Abstract

The filler effect is the most important physical mechanism of mineral admixtures in the early hydration of cement whose chemical properties greatly affect the precipitation of C–S–H. In this study, calcite, strontianite, magnesite, dolomite, quartz, whewellite and whitlockite were selected as the fillers. The morphology and reaction kinetics of synthetic C–S–H precipitated on the surfaces of different fillers were studied via electron microscopy observations and electrical conductivity and ion concentration measurements. The precipitation rate of C–S–H has a positive correlation with the affinity of Ca2+ for adsorption on the fillers, which can be explained by the nucleation barrier of C–S–H. Extremely ordered honeycomb-like morphology of the C–S–H is found on calcite and strontianite surfaces, while less regular leaf-like or honeycomb-like C–S–H is found on whewellite and whitlockite. The ordered C–S–H pattern is related to the lattice cleavage of the ionic compound filler. In the case of quartz, C–S–H prefers growth along the tangential direction, which is quite different from the normal-direction growth on ionic compounds. The in-plane growth of C–S–H on quartz is believed to be induced by a layer of loosely physically adsorbed Ca2+.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fine-grained limestone and quartz powders have been used as fillers (i.e., not the coarse-grained aggregates) in the preparation of concretes by partially replacing Portland cement [1,2,3]. These fillers are commonly recognized as inert materials in cementitious material systems [3,4,5,6]. The main positive effect of these added fillers on the hydration of cement is that they accelerate the nucleation of the hydration product (calcium silicate hydrate, C–S–H) by providing more nucleation sites on the surface [7, 8]. Such a nucleation effect of the fillers is quite important to the properties of cementitious materials during the early stage when the C–S–H is rapidly precipitating and the microstructure is rapidly developing.

The affinity of fillers for C–S–H is related to the chemical properties of their surfaces. French et al. [9], Bentz et al. [10], Mehta et al. [11] and Ouyang et al. [12] found that the bond strength between C–S–H and calcite is much stronger than that between C–S–H and silica. They proposed that this phenomenon is caused by the different interactions between the fillers and Ca2+: strong acid–base interactions between calcite and Ca2+ and a relatively weak electrostatic force between silica and Ca2+. Oey et al. [13] and Kumar et al. [14] also found that the accelerated effect of calcite on the Portland cement hydration is stronger than that of quartz. They proposed that the ion-exchange reactions between CO32− (from calcite) and OH− (from C–S–H) make limestone a superior filler to quartz. In addition to the precipitation kinetics, the morphology of C–S–H is also significantly affected by the chemical properties of filler surfaces. An ordered pattern of the precipitated C–S–H was observed on the surface of calcite by Sato et al. [15], Bentz et al. [10], Ouyang et al. [8] and Berodier et al. [7], which is also attributed to the strong chemical bonding of Ca2+ to the calcite surface. In the above investigations, only the differences in the filler effects between calcite and quartz were studied. Other types of inert materials should be studied to verify the effects of surface’s chemical properties on the affinity of fillers with the C–S–H. Additionally, no direct evidence has been found to prove that the adsorption affinity of Ca2+ with certain fillers leads to different bonding strengths and various morphologies of the C–S–H, although the higher adsorption affinity of Ca2+ on calcite has been observed by zeta-potential tests [8, 12].

This paper reports the morphology and precipitation kinetics of the synthetic C–S–H formed on the surfaces of various inert fillers. The properties of the synthetic C–S–H have been investigated in prior studies [16,17,18,19,20,21,22,23,24,25]. By selecting the synthetic C–S–H as the studied target, other undesired interferences from many factors can be eliminated, such as the reaction of the aluminate phases in Portland cement and the dissolution process of alite. In this study, seven different inert fillers with different adsorption capacities for calcium ions were selected as the substrates for the growth of synthetic C–S–H. Studying different types of inert fillers is helpful to verify the dominant mechanism of the filler effect.

Experimental

Raw materials

The as-received calcium nitrate tetrahydrate (Ca(NO3)2·4H2O), sodium silicate (Na2SiO3·9H2O) and sodium hydroxide (NaOH) produced by Aladdin Reagent Co., Ltd., were used for the synthesis of C–S–H. The fillers were calcite (CaCO3), strontianite (SrCO3), magnesite (MgCO3), dolomite (MgCa(CO3)2), quartz (SiO2), whewellite (CaC2O4) and whitlockite (Ca3(PO4)2). All of the fillers are fine powders, and the specific surface areas (SSAs) of these fillers were determined from nitrogen adsorption isotherms using the BET equations, which are presented in Table 1. The crystal systems and solubility product constant (Ksp) of these fillers are also given in Table 1.

Synthesis of C–S–H

First, Solution A was prepared by dissolving 3 mmol Ca(NO3)2·4H2O in 30 ml deionized (DI) water, and Solution B was prepared by dissolving 3 mmol Na2SiO3·9H2O in 30 ml DI water. Second, Solution C was prepared by dissolving 0.16 g NaOH (4 mmol) in 40 ml DI water and was used to maintain the alkalinity of the solutions during the synthesis process. Then, the C–S–H was synthesized according to the specific synthetic procedure, which is summarized schematically in Fig. 1. It should be noted that the total surface areas of different fillers added into solution C were all 6 m2. This is the most appropriate mix proportion: Both increasing and decreasing the total surface areas would change the distribution density of the C–S–H on the filler surfaces, which is not suitable for the observation of microstructure under SEM and TEM. The synthetic procedure of the pure C–S–H is similar to that presented in Fig. 1, but no fillers were added in Solution C.

XRD analysis was used to characterize the crystalline structure of synthetic C–S–H without fillers, and the result is presented in Fig. 2. The XRD pattern of synthetic C–S–H exhibits tobermorite-like reflections, which is consistent with those previously reported by Popova [28] and Plank [19]. The XRD pattern of the ordinary Portland cement (OPC) paste is also provided in Fig. 2, and it was found that the C–S–H produced in OPC paste mainly presented as amorphous bulge.

Morphology and structure observation

SEM imaging

A Quanta 200 FEG environmental scanning electron microscope (ESEM, FEI) was used for morphological and microstructural observations of synthetic C–S–H. Synthetic C–S–H with or without fillers was dispersed separately on the sample stage and treated with carbon plating. The SEM observation was conducted at an accelerating voltage of 10 keV.

TEM imaging

Transmission electron microscope (TEM, JEM-2010F) equipped with the additional feature of energy-dispersive X-ray spectroscopy (EDS) was used for the microstructural observation of the synthetic C–S–H. Approximately, 1.0 g synthetic C–S–H with or without fillers was diluted in 100 ml ethanol and further dispersed in an ultrasonic bath for 15 min. The well-dispersed dispersions were dropped on a #400 Cu mesh with carbon support films. Then, synthetic C–S–H was observed by TEM, and the elemental composition was collected by the EDS.

Precipitation kinetics monitoring

Electrical conductivity

To monitor the precipitation kinetics of synthetic C–S–H, the electrical conductivity of the preparation solutions was auto-recorded by a METTLER TOLEDO FE38 conductometer connected to a personal computer. Prior to the testing, the electrode was calibrated by KCl standard solutions with different conductivities of 0.1466, 1.408, 12.85 and 111.3 mS/cm. In the conductivity monitoring procedure, 30 ml of both Solutions A and B were pumped into 100 ml DI water at a rate of 0.5 ml/min with magnetic stirring. The electrical conductivity of the mixed solution was monitored and recorded continuously.

Ion concentrations

In addition to monitoring the electrical conductivity, the ion concentrations of the solutions were also determined to characterize the precipitation kinetics of the synthetic C–S–H. At 1, 3, 6, 9, 12, 15, 18, 30, 45, 60, 100, 200, 400, 800, 1400 and 2500 min, approximately 10 ml of the mixed solution was removed and centrifuged for 5 min at 10,500 rpm, and the supernatant liquid was collected and filtered using a syringe filter with filter paper of 0.22 μm in the opening size, followed by dilution with 2 wt% HNO3 solution. The concentrations of both Ca and Si were determined by an X series inductively coupled plasma optical emission spectrometer (ICP-OES, Thermo).

Adsorption of Ca2+ on the surfaces of fillers

Zeta-potential test

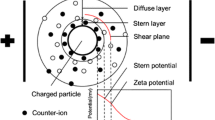

The surface charge or the zeta potential of the suspended particles is significantly affected by the adsorption of ions [29]; thus, many papers have presented the adsorption behavior of ions through the zeta-potential test [8, 12, 30, 31]. In this study, the preferential adsorptions of calcium on different fillers were characterized by determining the zeta potential of the fillers suspended in Ca(OH)2 solutions at various concentrations from 0.2 to 20 mM. The total surface areas of the different fillers were 6 m2 in 30 ml Ca(OH)2. After continuous stirring for 48 h under the N2 environment, the zeta potential of the suspensions was determined by a Malvern Zetasizer Nano instrument.

Measurement of Ca2+ concentration

The changes in the concentrations of the suspensions directly reflect the adsorption behavior of Ca2+ on the surface of the fillers. Fillers with total surface areas of 30 m2 were added into 30 ml Ca(OH)2 solutions. After continuous stirring for 48 h, the suspension was centrifuged for 5 min at 10,500 rpm, and the supernatant liquid was collected and filtered using a syringe filter (0.22 μm), followed by dilution with 2 wt% HNO3. Then, the concentrations of Ca in the diluted supernatant liquid were measured by ICP-OES. Considering the mineralogical transformation [32], the concentrations of Mg and Sr were also determined in the suspensions containing strontianite, magnesite and dolomite.

Results and discussion

Adsorption of Ca2+ on fillers

Ion concentrations

The adsorption of Ca2+ onto the surfaces of fillers in the alkaline Ca(OH)2 solutions with concentrations from 0.2 to 20 mM is presented in Fig. 3. In the aqueous suspensions of calcite, whewellite, whitlockite and quartz, no cation exchange occurs, and the amount of adsorbed Ca2+ can be considered as the difference between the initial and equilibrated Ca2+ concentrations. As shown in Fig. 3a, the adsorption affinity of Ca2+ on calcite is the largest, while that on quartz is the lowest. This phenomenon is caused by the different adsorption mechanisms of Ca2+ on calcite and quartz, which have been discussed by Ouyang et al. [8, 12]. The adsorption of Ca2+ on calcite was reported to be enthalpically driven, and the strong acid–base interaction results in strong adsorption and bonding between Ca2+ and calcite [30, 31]. Contrary to the situation in calcite systems, the adsorption of Ca2+ on quartz is governed by a relatively weak electrostatic force, which results in high mobility and low content of adsorbed Ca2+ [33,34,35]. Similar to calcite, whewellite and whitlockite are both ionic compounds. Thus, the adsorption of Ca2+ on whewellite and whitlockite is also expected to be enthalpically driven. In the case of calcite, the adsorption of Ca2+ on calcite is due to the strong acid–base interaction between Ca2+ and CO3−, while in the cases of whewellite and whitlockite, the active surface sites are C2O42− and PO43−, respectively. As shown in Fig. 3a, the adsorption contents of Ca2+ on whewellite and whitlockite are higher than that on quartz, illustrating the relatively high affinity of Ca2+ for adsorption on ionic compounds with low solubility. However, the affinity of Ca2+ for adsorption on whewellite and whitlockite is slightly less than that on calcite. It is believed that the abilities of ionic compounds to adsorb Ca2+ are related to the strength of the acid–base interaction and the lattice Ca2+ density on the surface of the fillers. Compared to that of whewellite and whitlockite, the lattice Ca2+ density on the surface of calcite is higher due to its smaller lattice volume.

In the cases of strontianite, magnesite and dolomite, cation exchanges between fillers and Ca(OH)2 occur:

In the suspension of strontianite, the ion activity ratio of {Sr2+} to {Ca2+} can be calculated according to the chemical equilibrium constant in Table 1:

The ion activity ratio of {Mg2+} to {Ca2+} in the suspensions of magnesite and dolomite can be determined with the same method:

It is obvious that the cation exchange in the suspension of strontianite is minimal, but that in the suspensions of magnesite and dolomite is substantial. The differences between the initial and equilibrated Ca2+ concentrations cannot be regarded as the adsorption content of Ca2+ on these fillers. Instead, the total adsorption of M2+ on strontianite, magnesite and dolomite was calculated by determining the difference in the initial and equilibrated M2+ concentrations, where M represents the sum of Ca, Mg and Sr. The total adsorption content of M2+ on strontianite, magnesite and dolomite is slightly lower than that on calcite.

Zeta potential

Figure 4 shows the zeta potentials of various filler suspensions as a function of the initial calcium concentrations. As shown in Fig. 4, the Ca2+ concentration is approximately 2 mM in the quartz suspension with zero zeta potential and is in good agreement with the isoelectric point (IEP) determined by Ouyang et al. [8, 12]. The zeta potentials of the calcite suspension at high Ca2+ concentrations are also consistent with the values reported by Ouyang, but the surface charge of calcite is positive even at the minimum Ca2+ concentration of 0.2 mM, illustrating that the IEP of the calcite suspension is less than 0.2 mM, which is only half of the value determined by Ouyang et al. [8, 12]. The IEP of the calcite suspension has also been researched by Huang et al. [30] and Foxall et al. [36], and the value of the IEP is approximately 0.043 mM. The zeta-potential results of Pourchet et al. [31] also show that the surface charge of calcite is positive at the minimum Ca2+ concentration of approximately 0.2 mM. In fact, the surface charges of all ionic compounds are positive even at the minimum Ca2+ concentration in this study. The strong acid–base interaction leads to strong adsorption of Ca2+ on ionic compounds, while the relatively weak electrostatic interaction results in the high mobility of adsorbed Ca2+ on covalent compounds (quartz). In addition, the zeta potentials of the calcite and strontianite suspensions are higher than those of other ionic compound suspensions, illustrating the relatively higher affinity of Ca2+ for adsorption on calcite and strontianite, which is consistent with the adsorption experiment results in “Ion concentrations” section.

Morphology and structure of synthetic C–S–H

It has been reported that the morphology of C–S–H on calcite is different from that on quartz sand: An orderly arrangement of C–S–H was found on the surface of calcite, while that on quartz was disorganized [7, 8]. However, the structure of the C–S–H that precipitated on the surface of fillers with various chemical characteristics has rarely been reported. Moreover, the dominant mechanism of the filler effect on the morphology of C–S–H has seldom been investigated. In this section, the morphology and structure of synthetic C–S–H on different fillers were observed.

SEM

The morphology of synthetic C–S–H was observed by SEM, and the results are presented in Fig. 5. As shown in Fig. 5a, the pure C–S–H that precipitated in solution showed a flocculent morphology with particle sizes from 10 to 100 μm and presented an irregular distribution. Conversely, an ordered honeycomb-like pattern of synthetic C–S–H was found on the surface of calcite (Fig. 5b), which was also observed in cement–calcite blended systems [7, 8, 10, 12, 15]. Interestingly, it was found in the sparse area (marked as red circle) that the synthetic C–S–H grew along the lattice direction. Bentz et al. [10] also reported that the initially precipitated C–S–H pattern was consistent with the distribution of Ca and O atoms on calcite cleavage surfaces, as observed by Rode et al. [37]. Most interestingly, an ordered honeycomb-like pattern of synthetic C–S–H was also found on the surface of strontianite (Fig. 5c). This suggests that not the intrinsic Ca atoms but the CO32− exposed on the surface due to the slight dissolution of fillers is more likely to be the cause of the regular arrangement of C–S–H. However, a quite irregular leaf-like morphology of synthetic C–S–H was found on the surface of magnesite (Fig. 5d), which is caused by the conflict between the precipitation of C–S–H and the phase equilibrium of the carbonate minerals. As shown in Fig. 5d, some calcite crystals (marked with red circles) were found in the magnesite and C–S–H systems. The ICP experimental results also presented the rapid transformation from magnesite with a relatively higher solubility to calcite with lower solubility. This means that magnesite cannot provide a “template surface” with stable physicochemical properties during the nucleation and growth of synthetic C–S–H. Thus, the initial C–S–H nuclei randomly formed on the surface of magnesite and then grew rapidly in this arrangement. As analyzed in “Ion concentrations” section (Eqs. 5 and 6), the cation exchange in the suspension of dolomite is weaker than that in the suspension of magnesite, and thus, the influence of the phase equilibrium of the carbonate minerals on the precipitation of C–S–H is less, resulting in a relatively ordered leaf-like morphology of C–S–H on the surface of dolomite (Fig. 5e). However, compared to those on other ionic compound fillers, the arrangement of C–S–H on dolomite is apparently irregular.

SEM morphology of synthetic C–S–H on fillers. a Pure C–S–H, irregular flocculent morphology; b C–S–H on calcite, ordered honeycomb-like morphology; c C–S–H on strontianite, ordered honeycomb-like morphology; d C–S–H on magnesite, irregular leaf-like morphology; e C–S–H on dolomite, irregular leaf-like morphology; f C–S–H on whewellite, vertical leaf-like morphology; g C–S–H on whitlockite, combined leaf-like and honeycomb-like morphology; h C–S–H on quartz, parallel leaf-like morphology. The small figures in white boxes in b–g are the morphology of the raw fillers

Similar to calcite and strontianite, whewellite and whitlockite are also ionic compounds; thus, the ordered honeycomb-like morphology of synthetic C–S–H is expected to be found on the surface of these fillers. However, the C–S–H on whewellite showed a leaf-like pattern (Fig. 5f). Interestingly, the leaf-like C–S–H is perpendicular to the surface of whewellite (marked as red circle in Fig. 5f), which is quite different from the irregularly distributed leaf-like morphology on dolomite. Both leaf-like C–S–H and honeycomb-like C–S–H were found on the surface of whitlockite, but the arrangements of C–S–H are not as ordered as those on calcite and strontianite. Most interestingly, the synthetic C–S–H on the surface of quartz presented a parallel leaf-like pattern. This means that the growth orientations of synthetic C–S–H vary on different types of fillers: preferred vertical growth on the surface of ionic compounds and parallel growth on the surface of covalent compounds.

TEM

The structures of synthetic C–S–H on various kinds of fillers were also observed by TEM equipped with EDS, and the results are presented in Fig. 6. It should be noted that the TEM structures of C–S–H on magnesite and dolomite have not been observed since the precipitation of C–S–H is apparently affected by cation exchange in the suspensions of magnesite and dolomite. As shown in Fig. 6a, a foil-like synthetic C–S–H was found, and the diffraction pattern showed that the synthetic C–S–H is amorphous. Foil-like synthetic C–S–H was also found on the surface of fillers, illustrating that although inert fillers with different physicochemical properties can obviously influence the SEM morphology of C–S–H, they rarely affect the TEM structure of C–S–H.

TEM morphology of synthetic C–S–H on fillers. a Pure C–S–H; b C–S–H on calcite; c C–S–H on strontianite; d C–S–H on whewellite; e C–S–H on whitlockite; f C–S–H on quartz. The Ca/Si ratio of C–S–H on strontianite is approximately 0.7, while that of the other C–S–H is approximately 1.0. (what are the insets?)

The element composition of synthetic C–S–H was determined by 1 μm line scanning with EDS. The Ca/Si ratio of C–S–H was calculated, and the result in Fig. 6a shows that the Ca/Si ratio of C–S–H is approximately 1.0, which is consistent with the element proportions in Solutions A and B during the synthesis process. The elemental compositions of C–S–H on the surface of the fillers are similar to those of C–S–H in solution, except for C–S–H on strontianite, which has a Ca/Si ratio of only 0.7. The decrease in the Ca/Si ratio is likely caused by the cation exchange between Ca and Sr, which results in a slight decrease in the Ca concentration in solution. Interestingly, the SEM morphology and TEM structure of C–S–H on calcite are similar to those of C–S–H on strontianite, although there is a significant difference between the Ca/Si ratios of C–S–H on the surface of these two fillers. This means that the variation in the Ca/Si ratio from 0.7 to 1.0 has little influence on the structure and morphology of synthetic C–S–H. Rodriguez et al. [38] reported that a foil-like C–S–H was obtained at Ca/Si ratios from 0.7 to 1.5, and fibrillar C–S–H was obtained at a high Ca/Si ratio (> 1.5) via a silica–lime reaction. The transformation of the morphology of synthetic C–S–H from foil to fibrils with increasing Ca/Si ratio has been reported by many studies [39, 40]. The TEM structure of C–S–H on quartz is similar to that on the surface of ionic compounds, illustrating that the type of chemical bond in the fillers only affects the SEM morphology but not the TEM structure of synthetic C–S–H.

Precipitation kinetics of synthetic C–S–H

The precipitation kinetics of synthetic C–S–H were monitored by the electrical conductivity of the solution, and the results are presented in Fig. 7. Figure 7a shows the electrical conductivity of the solution without fillers (red line) and its differential curve (black line). The electrical conductivity increases rapidly within the initial 10 min with the addition of Solutions A and B. At approximately 10 min, a platform was found on the electrical conductivity curve, and a valley appeared on the differential electrical conductivity curve, illustrating rapid consumption of the ions in solution that retards the growth of the electrical conductivity in solution. The appearance of the platform and the valley represents the start of the precipitation of C–S–H. According to the classical nucleation theory [41, 42], the precipitation of C–S–H requires a certain oversaturation degree to overcome the nucleation barrier, and once enough stable nuclei are produced, rapid growth of C–S–H on these nuclei will consume a massive number of ions, resulting in the decrease in the electrical conductivity growth rate of the solution.

Figure 7b shows the differential electrical conductivities of the solution with or without filler. For the initial 10 min, the growth rates of the electrical conductivities of the solutions containing fillers were lower than that of the pure solution, which is believed to be caused by the adsorption of ions on the fillers, as discussed in “Adsorption of Ca2+ on fillers” section. In fact, the growth rate of the suspension electrical conductivity was inversely proportional to the Ca2+ adsorption capacity of the filler. Similar to the case of the pure solution, a valley was found on the differential electrical conductivity curve of the quartz suspension, illustrating rapid precipitation of C–S–H. However, the valley occurred earlier and was smaller with the addition of quartz in solution. Additionally, the valleys in the differential electrical conductivity curves of the whewellite and whitlockite suspensions were inconspicuous. Most interestingly, no significant transition points were found on the differential electrical conductivity curves of the calcite and strontianite suspensions. This demonstrates that the precipitation of C–S–H did not occur suddenly in the filler suspension with the strong adsorption of calcium ions.

The ion concentrations were also measured to characterize the precipitation kinetics of C–S–H, and the results are presented in Fig. 8. The measured ion concentrations of the pure solution coincided exactly with the theoretical curve within the initial 10 min, while those of the filler suspensions were slightly smaller than the theoretical value due to the adsorption behavior of ions on fillers. This result is consistent with the electrical conductivity result. After approximately 10 min, the Ca concentration decreased gradually, while the Si concentration decreased rapidly. The transition points on the ion concentration curves represent the start of the precipitation of C–S–H. As expected, the transition point appears earlier, and the ion concentrations at the transition points are lower in the filler suspensions with higher adsorption capacities for Ca2+.

Myers et al. [43] investigated the thermodynamic data of C–A–S–H gels in Portland cement-based materials. In this study, C–S–H_T5C [43] was selected to represent the synthetic C–S–H product, and its thermodynamic data are provided in Table 2. The saturation index (SI, \({\text{SI}}\, = \ln \left( {{{\text{IAP}} \mathord{\left/ {\vphantom {{\text{IAP}} {K_{\text{sp}} }}} \right. \kern-0pt} {K_{\text{sp}} }}} \right)\)) was calculated via a thermodynamic program PHREEQC, where IAP and Ksp are the ion activity product and solubility product, respectively. The calculated SI is presented in Fig. 9. Similar to the trend of the ion concentration, the saturation index also increased rapidly with the addition of Solutions A and B and reached a maximum value at approximately 10 min, followed by a gradual decline to zero. The transition point also represents the start of the precipitation of C–S–H. As indicated in Fig. 9, the precipitation of C–S–H occurred earlier, and the critical oversaturation degrees were lower in the filler suspensions with higher adsorption capacity for Ca2+, illustrating a lower nucleation barrier in these systems.

According to the classical nucleation theory, the frequency of nucleation increases with the saturation index [41, 42, 44]:

where the nucleation barrier ΔG* is related to the interfacial crystal solution energy γ, the volume of the C–S–H molecule Ω and the saturation index (SI). For heterogeneous nucleation on fillers, the nucleation barrier \(\Delta G_{\text{het}}^{*}\) should be modified via the wetting angle α. As shown in Eqs. 7–9, the nucleation barrier decreases with the addition of fillers due to the transition from homogeneous to heterogeneous nucleation. Moreover, the high affinity of Ca2+ for adsorption on fillers is supposed to decrease the wetting angle between C–S–H and the filler, thus further lowering the nucleation barrier. In particular for calcite and strontianite, the active surface sites \(\left( {{\text{CO}}_{3}^{2 - } } \right)\) exposed due to slight dissolution could substitute with the \({\text{OH}}^{ - }\) in C–S–H [13, 14], which is supposed to increase the compatibility and decrease the wetting angle between the filler and C–S–H gel. Therefore, the precipitation of C–S–H on fillers with a higher adsorption capacity for Ca2+ occurred earlier at a relatively lower oversaturation degree. It should be noted that whether C2O42− and PO43− have similar ion-exchange effects as CO32− remains for further experimental verification.

Discussion

The mechanisms for the effects of different fillers with various physicochemical properties on the nucleation of C–S–H are summarized in Fig. 10. First, the adsorption affinity of Ca2+ onto the surfaces of fillers remarkably affects the precipitation kinetics of the synthetic C–S–H [45]. The adsorption affinities of Ca2+ on calcite and strontianite are higher than those on any other inert fillers studied in this work (Fig. 10a, b), which is attributed to the strong acid–base interactions between CO32− (from calcite and strontianite) and Ca2+, resulting in a high content of adsorbed Ca2+, a low nucleation barrier and strong bond strength of the synthetic C–S–H. Although whewellite and whitlockite are also ionic compounds and the adsorption of Ca2+ on these fillers is also governed by acid–base interactions, the smaller lattice Ca2+ densities in these fillers lead to the low adsorption affinities of Ca2+ (Fig. 10c, d) and a relatively high nucleation barrier of synthetic C–S–H. In the cases of the quartz suspension, the adsorption of Ca2+ is governed by a weak electrostatic force, hence resulting in the lowest adsorption of Ca2+ (Fig. 10e) and the highest nucleation barrier for the synthetic C–S–H.

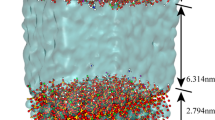

Second, the type of chemical bond in the fillers only affects the SEM morphology but not the TEM structure of synthetic C–S–H. The growth orientations of synthetic C–S–H vary on different types of fillers: preferred vertical growth on the surface of ionic compounds and parallel growth on the surface of covalent compounds (quartz in Fig. 10e). The structure of C–S–H is supposed to be a Ca–O sheet with silicate chains on both sides [46,47,48,49]. As shown in the right part of Fig. 10e (adapted from [48]), the two sets of paralleled dreierkette chains are not linked, and the extra interlayer space is occupied by an inner Ca2+ layer. The adsorption Ca2+ layer on the surface of quartz likely acts as the inner Ca2+ layer, and the silicate tetrahedral structure inside the quartz can be regarded as the silicate chains in the adjacent C–S–H structure. Thus, the C–S–H structure tends to grow parallel to the quartz surface and is linked with quartz via a loosely adsorbed Ca2+ layer. This hypothesis is similar to the double-layer interaction model reported by many research papers [12, 50].

Third, the lattice cleavage as well as the adsorption strength of Ca2+ determines the arrangement of synthetic C–S–H on fillers. The dislocations and defects are typically presented along the direction of the lattice cleavage of the crystal. The free energy of the crystal may be influenced by lattice defects [29], which makes the nucleation of synthetic C–S–H easier with a lower nucleation barrier in these positions. Additionally, both calcite and strontianite are crystals with obvious lattice cleavage (crystal structures shown in Fig. 10a, b). The solubility is also affected by the defects of the crystal [29], and the relatively high solubility at the defect results in more CO32− exposed on the surface, leading to the high affinity of Ca2+ for adsorption on these areas. The lattice cleavages of whewellite and whitlockite are not as regular as those of calcite and strontianite; thus, the guiding function of the lattice cleavage on the arrangement of C–S–H is weak. In summary, the regular distribution of defects along the lattice cleavage contributes to the ordered pattern of C–S–H on ionic compounds.

In addition, the active surface sites \(\left( {{\text{CO}}_{3}^{2 - } } \right)\) exposed due to the slight dissolution of calcite and strontianite could substitute the \({\text{OH}}^{ - }\) in the C–S–H [13, 14] (marked in black circle in Fig. 10), which further increases the compatibility of C–S–H and fillers and induces the regular arrangement of C–S–H. It should be noted that there is no direct evidence that C2O42− and PO43− have similar ion-exchange effects as CO32−.

Conclusions

This paper discusses the different “filler effects” of several inert fillers with various physicochemical properties on the nucleation and growth of synthetic C–S–H. The affinities of Ca2+ for adsorption on different fillers were evaluated via ion concentration tests and zeta-potential tests. The structure and morphology of synthetic C–S–H in different systems were observed by TEM and SEM. The precipitation kinetics of C–S–H on the surface of different fillers were also characterized by monitoring the electrical conductivities and ion concentrations of the suspensions. Based on the experimental results in this study, the following conclusions can be drawn:

-

(1)

A strong relationship between the affinity of Ca2+ for adsorption on fillers and the surface chemical properties is found due to the different driving forces of the adsorption process. A weak electrostatic force leads to the small affinity of Ca2+ for adsorption on inert covalent compounds (quartz), and a strong acid–base interaction results in a high affinity of Ca2+ for adsorption on inert ionic compounds. The abilities of ionic compounds to adsorb Ca2+ are related to both the strength of the acid–base interaction and the lattice Ca2+ density on the surface of fillers. The high affinity of Ca2+ for adsorption corresponds to a low nucleation barrier for synthetic C–S–H.

-

(2)

The synthetic C–S–H precipitated on ionic compounds prefers to form along the normal direction, while that on quartz prefers to form along the tangential direction. The variation of the growth orientation of synthetic C–S–H on the quartz surface can be explained by the fact that the adsorbed Ca2+ layer acts as a loose Ca–O sheet between the silicate tetrahedral chains in synthetic C–S–H and quartz.

-

(3)

An extremely ordered honeycomb-like pattern of synthetic C–S–H is found on the surface of calcite and strontianite, while C–S–H on whewellite and whitlockite present less regular leaf-like or honeycomb-like patterns. The order of the synthetic C–S–H pattern is related to the lattice cleavage of the filler.

References

Kumar A, Oey T, Kim S et al (2013) Simple methods to estimate the influence of limestone fillers on reaction and property evolution in cementitious materials. Cem Concr Compos 42:20–29. https://doi.org/10.1016/j.cemconcomp.2013.05.002

Poppe AM, De Schutter G (2005) Cement hydration in the presence of high filler contents. Cem Concr Res 35:2290–2299. https://doi.org/10.1016/j.cemconres.2005.03.008

Lawrence P, Cyr M, Ringot E (2005) Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength. Cem Concr Res 35:1092–1105. https://doi.org/10.1016/j.cemconres.2004.07.004

Lothenbach B, Le Saout G, Gallucci E, Scrivener K (2008) Influence of limestone on the hydration of Portland cements. Cem Concr Res 38:848–860. https://doi.org/10.1016/j.cemconres.2008.01.002

Bentz DP (2006) Modeling the influence of limestone filler on cement hydration using CEMHYD3D. Cem Concr Compos 28:124–129. https://doi.org/10.1016/j.cemconcomp.2005.10.006

Mohamed AR, Elsalamawy M, Ragab M (2015) Modeling the influence of limestone addition on cement hydration. Alexandria Eng J 54:1–5. https://doi.org/10.1016/j.aej.2014.11.004

Berodier E, Scrivener K (2014) Understanding the filler effect on the nucleation and growth of C-S-H. J Am Ceram Soc 97:3764–3773. https://doi.org/10.1111/jace.13177

Ouyang X, Koleva DA, Ye G, van Breugel K (2017) Insights into the mechanisms of nucleation and growth of C-S–H on fillers. Mater Struct Constr. https://doi.org/10.1617/s11527-017-1082-y

French CW, Mokhtarzadeh A (1993) High strength concrete: effects of materials, curing and test procedures on short-term compressive strength. PCI J 38:76–87. https://doi.org/10.15554/pcij.05011993.76.87

Bentz DP, Ardani A, Barrett T et al (2015) Multi-scale investigation of the performance of limestone in concrete. Constr Build Mater 75:1–10. https://doi.org/10.1016/j.conbuildmat.2014.10.042

Mehta P, Monteiro P (2006) Concrete: microstructure, properties, and materials. McGraw-Hill Education, Cambridge

Ouyang X, Koleva DA, Ye G, van Breugel K (2017) Understanding the adhesion mechanisms between C-S-H and fillers. Cem Concr Res 100:275–283. https://doi.org/10.1016/j.cemconres.2017.07.006

Oey T, Kumar A, Bullard JW et al (2013) The filler effect: the influence of filler content and surface area on cementitious reaction rates. J Am Ceram Soc 96:1978–1990. https://doi.org/10.1111/jace.12264

Kumar A, Oey T, Falzone G et al (2017) The filler effect: the influence of filler content and type on the hydration rate of tricalcium silicate. J Am Ceram Soc 100:3316–3328. https://doi.org/10.1111/jace.14859

Sato T, Diallo F (2010) Seeding effect of nano-CaCO3 on the hydration of tricalcium silicate. Transp Res Rec. https://doi.org/10.3141/2141-11

Plank J, Schönlein M, Kanchanason V (2018) Study on the early crystallization of calcium silicate hydrate (C-S-H) in the presence of polycarboxylate superplasticizers. J Organomet Chem 869:227–232. https://doi.org/10.1016/j.jorganchem.2018.02.005

Wang F, Kong X, Wang D, Wang Q (2019) The effects of nano-C-S-H with different polymer stabilizers on early cement hydration. J Am Ceram Soc. https://doi.org/10.1111/jace.16425

Kanchanason V, Plank J (2017) Role of pH on the structure, composition and morphology of C-S-H–PCE nanocomposites and their effect on early strength development of Portland cement. Cem Concr Res 102:90–98. https://doi.org/10.1016/j.cemconres.2017.09.002

Schönlein M, Plank J (2018) A TEM study on the very early crystallization of C-S-H in the presence of polycarboxylate superplasticizers: transformation from initial C-S-H globules to nanofoils. Cem Concr Res 106:33–39. https://doi.org/10.1016/j.cemconres.2018.01.017

Nicoleau L (2010) New calcium silicate hydrate network. Transp Res Rec. https://doi.org/10.3141/2142-07

Nicoleau L, Gädt T, Chitu L et al (2013) Oriented aggregation of calcium silicate hydrate platelets by the use of comb-like copolymers. Soft Matter 9:4864–4874. https://doi.org/10.1039/c3sm00022b

Li Y, Li H, Wang Z, Jin CC (2020) Effect and mechanism analysis of functionalized multi-walled carbon nanotubes (MWCNTs) on C-S-H gel. Cem Concr Res 128:105955. https://doi.org/10.1016/j.cemconres.2019.105955

Picker A, Nicoleau L, Burghard Z et al (2017) Mesocrystalline calcium silicate hydrate: a bioinspired route toward elastic concrete materials. Sci Adv. https://doi.org/10.1126/sciadv.1701216

Esteves LP (2011) Superabsorbent polymers: on their interaction with water and pore fluid. Cem Concr Compos 33:717–724. https://doi.org/10.1016/j.cemconcomp.2011.04.006

Sun J, Shi H, Qian B et al (2017) Effects of synthetic C-S-H/PCE nanocomposites on early cement hydration. Constr Build Mater 140:282–292. https://doi.org/10.1016/j.conbuildmat.2017.02.075

Parkhurst DL, Appelo CAJ (2005) Description of input and examples for PHREEQC inverse geochemical calculations batch-reaction, one-dimensional transport, and version 3—a computer program for speciation. Cso 6-43A. https://doi.org/10.1016/0029-6554(94)90020-5

Burgos-Cara A, Ruiz-Agudo E, Rodriguez-Navarro C (2017) Effectiveness of oxalic acid treatments for the protection of marble surfaces. Mater Des 115:82–92. https://doi.org/10.1016/j.matdes.2016.11.037

Popova A, Geoffroy G, Renou-Gonnord M-F et al (2004) Interactions between polymeric dispersants and calcium silicate hydrates. J Am Ceram Soc 83:2556–2560. https://doi.org/10.1111/j.1151-2916.2000.tb01590.x

Sposito G (1993) Chemistry of the solid-water interface. Wiley, New York

Huang YC, Fowkes FM, Lloyd TB, Sanders ND (1991) Adsorption of calcium ions from calcium chloride solutions onto calcium carbonate particles. Langmuir 7:1742–1748. https://doi.org/10.1021/la00056a028

Pourchet S, Pochard I, Brunel F, Perrey D (2013) Chemistry of the calcite/water interface: influence of sulfate ions and consequences in terms of cohesion forces. Cem Concr Res 52:22–30. https://doi.org/10.1016/j.cemconres.2013.04.002

Pokrovsky OS, Mielczarski JA, Barres O, Schott J (2000) Surface speciation models of calcite and dolomite/aqueous solution interfaces and their spectroscopic evaluation. Langmuir 16:2677–2688. https://doi.org/10.1021/la980905e

Papirer E (2000) Adsorption on silicon surfaces. CRC Press, Boca Raton

Jang HM, Fuerstenau DW (1987) The nature of simple monovalent cation-silica interaction as reflected in the spin-lattice relaxation time of 23 Na. Langmuir 3:1114–1118. https://doi.org/10.1021/la00078a041

Jönsson B, Nonat A, Labbez C et al (2005) Controlling the cohesion of cement paste. Langmuir 21:9211–9221. https://doi.org/10.1021/la051048z

Foxall T, Peterson GC, Rendall HM, Smith AL (1979) Charge determination at calcium salt/aqueous solution interface. J Chem Soc Faraday Trans 1 Phys Chem Condens Phases 75:1034–1039. https://doi.org/10.1039/F19797501034

Rode S, Oyabu N, Kobayashi K et al (2009) True atomic-resolution imaging of (1014) calcite in aqueous solution by frequency modulation atomic force microscopy. Langmuir 25:2850–2853. https://doi.org/10.1021/la803448v

Rodriguez ET, Richardson IG, Black L et al (2015) Composition, silicate anion structure and morphology of calcium silicate hydrates (C-S-H) synthesised by silica-lime reaction and by controlled hydration of tricalcium silicate (C3S). Adv Appl Ceram 114:362–371. https://doi.org/10.1179/1743676115Y.0000000038

Grudemo A (1954) Discussion following the paper by J.D. Bernal on ‘The structure of cement hydration compounds.’ In: Proceedings of the 3rd international symposium Chem. Cem., pp 247–253

Kalousek GL, Prebus AF (1958) Crystal chemistry of hydrous calcium silicates: III, morphology and other properties of tobermorite and related phases. J Am Ceram Soc 41:124–132

Pourchet S, Regnaud L, Perez JP, Nonat A (2009) Early C3A hydration in the presence of different kinds of calcium sulfate. Cem Concr Res 39:989–996. https://doi.org/10.1016/J.CEMCONRES.2009.07.019

Nielsen AE, Söhnel O (1971) Interfacial tensions electrolyte crystal-aqueous solution, from nucleation data. J Cryst Growth 11:233–242. https://doi.org/10.1016/0022-0248(71)90090-X

Myers RJ, Bernal SA, Provis JL (2014) A thermodynamic model for C-(N-)A-S-H gel: CNASH-ss. Derivation and validation. Cem Concr Res 66:27–47. https://doi.org/10.1016/j.cemconres.2014.07.005

Palberg T (1997) Colloidal crystallization dynamics. Curr Opin Colloid Interface Sci 2:607–614. https://doi.org/10.1016/S1359-0294(97)80053-2

Scrivener K, Ouzia A, Juilland P, Kunhi Mohamed A (2019) Advances in understanding cement hydration mechanisms. Cem Concr Res 124:105823. https://doi.org/10.1016/j.cemconres.2019.105823

Dharmawardhana CC, Misra A, Aryal S et al (2013) Role of interatomic bonding in the mechanical anisotropy and interlayer cohesion of CSH crystals. Cem Concr Res 52:123–130. https://doi.org/10.1016/J.CEMCONRES.2013.05.009

Richardson IG (2008) The calcium silicate hydrates. Cem Concr Res 38:137–158. https://doi.org/10.1016/J.CEMCONRES.2007.11.005

Bonaccorsi E, Merlino S, Kampf AR (2005) The crystal structure of tobermorite 14 Å (plombierite), a C-S-H phase. J Am Ceram Soc 88:505–512. https://doi.org/10.1111/j.1551-2916.2005.00116.x

Taylor HFW (1993) Nanostructure of C-S-H: current status. Adv Cem Based Mater 1:38–46. https://doi.org/10.1016/1065-7355(93)90006-A

Pellenq RJM, Lequeux N, van Damme H (2008) Engineering the bonding scheme in C-S-H: the iono-covalent framework. Cem Concr Res 38:159–174. https://doi.org/10.1016/j.cemconres.2007.09.026

Acknowledgements

The authors would like to acknowledge the support of National Natural Science Foundation of China (Grant No. 51822807) and Tsinghua University’s Scientific Research Initiative Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Wang, Q., Zhang, M. et al. A new understanding of the effect of filler minerals on the precipitation of synthetic C–S–H. J Mater Sci 55, 16455–16469 (2020). https://doi.org/10.1007/s10853-020-05185-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05185-2