Abstract

Microalgae present unexplored biotechnological potential and the ability to use different carbon sources in mixotrophic cultivation. Considering the need for efficient and low-cost industrial processes, the aim of this work was to evaluate the ability of microalgae and cyanobacteria to produce intra- and extracellular β-galactosidase. Eight species of Chlorophyta and Cyanophyta were cultivated in mixotrophic conditions with lactose as a carbon source. Dunaliella tertiolecta, Chlorella minutissima, and Nannochloropsis oculata were able to grow under mixotrophic conditions showing biomass production and growth rates higher than those of photoautotrophic cultures. β-Galactosidase extracellular production was 33.5 U L−1 on the 11th cultivation day for D. tertiolecta. For N. oculata and C. minutissima, the values were 29.6 and 11.02 U L−1 on the 14th and the 7th cultivation days, respectively. This study demonstrates the ability of microalgae to hydrolyze lactose under a mixotrophic regime and to outstanding great potential in the production of biomass and β-galactosidase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are a versatile and diverse group of microorganisms inhabiting a wide range of ecological habitats, but few species are utilized for human benefit (Odjadjare et al. 2015). The biotechnological applications of microalgae are diverse: human and animal nutrition, aquaculture, wastewater treatment, biofertilizers, biofuel production, and the cosmetic and pharmaceutical industries. Microalgae are a source of bioactive compounds such as antioxidants, antimicrobial compounds, polyunsaturated fatty acids, pigments (chlorophyll, astaxanthin, β-carotene, and phycocyanin), polysaccharides, and enzymes (Pulz and Gross 2004; Satyanarayana et al. 2011; Borowitzka 2013; Pina-Pérez et al. 2017). Although many microalgae strains are cultivated worldwide for different purposes, only the cyanobacterium Arthrospira and the green microalgae Chlorella, Dunaliella salina, and Haematococcus pluvialis are used for industrial biomass production (Benemann et al. 2018).

Currently, photoautotrophic production is the primary method used for large-scale algae biomass production (Brennan and Owende 2010). However, photoautotrophic growth in photobioreactors presents limited biomass production and requires long cultivation periods (Ceron Garcia et al. 2006). Due to these limitations, in recent years in addition to photoautotrophic cultivation, studies have been highlighted heterotrophic and mixotrophic culture systems for these microorganisms (Angelo et al. 2014). In mixotrophic growth, CO2 and organic carbon are simultaneously assimilated, and both respiratory and photosynthetic metabolisms occur (Perez-Garcia et al. 2011). The mixotrophic cultivation advantages are reduced irradiance requirement, lower production costs, and greater productivity in biomass when compared to photoautotrophic growth (Ceron Garcia et al. 2006; Li et al. 2014). Although mixotrophic cultivation can be efficient, there exist some limitations. Only a small group of species are capable of utilizing organic carbon substrates, contamination by bacteria and fungi can occur, and growth inhibition by the excess of organic substrate is possible (Perez-Garcia et al. 2011; Pires 2015).

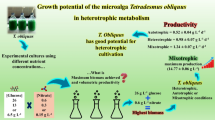

Glucose is the most studied monosaccharide in mixotrophic metabolism (Perez-Garcia et al. 2011). Glucose use by the genera Arthrospira, Chlorella, Nannochloropsis, and Scenedesmus has been reported (Cheirsilp and Torpee 2012; Chojnacka and Zielińska 2012). Nevertheless, few studies reported the assimilation of disaccharides such as lactose by microalgae. Some of the species reported are Tetradesmus obliquus, Arthrospira platensis, and Neochloris oleoabundans (Girard et al. 2014; Vieira Salla et al. 2016). The assimilation of lactose by microalgae requires β-galactosidase synthesis (β-D-galactohydrolase, EC 3.2.1.23), which hydrolyzes d-galactosyl residues from oligosaccharides.

Microalgae present an unexplored potential to synthesize enzymes for several industrial applications (Brasil et al. 2017). The aquatic environment presents unique characteristics such as high salinity, low temperature, and special lighting conditions, which may contribute to the significant differences between microalgae enzymes and homologous enzymes from yeasts and bacteria (Zhang and Kim 2010).

The main β-galactosidase industrial application has been the hydrolysis of lactose in milk and dairy products (Husain 2010). The industry demands new, improved, and increasingly versatile enzymes along with sustainable and economic production processes. Therefore, this study explored the mixotrophic cultivation of Chlorella minutissima, Chlorella vulgaris, Dunaliella tertiolecta, Nannochloropsis oculata, Tetraselmis gracilis, A. platensis, Synechococcus subsalsus, and Scenedesmus ecornis for β-galactosidase production. The studied species include freshwater and marine microalgae along with cyanobacteria. Some microalgae have already been studied in mixotrophic cultivation, but this is the first report on lactose assimilation by this species. β-Galactosidase synthesis was evaluated in extra- and intracellular conditions during the cultivation, and two cell disruption techniques were employed.

Material and methods

Microalgae and cyanobacteria strains, medium, and inoculum preparation

Chlorella minutissima (code 26a), Dunaliella tertiolecta (code 117), Nannochloropsis oculata (code 131), Tetraselmis gracilis (code 72), A. platensis (code 159), and Synechococcus subsalsus (code 164) strains were obtained from the São Paulo University Oceanography Institute (IOUSP, Brazil, WDCM 728). The Chlorella vulgaris (code 012) and Scenedesmus ecornis (code 088) strains were obtained from the São Carlos Federal University (São Carlos, Brazil, WDCM 835).

The cultures of N. oculata, T. gracilis, A. platensis, and S. subsalsus were maintained in liquid culture on artificial seawater enriched with f/2 nutrients (Guillard 1975). Chlorella vulgaris and S. ecornis were maintained in Bold’s Basal Medium (Andersen et al. 2005) and D. tertiolecta in modified Johnson’s medium (0.4 M NaCl) (Borowitzka 1988).

Each inoculum was grown in 500-mL flasks with 125 mL of culture in aseptic and axenic conditions under photoautotrophic conditions at 25 °C and under a light intensity of approximately 70 μmol photons m−2 s−1 and continuous aeration at 0.5 vvm.

Culture conditions

Mixotrophic cultivation was performed with a 15:1 C:N ratio, in accordance with the literature for mixotrophic microalgae growth (Silaban et al. 2014). Lactose was separately sterilized by filtration through 0.2-μm pore membranes (Millipore) and added to the culture medium supplemented with potassium tellurite (10 mg L−1) (Vetec, Brazil) for the cyanobateria A. platensis and S. subsalsus (Guillard 2005) and chloramphenicol (10 mg L−1) (Vetec, Brazil) for green microalgae. The initial lactose concentration was 5 ± 0.5 g L−1.

One-liter glass Erlenmeyer flasks were used for the cultivation, with 800 mL culture medium and the initial cellular concentration for each experiment was set at 1 × 105 cells mL−1 (day 0), using manual cell counts on a hemocytometer. Growth vessels were sparged with filter sterilized air (0.22 μm Sartorius, Germany) at 0.5 vvm. No additional CO2 (other than the atmospheric concentration) was added. Water loss by evaporation due to aeration was compensated by adding sterilized deionized water to maintain the original volume. Illumination was continuously supplied by cool-white fluorescent lamps to provide a light intensity of 70 μmol photons m−2 s−1. The initial pH was set to 6.5, and the temperature was 25 ± 0.5 °C. Cultures were grown in the conditions described above for 14 days. Photoautotrophic cultivation, in the same conditions described above without organic carbons source, was performed as a control. Axenic culture conditions were confirmed during the cultivation period by optical microscopy and by the spread plate technique on f/2, BBM, or modified Johnson’s medium added with agar (15 g L−1) and lactose (5 g L−1) (Vu et al. 2018). All experiments were performed in triplicate.

Growth parameters and pH determination

Cell concentration was measured by using an improved Neubauer hemocytometer. The microalgae growth rate (μ, day−1) was calculated using Eq. 1:

where N1 and N2 are the cell concentrations at the beginning (t1, day 0) and the end (t2, day 14) of the cultivation period, respectively.

The biomass concentration was estimated by cell dry weight using GF/F filters (0.7-μm pore size, Macherey-Nagel, Germany) after sample centrifugation (1800×g for 10 min). The cells were washed with 0.5 M ammonium bicarbonate solution, and the supernatant was discarded after centrifugation to avoid interference from salts (Zhu and Lee 1997). Filters were dried at 60 °C to a constant weight.

The biomass yield (YX/S) [g dry cells formed)/(g substrate consumed] was calculated as in Eq. 2.

The product yield from lactose (YP/S) was calculated using Eq. 3.

where CS is the lactose concentration, CX is the cell mass concentration, CP is the β-galactosidase concentration (U L−1), and CS0, CX0, and CP0 are the initial values of CS, CX, and CP, respectively (Katoh and Yoshida 2009; Doran 2013). Biomass and product yield were calculated between days 0 and 14. pH was monitored during microalgae cultivation using a pH meter (Lucadema, Brazil).

Microalgae cell disruption

The cells were firstly harvested by centrifugation at 1800×g for 10 min and the supernatant was tested for extracellular enzyme production. The biomass was washed with 1 mM or 200 mM sodium phosphate buffer (pH 6.8) and resuspended in the same buffer. Finally, two mechanical cell disruption techniques were evaluated separately: sonication and glass beads.

Cell disruption

For cell disruption using glass beads, 1.5 mL of microalgae cell suspension was vortexed with glass beads (1-mm diameter, 0.6 g of beads mL−1) in Falcon tubes for 5 min with cooling in an ice bath for 3 cycles.

The cell suspensions (50 mL) were sonicated using an ultrasonic processor (400 W, 20 kHz, UIP 500hdT, Hielscher, Germany) for 30 s with 30s cooling periods for 15 cycles. The samples were kept in an ice bath during the ultrasonic process, and the temperature was maintained below 15 °C.

The disrupted microalgae suspension was centrifuged (1800×g for 10 min) and enzyme activity was assayed from the obtained cell-free extract.

Cell disruption degree determination

After mechanical cell disruption, the cell suspensions were sampled for observation in an optical microscope (Olympus CX22, Japan). The intact cell count of each sample was determined with a standard Neubauer hemocytometer. Only undamaged cells were counted as intact. The disruption degree was calculated using Eq. 4.

where C0 and C are the intact cell counts (cells mL−1) of the sample before and after disruption, respectively (Wang et al. 2015).

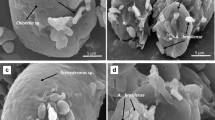

Morphological observation

The microalgae cell samples after and before mechanical disruption were prepared by fixation with 2.5% (v/v) glutaraldehyde in phosphate buffer (pH 7.5) for 1 h. After fixation, 500 μL was filtered through a polycarbonate membrane (Nucleopore, 1 μm, Whatman), washed with 100 mM pH 7.5 phosphate buffer 3 times and dehydrated successively with phosphate buffer containing 30, 50, 75, and 95% (v/v) ethanol for 3–5 min and finally with anhydrous ethanol for 5 min. After preparation, the samples were critical point dryed, gold coated, and observed with a scanning electron microscope (TESCAN VEGA3) at the Center for Electron Microscopy of the Federal University of Paraná (CME-UFPR, Curitiba, PR, Brazil) (Wang et al. 2015)

β-Galactosidase assay

The β-galactosidase activity was measured according to the method of the Food Chemical Codex (Specifications 1981) with modifications. o-Nitrophenyl β-D-galactopyranoside (ONPG, Sigma-Aldrich, Germany) was used as a synthetic substrate for the β-galactosidase assay. The activity was measured by ONPG hydrolysis in concentrations of 13, 40, and 82 mM, prepared in 1, 100, and 200 mM sodium phosphate buffer. The pH of the buffers was adjusted according to the cell-free supernatant pH (enzyme extract). Next, 0.5 mL of enzyme extract was incubated with ONPG substrate (2.5 mL) at 30 °C for 15 min. The reaction was stopped by adding 1 mL of 0.1 M of sodium carbonate solution. The absorbance at 420 nm was recorded. Enzymatic activity was calculated based on the release of different o-nitrophenol (ONP) concentrations based on a standard curve. The enzymatic activity unit (UONP) was defined as the rate of ONP released (μmol ONP min−1) under assay conditions. The procedure was performed in triplicate.

Carbohydrate concentration in culture media determination

Glucose, galactose, and lactose concentrations in culture media were determined by high-performance liquid chromatography (HPLC) using a Shodex KS-801 column in an Agilent 1260 Infinity equipped with refractive index detector (G1362A RID). The system used ultra-pure water as eluent at an isocratic flow rate of 1.0 mL min−1. The injection volume was 50 μL at a column temperature of 82 °C and a running time of 16 min. Sugars were identified by retention time and were quantified by peak area.

Statistical analysis

Data are presented as the mean ± standard deviation. The data were subjected to Anderson-Darling and Levene tests to analyze the adjustment of residuals to the normal distribution and homogeneity of variances. Statistical significances were assessed by one-way analysis of variance (ANOVA) and the mean values were compared with Tukey’s test using Microsoft Excel software (version 2016). A p value of less than 0.05 was considered as statistically significant.

Results

Microalgae strain screening

The results of microalgae screening on mixotrophic cultivation showed that A. platensis and S. ecornis strains suffered permanent cell damage, with 70% cell death occurring after 3 days. Tetraselmis gracilis, S. subsalsus, and C. vulgaris showed a slight increase in cell concentration, reaching 8 × 105 cells mL−1 after 14 days of cultivation. Cells grown autotrophically reached higher cell density (2 × 106 to 8 × 106 cells mL−1) compared to cells grown mixotrophically. The results demonstrated that A. platensis, S. ecornis, T. gracilis, S. subsalsus, and C. vulgaris did not grow in mixotrophic conditions using lactose as a carbon source.

Chlorella minutissima, D. tertiolecta, and N. oculata showed cell growth under mixotrophic cultivation that was statistically higher (p < 0.05) than that under photoautotrophic cultivation (Fig. 1). Nannochloropsis oculata presented a cell concentration of 7.44 × 107 cells mL−1 at the end of cultivation (day 14), followed by C. minutissima at 2.18 × 107 cells mL−1 and D. tertiolecta with 1.57 × 107 cells mL−1.

Growth parameters of mixotrophic cultivation

The initial lactose concentration decreased in the medium during the cultivation of the three studied species (Fig. 1). Dunaliella tertiolecta showed higher lactose metabolization, resulting in a 97.7% reduction in the initial concentration at the end of the cultivation period. Nannochloropsis oculata showed a 60% reduction and C. minutissima a 32.1% reduction. It was observed that glucose and galactose concentrations remained below 0.1 g L−1 in all analyzed periods, indicating that microalgae metabolized the monosaccharides.

Specific growth rates and final dry biomass concentrations of D. tertiolecta, N. oculata, and C. minutissima cultivated under photoautotrophic and mixotrophic conditions were compared and are summarized in Table 1. The highest specific growth rates and biomass concentrations were observed in mixotrophic cultivation. Furthermore, 8.57-, 3.47-, and 3.34-fold increases in biomass production were observed when comparing values of mixotrophic to photoautotrophic culture for D. tertiolecta, N. oculata, and C. minutissima, respectively.

The highest biomass yield (YX/S), based on consumed lactose, was 0.59 g biomass g−1 lactose, observed for D. tertiolecta (Table 1). The highest product yield (YP/S) was also observed for D. tertiolecta (8.42 U g−1 lactose).

β-Galactosidase production

β-Galactosidase production was evaluated during microalgae cultivation. The extracellular enzyme production was evaluated throughout the 14 days of cultivation and with respect to intracellular enzyme presence on cultivation days 7, 9, 11, and 14. The highest enzymatic activity values were observed in enzymatic reactions conducted with 82 mM ONPG and phosphate buffer with 1 mM for C. minutissima and N. oculata and 200 mM for D. tertiolecta. Enzyme precipitation was observed on C. minutissima and N. oculata when the enzymatic reaction was conducted with 100 and 200 mM concentration buffers.

Dunaliella tertiolecta showed higher extracellular (p < 0.05) enzymatic activity when compared to C. minutissima and N. oculata. The highest value found for D. tertiolecta was 33.5 ± 0.24 U L−1 on the 11th cultivation day. For N. oculata and C. minutissima, the values determined were 29.6 ± 0.49 and 11.02 ± 0.62 U L−1, respectively, on the 14th and the 7th cultivation days, respectively (Fig. 2). Increasing pH was observed during the cultivation; for the microalga C. minutissima, values increased from the 3rd day of culture onward to a final pH of 10.28. The pH increases of D. tertiolecta and N. oculata cultures were lower, reaching final values of 7.13 and 8.35, respectively, after which peaks of enzymatic activity were observed.

In intracellular β-galactosidase activity quantification, performed after cell disruption, no significant difference was observed between the results of samples disrupted by sonication and glass beads. The results of intracellular activity (Fig. 2) are expressed as the mean of the treatments. The highest values found corresponded to N. oculata and C. minutissima, with 16.13 ± 2.10 and 10.14 ± 1.12 U L−1 production, respectively.

Cell disruption

Sonication presented higher efficiency of cell disruption for the three studied species when compared to glass beads. For D. tertiolecta, all cells were disrupted after 5 sonication operation cycles (5 min). For C. minutissima and N. oculata, 10 and 15 cycles were necessary to obtain 84.2 and 76.8% disruption, respectively (Table 1).

Sonication and glass bead microalgae cell disruption effects can be observed using scanning electron microscopy (Figs. 3, 4, and 5). A higher proportion of completely disrupted cells can be observed using sonication as compared to glass beads for the three studied species, corroborating the results shown in Table 1.

Discussion

This study explored the mixotrophic cultivation of eight microalgae species for β-galactosidase production. Only three species were able to use lactose and to produce β-galactosidase. To date, no study has evaluated the mixotrophic growth of C. minutissima, D. tertiolecta, and N. oculata in medium supplemented with lactose.

Some microalgae species are obligate phototrophs due to the lack of efficient uptake mechanisms of sugars into cells or an incomplete tricarboxylic acid cycle (Chen and Chen 2006). Girard et al. (2014) evaluated Chlorella spp. cultivation in medium supplemented with lactose (5 g L−1) and did not observe the growth of the species C. vulgaris or C. protothecoides. The same result was observed by (Ribeiro et al. 2017): C. protothecoides showed a lower biomass concentration in mixotrophic condition with lactose when compared to the medium without sugar addition.

Microalgal metabolism generally resembles quite closely that of higher plants but has been studied to a much lesser extent than bacteria, fungi, or plants. It is not generally possible to predict which substrates can be used by any given microalgae (Neilson and Lewin 1974). Mixotrophic cultivation of microalgae is still minimally explored and the available examples are limited to species such as A. platensis, T. obliquus, Chorella spp., and Chlamydomonas reinhardtii (Heredia-Arroyo et al. 2011). Studies reported the growth of T. obliquus, C. vulgaris, and A. platensis in dairy waste (Abreu et al. 2012; Girard et al. 2014; Vieira Salla et al. 2016) as an alternative to microalgae biomass production and the waste treatments of the dairy products industry. Abreu et al. (2012) reported the mixotrophic cultivation of C. vulgaris using industrial dairy waste. The most successful results were obtained using hydrolyzed cheese whey (5 g L−1 of galactose and glucose) as opposed to the nonhydrolyzed form (10 g L−1 of lactose).

One of the advantages of mixotrophic cultivation is the enhanced biomass production. The results found in this study are in agreement with those of Cheirsilp and Torpee (2012) who found that freshwater Chlorella sp., marine Chlorella sp., and Nannochloropsis sp. growth under mixotrophic condition supplemented with glucose (2 g L−1) enhanced biomass concentration compared to the photoautotrophic growth.

Few studies have investigated the mixotrophic cultivation of D. tertiolecta, N. oculata, and C. minutissima. Velu et al. (2015) using D. tertiolecta and lactose (10 g L−1) as a carbon source observed no difference in the maximum growth rate in mixotrophic (μ = 0.23 day−1) and photoautotrophic (μ = 0.25 day−1) cultivation. The values of D. tertiolecta dry biomass found in the study were higher when compared to the mixotrophic culture supplemented with glucose. Rizwan et al. (2014) reported that D. tertiolecta presented biomass productivity of 1.7 g dry biomass L−1 in mixotrophic cultivation using low glucose concentration (1 and 5% w/w). Li et al. (2014) cultured C. sorokiniana mixotrophically with supplementation of 4 g L−1 glucose and reported a biomass yield of 0.82 g biomass g−1 glucose and a 3.5 g L−1 dry biomass production.

The mechanism of disaccharide utilization in green algae remains unknown. The monosaccharides might be generated through hydrolysis of disaccharides by a specific enzyme, or the disaccharides are directly transported across the plasmalemma by disaccharide carrier (Zhang et al. 2014). The synthesis of β-galactosidase by microalgae is necessary for lactose hydrolysis. This enzyme hydrolyzes D-galactosyl residues into glucose and galactose, resulting in a necessary internalization of the glucose and galactose molecules (Girard et al. 2014). The transport of hexoses and pentoses into the cytosol relies on a monosaccharide/H+ symport system. In Chlorella kessleri, three H+/hexose cotransporter genes (HUP1, HUP2, and HUP3) have been identified, displaying different affinities for glucose and galactose (Stadler et al. 1995; Gao et al. 2014).

Although the microalgal β-galactosidase activity results are lower when compared to those of yeasts and bacteria (Dagbagli and Goksungur 2008; Carević et al. 2015), this is the first study evaluating β-galactosidase production by D. tertiolecta, N. oculata, and C. minutissima in mixotrophic medium. β-Galactosidase was produced in medium containing NaCl (400 mM) and under alkaline and neutral pH conditions, presenting different characteristics from enzymes produced by bacteria and yeasts. β-Galactosidases with neutral pH optima show industrial application for the hydrolysis of lactose in milk and sweet whey (Panesar et al. 2010). Bentahar et al. (2018) reported β-galactosidase synthesis by T. obliquus using lactose as a carbon source, and the optimum production (86.45 U L−1) was recored after 7 days.

Microalgae have several advantages when compared to other microbial cells in industrial enzyme synthesis due to their cost-reducing minimal nutritional requirements (natural or artificial light, CO2, water, nitrogen source, and some salts) (Brasil et al. 2017).

The cell disruption techniques employed exhibited higher efficiency for D. tertiolecta. Microalgae present different sizes and cell wall structures, factors that significantly influence the lysis rates of cells. Dunaliella tertiolecta cell size varies from 5 to 18 μm in length and from 3 to 13 μm in width and shows the lack of a rigid cell wall as a genus characteristic (Borowitzka and Siva 2007). For N. oculata, cell disruption is hampered by small cell size (2–5 μm) (Fig. 3(I)) and cell wall composition (Shene et al. 2015). Its cell walls are composed of a cellulosic inner wall that is protected by an outer hydrophobic layer of algaenan, which confers resistance to cell disruption (Sukarni et al. 2014; Montalescot et al. 2015).

The results reported in the literature on microalgae disrupting sonication efficiency are quite divergent. Previous studies reported by Zheng et al. (2011) and Safi et al. (2014) showed lower efficiency using sonication for C. vulgaris when compared to manual disruption with quartz sand and high-pressure homogenization. Similar results were obtained by McMillan et al. (2013) when comparing different cell disruption methods for N. oculata, with 67.7% efficiency observed by using ultrasound.

Conclusion

Mixotrophic cultivation of D. tertiolecta, C. minutissima, and N. oculata presented biomass production and growth rates higher than those of photoautotrophic cultures. A 97.7% reduction in lactose concentration was observed for D. tertiolecta, 60% for N. oculata, and 32.1% for C. minutissima. Galactose and glucose metabolization by microalgae in culture medium was also observed. β-Galactosidase extracellular production was 33.5 U L−1 on the 11th cultivation day for D. tertiolecta. For N. oculata and C. minutissima, values were 29.6 and 11.02 U L−1 on the 14th and the 7th cultivation days, respectively. Even though enzyme activity values were low, mixotrophic microalgae cultivation demonstrated excellent biotechnological potential for contributing to biomass and biomolecule production and for the enhanced utilization of dairy products’ industry coproducts.

References

Abreu AP, Fernandes B, Vicente AA, Teixeira J, Dragone G (2012) Mixotrophic cultivation of Chlorella vulgaris using industrial dairy waste as organic carbon source. Bioresour Technol 118:61–66

Andersen RA, Berges JA, Harrisson PJ, Watanabe MM (2005) Recipes for freshwater and seawater media. In: Anderson RA (ed) Algal culturing techniques. Elsevier Academic Press, Amsterdam, pp 429–538

Angelo EA, Andrade DS, Filho AC (2014) Non-photoautotrophic cultivation of microalgae: an overview. Semina: Cienc Biol Saude 35(2):125–136

Benemann J, Woertz I, Lundquist T (2018) Autotrophic microalgae biomass production: from niche markets to commodities. Ind Biotechnol 14:3–10

Bentahar J, Doyen A, Beaulieu L, Deschênes J-S (2018) Investigation of β-galactosidase production by microalga Tetradesmus obliquus in determined growth conditions. J Appl Phycol. https://doi.org/10.1007/s10811-018-1550-y

Borowitzka MA (1988) Algal growth media and sources of cultures. In: Borowitzka MA, Borowitzka LJ (eds) Micro-algal biotechnology. Cambridge University Press, Cambridge, pp 456–465

Borowitzka MA (2013) High-value products from microalgae—their development and commercialisation. J Appl Phycol 25:743–756

Borowitzka MA, Siva CJ (2007) The taxonomy of the genus Dunaliella (Chlorophyta, Dunaliellales) with emphasis on the marine and halophilic species. J Appl Phycol 19:567–590

Brasil BSAF, de Siqueira FG, Salum TFC, Zanette CM, Spier MR (2017) Microalgae and cyanobacteria as enzyme biofactories. Algal Res 25:76–89

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energ Rev 14:557–577

Carević M, Vukašinović-Sekulić M, Grbavčić S, Stojanović M, Mihailović M, Dimitrijević A, Bezbradica D (2015) Optimization of β-galactosidase production from lactic acid bacteria. Hemijska Industrija 69(3):7

Ceron Garcia MC, Garcia Camacho F, Sanchez Miron A, Fernandez Sevilla JM, Chisti Y, Molina Grima E (2006) Mixotrophic production of marine microalga Phaeodactylum tricornutum on various carbon sources. J Microbiol Biotechnol 16:689–694

Cheirsilp B, Torpee S (2012) Enhanced growth and lipid production of microalgae under mixotrophic culture condition: effect of light intensity, glucose concentration and fed-batch cultivation. Bioresour Technol 110:510–516

Chen G-Q, Chen F (2006) Growing phototrophic cells without light. Biotechnol Lett 28:607–616

Chojnacka K, Zielińska A (2012) Evaluation of growth yield of Spirulina (Arthrospira) sp. in photoautotrophic, heterotrophic and mixotrophic cultures. World J Microbiol Biotechnol 28:437–445

Dagbagli S, Goksungur Y (2008) Optimization of β-galactosidase production using Kluyveromyces lactis NRRL Y-8279 by response surface methodology. Electron J Biotechnol 11 (4)

Doran PM (2013) Material balances. In: Bioprocess engineering principles (Second Edition). Academic Press, London, pp 87–137

Gao C, Wang Y, Shen Y, Yan D, He X, Dai J, Wu Q (2014) Oil accumulation mechanisms of the oleaginous microalga Chlorella protothecoides revealed through its genome, transcriptomes, and proteomes. BMC Genomics 15(1):582

Girard J-M, Roy M-L, Hafsa MB, Gagnon J, Faucheux N, Heitz M, Tremblay R, Deschênes J-S (2014) Mixotrophic cultivation of green microalgae Scenedesmus obliquus on cheese whey permeate for biodiesel production. Algal Res 5:241–248

Guillard RRL (1975) Culture of phytoplankton for feeding marine invertebrates. In: Smith WL, Chanley MH (eds) Culture of marine invertebrate animals. Plenum Press, New York, pp 29–60

Guillard RR (2005) Purification methods for microalgae. In: Andersen RA (ed) Algal Culturing Techniques. Elsevier Academic Press, Amsterdam, pp 117–132

Heredia-Arroyo T, Wei W, Ruan R, Hu B (2011) Mixotrophic cultivation of Chlorella vulgaris and its potential application for the oil accumulation from non-sugar materials. Biomass Bioenergy 35:2245–2253

Husain Q (2010) β Galactosidases and their potential applications: a review. Crit Rev Biotechnol 30:41–62

Katoh S, Yoshida F (2009) Biochemical engineering: a textbook for engineers, chemists and biologists. Wiley-VCH, Germany

Li T, Zheng Y, Yu L, Chen S (2014) Mixotrophic cultivation of a Chlorella sorokiniana strain for enhanced biomass and lipid production. Biomass Bioenergy 66:204–213

McMillan JR, Watson IA, Ali M, Jaafar W (2013) Evaluation and comparison of algal cell disruption methods: microwave, waterbath, blender, ultrasonic and laser treatment. Appl Energy 103:128–134

Montalescot V, Rinaldi T, Touchard R, Jubeau S, Frappart M, Jaouen P, Bourseau P, Marchal L (2015) Optimization of bead milling parameters for the cell disruption of microalgae: process modeling and application to Porphyridium cruentum and Nannochloropsis oculata. Bioresour Technol 196:339–346

Neilson AH, Lewin RA (1974) The uptake and utilization of organic carbon by algae: an essay in comparative biochemistry. Phycologia 13:227–264

Odjadjare EC, Mutanda T, Olaniran AO (2015) Potential biotechnological application of microalgae: a critical review. Crit Rev Biotechnol 37:37–52

Panesar PS, Kumari S, Panesar R (2010) Potential applications of immobilized beta-galactosidase in food processing industries. Enzyme Research 2010:16

Perez-Garcia O, Escalante FME, de-Bashan LE, Bashan Y (2011) Heterotrophic cultures of microalgae: metabolism and potential products. Water Res 45:11–36

Pina-Pérez MC, Rivas A, Martínez A, Rodrigo D (2017) Antimicrobial potential of macro and microalgae against pathogenic and spoilage microorganisms in food. Food Chem 235:34–44

Pires JCM (2015) Mass production of microalgae. In: Kim S-K (ed) Handbook of marine microalgae. Academic Press, Boston, pp 55–68

Pulz O, Gross W (2004) Valuable products from biotechnology of microalgae. Appl Microbiol Biotechnol 65:635–648

Ribeiro JES, Martini M, Altomonte I, Salari F, Nardoni S, Sorce C, da Silva FLH, Andreucci A (2017) Production of Chlorella protothecoides biomass, chlorophyll and carotenoids using the dairy industry by-product scotta as a substrate. Biocatal Agric Biotechnol 11:207–213

Rizwan M, Mujtaba G, Lee K (2014) Influence of organic carbon sources on growth and lipid content of marine green alga Dunaliella tertiolecta. J Mar Biosci Biotechnol 6:68–75

Safi C, Camy S, Frances C, Varela MM, Badia EC, Pontalier P-Y, Vaca-Garcia C (2014) Extraction of lipids and pigments of Chlorella vulgaris by supercritical carbon dioxide: influence of bead milling on extraction performance. J Appl Phycol 26:1711–1718

Satyanarayana KG, Mariano AB, Vargas JVC (2011) A review on microalgae, a versatile source for sustainable energy and materials. Int J Energy Res 35:291–311

Shene C, Monsalve María T, Vergara D, Lienqueo María E, Rubilar M (2015) High pressure homogenization of Nannochloropsis oculata for the extraction of intracellular components: effect of process conditions and culture age. Eur J Lipid Sci Technol 118:631–639

Silaban A, Bai R, Gutierrez-Wing MT, Negulescu II, Rusch KA (2014) Effect of organic carbon, C:N ratio and light on the growth and lipid productivity of microalgae/cyanobacteria coculture. Eng Life Sci 14:47–56

Specifications CC (1981) Food chemical codex. National Academy Press, Washington

Stadler R, Wolf K, Hilgarth C, Tanner W, Sauer N (1995) Subcellular localization of the inducible Chlorella HUP1 monosaccharide-H+ symporter and cloning of a co-induced galactose-H+ symporter. Plant Physiol 107:33–41

Sukarni S, Hamidi N, Yanuhar U, Wardana ING (2014) Potential and properties of marine microalgae Nannochloropsis oculata as biomass fuel feedstock. Int J Energy Environ Eng 5:279–290

Velu P, Peter MJ, Sanniyasi E (2015) Effect of various carbon sources on biochemical production in marine microalgae Nannochloropsis salina (Eustigmatophyceae), Dunaliella tertiolecta (Chlorophyceae) and Tetraselmis suecica (Chlorodendrophyceae). Int J Curr Microbiol Appl Sci 4(3):8

Vieira Salla AC, Margarites AC, Seibel FI, Holz LC, Brião VB, Bertolin TE, Colla LM, Costa JAV (2016) Increase in the carbohydrate content of the microalgae Spirulina in culture by nutrient starvation and the addition of residues of whey protein concentrate. Bioresour Technol 209:133–141

Vu CHT, Lee H-G, Chang YK, Oh H-M (2018) Axenic cultures for microalgal biotechnology: establishment, assessment, maintenance, and applications. Biotechnol Adv 36:380–396

Wang D, Li Y, Hu X, Su W, Zhong M (2015) Combined enzymatic and mechanical cell disruption and lipid extraction of green alga Neochloris oleoabundans. Int J Mol Sci 16:7707–7722

Zhang C, Kim S-K (2010) Research and application of marine microbial enzymes: status and prospects. Mar Drugs 8:1920–1934

Zhang W, Zhang P, Sun H, Chen M, Lu S, Li P (2014) Effects of various organic carbon sources on the growth and biochemical composition of Chlorella pyrenoidosa. Bioresour Technol 173:52–58

Zheng H, Yin J, Gao Z, Huang H, Ji X, Dou C (2011) Disruption of Chlorella vulgaris cells for the release of biodiesel-producing lipids: a comparison of grinding, ultrasonication, bead milling, enzymatic lysis, and microwaves. Appl Biochem Biotechnol 164:1215–1224

Zhu CJ, Lee YK (1997) Determination of biomass dry weight of marine microalgae. J Appl Phycol 9:189–194

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zanette, C.M., Mariano, A.B., Yukawa, Y.S. et al. Microalgae mixotrophic cultivation for β-galactosidase production. J Appl Phycol 31, 1597–1606 (2019). https://doi.org/10.1007/s10811-018-1720-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-018-1720-y