Abstract

While the specific recovery of valuable chemicals from waste streams represents an environmentally-friendly and potentially economically-relevant alternative to synthetic chemical productions, it remains a largely unmet challenge. This is partially explained by the complexity of designing sorption materials able to target one specific compound and able to function in complex matrices. In this work, a series of cyclodextrin-based polymers (CDPs) were designed to selectively extract phenolic compounds from a complex organic matrix that is olive oil mill wastewater (OMW). In order to endow these polymers with selective adsorption properties, several monomers and cross-linkers were screened and selected. The adsorption properties of the CDPs produced were first tested with selected phenolic compounds commonly found in OMW, namely syringic acid, p-coumaric acid, tyrosol and caffeic acid. The selected CDPs were subsequently tested for their ability to adsorb phenolic compounds directly from OMW, which is known to possess a high and complex organic content. It was demonstrated through high-performance liquid chromatography-mass spectroscopy analyses that efficient removal of phenolic compounds from OMW could be achieved but also that two compounds, namely tyrosol and hydroxytyrosol, could be selectively extracted from OMW.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the early days of supramolecular sciences, chemists have devoted great efforts to design molecular receptors capable of specific recognition of a wide variety of targets ranging from small inorganic ions to large biomolecules [1]. These molecular receptors have been widely used to produce (nano)-materials with selective molecular recognition properties [2]. These materials have been extensively studied for biomedical purposes, and to a lower extent for environmental applications.

Supramolecular materials, because of their efficient molecular recognition properties may find a wealth of new applications for the selective removal of harmful or valuable targets from industrial waste streams. One example of interest is the extraction of phenolic compounds from olive oil mill wastewater (OMW). Indeed, the large amount of OMW produced by the olive oil industry (more than 30 million m3/year) is a major environmental problem, as several organic components of this waste stream are known to possess phytotoxic activities [3]. However, some of these compounds are also valuable molecules (e.g. phenolic compounds) for different types of applications (e.g. food, cosmetic formulation or therapeutic application).

The design of synthetic materials with enhanced molecular recognition properties has been extensively approached from the perspective of molecular imprinting [4]. Although this strategy allows the production of polymers with high selectivity for their target molecules, it is still facing limitations for implementation at the industrial scale. These limitations include the need of large quantities of template molecules for the polymer production and the difficulties to extract the template from the imprints once the polymer is produced [5]. Activated carbon has been also extensively studied for the adsorption of toxic compounds and the remediation of contaminated water [6, 7] as well as other polymeric adsorbents or resins [8–10] and has shown good adsorption capacity but often lack specificity in the adsorption and in the recovery processes.

Another strategy to produce polymers with enhanced molecular recognition properties relies on the integration into the polymer structure of macrocyclic receptors such as crown ethers [11], cryptands [12], calixarenes [13], cucurbiturils [14], and cyclodextrins (CDs) [15].

CDs have attracted a special interest for the design of sorption materials as, besides their outstanding molecular recognition properties in water, they are produced through inexpensive biosynthetic processes at the industrial scale. CDs can also be integrated within insoluble polymers, as the macrocycle can be easily cross-linked with different monomers [16]. Therefore, the use of CD-based polymers (CDPs) has spread over a multitude of disciplines including environmental sciences [17].

CDPs have been developed and used as sorbents for several compounds including phenols but most often, despite high sorption capacities, they lack selectivity and recovery processes are either not specific or performed in simple matrices [18–20]. In order to tailor the recognition properties of CDPs, we previously developed synthetic methods that allow producing and testing molecular recognition properties, in a high throughput fashion, of a large number of different CDP formulations. We showed that CDPs' selectivity could be optimized by tuning the size of the CD macrocycle and the selection of the monomers [21, 22].

In the present work, we report the synthesis of cyclodextrin-based polyurethanes at gram scale quantities and demonstrate that the selective molecular recognition properties of CDPs for the selective extraction of relevant phenolic compounds from complex waste streams as OMW could be achieved by the selection of additional monomers, cross-linkers and a specific desorption solvent. We also demonstrate the efficiency of the CDP to extract specifically from OMW two polyphenolic compounds, namely tyrosol and hydroxytyrosol.

Experimental

Materials and methods

β-CD was purchased from CycloLab (Hungary). All other chemicals and solvents were purchased from Sigma-Aldrich (Switzerland) and used without further purification. Six different functional monomers were used for the preparation of the polymers: 1,4-phenylene diisocyanate (PDI), hexamethylene diisocyanate (HDI), 2,2-bis(hydroxymethyl)propionic acid (DMPA), dihydroxybenzoic acid (DHBA), 1,4-dihydroxy-2-naphthoic acid (DHNA) and 2,5-dihydroxyteraphthalic acid (DHTA). An Agilent HPLC 1100 system was used with a reversed-phase column Zorbax SB-C18 for HPLC analyses. The mobile phase consisted in solvent A (H2O:CH3CN:TFA, 95:4.9:0.1, v:v:v) and solvent B (H2O:CH3CN:TFA, 4.9:95:0.1, v:v:v). An isocratic gradient was applied and flow rate kept constant (1.0 mL/min). The HPLC-UV detector was set to 230 and 280 nm. Ion trap mass spectrometry analyses were performed on an Agilent 1260 liquid chromatography setup coupled to an Agilent 6320 ion trap spectrometer via a nano-ESI interface. Nanopure water (resistivity ≥18 MΩ cm) was produced by a Millipore Synergy purification system. Absorption measurements were carried out with a H1-Hybrid BioTek spectrophotometer using UV Star 96 well microtiter plates (Greiner Bio-one). Fourier transform infrared (FTIR) spectra were recorded using a Varian 670-IR spectrometer from 500 to 4000 cm−1.

OMW samples were kindly provided by an olive mill located in the Apulia region (Italy) and stored in the dark at 4 °C. To remove solid particles and aggregates from OMW, samples were centrifuged for 10 min at 3220×g and subsequently the supernatant was filtrated through a Teflon filter (0.45 μm) to remove insoluble residues. The removal of lipids from the OMW was achieved by liquid–liquid extraction with hexane and the phenolic compounds were extracted by liquid–liquid extraction with ethyl acetate [23, 24]. The organic phase was dried over MgSO4 and evaporated under reduced pressure at 30 °C. Solutions with the desired concentration of phenolic compounds were then prepared for further experiments.

Synthesis

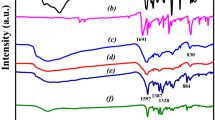

Dibutyltindilaurate (DBTDL) (1 mL) was added to 160 mL of DMF freshly dried over molecular sieves and degassed with nitrogen. Subsequently, the appropriate amount of monomers was added (Table 1). After 120 min of reaction under stirring at 65 °C (20 min for CDP 71 and 74), 200 mL of a solution of β-CD (12 mmol, 13.61 g) and 1 mL of DBTDL in DMF were added and allowed to react at 75 °C for 3 h. The mixture was then poured in 100 mL of acetone to yield a white precipitate that was washed with acetone (3 × 200 mL), water (3 × 200 mL) and ethanol (3 × 200 mL) to remove unreacted DBTDL, monomers, and β-CD. Finally, the CDP produced was dried under vacuum at 60 °C for 24 h prior to use. In Table 1 and Fig. 1 are given the quantities used for each polymerization reaction and the chemical structures of β-CD and the selected monomers. The reaction mechanism and schematic structure of the CDPs is shown in Fig. S1 and FTIR spectra are given in Fig. S2.

Chemical structures of β-cyclodextrin and the monomers used to produce CDPs: 1,4-phenylene diisocyanate (PDI), hexamethylene diisocyanate (HDI), and cross linkers: dihydroxybenzoic acid (DHBA), 1,4-dihydroxy-2-naphthoic acid (DHNA), 2,2-Bis(hydroxymethyl)propionic acid (DMPA) and 2,5-dihydoxyterephtalic acid (DHTA)

Binding assay of the selected phenolic compounds

The binding assay of the selected phenolic compounds (p-coumaric acid, caffeic acid, tyrosol and syringic acid, cf. Fig. 2) onto the CDPs in water was performed as follows. The selected polymer (100 mg) was added to 1.5 mL aqueous solution of phenolic compounds (1 mg/mL). The suspension was maintained at 25 °C for 2 h and subsequently centrifuged at 8050×g for 10 min. The supernatant was then collected to measure the absorbance at 270 nm for syringic acid and tyrosol, at 290 nm for p-coumaric acid and at 320 nm for caffeic acid.

Equilibrium isotherms

For the determination of adsorption isotherms, solutions of 2 mL with different concentrations (0.25, 0.1, 0.08, 0.05, 0.02 mg/mL) of tyrosol and hydroxytyrosol were prepared and stirred at 800 rpm at 25 °C with 20 mg of CDP for 2h. The suspension was then centrifuged at 8050×g for 5 min and the supernatant was recovered for absorbance measurement at 280 nm.

Binding assay of OMW phenolic compounds

A fraction of 1 mL of phenolic compounds solution extracted from OMW (2 mg/mL) was incubated with the CDP (100 mg) for 2 h at 25 °C. Consequently, the mixture was centrifuged at 8050×g for 10 min and the supernatant was recovered and analysed by HPLC. The adsorption and desorption of phenolic compounds from CDPs was also performed using a packed CDP column built using a classical chromatographic column filled with CDP. The sample of OMW was deposited on the CDP column and the OMW sample was eluted through the column using a mixture methanol/water to desorb the phenolic compounds from the CDP. Different solvents ratios were applied in sequence over the same CDP packed column affording thus different fractions. The different fractions recovered were then analysed by HPLC-DAD.

Results and discussions

Adsorption of selected phenolic compounds

In this study, six different water-insoluble polymers were produced (CDP 71, 74, 76, 78, 87 and 89) cf. Table 1. The presence of urethane and aromatic functions of the CDPs were confirmed for each polymer by FTIR spectroscopy. Each polymer was prepared with a different monomer composition in order to evaluate their binding efficiency first towards four selected phenolic compounds and then towards phenolic compounds present in OMW.

Four phenolic compounds were selected for the study upon their relevance and presence in OMW: p-coumaric acid, caffeic acid, tyrosol, and syringic acid. The chemical structures of the selected phenolic compounds are shown in Fig. 2, and the results of the binding assays are shown in Fig. 3.

As shown in Fig. 3, CDP 71 had a higher binding affinity than CDP 74 for the four phenolic compounds tested. This is explained by the presence of aromatic groups in CDP 71, absent in CDP 74 that induces π-π interactions with the target phenolic compounds. CDP 76 was the least efficient of those polymers to adsorb phenolic compounds because of the additional use of the DHBA cross-linker. This decrease of bound phenolic compounds can be explained by electrostatic repulsion occurring between the negatively charged carboxylic groups of the phenolic compounds and the cross-linker DHBA. At the pH of the phenolic solution (pH 6), 100% of the carboxylic acids of DHBA monomers (pKa 2.93) were deprotonated. The phenolic compounds syringic acid, p-coumaric acid and caffeic acid have respectively the following pKa: 3.86, 4.64, and 4.37 [25–27]. The deprotonated state of these phenolic compounds may lead to electrostatic repulsions. Oppositely, the chemical structure of tyrosol does not contain carboxylic functions; it was therefore not affected by the presence of other carboxylic functions within the polymer and remains well adsorb by all the CDPs. CDP 87 was produced with DMPA cross-linker, although it bears a carboxylic group (pKa 4.64) its pKa is higher than DHBA (pKa 2.93) used for CDP 76. Consequently a higher binding percentage was observed for CDP 87 than for CDP 76. Electrostatic interactions have thus an effect on the absorption process and play also, alongside π-π interactions, an important role on the different affinity between CDPs and phenolic compounds.

Adsorption of OMW phenolic compounds

The polymers were dispersed in an aqueous solution of phenolic compounds for 2h at 25 °C. The suspension was then centrifuged and the supernatant recovered and analysed by HPLC. The chromatogram of the corresponding supernatant and the binding efficiency of each polymer are given in Fig. 4.

a HPLC-DAD chromatograms of the supernatant after incubation of OMW samples with CDP 71, 74, 76, 87 and 89. (λ = 230 nm; injection vol.: 50 µL.) (CDP 71→CDP 89: curve bottom to top) b Binding capacity of CDP 71, 74, 76, 87 and 89 for the selected phenolic compounds. (CDP 71→ CDP 89: column left to right)

The HPLC chromatograms revealed different affinities for each CDP towards the target compounds. Binding capacity was evaluated by integration and comparison of the peaks before and after adsorption. The five major peaks at 4.3, 4.8, 5.3, 6.5 and 7.8 min elution time corresponding to the main phenolic compounds present in OMW were selected and named respectively A, B, C, D and E for clarity.

Among the tested CDPs, CDP 71 showed a binding profile with a high adsorption capacity where more than 70% of all the five labelled phenolic compounds were bound to the polymer with a maximum of 83% for compound B. CDP 74 and CDP 76 showed similar profiles where they bound more than 60% of A and D. CDP 87 is the only CDP tested that has higher adsorption for C but a low binding efficiency for B and E. Regarding CDP 89, it binds efficiently only A (50%) and D (52%), making it the less effective polymer probably because of its hydrophobicity and the difficulty to obtain a homogenous dispersion in water.

Desorption of OMW phenolic compounds

In order to improve the specific recovery of phenolic compounds a CDP-packed column was used. The desorption of these phenolic compounds was evaluated through the use of organic and non-organic solvents: ethanol, methanol, ethyl acetate, water, acidic (pH 2) and basic (pH 12) aqueous solutions, and methanol/water mixture. Only the latter provided appropriate desorption. The results shown in Fig. 5, were obtained with CDP 71 and a water/methanol mixture. The CDP packed column was first loaded with OMW sample and then desorbed with different ratio of a methanol/water mixture.

Desorbed phenolic compound is defined as the percentage of desorbed phenolic compound contained in the fraction over the initial amount of the same phenolic compound contained in the sample before adsorption and desorption from CDP. In the first fraction, up to 40% of phenolic compounds A and E were desorbed with water. A decrease of desorbed phenolic compound over the next fractions was expected as the concentration of phenolic compounds contained into the CDP is decreasing over the fractions. However, an increase of the concentration for compound D precisely for a ratio 40/60 methanol/water was observed. From these results, it appears that an enhanced selective desorption of compound D and for compound A (to a lesser extent) can be achieved using methanol/water mixture.

We thus realized the desorption of CDP packed column using methanol/water (60/40) to obtain eight different fractions, which were analysed by HPLC-DAD, (Fig. 6). The fraction composition has been determined from area peak of HPLC chromatograms.

From Fig. 6, it can be seen that the concentration of desorbed phenolic compounds is increasing until the fifth fraction where compound D represents about 40% of the overall fraction. Compounds A and D together represent almost 60% of the overall desorbed fraction in the fifth fraction. Compound A also reaches a maximum in fraction 4 where it represents 22% of the overall fraction. The enrichment ratios for each phenolic compound are showed in Fig. 7. The enrichment ratio was calculated as follow: percentage of the area of the phenolic compound over area of the total phenolic compounds after desorption, divided by the area of the phenolic compound over area of the total phenolic compounds before desorption.

The highest concentration was recovered in fraction 5 for compound D and its concentration is three times higher than in the original fraction. That allow us to confirm the selective desorption of compound D.

The chromatograms before adsorption and after desorption of phenolic compounds from OMW are presented in Fig. 8. Chromatogram after desorption corresponds to the fifth fraction where compound D has the major peak area. As it can be seen in Fig. 8, two major compounds were isolated: A and D (first peak corresponds to the solvent). Compound D has been recovered in an effective manner; to identify the compound additional ion trap mass spectroscopy analyses were carried out. The results allowed identifying tyrosol (marked as TY in chromatogram Fig. 8), a major phenolic component of olive oil known for its antioxidant properties [28]. Also compound A was identified by matching of retention time with the standard hydroxytyrosol. The compound is marked as HT in the chromatogram Fig. 8.

Adsorption isotherms

In order to determine the adsorption process of tyrosol and hydroxytyrosol onto CDPs, Langmuir and Freundlich models were studied. The results suggested that the adsorption of tyrosol and hydroxytyrosol onto CDPs were best described with the Freundlich model that defines a multilayer adsorption process (Figs. S3, S4). As the affinity of the CDPs for tyrosol and hydroxytyrosol depends only on the presence of π-π stacking and not electrostatic repulsion, CDP 78 was synthesised with another cross-linker (DHNA), which possesses two aromatic groups to assess how it might affect the adsorption. The isotherms confirmed the higher efficiency of CDP bearing aromatic groups (CDP 71, 76 and 78) for adsorbing tyrosol. The adsorption parameters are shown in Table S1 and indicated that CDP 71 was the best CDP to adsorb tyrosol despite the use of DHNA monomers for CDP 78.

Hydroxytyrosol differs from tyrosol by a unique hydroxyl group on the aromatic ring. Therefore it was assumed that CDP 74 and CDP 87 would exhibit the same binding capacity for hydroxytyrosol than for tyrosol. It was thus decided to perform the assay with the following polymers: CDP 71, 76 and CDP 78.

Despite the additional aromatic groups expected for CDP 78 because of the use of DHNA monomers, CDP 71 remains the best polymer to adsorb hydroxytyrosol (Fig S4). The different Freundlich constants derived from these plots are presented in Table S2.

Conclusion

Different CDPs were produced and showed different adsorption capacity towards four selected phenolic compounds. The different binding profiles allowed us to point out the important role that, besides inclusion, π-π and electrostatic interactions play. One of those polymers, CDP 71, showed a relative good absorption capacity for the phenolic compounds and was selected to recover specific phenolic compounds from OMW. CDP 71 was then shown to be effective for the specific recovery of tyrosol and hydroxytyrosol from the complex matrix that is OMW. The selective desorption using water/methanol mixture allows to recover tyrosol and hydroxytyrosol in an effective manner. The process of adsorption and desorption of phenolic compounds with CDP has been shown to be effective and allowed the concentration of fractions up to 40% of tyrosol. This concentration was three times higher than in the original fraction of OMW. The concentration went up to 60% of the desorbed fraction for tyrosol and hydroxytyrosol together. The linear Freundlich isotherm model provides the highest R2 regression coefficient among the two models studied and allow us to confirm the heterogeneous adsorption process of tyrosol and hydroxytyrosol onto the polymer. These two organic compounds are radical scavengers and strong antioxidants potentially useful for the cosmetic and the food industries. The use of CDP for water remediation combined with the specific recovery of valuable molecules appears to be a promising solution for environmental issue arising from OMW. The work is underway to upscale the polymer synthesis and optimize further the extraction to other phenolic compounds for its implementation on a pilot-plant and possible further industrial use.

References

Gale, P.A., Steed, J.W.: Supramolecular chemistry: from molecules to nanomaterials. John Wiley & Sons, Chichester (2012)

Ariga, K., Ito, H., Hill, J.P., Tsukube, H.: Molecular recognition: from solution science to nano/materials technology. Chem. Soc. Rev. 41, 5800–5835 (2012)

Rusan, M.M., Albalasmeh, A., Zuraiqi, S., Bashabsheh, M.: Evaluation of phytotoxicity effect of olive mill wastewater treated by different technologies on seed germination of barley (Hordeum vulgare L.). Environ. Sci. Pollut. Res. 22, 1–9 (2015)

Whitcombe, M.J., Chianella, I., Larcombe, L., Piletsky, S.A., Noble, J., Porter, R., Horgan, A.: The rational development of molecularly imprinted polymer-based sensors for protein detection. Chem. Soc. Rev. 40, 1547–1571 (2011)

Haupt, K.: Peer reviewed: molecularly imprinted polymers: the next generation. Anal. Chem. 75, 376–383 (2003)

Hameed, B.H., Rahman, A.A.: Removal of phenol from aqueous solutions by adsorption onto activated carbon prepared from biomass material. J. Hazard. Mater. 160, 576–581 (2008)

Sarswat, A., Mohan, D.: Sustainable development of coconut shell activated carbon (CSAC) & a magnetic coconut shell activated carbon (MCSAC) for phenol (2-nitrophenol) removal. RSC Adv. 6, 85390–85410 (2016)

Pan, B.C., Xiong, Y., Li, A.M., Chen, J.L., Zhang, Q.X., Jin, X.Y.: Adsorption of aromatic acids on an aminated hypercrosslinked macroporous polymer. React. Funct. Polym. 53, 63–72 (2002)

Frascari, D., Bacca, A.E.M., Zama, F., Bertin, L., Fava, F., Pinelli, D.: Olive mill wastewater valorisation through phenolic compounds adsorption in a continuous flow column. Chem. Eng. J. 283, 293–303 (2016)

Ku, Y., Lee, K.-C.: Removal of phenols from aqueous solution by XAD-4 resin. J. Hazard. Mater. 80, 59–68 (2000)

Terashima, T., Kawabe, M., Miyabara, Y., Yoda, H., Sawamoto, M.: Polymeric pseudo-crown ether for cation recognition via cation template-assisted cyclopolymerization. Nat. Commun. 4, 3321–3329 (2013)

Wei, P., Xia, B., Zhang, Y., Yu, Y., Yan, X.: A responsive supramolecular polymer formed by orthogonal metal-coordination and cryptand-based host-guest interaction. Chem. Commun. 50, 3973–3975 (2014)

Guo, D.-S., Liu, Y.: Calixarene-based supramolecular polymerization in solution. Chem. Soc. Rev. 41, 5907–5921 (2012)

Wang, Q., Chen, Y., Liu, Y.: Supramolecular ternary polymer mediated by cucurbituril and cyclodextrin. Polym. Chem. 4, 4192–4198 (2013)

Harada, A., Takashima, Y., Yamaguchi, H.: Cyclodextrin-based supramolecular polymers. Chem. Soc. Rev. 38, 875–882 (2009)

Au, A.K., Huynh, W., Horowitz, L.F., Folch, A.: 3D-Printed Microfluidics. Angew. Chem. Int. Ed. 55, 3862–3881 (2016)

Morin-Crini, N., Crini, G.: Environmental applications of water-insoluble β-cyclodextrin–epichlorohydrin polymers. Prog. Polym. Sci. 38, 344–368 (2013)

Romo, A., Peñas, F.J., Isasi, J.R., García-Zubiri, I.X., González-Gaitano, G.: Extraction of phenols from aqueous solutions by β-cyclodextrin polymers. Comparison of sorptive capacities with other sorbents. React. Funct. Polym. 68, 406–413 (2008)

Li, H., Meng, B., Chai, S.-H., Liu, H., Dai, S.: Hyper-crosslinked β-cyclodextrin porous polymer: an adsorption-facilitated molecular catalyst support for transformation of water-soluble aromatic molecules. Chem. Sci. 7, 905–909 (2016)

Raoov, M., Mohamad, S., bin Abas, M.R., Surikumaran, H.: New macroporous β-cyclodextrin functionalized ionic liquid polymer as an adsorbent for solid phase extraction with phenols. Talanta. 130, 155–163 (2014)

Xiao, P., Corvini, P., Dudal, Y., Shahgaldian, P.: Design of cyclodextrin-based photopolymers with enhanced molecular recognition properties: a template-free high-throughput approach. Macromolecules. 45, 5692–5697 (2012)

Xiao, P., Corvini, P.F.X., Dudal, Y., Shahgaldian, P.: Design and high-throughput synthesis of cyclodextrin-based polyurethanes with enhanced molecular recognition properties. Polym. Chem. 4, 942–946 (2013)

Allouche, N., Fki, I., Sayadi, S.: Toward a high yield recovery of antioxidants and purified hydroxytyrosol from olive mill wastewaters. J. Agric. Food Chem. 52, 267–273 (2004)

Naczk, M., Shahidi, F.: Extraction and analysis of phenolics in food. J. Chromatogr. A. 1054, 95–111 (2004)

Changenet-Barret, P., Espagne, A., Charier, S., Baudin, J.B., Jullien, L., Plaza, P., Hellingwerf, K.J., Martin, M.M.: Early molecular events in the photoactive yellow protein: role of the chromophore photophysics. Photochem. Photobiol. Sci. 3, 823–829 (2004)

Lee, P.T., Harfield, J.C., Crossley, A., Pilgrim, B.S., Compton, R.G.: Significant changes in pK(a) between bulk aqueous solution and surface immobilized species: ortho-hydroquinones. RSC Adv. 3, 7347–7354 (2013)

Kamm, B.: Introduction of biomass and biorefineries. In: Xie, H., Gathergood, N.. (eds.) The role of green chemistry in biomass procesing and conversion, pp. 1–26. Wiley, Hoboken (2013)

Bertin, L., Ferri, F., Scoma, A., Marchetti, L., Fava, F.: Recovery of high added value natural polyphenols from actual olive mill wastewater through solid phase extraction. Chem. Eng. J. 171, 1287–1293 (2011)

Acknowledgements

The financial support of the European commission Knowledge Based Bio-Economy (KBBE) through the Water4Crops project (L216-0222-2) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

El Idrissi, M., Molina Bacca, A.E., Frascari, D. et al. Cyclodextrin-based polymeric materials for the specific recovery of polyphenolic compounds through supramolecular host–guest interactions. J Incl Phenom Macrocycl Chem 88, 35–42 (2017). https://doi.org/10.1007/s10847-017-0708-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-017-0708-6