Abstract

The addition effects of cyclodextrin (CD) and methylated cyclodextrin (Me-CD) on the structure and mechanical properties of PLLA were investigated. Inclusion complexes (IC) of α, β and γ-CD and PLLA were prepared. The formation of IC was confirmed from 13C NMR chemical shifts and the number of peaks for α, β and γ-CD/PLLA IC. 10% of α, β and γ-CD/PLLA IC were mixed with PLLA and formed into films. The tensile test of the obtained films revealed the breaking strain is improved up to 350%. Me-CD was mixed with PLLA and prepared into films. The breaking strain of the films reached up to 250% and the addition effect was largest for Me-γ-CD10. From DSC measurements, one melting peak was observed and the peak moved to lower temperature as the amount of Me-CD increased. These results indicate Me-CD distributes homogeneously in PLLA. Solid state NMR of Me-α, β and γ-CD50 gave broad peaks and the molecular mobility of the mobile component increased. Therefore, Me-α, β and γ-CD do not form IC, but act as the plasticizer for PLLA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly(l-lactic acid) (PLLA) is a polymer having various advantages such as biocompatibility, biodegradability, high strength, high elasticity, transparency, etc. In the industrial field, it is used as a packaging material and it has also begun to be applied to medical equipment [1, 2]. However, it has disadvantages of low thermal resistance and brittleness [3, 4]. For this reason, improvement of these disadvantages is required to widely commercialize PLLA.

For the improvement of thermal resistance, the formation of the stereo complex (Sc) of PLLA and poly(d-lactic acid) (PDLA) were studied, because melting point of Sc is about 220 °C which is higher than that of PLLA, 170 °C. Many studies have been conducted for this purpose using Sc [5,6,7,8,9,10].

The second disadvantage hinders the high performance of the polymer. PLLA has a polar group, C=O, in the molecule and is slightly polarized. Such a polarization causes interchain interaction and restricts the molecular motion. Since it is conceivable that PLLA molecular chains are attracted to each other, the molecular motion of the amorphous part is constrained, leads to high Tg and brittleness. In order to achieve the high performance of PLLA, it is necessary to utilize the mechanical property of the polymer chain itself, that is, to orient the polymer chain. Drawing is the effective method to orient the polymer chain. In our previous works, the tensile drawing was applied to polyethylene, polypropylene, poly(tetrafluoroethylene) and so on [11,12,13,14,15,16,17,18,19,20,21,22]. The resultant oriented films exhibited excellent mechanical properties. For efficient drawing, brittleness is not appropriate and plasticization is necessary. Therefore, in order to improve the disadvantages of mechanical properties, it is indispensable to control the interchain interaction between PLLA chains.

Cyclodextrin (CD) is cyclic molecules composed of several glucose unit. CDs have hydrophobic cavity which can include guest molecules and form inclusion complex (IC). Therefore, inclusion of PLLA chains inside CD cavity might control the interaction between PLLA molecular chains [23]. By introducing CD, the distance between PLLA is increased. This leads to low Tg and the disadvantage and drawability of PLLA is expected to be improved.

The purpose of this study is to evaluate the effect of CD addition to PLLA film for the improvement of the brittleness and the drawability.

Experimental

Materials

α, β and γ-CD, and tri-o-methylated β-CD (Me-β-CD) were purchased from Wako Pure Chemical Ind. (Japan) and used as received. PLLA (Aldrich; Mw = 6.7 × 104) and PLLA (Mitsui Chemicals Inc.; Mw = 2.6 × 105) was used after removing the oligomer and polymerization catalyst by dissolution in chloroform and precipitation in methanol. The precipitated PLLA was dried at 100 °C for 24 h in vacuo prior to film preparation. Chloroform and methanol were purchased from Wako Pure Chemical Ind. (Japan) and used as received.

Synthesis of tri-O-methylated CDs

Under a nitrogen atmosphere, α-CD or γ-CD (0.973 g, 1 mmol or 1.30 g, 1 mmol) was dissolved in dry N,N-dimethylformamide (66.7 mL). To this solution, sodium hydride (1.03 g, 43.0 mmol) was added and stirred at room temperature. The mixture was immediately cooled to 0 °C and then methyl iodide (2.00 mL, 32.1 mmol) was added dropwise to the mixture. After the addition, the mixture was gradually warmed to room temperature and then stirred for 24 h. To the resulting mixture, methanol was added for quenching. The resultant solution was concentrated by reduced pressure at 60 °C and the residual solid was dissolved in distilled H2O (200 mL) and then extracted with chloroform (200 mL × 3). The organic phase was dried with magnesium sulfate, and the solvent was removed using a rotary evaporator. The residue was purified by silica gel column chromatography using chloroform/methanol (v/v = 20/1) to give tri-O-methylated α-CD(Me-α-CD: 96%) and tri-O-methylated γ-CD (Me-γ-CD: 67%) as colorless solids.

1H NMR (500 MHz, CDCl3, δ, ppm, at rt): Me-α-CD: 3.19 (dd, J = 9.53 Hz, 3.20 Hz, 1H), 3.42 (s, 3H), 3.51 (s, 3H), 3.54–3.62 (m, 2H), 3.66 (s, 3H), 3.70–3.72 (br, 1H), 3.80–3.86 (m, 2H), 5.05 (d, J = 3.2 Hz, 1H). Me-γ-CD: 3.24 (dd, J = 9.75 Hz, 3.60 Hz, 1H), 3.40 (s, 3H), 3.54 (s, 3H), 3.55–3.59 (m, 2H), 3.68 (s, 3H), 3.70–3.73 (m, 1H), 3.76–3.79 (br, 0.5 × 2H), 3.88 (dd, J = 10.5 Hz, 3.55 Hz, 0.5 × 2H), 5.26 (d, J = 3.60 Hz, 1H).

Inclusion complex preparation

A PLLA (Mw = 6.7 × 104) solution (0.25 wt% of dioxane) and α, β, and γ-CD solution (12 wt% of distilled water) were prepared. For the preparation of IC, PLLA solution was slowly added to CD solutions in continuous agitation at 50 °C for α and γ-CD and at 80 °C for β-CD. After this step the mixture was agitated for 3 h. Then the stirring was maintained for another 24 h at ambient temperature. Finally, the obtained suspension was filtered and the white powder was washed several times with dioxane and distilled water. IC samples are abbreviated the name of CD/PLLA IC such as α-CD/PLLA IC. For comparison, the powder of CD and PLLA was mixed mechanically, which is called “mixture”.

Sample film preparation

IC film

α-CD/PLLA IC was sandwiched between commercial polyimide films (UPILEX-125S, Ube) and compression molded into the film at 230 °C and 30 MPa for 10 min in vacuo, followed by quenching into ice water. The same procedure was applied to β and γ-CD/PLLA IC. In addition, films were prepared by mixing PLLA and α-CD/PLLA IC or β-CD/PLLA IC at a weight ratio of 90:10 with the same way.

PLLA/methylated CD film

For preparation of PLLA films containing trimethyl-CD (Me-CD), the sample solutions of 1 wt % PLLA (Mw = 2.6 × 105) and Me-CD were prepared separately in chloroform at room temperature. The solutions were mixed and vigorously stirred for 24 h. The solutions were cast onto a Petri dish and covered with an aluminum foil with holes to allow solvent evaporation at room temperature. The neat PLLA film was prepared with same way. The sample films prepared were listed in Table 1. The sample films abbreviated with the name of Me-CD followed by the weight fraction of the Me-CD, for example, the film consisting 90% PLLA and 10% Me-α-CD as Me-α-CD10.

Tensile drawing test

Tensile drawing of samples were carried out at 60 °C by using a Tensilon RTC-1325A tensile tester (A&D, Japan). The initial sample length was 10 mm. Tensile drawing measurements were performed at a cross-head speed of 20 mm min−1.

DSC measurements

For thermal behavior analysis, DSC measurements were conducted on a Diamond DSC instrument (PerkinElmer Japan Co., Ltd., Kanagawa, Japan) calibrated with indium and tin standards. Samples (2 mg) were packed in an Al pan and the measurements were performed at 10 °C min−1 under N2 gas flow (20 mL min−1).

13C NMR measurements

The solution 13C NMR and the solid-state CPMAS 13C NMR spectra were recorded on a Bruker AVANCE III spectrometer (Bruker BioSpin K.K., Kanagawa, Japan). The solution 13C NMR spectra were recorded at 75 MHz after samples were dissolved in chloroform.

For the solid-state CPMAS 13C NMR, all samples were packed in a zirconia rotor with a 4 mm diameter and spun at 4 kHz in the instrument. The contact and repetition times were set at 2 ms and 5 s, respectively.

1H pulse NMR measurements

1H pulse NMR measurements were performed on a JEOL MU-25 spectrometer (JEOL Ltd., Tokyo, Japan). A solid-echo pulse sequence provided free induction decay curves, which were fitted using a hybrid of exponential and Gaussian functions, and fraction ratio and the spin–spin relaxation time, T2, could be determined [24].

Results and discussion

Figure 1 shows the solid state high-resolution NMR spectra of PLLA, α-CD, α-CD/PLLA mixture and α-CD/PLLA IC. In PLLA, peaks of C=O, CH, and CH3 appear at about 170, 70 and 20 ppm respectively. These peaks split in several peaks, indicating that PLLA forms a regular structure 10/3 helix [25]. α-CD has very sharp peaks from C1 to C6, and the line width is narrow. This shows that α-CD has high crystallinity. Comparing the spectrum of α-CD/PLLA mixture with those of α-CD and PLLA, it can be seen that the spectrum of α-CD/PLLA mixture is a superposition spectrum of α-CD and PLLA. The spectrum of α-CD/PLLA IC is different from that of the mixture. Peaks of C1, C2, C3 and C5 carbons for IC are shifted to low field, and the peaks of C4 and C6 carbons shifted to high field. Not only is it shifting but also the number of peaks is changing. There are several reasons for NMR chemical shift change. As NMR chemical shift is affected by the electronic structure of molecule resulting from the change in the conformation, the interaction between molecules, chemical bond, etc [26, 27]. In IC, the chemical bond does not change. The interaction between molecules sometimes largely affects the chemical shift such as the ring current effect. However, phenyl ring does not contained in IC. Therefore, the main reason for the chemical shift change in this case may be the conformational change of CD. As a result of α-CD interacting with PLLA, α-CD is taking a specific conformation different from pure α-CD. It has reported the chemical shift change of ICs arise from the conformational change of α-CD [28, 29]. In the sample preparation, the precipitate is washed with water. If α-CD is merely mixed with PLLA, α-CD should not remain in the sample. Taking these into consideration, the change in the peaks of α-CD means that α-CD forms IC with PLLA.

On the other hand the peak position and the number of peaks of PLLA have not changed in the α-CD/PLLA IC. Therefore, PLLA is included in α-CD with maintaining 10/3 helix.

When PLLA takes a 10/3 helix, one ring height of α-CD corresponds to about three monomer units of PLLA. That is, if α-CD fully include PLLA, the molar ratio of PLLA monomer and α-CD is about 3:1. Since α-CD is composed of 6 glucose units, the molar ratio of monomer unit and glucose unit is about 1:2. From 1H NMR for the obtained IC, the amount of α-CD was 58% of fully included IC. Therefore, the molar ratio of the monomer units of PLLA is approximately 1:1 to α-CD glucose units. However, in the spectrum, the intensity of the α-CD is stronger. In the CPMAS spectrum, components with poor mobility are emphasized. Considering this, it means that the mobility of α-CD is more restricted than that of PLLA.

Figure 2 shows CPMAS NMR spectra for PLLA, β-CD, β-CD/PLLA mixture and β-CD/PLLA IC. The spectrum of β-CD has also sharp peaks, indicating the high crystallinity. Similar to α-CD/PLLA mixture, the spectrum of the β-CD/PLLA mixture is a superposition of individual spectra. In contrast, in the spectrum of the β-CD/PLLA IC, both the chemical shift value and the number of peaks deviated from β-CD, while peaks of PLLA are unchanged. That is, even in the case of β-CD, PLLA is included in β-CD with maintaining the original PLLA conformation.

Figure 3 shows the spectra of PLLA, γ-CD, γ-CD/PLLA mixture and γ-CD/PLLA IC. Compared to α, β-CD, the spectrum of γ-CD shows that the carbon peaks of C-1-6 is complicatedly split. γ-CD is thought to take various conformation because γ - CD has the largest number of glucose units and the ring radius is also large. In the case of γ-CD/PLLA mixture, it is also a superposition spectrum of each single substance like α, β-CD. In the spectrum of the γ-CD/PLLA IC, both the chemical shift position and the number are greatly changed with respect to the mixture. In particular, the number of peaks of C-1, 4, and 6 remarkably decreases. This means that γ - CD takes a specific conformation by the inclusion of PLLA. The inner diameter of the γ -CD is about 0.8 nm and the outer diameter of PLLA with 10/3 helix is about 0.3 nm. Since the diameter of the cavity is more than twice the outer diameter of PLLA helix and the spectral change is larger than the case for α and β-CD, there is a possibility that two PLLAs are included in the cavity of γ - CD.

From the measurement of CPMAS NMR, it became clear that α, β, γ-CD and PLLA form IC. Since PLLA and CD are interacting with each other in the inclusion complex, there should be a difference in the molecular motion. 1H pulse NMR measurements were carried out, and the temperature dependence of the molecular motion was confirmed. Figure 4 shows the temperature dependence of the spin–spin relaxation time (T2) and its component fraction of α-CD, PLLA, and α-CD / PLLA IC. The obtained free induction decay (FID) of α-CD was analyzed with two components [24]. In Fig. 4a, it can be seen that there is almost no temperature change of T2. As the melting point of α-CD is 280 °C or higher, molecular motion of α-CD has not activated in the measurement temperature range. The fraction of the rigid component is almost 100% at 30 °C and decreased slightly to about 85% at 190 °C. 15% of 1H for α-CD is activated at high temperature. There are 10 1Hs for glucose unit of α-CD. In 10 1Hs, the mobility of two 1Hs bonded to C6(side chain) may be activated by the temperature. As the fraction of these 1Hs is 20% which is close to the mobile fraction at 190 °C. The mobile and rigid fractions of α-CD are attributed to 1Hs bonded to C6 and the rest.

In contrast, PLLA has a melting point at about 180 °C. T2 of PLLA also had two components in Fig. 4c. As the temperature rises, T2 of the mobile component gradually increases above Tg and rapidly increases near the melting point. When the temperature exceeds Tg, the fraction of mobile component gradually increases. Near the melting point, the fraction of the mobile component rapidly increases and leads to almost 100%. That is, it turns out that melting is clearly occurring.

For α-CD/PLLA IC, three components were required to analyze the observed FID. From the results of α-CD (Fig. 4a) and PLLA (Fig. 4c), the mobile component is attributed to the mobile component of PLLA. As T2 of the rigid and mobile components for α-CD are almost constant for the temperature range measured, these components are attributed to the rigid and intermediate components in Fig. 4b. The rigid fraction of PLLA attributed to the rigid, intermediate fractions which changes dependent on temperature.

In Fig. 4b, T2 of the mobile component increases near the melting point of PLLA. However, it does not increase as much as PLLA (Fig. 4c), and the increase of T2 is suppressed to 2000 µs. The fraction of rigid component decreased to 75% and remains even at 190 °C. This is considered to be the result of PLLA being included in CD. As the molar fraction of IC is 1:1 for the glucose unit to PLLA monomer unit, the contributions to 1H pulse NMR signal from CD and PLLA are 10/14 (≈ 70%) and 4/14 (≈ 30%), respectively. Based on the decrease of rigid component (15%) for α-CD at high temperature (Fig. 4a), α-CD in α-CD/PLLA IC contributes to the decrease by 10% and rest of the decrease (15%) arises from PLLA. As 1H fraction of α-CD/PLLA IC from PLLA is about 30%, the half of PLLA component in α-CD/PLLA IC became the mobile fraction in Fig. 4b.

Since the results of CPMAS NMR and 1H pulse NMR show that PLLA formed IC with CDs, the interchain interaction of PLLA might be different from PLLA. In order to confirm this, the mechanical properties of the film are examined using these samples. Film molding was carried out using α-CD/PLLA IC, but uniform films could not be molded and powdery holes exist partly. This behavior means the material did not flow properly at the film preparation temperature. Since the outside of α-CD/PLLA IC is covered with α-CD, PLLA movement is restricted as can be seen from the results of 1H pulse NMR and it is reported IC composed of α-CD and PLA maintained IC structure up to the thermal degradation [23]. This result is also the evidence for the formation of IC.

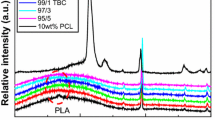

For the effective drawing, both the restricted part which transmits the stress and the mobile part which orient the polymer chain are required. For instance, the melted polyethylene cannot be drawn because of low viscosity, but the melted ultrahigh molecular weight polyethylene can be drawn because there are deep entanglements which can transmit the applied stress even at melted state [21]. For α, β and γ-CD/PLLA IC, ICs are rigid and the interchain interaction is too weak. As it has reported that the addition of IC improve the mechanical properties of PLLA [30], IC was mixed with pure PLLA to prepare a film. α-CD / PLLA IC and PLLA was mixed at a weight ratio in 1:9. As a result, a transparent film could be prepared. The stress strain curve for drawing of PLLA, PLLA mixed with 10 wt% of α-CD / PLLA IC and PLLA mixed with 10 wt% of β-CD / PLLA IC at 60 °C is shown in Fig. 5. For PLLA, breaking strain is very small and it is brittle. On the other hand, the film with α-CD/PLLA IC: PLLA = 1:9 has a very large breaking strain. Even in the film with β-CD/PLLA IC:PLLA = 1:9, the breaking stress and strain increased. It is thought that this is caused by cutting the interaction between PLLA. It became clear that it is possible to control brittleness and drawability of PLLA by cyclodextrin.

α, β, and γ-CDs dissolve in water and polar solvents but do not dissolve in organic solvents. Therefore, α, β, and γ-CD/PLLA inclusion complex were prepared by using a mixed solvent of water and dioxane. On the other hand, methylated-cyclodextrin, one of the modified cyclodextrin, dissolves in chloroform in which PLLA can be dissolved. Therefore, cast films were prepared by dissolving methylated-cyclodextrin and PLLA in chloroform, and their mechanical properties were investigated. Figure 6 shows stress–strain curves of cast films for PLLA, Me-α, β and γ-CD10 and 20. From Fig. 6a, it is found that the breaking strain of Me-α-CD10 is 125% which is higher than that of PLLA. Similar trends are observed for Fig. 6b, c, the breaking strain for Me-β-CD10 and Me-γ-CD10 are about 200 and 250%, respectively. The draw ability of the films increased by the addition of Me-α, β and γ-CD. The magnitude of breaking strain is in the order of α < β < γ. The drawing magnification is higher with the larger CD and the larger cavities. This means that Me-α, β and γ-CD inhibit the interaction between PLLA and that the more the cavity is, the stronger the inhibitory power is.

When the amount of Me-α, β and γ-CD increased from 10 to 20%, the breaking strain decreased. It is considered that the mutual interaction between PLLA weakened too much and it was impossible to maintain film structure for the films containing 20 wt% of Me-α, β and γ-CD.

DSC measurement was carried out to investigate the mixing state of samples. Figure 7 shows the results of DSC measurement. In Fig. 7, the melting point of PLLA decreases as the amount of Me-α, β and γ-CD increases. In the case of Me-β-CD, the melting point of Me-β-CD and PLLA is 158 °C and 170 °C, respectively. Even when Me-β-CD is added, only one melting point peak appears. This means that Me-β-CD and PLLA are homogeneously mixed. Similar behavior is also observed for Me-γ-CD. In Fig. 7a for Me-α-CD, the decrease in the melting point of PLLA is slight, and two melting peaks are observed for Me-α-CD50. As the melting peaks for PLLA is decreased slightly, the phase separation with PLLA rich and Me-α-CD rich occurs.

Solid state high resolution NMR measurement was carried out to investigate the interaction between PLLA and Me-α, β and γ-CD. For Me-α, β and γ-CD10, the CD peak was very weak. As the melting peak of PLLA is shifted to lower temperature with the amount of Me-α, β and γ-CD, the mixed state is considered to changes continuously. Measurements were performed for Me-α, β and γ-CD50. Figure 8a shows the solid state high resolution NMR spectrum for PLLA, Me-α-CD50 and Me-α-CD. Several sharp peaks appeared for each carbon in Me-α-CD, and the crystallinity of Me-α-CD is considered to be relatively high. The peaks of PLLA split, which means PLLA takes the regular conformation, 10/3 helix. In contrast, Me-α-CD50 has very broad peaks. This means that the crystallinity of Me-α-CD50 is decreased by mixing with PLLA. In addition, the split derived from the peak of PLLA is also unclear, and it is considered that amorphization has occurred by adding methylated α-CD to PLLA. That is, methylated CD may act as a plasticizer for PLLA.

Similar trend is observed for Me-β-CD in Fig. 8b. Since sharp peaks exist for Me-β-CD, Me-β-CD has high crystallinity. When it is mixed with PLLA, solid state NMR spectrum for Me-β-CD50 have the broad peaks, which indicates PLLA in Me-β-CD50 does not take the regular structure and Me-β-CD also act as plasticizer for PLLA.

Me-γ-CD gives the broad peaks even when it is not mixed with PLLA. This is because the ring size of Me-γ-CD is large and there is a possibility of taking various conformations. Even when Me-γ-CD is added to PLLA, the sharp peaks are not observed. Addition of methylated CD gives the broad peaks in common to Me-α, β, γ-CD, and it is considered that the plasticization of PLLA occurs. Also, from these spectra, the clear evidence that Me-α, β and γ-CD form IC with PLLA was not obtained. In other words, it is thought that Me-α, β and γ-CD exists between PLLA molecular chains and controls intermolecular interaction. When the NOESY spectrum of the solution was measured, the correlation between Me-β-CD and CH3 and CH of PLLA appeared. From this, it is considered that methylated CD interacts with CH3 and CH group of PLLA. By interacting with PLLA, Me-α, β and γ-CD act as plasticizer instead of IC. In Fig. 6, the expanded S-S curves at the small strain regime are shown. Compared with PLLA, MeCD added sample show gentle initial slope which corresponds to low Young’s modulus. The plasticizing effect is confirmed from Fig. 6.

If plasticization is occurring, the molecular mobility of PLLA might be affected and T2 of the amorphous component should be increased. Figure 9a shows the temperature dependence of T2 for the amorphous component of PLLA, Me-β-CD10, 20 and 50. For PLLA, T2 is about 40µs at 30 °C. T2 increases at Tg, 70 °C, indicating the start of the micro-Brownian motion. On the other hand for Me-β-CD10,20 and 50, T2 of the mobile component is high, about 70 µs, even at room temperature, which is close to T2 of PLLA above Tg. The mobility of the amorphous component is increased by adding Me-β-CD.

In Fig. 9b is shown the temperature dependence of the fraction for the mobile component for PLLA, Me-β-CD10, 20 and 50. The mobile fraction for PLLA is less than 5% at 30 °C and above Tg it increases with temperature. For Me-β-CD10, 20 and 50, the fraction is between 10 and 20% at 30 °C and increases with temperature. The mobile fraction for Me-β-CD10, 20 and 50 is much larger than PLLA. These results also arises from the plasticization of methylated CD.

Conclusions

The addition effects of cyclodextrin and methylated cyclodextrin on the mechanical properties of PLLA were investigated. ICs of α, β and γ-CD and PLLA were prepared. The structure of IC were confirmed by solid state NMR. 13C NMR chemical shifts and the number of peaks for α, β and γ-CD/PLLA IC were different from those of the mixtures. By formation of IC, the conformation of cyclodextrin changed. For γ-CD, the change of NMR spectrum was drastic and there was a possibility of γ-CD including two PLLA chains. The formation of IC also affected the molecular mobility of PLLA. The molecular mobility of PLLA was suppressed and the rigid component remains even above the melting temperature.

α, β and γ-CD/PLLA IC cannot be formed into films. Therefore, 10% of α, β and γ-CD/PLLA IC were mixed with PLLA and formed into films. The tensile test of the obtained films revealed the breaking strain is improved up to 350%.

Me-CD was mixed with PLLA and films were prepared. The breaking strain reached up to 250% and the addition effect was largest for Me-γ-CD10. The size of the cavity may affect the interchain interaction. From DSC measurements, only one melting peak was observed and the peak moved to lower temperature as the amount of Me-CD increased. These result indicate Me-CD distributes homogeneously in PLLA. Solid state NMR of Me-α, β and γ-CD50 gave broad peaks and the molecular mobility of the mobile component increased. Therefore, Me-α, β and γ-CD do not form IC, but act as the plasticizer for PLLA.

References

Drumright, R.E., Gruber, P.R., Henton, D.E.: Polylactic acid technology. Adv. Mater. 12, 1841–1846 (2000)

Ikada, Y., Tsuji, H.: Biodegradable polyesters for medical and ecological Applications. Macromol. Rapid Commun. 21, 117–132 (2000)

Pillin, I., Montrelay, N., Grohens, Y.: Thermo-mechanical characterization of plasticized PLA: is the miscibility the only significant factor. Polymer 47, 4676–4682 (2006)

Okamoto, K., et al.: Miscibility, mechanical and thermal properties of poly(lactic acid)/polyester-diol blends. Eur. Polym. J. 45, 2304–2312 (2009)

Ikada, Y., Jamshidi, K., Tsuji, H., Hyon, S.H.: Stereocomplex formation between enantiomeric poly(lactides). Macromolecules 20, 904–906 (1987)

Brizzolara, D., Cantow, H.-J., Diederichs, K., Keller, E., Domb, A.J.: Mechanism of the stereocomplex formation between enantiomeric Poly(lactide)s. Macromolecules 29, 191–197 (1996)

Tsuji, H., Ikada, Y.: Crystallization from the melt of poly(lactide)s with different optical purities and their blends, Macromol. Chem. Phys. 3483–3499 (1996)

Cartier, L., Okihara, T., Lotz, B.: Triangular polymer single crystals: stereocomplexes, twins, and frustrated structures. Macromolecules 30, 6313–6322 (1997)

Sawai, D., Tsugane, Y., Tamada, M., Kanamoto, T., Sungil, M., Hyon, S.H.: Crystal density and heat of fusion for a stereo complex of poly(l-lactic acid) and poly(d-lactic acid). J. Polym. Sci.Polym. Phys. 45, 2632–2639 (2007)

Kakiage, M., Ichikawa, T., Yamanobe, T., Uehara, H., Sawai, D.: Structure and property gradation from surface to bulk of Poly(l-lactic acid)/Poly(d-lactic acid) blended films as estimated from nanoscratch tests using scanning probe microscopy. Appl. Mater. Interfaces 2, 633–638 (2010)

Uehara, H., Nakae, M., Kanamoto, T., Zachariades, A.E., Porter, R.S.: Melt drawability of ultra-high molecular weight polyethylene. Macromolecules 32, 2761–2769 (1999)

Nakae, M., Uehara, H., Kanamoto, T., Ohama, T., Porter, R.S.: Melt drawing of ultra-high molecular weight polyethylene: comparison of ziegler- and metallocene-catalyzed reactor powders. J. Polym. Sci. Polym. Phys. Ed. 37, 1921–1930 (1999)

Nakae, M., Uehara, H., Kanamoto, T., Zachariades, A.E., Porter, R.S.: Structure development upon melt drawing of ultra-high molecular weight polyethylene: effect of prior thermal history. Macromolecules 33, 2632–2641 (2000)

Uehara, H., Kakiage, M., Yamanobe, T., Komoto, T., Murakami, S.: Phase development mechanism during drawing from highly entangled polyethylene melts. Macromol. Rapid Commun. 27, 966–970 (2006)

Kakiage, M., Yamanobe, T., Komoto, T., Murakami, S., Uehara, H.: Effects of molecular characteristics and processing conditions on melt-drawing behavior of ultra-high molecular weight polyethylene. J. Polym. Sci. Polym. Phys. Ed. 44, 2455–2467 (2006)

Kakiage, M., Yamanobe, T., Komoto, T., Murakami, S., Uehara, H.: Transient crystallization during drawing from ultra-high molecular weight polyethylene melts having different entanglement characteristics. Polymer 47, 8053–8060 (2006)

Uehara, H., Yoshida, R., Kakiage, M., Yamanobe, T., Komoto, T.: Continuous film processing from ultra-high molecular weight polyethylene reactor powder and mechanical property development by melt-drawing. Ind. Eng. Chem. Res. 45, 7801–7806 (2006)

Kakiage, M., Sekiya, M., Yamanobe, T., Komoto, T., Sasaki, S., Murakami, S., Uehara, H.: In-situ SAXS analysis of extended-chain crystallization during melt-drawing of ultra-high molecular weight polyethylene. Polymer 48, 7385–7392 (2007)

Morioka, T., Kakiage, M., Yamanobe, T., Komoto, T., Kamiya, H., Higuchi, Y., Arai, K., Murakami, S., Uehara, H.: Oriented crystallization from poly(tetrafluoroethylene) melt induced by uniaxial drawing. Macromolecules 40, 9413–9419 (2007)

Kakiage, M., Sekiya, M., Yamanobe, T., Komoto, T., Sasaki, S., Murakami, S., Uehara, H.: Phase transitions upon heating for melt-drawn ultra-high molecular weight polyethylenes having different molecular characteristics. J. Phys. Chem. B 112, 5311–5316 (2008)

Kakiage, M., Uehara, H., Yamanobe, T.: Novel in-situ nmr measurement system for evaluating molecular mobility during drawing from highly entangled polyethylene melts. Macromol. Rapid Commun. 29, 1571–1576 (2008)

Yamanobe, T., Kakiage, M., Miyazaki, N., Morita, S., Uehara, H.: Development and application of in situ pulse NMR measurement system for drawing of polymeric materials. Kobunshi Ronbunshu 69, 235–241 (2012)

Mano, J.F.: Thermal behaviour and glass transition dynamics of inclusion complexes of a-cyclodextrin with poly(d,l-lactic acid). Macromol. Rapid Commun. 29, 1341–1345 (2008)

Uehara, H., Yamanobe, T., Komoto, T.: Relationship between solid-state molecular motion and morphology for ultra-high molecular weight polyethylene crystallized under different conditions. Macromolecules 33, 4861–4870 (2000)

Thakur, K.A.M., Kean, R.T., Zupfer, J.M., Buehler, N.U., Doscotch, M.A., Munson, E.J.: Solid State 13C CP-MAS NMR studies of the crystallinity and morphology of poly(l-lactide). Macromolecules 29, 8844–8851 (1996)

Ando, I., Webb, G.A.: Theory of NMR Parameters. Academic Press, London (1986)

Yamanobe, T., Chujyo, R., Ando, I.: Carbon-13 N.M.R. chemical shift and electronic structure of an infinite polymer chain as studied by tight-binding MO theory Polyethylene, and cis and trans polyacetylenes. Mol. Phys. 50, 1231 (1983)

Kuan, F.-H., Inoue, Y., Chujo, R.: Structure and molecular dynamics of solid-state inclusion complexes of cyclodextrin and permethylated cyclodextrin with benzaldehyde studied by high-resolution CP/MAS 13C NMR. J. Incl. Phenom. 4, 281–290 (1986)

Ripmeeester, J.A.: Variable temperature CP/MAS 13C NMR study of cyclodextrin complexes of benzaldehyde. J. Incl. Phenom. 6, 31–40 (1988)

Li, X., Kang, H., Shen, J., Zhang, L., Nishi, T., Ito, K., Zhao, C., Coates, P.: Highly toughened polylactide with novel sliding graft copolymer by in situ reactive compatibilization, crosslinking and chain extension. Polymer 55, 4313–4323 (2014)

Acknowledgements

We thank Professor H. Kitagishi from Doshisha University for suggesting about the synthesis of tri-O-methylated CDs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamanobe, T., Takeda, H., Takada, Y. et al. Structure and physical properties of poly(lactic acid) and cyclodextrin composite. J Incl Phenom Macrocycl Chem 93, 117–126 (2019). https://doi.org/10.1007/s10847-018-0859-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-018-0859-0