Abstract

Toward the fast development of portable devices, the lightweight, flexible, and even wearable energy storage devices are very required. One effective device is the graphene-based fiber supercapacitors. Here we present the core–shell Co3O4/graphene hybrid fibers by hydrothermal method for the first time, where Co3O4 directly grows on the surface of graphene forming excellent hierarchical nanostructures. The combination of the Co3O4 shell and graphene core evidently improves the capacitive behaviors of the hybrid fibers. The Co3O4/graphene hybrid fibers are lightweight, flexible, and wearable, showing ultrahigh electrochemical performances such as large specific capacitance of 236.8 F g−1 (196.3 mF cm−2) at current density of 0.2 A g−1, outstanding rate capability, and excellent cycling stability (72.7% retention after 10000 cycles). The high electrochemical performances reveal the great potential of core–shell Co3O4/graphene hybrid fibers as electrodes in the energy storage system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the portable devices become an important trend, the requirement of flexible energy storage devices is very necessary [1]. In order to realize large-scale integration, the energy storage devices such as supercapacitors should be lightweight, small-sized, and flexible as much as possible [2,3,4,5]. However, the supercapacitors based on conventional materials and structures are heavy and hard, which are not suitable for large-scale integration of portable electronic devices [6, 7]. Recently, much efforts have been made to explore lightweight and flexible supercapacitors with the planar [8, 9] and fiber-shaped structures [2, 3]. They maintain good electrochemical performances, even after high mechanical bending and twisting. Compared with the planar ones, the fiber-shaped supercapacitors have advantages in flexibility, easiness to be woven into textiles, and thus are promising for wearable electronic devices.

In the last decade, various fibers based on carbon materials have been investigated for flexible supercapacitors [10,11,12,13,14,15,16]. In recent years, the emphasis has been placed on the improvement of both energy and power densities of devices [15, 17]. As compared to carbon and carbon nanotube fibers, the graphene fibers exhibit relatively high electrochemical behaviors due to the high specific surface area and electric conductivity of graphene. Meanwhile, it is convenient to produce graphene fibers by such methods as wet-spinning through injecting graphene oxide (GO) dispersion into a coagulation bath and then reducing [18,19,20]. Hence, the graphene-based fibers will certainly be very promising in wearable electrochemical devices.

For practical applications of supercapacitors, an effective strategy is to combine carbon materials with transition metal oxides [21,22,23,24], which may possess both high conductivity and capacitance and so have high power and energy densities. Among transition metal oxides hotly studied, cobalt oxide (Co3O4) has attracted considerable attention due to its rather high capacitance for pseudocapacitor electrodes [11, 25, 26]. Recently, the enhanced electrochemical performances of graphene fiber-based electrodes have been demonstrated by decorating the graphene with transition metal oxides such as MnO2 [27,28,29]. In theory, the decoration of Co3O4 on graphene fibers is expected to have much high electrochemical behaviors. However, few reports on this issue have appeared so far.

In this work, we provide a simple hydrothermal process to grow Co3O4 nanostructures directly on the surface of graphene fibers, forming a hierarchical core–shell structure of Co3O4/graphene hybrid fibers. Quite different from the core–shell hybrid fibers previously reported [27,28,29], the Co3O4 shell is not simply coated on the graphene core forming a flat layer without any nanotopography; in contrary, the Co3O4 directly grows from the surface of reduced graphene oxide (RGO) fibers, having excellent double nanostructures of nanosheets and nanowires, which can provide much large surface area of active materials. The Co3O4/graphene hybrid fibers exhibit a high specific capacitance of 236.8 F g−1 (196.3 mF cm−2, 165.7 F cm−3) at the current density of 0.2 A g−1, good rate capability, and long cycle stability (72.7% retention after 10000 cycles). The present studies reveal that the hierarchical core–shell Co3O4/graphene hybrid fibers are very potential as high-performance electrodes for supercapacitors (e.g., coiled yarn supercapacitors).

Experimental

The GO fibers were prepared by using a wet-spinning method. The GO aqueous dispersion was first concentrated by centrifugation at 15000 rpm for 1 h and then under ultrasonication treatment for 30 min, so the GO spinning dope (10 mg mL−1) was obtained. The GO spinning dope (2 mL) was injected into a coagulation bath (5 wt% CaCl2/ethanol solution) with an injection speed of 200 μL min−1. The obtained fibers were washed three times with ethanol and deionized water, respectively. The GO fibers were collected onto the graphite roller and then dried at 60 °C for 12 h. The GO fibers were first treated by HI at 100 °C for 8 h, and subsequently they were annealed at 1000 °C for 4 h in the H2/Ar (1:4 of volume ratio) atmosphere. Finally, the RGO fibers were obtained after being naturally cooled to room temperature. After weighing, the linear density of the RGO fibers could be calculated as 11.23 μg cm−1.

The 0.997 g of Co(CH3COO)2, 0.168 g of NH4F, and 1.201 g CO(NH2)2 were dissolved in 40 mL of deionized water. The solution was stirred for 2 h at room temperature. The RGO fibers were suspended in a 50-mL Teflon-lined autoclave. Then, the solution was transferred to the autoclave. The hydrothermal treatment was carried out at 120 °C for 5 h. The samples were washed in ethanol and deionized water. They were annealed at 300 °C to obtain the core–shell structure Co3O4/graphene hybrid fibers. After weighing, the linear density of the hybrid fibers could be calculated as 18.19 μg cm−1. Per centimeter of the RGO fibers had been loaded 6.96 μg of Co3O4. In the Co3O4/graphene hybrid fibers, the mass ratio of the Co3O4 and the RGO fiber is about 5:8.

The structures of Co3O4/graphene hybrid fibers were investigated by a HITACHI S4800 scanning electron microscope (SEM). The compositions of hybrid fibers were measured by X-ray energy-disperse spectra (EDS) in an Oxford Instruments EDS System and X-ray photoelectron spectroscopy (XPS) spectra with a Thermo ESCALAB-250 spectrometer using an Al Kα radiation (E = 1486.6 eV). The Raman spectra were recorded on a LabRAM HR Evolution spectroscopy with argon-ion laser (514.5 nm).

The electrochemical performances were measured at room temperature on the CHI760E electrochemical workstation, including cyclic voltammetry (CV), galvanostatic charge–discharge (GCD), and electrochemical impedance spectroscopy (EIS). The aqueous electrolyte was the 2.0 M KOH solution for electrochemical tests. In three-electrode measurements, the Co3O4/graphene hybrid fibers, Pt plate, and standard calomel electrode (SCE) were used as the working electrode, counter electrode, and reference electrode, respectively. The EIS was obtained under an ac voltage of 5 mV, frequency in the 106–0.01 Hz range, and open circuit. The specific capacitance (Cs) was calculated from the GCD curves,

where I, Δt, ΔV and m are the discharge current, discharge time, voltage range, and mass of the active materials on the electrodes, respectively.

Results and discussion

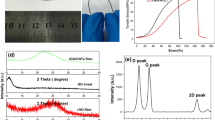

The morphologies of the RGO fibers and Co3O4/graphene hybrid fibers were observed by SEM, as shown in Fig. 1. The RGO fibers contain the wrinkle overlapped GO nanosheets with a smooth surface. The diameter of the RGO fibers is around 48 μm (Fig. 1a). This type of wrinkle structure enlarges the specific surface area effectively, so it is able to enhance the transportation efficiency of electrolyte ion. Compared to the bare RGO fibers, SEM images of Co3O4/graphene hybrid fibers are very different (Fig. 1b–d). The diameter of the Co3O4/graphene hybrid fibers is around 69 μm (Fig. 1b). The Co3O4 with morphology of nanowires and nanosheets is formed on the surface of RGO fibers, leading to that the diameter evidently increases and the surface becomes slightly rough. The Co3O4 nanostructures directly grow from the surface of RGO fibers. This kind of specific nanostructure in fibers has never been reported before. Quite different from the previous studies that pseudocapacitive materials (e.g., MnO2) were simply coated on the surface of RGO fibers without any nanotopography [27,28,29], the nanowires and nanosheets of Co3O4 nanostructure presented here display three-dimensional hierarchical structures and so have high specific surface area, having the ability to act as the active sites of redox reactions in full contact with the electrolyte, which may result in superior electrochemical properties compared with the solid nanoparticles. Figure 1e, f shows the EDS mapping images of the surface area of the Co3O4/graphene hybrid fibers. The images exhibit the presence of Co and O elements in the shell. The Co and O elements are uniformly distributed on the surface of the fibers, which confirms the Co3O4 grows homogeneously along the whole fiber. It is critical for improving the performances of supercapacitors based on the hybrid fibers.

Figure 2a shows Raman spectra of the RGO and Co3O4/graphene hybrid fibers. The peaks are found at around 1347.1 and 1586.6 cm−1 in both fibers, which are assigned to the defect induced D and G peaks, respectively. In addition, five new peaks appear at 186, 471, 513, 601, and 675 cm−1 for the Co3O4/graphene hybrid fibers, which are attributed to the F2g, E2g, F 12g , F 22g , and A 11g crystallization modes of Co3O4 crystal, respectively [30]. The observations reveal the formation of Co3O4 shell on the RGO core.

Figure 2b, c shows the core level XPS spectra of the Co3O4/graphene hybrid fibers. The C 1s spectra contain four peaks at 284.1, 285.6, 288.1, and 289.9 eV, which are ascribed to the C–C or C=C, C–O, C=O, and O–C=O bonds, respectively [31]. The observations indicate that the oxygen still exists in the graphene fibers. Note that the intensity of the oxygen-related peaks is rather low, suggesting the reduction in almost all GO. The Co 2p spectra contain two main components at 780.9 and 797.3 eV, which are assigned to the Co 2p3/2 and Co 2p1/2. They correspond to Co2+ and Co3+ in Co3O4, respectively, confirming that cobalt exists in the form of Co3O4. The two shake-up satellite peaks located around 786 and 803 eV are also characteristic of Co3O4, in good agreement with the former reports [30]. Now we can safely say that the observed results firmly confirm the successful growth of the Co3O4 nanostructures from the surface of the graphene fiber.

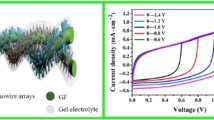

Figure 3a, b displays the photographs of the Co3O4/graphene fiber electrodes weaved into a textile and tied in a knot, which indicates the excellent flexibility and high strength of the hybrid fibers. The electrochemical properties of electrodes were studied by CV, GCD, and EIS measurements. As shown in Fig. 3c, the CV curves of Co3O4/graphene hybrid fiber electrodes show nearly rectangular shape, indicating a relatively good capacitive behavior under the 10–100 mV s−1 scan rates. Meanwhile, the CV curves show no evident faradaic current in the 0–0.8 V range, which demonstrates that the fiber electrodes are of ideal electrical double-layer capacitor behavior at the electrode/electrolyte interface. The highly conductive RGO fiber, combined with surface decorated Co3O4, is capable of accelerating ion transportation rate. It is seen that the current response displays the corresponding increases with the increase in the scan rate, exhibiting a good capacitive behavior of Co3O4/graphene hybrid fiber electrodes.

a, b Photographs of Co3O4/graphene hybrid fibers weaved into a textile and tied in a knot; c CV curves of Co3O4/graphene hybrid fibers at different scan rates; d EIS spectra of the RGO fibers and Co3O4/graphene hybrid fibers; e galvanostatic discharge voltage profiles of Co3O4/graphene hybrid fibers at various current densities

Figure 3d shows the Nyquist plots of the Co3O4/graphene fiber electrodes. The curve displays an approximately vertical line, revealing the nature of capacitive behavior of the hybrid fiber electrodes [32]. The semicircle in the high frequency region is amplified in the set of Fig. 3d. The charge-transfer resistance (Rct) is calculated by extrapolating the semicircle on the real axis. The charge-transfer resistances are 439 and 507 Ω for RGO fibers and Co3O4/graphene hybrid fibers electrodes, respectively. Moreover, the resistances of the electrochemical system (Rs) are 481 and 549 Ω for RGO fibers and Co3O4/graphene hybrid fibers electrodes, respectively. Note that the resistance ofCo3O4/graphene hybrid fibers is very close to that of RGO fibers, which is an encouraging result because there is no evident increase in resistance for RGO fibers with the formation of Co3O4 shell. The Co3O4 is of low electrical conductivity owing to its semiconductor characteristics. Compared with Co3O4, the observed data indicate that the electrical conductivity of Co3O4/graphene hybrid fiber electrodes is improved, which benefits from the highly conductive graphene. The effectively conductive links between Co3O4 and RGO fibers supply the rational paths for electrolyte ions, enhancing the electrical conductivity.

Figure 3e shows the GCD curves of the Co3O4/graphene hybrid fiber electrodes at current densities from 0.2 to 3.2 A g−1. All of the charging curves are symmetrical with their corresponding discharge counterparts, further indicating the ideal capacitive behavior of the electrodes. What is more, the GCD curves reveal excellent linear voltage–time appearances, suggesting the outstanding capacitive property of the hybrid fiber electrodes. Figure 4a shows the specific capacitance of the Co3O4/graphene hybrid fiber electrodes calculated from the GCD curves. At a current density of 0.2 A g−1, the specific capacitance is up to 236.8 F g−1 (196.3 mF cm−2, 165.7 F cm−3). This high specific capacitance is clearly resulted from the large surface area of Co3O4 shell nanostructures serving as active sites of redox reactions. As the current density increases to 3.2 A g−1, the specific capacitance of the Co3O4/graphene hybrid fiber electrode is 192 F g−1, retaining 81.1% of its value at 0.2 A g−1, where the current density is elevated 16 times. The results reveal that the Co3O4/graphene hybrid fiber electrode has excellent rate capability, having great significance for energy storage devices. With increase in the current density, the gradual decrease in specific capacitance is attributed to the diffusion effect, which restricts the diffusion and migration of the electrolyte ions into the inside of electrodes at high current densities [33]. To investigate the cycle stability, the GCD tests were measured at 0.5 A g−1 for 10000 cycles, as shown in Fig. 4b. The 72.7% capacitance remained after 10000 cycles, revealing the outstanding long-term cycling stability. What is more, the GCD tests of the hybrid fibers after 1000 and 2000 times bending were measured at the same test conditions for 10000 cycles. Figure 4b shows the cycle stability remained almost unchanged after bending for 1000 and 2000 cycles, which indicated the hybrid fiber electrodes were highly flexible and their electrochemical performances could be well maintained under various deformations.

The RGO fibers electrode we prepared has also a considerable specific capacitance (67.5 F g−1) at a current density of 1.0 A g−1, as shown in Figure S1 (in Electronic Supporting Information). Compared with RGO fibers, the electrochemical performances of Co3O4/graphene hybrid fibers have been significantly improved through growing Co3O4 nanostructures on the surface of RGO fibers. Note that, the capacitance value of 236.8 F g−1 (196.3 mF cm−2, 165.7 F cm−3) of the Co3O4/graphene hybrid fibers are significantly higher than most of the graphene-based fiber electrodes previously reported, such as RGO–GO–RGO fibers (1.2 mF cm−2) [3], PPy-decorated RGO/MWCNT fibers (25.9 F cm−3) [34], graphene/polymer electrolyte coaxial fibers (182 F g−1) [35], poly(vinyl alcohol)/graphene hybrid fibers (216 F g−1) [36], and MnO2-deposited graphene fibers (59.2 mF cm−2) [29]. Details of the comparison are found in Table S1 (in Electronic Supporting Information), where all the available values for graphene-based fibers in previous reports are listed.

Conclusions

In summary, a novel structure of Co3O4/graphene core–shell hybrid fibers has been developed by a hydrothermal method, exhibiting good flexibility and wearability with high electrochemical performances. The Co3O4 shell directly grows on the surface of the RGO fibers, forming 3D hierarchical morphology with double nanostructures of nanosheets and nanowires. The Co3O4/graphene hybrid fiber electrode shows a large specific capacitance of 236.8 F g−1 (196.3 mF cm−2) at a current density of 0.2 A g−1 with superior rate capability. The capacitance retention is about 72.7% after 10000 cycles, having outstanding long-term cycling stability. By combination of the intrinsic mechanical flexibility of RGO core and the unique hierarchical structure with the pseudo-capacitance of Co3O4 shell, the Co3O4/graphene hybrid fibers exhibit outstanding electrochemical capacitive behaviors with robust tolerance to mechanical deformation, very promising for wearable electronics.

References

Zhao Y, Zhang Y, Sun H, Dong XL, Cao JY, Wang L, Xu YF, Ren J, Hwang YN, Son IH, Huang XL, Wang YG, Peng HS (2016) A self-healing aqueous lithium-ion battery. Angew Chem Int Ed 55(46):14382–14386

Meng Y, Zhao Y, Hu C, Cheng H, Hu Y, Zhang Z, Shi G, Qu L (2013) All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles. Adv Mater 25(16):2326–2331

Hu L, Wu H, Cui Y (2010) Printed energy storage devices by integration of electrodes and separators into single sheets of paper. Appl Phys Lett 96(18):183502

Hu Y, Cheng H, Zhao F, Chen N, Jiang L, Feng Z, Qu L (2014) All-in-one graphene fiber supercapacitor. Nanoscale 6(12):6448–6451

Nagaraju G, Sekhar SC, Yu JS (2017) Utilizing waste cable wires for high-performance fiber-based hybrid supercapacitors: an effective approach to electronic-waste management. Adv Energy Mater 7(21):1702201

Lee M-T, Chang J-K, Hsieh Y-T, Tsai W-T (2008) Annealed Mn–Fe binary oxides for supercapacitor applications. J Power Sources 185(2):1550–1556

Stoller MD, Park SJ, Zhu YW, An JH, Ruoff RS (2008) Graphene-based ultracapacitors. Nano Lett 8(10):3498–3502

Lee G, Kim D, Yun J, Ko Y, Cho J, Ha JS (2014) High-performance all-solid-state flexible micro-supercapacitor arrays with layer-by-layer assembled MWNT/MnO(x) nanocomposite electrodes. Nanoscale 6(16):9655–9664

El-Kady MF, Strong V, Dubin S, Kaner RB (2012) Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 335(6074):1326–1330

Yuan LY, Lu XH, Xiao X, Zhai T, Dai JJ, Zhang FC, Hu B, Wang X, Gong L, Chen J, Hu CG, Tong YX, Zhou J, Wang ZL (2012) Flexible solid-state supercapacitors based on carbon nanoparticles/MnO2 nanorods hybrid structure. ACS Nano 6(1):656–661

Chen Z, Augustyn V, Wen J, Zhang Y, Shen M, Dunn B, Lu Y (2011) High-performance supercapacitors based on intertwined CNT/V2O5 nanowire nanocomposites. Adv Mater 23(6):791–795

Ren J, Li L, Chen C, Chen X, Cai Z, Qiu L, Wang Y, Zhu X, Peng H (2013) Twisting carbon nanotube fibers for both wire-shaped micro-supercapacitor and micro-battery. Adv Mater 25(8):1155–1159

Jost K, Stenger D, Perez CR, McDonough JK, Lian K, Gogotsi Y, Dion G (2013) Knitted and screen printed carbon-fiber supercapacitors for applications in wearable electronics. Energy Environ Sci 6(9):2698–2705

Chang Y, Han G, Fu D, Liu F, Li M, Li Y (2014) Larger-scale fabrication of N-doped graphene-fiber mats used in high-performance energy storage. J Power Sources 252:113–121

Yu D, Goh K, Wang H, Wei L, Jiang W, Zhang Q, Dai L, Chen Y (2014) Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nat Nanotechnol 9(7):555–562

Qu G, Cheng J, Li X, Yuan D, Chen P, Chen X, Wang B, Peng H (2016) A fiber supercapacitor with high energy density based on hollow graphene/conducting polymer fiber electrode. Adv Mater 28(19):3646–3652

Lee JA, Shin MK, Kim SH, Cho HU, Spinks GM, Wallace GG, Lima MD, Lepro X, Kozlov ME, Baughman RH, Kim SJ (2013) Ultrafast charge and discharge biscrolled yarn supercapacitors for textiles and microdevices. Nat Commun 4:1970

Zhao Y, Jiang CC, Hu CG, Dong ZL, Xue JL, Meng YN, Zheng N, Chen PW, Qu LT (2013) Large-scale spinning assembly of neat, morphology-defined, graphene-based hollow fibers. ACS Nano 7(3):2406–2412

Chen S, Ma W, Cheng Y, Weng Z, Sun B, Wang L, Chen W, Li F, Zhu M, Cheng H-M (2015) Scalable non-liquid-crystal spinning of locally aligned graphene fibers for high-performance wearable supercapacitors. Nano Energy 15:642–653

Xu Z, Gao C (2011) Graphene chiral liquid crystals and macroscopic assembled fibres. Nat Commun 2:571

Meng Y, Wang K, Zhang Y, Wei Z (2013) Hierarchical porous graphene/polyaniline composite film with superior rate performance for flexible supercapacitors. Adv Mater 25(48):6985–6990

Fan Z, Yan J, Wei T, Zhi L, Ning G, Li T, Wei F (2011) Asymmetric supercapacitors based on graphene/MnO2 and activated carbon nanofiber electrodes with high power and energy density. Adv Funct Mater 21(12):2366–2375

Zhi M, Manivannan A, Meng F, Wu N (2012) Highly conductive electrospun carbon nanofiber/MnO2 coaxial nano-cables for high energy and power density supercapacitors. J Power Sources 208:345–353

Wu Z-S, Zhou G, Yin L-C, Ren W, Li F, Cheng H-M (2012) Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 1(1):107–131

Liu J, Jiang J, Cheng C, Li H, Zhang J, Gong H, Fan HJ (2011) Co3O4 Nanowire@MnO2 ultrathin nanosheet core/shell arrays: a new class of high-performance pseudocapacitive materials. Adv Mater 23(18):2076–2081

Tang W, Hou YY, Wang XJ, Bai Y, Zhu YS, Sun H, Yue YB, Wu YP, Zhu K, Holze R (2012) A hybrid of MnO2 nanowires and MWCNTs as cathode of excellent rate capability for supercapacitors. J Power Sources 197:330–333

Zhang J, Yang X, He Y, Bai Y, Kang L, Xu H, Shi F, Lei Z, Liu Z-H (2016) δ-MnO2/holey graphene hybrid fiber for all-solid-state supercapacitor. J Mater Chem A 4(23):9088–9096

Zheng B, Huang T, Kou L, Zhao X, Gopalsamy K, Gao C (2014) Graphene fiber-based asymmetric micro-supercapacitors. J Mater Chem A 2(25):9736–9743

Chen Q, Meng Y, Hu C, Zhao Y, Shao H, Chen N, Qu L (2014) MnO2-modified hierarchical graphene fiber electrochemical supercapacitor. J Power Sources 247:32–39

Ma W, Chen S, Yang S, Chen W, Cheng Y, Guo Y, Peng S, Ramakrishna S, Zhu M (2016) Hierarchical MnO2 nanowire/graphene hybrid fibers with excellent electrochemical performance for flexible solid-state supercapacitors. J Power Sources 306:481–488

Xiang C, Li M, Zhi M, Manivannan A, Wu N (2013) A reduced graphene oxide/Co3O4 composite for supercapacitor electrode. J Power Sources 226:65–70

Li M, Cushing SK, Zhou X, Guo S, Wu N (2012) Fingerprinting photoluminescence of functional groups in graphene oxide. J Mater Chem 22(44):23374

Sun H, Sun X, Hu T, Yu M, Lu F, Lian J (2014) Graphene-wrapped mesoporous cobalt oxide hollow spheres anode for high-rate and long-life lithium ion batteries. J Phys Chem C 118(5):2263–2272

Wang S, Liu N, Su J, Li L, Long F, Zou Z, Jiang X, Gao Y (2017) Highly stretchable and self-healable supercapacitor with reduced graphene oxide based fiber springs. ACS Nano 11(2):2066–2074

Zhao X, Zheng B, Huang T, Gao C (2015) Graphene-based single fiber supercapacitor with a coaxial structure. Nanoscale 7(21):9399–9404

Chen S, Ma W, Xiang H, Cheng Y, Yang S, Weng W, Zhu M (2016) Conductive, tough, hydrophilic poly(vinyl alcohol)/graphene hybrid fibers for wearable supercapacitors. J Power Sources 319:271–280

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China under Grant No. 51372002 and Shenzhen Science and Technology Project under Grant No. JCYJ20150324141711644.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, W., Yuan, Y., Yang, J. et al. Hierarchical core–shell Co3O4/graphene hybrid fibers: potential electrodes for supercapacitors. J Mater Sci 53, 6116–6123 (2018). https://doi.org/10.1007/s10853-017-1971-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1971-z