Abstract

Verapamil hydrochloride (VH) is a calcium channel blocker. It shows short biological half life (t1/2 4 h) and hence high dosage frequency is required to maintain the desired plasma level upon its oral administration to cardiac patients. Therefore, the present study aims to prepare the controlled release formulation of VH loaded in the alginate–chitosan complex based microspheres. It also involves the study of the effect of drug to polymer ratio and the effect of different concentrations of crosslinking agent (CLA). Chitosan-alginate microspheres were prepared with two different drug to polymer ratios and two different concentrations of CLA (sodium tripolyphosphate) by solvent extrusion method; and were characterized for drug content, particle size, compressibility index, swelling index, surface morphology, in vitro floatability, FTIR, XRPD, DSC, in vitro drug release study and in vivo study. The characterization of fabricated microspheres showed spherical particles with smooth surface of particle size ranging from 1,123.50 to 1,534.40 µm, high drug content (74.8–84.4 %), good flow properties indicated by compressibility index (3.38–7.18 %), high percent swelling index, good floatability (55.4–84.6 % after 12 h). FTIR, XRPD and DSC data supported the formation of a polyelectrolyte alginate chitosan complex as a controlled release microparticulate drug delivery system for verapamil. Microspheres showed 85.0–95.45 % in vitro drug release in 12 h. The prepared microspheres showed controlled drug release during in vivo study with almost same Cmax as that of pure drug but with greater AUC. It was concluded that the alginate–chitosan polyelectrolyte complex based microspheres could be considered for controlled drug delivery of verapamil hydrochloride. The microspheres prepared with high drug to polymer ratio showed good drug content, compressibility index, swelling index, surface morphology, floatability, greater in-vitro drug release and in vivo bioavailability. An increase in concentration in CLA showed a decrease in the compressibility; increase in swelling in pH 1.2, pH 6.8 buffer media; and increase in drug release.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The oral drug delivery is the most convenient route of administration. Most of the pharmaceutical preparations are given by this route. The design of oral sustained drug delivery system primarily aims to achieve more predictable and increased bioavailability [1, 2]. Microspheres are one of the novel drug delivery systems which are capable to improve the performance of active pharmaceutical ingredients in term of drug utilization, absorption, bioavailability, targeting, safety, stability (in biological environment) and the patient compliance. Microspheres can be defined as solid, approximately spherical particles ranging from 1 to 1,000 µm. These can control drug release to give a sustained therapeutic effect, provide greater safety, and target a drug specifically to a desired tissue.

Chitosan and alginate, the naturally occurring biopolymers, have shown potential for use as scaffolds in tissue-engineered medical products, as an encapsulating matrix for immobilization of living cells, and as drug delivery systems [3].

Chitosan is a deacetylated product of the polysaccharide chitin. It is a natural polyaminosaccharide which is collected from a variety of living organisms. It is obtained from the exoskeleton of crustaceans (like lobsters, shrimps, prawns, crabs) and the cell walls of some fungi (like Zygomicetes, Mucor and Aspergillus). Chitosan is biocompatible, nontoxic and biodegradable natural polymer with high charge density. It also shows antitumoral and antiviral activity. It is a very useful biomedical and pharmaceutical carrier for the essential oils, oral proteins/peptide and controlled drug delivery of variety of drugs [4–6]. Alginates are naturally occurring polysaccharides obtained from marine brown-algae consisting of two monomeric units; β-D-mannuronic acid and α-L-guluronic acid. Sodium alginate shows gellation properties due to crosslinking of branched chain structure containing acidic contents with multivalent cations such as Ca++, Ba++, and Al+++ [7]. The production of alginate microspheres using internal gelation offers a scalable method of encapsulation of cells, DNA and drugs. The internal gelation method is based on the release of calcium ion from an acid soluble calcium salt, in emulsified sodium alginate solution [4]. Various alginate, chitosan and alginate–chitosan microspheres have been investigated for delivery of various drugs [8]. Alginate form polyelectrolyte complexes with chitosan. The amino groups of chitosan have the ability to interact (through ionic binding) with carboxylic groups of alginate. These alginate chitosan polyelectrolyte complexes have been investigated for oral drug delivery of various drugs including proteins and peptides [9–11].

Microspheres prepared with chitosan have been widely investigated for various drugs. The various techniques employed to prepare the microspheres with chitosan include ionotropic gelation, spray drying, emulsion phase separation, simple and complex coacervation, solvent extrusion etc. [12]. Various cross linking agents like glutaraldehyde, sulphuric acid, sodium tripolyphosphate, citric acid have been used in the development of chitosan microspheres [12–15]. Among crosslinking agents (CLA) citric acid is one of the strong to moderate absorption enhancers that cause tissue disturbance with a slow recovery of functional groups [15]. It is evident that alginate microspheres show instability in a phosphate buffer above pH 5 and hence it is a drawback in the design of controlled release dosage forms. Therefore, the chitosan coated alginate microspheres can help to provide the controlled drug release. Alginate–chitosan complex erode slowly in phosphate buffer, and this behavior leads to suppression of the initial release of drugs occurring for uncoated microspheres. Usually these microspheres are produced by a two stage method, where preformed alginate microspheres are recovered and subsequently coated with chitosan [3].

VH is a calcium ion influx inhibitor (slow channel blocker). VH is used in angina, arrhythmia, supraventricular tachycardias including paroximal supraventricular tachycardia, atrial fibrillation and/or flutter, and re-entrant tachycardias involving the AV node and essential hypertension [16]. Moreover, verapamil is a potent inhibitor of P-glycoprotein-mediated transport, and has been proven to modify multidrug resistance with cancer chemotherapy in in vitro experiments [17]. VH exerts its pharmacologic effects by modulating the influx of ionic calcium across the cell membrane of the arterial smooth muscle as well as in conductile and contractile myocardial cells. But it is associated with a short biological half life (t1/2 4 h) and low bioavailability (20–35 %). So a high dose frequency is usual with the VH therapy.

Chitosan microspheres have been reported to show high potential for developing a successful gastroretentive drug delivery system due to its mucoadhesion and floating properties. The drugs such as VH that are poorly soluble in intestinal medium and readily soluble in acidic medium are the most suitable candidates for developing chitosan microspheres. The combination of alginate and chitosan for developing the microspheres may serve as a potential matrix delivery system for providing the extended and gradual release of VH to the upper gastro intestinal tract. This may lead to the improvement of the drug release profile to release the drug for extended period of time and hence reducing the dosage frequency. Moreover, adverse effects are expected to be reduced highly.

Therefore, the present study aims to prepare and characterize the alginate–chitosan microspheres of VH for improving the drug release profile so as to release the drug for extended period of time and hence reducing the dosage frequency. The study also evaluated the effect of drug to polymer ratio and different concentrations of CLA on the performance of prepared microspheres.

Materials and methods

Materials

Verapamil HCl, Propranolol HCl, Chitosan from shrimp shells with ≥75 % degree of deacetylation, Sodium tripolyphosphate (Na-TPP) and Sodium Alginate (5–40 cP, 1 % w/v in water at 25 °C) were procured from Sigma Aldrich, USA. All other chemicals used were of analytical grade.

Methods

Preparation of microspheres of verapamil hydrochloride

The solvent extrusion method (as reported in various previous studies) was used for preparation of four formulations of alginate chitosan microspheres (Table 1) [9, 10]. The microspheres loaded with the drug were prepared using two different drug to polymer ratio [1:1 and 1:2] and two different concentration of CLA [1 and 2 % w/v of Na-TPP in distilled water]. Amount of drug was weighed according to formulation (Table 1) and dissolved in 2 % w/v aqueous bubble free solution of sodium alginate with continuous stirring (on a magnetic stirrer on 700 rpm for 2 h). This bubble free alginate–drug solution was added dropwise to a gelation medium using a push–pull pump through a hypodermic plastic syringe (21 gauge) at a pumping rate of 10 ml/min. An equal proportion of chitosan (2 % w/v in 3 % v/v glacial acetic acid) and calcium chloride solutions (5 % w/v aqueous solution) were mixed (2 h before use) to form the gelation medium and the pH of the medium was adjusted to 5 ± 0.1 with 0.1 N sodium hydroxide. To this solution, 50 ml of Na-TPP cross linking agent solution (1 or 2 %w/v depending on the composition as mentioned in Table 1) was added drop wise with continuous stirring for 1 h. Alginate–chitosan microspheres were formed due to ionogelation mechanism followed by crosslinking. All the crosslinked microspheres formed were cured in the gelation medium for 4 h and then taken out, washed with distilled water thrice. Then the microspheres were spread over glass sheet, dried in oven and then stored in a desiccator at room temperature.

Percentage yield

The percentage yield was calculated from the weight of dried microspheres recovered from each batch in relation to the sum of the initial weight of starting materials. The percentage yield was calculated using the following formula: % yield = [Practical mass of microspheres/(Theoretical mass of polymer + drug)] × 100.

Particle size

Using optical microscopy method particle size of the formulations was determined. At least 100 microspheres were analyzed for each formulation and the mean particle size was calculated.

Drug content

The drug content was calculated by taking the microspheres equivalent to 50 mg of drug. Microspheres were finely crushed and dissolved in 100 ml of 0.1 N HCl. Then it was stirred on magnetic stirrer for 24 h and filtered. At the end of 24 h, sample was withdrawn, filtered, diluted suitably and measured spectrophotometrically (Lambda 25 Perkin Elmer, UV/Visible Spectrophotometer, USA) at 278 nm for the drug content.

Compressibility index

The loose bulk density (ρb) and the tap (ρt) density of the microspheres were measured in a measuring cylinder [18]. An amount of 1 g of prepared microspheres was filled in 10 ml graduated cylinder. The initial volume was noted then cylinder was tapped on wooden surface. The density was measured by tapping the cylinder 100 times (from the height of one inch) at the rate of 240 taps/min. Each determination was carried out in triplicate and the densities were calculated from the mean of the three determinations. The density was calculated by using the formula: Density = Mass/Volume. The Compressibility index was calculated by the formula: Compressibility index = [(ρt – ρb)/ρt] × 100. The Hausner’s ratio was calculated by the formula: Hausner’s ratio = (ρt/ρb) × 100.

Swelling index

The swellability of microspheres in simulated physiological media (with respect to pH) was determined by swelling in the three different media which were (distilled water, pH1.2 acid buffer, pH 6.8 phosphate buffer) [19, 20]. Accurately weighed 500 mg of microspheres were immersed firstly in little excess of three different media viz. distilled water, pH 1.2 acid buffer and pH 6.8 buffer (one by one). At the end of 2 h the microspheres immersed in pH 1.2 media and distilled water were collected and weighed. The immersion in water was maintained in another batch till the 4 h. At the end of 4 h the microspheres immersed in pH 6.8 media and distilled water were collected and weighed. The degree of swelling was calculated using the formula: Percent swelling = (Ws−Wi) × 100; where Ws = Weight of the microspheres in the swollen state, Wi = Weight of the microspheres in the initial state.

In vitro floatability studies

In vitro floatability studies on floating microspheres were carried out using USP apparatus type II. To assess the floating properties, the microspheres were placed in 0.1 N Hydrochloric acid containing 0.02 % v/v Tween 80 with agitation speed of 100 rpm for 12 h. Tween (0.02 % v/v) was used to impart wetting effect of the natural surfactants such as phospholipids in the GIT. The floating and the settled fractions of the microspheres were recovered separately, dried and weighed. The buoyancy was calculated by: Buoyancy (%) = Wf/(Wf + Ws) 100; Where Wf and Ws are weights of the floating and the settled microspheres, respectively.

Scanning electron microscopy

To detect the surface morphology and particle size of the microspheres, SEM of the microspheres was performed by scanning electron microscope (Carl Zeiss SMT Evo Series).

Fourier transform infrared spectroscopy (FT-IR)

FTIR spectra for the various component (drug and polymers) of microspheres and their physical mixture were obtained on a Perkin Elmer FTIR spectrometer (Perkin Elmer Life and Analytical Sciences, MA, USA) in the transmission mode with the wave number region 4,000–500 cm−1. KBr pellets were prepared by gently mixing 1 mg sample powder with 100 mg KBr.

X-ray powder diffractometry (XRPD)

The change of drug crystallinity in microspheres was assessed by obtaining diffraction patterns on a Bruker Axs- D8 Discover Powder X-ray diffractometer (Germany) for drug and microspheres. The operating conditions of X-ray generator were: tube voltage 40 kV; tube current 40 mA; radiation source Ka lines of copper; scanning angle from 1 to 50° of 2θ; mode step scan with step width 1°/min.

Differential scanning calorimetry (DSC)

Thermograms of VH, chitosan, and microspheres were recorded using a differential scanning calorimeter (2910 Modulated DSC V4.4E, TA Instruments, US). The thermal behavior was studied by heating 2.0 ± 0.2 mg of each individual sample in a covered sample pan under nitrogen gas flow. The investigations were carried out over the temperature range 25–350 °C with a heating rate of 10 °C min−1.

In vitro drug release studies

In-vitro release profile of the microspheres was studied using 8 stage USP dissolution test apparatus using 900 ml of pH 1.2 acid buffer (first dissolution media) maintained at 37 ± 0.5 °C at 50 rpm. Accurately weighed microspheres equivalent to 100 mg of drug were placed and the dissolution was done for 2.5 h and at prefixed time of every 30 min, samples were withdrawn and replaced with the equal volume of fresh media for maintaining the sink condition. After filtration and suitably dilution, samples were assayed spectrophotometrically for the drug release at 278 nm using UV–Visible Spectrophotometer. Then the dissolution media was replaced by 900 ml (pH 6.8 phosphate buffer) maintained at 37 ± 0.5 °C at 50 rpm. The study was continued till the end of 12 h. Samples were withdrawn, diluted suitably and then assayed spectrophotometrically for the drug release at 278 nm.

Kinetics of drug release

For understanding the mechanism of drug release and release rate kinetics of the drug from dosage form, the in vitro drug release data was fitted to various mathematical models representing zero-order (Q v/s t), first-order (log (Qo–Q) v/s t), Higuchi’s square root of time (Q v/s t1/2) and Korsemeyer peppas double log plot (log Q v/s log t), respectively, where Q is the cumulative percentage of drug released at time t and (Q0–Q) is the cumulative percentage of drug remaining after time t.

In vivo drug release study

The microsphere formulation showing the best performance was selected for in vivo studies. Male Wistar rats (250–300 g) were used for the study after acclimatized at 12 h light cycle for at least 3 days before use. Rats were fed a normal standard diet ad libitum. Animals were divided in three groups (control, test and standard) consisting of six rats in each. After fasting overnight, suspensions of pure VH (standard) and selected microsphere formulation of VH (Test) in the dose of 10 mg/kg were administered orally to rats. Control group received the blank suspension with tween 80. The rats were anesthetized using ether and the blood samples were withdrawn from retro-orbital region at 0 (pre-dose), 0.5, 1, 2, 4, 6, 8, and 12 h in tubes containing anti-coagulant, mixed and centrifuged at 3,000 rpm for 20 min. The plasma was separated carefully and stored at −10 °C until drug analysis was carried out using HPLC.

Quantitation of VH by HPLC method in plasma

Samples were treated using propranolol HCl as an internal standard as per the method reported by Kunta et al. [21]. A total of 0.5 ml of in vivo plasma sample containing VH was mixed with 0.05 ml of the internal standard solution (propranolol, 1 µg/ml in water), 0.1 ml of 1 M sodium carbonate, and 5 ml of diethyl ether in 15-ml polypropylene tubes. For the calibration plot, serial dilutions of VH were made from the same stock solution used for the study and were spiked into the blank plasma. The in vivo plasma and standard samples were then vortexed for 10 min and centrifuged at 1,500 g for 10 min at 4 °C. The centrifuged samples were placed on dry ice for 1 min and the supernatant was transferred to another polypropylene tube containing 0.2 ml of 0.1 N hydrochloric acid, vortexed for 10 min, and centrifuged at 1,500 g for another 10 min at 4 °C. The supernatant was discarded and 0.1 ml of the aqueous phase containing drug and internal standard was analyzed by HPLC fluorometrically. VH was analyzed in plasma by HPLC under isocratic conditions on a reverse phase C18 column (Lichrosorb C18 RP-column 250 × 4.6 mm L.D). The mobile phase (acetonitrile:0.1 % trifluoroacetic acid solution in 40:60 ratio) was pumped at a flow rate of 1 ml/min. The calibration curve was developed in plasma for the VH within a range of 10–2,000 ng/ml and was found to be linear in the range.

Statistical analysis

Results were expressed as mean values and standard deviations (± SD) and the significance of the difference observed was analyzed by the Student’s t test.

Results and discussion

In the present work, the alginate–chitosan microspheres of VH were prepared by solvent extrusion method using chitosan and sodium alginate as polymers and sodium tripolyphosphate as cross linking agent. The method adopted provides the advantage over conventional methods because of less or minimum use of organic solvents. In the method of preparation, the electrostatic attraction between the amino (–NH3+) groups of chitosan and the carboxylic (–COO−) groups of alginate resulted into the formation of polyelectrolyte complexes. The effect of using different drug to polymer ratio and concentrations of CLA on the performance of prepared microspheres was also studied for various parameters like particle size, bulk density, tap density, swelling index, percent drug loading, in vitro floating and drug release (in vitro and in vivo both) study. The percentage yield for VH microspheres using sodium alginate and chitosan was found to be 78.1, 75.6, 85.2, and 82.0 % for V1, V2, V3, and V4, respectively.

Particle size analysis

The particle size range of all the formulations of microspheres was found to be 1,123.50–1,534.40 µm. The particle size distribution in each formulation was quite uniform and in a narrow range. Moreover, the gauge size of the needle used in the preparation and the other parameters related to preparation method (the extrusion technique) like the height from which the drops were added, the speed of dropping etc. play the role in governing the particle size and particle size distribution. Various previous reports have shown the particle size range of 1,200–1,500 µm obatined from the use of plastic syringe with 21 gauze needle at the pumping rate of 10 ml/min [9, 10]. It was observed that the particle size was greater for the formulation with higher chitosan concentration. This effect was might be due to interaction of the chitosan’s amino groups and sodium alginate’s carboxyl groups leading to the formation of a complex. Supporting this study, various previous reports also found the 1:1 binding ratio of chitosan to alginate as the optimal one. Moreover, previous studies also reported the similar result that the equal ratio yield small size particles which increase more with increase in the amount of chitosan [9, 22, 23]. The studies have also reported that the needle diameter show more pronounced effect on the determination of particle size rather than the alginate/chitosan ratio.

Drug content

Drug content or drug loading of the microsphere formulations was found to be 74.88, 78.64, 79.4, 84.4 % for V1, V2, V3, and V4, respectively (Table 2). It can be explained that an increase in chitosan concentration increased the viscosity of the dispersed phase and hence resulted in increase in drug loading of microsphere. Particle size also increased with viscosity. The higher viscosity of the chitosan solution at the higher polymer concentration would be expected to increase the diffusion of the drug into the external phase which would result in increased drug content [24].

Compressibility index and Hausner’s ratio

The physical parameters (Table 2) such as bulk density, tapping density, compressibility index, Hausner’s ratio were evaluated, which provided the basis for optimization of the flow property of microspheres. All the microspheres of various formulations showed good flow property. Bulk density is indicative of the package properties of the microspheres. All the microspheres of different formulations showed the buk density of less than 1 g/ml. The formulation V1 showed higher compressibility index and Hausner’s ratio in all Verapamil HCl formulations.

Swelling study

Swelling is an important and vital property for a gastroretentive floating drug delivery system. The swelling aids the floating and mucoadhesive properties. The order of swelling index (Fig. 1) for VH microspheres formulations were as followed: In pH 1.2 after 2 h-V3 > V1 > V2 > V4; In pH 6.8 after 4 h-V3 > V1 > V2 > V4; In Distilled water after 2 h-V4 > V3 > V1 > V2; In Distilled water after 4 h-V2 > V4 > V1 > V3.

It was evident that irrespective of CLA the microspheres with drug to polymer ratio 1:1 (V1 and V3) had the greater swelling properties in pH 1.2 and pH 6.8 media. On the other hand, in the distilled water microspheres prepared with the lower drug to polymer ratio formulations (V2 and V4) showed the greater swelling as compared to the microspheres with higher drug to polymer ratio (after 4 h). Though it was also evident that with the distilled water after the end of 2 h the formulations (V4 and V3) prepared with higher concentration of CLA (2 % w/v) showed greater swelling as compared to other formulations (V1 and V2).

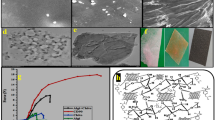

SEM

In the SEM study the shape of chitosan-alginate microsphere formulations were found to be spherical with smooth texture. There was no major difference except the particle size in the SEM of all the formlulations. The formulation V1 was found to be spherical with slight irregularities in surface morphology. On the other hand, the formulation V3 showed the spherical shape with smooth surface (Fig. 2). The smooth surface might have contributed vitally in the extended release of the drug.

In vitro floatability studies

The floatability of the microspheres (Table 2) was found to be in good tune with their swelling properties. All the formulation showed good % swelling in the range of 55.4–84.6 % at the end of 12 h of the study. It was evident the microspheres with drug to polymer ratio of 1:1 (V1 and V3) showed higher floatability as compared to the formulation V2 and V4 (with higher chitosan proportion). As far as the effect of CLA is concerned it was found that increase in concentration of CLA increased the floatability. Though the formulation (V3 and V4) with higher CLA (2 % w/v) concentration showed higher floatability the effect was more pronounced with V3 (with drug to polymer ratio of 1:1). So as in case of swelling, drug to polymer ratio again played an important role.

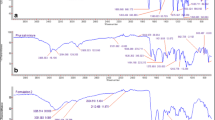

FTIR spectroscopy

The formation of the polyelectrolyte complex was confirmed by the FTIR Spectroscopy by comparing the spectrum of alginate–chitosan microspheres formulation with the spectrum of the individual components (Fig. 3). VH (Fig. 3a) showed the characteristic absorption band between 2,989 and 2,875 cm−1 corresponding to the superimposed C–H stretching vibrations of the various methyl and methylene groups; a sharp band corresponding to C–H stretching vibrations of the methoxyl group was observed at 2,840 cm−1; a sharp band at 2,236 cm−1 corresponding to C ≡ N stretching vibrations of the saturated alkyl nitrile; at 1,610 cm−1 due to the benzene skeletal stretching vibrations and; at the 1,018 cm−1 due to C–O–C stretching.

The FT-IR spectrum of sodium alginate showed characteristic peaks of hydroxyl group at 3,428 cm−1; stretching absorption bands of –CH, COO–, –CH and C–O–C at about 2,933, 1,623, 1,419 and 1,031 cm−1, respectively; carbonyl group at 1,623 cm−1 and; carboxyl and carboxylate groups between 1,000 and 1,400 cm−1.

The drug loaded alginate–chitosan microsphere formulation (V3) showed the characteristic peaks corresponding to VH with less intensity. The –OH band was broader in the drug loaded microsphere’s spectrum indicating the interaction responsible for probable complex formation. Moreover, the band 2,877 cm −1 corresponding to chitosan was shifted to 2,933 cm−1 indicating the confirmation of complex formation between chitosan and alginate.

Crystallinity study (XRPD)

The X-Ray diffraction pattern of the VH, blank microspheres and the drug loaded microspheres (V1 and V3) were studied for observing the change in crystallinity of the drug in the carrier system of polyelectrolyte complex i.e. alginate–chitosan microspheres (Fig. 4). In the X-ray diffractogram, VH showed intense diffraction peaks of crystallinity. X-ray diffraction pattern of the drug loaded microspheres (V1 and V3) showed the disappearance and/or drastic reduction in the intensity of many large diffraction peaks and it was not possible to distinguish the characteristic peaks of the drug. This indicated the decrease in crystallinity and presence of drug in amorphous form in the microspheres. Moreover, the formulation with higher CLA (V3) showed more diffused peaks indicating the more amorphous nature as compared to that of formulation V1.

Thermal analysis (DSC)

Differential scanning calorimetry (DSC) is a tool which indicates an interaction between the components of a system/complex by various parameters like elimination of endothermic peaks, appearance of new peaks, change in peak, shape and its onset, peak temperature, melting point and relative peak area or enthalpy. DSC analysis of VH, alginate, chitosan, physical mixture, blank microspheres and the drug loaded microspheres (V3) was performed (Fig. 5). Formulation V3 was selected on the basis of its best properties with respect to yield, drug content, swelling, floatability and amorphous nature (confirmed by XRPD). VH showed a sharp exothermic peak at 147 °C. The DSC curve of sodium alginate showed a broad endothermal phenomenon between 50 and 100 °C (due to the loss of water) and a sharp exothermic peak at 248 °C. The higher sharp exothermic peaks were observed due to degradation of polyelectrolytes via dehydration, depolymerization reactions, partial decarboxilation of the protonated carboxylic groups and oxidation reactions of the polyelectrolytes [25]. The DSC curve of chitosan showed a broad endothermal phenomenon between 25 and 80 °C (due to the loss of water) and higher exothermic peak at 310 °C (due to degradation of polyelectrolytes). Unlike the DSC curve of physical mixture (which was showing only the combination of peaks of both the materials) the blank alginate–chitosan microspheres showed the almost disappearance of exothermic peaks corresponding to alginate and chitosan both. Rather an intermediate and broader peak value compared (289 °C) with isolate polyelectrolyte was observed in blank microspheres and this indicated an interaction between both the components.

On the other hand the DSC curves of drug loaded microspheres prepared in 1:1 ratio with higher % (2 %) of CLA (V3) showed a significant shift in exothermic peak corresponding to the drug from 147 to 187 °C. Moreover, the peaks corresponding to alginate and chitosan disappeared from the drug loaded formulation. The shift of the exothermic peak (corresponding to that of VH) suggested the formation of a complex without any free VH.

In vitro drug release study

In vitro drug release studies of both the formulations were performed initially in Acid buffer (pH 1.2) for 2.5 h followed by phosphate buffer (pH 6.8). At the end of 12 h the percentage drug release was found to be 89.9, 85, 95.45 and 89.23 % at the end of 12 h for V1, V2, V3 and V4, respectively (Fig. 6). The drug release was poor in pH 1.2 and then triggered in pH 6.8. Poor drug release at pH 1.2 may be attributed to the poor swelling of the alginate microspheres at acidic pH due to the inability of the dissolution medium to penetrate the microspheres. However, the dissolution medium readily penetrated the beads at pH 6.8, easily leaching out the drug incorporated in them. The formulation V3 showed maximum drug release among all four formulations. For a constant concentration of CLA, higher the drug to polymer ratio (V1 and V3) the greater was the extent of drug release. A significant decrease in the rate and extent of drug release is attributed to the increase in the density of polymer matrix (as in case of V2 and V4) [24, 26]. The extent of drug release was found to be increased with the higher drug to polymer ratio (1:1). Additionally, the larger particle size at higher polymer concentration also restricted the total surface area resulting in slower release. The pH dependent release of drugs from chitosan coated alginate microspheres has been previously reported for insulin, albumin and hirudin [27–29]. There is a lack of knowledge of alginate microspheres behaviour under simulated gastric and intestinal fluids but the stability of chitosan–alginate complex may be influenced by environmental parameters, such as pH and ionic strength. Two-hour assay under simulated gastric conditions can lead to dissociation of ionic linkages and dissolution of the alginate matrix [30]. It is suggested that an uninterrupted coating method would allow sustaining drug release under GI conditions, suggested a chitosan–alginate membrane acting as diffusion barrier.

Kinetics of drug release

The mechanism of drug release and release rate kinetics of the drug from microspheres was determined by fitting the in vitro drug release data to the various mathematical models representing zero-order, first-order, Higuchi’s square root of time and Korsemeyer peppas plot. The correlation coefficients values were determined and studied for the best fit model (Table 3).

The release mechanism was determined using the Korsmeyer Peppas model. According to this model, n values indicate the type of release mechanism. For spheres, values of n between 0.45 and 0.85 are an indication of both diffusion-controlled and swelling-controlled release mechanisms (anomalous transport). Values greater than 0.85 and 1.0 indicate Case II and Super Case II transports, respectively, which relate to polymer relaxation. As all the values of n for all the formulations were greater than 1.0, the release mechanism was Super Case-II transport. It is most likely that the formation of polyelectrolyte complex membrane reduced the initial swelling and erosion of the microspheres and shifted the drug release mechanism toward anomalous transport or case II transport, indicating that the drug was diffusing through the microspheres at the same time as polymer relaxation was taking place.

Effect of concentration of CLA

To understand the effect of CLA the formulations were compared for all the parameters. The cross linking agents showed a significant effect on drug content. The microspheres prepared with 2 % CLA showed higher drug content that of CLA 2 % microspheres. An increase in concentration in CLA caused decrease in compressibility index (Table 2). Microspheres prepared with CLA 1 % showed high compressibility index than that of CLA 2 % microspheres. The formulation with increased concentration of CLA increased the swelling in pH 1.2 and pH 6.8 buffer for higher drug to polymer ratio at the end of 2 h (i.e. swelling of V3 > V1). But for the lower drug to polymer ratio increasing the CLA concentration could not show the increase in the swelling property (V2 > V4). With the distilled water at the end of 2 h the microspheres prepared with higher concentration of CLA (V3 and V4) showed greater swelling as compared to other formulations (V2 and V4).

In a nut shell, it was concluded that the formulation V3 (containing higher drug to polymer ratio i.e. 1:1 with higher CLA concentration i.e. 2 %) showed the greater swelling properties in both the different pH of gastrointestinal tract. It was also evident that increased swellability cause increase pore size on the surface of the microspheres. And this increased pore size by the swelling results in an increase in drug release from the microspheres [24, 26]. Microspheres’ swelling is ion-sensitive and the slow release from coated alginate matrix even in phosphate buffer suggested a strong chitosan diffusion barrier [30].

As far as the effect of CLA concentration on drug release was concerned the microspheres which contain CLA 2 % showed higher drug release than CLA 1 % formulations.

In vivo drug release study

Among all the alginate–chitosan microsphere formulations, formulation V3 was selected (due to its best in vitro release) fro in vivo drug release studies. The plasma drug concentration at different time intervals were noted and the plasma drug concentration–time profile curve was plotted (Fig. 7). In the present study, the peak plasma concentration (Cmax) was almost unchanged for the microsphere and the pure drug, but there was a significant difference in tmax and AUC. The delayed swelling followed by the slow release of the VH from the alginate–chitosan microspheres might have controlled and extended the release of VH.

Conclusion

To reduce the dosage frequency of Verapamil the controlled release microparticultate drug delivery system were prepared and investigated. The alginate–chitosan polyelectrolyte complex based microspheres of VH were prepared by solvent extrusion method using chitosan and sodium alginate (polymers) and Na-TPP (cross linking agent). The effect of drug to polymer ratio and concentrations of CLA on the performance of prepared microspheres was also studied.

It was concluded that irrespective of CLA concentration the microspheres with higher drug to polymer ratio 1:1 (V1and V3) showed the greater drug content, good flow properties (evidenced by density and compressibility index data), best floatability, best swelling properties (in both the pH) and promising in vitro drug release. With respect to the effect of concentration of CLA (citric acid) on microspheres of Verapamil, it was concluded that the microspheres prepared with CLA 2 % showed increased drug loading, increased floatability, decreased compressibility index, decreased water swellability (with the exception of increase in swellability in pH1.2 and in pH 6.8) and led to improved in vitro and in vivo drug release.

Among all the microsphere formulations the formulation V3 (drug to polymer ratio 1:1 and CLA 4 %) was considered as the best formulation on the basis of the best performance with respect to percent yield, drug content, flow properties (evidenced by density and compressibility index data), best swelling properties (in both the pH), floatability, in vitro drug release and in vivo bioavailability studies.

Therefore, it was concluded that the alginate–chitosan polyelectrolyte complex might be used as an effective carrier for sustaining the drug release of Verapamil hydrochloride; thereby minimizing the dosage frequency and ultimately leading to improved patient compliance.

References

Arul, B., Kothai, R., Sangmeswaran, B., Jayakar, B.: Formulation and evaluation of chitosan microspheres containing isoniazid. Indian J. Pharm. Sci. 65, 640–642 (2003)

Semalty, M., Yadav, S., Semalty, A.: Preparation and characterization of gastroretentive floating microspheres of ofloxacin hydrochloride. Int. J. Pharm. Sci. Nanotech. 3, 819–823 (2010)

Ribeiro, A.J., Silvam, C., Ferreira, D., Veiga, F.: Chitosan-reinforced alginate microspheres obtained through the emulsification/internal gelation technique. Eur. J. Pharm. Sci. 25, 31–40 (2005). doi:10.1016/j.ejps.2005.01.016

Tao, Y., Zhang, H.L., Hu, Y.M., Wan, S., Su, Z.Q.: Preparation of chitosan and water-soluble chitosan microspheres via spray-drying method to lower blood lipids in rats fed with high-fat diets. Int. J. Mol. Sci. 14, 4174–4184 (2013). doi:10.3390/ijms14024174

Illum, L.: Chitosan and its use as a pharmaceutical excipient. Pharm. Res. 15, 1326–1331 (1998). doi:10.1023/A:1011929016601

Hejazi, R., Amiji, M.: Chitosan based gastrointestinal delivery systems. J. Control. Releas. 89, 151–165 (2003). doi:10.1016/S0168-3659(03)00126-3

Sharma, V.K., Mazumder, B.: Gastrointestinal transition and anti-diabetic effect of Isabgol husk microparticles containing gliclazide. Int. J. Biol. Macro. 66, 15–25 (2014). doi:10.1016/j.ijbiomac.2014.02.014

Lanjhiyana, S.K., Bajpayee, P., Kesavan, K., Lanjhiyana, S., Muthu, M.S.: Chitosan-sodium alginate blended polyelectrolyte complexes as potential multiparticulate carrier system: colon-targeted delivery and gamma scintigraphic imaging. Expert Opin. Drug Deliv. 10, 5–15 (2013). doi:10.1517/17425247.2013.734805

Takka, S., Gürel, A.: Evaluation of chitosan/alginate beads using experimental design: formulation and in vitro characterization. AAPS PharmSciTech 11(1), 460–466 (2010). doi:10.1208/s12249-010-9406-z

Basu, S.K., Rajendran, A.: Studies in the development of nateglinide loaded calcium alginate and chitosan coated calcium alginate beads. Chem. Pharm. Bull. 56(8), 1077–1084 (2008). doi:10.1248/cpb.56.1077

George, M., Abraham, T.E.: Polyionic hydrocolloids for the intestinal delivery of protein drugs: alginate and chitosan—a review. J Cont Rel. 114, 1–14 (2006). doi:10.1016/j.jconrel.2006.04.017

Mitra, A., Dey, B.: Chitosan microspheres in novel drug delivery systems. Indian J. Pharm. Sci. 73(4), 355–366 (2011). PMid:22707817

Kumbar, S.G., Kulkarni, A.R., Aminabhavi, M.: Crosslinked chitosan microspheres for encapsulation of diclofenac sodium: effect of crosslinking agent. J. Microencapsul. 19(2), 173–180 (2002). doi:10.1080/02652040110065422

Desai, K.G., Park, H.J.: Encapsulation of vitamin C in tripolyphosphate cross-linked chitosan microspheres by spray drying. J. Microencapsul. 22(2), 179–192 (2005). doi:10.1080/02652040400026533

Varshosaz, J., Alinagri, R.: Effect of Citric acid as crosslinking agent on insulin loaded chitosan microspheres. Iran. Polym. J. 14(7), 647–656 (2005)

Semalty, M., Verma, D., Semalty, A.: Development and evaluation of microcapsules of Verapamil hydrochloride. Indian Drugs 48(8), 33–38 (2011)

Pauli-Magnus, C., Von Richter, O., Burk, O., Mettang, T., Eichelbaum, M.: Characterization of the major metabolites of verapamil as substrates and inhibitors of P-glycoprotein 1. J. Pharmacol. Exp. Ther. 293, 376–382 (2000). PMid:10773005

Shabaraya, A., Narayanachrayulu, R.: Design and evaluation of chitosan microspheres of metoprolol tartrate for sustained release. Indian J. Pharm. Sci. 65, 250–252 (2003)

Bahera, L., Sahoo, K., Patil, V.: Preparation and in vitro characterization of oral sustained release Chitosan coated Cefepime hydrochloride microspheres. Int. J. Pharm. Tech. Res. 2, 798–803 (2010)

Zhang, Y., Wei, W.: Preparation and evaluation of alginate–chitosan microspheres for oral delivery of insulin. Eur. J. Pharm. Biopharm. 77, 11–19 (2011). doi:10.1016/j.ejpb.2010.09.016

Kunta, J.R., Lee, S.H., Perry, B.A., Lee, Y.H., Sinko, P.J.: Differentiation of gut and hepatic first-pass loss of verapamil in intestinal and vascular access-ported (ivap) rabbits. Drug Metab. Dispos. 32(11), 1293–1298 (2004). doi:10.1124/dmd.104.000752

Takahashi, T., Takayama, K., Machida, Y., Nagai, T.: Characteristics of polyion complexes of chitosan with sodium alginate and sodium polyacrylate. Int. J. Pharm. 61, 35–41 (1990). doi:10.1016/0378-5173(90)90041-2

Douglas, K.L., Tabriziani, M.: Effect of experimental parameters on the formation of alginate–chitosan nanoparticles and evaluation of their potential application as DNA carrier. J. Biomater. Sci. Polym. Ed. 16, 43–56 (2005). doi:10.1163/1568562052843339

Anal, A., Stevens, W.: Chitosan alginate beads for controlled release of ampicillin. Int. J. Pharm. 290(1–2), 45–54 (2005). doi:10.1016/j.ijpharm.2004.11.015

Soares, J.P., Santos, J.E., Chierice, G.O., Cavalheiro, E.T.G.: Thermal behavior of alginic acid and its sodium salt. Ecl. Quím. São. Paulo. 29(2), 53–56 (2004)

Srinatha, A., Pandit, J., Singh, S.: Ionic cross linked chitosan beads for extended release of ciprofloxacin. Indian J. Pharm. Sci. 70, 16–21 (2008). doi:10.4103/0250-474X.40326

Anal, A.K., Bhopatkar, D., Tokura, S., Tamura, H., Stevens, W.F.: Chitosan–alginate multilayer beads for gastric passage and controlled intestinal release of protein. Drug Devel. Ind. Pharm. 29, 713–724 (2003). doi:10.1081/DDC-120021320

Onal, S., Zihnioglu, F.: Encapsulation of insulin in chitosan-coated alginate beads: oral therapeutic peptide delivery. Artif. Cells Blood Substit. Biotechnol. 30, 229–237 (2002). doi:10.1081/BIO-120004343

Chandy, T., Rao, G.H., Wilson, R.F., Das, G.S.: Delivery of LMW heparin via surface coated chitosan/peg-alginate microspheres prevents thrombosis. Drug Deliv. 9, 87–96 (2002). doi:10.1080/10426500290095584

Shu, X.Z., Zhu, K.J., Song, W.: Novel pH-sensitive citrate crosslinked chitosan film for drug controlled release. Int. J. Pharm. 212, 19–28 (2001). doi:10.1016/S0378-5173(00)00582-2

Conflict of interest

None.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, XZ., Tian, FJ., Hou, YM. et al. Preparation and in vitro in vivo characterization of polyelectrolyte alginate–chitosan complex based microspheres loaded with verapamil hydrochloride for improved oral drug delivery. J Incl Phenom Macrocycl Chem 81, 429–440 (2015). https://doi.org/10.1007/s10847-014-0471-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-014-0471-x