Abstract

Encapsulation of plumbagin using cyclodextrins (CDs), including α-cyclodextrin (αCD), β-cyclodextrin (βCD), and γ-cyclodextrin (γCD) to form inclusion complexes was investigated to prevent the loss of plumbagin in pharmaceutical and nutraceutical products. Computational simulations and phase solubility studies suggest that the complex formations of plumbagin with CDs are possible. βCD is chosen, as it has the lowest price and can form the complex in a wide concentration range with 1:1 host–guest molar ratio. Two techniques of the complex formation, co-precipitation and freeze-drying, were evaluated for both pure plumbagin and extracted plumbagin from Plumbago indica root to represent lab-scale and industrial-scale productions, respectively. The complexes from these two techniques can prevent the loss of plumbagin up to three-folds better than plumbagin in free form. The preservation by encapsulation can increase the remaining plumbagin from 22.68 to 60.26% after exposure at 50 °C for 6 weeks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Active compounds derived from plants have various applications across multiple industries, including foods, cosmetics, and pharmaceuticals. However, the instability of these compounds when exposed to sunlight, moisture, temperature, and oxidizers is a major obstacle for commercial utilization. The tendency of active compounds to degrade leads to a short shelf life and inconsistent product quality. Plumbagin is a natural naphthoquinone found in Plumbago indica [1, 2] with multiple pharmacological properties, including anti-bacterial, anti-inflammatory, and anti-cancer activities [3,4,5,6,7], but it is unstable when exposed to temperatures above 4 °C [4]. Plumbagin also has a hypolipidemic activity, as it can reduce the low-density lipoprotein form of cholesterol while increase the high-density lipoprotein form to prevent accumulation of cholesterol in blood vessels [8]. In order to utilize plumbagin in commercial products, a preservation technique of plumbagin from environmental conditions requires to be implemented. Encapsulation is an effective technique which can preserve active compounds in host molecules. This technique can prevent the degradation of active compounds from exposure to sunlight, high temperature, oxidizing agent, and moisture [9,10,11,12,13,14]. Since the applications of plumbagin are mainly in the pharmaceutical and food products, a suitable non-toxic host molecule is used in encapsulation.

Several compounds, such as phospholipid micelle, liposome, niosome, and cyclodextrin (CD) have been introduced as the host molecules for plumbagin encapsulation to enhance the anticancer efficacy and aqueous solubility [15,16,17,18,19]. Micelle and liposome were reported for plumbagin encapsulation for slow release applications in drugs. There is no report about the preservation of plumbagin in the solid form in these studies [15, 19]. Niosome was used for preservation of plumbagin. However, the preservation efficiency of plumbagin in niosome is low, especially in first 7 days [18]. Relative to other host molecules, CD is an interesting host for plumbagin preservation in pharmaceutical and food products due to the effectiveness of the cost and preparation methods. The computer simulation results from our previous study show multiple hydrogen bonds between plumbagin and CD in the form of inclusion complex that provides the potency of the preservation in the form of solid complex [20]. CD, a non-toxic cyclic oligomer of glucose [21,22,23], is commonly used as an encapsulating host molecule in pharmaceutical, food, cosmetic, and textile applications to increase solubility, preserve odor and color, and prevent the degradation of active compounds [24,25,26,27,28,29,30,31]. CD has a truncated cone shape with a hydrophilic outer surface and a hydrophobic inner cavity. The hydrophilic surface allows CD for preparation in an aqueous solution and the hydrophobic cavity provides the ability to encapsulate a hydrophobic active compound to form an inclusion complex [32]. Primary cyclodextrin is available in three forms: α-cyclodextrin (αCD; 6 glucose units), β-cyclodextrin (βCD; 7 glucose units), and γ-cyclodextrin (γCD; 8 glucose units) with cavity sizes of 0.47–0.83 nm [11, 33]. Several works have reported the inclusion complex preparation using βCD and its derivatives to increase the efficacy of pure plumbagin [16,17,18].

Computer simulations can be employed to investigate the stability, host–guest interactions, and proper conditions for plumbagin inclusion complex formation with αCD, βCD, and γCD. Our previous work reported the molecular interactions of plumbagin inclusion complexes with βCD and its two derivatives in aqueous phase using computer simulations [20]. There are two different conformations of plumbagin inside the βCD cavity with 1:1 host–guest molar ratio. However, there is no report of simulations and experiments on the inclusion complexes of plumbagin using αCD and γCD.

In pharmaceutical and food industries, the solid inclusion complex of plumbagin provides the ease in product storage and transportation. The solid complex can be formed by co-precipitation and freeze-drying. Co-precipitation is a widely used technique in lab-scale to obtain small amount of a solid complex, which can be used to evaluate complex formation and characterization. However, this technique is not efficient in industrial-scale production due to a large amount of solvent and wastewater disposal [34]. Freeze-drying is one of the attractive techniques for industrial-scale production of the inclusion complex, as it utilizes low temperatures to minimize the loss of heat-labile guest molecules during the process [24]. In this study, co-precipitation was used for lab-scale production using pure plumbagin while freeze-drying was used for industrial-scale production using extracted plumbagin from Plumbago indica root, which contains other compounds besides plumbagin. The conditions of these two techniques were also evaluated along with the economic considerations for the feasible industrial production. Moreover, there is no report on the differences in encapsulation efficiency and preservation capability between the inclusion complex formation from pure plumbagin and extracted plumbagin from Plumbago indica root.

Therefore, the objectives of this study are to: (1) investigate the possibility and host–guest molar ratio of the plumbagin/αCD, plumbagin/βCD, and plumbagin/γCD inclusion complex formations using computer simulation, (2) evaluate the complex formation of pure plumbagin with CDs using co-precipitation, (3) evaluate the complex formation of extracted plumbagin from Plumbago indica root by freeze-drying for scaling up and industrial production, and (4) investigate the preservation capability of the complexes using pure plumbagin and extracted plumbagin. The encapsulation technique in this study can effectively preserve plumbagin from storage environment. Other active compounds of interest to the pharmaceutical and food industries may also be preserved by utilizing the techniques outlined in this study.

Materials and methods

Computational simulation method

Molecular structure construction

The crystal structures of plumbagin, αCD, βCD, and γCD were obtained from Cambridge Crystallographic Data Centre [35] with the CSD entries: PVVAQS01 [36], BANXUJ [37], BCDEXD03 [38], and CIWMIE10 [39], respectively. Hydrogen atoms were added into the structures, and the structures were fully optimized by the semi-empirical quantum mechanical PM6 method using the Gaussian 16 software package [40].

Molecular docking calculation

The AutoDock 4.2.6 software [41] with the Lamarckian Genetic algorithm [42] was used to generate the possible conformations of plumbagin/CD inclusion complexes. The first step was to prepare of the guest (plumbagin) and host (CDs) molecule coordinate files, delete the non-polar hydrogen atoms, and merge their charges with the carbon atoms. The rotatable bonds of the guest molecule were defined while the host molecules were kept fixed. The systems were investigated in a three-dimensional volume divided into many small grid boxes with a grid spacing of 0.375 Å. The grid center of the boxes was set at the center of the host molecules. The boxes have (x × y × z) dimensions of (12.75 Å × 12.75 Å × 7.50 Å), (13.50 Å × 13.50 Å × 7.50 Å) and (16.50 Å × 16.50 Å × 7.50 Å) for αCD, βCD, and γCD, respectively. One hundred docking calculations were performed on each host–guest complex. The results were clustered to identify similar conformations based on all-atom root mean square deviation within 2 Å. At the end of the molecular docking calculations, the representative docked conformations with the lowest energy from molecular docking were selected for further full geometry optimization.

Complex formation energy calculation

The possible conformations from docking calculations of plumbagin/CD inclusion complexes were then constructed and fully geometry optimized by the PM6 method, in which all atoms were allowed to move freely. The most stable conformation of the complexes was evaluated by the complex formation energy (∆E) using Eq. (1).

where EPL/CD, EPL, and ECD are the heat of formations of the complex, plumbagin, and CD, respectively.

Materials

Plumbagin (99.9%, Acros Organics, Geel, Belgium) was used as the guest molecule, αCD (98.0%, Tokyo Chemical Industry, Tokyo, Japan), βCD (97.0%, Sigma-Aldrich, Missouri, USA), and γCD (99.0%, Tokyo Chemical Industry, Tokyo, Japan) were used as the host molecules in this study. Ethanol (99.9%, Merck, Massachusetts, USA) was used as the co-solvent in the inclusion complex preparation. Plumbago indica root powder (TPC Herb, Bangkok, Thailand) was used to obtain the crude extract by maceration in ethanol (95.0%, Spread Business, Pathum Thani, Thailand).

Phase solubility studies and thermodynamic parameters of inclusion complex formation

The phase solubility study [43] was performed to investigate the effect of αCD, βCD, and γCD to the plumbagin solubility. CDs were dissolved in deionized water to prepare the solutions with concentrations of 0 to 16 mM in sealed conical flasks. Ten milligrams of plumbagin (0.05 mmol) was added into 10 mL of each CD solution to form the inclusion complex. The mixtures were shaken in a thermostatic incubator (Model: NB-205V, N-Biotek, Gyeonggi-do, Korea) protected from light at 25 °C and 150 rpm for 48 h to attain the equilibrium. The mixtures were then filtered to separate undissolved plumbagin from the solution. The amount of dissolved plumbagin in filtrate was determined by HPLC. The phase solubility of plumbagin/βCD was also studied at 35 °C and 45 °C with the same procedure to determine the stability constant (KC). The value of KC of the complex can be calculated from the slope of the linear portion of the phase solubility profile at different temperatures using the Eq. (2).

where S0 is the intrinsic solubility of plumbagin in the absence of CD.

The thermodynamic parameters, including enthalpy change (∆H) and entropy change (∆S) of the complex formation were calculated using the van’t Hoff equation shown in the Eq. (3) [14, 44, 45].

Determination of host–guest molar ratio by Job’s method

The continuous variation method (Job’s method) was used to investigate the changes in absorbance of an inclusion complex solution for determination of an inclusion complex host–guest molar ratio. Plumbagin and βCD solutions were prepared in deionized water and mixed at different molar ratios (R) to make up the total solution of 0.3 mM. The absorbance of plumbagin was recorded at 254 nm and 25 °C using an UV/Visible spectrometer (Model: Genesys 10S, Thermo Fisher Scientific, Massachusetts, USA). The changes in absorbance multiplied by molar ratio, i.e., ∆A·R, were plotted with R to obtain the Job’s plot.

Preparation of plumbagin/CD inclusion complexes

Inclusion complex formation of pure plumbagin with CDs by co-precipitation

The plumbagin/CD inclusion complexes were prepared by mixing 400 mg of CDs in 50 vol% ethanol–water solution and plumbagin with the host–guest molar ratio of 1:1. The mixture was shaken in an orbital shaker (Model: NB-101M, N-Biotek, Gyeonggi-do, Korea) at 25 °C for 48 h. The solution was then kept in a refrigerator overnight to precipitate the plumbagin/CD inclusion complexes. The solid complexes were filtered, dried in an oven at 40 °C for 24 h, and then kept at − 20 °C prior to the characterization.

Effects of solvent in complex formation

Plumbagin dissolves well in ethanol but poorly dissolves in water. In order to encapsulate plumbagin by βCD in the form of inclusion complex, the effect of solvent (ethanol–water system) at various concentrations was evaluated. βCD (400 mg) was dissolved in 20 mL of 0, 30, 50, and 70 vol% of ethanol–water solutions. Plumbagin with the host–guest molar ratio of 1:1 was added to each βCD solution. The solution was then filtered to get rid of undissolved plumbagin. The solution was then kept in a refrigerator overnight to obtain the inclusion complex. The solid complex was filtered, dried in an oven at 40 °C for 24 h, and then kept at − 20 °C to prevent the loss of plumbagin prior to the composition analysis.

To determine the amount of plumbagin in the complex, plumbagin in the solid complex was extracted by 99.9% ethanol at 40 °C for 60 min using sonication (Crest Ultrasonics, New Jersey, USA) in a closed system. The solid βCD, which is not dissolved in pure ethanol, was filtered out. The amount of plumbagin in the solution was determined by using HPLC. The encapsulation efficiency was calculated using the Eq. (4).

The percentage of undissolved plumbagin and encapsulation efficiency are summarized in Table 1. Hence the appropriate concentration for complex formation in this study is 50 vol% of ethanol–water solution.

Inclusion complex formation of extracted plumbagin with βCD by freeze-drying

The Plumbago indica extract was prepared by maceration of the Plumbago indica root powder in ethanol with a 30-min sonication twice a day for 3 days. The filtered solution was concentrated and dried using a rotary evaporator (Model: R3, Büchi, Flawil, Switzerland) at 45 °C and 175 mbar with cooling water at 4 °C. The Plumbago indica extract was kept at − 20 °C before use. The yield was 0.37 mg of plumbagin/g of root.

The inclusion complex formation of extracted plumbagin was performed by an addition of extracted plumbagin to βCD in 50 vol% of ethanol–water solution. Since the Plumbago indica extract contains other compounds [46], the host–guest molar ratio was varied as 1:1, 3:1, and 5:1 to investigate a proper molar ratio. The mixture was shaken at 25 °C for 48 h. The obtained solution was concentrated by using a rotary evaporator prior to freeze-drying (Model: Freeze Dryer − 55 °C, Operon, Gyeonggi-do, Korea). The freeze-dried complex was kept at − 20 °C. The amount of encapsulated plumbagin after extracted by ethanol was determined by HPLC. The encapsulation efficiency was calculated using the Eq. (4).

Characterization of plumbagin/CD inclusion complexes

X-ray diffractometry (XRD)

The crystal structures of plumbagin/αCD, plumbagin/βCD, and plumbagin/γCD inclusion complexes were characterized by a X′Pert PRO diffractometer (PANalytical, Almelo, the Netherlands). Pure plumbagin, αCD, βCD, γCD, and physical mixtures were used to make comparisons. The physical mixtures of plumbagin and CDs were prepared by mixing plumbagin directly into each CD at 1:1 molar ratio. XRD was operated with a Ni-filter, a Cu Kα1 radiation, a voltage of 40 kV, and a current of 45 mA at 25 °C. The XRD patterns of the samples were recorded between 2θ of 3° and 40° with a step size of 0.02° and a step time of 0.5 s.

Fourier-transform infrared spectroscopy (FTIR)

The functional groups of the inclusion complexes were analyzed by a Nicolet iS50 FTIR spectrometer (Thermo Fisher Scientific, Massachusetts, USA). Solid samples for FTIR were prepared by mixing 1 wt% of each sample in spectral grade potassium bromide (Specac, Pennsylvania, USA) and pressed into thin disks. The spectrograms were recorded at wavenumbers between 400 and 4000 cm−1 with 16 scans and a resolution of 4 cm−1 in the transmission mode.

Differential scanning calorimetry (DSC)

The energy changes of the inclusion complexes were characterized by a DSC 1 (Mettler-Toledo, Ohio, USA). Each solid sample of 5 mg was placed in an aluminum crucible. The samples were heated from 30 to 200 °C at 10 °C/min under N2 with a flowrate of 50 mL/min.

Thermogravimetric analysis (TGA)

The thermal analysis of the inclusion complexes was performed on a TGA/DSC 3+ HT/1600/219 (Mettler-Toledo, Ohio, USA). The samples were weighed and placed in alumina crucibles. The samples were heated from 30 to 500 °C at 10 °C/min under N2 with a flowrate of 50 mL/min.

High performance liquid chromatography (HPLC)

The amount of plumbagin was determined by a 1260 Infinity II LC system (Agilent Technologies, California, USA) equipped with a quaternary pump (Model: G7111A), a vial sampler (Model: G7129A), a multicolumn thermostat (Model: G7116A), and a variable wavelength detector (Model: G7114A). The separation was performed on a Luna 5 µm C18(2) 100 Å, 250 mm × 4.6 mm column (Phenomenex, California, USA) controlled at 25 °C with an isocratic elution using 60 vol% of HPLC grade acetonitrile (RCI Labscan, Bangkok, Thailand) in aqueous solution at 1 mL/min flow rate. The injection volume was set at 10 µL and the separated compound was detected at 254 nm.

Evaluation of preservation capability of inclusion complex

The plumbagin/βCD inclusion complex and plumbagin in free form were exposed at 25 °C and 50 °C with a duration of 4 weeks in order to evaluate the plumbagin stability of both forms. Each sample of 10 mg was kept separately in batch mode. The remaining plumbagin after exposure was extracted by 99.9% ethanol (Merck, Massachusetts, USA) and determined by HPLC. The stability of extracted plumbagin from the Plumbago indica root in both inclusion complex and free form were also carried out using the same procedure with a duration of 6 weeks.

Results and discussion

Computational simulations of plumbagin/CD inclusion complexes

Molecular docking of inclusion complexes

The molecular docking technique was used to determine the possibility of binding between plumbagin and CDs by considering the complex binding energy. The docking was performed by fixing the host molecules and allowing the guest molecule to be flexible in the specified grid box. The binding energy of the complexes is presented in Table 2.

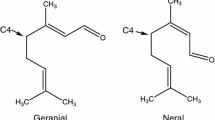

The calculations indicate three possible conformations of 1:1 host–guest molar ratio for all CD systems, as shown in Fig. 1. In conformation I, the hydroxyl phenolic group of plumbagin was placed in the CD’s cavity and located near the narrow-side of the host molecule. In conformation II, the methyl quinone group of plumbagin was placed in the cavity of CD and located near the narrow-side of the host molecule. Another model, conformation III, the naphthoquinone ring was inserted into the CD cavity, where its hydroxyl phenolic group located near the narrow-side of CD. However, the naphthoquinone ring in conformation III was oriented in different angles, compared with that in conformation I as shown in Fig. 1.

According to the size of CD, only conformation I was favorable for plumbagin/αCD, both conformation I and II were found in plumbagin/βCD, and only conformation III was favorable for plumbagin/γCD. However, the rigidity of the host molecules in the docking calculations was not similar to reality. Therefore, the semi-empirical PM6 calculation was further used to investigate the molecular interactions between plumbagin with three different CDs.

Energy of complex formation

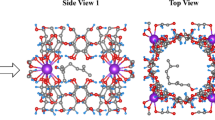

The inclusion complex of plumbagin with each CD systems was suggested by docking calculations. Both of conformation I and II were constructed for αCD and βCD. Plumbagin was possible to form the complex with γCD in all conformations due to the large cavity diameter of γCD. All complex conformations were then fully optimized by the PM6 method which provides the free motions for both host and guest molecules as shown in Fig. 2.

From the PM6 results, Tables 3 and 4 list the heat of formation and complex formation energy of minimized free compounds and inclusion complexes in this study. The negative values of the energy indicate possible formations of the plumbagin inclusion complexes with all CDs in this study. The lower value of complex formation energy indicates more favorable inclusion complex formation. The results show that the favorable formation is related to the cavity size of CDs, where the larger cavity leads to more favorable inclusion complex formation as follows: γCD > βCD > αCD. Moreover, the simulation shows that the favorable formation can occur at 1:1 host–guest molar ratio of plumbagin with three different CDs.

Table 5 presents the distance of intermolecular hydrogen bonds which are found in the PM6 minimized inclusion complex structures. Three types of hydrogen bonds were established between plumbagin and CD at the positions assigned in Fig. 3. The first type of hydrogen bonds, which is often found in the inclusion complex systems, occurred between an ether-like anomeric oxygen atom of CD and a hydrogen atom of plumbagin’s hydroxyl group (O4(CD)⋯H(OH−PL)). The second type occurred between an oxygen atom of plumbagin’s carbonyl group and the hydrogen atom of the secondary hydroxyl group at O3 of CD (O(CO−PL)⋯H(O3H−CD)) or the hydrogen atom of the primary hydroxyl group at O6 of CD (O(CO−PL)⋯H(O6H−CD)). The last type occurred between an oxygen atom of plumbagin’s hydroxyl group and the hydrogen atom of the secondary hydroxyl group at O3 of CD (O(OH−PL)⋯H(O3H−CD)) or the hydrogen atom of the primary hydroxyl group at O6 of CD (O(OH−PL)⋯H(O6H−CD)).

In this work, the theoretical configuration and molecular interaction of plumbagin/βCD inclusion complexes in gas phase, calculated using the PM6 method, agree with the previous work, which was calculated using the PM6 method in aqueous phase [20]. Both results suggest that conformation I and conformation II are favorable, with the complex formation energy (∆E) differences of 15.07 kJ mol−1 and 0.13 kJ mol−1, in gas phase and aqueous phase, respectively.

Phase solubility of plumbagin/CDs

The phase solubility of plumbagin/CDs was conducted to validate the simulation results. Figure 4a shows that CDs increase the plumbagin solubility in aqueous solution. However, αCD slightly increases the plumbagin solubility, compared to βCD and γCD. The results correspond to the simulation prediction (αCD < βCD < γCD) at low concentration of CDs below 1 mM. The behavior agrees well with simulations, which was performed in gas phase. At high concentration, the phase solubility diagram of plumbagin/γCD does not follow the simulations and shows a reduction of plumbagin solubility due to the self-aggregation of γCD [47] as evidenced by the precipitate formation in the experiment. The phase solubility diagram in Fig. 4a also shows that βCD exhibits the complex formation in a wide range of βCD concentration. The phase solubility diagram of plumbagin/βCD at 25 °C is linear with the slope less than one, which can be classified as AL type indicated 1:1 host–guest molar ratio [43]. The phase solubility of plumbagin/βCD was also performed at 35 °C and 45 °C as shown in Fig. 4b, which can be also classified as AL type at these given temperatures.

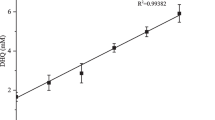

The slope and y-intercept (S0) of the phase solubility diagram were used to determine the stability constant (KC) at different temperatures as listed in Table 6. The value of KC was used to evaluate the thermodynamic properties of the complex formation.

Figure 5 shows the van’t Hoff plot from KC at different temperatures, in which the slope and y-intercept were used to calculate ∆H and ∆S of the complex formation. The calculated ∆H of − 14.85 kJ mol−1 shows the exothermic complex formation and indicates the weak interaction between plumbagin and βCD, such as hydrophobic interactions, van der Waals interactions, and hydrogen bonds [14], which correspond to the modeled complex in Table 5. The ∆S value of − 10.70 J mol−1 K−1 indicates that the plumbagin movement in βCD cavity is restricted by the host–guest interactions. The value of ∆G at 25 °C of − 11.66 kJ mol−1 indicates that the plumbagin/βCD inclusion complex formation is spontaneous.

Determination of host–guest molar ratio by Job’s method

Figure 6 shows the Job’s plot of the plumbagin/βCD inclusion complex system. The Job’s plot of plumbagin/βCD inclusion complex system exhibits the highest point on the curve at the molar ratio of host and guest (R) is 0.5. According to the Job’s method, the host–guest molar ratio of the complex is determined by the molar ratio (R) at the highest point of ∆A·R. The results suggest that the host–guest molar ratio of plumbagin/βCD inclusion complex system is at 1:1, which corresponds to the phase solubility results.

Characterization of plumbagin/CD inclusion complexes

X-ray diffractometry (XRD)

Figure 7 illustrates the XRD patterns of the plumbagin/αCD, plumbagin/βCD, and plumbagin/γCD inclusion complexes, compared to plumbagin, CDs, and their physical mixtures. The symbols (filled square, filled circle, open square, open circle) notify the changes of XRD pattern between inclusion complex and physical mixture to indicate the complex formation.

The XRD patterns of plumbagin and CDs contain peaks that indicate the crystalline nature of the compounds. The characteristic peaks of plumbagin locate at 2θ of 11.45°, 13.27°, 18.65°, 23.03°, 26.09°, and 26.51°. The XRD patterns of the physical mixtures show the peak combination of plumbagin and CDs in free form. The XRD patterns of plumbagin/βCD and plumbagin/γCD complexes exhibit the different patterns, compared to those of physical mixtures. The plumbagin/βCD complex pattern shows the disappearance of plumbagin’s peaks at 11.45°, 23.03°, 26.09°, and 26.51°, indicated by the filled circle symbols. A new peak, indicated by the filled square symbol, was found at 5.87°. For the plumbagin/γCD complex, the disappearance of plumbagin’s peaks at 11.45°, 13.27°, 23.03°, 26.09° also occured as indicated by the open circle symbols, and a new peak was also found at 7.53°, indicated by the open square symbols. The XRD results indicate the differences in the crystal structure of plumbagin/βCD and plumbagin/γCD inclusion complexes, compared to their physical mixture. In contrast, the plumbagin/αCD complex and the physical mixture show the same XRD patterns which indicate the same crystal structure.

Fourier-transform infrared spectroscopy (FTIR)

Figure 8 illustrates the FTIR spectra of the inclusion complexes, physical mixtures, and pure compounds. The characteristic peaks of plumbagin were observed as follows: (1) ring stretching (1258 cm−1), (2) combined modes of ring stretching, O–H in plane bending, and aromatic C–H in plane bending (1455 cm−1), (3) C=C stretching (1608 cm−1), (4) combined modes of C=O stretching and C=C stretching (1644 cm−1), and (5) combined modes of C=O stretching and C=C stretching (1663 cm−1) [48]. The physical mixtures of plumbagin and CDs exhibit the combination of peaks corresponding to both plumbagin and CDs in free form without any significant peak shift.

The IR spectra of plumbagin/βCD and plumbagin/γCD complexes reveal the shift of peak from their physical mixtures. The plumbagin/βCD complex exhibits peak shifts from the spectrum of physical mixture at 1262, 1461, 1615, 1646, and 1675 cm−1. The plumbagin/γCD complex also shows the peak shifts at 1260, 1458, 1615, and 1646 cm−1. The plumbagin/βCD and plumbagin/γCD complexes show the differences in the interactions between plumbagin and CDs, compared to the physical mixtures. For the plumbagin/αCD complex, there is no peak shift observed in the spectrum of the complex. The FTIR results agree with the XRD results as the plumbagin/αCD complex shows no difference from the physical mixture.

Differential scanning calorimetry (DSC)

Figure 9 shows the DSC curves of plumbagin/CD inclusion complexes. For the pure compound, plumbagin shows an endothermic peak from its melting point at 79 °C. The DSC curves of the physical mixtures and the plumbagin/αCD complex show the peaks of plumbagin’s melting point at the same temperature as the pure compound. In contrast, the plumbagin/βCD and plumbagin/γCD complexes show no plumbagin’s melting point peak at 79 °C. The missing peak of plumbagin’s melting point indicates the encapsulation of plumbagin by βCD and γCD.

Thermogravimetric analysis (TGA)

Figure 10 illustrates the TG and DTG curves of the compounds in this study. All CDs have two steps of weight loss from water and thermal decomposition. The weight loss of pure plumbagin starts to be observed at 110 °C and continues up to 240 °C. The DTG curves of physical mixtures shows the same temperatures of weight loss as observed in pure CDs and plumbagin. DTG curve of plumbagin/αCD complex is similar to that of physical mixture which shows no evidence of complex formation as shown in Fig. 10b.

In contrast, plumbagin/βCD and plumbagin/γCD complexes show no weight loss of plumbagin as shown in Fig. 10d, f, respectively. The missing weight loss of plumbagin indicates the encapsulation of plumbagin by βCD and γCD.

The XRD, FTIR, DSC, and TGA results indicate that plumbagin can form the inclusion complexes with βCD and γCD but not with αCD. From the phase solubility results, the plumbagin/γCD complex suffers from agglomeration of the complex in water at high concentration. The plumbagin can form the inclusion complex with βCD at wide range of concentration and βCD is relatively cheap, compared to other CDs. Therefore, βCD was selected as the proper host to form the inclusion complex with pure plumbagin and extracted plumbagin from Plumbago indica root in this study.

Preservation capability of pure plumbagin/βCD inclusion complex prepared by co-precipitation

The plumbagin/βCD inclusion complex and plumbagin in free form were exposed to the surrounding at 25 °C and 50 °C for 4 weeks to evaluate the preservation capability of the complex. Figure 11 shows the comparison of the preservation capabilities between plumbagin in free form and complex. Plumbagin in free form decreases as the storage duration increases. After 4 weeks, plumbagin remained at 81.67% at 25 °C and 70.43% at 50 °C. The results show that plumbagin in free form is not stable.

The inclusion complex shows a significant increment in stability as evidenced by a much slower plumbagin losing rate relative to that of plumbagin in free form. After 4 weeks, plumbagin in the complex remained at 97.20% at 25 °C and 93.46% at 50 °C. The encapsulation of plumbagin by βCD can be used to increase the stability of plumbagin in lab-scale. In real production, it is very difficult and costly for the purification of active compound. Therefore, the scale-up process of complex formation from Plumbago indica extract using freeze-drying was also investigated.

Preparation of plumbagin/βCD inclusion complex from Plumbago indica extract prepared by freeze-drying

Table 7 lists the encapsulation efficiency of complex prepared from the Plumbago indica extract by different host–guest molar ratios. The ratios were based on the amount of extracted plumbagin from Plumbago indica root. The encapsulation efficiency increases as the host–guest molar ratio increases up to 5:1. Unlike the complex formation of pure plumbagin, various compounds in the extract [46] can also compete with plumbagin to form the complex with βCD. The complex of extracted plumbagin might not follow the AL type (1:1 host–guest molar ratio) as the complex of pure plumbagin. Therefore, the host–guest molar ratio for plumbagin/βCD inclusion complex from the extract is an important factor to be considered for the industrial scale-up.

Preservation capability of plumbagin/βCD inclusion complex from Plumbago indica extract prepared by freeze-drying

Preservation of extracted plumbagin from Plumbago indica root in form of inclusion complex was evaluated at 25 °C and 50 °C for 6 weeks, compared to that of crude extract as shown in Fig. 12. The extracted plumbagin in form of crude extract remained at 38.64% at 25 °C and 22.68% at 50 °C after 6 weeks. The results show that the extracted plumbagin is not stable.

The inclusion complex shows an increment in the stability of plumbagin. Plumbagin decreases at a slower rate, compared to that of extracted plumbagin. After 6 weeks, plumbagin in form of complex remained at 62.41% at 25 °C and 60.26% at 50 °C. The encapsulation of plumbagin by βCD can be used to increase the stability of extracted plumbagin from Plumbago indica root in industrial-scale production using freeze-drying.

Conclusion

Encapsulation of plumbagin using αCD, βCD, and γCD were investigated, based on the simulation results of 1:1 host–guest molar ratio. The inclusion complexes of plumbagin using CDs were performed and found that plumbagin can form the complex only with βCD and γCD but not with αCD, evidenced by XRD, FTIR, DSC, and TGA results. The phase solubility study shows that βCD can form the complex formation in a wide range of concentration without agglomeration. The Job’s method confirms 1:1 host–guest molar ratio and agrees well with the simulation results of the spontaneous formation of plumbagin/βCD inclusion complex. The inclusion complex of pure plumbagin and extracted plumbagin from Plumbago indica root with βCD were performed by co-precipitation and freeze-drying, respectively to evaluate the preservation capability of plumbagin. The inclusion complexes can increase the preservation capability of plumbagin up to three-folds of the pure compound at a high storage temperature of 50 °C. Therefore, the encapsulation technique using CDs can serve as the preservation technique for the active compounds from plants in pharmaceutical and food products to maintain the quality and increase the shelf life of the products.

References

Padhye, S., Dandawate, P., Yusufi, M., Ahmad, A., Sarkar, F.: Perspectives on medicinal properties of plumbagin and its analogs. Med. Res. Rev. 32, 1131–1158 (2012)

Gangopadhyay, M., Sircar, D., Mitra, A., Bhattacharya, S.: Hairy root culture of Plumbago indica as a potential source for plumbagin. Biol. Plant. 52, 533–537 (2008)

Rattarom, R., Sakpakdeejaroen, I., Itharat, A.: Cytotoxic effects of the ethanolic extract from Benjakul formula and its compounds on human lung cancer cells. Thai J. Pharmacol. 32, 99–101 (2010)

Kaewbumrung, S., Panichayupakaranant, P.: Antibacterial activity of plumbagin derivative-rich Plumbago indica root extracts and chemical stability. Nat. Prod. Res. 28, 835–837 (2014)

Kuo, P.-L., Hsu, Y.-L., Cho, C.-Y.: Plumbagin induces G2-M arrest and autophagy by inhibiting the AKT/mammalian target of rapamycin pathway in breast cancer cells. Mol. Cancer Ther. 5, 3209–3221 (2006)

Checker, R., Sharma, D., Sandur, S.K., Khanam, S., Poduval, T.B.: Anti-inflammatory effects of plumbagin are mediated by inhibition of NF-kappaB activation in lymphocytes. Int. Immunopharmacol. 9, 949–958 (2009)

Tilak, J.C., Adhikari, S., Devasagayam, T.P.: a: Antioxidant properties of Plumbago zeylanica, an Indian medicinal plant and its active ingredient, plumbagin. Redox Rep. 9, 219–227 (2004)

Sharma, I., Gusain, D., Dixit, V.P.: Hypolipidaemic and antiatherosclerotic effects of plumbagin in rabbits. Indian J. Physiol. Pharmacol. 35, 10–14 (1991)

Pinho, E., Grootveld, M., Soares, G., Henriques, M.: Cyclodextrins as encapsulation agents for plant bioactive compounds. Carbohydr. Polym. 101, 121–135 (2014)

Popielec, A., Loftsson, T.: Effects of cyclodextrins on the chemical stability of drugs. Int. J. Pharm. 531, 532–542 (2017)

Szejtli, J.: Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 98, 1743–1754 (1998)

Koontz, J.L., Marcy, J.E., Barbeau, W.E., Duncan, S.E.: Stability of natamycin and its cyclodextrin inclusion complexes in aqueous solution. J. Agric. Food Chem. 51, 7111–7114 (2003)

Bhandari, B.R., D’Arcy, B.R., Padukka, I.: Encapsulation of lemon oil by paste method using β-cyclodextrin: encapsulation efficiency and profile of oil volatiles. J. Agric. Food Chem. 47, 5194–5197 (1999)

Mourtzinos, I., Salta, F., Yannakopoulou, K., Chiou, A., Karathanos, V.T.: Encapsulation of olive leaf extract in β-cyclodextrin. J. Agric. Food Chem. 55, 8088–8094 (2007)

Bothiraja, C., Kapare, H.S., Pawar, A.P., Shaikh, K.S.: Development of plumbagin-loaded phospholipid-Tween® 80 mixed micelles: Formulation, optimization, effect on breast cancer cells and human blood/serum compatibility testing. Ther. Deliv. 4, 1247–1259 (2013)

D’Souza, R., Singh, U.V., Aithal, K.S., Udupa, N.: Antifertility activity of niosomal HPβCD-plumbagin complex. Indian J. Pharm. Sci. 60, 36 (1998)

Singh, U.V., Udupa, N.: Reduced toxicity and enhanced antitumor efficacy of betacyclodextrin plumbagin inclusion complex in mice bearing Ehrlich ascites carcinoma. Indian J. Physiol. Pharmacol. 41, 171–175 (1997)

Oommen, E., Shenoy, B.D., Udupa, N., Kamath, R., Devi, P.U.: Antitumour efficacy of cyclodextrin-complexed and niosome—encapsulated plumbagin in mice bearing melanoma B16F1. Pharm. Pharmacol. Commun. 5, 281–285 (1999)

Sunil Kumar, M.R., Kiran Aithal, B., Udupa, N., Sreenivasulu Reddy, M., Raakesh, V., Murthy, R.S.R., Prudhvi Raju, D., Rao, S.: B.S.: Formulation of plumbagin loaded long circulating pegylated liposomes: In vivo evaluation in C57BL/6J mice bearing B16F1 melanoma. Drug Deliv. 18, 511–522 (2011)

Srihakulung, O., Maezono, R., Toochinda, P., Kongprawechnon, W., Intarapanich, A., Lawtrakul, L.: Host-guest interactions of plumbagin with β-cyclodextrin, dimethyl-β-cyclodextrin and hydroxypropyl-β-cyclodextrin: Semi-empirical quantum mechanical PM6 and PM7 methods. Sci. Pharm. 86, 1–11 (2018)

Astray, G., Gonzalez-Barreiro, C., Mejuto, J.C., Rial-Otero, R., Simal-Gandara, J.: A review on the use of cyclodextrins in foods. Food Hydrocoll. 23, 1631–1640 (2009)

Cravotto, G., Binello, A., Baranelli, E., Carraro, P., Trotta, F.: Cyclodextrins as food additives and in food processing. Curr. Nutr. Food Sci. 2, 343–350 (2006)

Jug, M., Beaeireviae-Laaean, M.: Cyclodextrin-based pharmaceuticals. Radiat. Med. Sci. 499, 9–26 (2008)

Del Valle, E.M.M.: Cyclodextrins and their uses: a review. Process Biochem. 39, 1033–1046 (2004)

Davis, M., Brewster, E.: M.: Cyclodextrin-based pharmaceutics: past, present and future. Nat. Rev. Drug Discov. 3, 1023–1035 (2004)

Buschmann, H.-J., Schollmeyer, E.: Applications of cyclodextrins in cosmetic products: a review. J. Cosmet. Sci. 53, 185–191 (2002)

Viernstein, H., Weiss-Greiler, P., Wolschann, P.: Solubility enhancement of low soluble biologically active compounds by beta-cyclodextrin and dimethyl-beta-cyclodextrin. J. Incl. Phenom. Macrocycl. Chem. 44, 235–239 (2002)

Savic, I.M., Savic-Gajic, I.M., Nikolic, V.D., Nikolic, L.B., Radovanovic, B.C., Milenkovic-Andjelkovic, A.: Enhencemnet of solubility and photostability of rutin by complexation with β-cyclodextrin and (2-hydroxypropyl)-β-cyclodextrin. J. Incl. Phenom. Macrocycl. Chem. 86, 33–43 (2016)

Lo Nostro, P., Fratoni, L., Baglioni, P.: Modification of a cellulosic fabric with β-cyclodextrin for textile finishing applications. J. Incl. Phenom. Macrocycl. Chem. 44, 423–427 (2002)

Layre, A.M., Gosselet, N.M., Renard, E., Sebille, B., Amiel, C.: Comparison of the complexation of cosmetical and pharmaceutical compounds with gamma-cyclodextrin, 2-hydroxypropyl-beta-cyclodextrin and water-soluble beta-cyclodextrin-co-epichlorhydrin polymers. J. Incl. Phenom. Macrocycl. Chem. 43, 311–317 (2002)

Batt, D.K., Garala, K.C.: Preparation and evaluation of inclusion complexes of diacerein with β-cyclodextrin and hydroxypropyl β-cyclodextrin. J. Incl. Phenom. Macrocycl. Chem. 77, 471–481 (2013)

Crini, G.: Review: a history of cyclodextrins. Chem. Rev. 114, 10940–10975 (2014)

Li, S.: Cyclodextrins and their applications in analytical chemistry. Chem. Rev. 92, 1457–1470 (1992)

Hedges, A.R.: Industrial applications of cyclodextrins. Chem. Rev. 98, 2035–2044 (1998)

Allen, F.H.: The Cambridge structural database: a quarter of a million crystal structures and rising. Acta Crystallogr. B. 58, 380–388 (2002)

Vijayalakshmi, J., Rajan, S.S., Srinivasan, R.: Structure of plumbagin. Acta Crystallogr. C43, 2375–2377 (1987)

Chacko, K.K., Saenger, W.: Topography of cyclodextrin inclusion complexes. 15. Crystal and molecular structure of the cyclohexaamylose-7.57 water complex, form III. Four- and six-membered circular hydrogen bonds. J. Am. Chem. Soc. 103, 1708–1715 (1981)

Steiner, T., Koellner, G.: Crystalline β-cyclodextrin hydrate at various humidities: fast, continuous, and reversible dehydration studied by X-ray diffraction. J. Am. Chem. Soc. 116, 5122–5128 (1994)

Harata, K.: The structure of the cyclodextrin complex. XX. Crystal structure of uncomplexed hydrated γ-cyclodextrin. Bull. Chem. Soc. Jpn. 60, 2763–2767 (1987)

Frisch, M.J., Trucks, G.W., Schlegel, H.B., Scuseria, G.E., Robb, M.A., Cheeseman, J.R., Scalmani, G., Barone, V., Petersson, G.A., Nakatsuji, H.: Gaussian 16 Revision A. 03. 2016. Gaussian Inc., Wallingford (2016)

Morris, G.M., Huey, R., Lindstrom, W., Sanner, M.F., Belew, R.K., Goodsell, D.S., Olson, A.J.: AutoDock4 and AutoDockTools4: automated docking with selective receptor flexibility. J. Comput. Chem. 30, 2785–2791 (2009)

Morris, G.M., Goodsell, D.S., Halliday, R.S., Huey, R., Hart, W.E., Belew, R.K., Olson, A.J.: Automated docking using a Lamarckian genetic algorithm and an empirical binding free energy function. J. Comput. Chem. 19, 1639–1662 (1998)

Higuchi, T., Connors, K.A.: Phase solubility technique. Adv. Anal. Chem. Instrum. 4, 117–212 (1965)

Wei, Y., Zhang, J., Zhou, Y., Bei, W., Li, Y., Yuan, Q., Liang, H.: Characterization of glabridin/hydroxypropyl-β-cyclodextrin inclusion complex with robust solubility and enhanced bioactivity. Carbohydr. Polym. 159, 152–160 (2017)

Tommasini, S., Raneri, D., Ficarra, R., Calabrò, M.L., Stancanelli, R., Ficarra, P.: Improvement in solubility and dissolution rate of flavonoids by complexation with β-cyclodextrin. J. Pharm. Biomed. Anal. 35, 379–387 (2004)

Kapadia, N.S., Isarani, S.A., Shah, M.B.: A simple method for isolation of plumbagin from roots of Plumbago rosea. Pharm. Biol. 43, 551–553 (2005)

Szente, L., Szejtli, J., Kis, G.L.: Spontaneous opalescence of aqueous gamma-cyclodextrin solutions: complex formation or self-aggregation? J. Pharm. Sci. 87, 778–781 (1998)

Sajan, D., Laladhas, K.P., Joe, I.H., Jayakumar, V.S.: Vibrational spectra and density functional theoretical calculations on the antitumor drug, plumbagin. J. Raman Spectrosc. 36, 1001–1011 (2005)

Acknowledgements

This study was financial supported by the Tobacco Authority of Thailand and the scholarship for the Excellent Thai Student (ETS) of Sirindhorn International Institute of Technology (SIIT), Thammasat University. The authors gratefully acknowledge the Center of Scientific Equipment for Advanced Research, Thammasat University (TUCSEAR) for providing an access to the analytical instruments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sinlikhitkul, N., Toochinda, P., Lawtrakul, L. et al. Encapsulation of plumbagin using cyclodextrins to enhance plumbagin stability: computational simulation, preparation, characterization, and application. J Incl Phenom Macrocycl Chem 93, 229–243 (2019). https://doi.org/10.1007/s10847-018-0870-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-018-0870-5