Abstract

Worldwide, there is growing interest in achieving a meaningful use of natural resources, as epitomized in this work, which demonstrates the use of saline wastewater (WW) from the demineralization of cheese whey as the main component of a medium for cultivation of spirulina (Limnospira maxima). Based on Zarrouk medium and the fundamental composition of spirulina biomass, a novel cultivation medium for photoautotrophic cultivation of spirulina was developed. The wastewater medium (WWM) consisted of WW supplemented with NaHCO3, urea, K2HPO4, and FeSO4. The suitability of WWM was evaluated by comparison of spirulina growth in laboratory scale tubular or gas-lift photobioreactors in WWM and Zarrouk medium (ZM). The maximum biomass productivity of 0.36 g L−1 day−1 was achieved in WWM, compared with 0.24 g L−1 day−1 in ZM. The cost of WWM was less than 50% of the cost of ZM.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cheese whey is a yellow-green liquid (de Wit 2001) generated from milk during the cheese production process, after the precipitation and removal of casein (Gonzáles-Siso 1996). Every kilogram of cheese produced results in 9 L of whey (Kosikowski 1968). The annual global production of whey is approximately 11 million tonnes (4.5 million tonnes of which originates within the EU) and continues to increase (FAO 2020). Consequently, there is an urgent need to find meaningful uses for whey and its byproducts.

Currently, approximately half of the total volume of cheese whey produced serves as a resource for biotechnologies, being used in the production of ethanol, biogas, single-cell proteins, animal feed, pharmaceuticals, and fertilizers (Ryan and Walsh 2016). However, other potential uses of whey are limited by its high mineral content (8–10% w/v). For example, high mineral and lactose levels can cause gastrointestinal problems when used for animal feed (Sienkiewicz and Riedel 1990) and the application of cheese whey to soil increases soil salinity, leading to reductions in crop yields (Ghaly et al. 2007). The mineral content of cheese whey can be reduced by electrodialysis, a process by which ion-exchange membranes are used to separate ions from an aqueous solution using an electrical potential driving force (Strathmann 1986). In principle, the input stream (original cheese whey) is separated by ion-exchange membranes in a direct electric field, cations moving towards the cathode are transmitted through cation-exchange membranes and held by anion-exchange membranes, while anions attracted towards the anode are transmitted through anion-exchange membranes and held on cation-exchange membranes, resulting in two output streams; (i) diluate (demineralized cheese whey suitable for further processing) and (ii) concentrate (wastewater containing most of the minerals initially present in the original cheese whey). The saline wastewater produced has been used in a culture medium for thraustochytrids (Humhal et al. 2016) and heterotrophic microalgae (Ghobrini et al. 2020).

Limnospira maxima (formerly Arthrospira maxima, common name spirulina) a non-toxic filamentous oxygenic cyanobacterium is found in tropical and subtropical waterbodies and grows in high-temperature, high salinity alkaline water containing high levels of bicarbonate and carbonate ions (Vonshak 2002). Due to its composition, Limnospira is considered an excellent dietary supplement that can be used as an ingredient in the development of functional foods (Gouveia et al. 2008, Lafarga et al. 2020). However, despite the wide range of possible uses, Limnospira production is still limited by its high production costs, with the typically used but expensive Zarrouk medium accounting for 15–25% of the total production costs of Limnospira biomass (Zarrouk 1966, Vonshak 2002).

The cost-effective large-scale cultivation of Limnospira is, therefore, strongly dependent on finding a low-cost nutrient-rich saline alkaline medium as an alternative to commonly used medium formulations. To date, various media based on inexpensive sources of minerals, such as commercial-grade fertilizers (Raoof et al. 2006; Gomez et al. 2020), or different types of wastewater have been tested. These have included the use of swine waste (Cañizares and Domínguez 1993), municipal wastewater (Djaghoubi et al. 2015), dairy wastewater (Pereira et al. 2019), olive oil mill waste (Markou et al. 2012), and digested sago starch wastewater (Phang et al. 2000). The various results were promising in the sense that Limnospira grew on these waste media, but no economic estimates of cultivation costs were reported.

In this study, we evaluate the feasibility of using wastewater from the demineralization of cheese whey (i.e., saline wastewater) as part of a culture medium for the autotrophic cultivation of L. maxima. The cultivations were evaluated through biomass productivities. Following optimization of the medium composition in a lab-scale tubular photobioreactor (PBR), the results were confirmed in a gas-lift PBR and an economic estimate of culture medium costs was carried out.

Materials and methods

Microorganism and media

Limnospira maxima strain CCALA 027 was purchased in the Culture Collection of Autotrophic Organisms of the Institute of Botany of the Czech Academy of Sciences, Trebon, Czech Republic).

Zarrouk medium (ZM) was used as the reference medium and in experiments, six types of modified Zarrouk media (MZM1-6) were used (Table 1). ZM and MZMs were sterilized in an autoclave (121 °C, 20 min, 1 bar) and the pH was maintained within the range of 9.0–10.0.

Saline wastewater was obtained by electrodialytic desalination (demineralization) of cheese whey from a dairy company (Dairyfood GmbH, Riedlingen, Germany). The process of electrodialysis was carried out using an EWDU 6xEDR-II/250–0.8, MEGA a.s. Prior to use, the crude saline wastewater was sterilized in an autoclave (121 °C, 1 bar, 20 min). After cooling, the sedimented solid precipitates were discarded, while the supernatant wastewater (WW) was used as the base for wastewater medium (WWM). The chemical composition of WW and its comparison with ZM are given in Table 2. The analyses were carried out by Laborator Monitoring s.r.o., Prague (Laborator Monitoring 2021), and the Research Institute of Brewing and Malting, Prague (RIBM 2021). The relative uncertainties of WW components analyzed ranged from 7 to 15%.

The different wastewater media (WWM) were prepared by dilution of WW with sterile distilled water and/or addition of salts such as NaHCO3, Na2CO3, NaNO3, K2HPO4, CaCl2, FeSO4.7H2O, and urea. The composition of all WWM used in this work is given in Table 3.

Cultivation

An inoculum of Limnospira culture was batch cultivated for 5 days in ZM in a conical-bottom tubular photobioreactor (PBR) with a working volume of 350 mL (internal diameter 35 mm, height 510 mm, height of algal suspension 380 mm) placed in a temperature-controlled water bath (30 °C) under continuous illumination with an LED panel (incident light intensity 300 µmol photons m−2 s−1). Aeration was with 0.2 µm filtered air enriched with CO2 to 2% vol. and a flowrate of 150 mL min−1. This was then used to inoculate fresh ZM, MZM, or WWM. Cultures in PBRs were cultivated for 9 days under the same conditions as described for cultivation of the inoculum. All experiments were carried out in duplicate and repeated twice.

With selected MZM and WWM (MZM6, WWM9, WWM10), bench-scale cultivation in a gas-lift PBR with a working volume of 1.4 L was carried out. Cultivation in a gas-lift PBR had the following parameters: temperature 30 °C, continuous illumination with an LED strip (incident light intensity 200 µmol photons m−2 s−1), and aeration with 0.2 µm filtered air enriched with CO2 to 2% vol. at a flowrate of 250 mL min−1. Cultures in the gas-lift PBRs were carried out for 9 days and repeated twice for each medium composition.

The growth curves are presented as experimental data fitted with linear regression. The coefficients of determination (R2) for linear regression of each growth curve were at least 0.98. The experimental data were statistically evaluated using t test. All statements of significance were based on a probability of p < 0.05. Statistical analyses were performed using MS Excel.

Analyses

During the cultivation, the absorbance at 750 nm wavelength (A750) was measured daily to quickly determine the actual biomass concentration (Griffiths et al. 2011). The absorbance was measured using a SPECTROstar Omega (BMG Labtech, Germany) spectrophotometer in the sample volume of 2 mL in 12-well plates (Greiner) in triplicates and the standard deviation was calculated. To calculate the biomass concentration from absorbance, the following calibration was used:

Once every 2 days, dry biomass content cx was evaluated by gravimetry—10 mL of a sample was filtered through a frit with a porosity class of P100 corresponding to a pore size of 40–100 µm (SIMAX, Kavalierglass, a.s., Czech Republic) and washed twice with 10 mL of distilled water in order to remove residual salts from the medium. Then, the frits were dried at 105 °C for 24 h and the dry matter content was calculated. All samples were analyzed in triplicate and the standard deviation was calculated.

The volumetric biomass productivity Px was calculated as:

For comparison of individual experimental results, the volumetric biomass productivity after 9 days of cultivation Px9 [g L−1 day−1] was used.

The phosphate concentration, cP, in the cultivation medium was determined by the ammonium molybdate spectrophotometric method according to EN ISO 6678:2004. To a sample of 0.5–40 mL of the supernatant after centrifugation of spirulina suspension (according to presumed cP), 1 mL of ascorbic acid solution (100 g L−1) and 2 mL of ammonium heptamolybdate [(NH4)6Mo7O24.4H2O] solution (32.5 g L−1 in 7 M H2SO4) were added. Distilled water was added to a final volume of 50 mL and after 30 min, the A820 nm was measured. The results were expressed as means with experimental errors < 5%.

Analysis of the biomass composition was performed. Individual groups of pigments were analyzed (chlorophyll a and carotenoids by methanol extraction and spectrophotometric determination as described by Lichtenthaler and Wellburn (1983) and phycocyanin by ultrasonication and spectrophotometric determination as described by Gorgich et al. (2020)). An analysis of biomass composition (total carbohydrates, lipids, and proteins) was carried out by the State Veterinary Institute, Prague (SVI 2021). Analysis of nitrates was carried out by HPLC–UV at the Research Institute of Brewing and Malting, Prague (RIBM 2021). The relative deviations in the determination of biomass composition were as follows: total carbohydrates (5%), lipids (5.4%), proteins (2%), chlorophyll a (5%), carotenoids (4%), phycocyanin (7%), and nitrates (8%).

Economic analysis

Comparisons of media costs (Table 4) were made on the basis of prices obtained for food or microbial culture grade chemicals purchased in large amounts (Alibaba 2020). The following assumptions were made: (i) the cost of sterilization in the autoclave was not included because it is independent of the type of medium being used and in a large-scale production it is not performed, (ii) the cost of FeSO4.7H2O was neglected, (iii) the calculation for WWMs did not include the price of WW as it is considered to be a freely available waste material, and (iv) transport costs of WW were applied from Humhal et al. (2016).

Results

Cultivation in Zarrouk medium

When cultivated in tubular PBR under the conditions described above, Limnospira grew linearly in ZM for 9 days with an average productivity of Px9 0.24 g L−1 day−1. All the subsequent cultivation experiments were, therefore, terminated after 9 days, when stable linear growth was clearly developed and the volumetric productivity (Px9) could be assessed with accuracy. The Px9 was used in subsequent experiments to compare the growth of Limnospira under different conditions.

Cultivation in modified Zarrouk medium

Nitrogen source

Replacing the commonly used source of nitrogen, sodium nitrate, with urea, at a concentration corresponding to the same nitrogen content in the medium, led to a surprisingly large increase in biomass productivity and a significant decrease in the cost of the medium (MZM1). Replacement of nitrate with urea increased significantly (p ˂ 0.05) Px9 by 42% from 0.24 to 0.34 g L−1 day−1 (Fig. 1), leading to a net cost reduction of more than 25%.

Carbon sources/buffer

Three types of media were prepared: the original ZM containing 10.5 g L−1 NaHCO3 and 7.6 g L−1 Na2CO3, a medium containing only 10.5 g L−1 NaHCO3 (MZM2), and a medium containing only 7.6 g L−1 Na2CO3 (MZM3). MZM2 led to a 20% reduction in the cost of the medium compared to ZM and to statistically significant (p ˂ 0.05) increase in Px9 of about 40% (from 0.24 to 0.34 g L−1 day−1). In contrast, MZM3 led to statistically insignificant (p ˃ 0.05) decrease in Px9 to 0.22 g L−1 day−1 (Fig. 2A), while it was 33% cheaper than ZM. The initial pH of MZM3 was the highest among all media compared in this experiment (Fig. 2B).

Phosphorus source

Two K2HPO4 concentrations were tested in this work, 0.25 g L−1 in MZM4 (N/P = 15/1.6) and 0.15 g L−1 (N/P = 15/1) in MZM5, which corresponds to 50 and 70% reductions compared to ZM, respectively. As expected, the reduction in phosphorus concentration had statistically insignificant (p ˃ 0.05) effect on biomass growth (Fig. 3A), while Px9 ranged from 0.22 to 0.25 g L−1 day−1. After 9 days of cultivation, the phosphorus concentration in MZM5 (3.64 ± 0.07 mgP L−1) was still not limiting (Fig. 3B).

Cultivation in wastewater medium

Diluted wastewater

Limnospira growth was tested in diluted (WWM2 and 4) and undiluted wastewater (WWM1) supplemented with buffer. The highest Px9 (0.05 g L−1 day−1) was achieved in WWM4 (Fig. 4). Therefore, this dilution ratio (1:1) was used as the basis for all media in subsequent experiments, where the addition of inorganic salts as nutrient sources was tested. In wastewater diluted with water (1:1) without addition of buffer (WWM3) showed Limnospira no growth (Fig. 4A). Growth of Limnospira in WWM1 and WWM2 was observed only during the first 2 days of cultivation (data not shown). When evaluated after 2 days of cultivation, Px reached 0.17 g L−1 day−1 in WWM1 and 0.14 g L−1 day−1 in WWM2.

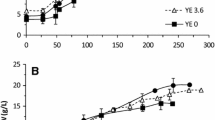

A Growth curves (cx) and B biomass productivity (Px) assessed for 9 days of cultivation of Limnospira maxima strain CCALA 027 growth in Zarrouk medium (ZM) and wastewater media WWM3 (dilution 1:1), WWM4 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3), WWM5 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.25 g.L−1 K2HPO4, 0.005 g.L−1 FeSO4), WWM6 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.5 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4, 0.03 g.L−1 CaCl2), WWM7 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.5 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4), WWM8 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.5 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4, 2.5 g.L−1 NaNO3, 0.03 g.L−1 CaCl2), WWM9 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.5 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4, 0.88 g.L−1 urea) in tubular PBR at 300 µmol photons m−2 s−1

Wastewater supplemented with inorganic salts

The highest Cx and Px9 (0.36 g L−1 day−1) were achieved in WWM9, which contained WW diluted with distilled water in a ratio of 1:1; buffer (NaHCO3, Na2CO3), nitrogen (urea), phosphorus (K2HPO4), and iron (FeSO4.7H2O) (Fig. 4). Moreover, Px9 in WWM9 was over 50% higher than in ZM, which is a statistically significant difference (p ˂ 0.05). Interestingly, Px9 in WWM8 was slightly, but not significantly (p ˃ 0.05) lower than that of ZM, with the difference between WWM8 and WWM9 being the nitrogen source and the addition of CaCl2 to WWM8. Biomass productivity Px9 in WWM6 was also significantly (p ˂ 0.05) lower than in WWM7 (Fig. 4B). This indicates that the high calcium concentration in WWM6 and 8 (20 mgCa L−1) had negative effect on Limnospira growth and that the amount of calcium in the diluted WW (10 mgCa L−1) was sufficient, which corresponds to the calcium concentration in ZM 10.8 mgCa L−1. Px9 in WWM3-7 was significantly (p ˂ 0.05) lower compared to ZM (Fig. 4B).

Cultivation in a gas-lift photobioreactor

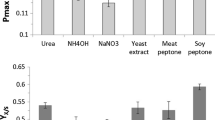

Cultivation of L. maxima in a bench-scale gas-lift PBR on four selected media (ZM, MZM6, WWM9, WWM10) confirmed the results obtained in tubular PBRs. In MZM6, NaNO3 was replaced by urea, the concentration of K2HPO4 was reduced to 30% of ZM, and Na2CO3 was not added (combination of MZM1, MZM2, and MZM5). In WWM10, the diluted wastewater was supplemented with buffer, and sources of nitrogen, phosphorus, and iron were added. In the modified media MZM6, WWM9, and WWM10, the biomass concentrations increased rapidly (Fig. 5A) and Px9 values were significantly higher (p ˂ 0.05) than in ZM (Fig. 5B). WWM9 and WWM10 showed the highest Px9, reaching an average of 0.28 g L−1 day−1, confirming these as the most productive media for Limnospira cultivation (Fig. 5B). The Px9 in WWM9 and WWM10 was even higher than in MZM6, but the difference was statistically not significant (p ˃ 0.05). Cultivation was also performed in non-autoclaved WWM10. Using non-autoclaved wastewater, the Px9 was reduced by approximately 25% compared to autoclaved WWM10 (statistically significant difference, p ˂ 0.05). However, it was still significantly higher (p ˂ 0.05) than the productivity reached in ZM. No bacterial contamination was observed during culture growth in non-autoclaved WWM10 under laboratory conditions. The comparison of Px9 for L. maxima growth in ZM and WWM9 in tubular and gas-lift PBR shows significantly (p ˂ 0.05) higher values in tubular PBR (Figs. 4 and 5).

A Growth curves (cx) and B biomass productivity (Px) assessed for 9 days of cultivation of Limnospira maxima strain CCALA 027 in Zarrouk medium (ZM), modified Zarrouk medium MZM6 (0.88 g.L−1 urea, without Na2CO3), wastewater media WWM9 (dilution 1:1, 10.5 g.L−1 NaHCO3, 7.6 g.L−1 Na2CO3, 0.5 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4, 0.88 g.L−1 urea), and WWM10 (dilution 1:1, 10.5 g.L−1 NaHCO3, 0.15 g.L−1 K2HPO4, 0.01 g.L−1 FeSO4, 0.88 g.L−1 urea) in gas-lift PBR at 200 µmol photons m−2 s−1

Biomass composition

An analysis of pigment concentration was performed on biomass cultivated in ZM and WWM10. The content of individual groups of pigments in biomass cultivated in ZM or WWM10 after 9 days of cultivation was as follows: chlorophyll a 0.47 and 0.29%, carotenoids 0.01 and 0.05%, and phycocyanin 2.34 and 1.20%, respectively. At the same time, compositional analyses of the biomass cultivated in ZM or WWM10 were performed with the following results: proteins 64.4 and 60.8%, total carbohydrates 28.5 and 30.4%, and lipids 2.7 and 4.6%, respectively. The differences found between the biomass composition from ZM and WWM10 were statistically significant (p ˂ 0.05) for all analyzed pigments, proteins, and lipids.

Discussion

The main factor limiting the marketing of Limnospira is its high production cost, which is largely driven by the need for an expensive cultivation medium. The most commonly used Zarrouk medium (ZM) accounts for around 20% of Limnospira production costs (Vonshak 2002). The aim of this study was, therefore, to develop a more cost-effective method for cultivating Limnospira.

In this work, Limnospira grew in ZM with Px9 (0.24 g L−1 day−1) comparable to the results of other researchers—0.21 g L−1 day−1 (Gouveia and Oliveira 2009) and 0.27 g L−1 day−1 (Gomez et al. 2020). The improved Px9 (Fig. 1) and reduced medium costs achieved by replacement of nitrate with urea are consistent with other studies that investigated the use of urea as a better nitrogen source for large-scale cultivation of spirulina (Fox 1996; Danesi et al. 2011; Rizal et al. 2017). In contrast, Costa et al. (2001) reported slightly higher productivity for nitrates rather than urea, although they also concluded that urea is a more suitable source of nitrogen in terms of the cost of biomass production. In addition to its low price, another advantage of urea is its enzyme catalyzed hydrolysis into carbonic acid, which serves as an additional source of carbon (Markou et al. 2014). However, a possible disadvantage is the toxicity of urea in large doses. For this reason, Fox et al. (1996) determined that the maximum concentration of ammonia in a medium for spirulina should be kept below 0.125 g L−1; this is considerably higher than was used in our study. Surprisingly, in other studies aimed at reducing medium costs for mass production of spirulina, nitrates were not replaced by urea (Raoof et al. 2006; Gomez et al. 2020).

Carbonate buffer is usually added to spirulina medium for two reasons: (i) to maintain an alkaline pH of the medium, and (ii) to serve as a carbon source because, in addition to carbon in the form of CO2, spirulina can also utilize bicarbonates. Because carbonates significantly increase cultivation costs, we tested the possibility of reducing their concentration. The utilization of MZM2 led to simultaneous increase of Px9 and decrease of medium costs. The reduction of NaHCO3 content by 50% without affecting Px was also recommended by Raoof et al. (2006). Furthermore, cost savings can be achieved by substituting expensive chemicals with commercial-grade fertilizers (Gomez et al. 2020). The pH strongly influences the form of inorganic carbon (CO2, H2CO3, HCO3− or CO32−) and their proportions (Pereira et al. 2019) present in the culture medium. Higher proportions of HCO3− and CO32− ions occur at an alkaline pH and while HCO3− is the preferred form of inorganic carbon for spirulina, the ideal pH for growth is in the range from 9.5 to 9.8. The highest initial pH of MZM3 could cause that there was a lower concentration of HCO3− ions than in ZM and MZM2. This was probably the reason why the Px9 decreased in MZM3.

Typically, some components of commonly used ZM are in excess of what is needed, which makes the medium unbalanced. This is particularly noticeable for phosphorus, which results in unnecessarily high costs of the medium. For example, according to elemental analysis of Limnospira biomass (Fox 1996), the N/P ratio in the biomass was 15/1 but 15/3.2 in ZM. Therefore, after depletion of nitrogen from ZM, growth of Limnospira would cease, but spent ZM would still theoretically contain 70% of the original phosphorus concentration, which would be wasted. In this work it was observed experimentally that at the end of the linear growth phase in ZM, the nitrate content was below the limit of detection, while the phosphorus content in the medium was reduced from the original concentration of 0.089 to 0.038 mgP L−1. A correction of the phosphorous imbalance in ZM, as suggested by Raoof et al. (2006) and Gomez et al. (2020), involved a 50% reduction in K2HPO4 content leading to an N/P ratio of 15/1.6. As expected, the reduction in phosphorus concentration in this work (MZM4, MZM5) had no effect on biomass growth but allowed further decrease in medium cost.

It was found that diluted wastewater (WW) from the demineralization of cheese whey can be used for Limnospira cultivation. The contents of lactose, glucose, and lactic acid in WW were low and no contamination occurred during cultivation. However, contamination problems cannot be ruled out when scaling up the process. Analysis of the wastewater composition (Table 2) suggested that the growth limitation was most probably caused by the lack of N, P, or Fe. The addition of inorganic salts to WW clearly showed that (i) the addition of P, Fe, and N was necessary to reach a high Px of Limnospira, (ii) a Ca2+ concentration of 20 mgCa L−1 had a negative effect on Limnospira growth, and (iii) the use of a carbon source/buffer as in ZM (NaHCO3 + Na2CO3) or MZM2 (NaHCO3) was necessary. As for calcium, similar observation was made for growth of the cyanobacterium Microcystis aeruginosa at high concentrations of calcium. The optimum calcium concentration observed was 60 mgCa L−1, while at 120–240 mgCa L−1, a reduction in growth and chlorophyll a content was found (Shi et al. 2012). Moreover, high calcium concentrations in alkaline cultivation medium can result in the formation of various calcium precipitates, which leads to a decrease in pH and losses of minerals such as phosphorus or iron (Markou et al. 2014). On the other hand, Fakhri et al. (2020) replaced NaNO3 with Ca(NO3)2 (2.5 g L−1) and they did not observe any negative effects on Spirulina platensis growth at a calcium concentration 596 mgCa L−1. Precipitation of inorganic salts can negatively affect Px by a reduction in light availability as it was shown in non-autoclaved WWM10. Decreased cell growth in consequence of shadow effect was reported for Arthrospira platensis in spent medium and piggery wastewater with organic matter and pigments (Depraetere et al. 2013; Morocho-Jácome et al. 2016). However, the productivity in non-autoclaved WWM10 was still higher than in ZM. Autoclaving of a WW-based medium is not feasible when scaling up the cultivation, but there are other methods available to reduce turbidity (adsorption, filtration, centrifugation, sedimentation).

According to the analysis of the wastewater composition, in WWM, the following levels of organic substances were potentially usable as carbon sources: 0.005 g L−1 of lactose, 0.05 g L−1 of glucose, and 1.9 g L−1 of lactic acid. According to available information, Limnospira can utilize glucose (Marquez et al., 1993) and lactose (Pereira et al. 2019) as a carbon source. If the maximal yield of these substances, Y = 0.5, is considered, the above glucose concentration would yield an increase of 0.0025 g L−1 of dry biomass and the above concentration of lactose would yield an increase of 0.025 g L−1 of dry biomass. Due to the fact that the stationary phase of growth occurred at a value higher than 3 g L−1 of dry biomass, the contribution of potential mixotrophic growth would be lower than 1%, which was considered negligible. The ability to utilize lactic acid has not been published, so this possibility was not considered.

The experiments in this work were carried out in either tubular or gas-lift PBR with differences in illumination (200 and 300 µmol photons m−2 s−1 for gas-lift and tubular PBR, respectively). Consequently, Px9 using the same medium were higher in tubular PBR. Productivities achieved in WWM9 and WWM10 were significantly higher than in similar studies made previously for A. platensis using waste materials as part of the medium. For example, Pereira et al. (2019) reported 0.1 and 0.18 g L−1 day−1 on ZM (phototrophic growth) and ZM enriched with cheese whey (mixotrophic growth), respectively. However, the illumination was somewhat lower (238 µmol photons m−2 s−1) and followed a 12 h light/dark photoperiod. Markou et al. (2012) reported Px (0.11 g L 1 day−1) for A. platensis on pretreated olive oil mill wastewater. These cultures were performed under 135 µmol photons m−2 s−1 of light intensity (cool white fluorescent lamps assumed) with a photoperiod of 20/4 (light/dark). Spirulina sp. in a complex medium consisting of untreated seawater supplemented with anaerobic effluents from digested pig waste had by 32% higher Px (0.1 g L−1 day−1) than in ZM (Olguín et al. 2001). The fact that Px is lower than achieved in our work can be ascribed to lower illumination (144 µmol photons m−2 s−1) and cultivation system (raceway pond). The most comparable Px (0.21 g L−1 day−1) was obtained for A. platensis growing on urea- and K2HPO4-supplemented digested sago wastewater in a 60-L high rate algal pond under light/dark photoperiod of natural illumination (Phang et al. 2000). However, the comparisons of the aforementioned studies with our work are not entirely possible due to the great differences between the used illuminations and cultivation systems. It can be hypothesized that the significantly higher biomass productivities obtained in WWM9 and WWM10, as compared to ZM, are associated with simultaneous use of urea and nitrate in WW-based media. The positive effect of the simultaneous use of different nitrogen sources on the biomass productivity of A. platensis has already been shown (Vieira et al. 2012). Another hypothesis of the improved biomass productivity can be the high content of sulfate, potassium, and magnesium in WW-based media. These nutrients have been identified to play important biological roles (Markou et al. 2014), but the positive effect of their surplus, relative to the amount in ZM, has not yet been investigated.

A detailed analysis of biomass composition, including quantification of pigments, was performed on biomass grown in ZM or WWM10. The content of chlorophyll a and carotenoids corresponded well to the expected values of chlorophyll a (0.26–1.1%) and carotenoids (0.03–0.38%) in A. platensis (Park et al. 2018). The content of phycocyanin is strongly dependent on the culture conditions and analytical method used for quantification, but is approximately 5% (Khandual et al. 2021). The average spirulina biomass composition is in the range 64–74% for proteins, 15–20% for carbohydrates, and 6–13% for lipids (Vonshak 2002). From this composition, the biomass obtained in this work differed in protein content (60.8%) for WWM10 and total carbohydrates (28.5 and 30.4%) and lipids (2.7 and 4.6%) for ZM and WWM10, respectively. The composition of spirulina biomass varies greatly depending on the culture conditions (Vonshak 2002). The difference between biomass from ZM and WWM10 can be ascribed to the used nitrogen source (nitrate vs. urea/ammonium), as this was shown to have an effect on biomass composition (Sachdeva et al. 2018).

The costs associated with the various media (ZM, MZM6, WWM9, WWM10) used in the gas-lift PBR experiments were compared in order to demonstrate the advantage of using WW from demineralization of cheese whey as part of a culture medium for L. maxima (Table 4). In the case of WWM10, the price of the culture medium was reduced by more than 50%. WWM10 was also cheaper than FM-II medium (4.1 US$ m−3) and RM6 medium (3.7 US$ m−3) based on commercial-grade fertilizers, as suggested by Gomez et al. (2020) and Raoof et al. (2006), respectively. Slightly lower preparative costs would be expected only in the case of FM-II medium with 50% reduced phosphate and bicarbonate content (2.4 US$ m−3) (Gomez et al., 2020). However, the apparent advantage of reduced FM-II over WWM10 stems from the fact that the non-economic benefit (environmental advantages such as waste disposal and water quality) of biotechnologically exploited WW is not quantifiable. The main disadvantage in the use of WW is its variable chemical composition. Due to this, the key components of the WW (nitrogen, phosphorus) must be analyzed prior to use. Overall, our results provide strong evidence that WW is suitable for cultivation of L. maxima and that its use will lead to a significant reduction in Limnospira production costs. However, when scaling up the cultivation process, other cost items, such as aeration and harvesting, will have to be considered too.

Conclusion

Spirulina is the most cultivated microalga worldwide, the incorporation of which into diverse food formulations is increasing (Kunsel and Sumant 2020). The importance of spirulina for future food applications is enhanced by its positive health benefits. One of the bottlenecks of its expansion into the food industry is the cost of its production. The results of this work demonstrate a successful application of WW from demineralization of cheese whey for the autotrophic cultivation of L. maxima. The cost of this alternative WW-based culture medium was estimated to be 54–58% less than ZM, with simultaneously improved biomass productivity. The biomass composition was not significantly affected by the composition of the medium used.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Alibaba (2020) Chemicals. https://www.alibaba.com/Chemicals_p8. Accessed 27 December 2020

Cañizares RO, Domínguez AR (1993) Growth of Spirulina maxima on swine waste. Bioresour Technol 45:73–75

Costa JA, Cozza K, Santos L, Magagnin G (2001) Different nitrogen sources and growth responses of Spirulina platensis in microenvironments. World J Microbiol Biotechnol 17:439–442

Danesi EDG, Rangel-Yagui OC, de Carvalho MJC (2011) Growth and content of Spirulina platensis biomass chlorophyll cultivated at different values of light intensity and temperature using different nitrogen sources. Braz J Microbiol 42:362–373

de Wit JN (2001) Lecturer’s Handbook on whey and whey products. European Whey Products Association, Brussels

Depraetere O, Foubert I, Muylaert K (2013) Decolorisation of piggery wastewater to stimulate the production of Arthrospira platensis. Bioresour Technol 148:366–372

Djaghoubi A, Bouhoun MD, Said SH, Saggaï A, Sobti S, Aissa BH (2015) Growth and nitrogen removal efficiency as protein content of Spirulina from tertiary municipal wastewater in Ouargla (Algerian Bas-Sahara). Energy Procedia 74:1402–1409

Fakhri M, Antika PW, Ekawati AW (2020) Growth, pigment and protein production of Spirulina platensis under different Ca(NO3)2 concentrations. J Aquacult Fish Health 9:38–47

Food and Agriculture Organization of the United Nations, FAO (2020) Overview of global dairy market developments 2019. Dairy Market Review. http://www.fao.org/3/ca8341en/CA8341EN.pdf

Fox RD (1996) Spirulina: production & potential. Édisud, Avignon. 234 p

Ghaly MN, Rushton D, Arab F (2007) Potential environmental and health impacts of high land application of cheese whey. Am J Agric Biol Sci 2:106–117

Ghobrini D, Potočár T, Smolová J, Krausová G, Yakoub-Bougdal S, Brányik T (2020) Heterotrophic cultivation of Chlorella vulgaris using saline waste water from the demineralization of cheese whey. Biotechnol Lett 42:209–217

Gonzáles-Siso MI (1996) The biotechnological utilization of cheese whey: a review. Bioresour Technol 57:1–11

Gomez C, Guzman-Carrasco A, Lafarga T, Acien-Fernandez FG (2020) Optimization of a new culture medium for the large-scale production of protein-rich Arthrospira platensis (Oscillatoriales, Cyanophyceae). J Phycol 57:636–644

Gorgich M, Passos MLC, Mata TM, Martins AA, Saraiva ML, Caetano NS (2020) Enhancing extracion and purification of phycocyanin from Arthrospira sp. with lower energy consumption. Energy Rep 6:312–318

Gouveia L, Batista AP, Sousa I, Raymundo A, Bandarra NM (2008) Microalgae in novel food products. In: Papadopoulos KN (ed) Food Chemistry Research Developments. Nova Science Publishers, New York, pp 1–37

Gouveia L, Oliveira AC (2009) Microalgae as a raw material for biofuels production. J Ind Microbiol Biotechnol 36:269–274

Griffiths MJ, Garcin C, van Hille RP, Harrison STL (2011) Interference by pigment in the estimation of microalgal biomass concentration by optical density. J Microbiol Methods 85:119–123

Humhal T, Kastanek P, Jezkova Z, Cadkova A, Kohoutkova J, Brányik T (2016) Use of saline waste water from demineralization of cheese whey for cultivation of Schizochytrium limacinum PA-968 and Japonochytrium marinum AN-4. Bioproc Biosyst Eng 40:395–402

Khandual S, Sanchez EOL, Andrews HE, de la Rosa JDP (2021) Phycocyanin content and nutritional profile of Arthrospira platensis from Mexico: efficient extraction process and stability evaluation of phycocyanin. BMC Chem 15:1–13

Kosikowski FV (1968) Nutritional beverages from acid whey powder. J Dairy Sci 51:1299–1301

Kunsel T, Sumant O (2020) Spirulina market. https://www.alliedmarketresearch.com/spirulina-market. Accessed 27 December 2020

Laborator Monitoring (2021) Wastewater analysis. https://www.moni.cz/en/services/wastewater-analysis. Accessed 26 October 2021

Lafarga T, Fernandez-Sevilla JM, Gonzalez-Lopez C, Acien-Fernandez FG (2020) Spirulina for the food and functional food industries. Food Res Int 137:109356

Lichtenthaler H, Wellburn A (1983) Determinations of total carotenoids and chlorophylls a and b of leaf extracts in different solvents. Biochem Soc Trans 11:591–592

Markou G, Chatzipavlidis I, Georgakakis D (2012) Cultivation of Arthrospira (Spirulina) platensis in olive-oil mill wastewater treated with sodium hypochlorite. Bioresour Technol 112:234–241

Markou G, Vandamme D, Muylaert K (2014) Microalgal and cyanobacterial cultivation: The supply of nutrients. Water Res 65:186–202

Marquez FJ, Sasaki K, Kakizono T, Nishio N, Nagai S (1993) Growth characteristics of Spirulina platensis in mixotrophic and heterotophic conditions. J Ferment Bioeng 76:408–410

Morocho-Jácome AL, Mascioli GF, Sato S, Monteiro de Carvalho JC (2016) Evaluation of physicochemical treatment conditions for the reuse of a spent growth medium in Arthrospira platensis cultivation. Algal Res 13:159–166

Olguín EJ, Galicia S, Angulo-Guerrero O, Hernández E (2001) The effect of low light flux and nitrogen deficiency on the chemical composition of Spirulina sp. (Arthrospira) grown on digested pig waste. Bioresour Technol 77:19–24

Park WS, Kim HJ, Li M, Lim DH, Kim J, Kwak SS, Kang CM, Ferruzzi MG, Ahn MJ (2018) Two Classes of Pigments, Carotenoids and C-Phycocyanin, in Spirulina Powder and Their Antioxidant Activities. Molecules 23(8):2065. https://doi.org/10.3390/molecules23082065

Pereira MIB, Chagas BME, Sassi R, Medeiros GF, Aguiar EM, Borba LHF, Silva EPE, Neto JCA, Rangel AHN (2019) Mixotrophic cultivation of Spirulina platensis in dairy wastewater: Effects on the production of biomass, biochemical composition and antioxidant capacity. PLoS ONE 14:1–17

Phang SM, Miah MS, Yeoh BG, Hashim MA (2000) Spirulina cultivation in digested sago starch factory wastewater. J Appl Phycol 12:395–400

Raoof B, Kaushik BD, Prasanna R (2006) Formulation of a low-cost medium for mass production of Spirulina. Biomass Bioenerg 30:537–542

Research Institute of Brewing and Malting, RIBM (2021) Analytical laboratories. https://beerresearch.cz/en/analyses-and-tests/analytical-laboratories/. Accessed 26 October 2021

Rizal M, Yeasmin F, Hossain M, Akter T, Rahman MM (2017) Replacement of sodium nitrate in Kosaric medium with urea for culture of Spirulina platensis. Int J Fish Aquat Stud 5:403–408

Ryan M, Walsh G (2016) The biotechnological potential of whey. Rev Environ Sci Biotechnol 15:479–498

Sachdeva N, Giambarresi G, Poughon L, Cabrera JC, Leroy B, Lasseur C, Dussap CG, Wattiez R (2018) Assessment of transient effects of alternative nitrogen sources in continuous cultures of Arthrospira sp. using proteomic, modeling and biochemical tools. Bioresour Technol 267:492–501

Shi JQ, Wu ZX, Song LR (2012) Physiological and molecular responses to calcium supplementation in Microcystis aeruginosa (Cyanobacteria). N Z J Mar Freshwater Res 47:51–61

Sienkiewicz T, Riedel CL (1990) Whey and whey utilization: possibility for utilization in agriculture and food stuff. Th. Mann, Germany, 215

State Veterinary Institute, SVI (2021) Food and feedstuff analysis. https://www.svupraha.cz/en/food-and-feedstuff-analysis. Accessed 26 October 2021

Strathmann H (1986) Electrodialysis. In: Bungay PM, Lonsdale HK, de Pinho MN (eds) Synthetic Membranes: Science, Engineering and Applications. D. Reidel Publishing, Dordrecht, pp 197–223

Vieira DCM, Matsudo MC, Sato S, Converti A, de Carvalho JCM (2012) Simultaneous use of urea and potassium nitrate for Arthrospira (Spirulina) platensis cultivation. Biotechnol J 7:649–655

Vonshak A (ed) (2002) Spirulina platensis (Arthrospira): Physiology, Cell-biology and Biotechnology. Taylor and Francis, London

Zarrouk C (1966) Contribution à l’étuded’unecyanophycée. Influence de Divers Facteurs Physiques et Chimiques Sur la Croissance et la Photosynthèse de Spirulina maxima. Thesis, Université de Paris, France

Funding

This work was supported by the Ministry of Agriculture of the Czech Republic through project QK1910300 and institutional support MZE-RO1918.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lucakova, S., Branyikova, I., Branyik, T. et al. Wastewater from the demineralization of cheese whey for cost-efficient cultivation of spirulina. J Appl Phycol 34, 89–99 (2022). https://doi.org/10.1007/s10811-021-02644-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-021-02644-4