Abstract

In order to develop the application of energy storage ceramics, the dielectric properties and energy storage density of Ba0.1Sr0.9Zr0.18Ti0.82O3 ceramics (BSZT-118) prepared by the modified sol–gel process were researched under different temperatures under electric field. The results show that the dielectric constant of BSZT-118 is consistent with Johnson’s formula based on Devonshire phenomenological theory, and the anharmonic constant (α) increases as the temperature rises. The energy storage density of BSZT-118 is influenced by the electric field and temperature. With the increase in temperature, the storage density of BSZT decreases and the fluctuation of storage density increases under electric field. The conduction mechanism of BSZT-118 is mainly space charge-limited conduction (SCLC) below 60 °C, and it is mainly Ohmic conduction above 60 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The high-energy density pulse capacitors are applied for electromagnetic weapon, medical defibrillators and other applications because of the increasingly deteriorated energy crisis [1,2,3]. Simultaneously, there is a great challenge for pulse capacitors to have larger energy density, less loss and better stability [4,5,6]. The barium titanate (BT) researched by many researchers is commonly used as the major component in ceramic capacitor dielectrics [7,8,9]. Furthermore, doping Sr can improve the room temperature dielectric constant through lowering the Curie temperature, and doping Zr has higher chemical stability as well as lower dielectric loss [10, 11]. In addition, Ricketts et al. [12] pointed that the stored dielectric energy density would reach 4 J/cm3 for Ba1−xSrxZryTi1−yO3 ceramics with x > 0.7 and y~ 0.2 and Qing et al. [13] obtained the Ba0.95Sr0.05Zr0.2Ti0.8O3 ceramic with storage density of 0.42 J/cm3 by doping. The Ba0.1Sr0.9Zr0.18Ti0.82O3 ceramics (BSZT-118) having high dielectric constant and low loss tangent have also been reported [14]. Based on the latest research, Mangaiyarkkarasi et al. [15] studied the precise electronic structure and bonding interactions of BSZT ceramics and Jian et al. [16] indicated that the BSZT ceramics change from a normal ferroelectric to a relaxor ferroelectric with increasing Zr4+ and Sr2+ ionic content.

However, the performance of the material is affected by the application environment. This work is to analyze the changes in dielectric properties and energy storage density of BSZT-118 under different external electric fields and temperatures, providing some basis for theoretical research on the use of energy storage capacitors, which is very important for the application of ceramic capacitors.

Experiment

BSZT-118 powders were prepared by the modified sol–gel process, i.e., polyacrylamide-gel method. Firstly, stoichiometric Ba(CH3COO)2, Sr(NO3)2 with Zr(NO3)4·5H2O were dissolved in the deionized water with continuous stirring to get transparent aqueous solution. Then, stoichiometric Ti(C4H9O)4 was added in a mixed solution of acetic acid and ethanol with acetylacetone as the stabilizer for getting the Ti source. Thirdly, the previous transparent aqueous solution mixed with Ti-containing solution with stirring 10 min in order to obtain a transparent sol. Next, N,N′-methylene-bis-acrylamide which was used as the cross-linking and acrylamide was dissolved into the sol with stirring for 1 h. Finally, azodiisobutyronitrile (AIBN) as the initiator was added into the as-prepared solution, which turned to hydrogel gradually when the solution was heated to 90 °C. After getting the dry gel, the xerogel was carbonized at 300 °C. Then, the xerogel after carbonization was calcined at 900 °C with urea as a sintering aid.

The as-prepared BSZT-118 powder was granulated using polyvinyl alcohol (PVA) as the binder and pressed into disks of 10 mm diameter with 1.0 mm thickness at 10 MPa using dry press forming. Next, the ceramic sheets were isostatic-pressed after excluding the binder. Then, the ceramic chips were sintered at 1300 °C. After that, the silver paste was sintered on both sides of the pellets at 700 °C for 10 min to form electrodes. Finally, the pellets were tested by different instruments.

Results and discussion

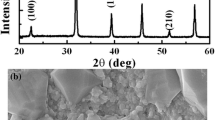

The typical XRD pattern of BSZT-118 shown in Fig. 1a was obtained by using the X-ray diffraction (XRD) (DX-1000, Dandong, China) in the range of diffraction angle 20°–90°, and it is cubic phase without impurity phase based on the diffraction pattern. The morphology of BSZT-118 was investigated using the HITACHI S4800 scanning electron microscope (SEM). As shown in Fig. 1b, BSZT-118 has high density and good micromorphology. In the meanwhile, the grain size of BSZT-118 is relatively uniform and the porosity is small.

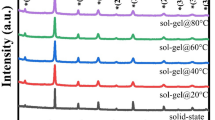

Further research on the dielectric constant of BSZT-118 at different temperatures under the maximum electric field 100 kV/cm is necessary. In Fig. 2a, it is obvious that BSZT-118 is paraelectric phase from 20 to 120 °C and this result is consistent with the XRD pattern diffraction. Besides, the slope of the polarization hysteresis loop shown in Fig. 2a decreases as the temperature rises, which means that the dielectric constant declines and interpreted in Fig. 3.

In Fig. 2b, the dielectric constant decreases with the temperature from room temperature (20 °C) to 120 °C and with the increase in external electric field. The dielectric constant of the nonlinear relationship is weakening under external electric field with temperature from 20 °C to 120 °C. This mean that the higher the temperature, the weaker the dielectric constant is affected by the electric field, which may be because of thermal motion. According to the formula:

where T is the rate of change and D0 and D100 are dielectric constant at 0 kV/cm and 100 kV/cm, respectively. Based on calculation, from 20 to 120 °C, the rate of change of dielectric constant is from 17.3 to 11.2% when the electric field increases to 100 kV/cm in Fig. 2b.

In Fig. 3, according to the peak characteristics at the Curie point, the Curie temperature is lower than − 160 °C, which is consistent with previous reports [17, 18], and the dielectric constant reduces with increasing temperature above − 160 °C. Furthermore, the slope of the polarization hysteresis loop is positively related to the dielectric constant because BSZT-118 is the paraelectric phase from 20 to 120 °C. The formula is as follows

where P, ε0, εr and E is the polarization intensity, vacuum dielectric constant, relative dielectric constant and applied electric field, respectively. Therefore, Fig. 3 explains why the slope of the polarization hysteresis loop decreases with the increase in temperature clearly. But the Curie temperature was not obtained because of limitation of the test conditions. Fig. 3 also shows that the curve becomes more smooth and stable from 20 to 120 °C that is consistent with the change rate of the permittivity in the above-mentioned results.

In addition, the dielectric constant of BSZT-118 is relative low because the test temperature (20–120 °C) is far from the Curie point and permittivity–temperature curve little affected by frequency has small peak about 0 °C, meanwhile, loss–temperature curve also has it, which might be caused by the phase change of water from the atmosphere (solid to liquid).

Researching the nonlinear dielectric response of BSZT-118, Johnson’s formula is very important to describe the relationship between the dielectric constant and electric field quantitatively [19,20,21]. The formula is as follows:

where ε(E) and ε(0) are the dielectric constant under external electric field and 0 kV/cm, respectively, and α is a positive constant associated with the anharmonic effect (here called anharmonic constant). This formula was derived by Johnson from the Devonshire phenomenological theory, as an approximation for the paraelectric phase when the Curie temperature is far from the test temperature.

To make it easier to observe the fit results, Johnson’s formula deformed as:

It is showed that ε(0)3/ε(E)3 with E2 is linear, and Fig. 4 shows good linear relationship between ε(0)3/ε(E)3 with E2; this means that results of linear fit accorded with Johnson’s formula, so BSZT-118 is suitable for Devonshire phenomenological theory and nonlinear dielectric behavior is mainly caused by the anharmonic interaction between Ti ion and Zr ion under high electric field [22, 23].

According to Fig. 4, there is anharmonic constant α obtained by above of linear fit at different test temperatures. The result shows that α increases as test temperature rises, which may be because anharmonic vibration enhanced with increasing temperature. Therefore, the permittivity–temperature (Fig. 3) and Devonshire phenomenological theory both explain the relationship between rate of change in dielectric constant and temperature under external electric field.

In light of Fig. 5, the energy storage density of BSZT-118 increases as the electric field from 30 to 100 kV/cm, but it decreases with the test temperature increasing. The tunability of energy storage density of BSZT-118 increases with increasing the electric field (see the change trend of the same color points in Fig. 5). Simultaneously, according to the formula [24, 25]:

where Pmax and Pr are the maximum polarization and remanent polarization, respectively. P is the polarization; E is the applied electric field. The energy storage density (W) increases with the increase in electric field (E), but the permittivity (ε) would decrease when temperature or electric field increases, so it is difficult to determine that the energy storage density increases or not due to improving electric field when the temperature is different. As shown in Fig. 5, the energy storage density at 20 °C and 90 kV/cm is larger than energy density at 120 °C and 100 kV/cm; this means that the permittivity because of impact of electric field and temperature is more influential than electric field on energy density in the situation. However, it also proves that α increases as test temperature rises and the application conditions are very important for the energy storage density.

In order to further illustrate the energy storage density under external electric field, it is important to focus on the impact of test temperature on the energy density at different electric fields. The energy density stability of the BSZT-118 against electric field at different temperatures is defined as:

where W20 and WT are the energy density of 20 °C and different test temperatures (70–120 °C) at different electric fields, respectively. In Fig. 6, the result shows that the value of R increases with temperature increasing, which means the energy density stability decreases as the temperature increases. Besides, this value is minimum when the electric field is 70 kV/cm from 70 to 120 °C that explains the dielectric properties of BSZT-118 are the most stable at 70 kV/cm from 70 to 120 °C.

Furthermore, the relationship between electric field and temperature on energy efficiency (η) has studied. Based on the following formula [26]:

We got Tables 1 and 2. As shown in Table 1, the energy efficiency of different temperatures is different under the electric field of 100 kv/cm, and the energy efficiency shows a downward trend with the increase in temperature, which is related to the increase in loss energy with the rising temperature. Furthermore, the discharge efficiency is little affected by temperature, below 100 °C. However, in light of Table 2, at 120 °C, the energy efficiency of BSZT is different under different electric fields and there is no obvious law. And the energy efficiency differs very little under different electric fields. Therefore, the energy efficiency shows a downward trend with the increase in temperature, but has little connection with the electric field.

The leakage current limiting the charge retention and influencing the ferroelectric hysteresis loop is an important characteristic of pulsed power capacitors [27]. There are many conduction mechanisms of dielectric material. For the ohmic conduction in a plane parallel platter of thickness (t), the current density (J) is defined as [28, 29]

where e is the electronic charge, n is the free charge carrier density, and \( \mu \) and V are the charge carrier mobility and the voltage applied to the electrodes of the sample, respectively. The J is directly proportional to the V, so the J–E curve is linear for the same sample. In the meanwhile, for the space charge-limited conduction (SCLC), the current density can be described based on [29]

where \( \theta \) is the ratio of the free charge carrier concentration and \( \varepsilon \) is the permittivity. Therefore, the J–E characteristic of SCLC is characterized by nonlinearity. In Fig. 7, the leakage current with electric field shows the different conduction mechanisms at different temperatures. Below 60 °C, the leakage current is nonlinear with the electric field, consistent with the J–V curve characteristics of the space charge-limited conduction (SCLC) [28], as shown in Fig. 7a. However, in Fig. 7b, the leakage current with electric field shows the Ohm’s law and increases when the temperature rises [30]. This shows that the leakage conduction mechanism of BSZT-118 below 60 °C is dominated by SCLC, and above 60 °C is the Ohm’s law.

Conclusions

The dielectric properties and energy storage density of BSZT-118 are affected by temperature and electric field. Nonlinear dielectric behavior of BSZT-118 under high electric field is mainly caused by anharmonic interaction between Ti ion and Zr ion, which is accorded with Johnson’s formula. Furthermore, it can give a quantitative explanation to its dielectric nonlinearity and the anharmonic constant \( \alpha \) increases with increasing temperature.

Temperature stability of energy storage density decreases when the electric field increases, and the dielectric properties of BSZT-118 are the most stable at 70 kV/cm from 70 to 120 °C. The energy efficiency shows a downward trend with the increase in temperature, but has little connection with the electric field. The BSZT-118 has different conduction mechanisms at different temperatures, and the leakage conduction mechanism of BSZT-118 below 60 °C is dominated by SCLC, but above 60 °C is the Ohm’s law.

References

Hu Q, Wang T, Jin L et al (2014) Dielectric and energy storage properties of barium strontium titanate based glass–ceramics prepared by sol–gel method. J Sol–Gel Sci Technol 71(3):522–529

Jo HR, Lynch CS (2016) A high energy density relaxor antiferroelectric pulsed capacitor dielectric. J Appl Phys 119(2):024104

Wisken HG, Podeyn F, Weise HGG (2001) High energy density capacitors for ETC gun applications. IEEE Trans Magn 37(1):332–335

MacDougall FW, Ennis JB, Cooper RA et al (2003) High energy density pulsed power capacitors. In: IEEE international pulsed power conference, vol 1, pp 513–517

Dai L, Lin F, Zhu Z et al (2005) Electrical characteristics of high energy density multilayer ceramic capacitor for pulse power application. IEEE Trans Magn 41(1):281–284

Gorzkowski EP, Pan MJ, Bender B et al (2007) Glass-ceramics of barium strontium titanate for high energy density capacitors. J Electroceram 18(3–4):269–276

Yang H, Liu P, Yan F et al (2019) A novel lead-free ceramic with layered structure for high energy storage applications. J Alloy Compd 773:244–249

Feng L, Mingxing Z, Jiwei Z et al (2018) Novel barium titanate based ferroelectric relaxor ceramics with superior charge-discharge performance. J Eur Ceram Soc 38:4646–4652

Feng L, Tao J, Jiwei Z et al (2018) Exploring novel bismuth-based material for energy storage applications. J Mater Chem C 6:7976–7981

Hilton AD, Ricketts BW (1996) Dielectric properties of ceramics. J Phys D Appl Phys 29(5):1321–1325

Kumar M, Garg A, Kumar R et al (2008) Structural, dielectric and ferroelectric study of Ba 0.9Sr0.1ZrxTi1−xO3 ceramics prepared by the sol–gel method. Phys B Condens Matter 403(s10–11):1819–1823

Ricketts BW, Triani G, Hilton AD (2000) Dielectric energy storage densities in Ba1−xSrxTi1−yZryO3 ceramics. J Mater Sci: Mater Electron 11(6):513–517

Xu Q, Zhan D, Huang DP et al (2013) Effect of MgO–CaO–Al2O3–SiO2 glass additive on dielectric properties of Ba0.95Sr0.05Zr0.2Ti0.8O3 ceramics. J Alloy Compd 558:77–83

Tang XG, Wang XX, Chew KH et al (2005) Relaxor behavior of (Ba, Sr)(Zr, Ti)O3 ferroelectric ceramics. Solid State Commun 136(2):89–93

Mangaiyarkkarasi J, Sasikumar S, Saravanan OV et al (2017) Electronic structure and bonding interactions in Ba1−xSrxZr0.1Ti0.9O3 ceramics. Front Mater Sci 11(2):182–189

Jian X, Lu B, Li D et al (2019) Enhanced electrocaloric effect in Sr2+-modified lead-free BaZrxTi1−xO3 ceramics. ACS Appl Mater Interfaces 11(22):20167–20173

Alexandru HV, Berbecaru C, Ioachim A et al (2006) BST solid solutions, temperature evolution of the ferroelectric transitions. Appl Surf Sci 253(1):354–357

Ho IC, Fu SL (1990) Effects of zirconium on the structural and dielectric properties of (Ba, Sr) TiO3 solid solution. J Mater Sci 25(11):4699–4703. https://doi.org/10.1007/BF01129927

Johnson KM (1962) Variation of dielectric constant with voltage in ferroelectrics and its application to parametric devices. J Appl Phys 33(9):2826–2831

Placeres-Jiménez R, Rino JP, Eiras JA (2015) Modeling ferroelectric permittivity dependence on electric field and estimation of the intrinsic and extrinsic contributions. J Phys D Appl Phys 48(3):035304

Ang C, Yu Z (1970) DC electric-field dependence of the dielectric constant in polar dielectrics: multipolarization mechanism mode l. Phys Rev B Condens Matter 69(17):1324–1332

Diamond H (1961) Variation of permittivity with electric field in perovskite-like ferroelectrics. J Appl Phys 32(5):909–915

Outzourhit A, Trefny JU, Kito T et al (1995) Tunability of the dielectric constant of Ba0.1Sr0.9TiO3 ceramics in the paraelectric state. J Mater Res 10(06):1411–1417

Li W, Zhou D, Pang L (2017) Enhanced energy storage density by inducing defect dipoles in lead free relaxor ferroelectric BaTiO3-based ceramics. Appl Phys Lett 110:132902

Yang H, Yan F, Lin Y, Wang T (2017) Novel strontium titanate-based lead-free ceramics for high energy storage applications. ACS Sustain Chem Eng 5:10215–10222

Wang T, Wang YH, Yang HB et al (2018) Structure, dielectric properties of low temperature-sintering BaTiO3-based glass-ceramics for energy storage. J Adv Dielect 08(06):1850041

Reshmi R, Asha AS, Krishnaprasad PS et al (2011) High tunability of pulsed laser deposited Ba0.7Sr0.3TiO3 thin films on perovskite oxide electrode. J Alloy Compd 509(23):6561–6566

Neusel C, Jelitto H, Schneider GA (2015) Electrical conduction mechanism in bulk ceramic insulators at high voltages until dielectric breakdown. J Appl Phys 117(15):154902

Kao KC (2004) Dielectric phenomena in solids. Dielectric phenomena in solids

Li R, Jiang S, Gao L et al (2012) Enhanced leakage current performance and conduction mechanisms of Bi1.5Zn1.0Nb1.5O7/Ba0.5Sr0.5TiO3 bilayered thin films. J Appl Phys 112(7):074113

Acknowledgements

This work is supported by the National Natural Science Foundation of China under Grant No. u1601208.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The manuscript is approved by all authors for publication and there is no conflict of interest exits in the submission of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Aziguli, H., Wu, Y. et al. Ba0.1Sr0.9Zr0.18Ti0.82O3 ceramics: dielectric properties and energy storage density under external electric field and temperature. J Mater Sci 55, 2764–2771 (2020). https://doi.org/10.1007/s10853-019-04248-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04248-3