonitrile, benzonitrile, methane, acetylene, ethylene, ethane, propene, propane, 1, 3 butadiene, ethyl nitrile, vinyl acetonitrile, dicyanobutene, crotonitrile, benzene, HCN, pyridine, adiponitrile, dicyanobenzene, naphthalene and ammonia like products leaving behind black orlon [74]. The peak located around 100ºC is due to the evaporation of water present on the samples.

Assessment of FT-IR spectroscopy analysis

To observe the structural and chemical changes occurred in the thermal stabilization stage, infrared spectroscopy was considered as an immensely suitable technique in the present work. Aqueous APS impregnation exhibits unique alterations in the infrared spectra of the stabilized polyacrylonitrile sample obtained by a multi-step annealing approach.

The polymer structure of the PAN multifilament sample is composed of approximately 90% acrylonitrile and 10% vinyl acetate monomeric units. For this reason, in the PAN fiber spectrum, some infrared bands are observed of vinyl acetate comonomer. The comparison of the infrared spectra in the region of 1850–850 cm−1 in the PAN multifilament sample and vinyl acetate monomer is shown in Fig. 9. It is observed that the infrared bands at about 1452 (CH2 bending) and 1070 cm−1 are present because of the existence of acrylonitrile units only. However, 1736 (C=O stretch), 1368, 1233, 1114, and 1022 cm−1 bands confirm the existence of vinyl acetate monomers. Figure 9 also presents the trivial contribution of vinyl acetate units in the infrared band located at about 1452 cm−1.

As a result of the aliphatic ketone stretching vibration of vinyl acetate monomer, a characteristic band at 1736 cm−1 is observed for the original PAN sample. The infrared spectra at 1452 cm−1 and 1368 cm−1 are allotted to methylene (CH2) and methine (CH), correspondingly [75, 76]. The CH2 twisting mode of CH2 groups is assigned for the band at 1233 cm−1 [77]. Some overlapping bands of the infrared spectrum in the region of 1154–980 cm−1 present mixed skeletal modes of C–C stretching, C–H bending, C–H rocking, C–H wagging, CH2 rocking, and C–C–CN bending at 1116, 1074, and 1035 cm−1, correspondingly [75, 76].

The infrared spectra of stabilized PAN fiber show some major deviations in the intensities due to different stabilization periods. The comparison of infrared spectra in the region 2000–450 cm−1 of untreated and thermally stabilized polyacrylonitrile multifilament impregnated with (NH4)2S2O8 for different treatment times is presented in Fig. 10. Significant structural transformation is observed in the spectra compared to the untreated polyacrylonitrile spectrum. After 5 min of stabilization of PAN multifilament, the carbonyl (C=O) stretching spectrum of aliphatic ketone group at 1736 cm−1 loses most of the intensity, and shifts to a lower frequency with increasing treatment time till it is noticed as a shoulder on the leading conjugation absorption (Fig. 10). This characteristic was mentioned as a probable sign of becoming part of the conjugated structure of the carbonyl groups [78].

From Fig. 10, it is clearly visible by the infrared bands at 1655, 1583, 1154, and 806 cm−1 that the presence of ammonium persulfate is characterized. Due to the occurrence of structural transformations during the thermal stabilization process, a new spectrum at 1583 cm−1 is noticed in the infrared band of the (NH4)2S2O8 impregnated and thermally stabilized polyacrylonitrile sample. With the increase in stabilization time, the spectrum is progressively expanded. The infrared band at 1583 cm−1 is supposed to be a sign of intra-molecular reaction and the transformation of nitrile (C≡N) group into nitrilo (C=N) group by the cyclization process. In published works, different assignments have been mentioned for this band. In some inquiries, it is allotted [78,79,80] to conjugated nitrilo (C=N) groups obtained from cyclization. This band is assigned as C=C and C=N groups by Clarke and Bailey [9]. This band is also assigned for the combination of C=C and C=N vibrations [81, 82]. For the stabilized polyacrylonitrile sample, the combination of C=C, C=N stretching, and N–H in plane bending vibrations is another assignment [83].

The development of the infrared bands at 1583 cm−1 and 1655 cm−1 are supposed to be produced by oxygen uptake reactions [84]. In the thermal stabilization process, the occurrence of an ongoing oxygen uptake reaction is indicated by functional groups containing oxygen like hydroxyl groups, aliphatic ketone, and conjugated ketone. This recommends that the oxidation reaction goes hand-in-hand with dehydrogenation and cyclization. In the thermal stabilization process, a C–C single bond is converted into a C=C double-bonded species, forming five and six member cyclized ring structures, where oxygen is supposed to play a crucial role by assisting the dehydrogenation reactions [84]. The formation of a new band at 1154 cm−1 points toward developing a C–O group in α, β-unsaturated esters, and carboxylic acids and is also believed to be due to oxygen uptake reactions [85]. Development of the functional groups containing oxygen as carbonyl (–C=O), hydroxyl (–OH), and carboxyl (–COOH) is considered the secondary role of oxygen, which is essential to produce intermolecular cross-linking in polymer chains. The development of structures characterized by high-temperature stability is assumed due to the creation of oxygen-containing functional groups [86]. Before performing the carbonization process for the stabilized sample, this type of characteristic holds greater importance.

With the increase in treatment time, the CH2 band and –C–O stretch (PVA) at 1452 cm−1 and 1233 cm−1, respectively, and lose their intensity (Fig. 10) and gradually become less dominant because of the occurring dehydrogenation and development of C=C bonds. The infrared spectra between 1600 and 1300 cm−1 are characterized by the extensive broadening and rise in intensity through a new band formation centered at 806 cm−1, which is allotted to a conjugated C–H (C=C–H) vibration [87]. In the early phases of the thermal stabilization process, only a few double-bonded C=C groups are produced and are mentioned as a weakness of this band. With the increased thermal stabilization period, the conjugated hydrocarbon structure becomes completely formed, which is indicated by increasing band intensity in the higher stabilization stages.

In Fig. 11, two prominent bands centered at 2920 cm−1 and 2852 cm−1 are positioned between the 3000 cm−1 and 2800 cm−1 regions, where the methylene (CH2) and the nitrile (C≡N) vibrations are located correspondingly. With the increase in stabilization time, the intensity variation of the nitrile (C≡N) groups of the acrylonitrile monomers, as a part of the PAN polymer, is also presented in Fig. 11. At about 2242 cm−1, a nitrile vibration is positioned. After just 5 min of the stabilization period, the methylene (CH2) bands lose their maximum intensity, which indicates hydrogen atom elimination because of the dehydrogenation reactions occurring in the polymer backbone in addition to the cross-linked structure. It is believed that due to the dehydrogenation reactions, oxygen is partly incorporated with the samples during the stabilization process.

In Fig. 11, a quick intensity loss is observed of the nitrile absorption spectrum at 2242 cm−1. However, at around 2120 cm−1, a new spectrum appears associated with thiocyanate (S=C=N) stretching [85]. Another newly appearing band occurs at about 2200 cm−1, allotted to nitrilo (C=N) conjugation and attributed to the ionic structures [78]. This band assignment is considered the result of the α, β-unsaturated, and β-imino nitrile groups rising from dehydrogenation reactions or from the isomerization and tautomerization of the ladder structure [88, 89]. This band is also associated with aminonitrile groups [82, 90]. In the oxygen-rich air environment, stabilized fibers show a higher intensity fall ratio of nitrile groups than at an elevated temperature [9]. The spectra between 3700 and 2300 cm−1 encompass a common leading peak position of 2920 cm−1, which is retained, even after the 60 min multi-step annealing. The dehydrogenation reactions occur in the backbone polymer chains and the cross-linked polymer structures due to the loss of hydrogen atoms, which is indicated by the continuous intensity loss of methylene spectrum at 2920 cm−1. Intensity deviation by the increase in treatment time of the nitrile (C≡N) groups of acrylonitrile monomers is also presented in Fig. 11. In thermal stabilization, constant intensity loss of the nitrile vibration points to the occurrence of the cyclization reactions. The intensity of the CH2 in-plane bending and the aliphatic methylene (CH2) stretching at 1452 cm−1 and 2920 cm−1 correspondingly weakens gradually with the increase in stabilization period accompanied by the boosted conjugation = C–H band at 806 cm−1. It indicates conjugated backbone polymer structure formation. Infrared curve fitting for the bands at 1850–850 cm−1 was used to achieve the precise peak heights in absorbance form used for the evaluation of the dehydrogenation index (A1432/A1366) values (Fig. 12).

Using Eq. (1), the IR-conversion index was evaluated to analyze the transformation of structures into an extremely cross-linked and cyclized structure with the help of the conjugated structure spectrum at 1583 cm−1 and the nitrile group at 2242 cm−1. APS pretreatment with PAN fibers exhibits faster transformation of raw polyacrylonitrile structure to the cross-linked and cyclized structure (Fig. 13). The IR-conversion index is generally used to characterize the development of the ladder structure of the polymer, which is faster in the initial phases. However, with the increase in stabilization time, it becomes slower. Within the first 5 min of the multi-step stabilization process, the IR-conversion index value rises very fast and reaches 92%. Though, it gradually slows down and reaches 96% for the 60 min multi-step annealing. The transformation of the polyacrylonitrile structure into a cyclized and cross-linked ladder-like structure occurred within the 5 min multi-step stabilization of the PAN sample, which is indicated by the outcomes of the infrared spectroscopy analysis.

Due to the occurrence of dehydrogenation reactions, the dehydrogenation index values specify the continuous hydrogen atom loss, which was assessed by using the absorbance ratios A1452/A1368 and A2920/A1368 (Fig. 14). The outcomes likewise point toward faster and accelerated dehydrogenation reactions. Therefore, it is mentionable that the hydrogen content decreases with the reduction in dehydrogenation index values. It is observable that there is a direct relationship between the dehydrogenation index and the hydrogen atom loss from the polymer chain. APS pretreatment on PAN samples speeds up converting the C–C bond into a C=C bond in the polymer chain due to the accelerated dehydrogenation reactions.

Assessment of X-ray diffraction analysis (XRD)

Equatorial X-ray diffraction curves of original and ammonium persulfate impregnated and thermally stabilized PAN fibers for the stabilization periods from 5 to 60 min are presented in Fig. 15. Assessment of the equatorial X-ray diffraction curve of the original polyacrylonitrile sample presented in Fig. 15 exhibits two ordered peaks with d-spacing of 0.539 and 0.308 nm, which are assigned to a hexagonal unit cell [24, 58, 60]. The results show that the ordered peaks (PE1 and PE3) can be assigned to the (100) and (110) reflections of a hexagonal unit cell with basal plane dimensions of a = b = 0.6 nm [24]. The results presented in Table 4 show that d-spacing of (110) reflection exhibited a lattice enlargement of 0.68% for the stabilization times ranging from 5 to 60 min. In the case of the (100) reflection, no such observation was made.

An additional but less ordered and broad peak (PE2) with d-spacing of 0.345 nm (at about 25.5° 2θ) is also present in the diffraction pattern (Fig. 16). This peak can be assigned to the unoriented and disordered phase. The d-spacing of this peak is attributed to (002) reflection of the pre-graphitic structure (such as ladder/aromatic) [24]. The intensity of this peak above the baseline is used to determine the X-ray stabilization index presented in Eq. (2).

The thermal stabilization process seems to significantly affect crystal structure through crystallite size and degree of crystallinity for the laterally ordered structure. A curve-fitting procedure is employed to attain precise peak parameters utilizing peak height, peak position, and half-height width [24, 58, 60]. Curve-fitted X-ray diffraction curves of original and stabilized polyacrylonitrile multifilament samples are presented in Figs. 15 and 16.

A close inspection of Fig. 15 suggests a rapid loss of laterally ordered structure assigned to the hexagonal crystal phase by the advancement of stabilization reactions [24, 58, 60]. The (100) reflection keeps its presence in the sample for the stabilization period of 5 min but disappears completely for the samples stabilized for 15 min and higher (Fig. 15). A similar observation was made for the (110) reflection, which kept its presence in minor quantity during the stabilization reactions up to the stabilization period of 60 min (Fig. 17). The resolution of equatorial X-ray diffraction curves shown in Fig. 16 reveals the presence of the (110) reflection as a broad peak because of de-crystallization reactions.

The apparent X-ray crystallinity is considered as a measure of lateral order. This is because of using equatorial X-ray diffraction curves following the curve fitting method. Hence, the term ‘apparent crystallinity’ should be employed in place of ‘crystallinity’, which suggests absolute crystallinity [24]. In this work, the apparent crystallinity values were evaluated by using Eq. (3). Curve fitting of the equatorial X-ray diffraction curves resulted in the successful evaluation of apparent X-ray crystallinity and amorphous fraction values presented in Fig. 18. The curve fitting procedure was also successfully utilized to acquire precise peak parameters, particularly the peak heights above baseline, to evaluate X-ray stabilization indices [24] utilizing Eq. (2). During the present investigation, the values of the X-ray stabilization index were observed to rise with the increase in stabilization period (Fig. 18) and could be considered as a dependable technique for evaluating the amount of aromatic structure formation at the time of the stabilization reactions [24].

The outcomes presented in Fig. 18 show that the values of the apparent X-ray crystallinity exhibited a descending and rising tendency, as was observed in the case of the amorphous fraction values. The values of the apparent X-ray crystallinity showed a descending tendency ranging from 19 to 12.7%. However, the values of the amorphous fraction exhibited a reverse tendency, escalated from 81 to 87% with the increase in stabilization period (Fig. 18). The outcomes of the evaluations are presented in Fig. 18. The results show that the X-ray stabilization index soared rapidly with the increase in the stabilization period (Fig. 18). The evaluation of lateral crystallite size, considering no influence from crystal perfection, was performed following the correction of instrumental broadening effects corresponding to the ordered PE1 and PE3 reflections (100 and 110 ordered reflections) using the Scherrer Eq. (4) of the original and stabilized PAN multifilaments [24]. The curve fitting method was applied to achieve precise peak parameters for the equatorial X-ray diffraction curves for determining lateral crystallite sizes corresponding to the (100) and (110) ordered reflections as listed in Tables 3 and 4.

The corrected, half-height widths of the ordered peaks (PE1 and PE3) were utilized to assess apparent crystallite sizes and are presented in Table 3. The outcomes presented in Table 3 indicate that the lateral dimension of the (100) peak was reduced from 9.66 to 4.42 nm. The number of chains in the hexagonal crystal structure normal to the (100) planes accountable for the lateral crystallite sizes is also presented in Table 3. However, the original sample size corresponds to 18 chains, while the lateral crystallite size, due to the 5 min stabilization time, was reduced to 8 chains.

The results presented in Table 4 also show that the lateral dimension of the (110) peak was reduced from 4.82 to 1.39 nm. The number of chains in the hexagonal crystal structure normal to the (110) planes liable for the lateral crystallite sizes is also presented in Table 4. Although the original sample size corresponds to 16 chains, the lateral crystallite size, due to 5 min stabilization time, was evaluated as 5 chains. The number of chains liable for the lateral crystallite size for the other samples stabilized for the stabilization periods from 15 to 60 min did not change considerably and remained at 5 chains (Table 4). The corresponding lateral dimensions (i.e., crystallite size) for the disordered peak (PE2), which underwent stabilization periods from 15 to 60 min was found to vary between 2.54 and 1.3 nm, correspondingly. It was observed that the rapid thermal stabilization in air resulted in the reduction in apparent crystallinity and the corresponding reduced lateral crystallite size because of the rapid stabilization reactions.

Assessment of scanning electron microscopy

Scanning electron microscopy (SEM) was utilized to investigate the surface properties of pristine, and APS incorporated and heat-stabilized PAN multifilaments in this study. Because of the effects of the fiber extrusion process in the wet spinning method, grove-like striations and irregular surface features are observed through the longitudinal axis of the filaments (Fig. 19). These surface features are supposed to be developed by releasing solvents from the filaments in the coagulation bath. The release of solvents also causes the development of the kidney-like cross-sectional shape of the PAN filaments (Fig. 20).

Figure 21 shows the surface images of APS impregnated and thermally stabilized PAN multifilaments. The SEM analysis revealed that the surface topographies do not show apparent changes of the stabilized PAN samples through different stabilization periods (Fig. 21). The development of central regions of the thermally stabilized polyacrylonitrile filament was studied by Layden [91]. In that study, it was noticed that the temperature of the surface area was lower than the interior temperature of the polyacrylonitrile filament. For this reason, the transferred heat in the stabilization phase is supposed to stimulate the cyclization reaction and to form a disorganized (i.e., amorphous) ladder-like structure in the core area of the stabilized PAN sample. Thus, the disorganized core area is estimated to reduce the oxygen diffusion from the outer surface area [92].

Conclusion

Integration of 15% APS aqueous solution with PAN multifilaments was accomplished prior to the thermal stabilization process. From the experiment, it was observed that APS pretreatment reduces stabilization time and results in quicker development of the cyclized structure, which is essential for tolerating higher temperatures during the carbonization stage. The impact of APS on PAN multifilaments at the time of thermal treatment was examined by using density, stabilization yield, tensile properties, infrared (IR) spectroscopy, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and X-ray diffraction (XRD) measurements. The thermal stabilization in the air environment caused major physical and structural transformations of the APS pretreated PAN multifilaments. Physical transformations were noticed by the decrease in linear density and the change of color of the PAN sample. By the increase in stabilization period, infrared results showed a faster and concurrent cyclization and dehydrogenation reaction. This is confirmed by the quick intensity loss of the nitrile spectrum at 2242 cm−1 and the methylene spectrum at 2920 cm−1. The conversion indices acquired from the X-ray diffraction and the infrared spectroscopy results demonstrated a fast conversion into a highly cross-linked and cyclized polymer structure from the open structure of the PAN fiber. By the progress of the stabilization period, a comparative enhancement in thermal stability was observed in the TGA thermograms, which were quantified by the increase in carbon yield. The highest carbon yield value was 69.12% at 1000 °C for the APS impregnated and stabilized PAN multifilament. The PAN samples stabilized at 250 °C for 60 min are likely to endure high temperatures in the carbonization stage. In carbon fiber manufacturing, the application of APS with PAN samples helps to speed up the thermal stabilization process. Thus, it may keep a vital role by decreasing the overall processing time and cost of carbon fiber production if the process parameters are properly controlled.

References

Yanagimoto J, Ikeuchi K (2012) Sheet forming process of carbon fiber reinforced plastics for lightweight parts. CIRP Ann 61:247–250. https://doi.org/10.1016/j.cirp.2012.03.129

Mrazova M (2013) Advanced composite materials of the future in aerospace industry. Incas Bull 5:139. https://doi.org/10.13111/2066-8201.2013.5.3.14

Roberts T (2006) The carbon fibre industry: global strategic market evaluation 2006–2010. Materials Technology Publications

Donnet JB, Bansal RC (1990) Carbon fibers. Marcel Dekker, New York

Bai Y, Huang Z-H, Kang F (2014) Electrospun preparation of microporous carbon ultrafine fibers with tuned diameter, pore structure and hydrophobicity from phenolic resin. Carbon N Y 66:705–712. https://doi.org/10.1016/j.carbon.2013.09.074

Council NR (1992) High performance synthetic fibers for composites. National Academies Press, Washington, DC

Red C (2006) Aerospace will continue to lead advanced composites market in 2006. Compos Manuf 22:24–26

Dumanlı AG, Windle AH (2012) Carbon fibres from cellulosic precursors: a review. J Mater Sci 47:4236–4250. https://doi.org/10.1007/s10853-011-6081-8

Clarke AJ, Bailey JE (1973) Oxidation of acrylic fibres for carbon fibre formation. Nature 243:146–150. https://doi.org/10.1038/243146a0

Ogawa H, Saito K (1995) Oxidation behavior of polyacrylonitrile fibers evaluated by new stabilization index. Carbon N Y 33:783–788. https://doi.org/10.1016/0008-6223(95)00007-Z

Jain MK, Balasubramanian M, Desai P, Abhiraman AS (1987) Conversion of acrylonitrile-based precursors to carbon fibres. J Mater Sci 22:301–312. https://doi.org/10.1007/BF01160585

Golkarnarenji G, Naebe M, Badii K et al (2018) Support vector regression modelling and optimization of energy consumption in carbon fiber production line. Comput Chem Eng 109:276–288. https://doi.org/10.1016/j.compchemeng.2017.11.020

Badii K, Naebe M, Golkarnarenji G, et al (2014) Energy saving in electric heater of carbon fiber stabilization oven. In: 2014 4th international conference on artificial intelligence with applications in engineering and technology. IEEE, pp 109–114

Golkarnarenji G, Naebe M, Badii K et al (2018) Production of low cost carbon-fiber through energy optimization of stabilization process. Materials 11:385. https://doi.org/10.3390/ma11030385 (Basel)

Maghe M, Creighton C, Henderson LC et al (2016) Using ionic liquids to reduce energy consumption for carbon fibre production. J Mater Chem A 4:16619–16626. https://doi.org/10.1039/C6TA06842A

Warren CD (2011) Low cost carbon fiber overview. Oak Ridge Natl Lab Oak Ridge, Tennessee

Holmes M (2013) Carbon fibre reinforced plastics market continues growth path. Reinf Plast 57:24–29. https://doi.org/10.1016/S0034-3617(13)70186-3

Soulis S, Dragatogiannis DA, Charitidis CA (2020) A novel methodology for designing thermal processes in order to optimize stabilization of polyacrylonitrile (PAN) fibers. Polym Adv Technol 31:1403–1413. https://doi.org/10.1002/pat.4870

Karacan I, Erdogan G (2012) The influence of thermal stabilization stage on the molecular structure of polyacrylonitrile fibers prior to the carbonization stage. Fibers Polym 13:295–302. https://doi.org/10.1007/s12221-012-0295-5

Nunna S, Naebe M, Hameed N et al (2017) Evolution of radial heterogeneity in polyacrylonitrile fibres during thermal stabilization: an overview. Polym Degrad Stab 136:20–30. https://doi.org/10.1016/j.polymdegradstab.2016.12.007

Cowie JMG (1973) Polymers: chemistry and physics of modern materials. International Textbook Co. Ltd, Guilford and London, p 215

Yoo SH, Park S, Park Y et al (2017) Facile method to fabricate carbon fibers from textile-grade polyacrylonitrile fibers based on electron-beam irradiation and its effect on the subsequent thermal stabilization process. Carbon N Y 118:106–113. https://doi.org/10.1016/j.carbon.2017.03.039

Reda SY (2011) Evaluation of antioxidants stability by thermal analysis and its protective effect in heated edible vegetable oil. Food Sci Technol 31:475–480. https://doi.org/10.1590/S0101-20612011000200030

Karacan I, Erdoğan G (2012) The role of thermal stabilization on the structure and mechanical properties of polyacrylonitrile precursor fibers. Fibers Polym 13:855–863. https://doi.org/10.1007/s12221-012-0855-8

Thorne DJ (1985) Manufacture of carbon fibre from PAN. Elsevier Sci Publ B V Handb Compos 1:475–494

Ehrburger P, Donnet J-B (1985) Carbon and graphite fibers. Marcel Dekker Inc, Handb Fiber Sci Technol 3:169–220

Fitzer E (1990) Carbon fibres—present state and future expectations. Carbon fibers filaments and composites. Springer, New York, pp 3–41

Fitzer E, Müller DJ (1972) Reaktionstechnische Betrachtung der kontinuierlichen Herstellung von Kohlenstoff-Fasern aus Polyacrylnitril. Chem Ztg 96:20–26

Grassie N, Hay JN (1962) Thermal coloration and insolubilization in polyacrylonitrile. J Polym Sci 56:189–202. https://doi.org/10.1002/pol.1962.1205616316

Clingerman ML (2001) Development and modelling of electrically conductive composite materials. Michigan Technological University Houghton

David LIB, Ismail AF (2003) Influence of the thermastabilization process and soak time during pyrolysis process on the polyacrylonitrile carbon membranes for O2/N2 separation. J Memb Sci 213:285–291. https://doi.org/10.1016/S0376-7388(02)00513-6

Ko T (1991) Influence of continuous stabilization on the physical properties and microstructure of PAN-based carbon fibers. J Appl Polym Sci 42:1949–1957. https://doi.org/10.1002/app.1991.070420719

Setnescu R, Jipa S, Setnescu T et al (1999) IR and X-ray characterization of the ferromagnetic phase of pyrolysed polyacrylonitrile. Carbon N Y 37:1–6. https://doi.org/10.1016/S0008-6223(98)00168-7

Burlant WJ, Parsons JL (1956) Pyrolysis of polyacrylonitrile. J Polym Sci 22:249–256. https://doi.org/10.1002/pol.1956.1202210107

Friedlander HN, Peebles LH Jr, Brandrup J, Kirby JR (1968) On the chromophore of polyacrylonitrile. VI. Mechanism of color formation in polyacrylonitrile. Macromolecules 1:79–86

Jing M, Wang C, Bai Y et al (2007) Effect of temperatures in the rearmost stabilization zone on structure and properties of PAN-based oxidized fibers. Polym Bull 58:541–551. https://doi.org/10.1007/s00289-006-0692-2

Fitzer E, Frohs W, Heine M (1986) Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon N Y 24:387–395. https://doi.org/10.1016/0008-6223(86)90257-5

Duan Q, Wang B, Wang H (2012) Effects of stabilization temperature on structures and properties of polyacrylonitrile (PAN)-based stabilized electrospun nanofiber mats. J Macromol Sci Part B 51:2428–2437. https://doi.org/10.1080/00222348.2012.676415

Paiva MC, Kotasthane P, Edie DD, Ogale AA (2003) UV stabilization route for melt-processible PAN-based carbon fibers. Carbon N Y 41:1399–1409. https://doi.org/10.1016/S0008-6223(03)00041-1

Wang B, Xiao S, Cao W et al (2012) Evolution of aggregation structure of polyacrylonitrile fibers in the cyclization reaction. J Appl Polym Sci 124:3413–3418. https://doi.org/10.1002/app.35361

Hou Y, Sun T, Wang H, Wu D (2009) Thermal-shrinkage investigation of the chemical reaction during the stabilization of polyacrylonitrile fibers. J Appl Polym Sci 114:3668–3672. https://doi.org/10.1002/app.30303

Ko T (1991) The influence of pyrolysis on physical properties and microstructure of modified PAN fibers during carbonization. J Appl Polym Sci 43:589–600. https://doi.org/10.1002/app.1991.070430321

Riggs JP (1972) Thermally stabilized acrylic fibers produced by sulfation and heating in an oxygen-containing atmosphere, US Patent 3,650,668.

Mladenov I, Ljubcheva M (1983) Polyacrylonitrile fibers treated by hydrazine hydrate as a basis for the production of carbon fibers. J Polym Sci Polym Chem Ed 21:1223–1226. https://doi.org/10.1002/pol.1983.170210429

Bahl DP, Mathur RB, Dhami TL (1985) Modification of polyacrylonitrile fibres to make them suitable for conversion into high performance carbon fibres. Mater Sci Eng 73:105–112. https://doi.org/10.1016/0025-5416(85)90300-3

Popovska N, Mladenov I (1983) Untersuchungen zur Herstellung von Kohlenstoffasern auf der Basis von mit Wasserstoffperoxid modifizierten PAN-Fasern. Carbon N Y 21:33–38. https://doi.org/10.1016/0008-6223(83)90153-7

Mathur RB, Mittal J, Bahl OP, Sandle NK (1994) Characteristics of KMnO4-modified PAN fibres—its influence on the resulting carbon fibres’ properties. Carbon N Y 32:71–77. https://doi.org/10.1016/0008-6223(94)90010-8

Ko T, Ting H, Lin C (1988) Thermal stabilization of polyacrylonitrile fibers. J Appl Polym Sci 35:631–640. https://doi.org/10.1002/app.1988.070350306

Jie L, Wangxi Z (2005) Structural changes during the thermal stabilization of modified and original polyacrylonitrile precursors. J Appl Polym Sci 97:2047–2053. https://doi.org/10.1002/app.21916

Shiedlin A, Marom G, Zilkha A (1985) Catalytic initiation of polyacrylonitrile stabilization. Polymer 26:447–451. https://doi.org/10.1016/0032-3861(85)90210-1 (Guildf)

McCabe M V (1987) Pretreatment of PAN fiber, US Patent 4,661,336.

Leung ACW, Hrapovic S, Lam E et al (2011) Characteristics and properties of carboxylated cellulose nanocrystals prepared from a novel one-step procedure. Small 7:302–305. https://doi.org/10.1002/smll.201001715

Lam E, Leung ACW, Liu Y et al (2013) Green strategy guided by Raman spectroscopy for the synthesis of ammonium carboxylated nanocrystalline cellulose and the recovery of byproducts. ACS Sustain Chem Eng 1:278–283. https://doi.org/10.1021/sc3001367

Jayakrishnan A, Shah DO (1984) Phase-transfer-catalyzed polymerization of acrylonitrile. J Appl Polym Sci 29:2937–2940. https://doi.org/10.1002/app.1984.070290921

Turrentine JW (2002) Action of ammonium persulphate on metals. J Phys Chem 11:623–631. https://doi.org/10.1021/j150089a004

Mascheroni E, Rampazzo R, Ortenzi MA et al (2016) Comparison of cellulose nanocrystals obtained by sulfuric acid hydrolysis and ammonium persulfate, to be used as coating on flexible food-packaging materials. Cellulose 23:779–793. https://doi.org/10.1007/s10570-015-0853-2

Kolthoff IM, Miller IK (1951) The chemistry of persulfate. I. The kinetics and mechanism of the decomposition of the persulfate ion in aqueous medium1. J Am Chem Soc 73:3055–3059

Karacan I, Erdoğan G (2012) An investigation on structure characterization of thermally stabilized polyacrylonitrile precursor fibers pretreated with guanidine carbonate prior to carbonization. Polym Eng Sci 52:937–952. https://doi.org/10.1002/pen.22160

Zeng Z, Shao Z, Xiao R, Lu Y (2017) Structure evolution mechanism of poly (acrylonitrile/itaconic acid/acrylamide) during thermal oxidative stabilization process. Chinese J Polym Sci 35:1020–1034. https://doi.org/10.1007/s10118-017-1945-2

Karacan I, Erdŏgan G (2012) The effect of ethylenediamine pretreatment on the molecular structure of thermally stabilized polyacrylonitrile fibers before carbonization. Polym Eng Sci 52:467–480. https://doi.org/10.1002/pen.22104

Hindeleh AM, Johnson DJ, Montague PE (1983) in fibre diffraction methods ACS Symp. No. 141, pp.149–182; French, AD, Gardner, KH, (eds)

Zhu Y, Wilding MA, Mukhopadhyay SK (1996) Estimation, using infrared spectroscopy, of the cyclization of poly (acrylonitrile) during the stabilization stage of carbon fibre production. J Mater Sci 31:3831–3837. https://doi.org/10.1007/BF00352799

Yu M-J, Bai Y-J, Wang C-G et al (2007) A new method for the evaluation of stabilization index of polyacrylonitrile fibers. Mater Lett 61:2292–2294. https://doi.org/10.1016/j.matlet.2006.08.071

Hindeleh AM, Johnson DJ (1978) Crystallinity and crystallite size measurement in polyamide and polyester fibres. Polymer 19:27–32. https://doi.org/10.1016/0032-3861(78)90167-2 (Guildf)

Stokes AR (1948) A numerical Fourier-analysis method for the correction of widths and shapes of lines on X-ray powder photographs. Proc Phys Soc 61:382. https://doi.org/10.1088/0959-5309/61/4/311

Sun J, Wang Q (2005) Effects of the oxidation temperature on the structure and properties of polyacrylonitrile-based activated carbon hollow fiber. J Appl Polym Sci 98:203–207. https://doi.org/10.1002/app.22052

Sun J, He C, Zhu S, Wang Q (2007) effects of oxidation time on the structure and properties of polyacrylonitrile-based activated carbon hollow fiber. J Appl Polym Sci 106:470–474. https://doi.org/10.1002/app.24508

Bahl OP, Manocha LM (1976) Methods of determining optimum preoxidation time of PAN fibres. Fibre Sci Technol 9:77–80. https://doi.org/10.1016/0015-0568(76)90026-9

Ko T (1993) Characterization of PAN-based nonburning (nonflammable) fibers. J Appl Polym Sci 47:707–715. https://doi.org/10.1002/app.1993.070470414

Ko T, Chiranairadul P, Ting H, Lin C (1989) The effect of modification on structure and dynamic mechanical behavior during the processing of acrylic fiber to stabilized fiber. J Appl Polym Sci 37:541–552. https://doi.org/10.1002/app.1989.070370219

Mathur RB, Gupta D, Bahl OP, Dhami TL (1984) Infrared spectral studies of preoxidized PAN fibres incorporated with cuprous chloride additive. Fibre Sci Technol 20:227–234. https://doi.org/10.1016/0015-0568(84)90043-5

Bajaj P, Roopanwal AK (1997) Thermal stabilization of acrylic precursors for the production of carbon fibers: an overview. J Macromol Sci Part C Polym Rev 37:97–147. https://doi.org/10.1080/15321799708014734

Takaku A, Hashimoto T, Miyoshi T (1985) Tensile properties of carbon fibers from acrylic fibers stabilized under isothermal conditions. J Appl Polym Sci 30:1565–1571. https://doi.org/10.1002/app.1985.070300421

Touheed A, Maab H (2012) Preparation and characterization of sulfonated polyacrylamide from polyacrylonitrile for proton conductive membranes. J Chin Chem Soc 59:1541–1547. https://doi.org/10.1002/jccs.201200009

Yamadera R, Tadokoro H, Murahashi S (1964) Normal vibrations of polyacrylonitrile and deuterated polyacrylonitriles. J Chem Phys 41:1233–1247. https://doi.org/10.1063/1.1726055

Tadokoro H, Murahashi S, Yamadera R, Kamei T (1963) Infrared absorption spectra of polyacrylonitrile and deuterated polyacrylonitriles. J Polym Sci Part A Gen Pap 1:3029–3042. https://doi.org/10.1002/pol.1963.100011003

Liang CY, Krimm S (1958) Infrared spectra of high polymers. VII. Polyacrylonitrile. J Polym Sci 31:513–522. https://doi.org/10.1002/pol.1958.1203112327

Grassie N, McGuchan R (1972) Pyrolysis of polyacrylonitrile and related polymers—VI. Acrylonitrile copolymers containing carboxylic acid and amide structures. Eur Polym J 8:257–269. https://doi.org/10.1016/0014-3057(72)90032-8

Rafalko JJ (1984) Fourier-transform infrared studies of the thermal degradation of isotopically labeled polyacrylonitriles. J Polym Sci Polym Phys Ed 22:1211–1222. https://doi.org/10.1002/pol.1984.180220706

Grassie N, McGuchan R (1971) Pyrolysis of polyacrylonitrile and related polymers—II: The effect of sample preparation on the thermal behaviour of polyacrylonitrile. Eur Polym J 7:1091–1104. https://doi.org/10.1016/0014-3057(71)90141-8

Mittal J, Bahl OP, Mathur RB, Sandle NK (1994) IR studies of PAN fibres thermally stabilized at elevated temperatures. Carbon N Y 32:1133–1136. https://doi.org/10.1016/0008-6223(94)90222-4

Fochler HS, Mooney JR, Ball LE et al (1985) Infrared and NMR spectroscopic studies of the thermal degradation of polyacrylonitrile. Spectrochim Acta Part A Mol Spectrosc 41:271–278. https://doi.org/10.1016/0584-8539(85)80105-7

Shimada I, Takahagi T, Fukuhara M et al (1986) FT-IR study of the stabilization reaction of polyacrylonitrile in the production of carbon fibers. J Polym Sci Part A Polym Chem 24:1989–1995. https://doi.org/10.1002/pola.1986.080240819

Ouyang Q, Cheng L, Wang H, Li K (2008) Mechanism and kinetics of the stabilization reactions of itaconic acid-modified polyacrylonitrile. Polym Degrad Stab 93:1415–1421. https://doi.org/10.1016/j.polymdegradstab.2008.05.021

Loginova EV, Mikheev IV, Volkov DS, Proskurnin MA (2016) Quantification of copolymer composition (methyl acrylate and itaconic acid) in polyacrylonitrile carbon-fiber precursors by FTIR-spectroscopy. Anal Methods 8:371–380. https://doi.org/10.1039/C5AY02264A

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab 92:1421–1432. https://doi.org/10.1016/j.polymdegradstab.2007.03.023

Chung T, Schlesinger Y, Etemad S et al (1984) Optical studies of pyrolyzed polyacrylonitrile. J Polym Sci Polym Phys Ed 22:1239–1246. https://doi.org/10.1002/pol.1984.180220708

Grassie N, McGuchan R (1971) Pyrolysis of polyacrylonitrile and related polymers—III. Thermal analysis of preheated polymers. Eur Polym J 7:1357–1371. https://doi.org/10.1016/0014-3057(71)90032-2

Dalton S, Heatley F, Budd PM (1999) Thermal stabilization of polyacrylonitrile fibres. Polymer 40:5531–5543. https://doi.org/10.1016/S0032-3861(98)00778-2 (Guildf)

Coleman MM, Petcavich RJ (1978) Fourier transform infrared studies on the thermal degradation of polyacrylonitrile. J Polym Sci Polym Phys Ed 16:821–832. https://doi.org/10.1002/pol.1978.180160507

Layden GK (1972) Retrograde core formation during oxidation of polyacrylonitrile filaments. Carbon N Y 10:59–63. https://doi.org/10.1016/0008-6223(72)90009-7

Ko T, Chiranairadul P, Lin C (1991) The influence of continuous stabilization on the properties of stabilized fibers and the final activated carbon fibers. Part I Polym Eng Sci 31:1618–1626. https://doi.org/10.1002/pen.760312210

Acknowledgements

This study was supported by a grant from the Higher Education Council of Turkey to Md. Mahbubor Rahman. We thank AKSA Acrylics AS for their cordial support in providing PAN multifilaments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest among the authors.

Additional information

Handling Editor: Gregory Rutledge.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahman, M.M., Demirel, T., Tunçel, K.Ş. et al. The effect of the ammonium persulfate and a multi-step annealing approach during thermal stabilization of polyacrylonitrile multifilament prior to carbonization. J Mater Sci 56, 14844–14865 (2021). https://doi.org/10.1007/s10853-021-06209-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06209-1