Abstract

In this work, we systematically investigated the effects of single-step and two-step sintering methods on the structural, dielectric and energy storage properties of pure AgNbO3 lead-free antiferroelectric ceramics. Compared with the single-step sintered ceramic, the ceramic prepared by two-step sintering method has smaller grain size, dense and homogeneous microstructure. In addition, the results of dielectric temperature spectra reveal that the two-step sintering method hardly changes the phase transition temperature of AgNbO3 ceramics but greatly decreases the dielectric loss value. Most importantly, the ceramic prepared by the two-step sintering method displays high breakdown electric field strength (22 kV/mm), larger recoverable energy storage density-Wrec (2.59 J/cm3) and higher energy storage efficiency-η (45%) as well as excellent temperature stability than those of the ceramic by single-step sintering method. Furthermore, it also exhibited high power density (PD = 25.7 MW/cm3) and extremely fast charge–discharge speed (25 ns). Our results provide a simple and novel way to design high-performance AgNbO3-based energy storage lead-free ceramics.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Compared with traditional electricity energy storage devices, such as lithium batteries, and supercapacitors, dielectric ceramic capacitors are characterized by high power density and ultrafast charge/discharge rates, and treated as crucial factors for pulsed power systems [1,2,3,4]. The evaluations of recoverable energy storage density (Wrec) and energy storage efficiency (η) are based on the polarization–electric field (P–E) hysteresis loop [3]:

where E is the applied electric field, Pmax is the saturated polarization, Pr is the remnant polarization, and Wloss is the energy loss density, which equals to the area surrounded by the hysteresis loop. From Eq. (1), we can clear see that to achieve high Wrec, dielectric energy storage materials must have both large ΔP (Pmax-Pr) value and high breakdown electric field strength (EB). Among a large number of dielectric energy storage ceramics, antiferroelectric (AFE) ceramics owing to their double polarization hysteresis loops show large ΔP (Pmax-Pr) (high Pmax and low Pr) and Wrec values [5,6,7,8,9,10,11,12]. Unfortunately, most of the AFE ceramics for energy storage application contain lead element [5,6,7,8,9,10], which is harmful for human health and environment. Therefore, the development of new lead-free AFE energy storage ceramics is extremely urgent.

In 2016, Zhao et al. reported that pure AgNbO3 lead-free ceramics showed typical double P–E loops (antiferroelectric behavior) and a high Wrec of 1.6 J/cm3 at 14 kV/mm [13]. This finding has triggered a burst of research activities on AgNbO3 ceramics [12,13,14,15,16,17,18,19]. So far, the effective method to further enhance Wrec of AgNbO3 ceramics is A- or B-site elements doping. For example, Zhao et al. found that Ta2O5 modified in AgNbO3 led to the EB value increasing from 17 to 24 kV/mm, and an ultrahigh Wrec value of 4.2 J/cm3 was obtained in AgNb0.85Ta0.15O3 ceramic [12]. In addition, Luo et al. also reported that Ag0.91Sm0.03NbO3 (ASN) sample showed excellent energy storage performances of Wrec = 5.2 J/cm3 and η = 68.5% [14].

It is generally known that sintering method has an important effect on the structural and electrical properties of ceramics [20,21,22]. In 2000, Chen and Wang et al. proposed a novel, low cost and extremely simple sintering technology, named as two-step sintering method [23]. A number of studies have confirmed that two-step sintering method can improve electrical properties of ceramics by increasing the density and suppressing grain growth [20, 23,24,25,26]. Additionally, the low dwelling temperature in two-step sintering method can effectively reduce the volatilization of elements with lower melting point, such as Na, Bi, K elements [20, 22, 26]. The currently reported sintering temperature of AgNbO3 ceramics is mostly between 1050 and 1150 °C [12,13,14,15,16,17,18,19]. However, the melting point temperature of Ag element (961 °C) is much lower than the sintering temperature of the AgNbO3 ceramics. This will inevitably cause the volatilization of Ag element, thus forming the defects such as Ag vacancies (\({\text{V}}_{{{\text{Ag}}}}^{^{\prime}} \;s\)) which, in turn, create oxygen vacancies (\({\text{V}}_{{\text{O}}}^{ \bullet \bullet } \; s\)) to maintain electrical neutrality. Defect dipole such as \(\mathop {\text{V}}\nolimits_{{{\text{Ag}}}}^{^{\prime}} - \mathop {\text{v}}\nolimits_{{\text{O}}}^{ \bullet \bullet } - \mathop {\text{V}}\nolimits_{{{\text{Ag}}}}^{^{\prime}}\), therefore, is formed in AgNbO3 ceramics. Moriwake et al. [27] using first principles calculations found that the presence of defect dipole \(\mathop {\text{V}}\nolimits_{{{\text{Ag}}}}^{^{\prime}} - \mathop {\text{v}}\nolimits_{{\text{O}}}^{ \bullet \bullet } - \mathop {\text{V}}\nolimits_{{{\text{Ag}}}}^{^{\prime}}\) in AgNbO3 could also lead to weak ferroelectricity in the Pbcm phase, which would reduce the energy storage efficiency (η) of the ceramic [19]. Therefore, it can be seen that controlling the volatilization of Ag element is very important to improve the energy storage characteristics of AgNbO3 ceramics.

In this work, we present a comparative study on the energy storage performances of AgNbO3 ceramics prepared by the traditional single-step sintering method and the two-step sintering method. Our results indicate that the sample prepared by the two-step sintering method exhibits high breakdown electric field strength (22 kV/mm), larger Wrec (2.59 J/cm3) and higher η (45%). These values not only are superior to those in the sample prepared by single-step sintering method, but also rival those reported in pure AgNbO3 ceramics [13, 16, 18, 21, 28,29,30,31,32,33,34].

Experimental procedure

All the AgNbO3 ceramics were prepared by traditional solid-state reaction method using high purity raw materials of Ag2O (99.7%) and Nb2O5 (99.99%). These raw materials were precisely weighed accordingly the corresponding stoichiometry and then ball milled at 300 rpm for 24 h. The milled powders were calcined at 870 °C for 6 h in O2 atmosphere. After that, the calcined powders were ball milled again for 12 h. The resultant powders were pressed into pellets of 14 mm in diameter and 1 mm in thickness under uniaxial pressure of 80 MPa using PVA as binder. After removing the PVA binder, the pellets by single-step sintering method were sintered at 1080 °C for 6 h in O2 atmosphere, and named as AN-S1. For comparison, the pellets by two-step sintering method were heated at 1100 °C without heat preservation, then cooled down directly to 950 °C for 10 h in air and then cool down to room temperature. After that, the sintered samples were annealed at 950 °C for 4 h in O2 atmosphere, and named as AN-S2. Notably, all the pellets are covered with powders of the same composition to reduce the volatilization of Ag element during the sintering process. It should be noted that the samples for measuring energy storage properties were polished to achieve parallel and smooth faces with thickness of ~0.2 mm and coated on both sides with Au electrodes with diameter of 2 mm. In addition, the power density of the ceramic samples was tested by a charge–discharge platform (Gogo Instruments Technology, Shanghai, China). The details of structural and electrical properties can be found in our previous work [35, 36].

Results and discussion

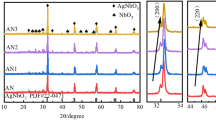

XRD patterns of the AN-S1 and S2 are indicated in Fig. 1. Both samples exhibit pure perovskite structure without no secondary phases. As shown in the inset of Fig. 1, the color of both samples is yellow. These results suggest that the AN-S1 and S2 show good crystallinity. The SEM images obtained from polished and thermally etched surface of AN-S1 and S2 are displayed in Fig. 2 a and b, respectively. It can be clearly seen that both of them show dense microstructure. The relative density (ρr) of AN-S2 sample was deduced by Archimedes method and found to be 97% of the theoretical value, which is more than 93% of AN-S1. Additionally, the AN-S2 sample also exhibits smaller grain size and homogeneous microstructure as indicated from Fig. 2 a and b and Fig. S1 of the supplementary materials. Both facts are helpful for energy storage. The element mappings performed on the AN-S2 ceramic are present in Fig. S2(a–c). It is seen that all the elements in the ceramic are homogeneously distributed.

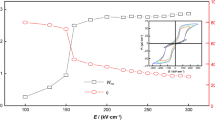

The temperature dependence of dielectric constant and loss tangent measured at various frequencies for the AN-S1 and S2 is presented in Fig. 3. A number of dielectric anomalies, signaling a series of phase transitions, have been observed in both samples. From low to high temperature, the first dielectric anomaly occurs at about 60 °C, relating to M1 (Pmc21)–M2 (Pbcm) phase transitions. The next dielectric anomaly observed at around 250 °C associated with M2 (Pbcm)–M3 (Pbcm) transition. Finally, a sharply increased dielectric constant is found around 340 °C, corresponding to the M3-O phase transition [28]. Details of the phase transition temperatures for both the samples are summarized in Table 1. It is worth noting that the dielectric loss tangent of AN-S2 sample is significantly smaller than that of AN-S1. In order to show that the AN-S2 sample has a smaller dielectric loss value, the inset shows the dielectric loss at −25 ~ 50 °C of both samples. As a result, the dielectric loss value of AN-S2 sample (tanδ = 0.0186 @25 °C 1 kHz) is indeed smaller than that of AN-S1 sample (tanδ = 0.0209 @25 °C 1 kHz). The reason for this finding may be that the two-step sintering method can effectively reduce the volatilization of Ag element, thereby reducing the oxygen vacancy concentration in the sample. In order to verify the above point, XPS measurements (0.1 s) are conducted on both AN ceramics, as shown in Fig. S3 of the supplementary materials. It is clearly shown that the 0.1 s spectrum can be fitted by two Gaussian peaks; from low to high binding energy, the peak corresponds successively to oxygen atoms at the lattice site and oxygen vacancies, which is similar to previously reported results [19]. Moreover, the oxygen vacancy concentration in AN-S2 sample (22.5%) is smaller than AN-S1 (29.2%). This result also better illustrates that the two-step sintering method can reduce the generation of oxygen vacancies by controlling the volatilization of Ag element. The low dielectric loss tangent value is an important factor for sample with high energy storage ability. Therefore, an enhanced energy storage performance would be expected in AN-S2.

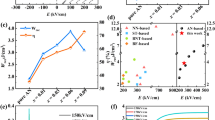

In order to well study the feasibility for practical dielectric energy storage applications, the Weibull distribution analysis plots of the EB values for the AN-S1 and S2 are given in Fig. 4a. It can be seen that the data were well fitted linearly, and high β values suggested the reliability of the Weibull analysis. Importantly, we can also observe that the average EB value of AN-S2 sample is much higher than that of AN-S1 sample, indicating that the AN-S2 sample can be operated at much higher electric field with an enhanced Wrec value. In general, the breakdown field strength is closely related to the ceramics microstructure features [3], such as grain size, density, secondary phase and so on. Among them, the grain size and density have strong effect on the breakdown field strength of dielectric ceramics; that is, small grain size, homogeneous and dense microstructure can significantly improve the dielectric breakdown strength [3]. Therefore, it is reasonable to believe that the high breakdown field strength of AN-S2 samples is related to their smaller grain size and higher density. Furthermore, Fig. 4b and c shows P–E and I–E loops of the AN-S1 and AN-S2 ceramics measured at room temperature. Typical antiferroelectric double P–E loops are observed in both samples. Moreover, four current peaks are seen in the I–E loops in both samples, with two peaks in both forward and backward branches. In each branch, the peak at higher electric field is related to the antiferroelectric-ferroelectric phase transition [37] (marked as EF), while another peak at lower electric field is associated to the ferroelectric-antiferroelectric phase transition [37] (marked as EA). In addition, based on Eqs. (1) and (2), the calculated Wrec and η values for both samples are present in Table 1. It should be noted that both the Wrec and η values of AN-S2 are much higher than those of AN-S1. These results suggest that two-step sintering method significantly enhances the energy storage properties of the AgNbO3 ceramics. To better verify this view, Fig. 4d comparisons of the η~Wrec of the AN-S2 ceramic prepared by two-step sintering method studied in this work with pure AgNbO3 ceramics reported in published literature [13, 16, 18, 21, 28,29,30,31,32,33,34]. It is obvious that the energy storage properties of the AN-S2 ceramic are superior to all of them.

Figure 5a shows P–E loops of the AN-S2 ceramic measured at 20 kV/mm and 10 Hz in the temperature range of 25–100 °C. It can be found that the double P–E loops can be seen in the temperature range. Moreover, the calculated Wrec and η values are presented in Fig. 5b; the Wrec values firstly slightly increased to 2.39 J/cm3, and then decreased to 2.13 J/cm3 at 100 °C. In general, the thermal stability of energy storage density can be calculated according to equation [36, 38]:

where ΔW and W25°C are the variation of energy storage density and the value of energy storage density measured at 25 °C, respectively. The corresponding thermal stability of energy storage density is lower than 10% in the temperature range of 25–100 °C. What is more, the η values of 43–52% can also be kept in the wide temperature range.

In order to systematically characterize the energy storage characteristics of AN-S2 samples, the undamped and damped discharge current curves are presented in Figs. 6 and 7, respectively. From Fig. 6a, it can be seen that the current peaks increase from 4.13 to 10.08 A as the applied electric field increases from 6 to 16 kV/mm. The power density (PD) can be calculated as the below formula:

where E is the applied electric field, Imax is the value of current peak, and S is the electrode area. A high power density (PD) value of 25.7 MW/cm3 is achieved in the AN-S2 sample. It is worth noting that the PD value of AN-S2 sample is higher than most of the reported values so far in different energy storage materials [39,40,41,42,43,44,45,46] as compared in Fig. 6b. Furthermore, the damped discharge current curves show that the value of current peak increases from 3.17 to 4.87 A as the electric field increases from 8 to 14 kV/mm (as seen in Fig. 7a). It is well known that the energy storage density in the discharge processes can be calculated as follows:

where R is the total resistance (for this work, it is 130 Ω), V is the total volume of the ceramic, i is the current, and t stands for the time. The evolution of energy storage density in the discharge process as a function of electric field is shown in Fig. 7b as well. The results reveal that the energy storage density gradually increases from 0.04 to 0.1 J/cm3 when the electric field increases from 8 to 14 kV/mm. On the other side, it is generally named the t0.9—the time of 90% of the total energy has been discharged as the discharging time in dielectric energy materials [35, 45, 47, 48], as also shown by the vertical line in Fig. 7b. And the t0.9 measured at room temperature is around 25 ns at 14 kV/mm, which suggests that the discharge speed is extremely fast in the AN-S2 ceramic.

Conclusions

In this study, the pure AgNbO3 lead-free antiferroelectric ceramic with improved energy storage properties was prepared by two-step sintering method. The ceramic prepared by two-step sintering method exhibited high breakdown electric field strength (22 kV/mm), large Wrec (2.59 J/cm3) and high η (45%) as well as excellent temperature stability. The main reason for above excellent energy storage characteristics may due to the ceramic prepared by the two-step sintering method has small grain size, dense and homogeneous microstructure. Furthermore, it also exhibited high power density (PD = 25.7 MW/cm3) and extremely fast charge–discharge speed (25 ns).

References

Chu BJ, Zhou X, Ren KL, Neese B, Lin MR, Wang Q, Bauer F, Zhang QM (2006) A dielectric polymer with high electric energy density and fast discharge speed. Science 313:334–336

Pan H, Li F, Liu Y, Zhang QH, Wang M, Lan S, Zheng YP, Ma J, Gu L, Shen Y, Yu P, Zhang SJ, Chen LQ, Lin YH, Nan CW (2019) Ultrahigh-energy density lead-free dielectric films via polymorphic nanodomain design. Science 365:578–582

Yang LT, Kong X, Li F, Hao H, Cheng ZX, Liu HX, Li JF, Zhang SJ (2019) Perovskite lead-free dielectrics for energy storage applications. Prog Mater Sci 102:72–108

Hao XH, Zhai JW, Kong LB, Xu ZK (2014) A comprehensive review on the progress of lead zirconate-based antiferroelectric materials. Prog Mater Sci 63:1–57

Yang Y, Liu P, Zhang YJ, Kandula KR, Xu JW, Zhang GZ, Jiang SL (2020) Low electric-field-induced strain and high energy storage efficiency in (Pb, Ba, La)(Zr, Sn, Ti)O3 antiferroelectric ceramics through regulating the content of La. Ceram Int 46:18106–18113

Huang KW, Ge GL, Yan F, Shen B, Zhai JW (2020) Ultralow electrical hysteresis along with high energy-storage density in lead-based antiferroelectric ceramics. Adv Electron Mater 6:1901366

Li L, Wang RX, Gu ZB, Lu MH, Zhu MW, Zhang ST (2020) Energy storage property of (Pb0.97La0.02)(Zr0.5Sn0.4Ti0.1)O3-(Na0.5Bi0.5)0.94Ba0.06TiO3 ceramics: effects of antiferroelectric-relaxor transition and improved breakdown strength. J Eur Ceram Soc 40:2996–3002

Qiao PX, Chen XF, Liu Z, Wang GS, Dong XL (2020) Enhanced energy storage performance in Pb0.97La0.02(ZrxSn0.90-xTi0.10)O3 antiferroelectric ceramics. Mater Lett 260:126877

Liu XH, Li Y, Sun NN, Hao XH (2020) High energy-storage performance of PLZS antiferroelectric multilayer ceramic capacitors. Inorg Chem Front 7:756–764

Liu Z, Chen XF, Peng W, Xu CH, Dong XL, Cao F, Wang GS (2015) Temperature-dependent stability of energy storage properties of Pb0.97La0.02(Zr0.58Sn0.335Ti0.085)O3 antiferroelectric ceramics for pulse power capacitors. Appl. Phys. Lett. 106:262901

Li QN, Zhou CR, Xu JW, Yang L, Zhang X, Zeng WD, Yuan CL, Chen GH, Rao GH (2016) Tailoring antiferroelectricity with high energy-storage properties in Bi0.5Na0.5TiO3-BaTiO3 ceramics by modulating Bi/Na ratio. J Mater Sci: Mater Electron 27:10810–10815

Zhao L, Liu Q, Gao J, Zhang SJ, Zhang JF (2017) Lead-free antiferroelectric sliver niobate tantalate with high energy storage performance. Adv Mater 29:1701824

Zhao L, Liu Q, Zhang SJ, Li JF (2016) Lead-free AgNbO3 anti-ferroelectric ceramics with an enhanced energy storage performance using MnO2 modification. J Mater Chem C 4:8380–8384

Luo NN, Han K, Zhuo FP, Xu C, Zhang GZ, Liu LJ, Chen XY, Hu CZ, Zhou HF, Wei YZ (2019) Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J Mater Chem A 7:14118–14128

Gao J, Zhang YC, Zhao L, Li KY, Liu Q, Studer A, Hinterstein M, Zhang SJ, Li JF (2019) Enhanced antiferroelectric phase stability in La-doped AgNbO3: perspectives from the microstructure to energy storage properties. J Mater Chem A 7:2225–2232

Xu YH, Guo Y, Liu Q, Yin YH, Bai JL, Lin L, Tian JJ, Tian Y (2020) Enhanced energy density in Mn-doped (1–x)AgNbO3-xCaTiO3 lead-free antiferroelectric ceramics. J Alloys Compd 821:153260

Tian Y, Jin L, Zhang HF, Xu Z, Wei XY, Viola G, Abrahams I, Yan HX (2017) Phase transitions in bismuth-modified silver niobate ceramics for high power energy storage. J Mater Chem A 5:17525–17531

Yan ZN, Zhang D, Zhou XF, Qi H, Luo H, Zhou KC, Abrahams I, Yan HX (2019) Silver niobate based lead-free ceramics with high energy storage density. J Mater Chem A 7:10702–10711

Luo NN, Han K, Zhuo FP, Liu LJ, Chen XN, Peng BL, Wang XP, Feng Q, Wei YZ (2019) Design for high energy storage density and temperature-insensitive lead-free antiferroelectric ceramics. J Mater Chem C 7:4999–5008

Ye G, Wade-Zhu J, Zou J, Zhang T, Button TW, Binner J (2020) Microstructure, piezoelectric properties and energy harvesting performance of undoped (K0.5Na0.5)NbO3 lead-free ceramics fabricated via two-step sintering. J Eur Ceram Soc 40:2977–2988

Ren PR, Ren D, Sun L, Yan FX, Yang S, Zhao GY (2020) Grain size tailoring and enhanced energy storage properties of two-step sintered Nd3+-doped AgNbO3. J Eur Ceram Soc 40:4495–4502

Ding JX, Liu YF, Lu YN, Qian H, Gao H, Chen H, Ma CJ (2014) Enhanced energy-storage properties of 0.89Bi0.5Na0.5TiO3-0.06BaTiO3-0.05K0.5Na0.5NbO3 lead-free anti-ferroelectric ceramics by two-step sintering method. Mater Lett 114:107–110

Chen I-We, Wang X-H (2000) Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 404:168

Wang XH, Deng XY, Bai HL, Zhou H, Qu WG, Li LT, Chen IW (2006) Two-step sintering of ceramics with constant grain-size, II: BaTiO3 and Ni-Cu-Zn ferrite. J Am Ceram Soc 89:438–443

Fathi MH, Kharaziha M (2009) Two-step sintering of dense, nanostructural forsterite. Mater Lett 63:1455–1458

Wang C, Fang BJ, Qu YH, Chen ZH, Zhang S, Ding JN (2020) Preparation of KNN based lead-free piezoelectric ceramics via composition designing and two-step sintering. J Alloys Compd 832:153043

Moriwake H, Fisher CAJ, Kuwabara A, Fu DS (2013) First-principles study of point defect formation in AgNbO3. Jpn J Appl Phys 52:09KF08

Gao J, Zhao L, Liu Q, Wang XP, Zhang SJ, Li JF (2018) Antiferroelectric-ferroelectric phase transition in lead-free AgNbO3 ceramics for energy storage applications. J Am Ceram Soc 101:5443–5450

Tian Y, Jin L, Zhang HF, Xu Z, Wei XY, Politova ED, Stefanovich SY, Tarakina NV, Abrahams I, Yan HX (2016) High energy storage density in sliver niobate ceramics. J Mater Chem A 4:17279–17287

Han K, Luo NN, Miao SF, Zhuo FP, Chen XY, Liu LJ, Hu CZ, Zhou HF, Zhou HF, Wang XP, Wei YZ (2019) Realizing high low-electric-field energy storage performance in AgNbO3 ceramics by introducing relaxor behaviour. J Materiomics 5:597–605

Luo NN, Han K, Liu LJ, Peng BL, Wang XP, Hu CZ, Zhou HF, Feng Q, Chen XY, Wei YZ (2019) Lead-free Ag1-3xLaxNbO3 antiferroelectric ceramics with high energy storage density and efficiency. J Am Ceram Soc 102:4640–4647

Xu CH, Fu ZQ, Liu Z, Wang L, Yan SG, Chen XF, Cao F, Dong XL, Wang GS (2018) La/Mn codoped AgNbO3 lead-free antiferroelectric ceramics with large energy density and power density, ACS sustain. Chem Eng 6:16151–16159

Mao SF, Luo NN, Han K, Feng Q, Chen XY, Peng BL, Liu LJ, Hu CZ, Zhou HF, Toyohisa F, Wei YZ (2020) Effect of Lu doping on the structure, electrical properties and energy storage performance of AgNbO3 antiferroelectric ceramics. J. Mater. Sci: Mater Electron 31:7731–7741

Ma JL, Yan SG, Xu CH, Cheng GF, Mao CL, Bian JJ, Wang GS (2019) Enhanced energy storage properties of silver niobate ceramics under hydrostatic pressure. Mater Lett 247:40–43

Li TY, Chen PF, Li F, Wang CC (2021) Energy storage performance of Na0.5Bi0.5TiO3-SrTiO3 lead-free relaxors modified by AgNb0.85Ta0.15O3. Chem. Eng. J. 406:127151

Li TY, Chen PF, Si RJ, Li F, Guo YM, Wang CC (2020) High energy storage density and efficiency with excellent temperature and frequency stabilities under low operating field achieved in Ag0.91Sm0.03NbO3-modified Na0.5Bi0.5TiO3-BaTiO3 ceramics. J Mater Sci: Mater Electron 31:6928–16937

Han K, Luo NN, Jing Y, Wang XP, Peng BL, Liu LJ, Hu CZ, Zhou HF, Wei YZ, Chen XY, Feng Q (2019) Structure and energy storage performance of Ba-modified AgNbO3 lead-free antiferroelectric ceramics. Ceram Int 45:5559–5565

Liu ZC, Ren PR, Wang LCB, X, Wan YH, Zhao GY, (2017) Enhanced energy storage properties of NaNbO3 and SrZrO3 modified Bi0.5Na0.5TiO3 based ceramics. J Alloys Compd 721:538–544

Xu R, Tian JJ, Zhu QS, Zhao T, Feng YJW, XY, Xu Z, (2017) Effects of La-induced phase transition on energy storage and discharge properties of PLZST ferroelectric/antiferroelectric ceramics. Ceram Int 43:13918–13923

Chen ZT, Bu XY, Ruan BX, Du J, Zheng P, Li LL, Wen F, Bai WF, Wu W, Zheng L, Zhang Y (2020) Simultaneously achieving high energy storage density and efficiency under low electric field in BiFeO3-based lead-free relaxor ferroelectric ceramics. J Eur Ceram Soc 40:5450–5457

Xu CH, Liu Z, Chen XF, Yan SG, Cao F, Dong XL, Wang GS (2016) High charge-discharge performance of Pb0.98La0.02(Zr0.35Sn0.55Ti0.10)0.995O3 antiferroelectric ceramics. J. Appl. Phys. 120:074107

Li F, Yang K, Liu X, Zou J, Zhai JW, Shen B, Li P, Shen J, Liu BH, Chen P, Zhao KY, Zeng HR (2017) Temperature induced high charge–discharge performances in lead–free Bi0.5Na0.5TiO3–based ergodic relaxor ferroelectric ceramics. Scripta Mater 141:15–19

Shi F, Tang B, Fang ZX, Li H, Zhang SR (2019) Enhanced energy storage and fast charge-discharge properties of (1–x)BaTiO3-xBi(Ni1/2Sn1/2)O3 relaxor ferroelectric ceramics. Ceram Int 45:17580–17590

Zhou MX, Liang RH, Zhou ZY, Yan SG, Dong XL (2018) Novel sodium niobate-based lead-free ceramics as new environment-friendly energy storage materials with high energy density, high power density, and excellent stability. ACS Sustain Chem Eng 6:12755–12765

Liu G, Li Y, Shi MQ, Yu LJ, Chen P, Yu K, Yan Y, Jin L, Wang DW, Gao JH (2019) An investigation of the dielectric energy storage performance of Bi(Mg2/3Nb1/3)O3-modified BaTiO3 Pb-free bulk ceramics with improved temperature/frequency stability. Ceram Int 45:19189–19196

Zhou MX, Liang RH, Zhou ZY, Dong XL (2018) Novel BaTiO3-based lead-free ceramic capacitors featuring high energy storage density, high power density, and excellent stability. J Mater Chem C 6:8528–8537

Wang JH, Li Y, Sun NN, Du JH, Zhang QW, Hao XH (2019) Bi(Mg0.5Ti0.5)O3 addition induced high recoverable energy-storage density and excellent electrical properties in lead-free Na0.5Bi0.5TiO3-based thick films. J Eur Ceram Soc 40:255–263

Liu JR, Yang K, Zhai JW, Shen B, Wang HT, Li F (2018) High energy storage density and rapid discharge speed of niobosilicate glasses. Mater Chem Phys 206:29–34

Acknowledgements

The authors acknowledge financial support from the National Natural Science Foundation of China (Grant Nos. 51872001 and 51572001). This work was supported in part by the Open Research Fund Program of the State Key Laboratory of Low-Dimensional Quantum Physics (Grant No. KF201803).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, T., Cao, W., Chen, P. et al. Effects of sintering method on the structural, dielectric and energy storage properties of AgNbO3 lead-free antiferroelectric ceramics. J Mater Sci 56, 13499–13508 (2021). https://doi.org/10.1007/s10853-021-06148-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06148-x