Abstract

Co-catalysts are well known for improving the charge carrier’s separation and transfer to species in solution, and hence, the photocatalytic hydrogen production. Thus, in this work, the effect of loading Cu and Pd species over the WO3–TiO2 structure was evaluated. The structure of WO3–TiO2 was obtained by direct hydrolysis of titanium isopropoxide (sol–gel method) in previously synthesized WO3 nanoparticles (6 mol% of WO3), forming a composite that provided direct contact between WO3 and TiO2 nanoparticles. Subsequently, 0.5 wt% of copper or 0.5 wt% of palladium loadings was deposited onto WO3–TiO2. The photocatalytic hydrogen production results show that the activity increased with the presence of Cu and Pd species, reaching hydrogen production rates of 1496 μmol g−1 h−1 and 5427.07 μmol g−1 h−1 for Cu/WT and Pd/WT, respectively, as compared to WT structure (770.10 μmol g−1 h−1). To understand this behavior, semiconducting properties of the synthesized materials were characterized by (photo)electrochemical techniques. The presence of Cu and Pd in the structure moved the flatband position, increased the photocurrent and modified the open circuit potential under illumination toward less negative values, indicating the formation of energy states in the interface between WO3–TiO2 and the co-catalysts. These energy states at the heterojunction allow the transfer of photogenerated electrons toward co-catalysts, preventing the recombination of photogenerated charge carriers.

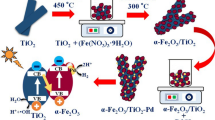

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Developing renewable clean energy is an approach to solve the global energy crisis, and photocatalytic production of hydrogen is considered one of them [1]. TiO2 is a semiconductor widely used in photocatalysis due to its high chemical stability, low cost and nontoxic nature [2]. However, it provides low photocatalytic efficiency due to the high recombination of photogenerated electron–hole pairs (e−–h+) [3, 4].

Therefore, coupling TiO2 with other metal oxides has been employed as a strategy to mitigate the recombination of (e−–h+). In this sense, tungsten trioxide (WO3) is an important semiconductor due to the variety of its applications as electrochromic device, gas sensor and photocatalyst [5]. The construction of an efficient coupling of TiO2 with WO3 generates a favorable band alignment at the WO3–TiO2 interface that allows charge separation [5,6,7,8]. However, it is important to ensure good contact between WO3–TiO2 oxides, creating pathways for (e−–h+) separation and improvement in the photocatalytic behavior of raw materials. In our previous work, MxOy (ZnO or SnO2)-TiO2 structures with different MxOy:TiO2 molar ratios (01:99, 03:97, 06:94, 12:88, and 20:80) were obtained by sol–gel method, forming a composite that provided intimate contact between MxOy and TiO2 by direct hydrolysis of titanium isopropoxide over previously synthesized MxOy nanoparticles, and the maximum photocatalytic activity was observed for 6 mol% of MxOy [9,10,11]. The analysis performed by means of photoelectrochemical techniques showed that the interaction between MxOy–TiO2 using this synthesis method provokes the formation of energy states at the interface of MxOy-TiO2 that improve the (e−–h+) separation [9,10,11]. On the other hand, in order to obtain a good photocatalytic hydrogen evolution, besides separating the (e−–h+), it is necessary to create active sites for the reduction reaction. So, co-catalysts are needed to improve the reduction and oxidation process on the surface of a photocatalyst [11].

For this, the impregnation method can be used to synthesize supported photocatalysts with different co-catalysts since it is faster, inexpensive and in the case of low content of co-catalyst, allows the control of its dispersion on the surface. For example, some researchers have recently found that impregnation of TiO2 with Cu species had a satisfactory photocatalytic activity for H2 evolution, improving the charge carrier separation and providing the active sites for hydrogen production [12,13,14,15]. Ni et al. reported that low Cu content improved hydrogen production since these metallic nanoparticles are highly dispersed on the TiO2 surface [16]. Chen et al. informed that low CuO loading on TiO2 showed the best performance for hydrogen generation since, at higher CuO contents, agglomerations are formed, causing the detriment of photocatalytic activity [17]. Also, Pd species have been used in conjunction with TiO2 for photocatalytic reactions in order to improve the water reduction process. Wu et al. reported an improved hydrogen production due to a synergistic effect between TiO2 and Pd. Pd nanoparticles are considered to act as active reduction sites, while methanol acts as a sacrificial agent [18].

Hence, WO3–TiO2 was synthesized with 6 mol% of WO3 by the sol–gel method, creating a direct contact between these oxides to then deposit Cu or Pd species (0.5 wt%) onto the WO3–TiO2 structure by impregnation method and evaluate its photocatalytic activity for hydrogen evolution. Photoelectrochemical performance studies of synthesized materials and their characterization allowed us to understand the effect of metallic nanoparticles on charge transfer processes and explain their photocatalytic behavior.

Experimental section

Reagents and chemicals

Sodium tungstate dihydrate (99% pure), dowex 50WX8 100–200 mesh, hydrochloric acid (37% pure), titanium isopropoxide (97% pure), isopropyl alcohol (99.9%), Pd(NO3)2*2H2O (99.9% pure) and Cu(NO3)2*2.5H2O (99.9% pure) were purchased from Sigma-Aldrich.

Milli-pore water with a resistivity of 18.2 MΩ cm−1 was used to prepare all aqueous solutions.

Synthesis of WO3 nanoparticles

Tungstate oxide nanoparticles were prepared by the ion-exchange resin method (Dowex 50WX8, 100–200 mesh). The ion-exchange resin (Dowex 50WX8, 100–200 mesh) was packed in a burette of 30 mL and activated with several washes of a concentrated HCl solution. Then, it was left in the HCl solution overnight to completely exchange the Na+ by H+. After the ion-exchange resin activation, several washes were made with deionized water to eliminate excess HCl and the presence of Cl−. Upon confirming the Cl− elimination (silver nitrate test), a 0.1 M Na2WO4 solution was passed through the ion-exchange resin, producing a clear solution of tungstic acid with a pH ~ 1.8. The solution was kept under stirring for 30 min. A yellow-white precipitate appeared within 5 h. Then, the precipitated solid was dried at 80 °C for 24 h. Finally, the WO3 nanoparticles were obtained when the solid was treated at 500 °C for 2 h, using an air flow of 0.5 ml min−1 per milligram of photocatalyst (heating rate of 2 °C min−1).

Synthesis of WO3–TiO2 structure

The WO3-TiO2 structures were synthesized by the sol–gel technique based on the synthesis method previously reported by our research group [9,10,11]. The synthesis procedure was as follows: the WO3-TiO2 structure with WO3 6 mol% was achieved by adding 6 mol % of WO3 nanoparticles (previously synthesized) to a solution with isopropyl alcohol and titanium isopropoxide in a 4:1 molar ratio under stirring. Then, to obtain full dispersion of WO3 nanoparticles, the formed suspension was sonicated for 30 min, followed by stirring for a similar time period. A solution with isopropyl alcohol and deionized water (1:1 molar ratio) was added to the suspension under stirring with the purpose of hydrolyzing isopropoxide over WO3 nanoparticles. The suspension was then kept under stirring for 30 min to be homogenized. Finally, it was aged for 24 h and dried at 80 °C for another 24 h. The structure obtained, WO3–TiO2 (WT), was thermally treated at 350 °C for 2 h, using an H2 flow of 0.5 ml min−1 per milligram of photocatalyst (heating rate of 2 °C min−1).

Synthesis of Pd–WT and Cu–WT structures

WO3–TiO2 (WT) structures, loaded with Pd and Cu (0.5 wt%) composites, were prepared by the incipient wetness impregnation (IWI) method. The WT composite was suspended in aqueous solutions of either Pd(NO3)2*2H2O to obtain a 0.5 wt% load for Pd–WT or Cu(NO3)2*2.5H2O to get a 0.5 wt% load for Cu–WT. The mixture was stirred for 16 h and dried at 80 °C for 8 h. Afterward, the dried photocatalysts were thermally treated at 300 °C for 2 h, using an H2 flow of 0.5 ml min−1 per milligram of photocatalyst (heating rate of 2 °C min−1).

Characterization

X-ray diffractograms of the oxides were measured in air at room temperature using a Bruker D-8 Advance diffractometer with the Bragg–Brentano θ-θ geometry, Cu Kα radiation, a Ni 0.5% Cu-Kβ filter in the secondary beam, and a one-dimensional position-sensitive silicon strip detector (Bruker, Lynxeye). The bandgap energies were calculated by a McLean analysis of the electronic spectra, which were obtained using a UV–visible Perkin-Elmer Lambda 40 spectrophotometer, equipped with an integrating sphere, and MgO used as a reference. Surface areas were measured by the BET method and were performed on an Autosorb–1 Quantachrome Instruments device.

The efficiency of Pd and Cu impregnation on the WO3–TiO2 structure was calculated by chemical analysis using inductively coupled plasma with optical emission spectrometry (ICP-OES) and Perkin-Elmer Optima 8300 equipment. Prior to analysis, samples were treated using microwave-assisted digestion in HCl at 175 °C.

XPS analyses were performed by a K-Alpha from Thermo Fisher Scientific X-ray photoelectron spectrometer with a monochromatic Al Kα X-ray source (1486.6 eV) and a base pressure of 1 × 10−9 Torr in the analytical chamber. The X-rays were microfocused at the source to project a spot size of 400 μm in diameter on the sample, using lenses in standard mode. The analyzer was run in constant analyzer energy (CAE) mode. Survey and high resolution spectra were collected using analyzer pass energies of 160 and 40 eV, respectively. The position of the adventitious oxygen O1s peak at 530.0 eV, from titanium oxide species, was monitored on each sample to ensure that no binding energy shift had occurred due to charging, associated with contact potential differences between the sample and the spectrometer. High resolution spectra were fitted using Gaussian–Lorentzian mix function and Shirley-type background subtraction. (Photo)electrochemical characterization was perfomed using the settings previously reported [9,10,11].

Photocatalytic hydrogen production

The photocatalytic activity of synthesized materials was evaluated in a borosilicate cylindrical photo-reactor with 200 mL of 90:10 water–methanol solution and 100 mg of the photocatalyst. The suspension was sonicated for 5 min and stirred in the dark for 30 min to disperse the photocatalyst; then, the dissolved air was displaced by bubbling nitrogen for 30 min. After bubbling with nitrogen, the light source was turned on. The light came from a UVP mercury lamp with primary emission at 254 nm (5.1 mW cm−2), which was located inside a quartz tube at the center of the photo-reactor. A gas chromatograph (Agilent7820A) was used to determine the amount of H2 that evolved over 7 h of the photoreaction. The GC device was equipped with an Agilent CP7429 column and a thermal conductivity detector. Argon was used as the carrier gas.

Results and discussion

Characterization of synthesized materials

The WO3–TiO2 structure (WT) was obtained by a sol–gel method developed by our research group [9,10,11]. The novelty of our approach consists in the use of previously synthesized WO3 nanoparticles and their incorporation during TiO2 formation. In this way, intimate WO3–TiO2 contact is ensured, creating pathways for electron–hole separation and improvement in the photocatalytic behavior of raw materials.

This was corroborated by carrying out TEM analysis of the WO3–TiO2 nanoparticle system, Fig. 1a and b. The micrographs reveal the presence of agglomerate particles, possibly associated with a nonhomogeneous layer (grey zones), which surrounds dark zones related to cores, i.e., individual nanoparticles. However, these images did not permit differentiation or elucidation of the distribution between the WO3–TiO2 nanoparticles. The usage of electron energy loss spectroscopy (EELS) mapping analysis allowed us to overcome this problem in Fig. 1b. The series of mapping spatial distribution images for W, Ti and W/Ti can be seen in Fig. 1c–e, respectively. From TEM and EELS mapping analyses, it was concluded that WO3 nanoparticles were successfully coated with TiO2.

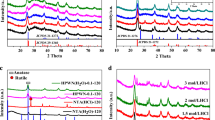

To gain more insight into the interfacial interaction between WO3–TiO2, the presence of co-catalysts (Cu and Pd), and the crystal structure of synthesized materials, high-resolution TEM (HRTEM) and XRD analyses were used. Figures 2a and b show the HRTEM of WO3–TiO2 with Cu and Pd nanoparticles. In both figures, the interfacial interaction between WO3 and TiO2 nanoparticles can be clearly observed with the presence of interplanar distances 0.37, 0.38 and 0.26 nm corresponding to (0,2,0), (0,0,2) and (2,2,0) monoclinic planes of WO3 and 0.35 nm corresponding to the (1,0,1) anatase plane of TiO2 [19,20,21,22,23]. These results are consistent with those observed in EELS-TEM (Fig. 1) and XRD analysis (Fig. 2c). For all synthesized materials, the monoclinic WO3 phase (JCPDS No.83-950) with (0,0,2) preferred orientation was observed in Fig. 2c. This phase (monoclinic WO3) is related to the calcination, at 500 °C, of the previously synthesized WO3 nanoparticles before the formation of the WT structure, which gives this structure thermal stability [24, 25]. Likewise, the diffraction peaks of anatase phase (TiO2, JCPDS No.84‐1286) were observed for all synthesized materials (Fig. 2c). Cu and Pd diffraction peaks are not detected in the XRD analysis, which can be attributed to the low content (~ 0.5% wt) and thorough dispersion of co-catalysts on the WT surface. However, interplanar distances of 0.24 nm, corresponding to (1,1,1) cubic plane of Cu2O (Fig. 2a), and 0.262, 0.238 and 0.224 nm corresponding to (1,0,1) plane of PdO and (1,1,1) plane of Pd metallic nanoparticles, can be observed in HRTEM images, as shown in Fig. 2a and b, respectively [26,27,28,29].

Chemical analysis using inductively coupled plasma with optical emission spectrometry (ICP-OES) was employed to determine the efficiency of the impregnation of co-catalysts (see Table 1). The results showed that the theoretical and real co-catalyst contents are very close to each other, confirming the effective impregnation of the metal precursors onto WO3–TiO2 (WT).

The HRTEM and ICP-OES results confirm the presence of Cu and Pd species on WT, and interfacial interaction between co-catalysts and the base material (WT) is observed, which leads to an improvement in the photocatalytic performance.

Also, the textural properties of synthesized materials were measured by N2 adsorption–desorption isotherms to evaluate the effect of Cu and Pd impregnation on the WT structure. The specific surface area values (Table 1), calculated by the BET method, show that Cu–WT and Pd–WT systems exhibit a lower specific surface area than the WT pristine material. However, they are high enough to perform oxidation and reduction reactions on the photocatalyst surface. These results suggest that copper and palladium co-catalysts are well dispersed on the surface of the WT material [30,31,32].

On the other hand, UV–vis diffuse reflectance spectroscopy (DRS) was used to evaluate the optical properties of synthesized materials to obtain more information about the effect of Cu and Pd on the WT structure. The UV–vis spectra in Fig. 3a show an adsorption edge at ~ 373 nm for the WT structure, characteristic of tetrahedral symmetry of Ti4+ in TiO2, the material present in large proportion [33, 34]. Furthermore, the WT structure showed no absorption in the visible region. However, the modification of WT with Cu and Pd nanoparticles caused a significant increase in the absorption in this region. In the same way, the absorptions at around 560 and 630 nm, attributed to a damping effect caused by d–d interband transitions, originated from copper species in the case of Cu–WT material and from palladium species in the case of Pd–WT material [26, 35, 36]. A schematic presentation of the McLean analysis of the absorption edge, used to determine the band gap energy of the synthesized materials, is shown in Fig. 3b. The bandgap energy of WT with co-catalysts shifted slightly toward lower energy compared to the base material (WT), implying that copper and palladium species were not doped into the lattice structure of WO3 or TiO2 but highly dispersed on the WT surface, which confirms the results observed in HRTEM and textural properties. The bandgap energy values (Eg) of the synthesized materials are summarized in Table 1.

a UV–vis spectra of: (i) WO3–TiO2, (ii) WO3–TiO2 with 0.5 wt% of Cu and (iii) WO3–TiO2 with 0.5 wt% of Pd and b Insert of schematic presentation of the McLean analysis of the absorption edge for determining the bandgap energy (Eg) of: (i) WO3–TiO2, (ii) WO3–TiO2 with 0.5 wt% of Cu and (iii) WO3–TiO2 with 0.5 wt% of Pd

The surface electronic state and composition of the chemical species involved in the charge transfer process during photocatalytic hydrogen production were explored by performing high resolution X-ray photoelectron spectroscopy in all the synthesized materials and those thermally treated in hydrogen. Thus, in the narrow scan corresponding to the bonding energies for the Ti2p region, titanium was identified in three different oxidation states (Fig. 4a). A weak peak centered at 461.2 and 455.6 ± 0.2 eV corresponds to Ti 2p1/2 and Ti 2p3/2, respectively, related to the presence of Ti2+ species. In addition, the peaks centered at 462.5 and 456.9 ± 0.2 eV corresponding to Ti 2p1/2 and Ti 2p3/2, respectively, indicate the presence of Ti3+ species in the form of Ti2O3 [37, 38]. Ti2+ and Ti3+ species are a signature of oxygen vacancy defects in the structure, associated with the thermal treatment in hydrogen. On the other hand, the typical bonding of Ti–O at 457.8 and 463.5 ± 0.2 eV, related to Ti4+ species in the structure, is discerned. Similarly, the major TiO2 contribution in the structure (~ 94%) with oxidation state Ti4+ exhibited the characteristic bonding energies at 458.6 and 464.4 ± 0.2 eV [37,38,39,40]. Moreover, the peaks centered at 459.7 and 465.5 ± 0.2 eV are related to the formation of Ti–O–W bonds, which confirms the chemical environment composed of TiO2 and WO3, and indicates a strong interaction between them [41, 42].

XPS high-resolution spectra of a Ti2p high resolution of: (i) WO3–TiO2, (ii) WO3–TiO2 with 0.5 wt% of Cu and (iii) WO3–TiO2 with 0.5 wt% of Pd, b W4f high resolution of: (i) WO3–TiO2, (ii) WO3–TiO2 with 0.5 wt% of Cu and (iii) WO3–TiO2 with 0.5 wt% of Pd, c Cu2p high resolution of WO3–TiO2 with 0.5 wt% of Cu and d Pd3d high resolution of WO3–TiO2 with 0.5 wt% of Pd

The narrow scan corresponding to the bonding energies for the W4f region revealed a multi-contribution (Fig. 4b). The major contribution corresponds to Ti3p at 37.2 ± 0.2 eV due to Ti4+ species in anatase TiO2 phase [43, 44]. Likewise, tungsten was identified in three different oxidation states. A weak double contribution, centered at 36.0 and 33.6 ± 0.2 eV corresponds to W4f5/2 and W4f7/2, respectively, related to W4+ species [45]. Additionally, the peaks centered at 36.6 and 34.6 ± 0.2 eV correspond to W4f5/2 and W4f7/2, indicating the presence of W5+ species [45, 46]. As observed in the titanium region, the presence of W5+ and W4+ species is correlated with oxygen vacancies due to the hydrogen thermal treatment. Furthermore, the peaks centered at 37.7 and 35.4 ± 0.2 eV are related by W atoms to oxidation state + 6 [46, 47]. Besides, the contributions observed at 38.1 and 35.9 ± 0.2 eV correspond to W4f5/2 and W4f7/2, and the peaks centered at 38.8 and 36.5 ± 0.2 eV are attributed to W6+ species related to the typical W–O bonding present in WO3 and a residue of the H2WO4 precursor used during the synthesis process [48]. Moreover, the contribution to higher binding energies at 40.8 and 39.7 ± 0.2 eV is attributed to the formation of W–O–Ti surface bonds, in agreement with the Ti–O–W contribution detected in the Ti2p region, which confirms a strong interaction between them [41].

Meanwhile, the Cu2p spectrum (Fig. 4c) was decomposed into four different chemical species. The smallest contribution is associated with metallic copper (Cu0), located at 951.4 and 931.9 ± 0.2 eV, corresponding to Cu2p1/2 and Cu2p3/2, respectively. However, metallic copper corresponds to similar binding energy values as Cu+ observed at 952.6 and 933.0 ± 0.2 eV, Cu2p1/2 and Cu2p3/2, respectively, and these oxidation states are generally difficult to distinguish from XPS analysis of the Cu2p region [49, 50]. On the other hand, the main contribution of Cu species is in the form of Cu2+ dispersed on the surface of the WT structure, whose peaks Cu2p1/2 and Cu2p3/2 are located at 953.6 and 933.8 ± 0.2 eV, respectively. Additionally, the gap between these two energy levels is about ~ 20 eV, which is a strong indication of the CuO presence [51,52,53]. The double contribution, detected at 954.6 and 934.8 ± 0.2 eV, to Cu2p1/2 and Cu2p3/2, respectively, corresponds to Cu(NO3)2 remnants of the impregnation process [53]. Finally, the characteristic copper multi-component satellites were observed at higher binding energies (941–946 eV). It is important to point out that the impregnation of Cu does not modify titanium and tungsten species in the WT structure [see Fig. 4a(ii) and b(ii)].

Pd3d core level spectra are shown in Fig. 4d. After fitting the experimental data, the characteristic metallic Pd binding energies were identified at 340.9 and 335.6 ± 0.2 eV for Pd3d3/2 and Pd3d5/2 peaks. The gap between these two energy levels is about ~ 5.3 eV, confirming the presence of metallic Pd nanoparticles dispersed on the surface of the WT structure [54, 55]. The second double contribution, associated with the Pd3d3/2 and Pd3d5/2, at 341.8 and 336.5 eV, is assigned to the Pd2+ species [56]. The thermal treatment in a hydrogen atmosphere (at 300 °C for 2 h, using an H2 flow of 0.5 ml min−1 per milligram of photocatalyst, with a heating rate of 2 °C min−1) causes the formation of PdO in several steps. As a result, at low binding energies (336.5 eV), PdO nanoparticles with low crystallinity are obtained [57]. However, other contributions at 342.8 and 337.6 ± 0.2 eV for Pd3d3/2 and Pd3d5/2 peaks are related to the formation of well-crystallized PdO nanoparticles [57]. It is important to mention that the use of a reducing atmosphere does not allow the formation of Pd4+ in the form of PdO2 since this chemical species is highly unstable [58]. On the other hand, the contribution detected at 343.7 and 338.6 ± 0.2 eV for Pd3d3/2 and Pd3d5/2 peaks is related to Pd2+ species in the form of Pd(NO3)2 as a residue of the impregnation process [59]. Finally, the characteristic satellites were observed at 344.2 and 339.0 ± 0.2 eV for Pd3d3/2 and Pd3d5/2 related to Pd2+ species [57, 60]. As in the case of Cu, the impregnation of Pd species does not modify the species of titanium and tungsten present in the WT structure [see Fig. 4a(iii) and b(iii)].

Photocatalytic evaluation of hydrogen production

The performance of synthesized materials was evaluated for the photocatalytic hydrogen production from methanol–water mixtures (10:90 methanol:water) under UV irradiation, with a low concentration of sacrificial agent (methanol), compared to the normally used 1:1 methanol–water volume ratio.

First, we have investigated the H2 production without photocatalyst under UV light irradiation (photolysis), as a function of time reaction, which is shown in Fig. 5a(i). As can be observed, the hydrogen amount increases progressively during the reaction, reaching 63.03 µmol at 6 h, which can be translated as a hydrogen production rate of 10.50 µmol h−1. In the case of pristine materials, WO3 and TiO2, thermally treated in a reducing atmosphere [Fig. 5a(ii) and (iii)], the hydrogen production rate was 391.33 and 510.11 µmol g−1 h−1, respectively, being almost 37 and 48 times higher than the H2 production by photolysis (see Fig. 5b). Also, when the WO3–TiO2 structure is tested, a higher hydrogen production rate (770.10 µmol g−1 h−1) than with the pristine materials is obtained. This value is 1.5 times higher than that measured when using TiO2 (thermally treated in a reducing atmosphere), see Fig. 5b.

a Hydrogen production of synthesized materials: (i) photolysis, (ii) WO3, (iii) TiO2, (iv) WO3–TiO2, (v) WO3–TiO2 with 0.5 wt% Cu and (vi) WO3–TiO2 with 0.5 wt% Pd (UV light irradiation measured in methanol–water mixture 10:90), b Hydrogen production rate of synthesized materials as a function of the reaction time (UV light irradiation measured in methanol–water mixture 10:90)

When WO3 and TiO2 are coupled with the synthesis method used in this work, intimate contact and strong interaction are generated between them, as observed in the HRTEM and XPS analyses. This interaction creates a synergistic effect on photocatalytic hydrogen production. Similarly, the formation of oxygen vacancies (mixed-valance) due to the reducing atmosphere during heat treatment helps to generate surface and/or energy states at the WO3/TiO2 interface, which prevent the recombination of charge carriers, as discussed in detail in previous studies [11, 61].

On the other hand, the photocatalytic activity toward hydrogen production is enhanced in the presence of co-catalysts (Cu or Pd species) compared to the WT structure (Fig. 5a and b). This can be associated with n–p interaction as expected, causing a better separation of the charge carriers. When co-catalysts are loaded on WT, the photogenerated electrons can be rapidly transported to Cu or Pd nanoparticles, which have been spotted as active sites for the hydrogen evolution reaction from water reduction. Analogously, photogenerated holes are removed by methanol that acts as a hole scavenger [62]. Although the co-catalyst content loaded was almost the same in both cases (for Cu and Pd), the activity drastically varied; the hydrogen production rate was 5427.07, 1496.39 and 770.10 μmol g−1 h−1 for Pd/WO3–TiO2, Cu/WO3–TiO2, and WO3–TiO2, respectively. These results may be attributed to the properties of the different metals, such as surface energy, redox potential and the modification of the chemical environment and its interaction with the components of the solution [63].

It is worth mentioning that the Pd/WO3–TiO2 performance enhanced 7 times the activity of the WO3–TiO2 structure. Moreover, on comparing the photocatalytic activity and stability of Pd and Cu loaded on WT structure in successive cycles (Fig. 6), the hydrogen production yield is found to decrease after 3 re-use cycles. For instance, the photocatalytic activity of Cu/WO3–TiO2 and Pd/WO3–TiO2 decreased by 9.7 and 15.2%, respectively. This decrease in the photocatalytic activity must be associated with various factors. It is well known that palladium species are active in the methanol oxidation reaction. However, their photocatalytic functions for methanol conversion differ drastically from copper species. For example, Pd metallic nanoparticles for methanol reforming produce mostly the decomposition products CO and H2 [64, 65]. In a previous study with the Au–Pd/TiO2 material in our laboratory, after several hydrogen reaction cycles, a band was identified at 2088 cm−1 in the FTIR CO adsorption experiment, attributed to the adsorption of CO on metallic Pd nanoparticles [66]. These results give clear proof that both CO selectivity and hydrogen production rates are higher over Pd species than over Cu species under the same reaction conditions. Therefore, the decrease in photocatalytic activity could be due to CO adsorbed on the surface of co-catalysts, which disrupts the interactions between the WT structure and co-catalysts (Pd and Cu species), provoking a decrease in the H2 production yield. However, it is important to point out that hydrogen production in these materials was still much higher than the activity of the WT structure, being almost 2 and 6 times higher for Cu/WO3–TiO2 and Pd/WO3–TiO2, respectively.

(Photo)electrochemical characterization, band alignment and determination of energy states

To gain a deeper understanding of the photocatalytic performance of the synthesized materials and the charge transfer process between n–p heterojunctions, the semiconducting properties of these materials were estimated from Mott–Schottky curves (Figure S1. Supplementary Information). The flatband potential (Efb) of the synthesized materials was estimated by extrapolating the linear region, formed in \({C}_{SC}^{-2}\) versus potential curves, to the potential axis. The values of Efb estimated for all synthesized materials are shown in Table 2.

WO3 and TiO2 exhibited an n-type behavior with a positive slope in the linear region of \({C}_{SC}^{-2}\) versus potential curve; the values of Efb here obtained for WO3 and TiO2 are − 0.76 V and − 0.71 V, respectively. When WO3 and TiO2 are coupled with this synthesis method, the Efb displaces toward more negative values (Table 2); this effect has been observed in previous studies with different composite materials and is related to the energy states generated at grain boundaries between oxides that directly impact the charge transfer through the interface, as sketched in Fig. 7a [9,10,11].

Contrastingly, when Cu species are coupled with the WT structure, the Efb value of the composite becomes less negative (see Fig. 7b) due to the Fermi level alignment through the composite. On the other hand, the WT structure modified with Pd species exhibits the most negative Efb value among the composites (Fig. 7c), which means that the photogenerated electron will have a more reducing capacity, i.e., a more negative potential to perform the hydrogen evolution reaction from water. It should be noted that base materials and WT with co-catalysts exhibited a higher Efb than the potential for hydrogen evolution reaction [− 0.62 V versus Ag/AgCl (3.0 M KCl) at neutral pH], showing that all synthesized materials meet the minimal thermodynamic requirements to perform the water reduction (see Fig. 7).

In addition, photoelectrochemical experiments were performed to study the photoinduced electron transfer process at the interface between WT and the co-catalysts (Cu and Pd species) under illumination and its impact on hydrogen production. The photocurrent responses of the WT structure with and without the co-catalyst are shown in Fig. 8a. Initially, the current was measured at 0.5 V versus Ag/AgCl bias voltage for 60 s to stabilize the current in the dark. Then, the film with the synthesized material was illuminated for another 60 s, causing an increase in the recorded current. After that, the light was interrupted again, causing the currents to decrease rapidly until reaching their value in the dark.

The photocurrent is generated by several consecutive steps such as photon absorption by TiO2 and WO3, charge separation favored by the creation of heterojunction, the presence of co-catalysts and transport of photogenerated electrons through the film toward the current collector, favored by the potential differences imposed for the measurement. Meanwhile, holes are rapidly transported to the semiconductor/electrolyte interface to perform the methanol or water oxidation process.

Figure 8a shows that the film with the WT structure exhibited the lowest photocurrent. However, the addition of Cu and Pd co-catalysts enhanced the photocurrent mainly due to a more efficient charge separation promoted by them. The presence of both co-catalysts could facilitate methanol and water oxidation processes. The considerably larger photocurrent measured in the presence of Pd can be attributed to the combination of two effects related to improved charge separation and a surface with higher catalytic activity to promote the charge transfer at the electrode/electrolyte interface.

Besides, open circuit potential (OCP) measurements were performed for WT, WT–Cu and WT–Pd structures. The effect of illumination on the OCP as a function of time is shown in Fig. 8b.

When the films containing the synthesized materials were illuminated (WT with and without co-catalyst), the OCP began to change toward more negatives values (typical of n-type semiconductors). This behavior indicates the accumulation of the photogenerated electrons in the conduction band or/and energy levels located below it (Fig. 8b). By interrupting the illumination of the films, the OCP slightly changed toward less negative values but moved in the opposite direction when the films were illuminated again. This behavior proves the stability of the electron accumulation process in the films (Fig. 8b).

Significant changes are observed in the response of Cu–WT and Pd–WT structures under illumination compared to the base WT structure. The structures with the presence of co-catalysts reach less negative OCP values, showing a slower response to reach a stable value of OCP under illumination [Fig. 8b(ii) and (iii)]. This delay in reaching a stable OCP is normally related to the filling of energy states with lower energy, probably generated at the co-catalysts–WT interface. These energy states can act as electron traps, improving the separation of the charge carriers. As seen in Fig. 8b, the material with the slowest and most unstable response to on/off intervals is the structure with Pd species. This behavior can be attributed to the fact that Pd species are well dispersed on the WT structure, contributing to a quicker separation and transfer of electrons to the solution. So, the presence of a co-catalyst improves the photocatalytic hydrogen production, which is confirmed by photoelectrochemical analysis.

Therefore, the interaction between co-catalysts and the WT structure has been discussed as follows. After irradiation with UV light of WT with Cu species on the surface, the photogenerated electrons are separated across the entire structure and can take two paths: (1) migrate to the surface and carry out the water reduction process or (2) migrate to the copper nanoparticles (see Scheme 1a). In this second path, the electrons can be rapidly transferred with the help of the copper species on the surface and catalyze hydrogen production or/and reduce Cu2+ to Cu+ (see Scheme 1a and Reaction 1) [11]. The Cu+ species can be reoxidized to Cu2+ by the holes photogenerated in CuO or WT structure (see Scheme 1a and Reaction 2) [11]. Moreover, the existence of metallic copper nanoparticles in the WT structure helps to improve the transport and conductivity of electrons, thereby increasing their photocatalytic activity and catalyzing hydrogen production [11].

In the case of WT with Pd species on the surface, after irradiation with UV light, the photogenerated electrons are separated and can take three paths: (1) migrate to the WT surface and carry out the water reduction process, (2) migrate to metallic Pd nanoparticles, improving the transport and conductivity of electrons and catalyzing hydrogen production or (3) migrate to the surface of WT and reduce PdO nanoparticles (Pd2+) in situ into Pd0 (see Scheme 1b and Reaction 3). Once PdO is reduced to Pd0, this metallic nanoparticle promotes the high photocatalytic activity by generating a Schottky junction between the metal and the WT structure. It can trap, store and transport the photogenerated electrons reducing the rate of the (e−–h+) recombination [32, 67].

Also, metallic Pd nanoparticles deposited onto WT can be reoxidized by photogenerated holes (see Scheme 1b and Reaction 4).

To sum up, all of the experimental evidence provided in this research sheds light on the effect of Cu and Pd species loading on WO3–TiO2 that occurs during the photocatalytic hydrogen production under UV light. The EELS-TEM and HRTEM analyses show the intimate contact and interfacial interaction between WO3 and TiO2. Similarly, HRTEM shows the interaction between Cu and Pd co-catalysts with WO3–TiO2, where a uniform distribution around the WT structure is observed, causing a decrease in the surface area. The XRD characterization shows that there are no considerable structural changes in the WT matrix associated with the treatment used to load Cu and Pd by the incipient wetness impregnation method, which is related to their uniform dispersion and low concentration.

The XPS analysis shows the chemical environment and the species that participate in the charge transfer process during the production of photocatalytic hydrogen. This technique allowed us to observe a strong interaction between WO3 and TiO2 generated by the sol–gel method used. The presence of mixed-valence titanium, tungsten and co-catalyst species is also observed. These mixed-valence compounds in the structure generate defects in the material by creating energy states at the interface, thus modifying its semiconducting properties. Therefore, the determination of semiconducting properties by photoelectrochemical techniques, when WO3 and TiO2 are coupled, reveals that Efb of the structure becomes more negative than that of the pristine materials (see Table 2), due to the generation of energy states at the interface. These states can behave as shallow energy states to separate the charge carriers, and thus provide a path for electron transfer toward the co-catalysts and improve the photocatalytic activity.

The addition of Cu and Pd increases the (e−–h+) separation, mobility and transfer of the electrons to the solution for the reduction of water to hydrogen, obtaining the best performance for the Pd/WT structure.

Conclusion

The sol–gel synthesis method, used in this work, allowed TiO2 nanoparticles to grow on the previously synthesized WO3 nanoparticles, generating direct contact between them and thus allowing the formation of a heterojunction. The dispersion of Cu and Pd species onto the surface of WT material causes a decrease in the surface area and creates additional defect states in the optical properties. HRTEM and XPS experiments showed a strong interaction at the interface of TiO2 and WO3. The photocatalytic activity for H2 evolution shows that the use of Cu and mainly Pd species over WO3–TiO2 favors hydrogen production due to the fact that Cu and Pd species improve the charge carrier separation process, acting as co-catalysts and increasing the transfer of electrons to the solution. The presence of Cu and Pd in the structure, moved the flatband position increased the photocurrent, and changed the open-circuit potential under illumination toward less negative values, indicating the formation of energy states at the interface between WO3–TiO2 and co-catalysts. These energy states at the heterojunction act as traps during the photocatalytic process, preventing the recombination of photogenerated charge carriers.

References

Liu G, Kolodziej C, Jin R, Qi S, Lou Y, Chen J, Jiang D, Zhao Y, Burda C (2020) MoS2-Stratified CdS-Cu2–xS core–shell nanorods for highly efficient photocatalytic hydrogen production. ACS Nano 14:5468–5479. https://doi.org/10.1021/acsnano.9b09470

Lu M, Shao C, Wang K, Lu N, Zhang X, Zhang P, Zhang M, Li X, Liu Y (2014) p-MoO3 nanostructures/n-TiO2 nanofiber heterojunctions: controlled fabrication and enhanced photocatalytic properties. ACS Appl Mater Interfaces 6(12):9004–9012. https://doi.org/10.1021/am5021155

McCullagh C, Skillen N, Adams M, Robertson PKJ (2011) Photocatalytic reactors for environmental remediation: a review. J Chem Technol Biotechnol 86:1002–1017. https://doi.org/10.1002/jctb.2650

Chan SHS, Wu TY, Juan JC, The CY (2011) Recent developments of metal oxide semiconductors as photocatalysts in advanced oxidation processes (AOPs) for treatment of dye waste-water. J Chem Technol Biotechnol 86:1130–1158. https://doi.org/10.1002/jctb.2636

Pan Hong J, Lee in W, (2006) Preparation of highly ordered cubic mesoporous WO3/TiO2 films and their photocatalytic properties. Chem Mater 18:847–853. https://doi.org/10.1021/cm0522782

Rey A, García-Muñoz P, Hernández-Alonso MD, Mena E, García-Rodríguez S, Beltrán FJ (2014) WO3–TiO2 based catalysts for the simulated solar radiation assisted photocatalytic ozonation of emerging contaminants in a municipal wastewater treatment plant effluent. Appl Catal B Environ 154–155:274–284. https://doi.org/10.1016/j.apcatb.2014.02.035

Toledo Camacho SY, Rey A, Hernández-Alonso MD, Llorca J, Medina F, Contreras S (2018) Pd/TiO2–WO3 photocatalysts for hydrogen generation from water-methanol mixtures. Appl Surf Sci 455:570–580. https://doi.org/10.1016/j.apsusc.2018.05.122

DohĿeviĿ-MitroviĿ Z, StojadinoviĿ S, Lozzi L, AškrabiĿ S, RosiĿ M, TomiĿ N, PaunoviĿ N, LazoviĿ S, NikoliĿSantucci MGS (2016) WO3/TiO2 composite coatings: structural, optical and photocatalytic properties. Mater Res Bull 83:217–224. https://doi.org/10.1016/j.materresbull.2016.06.011

Ramírez-Ortega D, Meléndez AM, Acevedo-Peña P, González I, Arroyo R (2014) Semiconducting properties of ZnO/TiO2 composites by electrochemical measurements and their relationship with photocatalytic activity. Electrochim Acta 140:541–549. https://doi.org/10.1016/j.electacta.2014.06.060

Ramírez-Ortega D, Acevedo-Peña P, Tzompantzi F, Arroyo R, González F, González I (2017) Energetic states in SnO2–TiO2 structures and their impact on interfacial charge transfer process. J Mater Sci 52:260–275. https://doi.org/10.1007/s10853-016-0328-3

Guerrero-Araque D, Acevedo-Peña P, Ramírez-Ortega D, Lartundo-Rojas L, Gómez R (2017) SnO2–TiO2 structures and the effect of CuO, CoO metal oxide on photocatalytic hydrogen production. J Chem Technol Biotechnol 92:1531–1539. https://doi.org/10.1002/jctb.5273

Lalitha K, Sadanandam G, Kumari VD, Subrahmanyam M, Sreedhar B, Hebalkar NY (2010) Highly stabilized and finely dispersed Cu2O/TiO2: a promising visible sensitive photocatalyst for continuous production of hydrogen from glycerol: water mixtures. J Phys Chem C 114:22181–22189. https://doi.org/10.1021/jp107405u

Li L, Xu L, Shi W, Guan J (2013) Facile preparation and size-dependent photocatalytic activity of Cu2O nanocrystals modified titania for hydrogen evolution. Int J Hydrog Energy 38:816–822. https://doi.org/10.1016/j.ijhydene.2012.10.064

Lo SS, Mirkovic T, Chuang C-H, Burda C, Scholes GD (2011) Emergent properties resulting from type-II band alignment in semiconductor nanoheterostructures. Adv Mater 23:180–197. https://doi.org/10.1002/adma.201002290

Wang Y, Zhang Y, Zhao G, Tian H, Shi H, Zhou T (2012) Design of a novel Cu2O/TiO2/carbon aerogel electrode and its efficient electrosorption-assisted visible light photocatalytic degradation of 2,4,6-trichlorophenol. ACS Appl Mater Interfaces 4:3965–3972. https://doi.org/10.1021/am300795w

Ni D, Shen H, Li H, Ma Y, Zhai T (2017) Synthesis of high efficient Cu/TiO2 photocatalysts by grinding and their size-dependent photocatalytic hydrogen production. Appl Surf Sci 409:241–249. https://doi.org/10.1016/j.apsusc.2017.03.046

Chen W-T, Jovic V, Sun-Waterhouse D, Idriss H, Waterhouse GIN (2013) The role of CuO in promoting photocatalytic hydrogen production over TiO2. Int J Hydrog Energy 38:15036–15048. https://doi.org/10.1016/j.ijhydene.2013.09.101

Wu J, Lu S, Ge D, Zhang L, Chen W, Gu H (2016) Photocatalytic properties of Pd/TiO2 nanosheets for hydrogen evolution from water splitting. RSC Adv 6:67502–67508. https://doi.org/10.1039/C6RA10408H

Vuong NM, Kim D, Kim H (2013) Electrochromic properties of porous WO3–TiO2 core–shell nanowires. J Mater Chem C 1:3399–3407. https://doi.org/10.1039/C3TC30157E

Patil SM, Deshmukh SP, More KB, Shevale VB, Mullani SB, Dhodamani AG, Delekar SD (2019) Sulfated TiO2/WO3 nanocomposite: an efficient photocatalyst for degradation of Congo red and methyl red dyes under visible light irradiation. Mater Chem Phys 225:247–255. https://doi.org/10.1016/j.matchemphys.2018.12.041

Wei Y, Huang Y, Fang Y, Zhao Y, Luo D, Guo Q, Fan L, Wu J (2019) Hollow mesoporous TiO2/WO3 sphere heterojunction with high visible-light-driven photocatalytic activity. Mater Res Bull 119:110571–110578. https://doi.org/10.1016/j.materresbull.2019.110571

Mathankumar G, Bharathi P, Mohan MK, Harish S, Navaneethan M, Archana J, Suresh P, Mani GK, Dhivya P, Ponnusamy S, Muthamizhchelvan C (2020) Synthesis and functional properties of nanostructured Gd-doped WO3/TiO2 composites for sensing applications. Mater Sci Semicond Process 105:104732–104740. https://doi.org/10.1016/j.mssp.2019.104732

Prabhu S, Cindrella L, Kwon OJ, Mohanraju K (2019) Photoelectrochemical, photocatalytic and photochromic performance of rGO–TiO2–WO3 composites. Mater Chem Phys 224:217–228. https://doi.org/10.1016/j.matchemphys.2018.12.030

Ke D, Li H, Peng T, Liu X, Ke D (2008) Preparation and photocatalytic activity of WO3/TiO2 nanocomposite particles. Mater Lett 62:447–450. https://doi.org/10.1016/j.matlet.2007.05.060

Ramana CV, Utsunomiya S, Ewing RC, Julien CM, Becker U (2006) Structural stability and phase transitions in WO3 thin films. J Phys Chem B 110:10430–10435. https://doi.org/10.1021/jp056664i

Mondal I, Pal U (2016) Synthesis of MOF templated Cu/CuO@TiO2 nanocomposites for synergistic hydrogen production. Phys Chem Chem Phys 18:4780–4788. https://doi.org/10.1039/C5CP06292F

Zhen W, Jiao W, Wu Y, Jing H, Lu G (2017) The role of a metallic copper interlayer during visible photocatalytic hydrogen generation over a Cu/Cu2O/Cu/TiO2 catalyst. Catal Sci Technol 7:5028–5037. https://doi.org/10.1039/C7CY01432E

Yuan J, Zhang J-J, Yang M-P, Meng W-J, Wang H, Lu J-X (2018) CuO Nanoparticles supported on TiO2 with high efficiency for CO2 electrochemical reduction to ethanol. Catalysts 8:171–181. https://doi.org/10.3390/catal8040171

Zhao Q, Li H, Zhang L, Cao Y (2019) Study of PdO species on surface of TiO2 for photoreduction of CO2 into CH4. J Photochem Photobiol A 384:112032–112039. https://doi.org/10.1016/j.jphotochem.2019.112032

Dong X, Ma X, Xu H, Ge Q (2016) Comparative study of silicasupported copper catalysts prepared by different methods: formation and transition of copper phyllosilicate. Catal Sci Technol 6:4151–4158. https://doi.org/10.1039/C5CY01965F

Rungjaroentawon N, Onsuratoom S, Chavadej S (2012) Hydrogen production from water splitting under visible light irradiation using sensitized mesoporous-assembled TiO2–SiO2 mixed oxide photocatalysts. Int J Hydrog Energy 37:11061–11071

Rusinque B, Escobedo S, de Lasa H (2020) Photoreduction of a Pd-doped mesoporous TiO2 photocatalyst for hydrogen production under visible light. Catalysts 10:74–97. https://doi.org/10.3390/catal10010074

López R, Gómez R, Llanos ME (2010) Photophysical and photocatalytic properties of nanosized copper-doped titania sol–gel catalysts. Catal Today 148:103–108. https://doi.org/10.1016/j.cattod.2009.04.001

Chen J, Lin L-B, Jing F-Q (2001) Theoretical study of F-type color center in rutile TiO2. J Phys Chem Solids 62:1257–1262. https://doi.org/10.1016/S0022-3697(01)00018-X

Yu H, Irie H, Hashimoto K (2010) Conduction band energy level control of titanium dioxide: toward an efficient visible-light-sensitive photocatalyst. J Am Chem Soc 132:6898–6899. https://doi.org/10.1021/ja101714s

Wu Y, Lu G, Li S (2009) The role of Cu(I) species for photocatalytic hydrogen generation over CuOx/TiO2. Catal Lett 133:97–105. https://doi.org/10.1007/s10562-009-0165-y

Mekasuwandumrong O, Chaitaworn S, Panpranot J, Praserthdam P (2019) Photocatalytic liquid-phase selective hydrogenation of 3-nitrostyrene to 3-vinylaniline of various treated-TiO2 without use of reducing gas. Catalysts 9:329–343. https://doi.org/10.3390/catal9040329

Kumar Paul K, Jana S, Giri PK (2018) Tunable and high photoluminescence quantum yield from self-decorated TiO2 quantum dots on fluorine doped mesoporous TiO2 flowers by rapid thermal annealing. Part Part Syst Char 35:1800198–1800213. https://doi.org/10.1002/ppsc.201800198

Zakrzewska K (2012) Nonstoichiometry in TiO2−y studied by ion beam methods and photoelectron spectroscopy. Adv Mater Sci Eng 826873:1–13. https://doi.org/10.1155/2012/826873

Kato K, Xin Y, Shirai T (2019) Structural-controlled synthesis of highly efficient visible light TiO2 photocatalyst via one-step single-mode microwave assisted reaction. Sci Rep 9:4900–49008. https://doi.org/10.1038/s41598-019-41465-x

Grandcolas M, Cottineau T, Louvet A, Keller N, Keller V (2013) Solar light-activated photocatalytic degradation of gas phase diethylsulfide on WO3-modified TiO2 nanotubes. Appl Catal B Environ 138–139:128–140. https://doi.org/10.1016/j.apcatb.2013.02.041

Gao L, Gan W, Qiu Z, Zhan X, Qiang T, Li J (2017) Preparation of heterostructured WO3/TiO2 catalysts from wood fibers and its versatile photodegradation abilities. Sci Rep 7:1102–1114. https://doi.org/10.1038/s41598-017-01244-y

Chang F, Wang J, Luo J, Sun J, Deng B, Hu X (2016) Enhanced visible-light-driven photocatalytic performance of mesoporous W-Ti-SBA-15 prepared through a facile hydrothermal route. Colloid Surf A 499:69–78. https://doi.org/10.1016/j.colsurfa.2016.04.013

Patrocinio AOT, Paula LF, Paniago RM, Freita J, Bahnemann DW (2014) Layer-by-layer TiO2/WO3 thin films as efficient photocatalytic self-cleaning surfaces. ACS Appl Mater Interfaces 6:16859–16866. https://doi.org/10.1021/am504269a

Terohid SAA, Heidari S, Jafari A (2018) Effect of growth time on structural, morphological and electrical properties of tungsten oxide nanowire. Appl Phys A 124:567–575. https://doi.org/10.1007/s00339-018-1955-0

Alonso-Tellez A, Robert D, Keller V, Keller N (2014) H2S photocatalytic oxidation over WO3/TiO2 Hombikat UV100. Environ Sci Pollut Res 21:3503–3514. https://doi.org/10.1007/s11356-013-2329-y

Gui Y, Blackwood DJ (2014) Electrochromic enhancement of WO3–TiO2 composite films produced by electrochemical anodization. J Electrochem Soc 161:E191–E201. https://doi.org/10.1149/2.0631414jes

Reale F, Palczynski P, Amit I, Jones GF, Mehew JD, Bacon A, Ni N, Sherrell PC, Agnoli S, Craciun MF, Russo S, Mattev C (2017) High-mobility and high-optical quality atomically thin WS2. Sci Rep 7:14911–14920. https://doi.org/10.1038/s41598-017-14928-2

Drouet C, Laberty C, Fierro JLG, Alphonse P, Rousset A (2000) X-ray photoelectron spectroscopic study of non-stoichiometric nickel and nickel–copper spinel manganites. J Inorg Mater 2:419–426. https://doi.org/10.1016/S1466-6049(00)00047-7

Monte M, Munuera G, Costa D, Conesa JC, Martínez-Arias A (2015) Near-ambient XPS characterization of interfacial copper species in ceria-supported copper catalysts. Phys Chem Chem Phys 17:29995–30004. https://doi.org/10.1039/C5CP04354A

Mohammad A, Chandra P, Ghosh T, Carraro M, Mobin SM (2017) Facile access to amides from oxygenated or unsaturated organic compounds by metal oxide nanocatalysts derived from single-source molecular precursors. Inorg Chem 56:10596–10608. https://doi.org/10.1021/acs.inorgchem.7b01576

Richharia P, Chopra KL, Bhatnagar MC (1991) Surface analysis of a black copper selective coating. Sol Energy Mater 23:93–109. https://doi.org/10.1016/0165-1633(91)90156-F

Biesinger MC (2017) Advanced analysis of copper X-ray photoelectron spectra. Surf Interface Anal 49:1325–1334. https://doi.org/10.1002/sia.6239

Tressaud A, Khairoun S, Touhara H, Watanabe N (1986) X-ray photoelectron spectroscopy of palladium fluorides. Chemie 540–541:291–299. https://doi.org/10.1002/zaac.19865400932

Priolkar KR, Bera P, Sarode PR, Hegde MS, Emura S, Kumashiro R, Lalla NP (2002) Formation of Ce1−xPdxO2−δ solid solution in combustion-synthesized Pd/CeO2 catalyst: XRD, XPS, and EXAFS investigation. Chem Mater 14:2120–2128. https://doi.org/10.1021/cm0103895

Cai G, Luo W, Xiao Y, Zheng Y, Zhong F, Zhan Y, Jiang L (2018) Synthesis of a highly stable Pd@CeO2 catalyst for methane combustion with the synergistic effect of urea and citric acid. ACS Omega 3:16769–16776. https://doi.org/10.1021/acsomega.8b02556

Kibis LS, Titkov AI, Stadnichenko AI, Koscheev SV, Boronin AI (2009) X-ray photoelectron spectroscopy study of Pd oxidation by RF discharge in oxygen. Appl Surf Sci 255:9248–9254. https://doi.org/10.1016/j.apsusc.2009.07.011

Moroseac M, Skála T, Veltruská K, Matolίn V, Matolίnová I (2004) XPS and SSIMS studies of Pd/SnOx system: reduction and oxidation in hydrogen containing air. Surf Sci 566–568:1118–1123. https://doi.org/10.1016/j.susc.2004.06.068

Tan H-Z, Wang Z-Q, Xu Z-N, Sun J, Chen Z-N, Chen Q-S, Chen Y, Guo G-C (2017) Active Pd(ii) complexes: enhancing catalytic activity by ligand effect for carbonylation of methyl nitrite to dimethyl carbonate. Catal Sci Technol 7:3785–3790. https://doi.org/10.1039/C7CY01305A

Veziroglu S, Hwang J, Drewes J, Barg I, Shondo J, Strunskus T, Polonskyi O, Faupel F, Aktas OC (2020) PdO nanoparticles decorated TiO2 film with enhanced photocatalytic and self-cleaning properties. Mater Today 16:100251. https://doi.org/10.1016/j.mtchem.2020.100251

Guerrero-Araque D, Acevedo-Peña P, Ramírez-Ortega D, Calderon HA, Gómez R (2017) Charge transfer processes involved in photocatalytic hydrogen production over CuO/ZrO2–TiO2 materials. Int J Hydrog Energy 42:9744–9753. https://doi.org/10.1016/j.ijhydene.2017.03.050

Sreethawong T, Yoshikawa S (2005) Comparative investigation on photocatalytic hydrogen evolution over Cu-, Pd-, and Au-loaded mesoporous TiO2 photocatalysts. Catal Commun 6:661–668. https://doi.org/10.1016/j.catcom.2005.06.004

Xu C, Wang X, Zhu J (2008) Graphene−metal particle nanocomposites. J Phys Chem C 112:9841–19845. https://doi.org/10.1021/jp807989b

Agrell J, Hasselbo K, Jansson K, Järåsa G, S, Boutonnet M, (2001) Production of hydrogen by partial oxidation of methanol over Cu/ZnO catalysts prepared by microemulsion technique. Appl Catal A Gen 211:239–250. https://doi.org/10.1016/S0926-860X(00)00876-0

Agrell J, Germani G, Järås SG, Boutonnet M (2003) Production of hydrogen by partial oxidation of methanol over ZnO-supported palladium catalysts prepared by microemulsion technique. Appl Catal A Gen 242:233–245. https://doi.org/10.1016/S0926-860X(02)00517-3

Barrios CE, Albiter E, Gracia y Jimenez J.M., Tiznado H, Romo-Herrera J, Zanella R, (2016) Photocatalytic hydrogen production over titania modified by gold–metal (palladium, nickel and cobalt) catalysts. Int J Hydrog Energy 41:23287–23300. https://doi.org/10.1016/j.ijhydene.2016.09.206

Bahruji H, Bowker M, Davies PR, Morgan DJ, Morton CA, Egerton TA, Kennedy J, Jones W (2015) Rutile TiO2–Pd photocatalysts for hydrogen gas production from methanol reforming. Top Catal 58:70–76. https://doi.org/10.1007/s11244-014-0346-9

Acknowledgements

The authors would like to thank the financial support provided by Consejo Nacional de Ciencia y Tecnología (CONACYT) through the CB-18269 Grant and Dirección General de Asuntos del Personal Académico-UNAM through the PAPIIT IN103719 Grant. We also thank the Laboratorio Universitario de Caracterización Espectroscópica (LUCE-UNAM) and the Laboratorio Universitario de Nanotecnología Ambiental (LUNA-UNAM) and the technical support provided by Viridiana Maturano Rojas and Selene Islas Sánchez. David A. Ramírez Ortega (CVU 329398) thanks CONACYT postdoctoral Grant.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that contents of this work have not conflict of interest with any individual or organization.

Additional information

Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ramírez-Ortega, D., Guerrero-Araque, D., Acevedo-Peña, P. et al. Effect of Pd and Cu co-catalyst on the charge carrier trapping, recombination and transfer during photocatalytic hydrogen evolution over WO3–TiO2 heterojunction. J Mater Sci 55, 16641–16658 (2020). https://doi.org/10.1007/s10853-020-05188-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05188-z