Abstract

Carvacrol is a known antioxidant molecule and commonly used in food and cosmetics as a flavor and fragrance agent; however, carvacrol has major issues such as high volatility, low water solubility, and stability. In this study, carvacrol/cyclodextrin inclusion complex fibers (carvacrol/CD-IC fibers) were produced via electrospinning in order to enhance thermal stability, water solubility and shelf-life of carvacrol having antioxidant activity. The phase solubility and computational modeling studies showed that carvacrol can form inclusion complexes with two types of modified CDs, hydroxypropyl-β-cyclodextrin (HPβCD) and hydroxypropyl-γ-cyclodextrin (HPγCD). The carvacrol/cyclodextrin inclusion complex electrospun fibers (carvacrol/HPβCD-IC fibers and carvacrol/HPγCD-IC fibers) were obtained as free-standing fibrous webs. Although pure carvacrol is highly volatile, the electrospun carvacrol/CD-IC fibers were quite effective to preserve high amount of carvacrol due to the inclusion complexation. In addition, carvacrol/CD-IC fibers have shown higher temperature stability for carvacrol. Moreover, carvacrol/CD-IC fibers showed more effective antioxidant activity as compared to pure carvacrol. The carvacrol/CD-IC fibrous webs have shown fast-dissolving character in water due to the enhanced water solubility of carvacrol/CD-IC and their ultrafine fiber structure. In short, encapsulation of carvacrol in electrospun CD-IC fibrous webs has shown potentials for food and oral care applications due to free-standing and fast-dissolving character along with high water solubility, high temperature stability and enhanced antioxidant by carvacrol/cyclodextrin inclusion complexation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

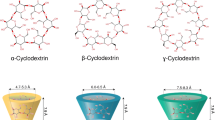

Encapsulation of active agents has attracted attention of many fields from food to cosmetics since such encapsulated active agents can be protected against light, moisture, heat and other conditions. Cyclodextrins (CDs), which are produced from enzymatic degradation of starch, are one of the most-common molecular encapsulating additive for encapsulation of active agents. CDs are truncated cone-shaped cyclic oligosaccharides with relatively hydrophobic cavity which make host–guest inclusion complexes preferably with nonpolar molecules [1, 2]. Besides being very attractive host material, non-toxic nature of CDs makes them quite useful for drugs, food and cosmetics [3], etc. The inclusion complex (IC) formation with CDs is quite useful for many applications since CD-IC formation improves solubility, stability and bioavailability of the guest molecules. There are three common native CDs consisting of six (α-CD), seven (β-CD) and eight (γ-CD) glucopyranose units in the cyclic structure linked by α-(1,4) linkage. In addition, highly water soluble modified CDs are also quite common in which some of the hydroxyl groups of the native CDs are substituted with hydroxypropyl (Fig. 1a), sulfobutyl ether or methyl groups [1,2,3].

Electrospinning (Fig. 1b) is a widely used versatile technique for the fabrication of ultrafine fibers from various materials including polymers, composites and sol–gels [4]. Electrospun fibers have many remarkable properties such as large surface area-to-volume ratio, nanoporous structure, lightweight and design flexibility; therefore, they can be used in various areas such as biotechnology, membranes/filters, food, active food packaging, agriculture textiles, composites, sensors and energy [5,6,7]. In general, for the electrospun fiber fabrication, polymers with high molecular weight and high concentration are used in order to have certain degree of chain entanglements and overlapping during electrospinning process [8,9,10]. In other words, without using any carrier polymeric matrix, electrospinning of fibers from small molecules and non-polymeric systems presents a challenge. Nonetheless, in our previous studies, uniform fibers from cyclodextrins have been successfully electrospun since cyclodextrin molecules can form aggregates via intermolecular hydrogen bonding in their highly concentrated solutions which results in formation of continuous jet without breaking up [11, 12]. Moreover, in our recent studies, it has been shown that the fabrication of functional fibers from cyclodextrin inclusion complexes (CD-IC) with food additives and antibacterial substances is also possible [13,14,15,16,17,18,19,20,21,22,23,24].

Essential oils are natural and volatile compounds obtained from plants [25]. Essential oils are generally used as flavoring and fragrance agents in food and cosmetics, and also they are widely used in many applications due to their various properties like being antimicrobial, antiseptic and insecticidal [26]. However, the use of essential oils in many application is restricted due to their drawbacks such as low aqueous solubility, high volatility, low stability and high reactivity. In recent years, there is a growing interest to form inclusion complexes of essential oils and volatile active agents with CDs to eliminate or reduce their drawbacks [27,28,29]. Carvacrol (Fig. 1a) is a phenolic monoterpene found in oregano and thyme plants essential oil [30]. It is known by its antimicrobial and antioxidant activities. Also, carvacrol is approved by US Food and Drug Administration for food use and it is accepted as flavorings in the list of the Council of Europe which make its addition to foodstuff safe [31]. However, the use of carvacrol is limited due to its high volatility, poor water solubility (1.00–1.25 mg mL−1) and low stability. Besides, due to low flavor threshold, it causes change in sensory properties of food [32].

In this study, we produced ultrafine fibers from the inclusion complexes of carvacrol with two types of modified CDs, hydroxypropyl-β-cyclodextrin (HPβCD) and hydroxypropyl-γ-cyclodextrin (HPγCD) without using any additional polymeric matrices via electrospinning. Phase solubility test was performed to investigate the solubility of carvacrol when complexed with CDs, and also the complexation stability constant (Ks) for carvacrol/CD-IC systems was also determined. Molecular modeling by ab initio computational method was performed to examine the optimal CD-IC molar ratio and the most favorable orientation of inclusion complexation between CD and carvacrol. Based on the molecular modeling data, the carvacrol/CD-ICs were prepared with molar ratio of 1:1 (carvacrol/CD). The morphological, structural and thermal characterizations of carvacrol/CD-IC electrospun fibers were performed by SEM, FTIR, XRD, 1H-NMR and TGA. Furthermore, antioxidant activity of carvacrol/CD-IC fibers was analyzed by 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging assay. Besides, the fast-dissolving character of carvacrol/CD-IC fibrous webs was analyzed visually by exposing them to water.

Materials and methods

Materials

Carvacrol (98%) and 2,2-diphenyl-1-picrylhydrazyl (DPPH) were purchased from Sigma-Aldrich. The hydroxypropyl-β-cyclodextrin (HPβCD) (degree of substitution ~ 0.6, Cavasol®W7 HP Pharma) and hydroxypropyl-γ-cyclodextrin (HPγCD) (degree of substitution ~ 0.6, Cavasol®W8 HP) were kindly donated by Wacker Chemie AG (Germany). Deuterated dimethylsulfoxide (DMSO-d6, deuteration degree min 99.8% for NMR spectroscopy) was obtained from Merck. The deionized water used was from a Millipore Milli-Q ultrapure water system. The materials were used as-supplied.

Electrospinning

For the preparation of carvacrol/CD-IC solutions, firstly, HPβCD (200%, w/v) and HPγCD (200%, w/v) were dissolved in water; then, carvacrol was added to these systems to get 1:1 molar ratio between carvacrol and CDs. These dispersions were stirred overnight at room temperature. At the end, the solutions of carvacrol/HPβCD-IC and carvacrol/HPγCD-IC were obtained. In addition, HPβCD and HPγCD were dissolved in water at concentration of 200% (w/v) to produce pure CD fibers (HPβCD fibers and HPγCD fibers) without carvacrol for comparative measurements [11].

Each solution of pure CDs (HPβCD and HPγCD) and carvacrol/CD-ICs (carvacrol/HPβCD-IC and carvacrol/HPγCD-IC) was loaded to the 1-mL syringe with a metallic needle inner diameter of 0.4, separately. Syringe pump (KD Scientific, KDS 101) was used to pump solutions with a constant rate of 0.5–1 mL h−1. Collector was placed at 10–15 cm distance from tip of needle, and high voltage at 10–15 kV was applied between tip of needle and the collector by the high voltage–power supply (Spellman, SL Series). Electrospun fibers were collected on the metal collector covered by piece of aluminum foil. Electrospin apparatus was enclosed by plexiglass box at 25 °C and 40% relative humidity.

Measurements and characterization

Phase solubility diagram was obtained according to the method reported by Higuchi and Connors [33]. In this experiment, an excess amount of carvacrol was added to aqueous solutions of HPβCD and HPγCD in capped vials which were shaken at room temperature in the dark for 48 h and then the solutions were filtered through a 0.45-µm membrane filter. Then, concentration of carvacrol was spectrophotometrically (Varian, Cary 100) determined from filtered solutions. The experiment was carried out in triplicate, and average of three measurements was taken. The apparent stability constant (Ks) of carvacrol/CD-ICs was calculated from the phase solubility diagram according to the following equation:

where S0 is the intrinsic solubility of carvacrol.

To reveal the mechanism of inclusion complex, ab initio calculations based on density functional theory were done according to our previous studies [21, 23].

The rheological behavior of the pure CDs and carvacrol/CD-IC solutions was measured by a rheometer (Anton Paar Physica MCR 301) equipped with a cone/plate accessory (spindle type CP 20-4). The constant shear rate was adjusted as 100 s−1. The conductivity of the solutions was measured by a Multiparameter InoLab® Multi 720-WTW at room temperature.

Scanning electron microscope (SEM) (FEI Quanta 200 FEG) was used to perform the morphological analyses of the electrospun fibers. Each sample was sputtered with 5 nm Au/Pd prior to SEM imaging by PECS-682 to minimize charging problem. The diameter of 100 single fibers was measured to calculate average fiber diameter (AFD).

Fourier transform infrared spectrometer (FTIR) (Bruker-VERTEX 70) was used to obtain the infrared spectra for pure carvacrol, pure CD fibers, and carvacrol/CD-IC fibers. Pellets were prepared by pressing the blend of potassium bromide (KBr) and samples, respectively. The 64 scans were recorded between 4000 and 400 cm−1 at resolution of 4 cm−1. The molar ratio of carvacrol to CD was determined by using proton nuclear magnetic resonance (1H NMR, Bruker D PX-400) system. The electrospun fibrous web was dissolved in d6-DMSO at the 30 g L−1 concentration. The spectra were recorded at 400 MHz and at 16 total scan. Thermogravimetric analyses (TGA, TA Q500, USA) were performed for carvacrol, pure CD fibers, and carvacrol/CD-IC fibers. The TGA experiments were conducted under nitrogen atmosphere by heating the samples from 25 to 600 °C at the heating rate of 20 ºC min−1.

2,2-Diphenyl-1-picrylhydrazyl (DPPH) radical scavenging method was used to examine antioxidant activity of samples. For this, DPPH· solution in methanol (7.5 × 10−5 M) was prepared. The concentration of CD-IC fibers in water was arranged to have carvacrol ranging from 8 to 0.0625 mg mL−1. On the other hand, pure carvacrol system including the highest amount of carvacrol which is 8 mg mL−1 concentration was prepared and undissolved part of carvacrol was filtered. Then, 200 µL of aqueous solutions of water-based carvacrol/CD-IC fibers at different concentrations and pure carvacrol were mixed with 2.3 mL of DPPH· solution, and they were stirred for 1 h. DPPH· solution has maximum absorption at 517 nm, and the absorption of DPPH· solution disappears along with its reduction by antioxidant compound [34]. UV–Vis spectroscopy (Varian, Carry 100) was used to examine the reduction at the absorbance intensity (517 nm) for aqueous solutions of carvacrol/CD-IC fibers at different concentrations. The experiment was carried out in triplicate, and the DPPH radical scavenging efficiency was expressed as the inhibition percentage and was calculated by the following formula:

Besides, carvacrol concentration providing 50% inhibition (IC50) was calculated from the graph. To investigate the stability of fibers with time in terms of antioxidant activity, the 3-year-old carvacrol/CD-IC fibers (stored at 4 °C in the refrigerator) were tested as well. These 3-year-old carvacrol/CD-IC fiber samples were weighed such that their weights were the same with the fresh fibers providing IC50 value. The antioxidant activity test was also performed for the 3 years old carvacrol/CD-IC fibers, and the inhibition percentage was calculated.

The fast-dissolving character of carvacrol/CD-IC fibers in water was visually investigated. Carvacrol/HPβCD-IC fibrous web and carvacrol/HPγCD-IC fibrous web with the same weight were placed into petri dishes; then, 5 mL of water was added to these petri dishes.

Results and discussion

Phase solubility studies

The phase solubility profiles of carvacrol/CD-ICs are presented in Fig. 2. From these profiles, it was observed that there was a linear increase in the solubility of carvacrol as CD concentration increases in a range of 0–16 mM. However, when the concentration of CD exceeded 16 mM, the negative deviation from linear profile was observed; in other words, the CD was proportionally less effective for solubilizing of carvacrol at higher concentrations. This type of profile is called as AN-type [35]. The negative deviation from linearity has several explanations including CD self-association at high concentrations [36]. The stability constant (Ks) values for carvacrol/HPβCD-IC and carvacrol/HPγCD-IC were calculated from the linear part of the diagrams according to Eq. 1. Ks values were calculated as 3321 and 288 M−1 (R2 > 0.99) for carvacrol/HPβCD-IC and carvacrol/HPγCD-IC, respectively, which indicated that carvacrol forms more stable complex with HPβCD than HPγCD.

Computational modeling for carvacrol/CD-ICs

In this section, we studied the interaction of carvacrol molecule with HPβCD and HPγCD by performing ab initio modeling techniques. Firstly, all the structures were relaxed without any constraint both in vacuum and in water to obtain the optimized geometries. Next, the guest molecule was approached to CD through wider rim with 1 Å steps and the total energy was calculated at each step. For carvacrol, there were two possible vertical orientations which were labeled as tail (–CH3 and –OH end) and head (–CH3 and –CH3 end) as shown in Fig. 3. Accordingly, the interaction of carvacrol with both CDs was revealed by taking into account the position (or site) and orientation. Our calculations indicated that carvacrol molecule forms inclusion complexes with HPβCD and HPγCD without energy barrier, and the most favorable geometries are illustrated in Fig. 3. In both cases, carvacrol was completely settled in CD and head and tail orientation for HPβCD and HPγCD was preferred, respectively. As width of HPγCD is larger, carvacrol shifted toward the sides to enhance the interaction while it remained at the center of HPβCD. Due to size mismatch, carvacrol cannot laterally fit into HPβCD but the cavity of HPγCD is large enough to accommodate carvacrol in lateral orientation, as well. When the results in vacuum and water are compared, a significant change in geometries cannot be noticed but the strength of interaction (or complexation energies) alters. The complexation energy (Ecomp) for 1:1 stoichiometry can be defined as:

where ECD, Ecarvacrol, and EIC are the total energy of CD (HPβCD or HPγCD), the guest carvacrol molecule, and their inclusion complexes, respectively. Total energies were calculated in both vacuum and solvent. Ecomp values are listed in Table 1.

The obtained results indicated that carvacrol molecule can form stable inclusion complexes with HPβCD and HPγCD. The highest Ecomp was obtained for carvacrol/HPβCD-IC with head orientation where the carvacrol was slightly tilted, –OH group was inside the cavity, and –CH3 groups were between hydroxypropyl arms. When compared, the energy differences between the head and tail orientations were small which suggests the possibility of complex formation with both configurations. In addition, even it is less favorable, carvacrol can laterally fit into HPγCD with significant complexation energy. To reveal the effect of solvent environment, the calculations were repeated in water for the most favorable configurations. Ecomp decreases for both CDs when inclusion complex is formed in water which can be attributed to interaction of phenolic functional group with the water.

As mentioned before, carvacrol has poor solubility in water but its solubility can be enhanced by complexation with CDs [32]. The change in solvation energy (Esolv) can be used to reveal this claim. Esolv is defined as:

Ewater and Evacuum are the total energy of carvacrol, CD, or inclusion complex in water and vacuum, respectively (Table 1). Esolv of carvacrol molecule was calculated as − 4.31 kcal mol−1 confirming the low solubility in water. On the other hand, Esolv was − 71.17 and − 83.34 kcal mol−1 for carvacrol/HPβCD-IC and carvacrol/HPγCD-IC, suggesting a substantial increase in solubility upon complexation. This finding is also correlated with the phase solubility analyses where the water solubility of carvacrol has increased by inclusion complexation with the CDs.

Electrospinning of carvacrol/CD-IC fibers

The solutions of carvacrol/CD-IC and pure CD were electrospun at optimized parameters to produce bead-free fibers. The photographs and SEM images of these bead-free fibrous webs of carvacrol/CD-IC having self-standing and flexible characteristics are given in Fig. 4. The solution properties of carvacrol/CD-IC that directly have an impact on the morphology of the electrospun fibers and the fiber diameters are summarized in Table 2. The SEM images of the pure CD fibers and solution properties for pure CD are given in Fig. S1 and Table S1. The average fiber diameter (AFD) value was calculated as 1600 ± 640 nm for carvacrol/HPβCD-IC fibers and as 2735 ± 760 nm for carvacrol/HPγCD-IC fibers. On the other hand, AFD was measured as 1445 ± 430 and 2390 ± 1075 nm for pure HPβCD and HPγCD fibers, respectively. This difference in their AFD is mostly related to the viscosity of their solutions since higher viscosity results in less stretching of the electrified jet that forms thicker fibers during electrospinning process [8, 37].

Structural characterization of carvacrol/CD-IC fibers

FTIR measurements were taken to characterize the carvacrol/CD-IC fibers. Besides carvacrol/CD-IC fibers, pure carvacrol and pure CD fibers were also characterized to make a comparison (Fig. 5). The characteristic absorption bands of pure CD fibers were observed at around 3400 cm−1 (O–H stretching vibrations), 2932 cm−1 (C–H stretching vibrations), 1649 cm−1 (H–O-H bending vibrations) [38], 1155 cm−1 (asymmetric stretching vibration of C–O–C glycosidic bridge) 1032 and 1083 cm−1 (C–C, C–O stretching vibrations) [39]. The spectrum for carvacrol showed also wide absorption band at around 3400 cm−1 (O–H stretching vibrations), and band between 2800 and 3000 cm−1 (stretching vibrations of C–H bonds), peaks between 1400 and 1650 cm−1 (aromatic C=C stretching), peak at around 1250 cm−1 (aromatic O–H stretching vibrations), peaks between 800 and 900 cm−1 (aromatic C–H bending). Absorption peaks for pure carvacrol and CD were overlapped which made the identification of each compound complicated for carvacrol/CD-IC fibers. However, there was an increase in the intensity of peaks for carvacrol/CD-IC fibers at two locations: 1250 and 1585 cm−1 (Fig. 5). This result suggested the presence of carvacrol in both carvacrol/CD-IC fibers.

The molar ratio of carvacrol in carvacrol/CD-IC fibers

The molar ratio of carvacrol to HPβCD and HPγCD in carvacrol/CD-IC fibers was analyzed mainly by 1H-NMR study (Fig. 6). In order to calculate the molar ratio, integration of characteristic peaks of carvacrol at around 1.14 ppm and CD peak at around 1.03 ppm was taken for both carvacrol/CD-IC fibers. The molar ratio of carvacrol/CD was calculated as 0.73:1.00 for carvacrol/HPβCD-IC fibers and 0.98:1.00 for carvacrol/HPγCD-IC fibers. From these results, it can be concluded that carvacrol was mostly preserved for both fibers during electrospinning process with encapsulation efficiencies of 73% for carvacrol/HPβCD-IC fibers and 98% for carvacrol/HPγCD-IC fibers. Besides, the molar ratio of 3-year-old fibers stored at 4 °C was also calculated from 1H-NMR (Fig. S2). The molar ratio of old fibers was calculated as 0.70:1.00 for carvacrol/HPβCD-IC fibers and 0.94:1.00 for carvacrol/HPγCD-IC fibers. This finding confirmed that carvacrol was effectively preserved in both carvacrol/HPβCD-IC fibers and carvacrol/HPγCD-IC fibers during such long storage period. These ratios were also confirmed by molar ratio found by thermal gravimetric analysis (TGA) as discussed in the following section which were calculated as 0.88:1.00 and 0.94:1.00 for carvacrol/HPβCD-IC fibers and carvacrol/HPγCD-IC fibers, respectively.

Thermal characterization of carvacrol/CD-IC fibers

The TGA was performed for fibers and pure carvacrol to investigate the thermal stability and volatility of carvacrol and the obtained TGA thermograms are given in Fig. 7. Pure CD fibers showed two step weight losses: the water loss below 100 °C and the main thermal degradation of CDs above 300 °C. On the other hand, both carvacrol/CD-IC fibers exhibited three steps weight losses; initial weight loss below 100 °C is due to water loses, the third weight loss which is the major one belongs to the CD degradation. For carvacrol/CD-IC fibers, the second weight loss belonging to evaporation of carvacrol starts at around 90 °C and continues till 275 °C, while for pure carvacrol thermogram, it starts at around 50 °C and ends at around 185 °C. In other words, for both CD types, the second degradation that belongs to carvacrol evaporation was observed at higher degrees in temperature when compared to pure carvacrol. As a result, the higher thermal evaporation temperature was achieved for both carvacrol/CD-IC fibers confirming that the thermal stability of carvacrol was increased thanks to the interaction with CD by inclusion complex formation.

Antioxidant property of carvacrol/CD-IC fibers

The antioxidant property of carvacrol was tested by DPPH radical scavenging assay. This assay is based on reduction of DPPH molecule by a hydrogen donor. As DPPH molecule is reduced, its strongest absorption band observed in UV–Vis spectrum decreases, and the purple color of the solutions turns to yellow [34]. In this study, as mentioned in experimental section, antioxidant test was performed as concentration dependent in which concentration of CD-IC fibers was adjusted to have carvacrol ranging from 8 to 0.0625 mg in 1 mL of aqueous solution of fibers. On the other hand, pure carvacrol was prepared with 8 mg mL−1 concentration and undissolved part of carvacrol was filtered. Figure 8 shows change in the percentage of DPPH radical scavenging by carvacrol concentration and their corresponding photographs. As expected, DPPH reduction increased with the increase in amount of carvacrol in CD-IC fibers and DPPH was completely reduced by the 8 mg mL−1 carvacrol having fibers after 1 h of incubation time. On the other hand, for pure carvacrol system prepared by 8 mg mL−1 carvacrol in water, the antioxidant activity was observed as 63.7% under the same condition (Fig. S3). This result confirmed that the antioxidant activity of carvacrol was enhanced by the formation of inclusion complex with CD. The reason for enhanced antioxidant activity of carvacrol is an increase in water solubility by inclusion complexation with CD which was confirmed by phase solubility test and molecular modeling studies; in other words, less amount of carvacrol is required for DPPH reduction in the case of CD-IC systems. Besides, IC50 value for carvacrol/HPβCD-IC fibers and carvacrol/HPγCD-IC fibers was calculated as 0.5 and 0.63 mg mL−1, respectively. The possible reason for this difference in IC50 value is that carvacrol formed more stable complex with HPβCD which resulted in higher degree of protection for carvacrol and so higher antioxidant activity was observed [40]. The stability of carvacrol/CD-IC fibers in terms of antioxidant activity was also investigated by using 3-year-old fibers. The 3-year-old carvacrol/CD-IC fibers showed almost same 50% inhibition activity when compared to fresh samples (Fig. S4), revealing the long-term stability of the carvacrol/CD-IC fibers for their antioxidant activities. As discussed in the 1H-NMR section above, the amount of carvacrol found in old samples and the fresh samples was almost same, indicating that there was only very minimal loss of carvacrol during the 3-year storage (at 4 °C in the refrigerator) and this further proved that carvacrol was well protected in the fiber matrix due to inclusion complexation.

Fast-dissolving character of carvacrol/CD-IC fibers

The fast-dissolving character of carvacrol/CD-IC fibers in water was visualized by a video and photographs (Video S1 of supplementary information and Fig. 9). When the carvacrol/CD-IC fibrous webs were exposed to water, they were suddenly (< 1 s) dissolved which showed the fast-dissolving character of these carvacrol/CD-IC fibrous webs. As mentioned before, carvacrol has a very low water solubility; however, carvacrol/CD-IC fibers are quite soluble which indicates the water solubility enhancement of carvacrol.

Conclusion

Here, the production of handy, self-standing and fast-dissolving fibrous webs from carvacrol/cyclodextrin inclusion complexes (carvacrol/CD-IC) by using the electrospinning technique was achieved. The molar ratio of carvacrol/CD was found 1:1 for both CD types (HPβCD and HPγCD) by phase solubility and molecular modeling studies. The enhanced water solubility of carvacrol due to inclusion complex formation was confirmed by the phase solubility and computational modeling studies. SEM images revealed that the carvacrol/CD-IC fibers were uniform and bead free. FTIR, TGA, and 1H-NMR studies confirmed the inclusion complex formation and the presence of carvacrol in fibers. Moreover, TGA and 1H-NMR studies indicated that very high amount of carvacrol (up to ~ 75 to 95%) was preserved during/after electrospinning in carvacrol/CD-IC fibers although carvacrol has a highly volatile nature. Besides, TGA results showed that thermal stability of carvacrol in carvacrol/CD-IC fibers has increased due to the inclusion complex formation. In addition, antioxidant activity of carvacrol was enhanced due to inclusion complex formation for carvacrol/CD-IC fibers. Moreover, 3-year-old carvacrol/CD-IC fibers showed almost same antioxidant activity when compared to fresh samples, revealing the long-term stability of the carvacrol in CD-IC fibers. Also, the amount of carvacrol found in 3-year-old carvacrol/CD-IC fibrous web samples was almost same with the fresh samples, confirming that carvacrol was well protected in the fiber matrix due to inclusion complexation. In the light of all these results, it can be concluded that main drawbacks of carvacrol like high volatility, low solubility, and low stability were eliminated or minimized; besides, its antioxidant activity was enhanced by the formation carvacrol/CD-IC fibers. These promising results suggest that carvacrol/CD-IC fibrous materials may be applicable in food, cosmetic, and oral care industries as fast-dissolving tablet/web/strip.

References

Del Valle EM (2004) Cyclodextrins and their uses: a review. Process Biochem 39(9):1033–1046

Hedges AR (1998) Industrial applications of cyclodextrins. Chem Rev 98(5):2035–2044

Szejtli J (1998) Introduction and general overview of cyclodextrin chemistry. Chem Rev 98(5):1743–1754

Wendorff JH, Agarwal S, Greiner A (2012) Electrospinning: materials, processing, and applications. Wiley, Weinheim

Aytac Z, Keskin NOS, Tekinay T, Uyar T (2017) Antioxidant α-tocopherol/γ-cyclodextrin–inclusion complex encapsulated poly (lactic acid) electrospun nanofibrous web for food packaging. J Appl Polym Sci 134:44858

Sahay R, Kumar PS, Sridhar R, Sundaramurthy J, Venugopal J, Mhaisalkar SG, Ramakrishna S (2012) Electrospun composite nanofibers and their multifaceted applications. J Mater Chem 22(26):12953–12971

Uyar T, Kny E (eds) (2017) Electrospun materials for tissue engineering and biomedical applications. Woodhead Publishing, Cambridge

Ramakrishna S, Fujihara K, Teo WE, Lim TC, Ma Z (2005) An introduction to electrospinning and nanofibers. World Scientific, Singapore

Shenoy SL, Bates WD, Frisch HL, Wnek GE (2005) Role of chain entanglements on fiber formation during electrospinning of polymer solutions: good solvent, non-specific polymer–polymer interaction limit. Polymer 46(10):3372–3384

Theron SA, Zussman E, Yarin AL (2004) Experimental investigation of the governing parameters in the electrospinning of polymer solutions. Polymer 45(6):2017–2030

Celebioglu A, Uyar T (2012) Electrospinning of nanofibers from non-polymeric systems: polymer-free nanofibers from cyclodextrin derivatives. Nanoscale 4(2):621–631

Celebioglu A, Uyar T (2013) Electrospinning of nanofibers from non-polymeric systems: electrospun nanofibers from native cyclodextrins. J Colloid Interface Sci 404:1–7

Aytac Z, Yildiz ZI, Kayaci-Senirmak F, San-Keskin NO, Kusku SI, Durgun E, Tekinay T, Uyar T (2016) Fast-dissolving, prolonged release, and antibacterial cyclodextrin/limonene-inclusion complex nanofibrous webs via polymer-free electrospinning. J Agric Food Chem 64(39):7325–7334

Aytac Z, Yildiz ZI, Kayaci-Senirmak F, San-Keskin NO, Tekinay T, Uyar T (2016) Electrospinning of polymer-free cyclodextrin/geraniol–inclusion complex nanofibers: enhanced shelf-life of geraniol with antibacterial and antioxidant properties. RSC Adv 6(52):46089–46099

Celebioglu A, Uyar T (2011) Electrospinning of polymer-free nanofibers from cyclodextrin inclusion complexes. Langmuir 27(10):6218–6226

Celebioglu A, Kayaci-Senirmak F, İpek S, Durgun E, Uyar T (2016) Polymer-free nanofibers from vanillin/cyclodextrin inclusion complexes: high thermal stability, enhanced solubility and antioxidant property. Food Funct 7(7):3141–3153

Celebioglu A, Umu OC, Tekinay T, Uyar T (2014) Antibacterial electrospun nanofibers from triclosan/cyclodextrin inclusion complexes. Colloids Surf B 116:612–619

Aytac Z, Yildiz ZI, Kayaci-Senirmak F, Tekinay T, Uyar T (2017) Electrospinning of cyclodextrin/linalool-inclusion complex nanofibers: fast-dissolving nanofibrous web with prolonged release and antibacterial activity. Food Chem 231:192–201

Celebioglu A, Uyar T (2017) Antioxidant vitamin E/cyclodextrin inclusion complex electrospun nanofibers: enhanced water-solubility, prolonged shelf-life and photostability of vitamin E. J Agric Food Chem 65(26):5404–5412

Celebioglu A, Yildiz ZI, Uyar T (2017) Electrospun nanofibers from cyclodextrin inclusion complexes with cineole and p-cymene: enhanced water solubility and thermal stability. Int J Food Sci Technol 53:112–120

Celebioglu A, Aytac Z, Kilic ME, Durgun E, Uyar T (2017) Encapsulation of camphor in cyclodextrin inclusion complex nanofibers via polymer-free electrospinning: enhanced water solubility, high temperature stability, and slow release of camphor. J Mater Sci 53:5436–5449. https://doi.org/10.1007/s10853-017-1918-4

Celebioglu A, Yildiz ZI, Uyar T (2018) Fabrication of electrospun eugenol/cyclodextrin inclusion complex nanofibrous webs for enhanced antioxidant property, water solubility, and high temperature stability. J Agric Food Chem 66:457–466

Yildiz ZI, Celebioglu A, Kilic ME, Durgun E, Uyar T (2018) Menthol/cyclodextrin inclusion complex nanofibers: enhanced water-solubility and high-temperature stability of menthol. J Food Eng 224:27–36

Celebioglu A, Yildiz ZI, Uyar T (2018) Thymol/cyclodextrin inclusion complex nanofibrous webs: enhanced water solubility, high thermal stability and antioxidant property of thymol. Food Res Int 106:280–290

Burt S (2004) Essential oils: their antibacterial properties and potential applications in foods—a review. Int J Food Microbiol 94(3):223–253

Bakkali F, Averbeck S, Averbeck D, Idaomar M (2008) Biological effects of essential oils–a review. Food Chem Toxicol 46(2):446–475

Marques HMC (2010) A review on cyclodextrin encapsulation of essential oils and volatiles. Flavour Fragr J 25:313–326. https://doi.org/10.1002/ffj.2019

Wadhwa G, Kumar S, Chhabra L, Mahant S, Rao R (2017) Essential oil–cyclodextrin complexes: an updated review. J Incl Phenom Macrocycl Chem 89:39–58. https://doi.org/10.1007/s10847-017-0744-2

Ciobanu A, Landy D, Fourmentin S (2013) Complexation efficiency of cyclodextrins for volatile flavor compounds. Food Res Int 53:110–114. https://doi.org/10.1016/j.foodres.2013.03.048

Can-Baser KH (2008) Biological and pharmacological activities of carvacrol and carvacrol bearing essential oils. Curr Pharm Des 14(29):3106–3119

De Vincenzi M, Stammati A, De Vincenzi A, Silano M (2004) Constituents of aromatic plants: carvacrol. Fitoterapia 75(7):801–804

Santos EH, Kamimura JA, Hill LE, Gomes CL (2015) Characterization of carvacrol beta-cyclodextrin inclusion complexes as delivery systems for antibacterial and antioxidant applications. LWT Food Sci Technol 60(1):583–592

Higuchi T, Connors KA (1965) Phase solubility techniques. Adv Anal Chem Instrum 4:117–210

Pyrzynska K, Pękal A (2013) Application of free radical diphenylpicrylhydrazyl (DPPH) to estimate the antioxidant capacity of food samples. Anal Methods 5(17):4288–4295

Brewster ME, Loftsson T (2007) Cyclodextrins as pharmaceutical solubilizers. Adv Drug Deliv Rev 59(7):645–666

Sá Couto A, Salústio P, Cabral-Marques H (2015) Cyclodextrins. In: Ramawat K, Mérillon JM (eds) Polysaccharides. Springer, Cham, pp 247–288

Uyar T, Besenbacher F (2008) Electrospinning of uniform polystyrene fibers: the effect of solvent conductivity. Polymer 49(24):5336–5343

Lu Y, Liu S, Zhao Y, Zhu L, Yu S (2014) Complexation of Z-ligustilide with hydroxypropyl-β-cyclodextrin to improve stability and oral bioavailability. Acta Pharm 64(2):211–222

Kayaci F, Uyar T (2011) Solid inclusion complexes of vanillin with cyclodextrins: their formation, characterization, and high-temperature stability. J Agric Food Chem 59(21):11772–11778

Wei Y, Zhang J, Memon AH, Liang H (2017) Molecular model and in vitro antioxidant activity of a water-soluble and stable phloretin/hydroxypropyl-β-cyclodextrin inclusion complex. J Mol Liq 236:68–75

Acknowledgements

Dr. Uyar acknowledges The Scientific and Technological Research Council of Turkey (TUBITAK), Turkey (Project #213M185) for funding this research. Z. I. Yildiz thanks to TUBITAK-BIDEB for the PhD scholarship. Dr. Durgun acknowledges the support from the Turkish Academy of Sciences—Outstanding Young Scientists Award Program (TUBA-GEBIP)—Turkey.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (MPG 8806 kb)

Rights and permissions

About this article

Cite this article

Yildiz, Z.I., Celebioglu, A., Kilic, M.E. et al. Fast-dissolving carvacrol/cyclodextrin inclusion complex electrospun fibers with enhanced thermal stability, water solubility, and antioxidant activity. J Mater Sci 53, 15837–15849 (2018). https://doi.org/10.1007/s10853-018-2750-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2750-1