Abstract

Generally speaking, various seaweed resources, if properly managed, can be a renewable resource with the ability to be sustainably and commercially exploited on a global basis, according to the species available, for a variety of products of industrial importance. In recent times, agar, derived from certain red seaweeds, is the only phycocolloid to have registered a surge in demand and value. However, little emphasis has been given to this emerging opportunity in India, which to our best judgment has the potential to be a significant commercial success. This review reports on steps taken to ensure Indian self-reliance on the production of agarophytes, their resource availability, management, agar characterization, and various methods of extraction. Historically fluctuating landings have reported the availability of different agarophytes of which maximum biomass of 982 dry t for Gracilaria edulis was harvested during 1990–1991 along with 665 dry t of Gelidiella acerosa during 2002–2003. Meanwhile, data for the industrial production of agar reported ca. 197 t of food-grade agar and ca. 92 t of bacteriological grade agar annually, which is very low in quantity as opposed to domestic requirements. Despite this, farming of agarophyte holds considerable promise. A model is proposed here whereby productivity of 1 t agarophyte per day (TPD) could realize US$827,22–287,440 as net profit. Technical interventions are required in order to improve the growth and yield of commercial open-water farming of agarophytes. During the last two decades, agar imports to India increased ca. 7 times in volume and ca. 42 times in value, while export figures were ca. 198 times and ca. 149 times, respectively. This review examines the existing policies and legislations acting as constrains for the agarophyte trade and products which would provide a framework for improving the overall prospects of agar producing red seaweeds in India.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Seaweed resources are increasingly considered as important commercial commodities in several South-East Asian countries, the sustainable utilization of which can provide considerable socio-economic benefits (Neish et al. 2017). Some maritime nations are fast expanding their trade in various seaweeds largely for emerging applications in consumer-driven commodities such as processed foods. Global seaweed farming comprises about 27.3% of the total world marine aquaculture production by weight, about 31.2 million t having a trade value of US$11.7 billion in 2016 (FAO 2018). Traditionally, selected seaweeds have been used for food, feed, and agricultural applications; however, since the 1970s, focus has shifted to polysaccharides and their derivatives having applications in pharmacology, biomedical, bioengineering, and molecular biology domains (Meena et al. 2007; Kondaveeti et al. 2013; Chudasama et al. 2016). Despite possible economic recession looming largely all over the world in the past decade, the global hydrocolloid market remained steady. Agar is the primary hydrocolloid derived from select red seaweed taxa, exhibiting the unique ability to form thermo-reversible gels. After its introduction into medical bacteriology, the trade has assumed considerable importance. Globally, agar manufacturing industries consume over 125,200 dry t year−1 of seaweed biomass in order to produce ca. 14,500 t of agar having a value over US$246 million worldwide (Porse and Rudolph 2017). The dearth of raw material due to overharvesting of natural resources has pushed up the wholesale price of bacteriological and technical grade agars to an all-time high of around US$35–45 kg−1, nearly triple the price before the onset of scarcities (Santos and Melo 2018). The dwindling wild supply considerably hastens the efforts to seek diversified resource coupled with the advent of mariculture practices (Friedlander 2008; Padhi et al. 2011; Ganesan et al. 2017).

In India, Gelidiella acerosa is the principal source for the production of bacteriological grade agar while Gracilaria edulis yields food-grade agar and Gracilaria dura, agarose (Veeragurunathan et al. 2016). The commercial farming of seaweeds in India is gaining popularity since it is an important facet of fisheries for augmenting revenue (Mantri et al. 2017). Novel applications utilizing agar and agarophytes in several commodity products specifically in food, agriculture, and energy have engendered optimistic sentiment required for market growth in India (Sudhakar et al. 2015; Reddy et al. 2016). However, adequate emphasis has not been given to this emerging sector especially in the business and policy fronts. Although the traditional agar trade is well-established registering considerable commercial success creating export opportunities, the following aspects need to be kept in view to make this area of commercial activity sustainable. These are the following: (a) biotechnological interventions in germplasm improvement for superior growth and yields; (b) growing technological advances, especially novel methods for extraction leading to cost-effective processes; and (c) evolving business models based on superior farming and production practices. In addition, comprehensive documentation of agar trade ought to embody changing socio-economic narrative as well as that of seaweed business economy.

History of the trade in agarophytes in India

All over the Commonwealth countries, the need for self-reliance on the production of seaweed hydrocolloids was realized post–World War II. In India, active steps were also taken by the Board of Scientific and Industrial Research to manufacture agar within the Research Department of the University of Travancore. A small supply of indigenously produced agar was made available for the preparation of cholera vaccine between 1942 and 1946 (cf. Subba Rao and Mantri 2006). The sporadic export trade of agarophytes intensified post 1960s since several foreign countries registered large raw material demand thereby promoting India as a leading exporter (Krishnamurthy 1971). The establishment of landing centers between Rameswaram and Kanyakumari in the Gulf of Mannar and the Sethubhavachatram; Palk Bay in 1960 gave impetus to the production of ~ 30 t of agar at cottage-scale levels (Desai 1967). Nevertheless, the seaweed export was soon banned in order to negate the consequences of over-harvesting. Several industrial units located in and around Madurai, Tamil Nadu, with a few factories in Kerala and Andhra Pradesh currently produce agar utilizing process developed by CSIR-Central Salt and Marine Chemicals Research Institute (CSMCRI), Bhavnagar, Gujarat, India (Subba Rao and Mantri 2006).

Diversity of species and resource availability

The commercially exploited agarophytes in India belong to red algal genera Gracilaria (food grade), Gelidium, and Gelidiella (microbiological quality); but these terms are often used informally in trade despite being taxonomically different (Kalkman et al. 1991). About 28 species and 2 varieties of Gracilaria have been recorded, while only 6 of Gelidiella and 8 Gelidium spp. have been documented from Indian waters (Oza and Zaidi 2001). Life cycles, habitats, and distribution patterns also have been investigated; knowledge of which is critical for farming. There has been an attempt to resolve phylogeny employing nucleotide sequencing data of 18S rRNA, RUBISCO spacer, and cox2–3 intergenic spacer from the Indian Gracilaria spp. (Pareek et al. 2010). The common agarophytes are enumerated along with their distribution in Supplementary Table 1.

A pan-Indian project “Survey of economic seaweed resources” was funded by the National Committee on Science and Technology, and ascertained the standing stocks of seaweed in Gujarat, Tamil Nadu, and Lakshadweep as well as Andhra Pradesh during 1961–1991. It was coordinated by CSMCRI in collaboration with ICAR-Central Marine Fisheries Research Institute (CMFRI) and the respective State Fisheries Departments. The availability of 5685 t fresh biomass was recorded; of which upper limit was 4365 fresh t while lower limit was 1320 fresh t (for details pertaining to methodology etc. refer Subbaramaiah et al. 2006). The cumulative biomass estimates are shown in Table 1.

Characterization of agar, agarose, and agaroid from Indian agarophytes, extraction procedure, and industrial production

The prospects of cottage-scale agar producers in India have remained unchanged during the last few decades. The gel strength ranging between < 100 to 300 g cm−2 thus has not been acknowledged for superior quality. Appropriate and practical methods were developed to obtain superior quality agar from select agarophytes (Table 2). Subsequently, an eco-friendly method for producing agarose of high gel strength > 1950 g cm−2 in 1% gel at 20 °C; gelling point 35 ± 1 °C and melting point 98 ± 1 °C of 20–22% yield from G. dura was developed by CSMCRI (Meena et al. 2014).

The extraction employed non-ionic surfactants (cf. Prasad et al. 2005) as well as bio-ionic liquids (Sharma et al. 2015) using a reduced quantity of process water. Nevertheless, industrial production is yet to adapt these techniques, rather than relying heavily on traditional energy intensive processes.

The Indian Standard specifications exist for food grade, microbiological grade agars, as well as agarophytes (Tables 2, 3, and 4; Supplementary material). However, no specifications have been put in place with regard to gel strength, providing little incentives for the producers to improve the quality of the product (Krishnan and Narayankumar 2010). The scale of industrial production is often family-run enterprises presenting a dismal prospect. The average production is 2–4 kg agar day−1 corresponding to 0.5–1 t year−1, with medium scale producing 10–40 kg agar day−1 corresponding to 2–10 t year−1, catering primarily to the domestic market. Agar production in India for the last 15 years (2002–2017) is shown in Table 4. The food-grade agar as well as bacteriological grade agar production increased steadily and attained a significant increase from 2011 to 2012 onwards with maximum production of 300 t for food grade during 2014–2015 and 90 t for bacteriological grade in 2016–2017. Industries extract only agar from feedstock which accounts for about 15–20% of raw material, leaving a large proportion unutilized. The integrated process that has been developed by CSMCRI enables the sequential extraction of value-added products making the entire process more competitive and remunerative (Reddy et al. 2016). The seaweed-derived biostimulant obtained from G. edulis has been shown to improve the yields of cash crops, and life-cycle assessment of methodology confirmed lower carbon footprints (Layek et al. 2016; Anand et al. 2018).

Seaweed collection as livelihood option and landings

The southern stretch encompassing Kanyakumari along peninsular India that forms the Gulf of Mannar (GoM) is popularly known as “Seaweed belt.” Immanuel and Sathiadhas (2004) reported that about 5000 women along this region depended on seaweed collection for earning their livelihood, as they were not engaged actively in fishing trade. Agents pay non-negotiable price to the collectors, and the latter usually borrow money from the former to meet their daily expenses. Debts are adjusted against the proceeds of seaweeds harvested during the entire season. Gelidiella acerosa commands highest price of about US$1884 per dry t and Gracilaria US$1884–628 per dry t in the local market. The landings of agarophyte seaweeds from southern India during 1978–2016 are provided in Table 3.

Seasonal employment, exploitation by middlemen, inconsistent income, lack of recognition, and job insecurity are major impediments encountered by the seaweed harvesters (Ganesan et al. 2017). As major collection areas fall into Marine National Park, to overcome the issue of over-harvesting, the women implemented self-imposed measures such as limiting the harvesting to 12 days in a lunar month as well as having 45 days harvest ban starting from 1 April along with prohibiting the use of metal tools for collecting seaweeds (Krishnan and Narayankumar 2010).

Agar production and import–export trend

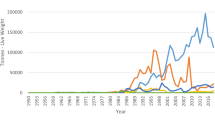

India has witnessed remarkable growth in agar import–export market drawing attention to future supply and demand on a global scale. Reliable and periodic assessment of volumes and corresponding trade are necessary for decision-making, planning, and policy development in this sector. Besides, knowledge of this trade is essential for regulating the import and export alike. Such information is not available at the national level, and one needs to tediously collect the data through various ports of embarkation and disembarkation. The recent data revealed that India imported agar from about 14 different countries of which the share from China was the greatest, 78 t in volume valued at US$3,552,257 in trade (Fig. 1). India exported about 20 t of agar worth US$18,826,473 to Morocco during January to December 2017 (Fig. 2). The comparison of agar trade two decades ago with the current scenario reveals that today the import was 7 times high in volume (about 12.4 t in 1997) and 42 times high in value (approximately US$163,342) (Rao and Mantri 2006). The increase in export has been about 198 times high in volume (about 0.55 t in 1997) and 149 times high in value (approximately US$1,907,915) today. The increase in export–import trade could be explained by significant rise in domestic demand, while the improved production facilities are responsible for enhanced import trade.

Prospects of commercial farming of agarophytes in India and business model

Seaweed aquaculture industry is fast evolving globally. Gracilaria and Gracilariopsis together accounted for ac. 3.8 million t of annual production worth about US$1 billion (Kim et al. 2017). In India, commercial farming of seaweeds has been carried out only for the carrageenophyte Kappaphycus alvarezii (Mantri et al. 2017). There exists ample scope for extending the farming activity to industrially important Gracilaria species. It would have an enormous bearing to the diversification of livelihood of the artisanal fishermen and considerable potential of social diffusion in coastal areas especially involving womenfolk. Management of seaweeds has received least priority, and necessity to initiate farming of agarophyte in particular has been realized only recently in India.

The large scale cultivation trials of G. edulis in Ramnathapuram were initiated under the Bay of Bengal Program (BOBP). The project was jointly implemented in 1986 by the Swedish International Development Agency, Overseas Development Administration of United Kingdom, Food and Agriculture Organization (FAO) of United Nations, as well as the Department of Fisheries, Government of Tamil Nadu (Kalkman et al. 1991). Despite the best efforts, these trials remained only at experimental level. But, refinement in the farming technology took place in subsequent years, with coir/nylon rope, net, single-rope floating technique, coral stone, bamboo floating rafts etc. having been tested for their efficiency and suitability in farming (Subba Rao et al. 2006). The farming was well received in Tamil Nadu and was mostly undertaken by Self Help Groups largely consisted of women fisher folk (Fig. 3). An average crop yield of 3.5 to 4 kg fresh weight m−1 length rope was reported for different species of Gracilaria either at experimental or pilot-scale mariculture (Raju and Thomas 1971; Rao 1974; Subbaramaiah and Thomas 1990; Kaladharan et al. 1996). The suspended stone method was recently developed for field cultivation of G. acerosa which gave significantly higher yield of 3.64 kg fresh wt. m−2. However, in both cases, the floating raft method was found to be more suitable for obtaining higher growth and yield (Ganesan et al. 2011). Cultivation of G. edulis was demonstrated at 25 raft scale at Badabalu and Shippighat in the Andaman Islands and at Campbell Bay in Nicobar Island to M/s. Community Enterprise Forum International (CEFI), Port Blair, under cultivation knows how transfer agreement with CSMCRI (CSMCRI 2006). Further, 603 seaweed collectors (68 men and 304 women) were trained in agarophyte farming recently by CSMCRI (Table 5, Supplementary material). It may be noted that about 1002 kg day wt. Gracilaria debilis, 192 kg G. edulis, and 120 kg Gelidiella acerosa produced by trainees were sold in the open market at prevailing rates and accrued considerable economic gain.

We propose herein a model to achieve production of 1 t (dry) biomass of industrially valuable agarophytes, namely, G. acerosa, G. edulis, and G. dura. The floating bamboo raft of 2 × 2 m has been considered as a standard method of farming first two seaweeds and the 25-m tube net method for last. Based on our experience for the past four decades of farming these species, average yields were considered 14.34-kg raft−1 and 17-kg raft−1 for G. acerosa and G. edulis, respectively, and 20-kg tube−1 for G. dura. The dry yield has been computed based on average water content in these taxa and found to be 3.5-kg raft−1 and 2.1-kg raft−1 for G. acerosa and G. edulis, respectively, and 2.8-kg tube−1 for G. dura. The number of cultivation units required to achieve 1 t (dry) production of G. acerosa was 279 rafts, 471 rafts for G. edulis, and 350 tube nets for G. dura. The typical growth cycle for G. acerosa was 90 days, 45 days for G. acerosa, and 40 days for G. dura. Therefore, only three harvests are possible for G. acerosa, seven for G. edulis, and five for G. dura excluding the monsoon period. The total production in a year therefore would be 180 t of G. acerosa, 270 t of G. edulis, and 160 t G. dura (all dry wt.). This corresponds to market value of US$339,120 for G. acerosa; US$169,560 for G. edulis; and US$301,440 of G. dura at the prevailing market rates. The model yields an annual profit of US$234,540 for G. acerosa; US$827,22 for G. edulis; and US$287,440 for G. dura after deducting 50% infrastructure cost given as subsidy by the Fisheries Department (Table 5, Supplementary material).

Technological interventions for improving yield and growth in agarophytes

The traditional crop improvement methodologies in seaweeds never looked beyond breeding and natural selection. Sexual hybridization is not of much impact beyond academic interest. The cellular biotechnology might hold considerable promise in propagation and selection of superior seaweed strain of economic implications. Tissue culture was successful in obtaining ca. 60% viable and axenic explants in G. corticata. The uniseriate branched filamentous callus and subculture of excised callus showed shoot development within 10 days in liquid PES medium (Kumar et al. 2007). Similarly, protoplast yield of 3.7 ± 0.7 × 106 cells g−1 fresh wt for G. dura and 1.2 ± 0.78 × 106 cells g−1 fresh wt for G. verrucosa was successfully achieved (Gupta et al. 2011). But, regeneration of plantlets form these protoplasts remains elusive. There exists only one study which dealt with the use of the mutagen ethyl methanesulphonate at 0.1–0.2 M concentration on the growth and agar content of G. acerosa, but the improved growth was reported in the field trials with lower yield and quality of agar (Subbaramaiah et al. 1990). It would, however, be interesting to study why yield and quality were low. The use of gamma irradiation in removing sulfate impurities for obtaining stable agar has been reported improving shelf life of this important commodity (Doshi and Rao 1967). No further research in this direction has been reported in the literature. The feasibility of rapid production of viable seedlings clonally through selective propagation of apical fragments of G. dura was attempted (Saminathan et al. 2015). This is the only study where outdoor cultures and out plating of laboratory-derived seedlings was attempted and thus holds great promise. These studies required a great deal of expertise, infrastructure, and expenditure besides ascertaining their viability for commercial farming through field trial experiments. These could be essential prerequisites for maintenance and storage of elite germplasm as seed bank for sustainable cultivation practices.

Proposed framework for improving agar trade

CSIR-Central Salt and Marine Chemicals Research Institute (CSMCRI), Bhavnagar, along with Technology Information, Forecasting and Assessment Council (TIFAC), Department of Science and Technology, New Delhi, conducted a meeting of seaweed researchers, industry experts, and other stakeholders in November 2017. Indian Chambers of Commerce in collaboration with CSMCRI conducted “Indian Seaweed Summit” in February 2018. These two important events took stock of the issues confronting the sector and called for taking up commercial cultivation and processing of seaweeds on priority at pan-Indian level, under a mission mode program. We, therefore, recommend having a common platform consisting of academia, industry, and government representatives to implement this program (Fig. 4). This body of agencies will largely handle three domains—farming, marketing, and industry. The farming sector will liaise with Indian Chambers of Commerce through Regional Seaweed Produce Committee (for both biomass production and product) which would in turn facilitate obtaining permits required for commercial farming, linking seaweed growers to government schemes and incentives, and disseminating R&D information and other details that would improve the farming techniques. The second domain deals with marketing aspect of Strategic Market Analysis Group that would conduct in-depth studies pertaining to market assessment, import export opportunities, and novel applications to boost farming and products. The third domain consisted of industry partners which would provide crucial support to overall development of trade infrastructure and production requirements, advocating green processes and technologies and facilitating development of new standards for the range of agar products. This will help realize greater value of the produce thereby facilitating seaweed farming for positive gains. These three domains are interlinked and should work together improving the growth of agar trade in India.

Legislation and policy background relevant to agarophyte trade

The legislation and policy interventions pertaining to commercial cultivation, processing, and trade of agarophytes in India assume considerable significance, as currently only 30% of agar requirement is being produced indigenously (Subba Rao and Mantri 2006), and there is a need to expand the production of biomass and agar as well, given the potential in India and expanding seaweed market, globally. The first policy paper on seaweed cultivation and utilization was published by the National Academy of Agricultural Sciences (NAAS 2003). The key recommendations of ICAR-Central Marine Fisheries Research Institute (CMFRI) pertaining to various dimensions of seaweed resource management, cultivation, trade, and regulation are summarized in Table 6.

The government of India has identified seaweed culture as one of the components under the blue revolution scheme, and National Fisheries Development Board (NFDB) has evolved guidelines for seaweed cultivation and specific programs for its promotion in India (NFDB 2015). Gujarat, with its long coast line (1600 km), has launched state-specific schemes for promoting culture of suitable and appropriate seaweed species along its coast as a means for self-employment and livelihood generation for the coastal community (GIDB 2006; Dept. of Fisheries, Gujarat Govt. 2017).

Selected seaweeds are known to co-occur in the reef areas, which are protected under different regulatory regimes. Various stretches of coastal areas comprising of coral reefs including seaweed beds have been declared as ecologically sensitive areas (ESAs) or ecologically sensitive zones (ESZ) under the provisions of Environment (Protection) Act (MoEF 1986). Seaweed beds are classified as ecologically sensitive areas as per the Island (Protection) Zone notification (MoEF 2011), which has a spatial jurisdiction limited to the island territories of India, viz., Andaman and Nicobar Islands in the Bay of Bengal and Lakshadweep Islands in the Arabian Sea. Ironically, the counterpart of the law, applicable to the mainland India, viz., Coastal Regulation Zone notification (MoEF 2011), does not classify the seaweed beds existing along the coastal as ESAs. Such differential regulatory provisions within the union encumber implementation of specific schemes aimed at promoting seaweed farming or establishment of seaweed industry.

The National Policy on Marine Fisheries, 2017, called for periodic review and evaluation of the existing spatial conservation measures for providing legislative support to protect the rights of the traditional fishermen and their livelihoods (MoAFW 2017). It highlights that evolving leasing policies and guidelines for spatial planning, environmental, and social impacts assessment are essential for promoting mariculture. CRZ (MoEF 2019) provides for demarcation of sensitive coastal ecosystems as critically vulnerable coastal areas (CVCA), which in turn can be managed as per the integrated management plans (IMP), prepared involving the community. The seaweed beds and farming areas can be demarcated as CVCAs as per the guidelines under the notification, within the ambit of EPA, 1986.

The Biological Diversity Act 2005 provided for equitable sharing of benefits arising from the use of traditional biological resources which also includes seaweeds (MoLJ 2002). It also provides for constitution of local-level Biodiversity Management Committees (BMC), thus empowering the local traditional dwellers for sustainable use of seaweeds. The Coastal Aquaculture Authority (CAA) under the Ministry of Agriculture is mandated to regulate all coastal aquaculture efforts in India including that of seaweed farming (Coastal Aquaculture Authority 2005).

However, in spite of the enabling policies and schemes for promoting seaweed culture in the coastal regions of India, the sector has not witnessed growth, commensurate with the efforts. This could be attributed to inconsistencies in the regulatory framework, weak institutional mechanisms, and poor awareness among the community, and hence, necessary steps need to be taken in this regard. Penetration of farming technology of agarophytes in coastal rural areas is crucial to meet the existing domestic demand of agar.

Cultivated seaweed should be treated as agricultural product, which would enable the seaweed farmers to have quick and timely access to affordable credit through schemes such as Kisan Credit Card (KCC) and access to insurance for their product. Product development is a critically component in the seaweed value chain, and innovative support schemes should be formulated for the same. New standards need to be established for edible, micobiological agar and agarose, with clear specifications for gel strength and various other quality criteria for economic competitiveness. The linkage between research organizations and the industry needs to be strengthened by easing the procedures for exchange of knowledge and manpower, so as to meet the targeted production.

To ensure the supply of quality seed material of agarophytes in a sustainable manner to the seaweed cultivators, government should set up seed banks. The government may promote implementation of agarophyte farming projects through Corporate Social Responsibility (CSR) funding, to reach the social equilibrium. The novel applications of functionally modified agar and agarose should pave the avenues of growth. The application of matrigel–agarose hybrid hydrogels in 3D printing of biological architectures that mimic the structural and functional features of in vivo tissues (Fan et al. 2016) would aid in tissue engineering and development of transplantable organ constructs. The government should consider instituting a “Technology Development Fund,” with active participation of agar manufacture association, to promote more start-ups in the domain.

Since majority of the Indian seaweed cultivators are women, the expansion of seaweed farming through appropriate promotional policies and schemes would aid in meeting various societal goals, viz., rural employment, alleviating poverty, social equity, and empowerment, which in turn would contribute to improving living standards of their family, child education, health, enhancing access to better amenities, and thus attract more participation of the women in sector (Mantri et al. 2017). The National Mariculture Policy 2018 of government of India is a welcome step in this direction.

The following issues are crucial for a creating a policy framework, and some recommendations are proposed for consolidating agar trade in India

-

Mapping the agarophytes along the Indian coast and pertinent water bodies to understand the current availability status as well as to bring new species under the ambit of commercial farming.

-

It is desirable to have appropriate international collaborations for fine tuning existing processes and adopting new technologies for agar production.

-

End-user protection for sustained supply of agarophytic raw materials preferably through crop insurance programs against impending disease outbreak and epiphytic infestation–, natural calamity–, and climate change–related environmental disasters.

-

Intensifying the efforts for skill development, followed by undertaking feasibility studies for pilot-scale farming for greater geographical reaches.

-

Fixing minimum assured price for various agarophyte species like most of the agricultural crops in order to ensure regular income by engaging government agencies and leading seaweed industries.

-

Integrating farming and processing together for facilitating empowerment model at the grass-root level for extending direct benefits to farmers.

-

Export license should be granted to all those engaged in agarophyte farming as it directly helps in improving livelihood of local communities.

References

Anand KV, Eswaran K, Ghosh A (2018) Life cycle impact assessment of a seaweed product obtained from Gracilaria edulis—a potent plant biostimulant. J Clean Prod 170:1621–1627

Chudasama NA, Prasad K, Siddhanta AK (2016) Agarose functionalization: synthesis of PEG-agarose amino acid nano-conjugate—its structural ramifications and interactions with BSA in a varying pH regime. Carbohydr Polym 151:735–742

Coastal Aquaculture Authority (2005) Guideline for regulating coastal aquaculture http://caa.gov.in/uploaded/doc/Guidelines-Englishnew.pdf [as accessed on 4 March 2019]

CSMCRI (2006) Biennial report Central Salt and Marine Chemicals Research Institute Bhavnagar, India, 2004–2006., Cultivation of Gracilaria edulis in Andaman & Nicobar Islands. http://www.csmcri.org/Files/Biennial_04-06.pdf [accessed on 04 March, 2019]

Department of Fisheries, Government of Gujarat (2017) Development of seaweed culture, agro and food processing sector, 8th Vibrant Gujarat Summit https://gaic.gujarat.gov.in/writereaddata/images/pdf/26-Seaweed-Culture.pdf [accessed on 4 March 2019]

Desai BN (1967) Seaweed resources and extraction of alginate and agar. Proceedings, Seminar, Sea, Salt and Plants, Central Salt and Marine Chemicals Research Institute, Bhavnagar: 343

Doshi YA, Rao PS (1967) Stable agar by gamma irradiation. Nature 216:931–932

Fan R, Piou M, Darling E, Cormier D, Sun J, Wan J (2016) Bio-printing cell-laden matrigel–agarose constructs. J Biomater Appl 31:684–692

Food and Agriculture Organization of the United Nations (2018) The state of world fisheries and aquaculture: meeting the sustainable development goals. FAO, Rome, pp 210

Friedlander M (2008) Advances in cultivation of Gelidiales. J Appl Phycol 20:451–456

Ganesan M, Thiruppathi S, Eswaran K, Reddy CRK, Jha B (2011) Development of an improved method of cultivation to obtain high biomass of the red alga Gelidiella acerosa (Gelidiales, Rhodophyta) in the open sea. Biomass Bioenergy 35:2729–2736

Ganesan M, Eswaran K, Reddy CRK (2017) Farming of agarophytes in India—a long-time sustainability for the industry and preserving wild stocks. J Appl Phycol 29:2239–2248

Gujarat Infrastructure Development Board, Final Report (2006) Study of Saurashtra coastal corridor of Gujarat, section 1—industry analysis, Government of Gujarat. http://www.gidb.org/pdf/section2InfrastructureAssessment.PDF [as accessed on 4 March 2019]

Gupta V, Kumar M, Kumari P, Reddy CRK, Jha B (2011) Optimization of protoplast yields from the red algae Gracilaria dura (C. Agardh) J. Agardh and G. verrucosa (Huds.) Papenfuss. J Appl Phycol 23:209–218

Immanuel S, Sathiadhas R (2004) Employment potential of fisherwomen in the collection and post-harvest operations of seaweeds in India. Seaweed Res Util 26:209–215

Kaladharan P, Vijayakumaran K, Chennubhotla VSK (1996) Optimization of certain physical parameters for the mariculture of Gracilaria edulis (Gmelin) Silva in Minicoy lagoon (Laccadive archipelago). Aquaculture 139:265–270

Kalkman I, Rajendran I, Angell CL (1991) Seaweed (Gracilaria edulis) farming in Vedalai and Chinnapalam, India. FAO Working Paper BOBP/WP/65

Kim JK, Yarish C, Hwang EK, Park M, Kim Y (2017) Seaweed aquaculture: cultivation technologies, challenges and its ecosystem services. Algae 32:1–13

Kondaveeti S, Prasad K, Siddhanta AK (2013) Functional modification of agarose: a facile synthesis of a fluorescent agarose-tryptophan based hydrogel. Carbohydr Polym 97:165–171

Krishnamurthy V (1971) Seaweed resources of India and their utilisation. Seaweed Res Util 423:55–67

Krishnan M, Narayankumar R (2010) Socio-economics of seaweed farming in India. Central Marine Fisheries Research Institute, Kochi, India, Special Bulletin No 104:103

Kumar GR, Reddy CRK, Jha B (2007) Callus induction and thallus regeneration from callus of phycocolloid yielding seaweeds from the Indian coast. J Appl Phycol 19:15–25

Layek J, Das A, Ramkrushna GI, Ghosh A, Panwar AS, Krishnappa R, Ngachan SV (2016) Effect of seaweed sap on germination, growth and productivity of maize (Zea mays) in North Eastern Himalayas. Indian J Agron 61:354–359

Mantri VA, Eswaran K, Shanmugam M, Ganesan M, Veeragurunathan V, Thiruppathi S, Reddy CRK, Seth A (2017) An appraisal on commercial farming of Kappaphycus alvarezii in India: success in diversification of livelihood and prospects. J Appl Phycol 29:335–357

Meena R, Siddhanta AK (2006) Recent advances on applied aspects of Indian marine alga with reference to global scenario. In: Tewari A (ed) Agar and value addition of Indian agarophytes, Vol. 2 pp 172–184

Meena R, Prasad K, Siddhanta AK (2006) Studies on “sugar reactivity” of agars extracted from some Indian agarophytes. Food Hydrocoll 20:1206–1215

Meena R, Prasad K, Ramavat BK, Ghosh PK, Eswaran K, Thiruppathi S, Mantri VA, Subbarao PV, Siddhanta AK (2007) Preparation, characterization and benchmarking of agarose from Gracilaria dura of Indian waters. Carbohydr Polym 69:179–188

Meena R, Prasad K, Ganesan M, Siddhanta AK (2008) Superior quality agar from Gracilaria species (Gracilariales, Rhodophyta) collected from the Gulf of Mannar, India. J Appl Phycol 20:397–402

Meena R, Prasad K, Ganesan M, Siddhanta AK (2011) Preparation of superior quality products from two Indian agarophytes. J Appl Phycol 23:183–189

Meena R, Chaudhary JP, Agarwal PK, Maiti P, Chatterjee S, Raval HD, Agarwal P, Siddhanta AK, Prasad K, Ghosh PK (2014) Surfactant-induced coagulation of agarose from aqueous extract of Gracilaria dura seaweed as an energy-efficient alternative to the conventional freeze–thaw process. RSC Adv 4:28093–28098

Mehta GK, Meena R, Prasad K, Ganesan M, Siddhanta AK (2010) Preparation of galactans from Gracilaria debilis and Gracilaria salicornia (Gracilariales, Rhodophyta) of Indian waters. J Appl Phycol 22:623–627

Ministry of Agriculture and Farmers Welfare (MoAFW) (2017) National Policy for Marine Fisheries. http://dahd.nic.in/news/notification-national-policy-marine-fisheries-2017 [accessed on 4 March 2019]

Ministry of Environment and Forest (MoEF), Government of India (1986) The Environmental Protection Act. http://www.moef.nic.in/sites/default/files/eprotect_act_1986.pdf [accessed on 4 March 2019]

Ministry of Environment and Forest (MoEF) Government of India Island protection zone (2011) http://www.indiaenvironmentportal.org.in/files/IslandProtectionZoneNotification2011.pdf [accessed on 4 March 2019]

Ministry of Environment and Forest (MoEF) Government of India (2019) Coastal Regulation Zone Notification. http://www.moef.nic.in/content/gsr-37e%E2%80%94-18012019-coastal-regulation-zone-notification [accessed on 4 March 2019].

Ministry of Law and Justice (MoLJ) (2002) The Biological Diversity Act http://nbaindia.org/uploaded/Biodiversityindia/Legal/31.BiologicalDiversityAct2002.pdf [accessed on 4 March 2019]

NAAS (2003) Seaweed cultivation and utilization. National Academy of Agricultural Sciences, vol 22. Policy Paper, India, p. pp 5 http://naasindia.org/Policy%20Papers/policy%2022.pdf [accessed on 4 March 2019]

National Fisheries Development Board (2015) Guidelines for seaweed cultivation. http://nfdb.gov.in/PDF/Draft%20National%20Policy%20on%20Mariculture%20NFDB%20-%20CMFRI%2028%20Sept.2018.pdf [accessed on 4 March 2019]

Neish IC, Sepulveda M, Hurtado AQ, Critchley AT (2017) Reflections on the commercial development of eucheumatoid seaweed farming. (Eds) Tropical seaweed farming trends, problems and opportunities. Springer, Cham pp 1–27

Oza RM, Zaidi SH (2001) A revised checklist of Indian marine algae. Central Salt and Marine Chemicals Research Institute, Bhavnagar, India p 286

Oza MD, Mehta GK, Kumar S, Meena R, Siddhanta AK (2011) Galactans from Gracilaria millardetii and G. textorii (Gracilariales, Rhodophyta) of Indian waters. Phycol Res 59:244–249

Padhi S, Swain PK, Behura SK, Baidya SK, Behera SK, Panigrahy MR (2011) Cultivation of Gracilaria verrucosa (Huds) Papenfuss in Chilika Lake for livelihood generation in coastal areas of Orissa State. J Appl Phycol 23:151–155

Pareek M, Mishra A, Jha B (2010) Molecular phylogeny of Gracilaria species inferred from molecular markers belonging to three different genomes. J Phycol 46:1322–1328

Porse H, Rudolph B (2017) The seaweed hydrocolloid industry: 2016 updates, requirements, and outlook. J Appl Phycol 29:2187–2200

Prasad K, Siddhanta AK, Rakshit AK, Bhattacharya A, Ghosh PK (2005) On the properties of agar gel containing ionic and non-ionic surfactants. Int J Biol Macromol 35:135–144

Prasad K, Goswami AM, Meena R, Ramavat BK, Ghosh PK, Siddhanta AK (2006) Superior quality agar from red alga Gelidiella acerosa (Rhodophyta, Gelidiales) from Gujarat coast of India: an evaluation. Ind J Mar Sci 35:268–274

Prasad K, Siddhanta AK, Ganesan M, Ramavat BK, Jha B, Ghosh PK (2007) Agars of Gelidiella acerosa of west and southeast coasts of India. Bioresour Technol 98:1907–1915

Raju PV, Thomas PC (1971) Experimental field cultivation of Gracilaria edulis (Gmel.) Silva. Bot Mar 14:71–75

Rao MU (1974) On the cultivation of Gracilaria edulis in the near shore areas around Mandapam. Curr Sci 43:660–661

Rao PS, Mantri VA (2006) Indian seaweed resources and sustainable utilization: scenario at the dawn of a new century. Curr Sci:164–174

Reddy CRK, Baghel RS, Kumari N, Kumari P, Gupta V, Prasad K., Meena R (2016) An integrated process to recover a spectrum of bioproducts from fresh seaweeds. U.S. Patent Application No. 15/109232

Saminathan KR, Ashok KS, Veeragurunathan V, Mantri VA (2015) Seedling production in the industrially important agarophyte Gracilaria dura (Gracilariales, Rhodophyta). J Appl Phycol 27:1541–1548

Santos R, Melo RA (2018) Global shortage of technical agars: back to basics (resource management). J Appl Phycol 30:2463–2473

Sharma M, Chaudhary JP, Mondal D, Meena R, Prasad K (2015) A green and sustainable approach to utilize bio-ionic liquids for the selective precipitation of high purity agarose from an agarophyte extract. Green Chem 17:2867–2873

Subba Rao PV, Mantri VA (2006) Indian seaweed resources and sustainable utilisation: scenario at the dawn of new century. Curr Sci 91:164–174

Subba Rao PV, Eswaran K, Ganesan M (2006) Cultivation of agarophytes in India: retrospect, prospect and future strategies. Seaweed Res Util 26:181–184

Subbaramaiah K, Thomas PC (1990) Raft cultivation of Gracilaria edulis (Gmel.) Silva. Proc Indian Acad Sci (Plant Sci) 100:123–127

Subbaramaiah K, Thomas PC, Rao PSN (1990) Effect of ethyl methanesulfonate on growth and agar content in marine alga Gelidiella acerosa (Rhodophyta). Indian J Mar Sci 19:288

Subbaramaiah K, Zaidi SH, Chauhan VD (2006) Recent advances on applied aspects of Indian marine alga with reference to global scenario. In Tewari A (ed) Standing stock of seaweeds on Indian coast, vol 1, pp 147–173

Sudhakar MP, Jagatheesan A, Perumal K, Arunkumar K (2015) Methods of phycobiliprotein extraction from Gracilaria crassa and its applications in food colourants. Algal Res 8:115–120

Veeragurunathan V, Prasad K, Singh N, Malarvizhi J, Mandal SK, Mantri VA (2016) Growth and biochemical characterization of green and red strains of the tropical agarophytes Gracilaria debilis and Gracilaria edulis (Gracilariaceae, Rhodophyta). J Appl Phycol 28:3479–3489

Acknowledgements

Thanks are also due to Dr. CRK Reddy for critical discussions; Dr. S. Kannan, Head Business Development, for helping in proposing 1 TDP production model; and Dr. V. Veeragurunathan for sharing the photographs pertaining to Gracilaria debilis farming. The comments from reviewers and handling editor have tremendously helped to improve the previous draft of the manuscript, which is acknowledged with special thanks. We thank Dr. Amitava Das, Director, CSIR-Central Salt and Marine Chemicals Research Institute, Bhavnagar; Dr. Sunil K. Singh, CSIR-National Institute of Oceanography, Goa; and Dr. Ch. Srinivasa Rao, ICAR-National Academy for Agricultural Research Management, Hyderabad, for their support and encouragement to write this review. We thank M/s. SNAP Natural and Alginate Products Pvt. Ltd. for partnering with CSIR-CSMCRI in agrophyte cultivation. We are equally grateful to Madurai Agar and Alginate Manufacturing Association, Maduarai, and Marine Chemicals, Chochin, for sharing the landing and production data and M/s. Lifescience Intellipidia, Noida, for providing export–import data. This manuscript has CSIR-PRIS registration no. 117/2018 dt. 14.06.2018.

Funding

This work is financially supported by the Council of Scientific and Industrial Research, New Delhi. AKS is financially supported by the CSIR under Emeritus Scientist Scheme (21(937)/12/EMR-II). Department of Biotechnology, New Delhi, and Department of Science and Technology, New Delhi, gave financial support in the past to take agarophyte farming and value addition work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 19415 kb)

Rights and permissions

About this article

Cite this article

Mantri, V.A., Ganesan, M., Gupta, V. et al. An overview on agarophyte trade in India and need for policy interventions. J Appl Phycol 31, 3011–3023 (2019). https://doi.org/10.1007/s10811-019-01791-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-019-01791-z