Abstract

The effect of annealing temperature (Ta= 200, 250, and 300 °C) on the structural properties, ac conductivity, and complex dielectric constants (\({\epsilon }^{{\prime }}\) and \({\epsilon }^{{\prime }{\prime }}\)) of indium-doped tin oxide (ITO) thin films (~ 90 nm thick)/0.5 mm boro-float substrates (BFS) synthesized by radio frequency (RF) sputtering is investigated. The X-ray diffraction (XRD) examination demonstrated that indium was successfully substituted with tin atoms to form ITO films and the crystallite size for the cubic phase, as well as particle size, were impacted by Ta. The real part of complex dielectric constants (\({\epsilon }^{{\prime }}\)) was significantly reduced for all ITO/BFS from the range of 2.7 × 104–5.1 × 104 to 5.3–19 as the frequency (f) was increased to 0.25 Hz, while it remained constant for further increases in f. The value of \({\epsilon }^{{\prime }}\) for the as-prepared ITO/BFS was increased as Ta increased up to 250 °C, then was decreased at Ta=300 °C. A similar finding was detected for the loss factor with no observation of any relaxation peaks. The Q-factor was increased for all ITO/BFS as f increased to 100 Hz and then was reduced with increasing f up to 20 MHz, while steadily increasing with Ta. The deduced frequency exponent is greater than 0.5 for the ITO/BFS, indicating their electronic conduction nature. The density of the localized states and hopping frequency of the ITO/BFS were increased by annealing at 200 °C, meanwhile was decreased for Ta = 300 °C. The binding energy was decreased from 0.647 eV for the as-prepared ITO/BFS to 0.518 eV by annealing at 200 °C, meanwhile was increased to 0.74 and 0.863 eV for Ta equals 250, and 300 °C, respectively. The Cole-Cole plots revealed a single semicircular arc for all films, and their corresponding equivalent circuit was analyzed. The equivalent bulk resistance was gradually decreased by annealing in the range of 200–300 °C, whereas the equivalent capacitance was increased. The resistance of grains and resistance of grain boundaries of the as-prepared ITO/BFS was gradually decreased by increasing Ta to 250 °C, while it was increased for Ta = 300 °C. These outcomes recommended the RF sputtered ITO/BFS for high-frequency devices, integrated circuits, and supercapacitors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The indium-doped tin oxide (ITO) films on glass or plastic substrates are usually employed in several technologies, such as electrodes in solar cells, electro-optic antennas, and architectural coatings, due to their unique properties such as their high conduction, high optical transmittance, high infrared reflectance, and great adhesion with diverse substrates [1, 2]. The physical and chemical properties of ITO films are similar to those of other materials depending on their fabrication method and processing conditions [3, 4]. Many approaches may be used for the synthesis of ITO films, e.g., pulsed laser deposition, electron beam evaporation, co-precipitation, electroplating, sol-gel, DC magnetron sputtering, and radio frequency (RF) magnetron sputtering, etc. [5,6,7,8,9,10].

The ITO films exhibit high transmittance as well as outstanding optical characteristics [11,12,13]. The electrical features of sputtered ITO rely on the synthesizing technique and the circumstances of deposition including the substrate deposition temperature, oxygen flow rate, and power of the sputtering source [13,14,15]. Most n-type semiconductor electronic traps are often localized near grain boundaries, where they absorb oxygen and catch some donor state electrons [16, 17]. The Schottky barrier capacitance frequently depends on the operating frequency as a result of the low time constants of the deep trap states of the depletion layer [18]. Furthermore, internal imperfections like space charge electrons and oxygen vacancies affect the dielectric properties [19]. The complex dielectric properties versus the frequency (up to 10 GHz) characterize this response [6]. Conduction takes place via a bipolaron hopping mechanism in which two electrons hop over the potential barrier between two charged states of defects at the same duration, and the height of the barrier is proportional to their separation [20]. High dielectric constant materials have attracted interest in telecommunications and integrated microwave electronics [21]. On the other hand, materials with a low dielectric constant are prospective employees for high-frequency and nonlinear optical systems [22]. The Q-factor, which displays the ratio of energy stored in the capacitor to energy dissipated in the corresponding series resistance, is an interesting dielectric parameter [23]. Since the Q-factor is the measure of efficiency, therefore materials have a high value of the Q-factor required to limit the energy lost for energy storage applications. Likewise, the F-factor can be evaluated from dielectric measurements, which provides good evidence for the application in color cell devices as well as in photocatalytic and optical technologies [24].

The impacts of Cu dopants on the thermal, dielectric, and antibacterial characteristics of ITO were examined [25]. Recently, Abd-Elnaiem and Hakamy investigated the influence of the annealing process on the structural, and optoelectronic characteristics of the sputtered ITO films on a BFS [11]. The cubic crystal structure of the ITO films was formed through RF sputtering, and the annealing showed a substantial impact on the linear and nonlinear optical parameters, making them the favored selection for solar cells and optoelectronic devices. Guizzardi et al. reported the photophysical investigation of one-dimensional (1D) ITO grating [1]. The 1D ITO grating revealed a strong optical nonlinearity in the visible spectrum and the photonic band gap was increased by pulsing at the surface plasmon resonance in the near-infrared range. De-localized states were employed for disordered ITO films to transfer charge carriers, such as electrons, and the disorder effects led to a metal-insulator transition at low temperatures (− 163 °C) [26]. Chen et al. applied terahertz time-domain spectroscopy at various frequencies to explore the complex conductivities and dielectric responses of many sputtered ITO films with a thickness range of 189–962 nm [14]. The frequency-dependent electrical and dielectric characteristics of ITO films were rarely documented in the literature [15].

In this work, the structural properties of ITO films (~ 90 nm thick), formed by RF sputtering on boro-float substrates (BFS) were investigated. Additionally, the dielectric characteristics and ac electrical conductivity at various frequencies (0.10–10 MHz) of ITO/BFS were evaluated and discussed.

2 Experimental details

ITO thin films, 90 nm thick, were fabricated by RF sputtering on 0.5 mm BFS. More information regarding the preparation techniques may be found elsewhere [11]. The ITO films were annealed for 3 h at 200, 250, and 300 °C in a muffle furnace under air conditions.

The crystal structure of as-deposited and annealed ITO films was examined via a Philips X-ray diffractometer of type-1710 with CuKα radiation of wavelength (λ) of 1.5418 Å. The diffraction angle (2θ) was adjusted to 70 ≥ 2θ (°) ≥ 10, and the XRD patterns were produced at a scanning speed of 0.06 °/min. Fourier transforms infrared (FTIR) spectroscopy of ITO films was performed in the wavenumber range of 400–4000 cm–1 at room temperature (RT) using a Shimadzu spectrophotometer model Nicolet 6700. The surface and cross-section morphology of ITO films was carried out via a Zeiss Sigma 500 VP field emission scanning electron microscope (FE-SEM) operated at 3 and 8 kV. The surface morphologies of some ITO films were examined using a JEOL Type T200 scanning electron microscope operated at 15 kV.

The dielectric characteristics of ITO/BFS were investigated and recorded using a high-resolution Alpha analyzer with an active sample head at a frequency range of 0.10–10 MHz at RT. The ITO/BFS samples were positioned between two stainless steel parallel plates, each plate has a diameter of 20 mm and was coated by gold. Around 50 mm diameter fused silica fibers were used as a spacer material between the two plates. More information regarding the dielectric measurements and setup techniques may be found elsewhere [17].

3 Results and discussion

3.1 Structural properties

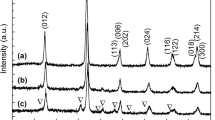

Figure 1 illustrates the XRD charts of as-prepared and annealed ITO films at 200, 250, and 300 °C. The XRD pattern for the as-sputtered ITO shows two diffraction peaks with low intensity at 2θ equals 29.6, and 41.55° which are ascribed to the diffraction from the crystal planes of (222), and (332), respectively. The detected diffraction peaks are assigned to the cubic crystal structure of ITO (JCPDS card no. 01-089-4598). The absence of the other peaks related to individual SnO2, metallic tin, or indium phases emphasized that indium is well replaced by tin as a substitution dopant which agrees with other work elsewhere [26]. The XRD patterns for annealed ITO at 200, 250, and 300 °C revealed the existence of other diffraction peaks at 2θ of 50.5 and 60.2° which are ascribed to the diffraction from crystal planes with Miller indices of (440), and (622), respectively. Besides, the intensity of diffraction peaks observed for as-prepared film detected at 2θ equals 29.6° becomes higher. The position of the diffraction peaks moved somewhat to higher 2θ while Ta increased from 200 to 300 °C.

The average value of the crystallite size (D) was determined from the well-known Scherrer formula and equals 15.34, 27.44, 21.82, and 21.67 nm for as-prepared ITO, and ITO annealed at 200, 250, and 250 °C, respectively. The crystallite size of the as-prepared ITO films was raised by annealing at 200 °C and subsequently decreased to a constant value of ~ 22 nm for successive increases in annealing temperatures at 250 and 300 °C. The annealing of as-prepared ITO films at 200 °C decreases imperfections as well as the number of grains, resulting in a considerable increase in crystallite size. On the other side, thermal annealing at higher temperatures (> 200 °C) may cause oxygen to escape from the lattice, reducing lattice parameters including interplanar spacing and crystallite size. The change (increase or decrease) in ITO films upon the thermal annealing was identified elsewhere [27]. Table 1 summarizes the microstrain (ε), dislocation density (ρd), interplanar spacing (dhkl), and crystallite size at certain selected diffraction angles for each annealing condition.

The FTIR spectra of the as-deposited and annealed ITO/BFS are displayed in Fig. 2. The FTIR spectrum of the as-prepared ITO/BFS shows many bands and can be ascribed as follows. The band at 3436 cm− 1 is ascribed to the O − H stretching vibration, while the band at 2919 cm− 1 and 2849 cm− 1 are ascribed to the C − H stretching vibration [28]. The detected band at 1426 cm− 1 is a symmetric stretching relaxation of the B − O bond of trigonal BO3 units [29]. The band at 1093 cm− 1 is ascribed to the tri-, tetra-, pentaborate, and diborate groups belonging to BO3 and BO4 groups and asymmetric stretching Si − O−Si bonds [29]. The band at 907 cm− 1 is ascribed to the B − O vibration of BO4 units and the stretching frequency of Si − O−B [30]. The band at 796 cm− 1 is ascribed to the symmetric stretching vibration of O − Si − O, while the band at 675 cm− 1 is ascribed to the bending vibration of bridging oxygen (B − O) between trigonal BO3 groups as well as the Sn − O−Sn stretching mode of surface bridging of oxide [31]. The band at 454 cm− 1 belongs to the In − O bond [32]. The FTIR spectra of the annealed ITO films at various Ta showed the same bands as that observed in the as-prepared ITO/BFS with some variation in their intensities and position. It was observed that the characteristic bands of SnO2 and In2O3 decreased in the annealed ITO/BFS, while the bands related to the BFS were enhanced. In addition, the O − H stretching vibration band in the annealed ITO/BFS was enhanced in comparison to the as-prepared ITO/BFS, which reflects that the annealed ITO/BFS has a high affinity to adsorb atmospheric water vapor.

FE-SEM (top-view, and cross-section) images of as-prepared and ITO films annealed at 200 and 250 °C are illustrated in Fig. 3a-d. The measured thickness of the formed ITO layer over BFS is around 90 ± 2 nm, as illustrated in Fig. 3a. The synthesized ITO thin films have an exceedingly smooth and homogenous surface morphology as seen in Fig. 3b.

The annealing of ITO leads to a different morphology compared to as-prepared ITO as seen in Fig. 3c and d, and 3e at Ta equals 200, 250, and 300 °C, respectively. The annealed ITO/BFS at 200 °C for 3 h are composed of extremely tiny precipitates with a homogeneous distribution across the whole surface. The average particle size of the precipitates is 12 ± 3 nm estimated using ImageJ software. The estimated particle size from the FE-SEM image for the as-prepared ITO/BFS sample is extremely close to the crystallite size determined by the XRD analysis using the Scherrer formula. The increase in annealing temperature to 250 °C results in greater particle sizes and a decrease in particle number, and granular boundaries. The typical size of spherical particles is 50 ± 10 nm, which is substantially larger than the particle size of films annealed at 200 °C. Figure 3e shows a top-view SEM image of ITO/BFS that have been annealed at 300 °C for 3 h. The morphology is comparable to previous annealed ITO samples in that it is made up of spherical agglomeration particles with sizes in the range of 0.2–0.8 μm. In general, increasing the annealing temperature resulted in larger particle sizes in the investigated ITO/BFS. An accumulation of smaller precipitates or the growth of precipitates might explain the rise in particle size.

The shape of the formed ITO is determined by the annealing temperature, the formation process and its condition, the depositing substrate, the film thickness, and other factors [5, 11, 28]. The increase in particle size by annealing ITO films is consistent with previously reported results [11, 12]. The estimated value of average particle sizes at each annealing temperature is more than the value derived from the XRD investigation, indicating that each particle may consist of several crystallites.

3.2 Dielectric properties

The real part of the complex dielectric constant (ϵ′), loss factor (tan(δ)), and Q-factor of a material can be represented by [33]:

where C and C0 (\({C}_{0}=\frac{{\epsilon }_{0}A}{d}\)) are the capacitances of the sample and empty cell, respectively, and \({\epsilon }^{\prime\prime}\) is the imaginary part of the complex dielectric constants.

The plots of \({\epsilon }^{{\prime }}\) against f for the ITO/BFS are illustrated in Fig. 4a. The value of \({\epsilon }^{{\prime }}\) was significantly decreased for all films from 2.7× 104 – 5.1 × 104 to 5.3–19 range as f increased to 0.25 Hz, but above that, it was nearly constant. The values of steady \({\epsilon }^{{\prime }}\) is 14, 17.5, 17.55, and 5.2 ± 1 for as-prepared ITO/BFS and annealed ITO/BFS at 200, 250, and 300 °C, respectively. This behavior is attributed to the space charge polarization at low f. However with increasing f, the charge carriers accumulate at the grain boundaries and create an electronic polarization that cannot follow the field reversal [34]. The value of \({\epsilon }^{{\prime }}\) has slightly increased as Ta increases up to 250 °C, followed by a remarkable decrease in \({\epsilon }^{{\prime }}\) with more increase of Ta to 300 °C. Similar results are obtained for the tan(δ), Fig. 4b, which did not show any relaxation peaks for the investigated films, indicating a steady state of charge carrier dielectric conduction between the electrodes. The tan(δ)-f plots for ITO/BFS rapidly dropped and then hit a minimum value, followed by a minor increase as the frequency increased. Furthermore, the change in the loss factor with Ta behaves similarly to the change in \({\epsilon }^{{\prime }}\). The Q-factor as a function of f for the ITO/BFS is shown in Fig. 4c. It is generally noticed that the Q-factor shows an opposite trend to the change of tan(δ) (according to Eq. 1) and has increased as f increases to 100 Hz, and then reduced with increasing f up to 20 MHz. Interestingly, the Q-factor was gradually increased as Ta increased to 300 °C, which is attributed to decreasing the friction of the dissipation energy of dipoles through improving crystallite size [35]. Therefore, the current films are convenient for high-frequency devices, integrated circuits, and supercapacitors, as reported elsewhere [36].

The possible source of induced polarization is the existence of oxygen vacancies and interstitial ions in the ITO matrix. The ions and the oxygen vacancies in the neighborhood can change positions by a single jump and try to align along the field as described by Kröger-Vink notation when an external field is applied [22]. The \({\epsilon }^{{\prime }}\) was generally increased against Ta, but it reached its height value of 17.55 at 250 °C, but it depressed to 5.2 ± 1 with more increase of Ta 300 °C to be less than of as prepared ITO/BFS. In addition, the increase of Ta from 250 to 300 °C does not add more to the values of ϵ′. The increase of \({\epsilon }^{{\prime }}\) by the increase of Ta up to 250 °C can be explained by the induced interfacial/space charge polarization related to oxygen vacancies and microspores introduced when the size of grains was increased, as obtained [10]. The increase in size may lead to an increase in the number of dipoles, which then increases the value of \({\epsilon }^{{\prime }}\). The decrease in \({\epsilon }^{{\prime }}\) at 300 °C may be related to the fact that some hopping carriers are trapped by these structural inhomogeneities that lead to a dominant space charge polarization [9].

The total conductivity \(({\sigma }_{t})\) as a function of the angular frequency \((\omega)\) can be obtained by [37]:

where \({\sigma }_{dc}\) is the dc conductivity estimated at f = 0, while B is a constant, and s is the frequency exponent. Figure 5a illustrates the real part of the complex ac conductivity (\({\sigma }^{{\prime }}\)) versus f for the ITO/BFS at different Ta. It is obvious from the plots that \({\sigma }^{{\prime }}\) steadily decreases with increases f up to 20 MHz. Therefore, the displacement of carriers is increased, and f is not sufficient for reaching the hopping process and liberating the charge carriers trapped in deep traps [38]. Likewise, \({\sigma }^{{\prime }}\) was decreased as Ta increased, which could be ascribed to the reduction in the number of electrons resulting from charge transfer, as indicated by the small polaron hopping model [39]. The fit in Fig. 5b reveals the linear relation between ln\({(\sigma }^{{\prime }})\) and ln(ω) and their slopes give the values of the s parameter as summarized in Table 2. The calculated s for all examined ITO/BFS is greater than 0.5, indicating that ITO/BFS are electronic conduction materials. The values of \({\sigma }_{dc}\) may be determined from the intercept in Fig. 5b according to Eq. 2, and their numerical values for various ITO/BFS are summarized in Table 2. For all studied ITO/BFS, the value of \({\sigma }_{dc}\) is almost constant at 8.9 ± 0.3 (Ω.cm)−1 and is unaffected by annealing temperature. The hopping frequency \(({\omega }_{h})\) of the charge carrier was calculated and summarized in Table 2. The value of \({\omega }_{h}\) was improved from 4.68 × 104 Hz for the as-prepared ITO/BFS to 1.53 × 106 THz by annealing ITO/BFS at 200 °C and then decreased to 2.55 × 103 and 1.22 × 103 with increasing Ta to 250, and 300 °C, respectively. The increase in the dc electrical conductivity by the increase in Ta from 200 to 300 °C may be attributed to the increase in charge carrier mobility caused by annealing, which is consistent with prior findings [7]. Increasing Ta results in bigger particles, as can be observed in the FE-SEM and SEM images of annealed ITO/BFS, which reduces grain boundaries and thus, grain-boundary scattering, and hence improves charge carrier mobility. The electrical resistivity generally increased slightly when the annealing temperature was raised in the 200–300 °C range, but it increased dramatically when the temperature was raised to 400, 500, and 600 °C [9]. The interaction of ITO films with O2 in the air at higher annealing temperatures (> 300 °C) was found to cause a significant rise in resistance. In contrast, it has been found that annealing ITO, prepared using a high-frequency magnetron sputtering method, at temperatures above 300 °C somewhat reduces electrical resistivity [10].

The effective barrier height (Wm) was estimated for various ITO/BFS using the correlated barrier hopping model [40]:

where \({\tau }_{0}\) equals 10− 13 s, and it is the relaxation time of atomic vibration. The numerical values of Wm are summarized in Table 2. The numerical value of Wm was reduced from 0.647 eV for the as-deposited ITO/FBS film to 0.518 eV by annealing at 200 °C, but they increased with an increase in Ta to 0.74 and 0.863 eV for ITO/BFS annealed at 250 and 300 °C, respectively. The rise in Wm resulting from high-temperature annealing might be due to increased overlapping between potential wells inside the film matrix, as studied using the Pike model [41]. The figure of merit (F-factor) given is good evidence for the use of solar cell design [17]. Figure 5c shows the F-factor against f for prepared and annealed films. It is seen that the F-factor steadily reduced as f increased up to 20 MHz for all ITO/BFS. It is slightly decreased by annealing except for the annealing at 200 °C, where its F-factor is higher. These outcomes recommended the as-prepared film and film annealed at 200 °C for solar cell devices, but above 104 Hz. Other important parameters such as the minimum hopping distance (Rmin) and the density of localized states (N) were calculated using the following Eqs. [42, 43]:

Figure 5d illustrates the plot of N against f for ITO/BFS, in which N has decreased by increasing f to 20 MHz, while it increases at Ta equal 200 °C then was reduced with a more significant increase in Ta up to 300 °C. The anticipated value of N is significantly larger than that, ~1021 cm− 3, observed for ITO thin films made using the DC magnetron sputtering technique [26]. The findings emphasize the decreasing density of defect energy states with increased Ta which agrees with work reported elsewhere [44].

The real part (\({Z}^{{\prime }}\)) and imaginary part (\({Z}^{{\prime }{\prime }}\)) of complex ac impedance (Z) are deduced using [45]:

Figure 6a and 6b depict the plots of \({Z}^{{\prime }}\) and \({Z}^{\prime\prime}\) versus f for the ITO/BFS. The figure demonstrates that when f rises to 20 MHz, both \({Z}^{{\prime }}\) and \({Z}^{\prime\prime}\) increase. The low values of Z at lower f confirm the low resistivity, which is ascribed to the lower resistivity of grain boundaries. Furthermore, both of them decrease by annealing to 250 °C and then increase to 300 °C. The increase/decrease of Z could be attributed to the change in the resistivity of ITO/BFS. High Z values observed for ITO/BFS at low f are beneficial for conventional electrical devices that use electrical insulators at low audio frequencies [22]. The Cole-Cole plots (\({Z}^{\prime\prime}\) versus \({Z}^{{\prime }}\)) in Fig. 6c shows a single semicircular arc that is almost one-quarter of a circle for all ITO/BFS. The arc radius of the as-prepared film was decreased by annealing from 200 to 250 °C and then increased at 300 °C.

The increase or decrease in arc radius reveals a decrease or increase in capacitance as well as electrical conductivity. The ensuing semicircular arcs are centered below the \({Z}^{{\prime }}\) axis, showing non-Debye relaxation with varied relaxation durations for the dipole moments [46]. A single arc spectrum indicates that the time constants (\(\tau =\frac{1}{\omega }=RC\)) for conduction processes across the grain and the grain boundary are the same. The results reveal that conduction in the grain and conduction at the grain boundary belong to the same process but cannot be divided [47]. Other research suggested that a single arc was triggered by the core resistive of grain and the grain boundary [17].

The impedance spectrum represents an electric process and may be solved by a representation of an analogous electrical circuit made up of resistive and capacitive parts. The high f semicircle is caused by a parallel arrangement of bulk resistance and capacitance, whereas the low f semicircle is caused by the parallel combination of grain boundary resistance and capacitance. In both cases, the applied f is inadequate to cover the grain boundary but adequate for the bulk characteristic. The radius (or diameter) of each semicircular is used to calculate the resistance of the grain, \({Z}^{{\prime }}\)(g), and resistance of grain boundaries, \({Z}^{{\prime }}\)(gb), and are listed in Table 2.

The values of \({Z}^{{\prime }}\)(g) and \({Z}^{{\prime }}\)(gb) of the as-prepared ITO/BFS are steadily decreased by increasing Ta up to 250 °C, however, they are increased at Ta=300 °C as well as obtained for \({Z}^{{\prime }}\)(gb)/\({Z}^{{\prime }}\)(g) and shown in Table 2. The real part of the complex impedance (\({Z}^{{\prime }}\)) at diffrent f is given by [40]:

The intercepts of the linear relation between \(\frac{1}{{Z}^{{\prime }}}\) and (\({\omega }^{2}\)), according to Eq. 7, give the equivalent bulk resistance (\({R}_{s}\)) and then the equivalent capacitance (\({C}_{eq}\)) can be determined from the slope. The deduced values of \({R}_{s}\) and \({C}_{eq}\) for investigated ITO/BFS are listed in Table 2. \({R}_{s}\) were gradually decreased by annealing, whereas \({C}_{eq}\) increased. The increase in connected conducting channels causes a decrease in \({R}_{s}\) by annealing [48]. In contrast, the increase in \({C}_{eq}\) can be attributed to the strength of micro-capacitors and further to the increase in the crystallite size of the as-prepared ITO/BFS by annealing.

Annealing at higher temperatures (> RT) preserves the cubic structure of ITO while increasing crystallite and particle sizes as well as enhancing the O − H stretching vibration band. Most dielectric parameters, such as the dielectric constant, loss factor, ac conductivity, and binding energy, were enhanced. Furthermore, annealing reduced the equivalent bulk resistance, grain impedance, and grain boundary impedance, while increasing the equivalent capacitance. These results typically show a good correlation between the crystal structure, FTIR, and dielectric behaviors of the ITO/BFS against annealing. Moreover, the findings recommend the synthesized ITO/BFS to be applied for high-frequency devices, integrated circuits, and supercapacitors, emphasizing this present study.

4 Conclusion

The XRD analysis revealed that indium was effectively substituted with tin atoms for the formation of ITO films using the RF sputtering method and that the annealing process influences the cubic phase crystallite as well as particle sizes. The FTIR spectra of all samples confirm the production of Sn − O−Sn and In− O bonds and reveal a comparable structure, although the strength and location of the peaks shift. The dielectric constant and ac conductivity measurements for the as-deposited and annealed ITO/BFS have been studied. The \({\epsilon }^{{\prime }}\) and tan(δ) of the prepared ITO/BFS was slightly increased as Ta increased to 250 °C, followed by a decrease with more increase in Ta to 300 °C. Interestingly, the Q-factor was gradually increased as Ta increased to 300 °C. The electronic conduction nature was detected for all studied ITO/BFS. Although the Wm of the as-prepared film decreased from 0.647 eV to 0.518 eV by annealing at 200 °C, it was increased to 0.74 and 0.863 eV with more increase in Ta. A single semicircular arc could be obtained for ITO/BFS such that \({Z}^{{\prime }}\)(g) and \({Z}^{{\prime }}\)(gb) of the as-prepared ITO/BFS are steadily decreased by increasing Ta to 250 °C, but they are increased at 300 °C. The equivalent bulk resistance was gradually decreased by annealing to 300 °C, whereas the equivalent capacitance increased. The considered ITO/BFS is recommended for high-frequency devices, integrated circuits, and supercapacitors applications.

Data availability

Not Applicable.

5. References

M. Guizzardi, S. Bonfadini, L. Moscardi, I. Kriegel, F. Scotognella, L. Criante, Phys. Chem. Chem. Phys. 22(13), 6881–6887 (2020)

M.A. Alim, M.R. Repon, T. Islam, K.F. Mishfa, M.A. Jalil, M.D. Aljabri, M.M. Rahman, ChemistrySelect 7(23), e202201557 (2022)

C. Nefzi, B. Yahmadi, N.E. Guesmi, N. Kamoun-Turki, S.A. Ahmed, J. Mol. Struct. 1251, 131943 (2022)

R.M. Ibrahim, J. Umm Al-Qura Univ. Appll. Sci. 1–19 (2024). https://doi.org/10.1007/s43994-023-00098-7

S. Karthik Kannan, P. Thirunavukkarasu, R. Marnadu, J. Chandrasekaran, S. Maruthamuthu, A.M. Ali, M. Shkir, J. Electron. Mater. 50, 3937–3948 (2021)

D.H. Lee, K.D. Vuong, R.A. Condrate Sr, X.W. Wang, Mater. Lett. 28(1–3), 179–182 (1996)

W.F. Wu, B.S. Chiou, Appl. Surf. Sci. 68(4), 497–504 (1993)

C.H.L. Weijtens, P.A.V. Loon, Thin Solid Films. 196(1), 1–10 (1991)

Z. Xu, P. Chen, Z. Wu, F. Xu, G. Yang, B. Liu, C. Tan, L. Zhang, R. Zhang, Y. Zheng, Mater. Sci. Semicond. Process. 26, 588–592 (2014)

N.M. Ahmed, F.A. Sabah, H.I. Abdulgafour, A. Alsadig, A. Sulieman, M. Alkhoaryef, Results Phys. 13, 102159 (2019)

A.M. Abd-Elnaiem, A. Hakamy, J. Mater. Sci. Mater. Electron. 3330, 23293 (2022)

M. Ahmed, A. Bakry, A. Qasem, H. Dalir, Opt. Mater. 113, 110866 (2021)

H. Askari, H. Fallah, M. Askari, M.C. Mohmmadieyh, arXiv preprint arXiv:1409.5293 (2014). https://doi.org/10.48550/arXiv.1409.5293

C.W. Chen, Y.C. Lin, C.H. Chang, P. Yu, J.M. Shieh, C.L. Pan, IEEE J. Quantum Electron. 46(12), 1746–1754 (2010)

E.A. Alwan, A. Kiourti, J.L. Volakis, IEEE Access. 3, 648–652 (2015)

H. Jin, E. Debroye, M. Keshavarz, I.G. Scheblykin, M.B. Roeffaers, J. Hofkens, J.A. Steele, Mater. Horiz. 7(2), 397–410 (2020)

A. Sedky, N. Afify, A.M. Ali, H. Algarni, Appl. Phys. A 128(2), 102 (2022)

I. Hussain, M.Y. Soomro, N. Bano, O. Nur, M. Willander, J. Appl. Phys. 112(6), 064506 (2012)

S.C. Baral, P. Maneesha, E.G. Rini, S. Sen, Prog Solid State Ch. 72, 100429 (2023)

K. Saravanakumar, P. Sakthivel, R.K. Sankaranarayanan, Spectrochim Acta - A: Mol. Biomol. Spectrosc. 267, 120487 (2022)

K. Irshad, M.T. Khan, A. Murtaza, Phys. B: Condens. 543, 1–6 (2018)

J. Singh, R.C. Singh, J. Mol. Struct. 1215, 128261 (2020)

L.K. Smirani, M. Kumari, S.H. Ahammad, M.A. Hossain, M.G. Daher, A.N.Z. Rashed, A. Ibrahim, K.M. Abohassan, A. Panda, J. Opt. Commun. (2022). https://doi.org/10.1515/joc-2022-0129

M. Morad, T.M. Habeebullah, I. Althagafi, B.H. Asghar, A.A. Bayazeed, T.M. Bawazeer, A.M. Al-Solimy, N. El-Metwaly, Res. Chem. Intermed. 46, 4543–4562 (2020)

A.M. El Nahrawy, A.B. Abou Hammad, A.M. Youssef, A.M. Mansour, A.M. Othman, Appl. Phys. A 125, 46 (2019)

D.K. Kaushik, K.U. Kumar, A. Subrahmanyam, AIP Adv. 7(1), 015109 (2017)

J.H. Park, C. Buurma, S. Sivananthan, R. Kodama, W. Gao, T.A. Gessert, Appl. Surf. Sci. 307, 388–392 (2014)

R.Y. Yang, C.J. Chu, Y.M. Peng, H.J. Chueng, Adv. Mater. Sci. Eng. 2012 (2012). https://doi.org/10.1155/2012/741561

G. Shao, X. Wu, Y. Kong, S. Cui, X. Shen, C. Jiao, J. Jiao, Surf. Coat. Technol. 270, 154–163 (2015)

T.G.V.M. Rao, A.R. Kumar, K. Neeraja, N. Veeraiah, M.R. Reddy, J. Alloys Compd. 557, 209–217 (2013)

M. Akram, A.T. Saleh, W.A.W. Ibrahim, A.S. Awan, R. Hussain, Ceram. Int. 42(7), 8613–8619 (2016)

M. Thirumoorthi, J.T.J. Prakash, J. Asian Ceram. Soc. 4(1), 124–132 (2016)

S. Selvakumar, R. Murugaraj, E. Viswanathan, S. Sankar, K. Sivaji, J. Mol. Struct. 1056, 152–156 (2014)

X. Wang, Y. Zhang, Mater. Lett. 188, 257–259 (2017)

A. Sedky, A.M. Ali, H. Algarni, Opt. Quantum Electron. 54(6), 376 (2022)

A. Sedky, M.I. Youssif, T.A. El-Brolossy, Nat. Sci. 14(2), 66–73 (2016)

A.Q. Abdullah, N.A. Ali, S.I. Hussein, A. Hakamy, A.M. Abd-Elnaiem, J. Inorg. Organomet. Polym. Mater. 33, 3882–3893 (2023)

A. Eroğlu, A.D.E.M. Tataroğlu, Ş. Altındal, Microelectron. Eng. 91, 154–158 (2012)

H. Bouaamlat, N. Hadi, N. Belghiti, H. Sadki, M.N. Bennani, F. Abdi, T.D. Lamcharfi, M. Bouachrine, M. Abarkan, Adv. Mater. Sci. Eng. 1–8 (2020). https://doi.org/10.1155/2020/8689150

D.A. Nasrallah, E.G. El-Metwally, A.M. Ismail, Polym. Adv. Technol. 323, 1214 (2021)

N.C.R. Babu, M.A. Valente, N.N. Rao, M.P.F. Graça, G.N. Raju, M. Piasecki, I.V. Kityk, N. Veeraiah, J. Non-Cryst Solids. 358(23), 3175–3186 (2012)

R.F. Loane, P.R. Xu, J. Silcox, Acta Crystallogr. A 47(3), 267–278 (1991)

S.R. Elliott, Adv. Phys. 36(2), 135–217 (1987)

M. Shoab, Z. Aslam, J. Ali, M. Zulfequar, J. Mater. Sci. Mater. Electron. 34(7), 681 (2023)

S.I. Qashou, Z. Khattari, M. Rashad, A.A.A. Darwish, A. Shaheen, Mater. Res. Express. 6(8), 086317 (2019)

F. Baig, M.W. Ashraf, A. Asif, M. Imran, Optik. 208, 164534 (2020)

J. Jose, M. Abdul Khadar, Mater. Sci. Eng. A 304, 810–813 (2001)

S. Patel, R. Kumar, J. Alloys Compd. 789, 6–14 (2019)

Acknowledgements

The authors extend their appreciation to the Deanship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research work through the project number :IFP22UQU4250045DSR055.

Funding

The work is funded by the Deanship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research work through the project number: IFP22UQU4250045DSR055.

Author information

Authors and Affiliations

Contributions

A.H. formal analysis; validity, funding. A.M.M revised and edited the manuscript. A.S. Data curation; formal analysis; investigation, writing the original draft. A.M.A Data curation; methodology; writing the original draft. All authors have read and agreed to the final version of the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hakamy, A., Mebed, A.M., Sedky, A. et al. Effect of annealing temperature on the structure and dielectric characterization of ITO thin films on a boro-float substrate prepared by radio frequency sputtering. J Electroceram (2024). https://doi.org/10.1007/s10832-024-00348-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10832-024-00348-y