Abstract

Product service systems (PSS) have led global manufacturers to change from providing product only to offering both product and its services as a whole. The existing decision-making methods have difficulties in evaluating design alternatives systematically during PSS conceptual design process involving cognition vagueness and related complex factors. A new systematic decision-making method is developed for judging these alternatives. PSS is divided into multiple-modules associated with function characteristics and then evaluated by using the outputs of parallel houses of quality (HoQs). HoQs can efficiently deal with customer requirements and the relationships between product and service. A variable precision rough set-based approach is proposed to evaluate these alternatives, which can flexibly handle subjectivity and vagueness during the decision-making process. An optimizing model of least squares model is used to integrate individual judgments into a consensus group judgment. A non-deterministic ranking method is developed to identify optimal alternative based on the final judgments which are obtained by using a rough weighted geometric mean method. The proposed method is validated through a real-world case study for a horizontal directional drilling machine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the increasing needs of sustainable production and consumption, service as a source of core value, is becoming more and more important for manufacturing enterprises. Meanwhile, customer requirements (CRs) are shifting from purchasing just a physical product to acquiring a result or a function provided by the product combining with its related services (Baines et al. 2007). Enterprises are then shifting their business focus from designing physical product only, to designing the offering of product and related services which are jointly capable of satisfying the specific CRs. Product service systems (PSS), a combined offering of physical product and non-physical service, has thus been developed and implemented (Cavalieri and Pezzotta 2012). It revolutionizes consumer experience, increases manufacturers’ profits and reduces environmental impacts (Mont 2002). Generally, new concept development involves a series of critical decision-making process (Krishnan and Ulrich 2001). Similarly, design alternative selection also plays an important role in the PSS development, where a set of new alternatives are evaluated with respect to different criteria to select an optimal one (Büyüközkan et al. 2012; Ayağ and Ozdemir 2007). Since a lot of subjectivity and vagueness is involved in the designers’ cognition and judgments during PSS, a systematic decision-making environment is required for identifying optimal alternative which can consider both objectivity granularity and evaluation accuracy.

Recently, various engineering methods and tools have been developed to implement the PSS development. Aurich et al. (2006) proposed that life-cycle engineering can be used for PSS development and introduced a systematic design process to deliver product-related technical services. The integrated product and service offering (IPSO) concept was developed from the life cycle perspective to provide an optimized product and service combination to satisfy CRs, and corresponding development methods and tools were also given for mass customization environment (Lindahl et al. 2006; Sundin et al. 2007). Komoto and Tomiyama (2009) developed an integrated life-cycle simulation design tool–integrated service CAD with life-cycle simulator (ISCLS) for PSS development. Garetti et al. (2012) also deemed the life cycle simulation modeling as an effective way to support PSS design and provided reference architecture for life cycle simulation.

To implement PSS development more effectively, Sakao and Shimomura (2007) and Sakao et al. (2009) proposed a computer-aided design system—Service Explorer for integrated product and service design, which includes four models, flow model, domain model, scenario model and view model. Zhang and Chu (2010) developed a conceptual design framework based on parallel houses of quality (HoQs), which can effectively translate CRs into function characteristics (FCs) and module characteristics (MCs) of product and maintenance considering their interrelationships. Failure mode and effects analysis was used to analyze interchange information to match product concept and maintenance concept. Configuration design is a useful way for PSS development. Mannweiler and Aurich (2011) suggested a framework for customer-oriented PSS configuration which consisted of dealing with the prerequisites for PSS configuration and implementing its configuration activities. Long et al. (2013) proposed a support vector machine based approach to support PSS configuration considering customer perception. Wang et al. (2011) proposed a modular design approach for PSS, where the PSS concept is divided into functional modules, product modules and service modules. Li et al. (2012) used mapping matrix to support module division of integrated service offerings (like PSS) based on “top down” and “bottom-up” strategies for facilitating configuration design. Meier et al. (2010) summarized the current industrial PSSs (IPS2) research progress and claimed IPS2 is a knowledge-intensive “social-technical systems”. The related work and approaches were discussed in detail from the aspects of design, development, architecture building, delivery and lifecycle knowledge management. To effectively exploit design knowledge, Baxter et al. (2009) developed a knowledge management framework and methodology, which enables access to design knowledge, manufacturing capability knowledge and service knowledge for supporting collaborative PSS development. And a PSS knowledge reuse and management system was established for construction machinery industry (Zhang et al. 2012).

Generally, PSS design alternative evaluation is considered as a complex multi-criteria decision making problem under designers’ cognition environments. Considering the impacts of these complex criteria and uncertainty factors, many decision-making methods are developed in the PSS evaluation field. Huang et al. (2011) developed a performance evaluation metrics for selecting and combining proper services. Sun et al. (2012) introduced a performance evaluation method for product and service from five indicators, time, quality, cost, stability and reliability. Yoon et al. (2012) proposed an evaluation method for designing a car-sharing service (i.e. one of use-oriented PSSs), where the evaluation indices take into account the perspectives of service providers as well as customers. Kuo and Wang (2012) used a multi-attribute utility analysis method for identifying maintenance service levels in PSS development. Chen et al. (2014) proposed a new Information Axiom based decision-making approach to improve the objectivity and effectiveness of PSS concept evaluation in a fuzzy-stochastic environment.

Although researchers have proposed many methods for PSS evaluation, objectivity complexity and cognitive vagueness have not been addressed adequately for controlling evaluation risk during the decision-making process. This is not an easy task for the designers under the impacts of subjective vagueness and concept complexity. And a systematic decision-making method is still required for effectively implementing the evaluation of PSS design alternatives. Three characteristics of PSS evaluation are considered in the study.

-

(1)

More complexity in PSS than single product or service.

-

(2)

Vagueness during the decision-making process.

-

(3)

Effective ranking method for complex PSS design alternatives.

In most existing methods for evaluating design alternatives, the decision-making stage is not closely integrated with previous design stages [e.g. customer requirement (CR) analysis, concept generation]. Criteria establishment and alternative evaluation are mainly implemented based on the designers’ judgments. A systematic mechanism is deficient during the decision-making process, where inconsistencies may be caused. To improve the accuracy and availability of decision-making, it is necessary to sufficiently use existing information in the PSS conceptual design and develop highly individualized method.

In this study, a systematic decision-making method is proposed by using the previous stages’ information and mixing several decision-making approaches based on the above three characteristics. The proposed method uses previous information in conceptual design and then forms a feedback mechanism which can ensure the selected alternative satisfy CRs as much as possible. In the PSS conceptual design, CRs are translated into function characteristics (FCs) and maintenance characteristics (MCs) by using the parallel HoQs (Zhang and Chu 2010). In this paper, the outputs and the relationships in the HoQs are used to help the designers establish evaluation criteria and to evaluate PSS design alternatives. Generally, it is difficult for the designers to give precise judgments during the PSS evaluation process. The traditional decision-making methods have successfully used fuzzy sets (Kuo et al. 2007), vague sets (Pawlak 1982) and intuitionistic fuzzy sets (Atanassov and Gargov 1989) in engineering design evaluation to deal with subjective vagueness. However, these methods are limited to use pre-defined functions with fixed boundaries, which rely on the designers’ knowledge and experiences. This is not realistic because available data are relative insufficient during the conceptual design stage (Pahl and Beitz 1996). These membership functions may also be dynamically changed following different decision-making objects. Furthermore, different membership functions are critical for the performance of a fuzzy system and have great influences on the final results (Jin 2003). Zhai et al. (2009) proposed an effective concept known as rough number to manage and express the imprecise individual judgments in product development. The approach has also been applied in the ranking of CRs in PSS development (Song et al. 2013). However, the designers may have different cognitive vagueness for expressing their judgments. They also cannot accurately give fuzzy ranges or boundaries for different judgments. This usually can be solved through multiple formatted preferences (Büyüközkan and Çifçi 2013). By contrast, the study develops a new variable precision rough set method to automatically generate rough numbers to express individual judgments without any priori-knowledge and experience. The individual judgments are integrated into consensus group judgments, which should adequately reflect each individual judgment with as small deviation as possible. These group judgments can be weighted summed into a final result for evaluating and ranking the PSS design alternatives. The result intervals should also be as small as possible to facilitate the ranking of PSS design alternatives. In this paper, a rough least square model (RLSM) is proposed to integrate individual judgments into consensus group judgments, and then a rough weighted geometric mean (RWGM) is used to calculate the weighted sum of these group judgments to form the final result. A non-deterministic ranking method for interval values is then developed for identifying an optimal one from the PSS concept alternative set.

The main contributions of this study are given as follows:

-

(1)

This study provides a structural mechanism for establishing criteria and identifying their importances, which enables the criteria to be produced from the viewpoint of customers and the relationships between product and service. Furthermore, the mechanism can efficiently use existing information during the PSS conceptual design process.

-

(2)

The variable precision rough set method can address a more flexible and credible expression for the designers’ judgments without any prior knowledge.

-

(3)

The systematic decision making method produces more rational and reliable group judgments and ranking results for evaluating the PSS design alternatives.

The paper is organized as follows. The decision-making process is summarized in the next section. The third section describes the systematic decision-making method for evaluating PSS design alternatives. In the fourth section the proposed method is applied in a real-world case concerning PSS design alternative selection for a horizontal directional drilling (HDD) machine. Conclusions are then presented in the final section.

Decision-making process

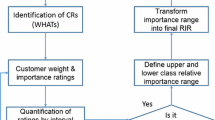

The decision-making process generally includes three steps: establishing evaluation criteria, implementing evaluation for each alternative, and ranking all alternatives. A blueprint is summarized for the PSS decision-making process (Fig. 1):

-

(1)

PSS concept is decomposed into several modules based on the outputs of parallel HoQs for facilitating the evaluation considering its complexity. The evaluation criterion for each module can be identified based on the relationship matrix between FCs and modules in the parallel HoQ. Importance weights of these criteria can be determined by the relationship and correlation matrices and input weights in the HoQs which has been calculated in the CRs mapping stage.

-

(2)

The decision-making process adequately considers the following factors, including customer, manufacturer, market, environment, and so on. Individual judgment is flexibly expressed in rough number considering the individual personality and other individual judgments in the same set. All these individual rough judgments are integrated into group judgments with minor deviation.

-

(3)

Based on the importance weights of different criteria, group judgments are weighted summed into the final result for the PSS design alternatives with as small interval as possible. The optimal one in the alternative set can be identified based on their ranking results.

A systematic decision-making method for evaluating PSS design alternatives

In the PSS conceptual design, a systematic decision-making method is developed for choosing the most suitable alternative among all possible candidates with respect to different criteria. The study aims at combing HoQ, RLSM, RWGM and non-deterministic ranking with variable precision rough set to evaluate design alternatives under a complex and vagueness environment, which is illustrated as shown in Fig. 2.

PSS concept decomposition and criteria identification

The HoQ tool has been widely used in the product/service development and developed into a proven methodology which can facilitate the understanding and response to CRs at the design stage. The traditional HoQ does not give the visualization of relations between product and service (Lindahl et al. 2006). Two parallel HoQs were then developed to translate CRs into MCs in an integrated mechanism, which can be seen in Reference Zhang and Chu (2010).Two separate sets of product and service characteristics are parallel considered in the proposed HoQs. Their relationship matrices are divided into parallel matrices of product and service. The correlations between product and service are also identified in the correlation matrices.

Based on the outputs of HoQs, PSS concept can be decomposed into several modules for facilitating evaluation accurately. Criteria for each module are identified from FCs based on the relationships between FCs and modules. The importance weights of criteria can be determined in the light of the importance weights of FCs, relationship and correlation matrices in the HoQs, which can effectively reflect the relationships between product and service.

PSS design alternatives evaluation with variable precision rough set

The designers evaluate design alternatives with each criterion to form some judgment sets. Let us assume a judgment set \(P=\left\{ {p_{1,} p_{2,} \ldots ,p_h } \right\} \) with h ordered judgments, in the manner of \(p_1 \le p_2 \le \cdots \le p_h \). Let \(p_i \in \left[ {0,9} \right] \) be a random judgment in the set P and d is defined as the distance of P, where \(d=p_h-p_1 \). Designers have their own individual experience and knowledge. Therefore, they may have different cognitive vagueness for design alternatives. To express the cognitive vagueness degree of a designer’s judgment, a factor of variable precision \(\beta \) can be defined in \(\left[ {0,1} \right] \). Overall, designer’s judgments under vagueness can be expressed by rough numbers. Rough number can provide flexibility and accuracy of designer’s judgment. The general rough number can be calculated by using a variable precision rough set method. Lower approximation \(\underline{Apr}^{\beta }\left( {p_i } \right) \) and upper approximation \(\overline{\hbox {Apr}} ^{\beta }\left( {p_i } \right) \)of the judgment \(p_i \) can be identified as follows

The judgment set can be converted into a general rough number form through the calculation of lower approximation and upper approximation. The judgment \(p_i \) is then represented by a rough number \(R\left( {p_i } \right) \) defined by its lower limit \(p_i^L \) and upper limit \(p_i^U \) as following:

where

where \(x_{ij} \) and \(y_{ij} \) are the elements of the lower approximation set \(\underline{Apr}^{\beta }\left( {p_i } \right) \) and the upper approximation set \(\overline{\hbox {Apr}} ^{\beta }\left( {p_i } \right) \)of \(p_i \) respectively, and m and n are the number of elements in the two sets respectively. Only in rare cases, the low limit and upper limit should be calculated by using arithmetic average when any \(\hbox {x}_{\mathrm{ij}} \) and \(\hbox {y}_{\mathrm{ij}} \) is equal to zero.

Thus, the rough set of P is expressed as follows:

Three scenarios are distinguished for definition of the factor of variable precision \({\upbeta }\), which expresses the cognitive vagueness degree of a designer:

-

1.

“\(\beta =0\)” means “no vagueness”. In this scenario, the judgment is completely determined and its vagueness range is equal to zero within the cognition of a designer. Here, \(\underline{Apr}^{\beta }\left( {p_i } \right) =\overline{Apr} ^{\beta }\left( {p_i } \right) \), \(R\left( {p_i } \right) =p_i \) and \(R\left( P \right) =P=\left\{ {p_1 ,p_2 ,\ldots ,p_h } \right\} \). The judgment in this scenario is degenerated into a crisp judgment.

-

2.

“\(0<\beta <1\)” means “partial vagueness”. In this scenario the judgment is partially vague. Here, the vagueness range of the judgment can be calculated by using \(\underline{Apr} ^{\beta }\left( {p_i } \right) and\, \overline{Apr} ^{\beta }\left( {p_i } \right) \) in Eq. (1). The vagueness degree is identified by synthesizing the judgment \(p_i \) with the adjacent judgments of other designers. Its adjacent range is determined by using the value of \(\beta d\).

-

3.

“\(\beta =1\)” means “complete vagueness”. In this scenario the judgment of a designer is completely vague. Obviously, the vagueness range of the judgment is identified by all the judgments in the set P. Here, the lower approximation \(\underline{Apr}^{\beta }\left( {p_i } \right) \) and the upper approximation \(\overline{Apr} ^{\beta }\left( {p_i } \right) \)of \(p_i \) can be simplified as:

$$\begin{aligned}&\underline{Apr}^{\beta }\left( {p_i } \right) =\cup \left\{ {p_j \in P\hbox {|}p_j \le p_i } \right\} \end{aligned}$$(4a)$$\begin{aligned}&\overline{Apr} ^{\beta }\left( {p_i } \right) =\cup \left\{ {p_j \in P|p_j \ge p_i } \right\} \end{aligned}$$(4b)

Cognitive vagueness of a decision maker is expressed by the value of \({\upbeta }\). If the individual cognitive level is increasing then vagueness range is decreasing with the decrease of \(\beta \), and vice versa. Group cognition reflects the consensus in a judgment set. Group certainty is higher with the lower distance d and closer or identical judgments.

Generally, group judgment is expected to be as close to each decision maker’s opinion as possible (Bordogna et al. 1997). Therefore, the deviation degree between each individual judgment and group judgment should be as small as possible. To represent the group judgment, a rough least square model (RLSM) is developed to calculate the rough number \(R\left( P \right) =\left[ {p^{L},p^{U}} \right] \) as follows:

where \(\hbox {Di}\) is the deviation degree between each individual judgment and the final group judgment, \(p^{L}\) and \(p^{U}\) are the lowest limit and upper limit of \(R\left( P \right) \), respectively.

Calculating group consensus on PSS design alternatives

From the outputs of parallel HoQs, the importance weights of criteria can be easily identified as \(W_i =\left\{ \left[ {w_1^L ,w_1^U } \right] ,\left[ {w_2^L ,w_2^U } \right] ,\ldots ,\left[ {w_k^L ,w_k^U } \right] \right\} \), where k is the number of these criteria. Correspondingly, group judgments of each design alternative can be expressed in the form of rough numbers, \(R\left( {B_i } \right) =\left\{ {\left[ {b_1^L ,b_1^U } \right] ,\left[ {b_2^L ,b_2^U } \right] ,\ldots ,\left[ {b_k^L ,b_k^U } \right] } \right\} \). The group judgments should be integrated to calculate the consensus for each design alternative. A nonlinear programming model, called RWGM improved from Wang et al. (2006), can be used to calculate the rough numbers \(\left[ {M_j^L ,M_j^U } \right] \) for calculating the group consensus on a design alternative \(j,1\le j\le k\). The mathematical models for calculating the group consensus on the design alternative \(j,1\le j\le k,\) are formulated as follows:

Ranking the PSS design alternatives

A non-deterministic ranking method is proposed to identify the preference relation of PSS design alternatives represented by the rough numbers. Let \(p_i =\left[ {p_i^L ,p_i^U } \right] \) and \(p_j =\left[ {p_j^L ,p_j^U } \right] \) be two interval-valued rough numbers, and \(D(p_i ,p_j )\) be their mutual rough preference relations. The dominating degree between two interval-valued rough numbers can be calculated as follows:

\(\hbox {where}\, D(p_j ,p_i )=-D(p_i ,p_j ).\) The preference relations can be classified as follows:

-

If \(D(p_i ,p_j )\ge \delta , p_i \) dominates \(p_j \) distinctly.

-

If \(\left| {D(p_i ,p_j )} \right| <\delta ,p_i \)is indistinctive to \(p_j\).

where \(\delta \) is the indifference threshold that is used for identifying the preference relation between \(p_i \) and \(p_j \). Only when the dominating degree exceeds \(\delta \), a distinct discrimination can be identified. Through the adjusting of \(\delta \), the vagueness of input information can be managed and eliminated in the ranking results.

The non-deterministic ranking method can decrease the effects of vagueness in the decision-making process and ensure more stable results. All the design alternatives are ranked by using the preference relations and then the global dominating one can be selected as optimal alternative for the following development.

Case study

HDD machine is a typical equipment for trenchless construction, which consists of several multidisciplinary modules (e.g. engine module, hydraulic module, electric module, etc). A heavy industry enterprise in China is going to pay attention to the PSS development of HDD machine. During its conceptual design phase, multiple feasible design alternatives co-exist and various uncertain factors interact. The major challenge that the designers are facing is how to select an optimal alternative effectively under vague environment. The proposed method is applied for evaluating PSS design alternatives of an ongoing developing HDD machine. Considering the diversity and complexity of services, maintenance is selected as the representative of services in the case study.

Criteria establishment

According to a market investigation, the major CRs are identified as follows: CR1 higher construction reliability, CR2 higher construction ability, CR3 higher construction efficiency, CR4 good eco-design, CR5 comfort for driver, CR6 enough security, CR7 moderate cost and CR8 good technical ability for maintenance.

Referring to these above requirements, Product-FCs (P-FCs) and Maintenance-FCs (M-FCs) are categorized respectively as follows: P-FC1 core ability, P-FC2 module reliability, P-FC3 controlling technology, P-FC4 security protection, P-FC5 working mode, P-FC6 eco-design factors, P-FC7 structure performance, and P-FC8 slurry ability; M-FC1 reliability and security, M-FC2 maintenance technology, M-FC3 maintenance cost, M-FC4 adding values, M-FC5 technical ability of maintenance and M-FC6 response timeliness.

Seven key modules for PSS concept are specified: M1 engine module, M2 hydraulic module, M3 electric module, M4 aiding module (including drill pipe, anchor equipment, etc.), M5 dynamic head, M6 slurry module (as shown in Fig. 3) and M7 maintenance module. Seven design alternatives are generated during the PSS development. The corresponding evaluation criteria of FCs are given in Table 1.

The importance weights of FCs and relationship matrices in the parallel HoQs are directly given in Tables 2 and 3 based on the study of Zhang and Chu (2010).

According to the outputs in Tables 2 and 3, the hierarchical evaluation criteria of PSS modules can be identified, and corresponding importance weights for each module are given in the third Column (weights) of Table 4.

PSS design alternative evaluation

A decision-making team which includes five designers is established to implement the PSS design alternatives’ evaluation. These experts are from design and market departments, who have rich professional knowledge and development experiences. These five members make their judgments for each design alternative with respect to each criterion. A judgment set \(P=\left\{ {p_{1,} p_{2,} \ldots ,p_5 } \right\} \), with five ordered judgments by the standard less-than-or-equal relation, is formed for each couple (design alternative, criterion) as shown in Table 4.

For example, let to consider the design alternative A5 and the P-FC1 core ability criterion. Then, for the Power module the judgment set is \(P_{15} = \{4, 5, 6, 6, 7\}\), with the distance \(d=7-4=3\). Let to illustrate the calculation process with this set. Considering three scenarios (no vagueness, partial vagueness, complete vagueness) for defining the factor of variable precision, the lower approximation \(\underline{Apr}^{\beta }\left( {p_i } \right) \) and the upper approximation \(\overline{\hbox {Apr}} ^{\beta }\left( {p_i } \right) \) of the judgment \(p_i \) in this set are given as follows:

Thus, individual judgments in the set \(P_{15}\) can be expressed in the general rough number form by using Eq. (2).

Based on Eq. (5), the group rough judgment can be calculated as \(\beta =1, \hbox {R}\left( P \right) =\left[ {4.867,6.218} \right] \), \(\beta =0.5, \hbox {R}\left( P \right) =\left[ {5.216,5.95} \right] \), and \(\beta =0, \hbox {R}\left( P \right) =\left[ {5,6} \right] \). Similarly, the group judgments can be identified in the form of rough numbers and the results with \(\beta =0.5\) are given in Table 5.

Calculating the group consensus on PSS design alternatives

Based on the rough group judgments, the group consensus on PSS design alternatives can be obtained by using Eqs. (6a) and (6a). The final results with three vagueness degrees (\(\beta =0\), \(\beta =0.5\), and \(\beta =1\)) are shown in Table 6.

Ranking PSS design alternatives

According to Eq. (7), the dominating degrees of the seven alternatives are identified by using these rough intervals considering three vagueness degrees \(\beta =0, \beta =0.5\), and \(\beta =1\) (see Table 7). For example, when \(\beta =0\), the dominating degree between A4 and A5 is 1.000 and the dominating between A6 and A7 is 0.968.

The decision team uses the calculated results to determine the final preference rating of these seven PSS design alternatives as follows:

Obviously, the alternative A4 is always the best one and A5 is the sub-optimal one under the three decision-making levels. Here, A4 can be prioritized as the developing HDD machine concept for the following engineering design and manufacturing.

Comparison and sensitivity analysis

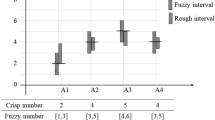

In order to validate its availability and robustness of the proposed method, a comparison analysis is implemented targeting several aspects. For the expression of designer’s judgments, fuzzy numbers are usually used some priori knowledge to determine the boundary of each number (Zhang and Chu 2010). The proposed method can provide a more flexible and accurate expression for designer’s judgments contrasted with the traditional methods. According to the designer’s cognition, the proposed method can express crisp numbers and multi-boundaries rough numbers through adjusting the variable precision coefficient \(\beta \).

For example, let to consider the judgment sets \(\hbox {P}_{15} = \{4, 5, 6, 6, 7\}\) of the design alternative A5 in respect to P-FC1 core ability criterion, and the judgment set \(\hbox {P}_{26} = \{4, 4, 5, 5, 6\}\) of the alternative A6 in respect to P-FC2 module reliability criterion in Table 4. These two judgment sets can be expressed in three fixed fuzzy numbers according to the given forms in the study of Herrera et al. (2000) (see Table 8). For instance, the judgment \(p_1 =4\) in the sets \(\hbox {P}_{15}\) and \(\hbox {P}_{26}\) is represented by the same interval [3, 5] in theirs corresponding fuzzy numbers.

In the proposed method, the judgment can be represented by a more flexible and accurate form. Table 9 shows the results for these two judgment sets. For instance, the judgment \(p_1 =4\) in the judgment sets \(\hbox {P}_{15}\) and \(\hbox {P}_{26}\) is represented respectively by the rough numbers [4, 5.502] and [4, 4.743] (\(\upbeta =1\)) (see Table 9). Thus, the general rough number expresses better cognitive vagueness through the variable precision \(\beta \). Indeed, the lower approximation \(\underline{Apr}^{\beta }\left( {p_i } \right) \) and the upper approximation \(\overline{Apr} ^{\beta }\left( {p_i } \right) \)of a judgment \(p_i \) depend on the factor \(\beta \) as well as on the distance in the judgment set.

When \(\beta =1\), the expression is approximately equal to the rough number developed by Zhai et al. (2009). When \(\beta =0\), the judgments degenerate into crisp form, which means that all the individual judgments are completely determined. The proposed rough numbers and fuzzy numbers of 4, 5 and 6 in the above two judgment sets are compared in Fig. 4. Several important characteristics can be identified from this comparison.

-

With the increasing of \(\beta \), i.e. the increasing of decision makers’ vagueness, the rough boundary intervals depicted by the lengths of the bars become larger. The coefficient \(\beta \) in the proposed variable precision rough set method can effectively address individual cognition and evaluation vagueness of each decision maker.

-

Fuzzy numbers should be preset by using priori knowledge, which have fixed boundary during the decision-making process. On the contrary, the general rough numbers can flexibly adjust their boundaries with the group consensus in a judgment set. Rough boundary interval goes to lower with the increase of group consensus and vice versa. For example, \(p_1 =5\) in the two judgments sets \(\hbox {P}_{15} = \{4, 5, 6, 6, 7\}\) and \(\hbox {P}_{26} = \{4, 4, 5, 5, 6\}\) can be expressed in rough numbers [4.472, 5.646] and [4.472, 5.313] with \(\beta =0.5\), respectively. This is more reasonable because the decision makers have their own individual experience and knowledge and may have different cognitive vagueness for different PSS design alternatives.

-

Generally, the general rough numbers can have smaller boundary intervals than those of fuzzy numbers because rough numbers’ boundaries depend on the cognitive vagueness degree \(\beta \) of designers’ judgments as well as the distances d in the judgment sets. This means that rough number can reasonably and credibly express decision maker’s judgments under vagueness in different situations.

Obviously, the proposed method is more flexible and accurate than the existing studies in the expression of vagueness degree. All the rough intervals are identified by considering individual cognition and group consensus. The group judgment can be obtained by using the data calculated as above.

Two well-known calculation methods for integrating individual judgments are fuzzy geometric mean (FGM) and ordered weighted averaging (OWA) operator (Bordogna et al. 1997), which were used in various engineering applications. The OWA operator has three linguistic quantifiers, namely “most”, “at least half”, and “as many as possible”. Let us consider the judgment sets \(\hbox {P}_{15} = \{4, 5, 6, 6, 7\}\) of the design alternative A5 in respect to P-FC1 core ability criterion. The proposed rough numbers and fuzzy numbers of 4, 5 and 6 in the above two judgment sets are compared in Fig. 4. The comparison results between the proposed variable precision rough method and fuzzy number with FGM operator as well as fuzzy number with OWA operator, are given in Fig. 5. Here, fuzzy numbers use fuzzy1 \(=\) {[3, 5], [4, 6], [5, 7], [5, 7], [6, 8]}. Compared with the results obtained from the two methods, the proposed variable precision rough method has higher accuracy in integrating individual judgments. Firstly, the proposed method can flexibly address different decision making scenarios with adjusting the factor of variable precision \(\beta \). The group judgments are identified from individual judgments without any priori knowledge for the determination of the possible boundaries of the rough numbers. The identification of the group consensus follows the same principle. Secondly, the proposed rough numbers have smaller boundaries than the other methods. For instance, in the proposed method, the group rough judgment is represented by three group rough numbers: \(\beta =1, \hbox {R}\left( P \right) =\left[ {4.867,6.218} \right] \), \(\beta =0.5, \hbox {R}\left( P \right) =\left[ {5.216,5.95} \right] \), and \(\beta =0, \hbox {R}\left( P \right) =\left[ {5,6} \right] \). In contrast, the group fuzzy number using FGM is [4.478, 6.518]. Obviously, the proposed method is more accurate and robust in the engineering application which can distinguish the variation and consensus of decision makers’ judgments. Small-boundary form and high-precision calculation model (RLSM) in the proposed method address the issue.

For further comparison, the PSS alternatives are evaluated by using fuzzy numbers with the calculation Eqs. (5) and (6) in the proposed method and FGM, respectively. The comparison results of the proposed rough method and the above two fuzzy numbers are shown in Table 10. The final results in Table 10 reveal that the rough boundary intervals calculated have smaller boundary intervals than the fuzzy intervals. It is obvious that the proposed method can identify the ranking easy and facilitate making PSS development decisions. The ranking results are given in Table 11. For the same \(\delta \) level, the alternatives are totally ranked with the proposed method when the factor of vagueness degree is equal to zero \((\beta =0)\), which shows that any pair of alternatives is comparable. For the increased values of the factor of vagueness degree \(\beta \) the alternatives are not always totally ranked. For example, when \(\delta =0.05\), all the alternatives can be ranked in rough interval \((\beta =0.5)\), but the preference relation cannot be identified among (A5, A1, A3) and (A2, A6) respectively. Here, for example A5, A1, A3 have the same ranking Accordingly, the identification of the preference relation goes lower with the increasing of \(\delta \). For example, from \(\delta =0.05\) to \(\delta =0.2\), the results are always totally ranked with rough interval \((\beta =0)\), the results are from totally ranked to partially ranked with rough interval (\(\beta =0.5\) and \(\beta =1\)). However, the results cannot be totally ranked with fuzzy interval (FGM). Fuzzy numbers lead to the enlargement of the fuzzy intervals in final results and the enlargement are further increased from the proposed method to FGM. Accordingly, excessive ranges in fuzzy intervals can overlap the original differences among the decision-making results, which have negative impacts on the ranking of PSS alternatives as the above analysis indicated.

Conclusions

PSS has drawn the attention of global manufacturers. Design alternative evaluation is an important and critical issue during PSS development. It is difficult to cope with the complexity and vagueness of PSS for information insufficiency and cognitive vagueness during the conceptual design stage. An integrated decision-making method for design alternative selection is then developed to systematically evaluate PSS design alternatives. PSS concept is divided into multi-modules for facilitating judgments, where the criteria and related importance weights can be identified through the outputs of parallel HoQ. A variable precision rough set based approach is proposed to design alternatives with different criteria. RLSM and RGWM are developed to integrate individual judgment into group judgments and further calculate the final results for PSS concepts, respectively. A new non-deterministic method is developed to rank these alternatives in order to identify the optimal one. The proposed method is applied in a real-world PSS case study for a HDD machine.

The proposed systematic decision-making method has the following advantages:

-

(a)

Design alternative decomposition helps designers evaluate easily. And the use of HoQ outputs can fuse the previous design information into the decision process systematically, which can adequately consider the voices of customers and the relationships between product and service.

-

(b)

The systematic decision-making method can effectively deal with the complex evaluation under vagueness environments. The variable precision rough sets method with RWGM can help decision-makes capture judgment vagueness and form consensus judgments for design alternative selection.

-

(c)

The non-deterministic ranking method can identify the preference ratings of the concepts reliably and credibly.

Although the approach provides an effective mechanism for evaluating design alternatives of PSS involving subjective judgments in group decision environment, it also has some limitations. The integration of HoQs and optimization model may lead to more complexity of the calculation. The designers give their judgments based on their knowledge and experience individually. The designers’ lack of rough logic domain knowledge may affect efficient use of the proposed approach. Further work would consider other expression to ensure that the designers can make more accurate individual judgments. Besides, additional guidance mechanism may be integrated into the proposed method in order to better aid the designers give more rational judgments.

References

Atanassov, K., & Gargov, G. (1989). Interval valued intuitionistic fuzzy sets. Fuzzy Sets and Systems, 31, 343–349.

Aurich, J. C., Fuchs, C., & Wagenknecht, C. (2006). Life cycle oriented design of technical product service systems. Journal of Cleaner Production, 14(17), 1480–1494.

Ayağ, Z., & Ozdemir, R. G. (2007). An analytic network process-based approach to concept evaluation in a new product development environment. Journal of Engineering Design, 18(3), 209–226.

Baines, T. S., Lightfoot, H. W., Evans, S., et al. (2007). State-of-the-art in product-service systems. Proceedings of the Institution of Mechanical Engineers, Part B: Journal Engineering Manufacture, 221(10), 1543–1552.

Baxter, D., Roy, R., Doultsinou, A., et al. (2009). A knowledge management framework to support product-service systems design. International Journal of Computer Integrated Manufacturing, 22(12), 1073–1088.

Bordogna, G., Fedrizzi, M., & Pasi, G. (1997). A linguistic modeling of consensus in group decision making based on OWA operators. IEEE Transactions on Systems, Man and Cybernetics-Part A: Systems and Humans, 27, 126–132.

Büyüközkan, G., Arsenyan, J., & Ruan, D. (2012). Logistics tool selection with two-phase fuzzy multi criteria decision making: A case study for personal digital assistant selection. Expert Systems with Applications, 39, 142–153.

Büyüközkan, G., & Çifçi, G. (2013). An integrated QFD framework with multiple formatted and incomplete preferences: A sustainable supply chain application. Applied Soft Computing, 13, 3931–3941.

Cavalieri, S., & Pezzotta, G. (2012). Product-service systems engineering: State of the art and research challenges. Computers in Industry, 63(4), 349–360.

Chen, D. P., Chu, X. N., Sun, X. W., et al. (2014). A new product service system concept evaluation approach based on Information Axiom in a fuzzy-stochastic environment. International Journal of Computer Integrated Manufacturing,. doi:10.1080/0951192x.2014.961550.

Garetti, M., Rosa, P., & Terzi, S. (2012). Life cycle simulation for the design of product-service systems. Computers in Industry, 63(4), 361–369.

Herrera, F., Herrera-Viedma, E., & Martínez, L. (2000). A fusion approach for managing multi-granularity linguistic term sets in decision-making. Fuzzy Sets and Systems, 114, 43–58.

Huang, S. X., Zeang, S., Fan, Y. S., et al. (2011). Optimal service selection and composition for service-oriented manufacturing network. International Journal of Computer Integrated Manufacturing, 24(5), 416–430.

Jin, Y. C. (2003). Advanced fuzzy systems design and applications. London: Springer.

Komoto, H., & Tomiyama, T. (2009). Systematic generation of PSS concepts using a service CAD tool. In T. Sakao & M. Lindahl (Eds.), Introduction to product/service-system design. London: Springer.

Krishnan, K., & Ulrich, K. T. (2001). Product development decisions: A review of the literature. Management Science, 47(1), 1–21.

Kuo, M. S., Tzeng, G. H., & Huang, W. C. (2007). Group decision-making based on concepts of ideal and anti-ideal points in a fuzzy environment. Mathematical and Computer Modelling, 45, 324–339.

Kuo, T. C., & Wang, M. L. (2012). The optimization of maintenance service levels to support the product service system. International Journal of Production Research, 50(23), 6691–6708.

Li, H., Ji, Y. J., Gu, X. J., Qi, G. N., et al. (2012). Module partition process model and method of integrated service product. Computers in Industry, 63(4), 298–308.

Lindahl, M., Sundin, E., & Shimomura, Y., et al. (2006). An interactive design model for service engineering of functional sales offers. In Proceedings of the international design conference, Dubrovnik, Croatia.

Long, H. J., Wang, L. Y., Shen, J., et al. (2013). Product service system configuration based on support vector machine considering customer perception. International Journal of Production Research, 51(18), 5450–5468.

Mannweiler, C., & Aurich J. C., (2011). Customer oriented configuration of product-service systems. Function thinking for value creation. In Proceedings of the 3rd CIRP international conference on industrial product service systems, May 5–6 (pp. 81–86). Braunschweig, Germany

Meier, H., Roy, R., & Seliger, G. (2010). Industrial product-service systems-IPS2. CIRP Annals: Manufacturing Technology, 59(2), 607–627.

Mont, O. (2002). Clarifying the concept of product-service system. Journal of Cleaner Production, 10(3), 237–245.

Pahl, M. L., & Beitz, W. (1996). Engineering design: A systematic approach. London: Springer.

Pawlak, Z. (1982). Rough sets. International Journal of Computer Information Science, 11(5), 341–356.

Sakao, T., & Shimomura, Y. (2007). Service engineering: A novel engineering discipline for producers to increase value combining service and product. Journal of Cleaner Production, 15(6), 590–604.

Sakao, T., Shimomura, Y., Sundin, E., & Comstock, M. (2009). Modeling design objects in CAD system for Service/Product Engineering. Computer-Aided Design, 41(3), 197–213.

Song, W. Y., Ming, X. G., Han, Y., et al. (2013). A rough set approach for evaluating vague customer requirement of industrial product-service system. International Journal of Production Research, 51(22), 6681–6701.

Sun, H. B., Wang, Z., Zhang, Y. F., et al. (2012). Evaluation method of product-service performance. International Journal of Computer Integrated Manufacturing, 20(5), 150–157.

Sundin, E., Lindahl, M., & Comstock, M., et al. (2007). Integrated product and service engineering enabling mass customization. In Proceedings of 19th international conference on production research, Santiago.

Wang, P. P., Ming, X. G., et al. (2011). Modular development of product service systems. Concurrent Engineering: Research and Applications, 19(1), 85–96.

Wang, Y. M., Elhag, T. M. S., & Hua, Z. S. (2006). A modified fuzzy logarithmic least squares method for fuzzy analytic hierarchy process. Fuzzy Sets and Systems, 157, 3055–3071.

Yager, R. R. (1988). On ordered weighted averaging aggregation operators in multicriteria decision-making. IEEE Transaction on Systems, Man and Cybemetics, 18(1), 183–190.

Yoon, B., Kim, S., & Rhee, J. (2012). An evaluation method for designing a new product-service system. Expert Systems with Applications, 39(3), 3100–3108.

Zhai, L. Y., Khoo, L. P., & Zhong, Z. W. (2009). A rough set based QFD approach to the management of imprecise design information in product development. Advanced Engineering Informatics, 23(2), 222–228.

Zhang, D. M., Hu, D. C., Xu, Y. C., et al. (2012). A framework for design knowledge management and reuse for product-service systems in construction machinery industry. Computers in Industry, 63(4), 328–337.

Zhang, Z. F., & Chu, X. N. (2010). A new approach for conceptual design of product & maintenance. International Journal of Computer Integrated Manufacturing, 23(7), 603–618.

Acknowledgements

The project was supported by National Natural Science Foundation of China (Nos. 51205242, 71101084, 51405281) and Shanghai Science and Technology Innovation Action Plan (No. 16111106402).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Xu, D., Ostrosi, E. et al. A systematic decision-making method for evaluating design alternatives of product service system based on variable precision rough set. J Intell Manuf 30, 1895–1909 (2019). https://doi.org/10.1007/s10845-017-1359-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1359-6