Abstract

Drying kinetics, proximate composition, dietary fiber, total phenolic compounds, pigments, amino acid profile, and antioxidant capacity (2,2-diphenyl-1-picrylhydrazyl (DPPH) and oxygen radical absorbance capacity) of a red edible seaweed (Pyropia orbicularis) subjected to vacuum drying at five temperatures (40–80 °C) were evaluated. The experimental drying curves were satisfactorily fitted to the Weibull model. The total dietary fiber (TDF) of this seaweed presented a value of 64.37 g (100 g)−1 d.m. The ratio IDF:TDF was 81.1%. The values for protein ranged between 22.34 and 24.92 g (100 g)−1 d.m. in dried seaweed, and His, Thr, and Pro were the most abundant amino acids. The chlorophyll a content was higher than that for chlorophyll b. Total phenolic content (TPC), phycoerythrin and phycocyanin contents, and carotenoid content as well as antioxidant capacity showed an increase at 70 °C. Moreover, at 70 °C, ΔE presented a value of 15.66. Correlations between the TPC and DPPH values (r 2 = 0.899) as well as lightness and hue angle (r 2 = 0.776) were found during food drying. This work provides important information about the chemical composition and nutraceutical properties of the Chilean edible red seaweed, P. orbicularis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Seaweeds are one of the living renewable resources of the marine environment with feeding potential as well as therapeutic applications, especially for the extraction of phycocolloids and phytochemicals (Agregán et al. 2016; Roohinejad et al. 2016). In particular, Pyropia orbicularis, also known by its common name luche, is an important red seaweed which is distributed along the upper rocky intertidal zone of the Chilean coast from Arica (18° S) to Tierra del Fuego (55° S) (Hayashi et al. 2014; Ramírez et al. 2014). This seaweed has a significant economic interest mainly due to its high nutritional and functional values, including important contents of vitamins, dietary fiber, protein, and bioactive peptides (Pérez et al. 2007; Contreras-Porcia et al. 2013; Cian et al. 2012, 2014a, 2015).

Bioactive peptides from algae have shown to exert many physiological functions within the body, including anticoagulant, antihypertensive, and immune-modulatory, besides being a source of nitrogen and amino acids (Cian et al. 2012, 2015). Moreover, P. orbicularis-derived compounds are of particular interest due to strong anti-inflammatory, hepatoprotective, and antioxidant activities exerted by light-harvesting pigments bound to proteins that can capture solar radiation to form phycobiliproteins (PBPs) (Pina et al. 2014). For this reason, PBPs are used as colorants in food and cosmetics (Tello-Ireland et al. 2011), with R-phycoerythrin (R-PE) and phycocyanin (PC) being the most important pigments in red seaweeds (Cian et al. 2014b). Traditionally, this species grows abundantly between September and March (Ramírez et al. 2014); nevertheless, its postharvest shelf life is very short, because it contains a large amount of water (75–85% wet basis). Hence, it is very important to explore preservation methods for extending its shelf life and potentially increase the use of this red seaweed as a functional product. The traditional way to preserve this seaweed is by sun drying (Cox et al. 2012). However, its bioactivity and nutritional value depend mainly on the drying process. An alternative to the traditional drying process (sun drying) is the use of vacuum drying, since the temperature of the product can be easily controlled leading to reduce drying times by lowering the pressure during the process (Michalska et al. 2016). Vacuum drying prevents some of the thermal damages from occurring on bioactive compounds and highlights beneficial nutrients from alga-derived compounds (Mohamed et al. 2012; Brown et al. 2014).

Moisture removal and its dependence on the process variables are expressed in terms of the drying kinetics, being essential for the development of a reliable process model. Empirical equations frequently used to model the drying kinetics of seaweeds include the Weibull distribution (Tello-Ireland et al. 2011). The present work aimed to assess the influence of temperature (40–80 °C) on vacuum drying of red seaweed (P. orbicularis) on drying kinetics, physicochemical composition, bioactive compounds, antioxidant capacity, pigments, and amino acid profile.

Materials and methods

Seaweed sampling and vacuum drying conditions

Vegetative thalli of Pyropia orbicularis from the same population were manually collected from the upper and mid intertidal zones having low-wave exposure along 300–500 m of coastline at Caleta Sierra, Region of Coquimbo, Chile (71° 40′ 11″ W). The seaweeds were stored immediately in plastic bags containing seawater and transported to the laboratory in a cooler at 5–7 °C. Then, they were rinsed quickly with distilled water to eliminate the salt excess, and were subjected to visual inspection by size, homogenous color, and absence of mechanical damage. A sample batch taken as control was freeze-dried to prevent spoilage, except for samples taken for proximate composition analysis which were measured immediately upon arrival at the laboratory.

Sample batches (300 g) were dried at 40, 50, 60, 70, and 80 °C using a vacuum oven (Memmert, model VO 400, Germany) at 15 kPa pressure (Uribe et al. 2016). The batches were placed in a thin layer on stainless steel trays with a charge density of 2.49 kg m−2. After drying, each sample batch was ground using a basic analytical mill (IKA A-11, USA), sieved with a stainless steel sieve #35 of 500 μm mesh (U.S. Standard Sieve Series, Dual Manufacturing Co., USA), and then stored in sealed plastic bags at 5 ± 1 °C.

Experimental and simulated drying curves

To determine the equilibrium moisture content (X we) of seaweeds, a desorption isotherm was determined at 50 °C in triplicate (Lemus et al. 2008). The Halsey model (Eq. (1)) was used to predict the equilibrium moisture content.

In this equation, A (g water g−1 d.m.) and B (dimensionless) are the Halsey model parameters and a w (dimensionless) is the water activity. This equation has been widely used to describe the equilibrium moisture content of seaweeds (Lemus et al. 2008; Moreira et al. 2016a, b).

To determine the drying kinetics, the data obtained experimentally for the five different temperatures studied were plotted as a dimensionless variable moisture ratio (MR, Eq. (2)) versus time, where MR relates the sample moisture content in real time (X wt) to the initial moisture content (X wo) and the equilibrium moisture content (X we). Drying experiments were carried out in triplicate.

The experimental data (MR vs time, t) were fitted to the Weibull model (Eq. (3)), where t is the process time and α and β are the shape and scale parameters of the Weibull model, respectively. This equation has been used previously by Tello-Ireland et al. (2011) to describe the drying kinetics of Gracilaria chilensis, a red seaweed.

The fit quality of the experimental data to the Weibull model was evaluated using the determination coefficient (r 2) and chi-square (χ 2, Eq. (4)) statistics (Lemus et al. 2008; Tello-Ireland et al. 2011), where N is the number of experiences and m is the number of model parameters.

Finally, to determine the influence of the vacuum-drying process temperature on the kinetic parameters of the Weibull model, an Arrhenius-type equation was applied (Eq. (5)). From this equation, the activation energy (E a) was estimated by plotting ln φ versus T −1.

where φ is the α or β parameter of the Weibull model, φ 0 is the Arrhenius factor, and R is the universal gas constant (8.314 J mol−1 K−1) (Tello-Ireland et al. 2011).

Determination of proximate composition and dietary fiber

The moisture content (AOAC no. 934.06), crude proteins (AOAC no. 960.52), fat (AOAC no. 960.39), crude fiber (AOAC no. 962.09), and crude ash (AOAC no. 923.03) were determined according to AOAC methods (1990). The total carbohydrates were calculated by difference (Matanjun et al. 2009). The water activity (a w) of the samples was measured at 25 °C by an AQUA LAB equipment (4 TE, Pullman, WA, USA).

All algae samples were analyzed for soluble (SDF) and insoluble dietary fiber (IDF) fractions according to a gravimetric enzymatic method (AOAC no. 991.43). A Total Dietary Fiber Assay Kit (TDF100A; Sigma-Aldrich, USA), an Enzymatic Digestion Unit, and a Filtration System (VELP Scientifica, GDE - CSF6, Italy) were used. The total dietary fiber (TDF) was calculated as the sum of soluble and insoluble dietary fibers, and expressed as g (100 g)−1 dry matter (d.m.). All measurements were performed in triplicate.

Extraction procedure and determination of total phenolic compounds

A milled seaweed sample (1.0 g) was accurately weighed and transferred into an Erlenmeyer flask, mixed with 50 mL of 60% aqueous methanol using a solid/liquid ratio of 1:5, placed on an orbital shaker (Boeco, OS20, Germany) for 24 h at 200 rpm (room temperature), then filtered through Whatman #1 filter paper. The filtrate was transferred into a 250-mL round-bottom flask. The solvent was evaporated to dryness under a reduced pressure in a rotary evaporator at 40 °C. The dried residue was dissolved in 10 mL of 60% aqueous methanol. For all extraction steps, the extracts were protected from light by covering them with aluminum foil.

Total phenolic content (TPC) was determined colorimetrically by using the Folin-Ciocalteau (FC) reagent according to the method of Chuah et al. (2008) modified by Uribe et al. (2016). Absorbance was read at 725 nm. The phenolic content was obtained using a gallic acid standard for a calibration curve (y = 0.0041x + 0.0008; r 2 = 0.999). Results were expressed as gallic acid equivalent per 100 g d.m. (mg GAE (100 g)−1 d.m.). Samples and standards were carried out in triplicate. All reagents were purchased from Merck (Germany).

Determination of antioxidant activity by the DPPH and ORAC assays

The radical scavenging activity of the methanolic extracts was assessed using the DPPH method of Brand-Williams et al. (1995). The synthetic antioxidant Trolox was used for generating a calibration curve (y = −0.4933x + 0.4277; r 2 = 0.996), and the results of the antioxidant activity were expressed as micromol Trolox equivalent per 100 g dry matter (μmol TE (100 g)−1 d.m.).

For determining the oxygen radical absorbance capacity (ORAC), an extract of the red seaweed was prepared with 60% aqueous methanol and then was followed by the procedure described by Ou et al. (2002). The ORAC assay was carried out according to Zhang et al. (2010) with slight modifications described by Uribe et al. (2016). Trolox was used as a reference standard and for generating a calibration curve (y = 0.0002x − 21.951; r 2 = 0.973), and the results of the antioxidant activity were expressed as micromol Trolox equivalent per 100 g dry matter (μmol TE (100 g)−1 d.m.). Samples and standards were determined in triplicate.

Photosynthetic pigments

The phycobiliproteins phycoerythrin (PE) (Eq. (6)) and phycocyanin (PC) (Eq. (7)) from dried seaweed samples were extracted according to Tello-Ireland et al. (2011). The absorbances of the supernatants were read at 455, 564, 592, 618, and 645 nm. The phycobiliproteins were quantified following the equations of Beer and Eshel (1985).

Chlorophyll a was estimated by spectrophotometry. Briefly, the milled dried seaweed samples (0.2 g) were accurately weighed and extracted overnight with 90% aqueous acetone (25 mL) at 4 °C. The extracts were centrifuged at 4500×g at 4 °C for 5 min. The absorbance of the supernatants was read at 630 and 664 nm, and the chlorophyll a concentration was calculated according to the following equation (Jeffrey and Humphrey 1975):

Total carotenoids (Eq. (9)) was determined according to the methodology of Chan and Matanjun (2017). The milled dried seaweed samples (3.0 g) were extracted with 75 mL of a mixture of hexane:acetone:ethanol (2:1:1, v/v) for 1 h at room temperature. The homogenate was filtered and the supernatant collected was made up to 100 mL with extraction solvent. Then, 25 mL of water was added and shaken vigorously for separation of the phases. After 30 min of being protected from light, two layers were observed, an organic upper layer and an aqueous lower layer. The absorbance of the organic layer was measured at 470 nm. The total carotenoids was calculated according to the following equation:

where v = total volume of extract, w = sample weight (g), and A 1% = 2600 (β-carotene extinction coefficient in hexane).

Surface color

The surface color of the seaweed samples was measured using a colorimeter (HunterLab, MiniScan XE Plus, USA) and described by the CIE coordinates, L * (lightness), a * (redness/greenness), and b * (yellowness/blueness) at standard illuminant D65 and an observer angle of 10°. Five replicate measurements were taken and results were averaged. The total color difference (∆E) was calculated using Eq. (10), where L 0, a 0, and b 0 are the control values for fresh seaweed (Tello-Ireland et al. 2011); also, the polar coordinates of color chroma (C *; Eq. (11)) and hue angle (h *; Eq. (12)) were calculated using the following equations:

Amino acid profile determination

The amino acid profile (except cystine and tryptophan) in P. orbicularis was determined by a HPLC equipped with a UV detector and a post-columnn ninhydrin derivatization according to Wright et al. (2002) with some slight modifications. Dried samples (0.20 g) were weighed in screw cap test tubes adding 5 mL of 6 N HCl. The test tubes were tightly capped and placed in an oven at 110 °C for 22 h under nitrogen to allow complete hydrolysis. Amino acids were determined after buffering to pH 2.2 by high-performance liquid chromatography (HPLC), using norleucine as internal standard. The HPLC system comprised a Spectra-Physics spectra system pump P4000, an autosampler (AS1000), a UV2000 detector, and a PCX3100 Pickering Laboratories Post Column Reactor (Pickering Laboratories, USA).

Statistical analysis

A one-way analysis of variance (ANOVA) was performed using Statgraphics Centurion XVI (Statistical Graphics Corp., USA) to determine significant differences among the different treatments. Differences between the media were analyzed by using the least significant difference (LSD) test with a significance level of α = 0.05 and a confidence interval of 95% (p < 0.05). In addition, the multiple range test (MRT) included in the statistical program was used to demonstrate the existence of homogeneous groups within each of the parameters.

Results and discussion

Desorption isotherm and drying kinetics

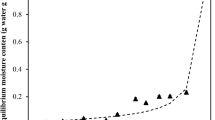

The vacuum-drying process is characterized by a progressive decrease in moisture content of the product as a function of time; however, the moisture content of samples was converted to a dimensionless moisture ratio (MR) parameter using Eq. (2) (Fig. 1 (A)). X we is required to evaluate the MR parameter, and it is obtained by means of the water desorption isotherm of the product. Figure 1(B) shows the experimental data of water desorption isotherms for Pyropia orbicularis at 50 °C. As expected, an increase in moisture content with an increase of water activity was observed. Other authors also have reported this behavior for some seaweeds such as Gelidium sesquipedale (Ait Mohamed et al. 2005), Gracilaria (Lemus et al. 2008), Bifurcaria bifurcata (Moreira et al. 2016a), and Fucus vesiculosus (Moreira et al. 2016b). In addition, the water desorption isotherm was modeled throughout the range of water activities tested using the Halsey model (Eq. (1)), which shows a good fit of experimental data (r 2 > 0.970). This model can be considered suitable for predicting the equilibrium moisture content of this seaweed like in previous work (Lemus et al. 2008; Moreira et al. 2016a, b). In this regard, the equilibrium moisture contents in the vacuum-drying process for P. orbicularis were estimated with the Halsey parameters obtained (A = 0.007 g water g−1 d.m. and B = 2.068). Then, X we (40 °C) = 0.1252, X we (50 °C) = 0.0875, X we (60 °C) = 0.0785, X we (70 °C) = 0.0608, and X we (80 °C) = 0.0574 g water g−1 d.m., respectively.

To evaluate the influence of process temperature on drying kinetics of the red seaweed P. orbicularis, experimental runs were carried out at temperatures ranging from 40 to 80 °C (Fig. 1(A)). In these experiments, all the drying curves showed a clear exponential tendency and an increase in the temperature removes more rapidly the moisture content, accelerating the drying process of this seaweed. These drying characteristics agree with those reported by other authors who studied seaweed drying by different techniques (Ait Mohamed et al. 2008; Lemus et al. 2008; Tello-Ireland et al. 2011; Kadam et al. 2015; Moreira et al. 2016 a, b).

Weibull model

The fitted drying curves based on the Weibull model (Eq. (3)) provided excellent fits to the experimental data for all the drying kinetic curves as shown in Fig. 1(A). The model parameters are shown in Table 1. The Weibull model showed statistical parameters such as coefficients of determination (r 2) higher than 0.98 and chi-square (χ 2, Eq. (4)) values lower than 0.002, indicating a good fit to the experimental data. This suggests that the Weibull model can be used for estimating the moisture content of P. orbicularis during vacuum drying at each temperature studied.

The values of α and β parameters of the Weibull model as well as the applied statistical tests are presented in Table 1 for the five tested temperatures. Values of α, related to product behavior (Ahmad-Qasem et al. 2013), ranged from 1.07 to 1.34. These values were similar to the ones obtained by Tello-Ireland et al. (2011) for G. chilensis (1.06–1.14) at different hot-air drying temperatures (40–70 °C). The α parameter showed a slight increase in the temperature range of 40–70 °C. However, the value obtained at 80 °C (1.34) was significantly (p < 0.05) higher. Therefore, ANOVA indicated that α is dependent on the vacuum drying temperature according to an Arrhenius-type equation (Eq. (5)). Nevertheless, at 80 °C, α did not follow that relationship. For this reason, the values corresponding to 80 °C were not considered when Eq. (5) was used to estimate the activation energy (E a = 3.15 kJ mol−1). This fact could be linked to structural modifications associated with food damage, especially at high temperatures (e.g., 80 °C).

The drying temperature also affected the β, with β being the parameter that defines the rate and represents the drying time (Corzo et al. 2008). Values of β ranged from 66.40 to 312.5 min−1, being higher than those reported by Tello-Ireland et al. (2011) in G. chilensis (44.18–115.9 min−1). The same authors also have reported that the inverse of parameter β increased (p < 0.05) when the process temperature rose, showing that, over the range studied, the higher the temperature applied, the faster the drying, which is consistent with the present results.

The influence of temperature on the Weibull β parameter also was well described using an Arrhenius-type relationship. The calculated E a was 35.36 kJ mol−1 for P. orbicularis from the β parameter, showing a positive coefficient of determination value (r 2 = 0.991). This indicated that there is a direct relationship between the β parameter and drying temperature. The E a value reported for P. orbicularis was in the same order of magnitude as that obtained by other authors. Thus, Tello-Ireland et al. (2011) reported a value of 28.4 kJ mol−1 (40–70 °C) in G. chilensis and Ahmad-Qasem et al. (2013) of 20.3 kJ mol−1 (50–120 °C) in olive pomace.

Effect of vacuum-drying temperature on proximate composition and dietary fiber of the red seaweed

Proximate composition analysis and dietary fiber content were determined to examine the chemical composition and nutritional value of the control and P. orbicularis samples subjected to vacuum drying at 40, 50, 60, 70, and 80 °C. The obtained results are summarized in Table 2. Water is the main constituent of P. orbicularis; the moisture content of the fresh sample was 87.16 ± 0.16 g (100 g)−1 (wet basis). The moisture content of fresh seaweeds was reported to be between 70 and 90% (Makkar et al. 2016). The moisture content and water activity of vacuum-dried samples varied in the ranges of 6.40 to 12.05 g (100 g)−1 and 0.332 to 0.528, respectively. The water activity of this seaweed decreased with the decrease of moisture content according to the experimental data (Table 2), reaching values below 0.60. This means that all samples hold relative stability against microbial attack or chemical changes (enzymatic or oxidation reactions).

The fat content was very low in the control seaweed sample (1.30 ± 0.18 g (100 g)−1 d.m.), but this value was similar to those reported previously for other seaweeds (Gómez-Ordóñez et al. 2010; Astorga-España and Mansilla 2014; Olivares-Molina and Fernández 2016). After vacuum drying, the fat content significantly decreased (p < 0.05) in most cases, except at 70 °C (Table 2). A recent study also reported a significant decrease of fat content in one Malaysian red seaweed after vacuum drying in comparison with a freeze-dried sample (Neoh et al. 2016), probably as a consequence of lipid oxidation by prolonged drying times. The ash contents of P. orbicularis ranged from 12.54 to 16.45% (at 50 °C) (p < 0.05) which are comparable with data on other red seaweeds (Gómez-Ordóñez et al. 2010).

Total dietary fiber and protein were the two most abundant components of this seaweed. Thus, the protein presented an initial value of 4.42 ± 0.25 g (100 g)−1 d.m., but a significant (p < 0.05) improvement when comparing it with the vacuum-dried samples at different temperatures was observed, ranging between 22.34 and 24.92 g (100 g)−1 d.m. These values are within the range recently reported by Makkar et al. (2016) for Porphyra and Pyropia dehydrated species (18–50% d.m.), which are even higher than high-protein legumes such as soybean (around 36%) (Chan and Matanjun 2017). Our results suggest that the use of vacuum drying could result in increased amounts of proteins. This phenomenon might be related to drying temperature, because high temperatures may promote proteolysis of amino acids during drying (Zhao et al. 2017). Regarding dietary fiber, the TDF of P. orbicularis (control sample) was comparable to that of Hizikia fusiforme (62 g (100 g)−1 d.m.) (Dawczynski et al. 2007) but higher than those of U. lactuca (54.85 g (100 g)−1 d.m.), U. pertusa (52 g (100 g)−1 d.m.), Porphyra columbina (48.02 g (100 g)−1 d.m.), and several brown Spanish seaweeds (Rupérez and Saura-Calixto 2001; Cian et al. 2014a; Yaich et al. 2015). According to Table 1, the TDF, SDF, and IDF of P. orbicularis agree with previous results of TDF ranging from 44.75 to 64.37% d.m., of which SDF constitutes 8.11−11.30% d.m. and IDF ranging from 35.24 to 53.98% d.m. during drying (p < 0.05) (Yaich et al. 2015). The SDF are within the range of other seaweeds (Matanjun et al. 2009). The ratio of SDF:TDF and IDF:TDF were 18.8 and 81.1% (average values), respectively, indicating that the dietary fiber of P. orbicularis was mainly composed of IDF. These results are comparable with those for U. lactuca (Yaich et al. 2015) but differed from data reported previously for G. changii (Chan and Matanjun 2017).

Thermal treatments as the drying can change the ratio between soluble and insoluble fiber (SDF:IDF) and total dietary fiber content. These modifications are largely dependent on drying temperatures (Elleuch et al. 2011; Ozyurt and Ötles 2016). Loss of SDF and solubilization of structural polymers may occur during the dehydration process of high-fiber products. In addition, IDF may degrade into smaller fragments at higher temperatures (Ozyurt and Ötles 2016).

Effect of vacuum-drying temperature on TPC and antioxidant activity of red seaweed

In preliminary studies, we found that 60% aqueous methanol was the best solvent for the extraction of phenolics from dried P. orbicularis samples. Thus, with this solvent, the extraction yields ranged between 20.49 and 51.11% (Table 3). The highest yield was observed at 70 °C, whereas the lowest yield was found at 40 °C (p < 0.05). Higher recovery of extract in a dried algae sample at 70 °C may be due to the low degradation rate of thermally sensible compounds, increasing the extraction yield from the P. orbicularis compounds, particular due to low drying exposure times. Comparable extraction yields were reported in previous investigations of seaweeds (Farvin and Jacobsen 2013; Hwang and Do Thi 2014). Nevertheless, considerable variations in extraction yield were found among different seaweed species, and this might be attributed to the polarities of different compounds present in these plants as well as the use of different solvents (e.g., water, ethanol, etc.) (Farvin and Jacobsen 2013; Rajauria et al. 2013; El-Din and El-Ahwany 2016).

The TPC and the antioxidant activity of the seaweed extracts are also presented in Table 3.

The initial total phenol content was 308.50 ± 19.08 mg GAE (100 g)−1 dry seaweed. This content was found to be lower than the correspondent values of the algae Gracilaria and Laurencia obtusa (Tello-Ireland et al. 2011; Lajili et al. 2016), but higher than those of Padina antillarum, Caulerpa racemosa, and Kappaphycus alvarezii (Nguyen et al. 2011). However, the values of TPC showed an increase with drying temperature when comparing with control samples, in particular at 70 and 80 °C (p < 0.05). Also, the lower drying temperatures used in the present study probably did not inactivate the oxidative enzymes completely, which may have in turn resulted in some oxidation of the phenolic substances and in consequence in a relatively lower phenolic content (Gupta et al. 2011). Regarding the antioxidant capacity, initial values were 409.35 ± 27.63 μmol TE (100 g)−1 d.m. for DPPH and 3901.68 ± 124.08 μmol TE (100 g)−1 d.m. for ORAC. A high antioxidant capacity was observed at 70 and 80 °C (p < 0.05) for both assays. This increase of antioxidant capacity level might be attributed to the fact that during the drying process compounds with antioxidant properties are generated and accumulated or improve the antioxidant capacities of naturally occurring antioxidants (Uribe et al. 2016).

A reduction in TPC values at various drying temperatures was accompanied by a reduction in the antioxidant activity as well (Table 3). In addition, a correlation between the TPC and DPPH values during food drying was found (r 2 = 0.776) indicating that phenolic compounds might be contributors to the antioxidant activity of this seaweed. Moreover, according to earlier reports, DPPH radical scavenging activity differs between brown and red algae indicating that different species contain some very efficient compounds which are responsible for the DPPH scavenging activity. For example, some red algae of the family Rhodomelaceae, especially the genera Rhodomela, Odonthalia, and Polysiphonia, were reported to contain several kinds of bromophenols, chemical compounds responsible for the antioxidant capacity of these red algae (Farvin and Jacobsen 2013).

Effect of vacuum-drying temperature on photosynthetic pigment concentration of red seaweed

As detailed in Table 4, the initial concentrations of photosynthetic pigments namely, phycoerythrin (PE) and phycocyanin (PC) of P. orbicularis, were 78.04 ± 2.11 and 18.97 ± 3.70 mg (100 g)−1 d.m., respectively. The PE value was higher than the corresponding value for G. chilensis PE (0.46 mg g−1) but lower than the PE content of Gracilaria sp. (1.25 mg g−1) and Grateloupia turuturu (5.28 mg g−1) (Tello-Ireland et al. 2011; Munier et al. 2015). The PC values were comparable with those reported by Tello-Ireland et al. (2011) for Gracilaria. PE and PC contents were affected by all treatments compared to the correspondent control sample value (p < 0.05). Drying temperature at 70 °C presented the higher values of these pigments. High drying temperatures (short drying times) or low temperatures (long drying times) resulted in thermal denaturation of these oligomeric proteins that produce modifications of their biological chromo-properties as well as their nutraceutical characteristics (Munier et al. 2015; Fernández-Rojas et al. 2014). In addition, correlations between the PC and both DPPH and ORAC values during drying were found (r 2 = 0.770; r 2 = 0.598), indicating that phycocyanin of P. orbicularis might contribute to the antioxidant activity of this seaweed as well (Fernández-Rojas et al. 2014; Nakagawa et al. 2016).

The initial content of chlorophyll a in our seaweed species was 352.1 μg g−1 d.m., whereas in dried samples it ranged between 176.8 and 603.0 μg g−1 d.m (Table 4). These results are consistent with the literature in other red seaweeds as Porphyra umbilicalis, Palmaria palmata, and Gracilaria changii (Ferraces-Casais et al. 2012; Chan and Matanjun 2017). It can be observed that from 40 to 60 °C of process temperature, the chlorophyll a content decreases on average by 38% compated to the control sample, but an important increase at high temperatures (i.e., 70 and 80 °C) was observed. This probably occurred because the high temperatures may lead to the replacement of magnesium in the chlorophylls by hydrogen, thereby converting chlorophyll a to pheophytin a (Uribe et al. 2016).

Pyropia orbicularis total carotenoid content showed a decrease during drying, in particular at low temperatures (i.e., 40 and 50 °C). Degradation occurred probably as a result of oxidation that caused breakdown of the hydrocarbon backbone of provitamin A (Vimala et al. 2011). Moreover, even though carotenoids have widespread applications as food colorants, cosmetics and feed additives, they also have a protective role for humans. Many studies have reviewed the health benefits of seaweed carotenoids which are usually related to their anti-oxidant and anti-cancer activities (Gong and Bassi 2016; Chan and Matanjun 2017).

Effect of vacuum-drying temperature on surface color of red seaweed

Table 5 presents the color of control and treated samples of P. orbicularis at the five temperatures under study. The colorimetric coordinates for the control samples were 11.75, −0.56, and 6.50 for L *, a * and b *, respectively. From Table 5, it can be seen that the brightness of the product (L *) increased its value during processing (p < 0.05) showing the highest value at 70 °C.

Regarding coordinate a * (greenness-redness), all the treatments increased this value parameter compared to the control sample showing a maximum value at 50 °C (p < 0.05) (Tello-Ireland et al. 2011). These results could be related to changes in the algal pigments due to thermal treatment, in particular to the red phycoerythrin (18,967 ± 3703 μg (100 g)−1 d.m. in control samples) which is the major light-harvesting pigment of red algae (Fernández-Rojas et al. 2014). Coordinate b * (blueness-yellowness) showed a different pattern during drying (p > 0.05); its value decreased at all treatments compared to the control sample (p < 0.05). From Table 5, it can be observed that the overall color (ΔE) of seaweed increased (became brighter) as drying temperature increased (p < 0.05); 70 °C presented ΔE = 15.66. These results are comparable with those reported in previous studies of Gracilaria (Tello-Ireland et al. 2011) and Himanthalia elongata (Cox et al. 2011). Moreover, a correlation between lightness and color hue was found (r 2 = 0.899) allowing the possibility to follow the color change during drying by measuring only the lightness (L *). The saturation index or chroma (C *) provides more information about the spatial distribution of colors than direct values of tristimulus measurements. The values of C * were also affected by temperature; all drying treatments decreased this value (p < 0.05) indicating color changes in the original P. orbicularis samples.

Effect of vacuum-drying temperature on the amino acid profile of red seaweed

The amino acids are often lost, changed, or even destroyed during drying, depending on drying conditions (Zhao et al. 2017). Table 6 shows the changes in the quantity of amino acids of P. orbicularis before and after vacuum drying under different drying temperatures. A total of 15 amino acids among the 22 amino acids found in nature were identified in these samples out of which the average amounts of histidine and threonine were greater than 20 g (100 g)−1 of protein in control samples, being the most abundant amino acids. Besides, the histidine and threonine contents were higher than in other red seaweed species such as P. columbina (Cian et al. 2012, 2014a), G. changii (Chan and Matanjun 2017), and several red Magellan Straits seaweeds (Astorga-España et al. 2016). On the other side, it was found that P. orbicularis contained almost all the essential amino acids except lysine. Vacuum-drying of P. orbicularis resulted in a significant (p < 0.05) degradation of the amino acid content at all temperatures between 40 and 80 °C compared with those in the control sample, with a reduction in amino acid content to around 30% of the original value. The loss of amino acids after drying may be related to protein denaturation and/or the release of amino acids from the proteins after denaturation which could have certain incidence of the Maillard reactions.

Conclusions

Seaweeds are a good source of bioactive compounds with functional bioactivity, in particular, antioxidants. In this investigation, P. orbicularis subjected to vacuum drying at five processing temperatures presented relevant results based on drying kinetics and psychochemical and functional properties. On the basis of the obtained results, P. orbicularis could be valorized by the extraction of their insoluble dietary fiber (IDF) rather than the total fiber (TDF). IDF extract has been demonstrated its potential usefulness in the formulation of low-calorie foods and in the stabilization of foods rich in fat and emulsions. Moreover, vacuum drying at 70 °C presented the higher total phenolic, carotenoid and phycoerythrin and phycocyanin contents, lightness as well as antioxidant capacity. Further studies, however, should be done in the future to identify and quantify the individual phenolic compounds responsible for the relatively high antioxidant capacity of this seaweed and to determine the correlation between antioxidant effect and dietary fiber, phycoerythrin and phycocyanin, and chlorophyll contents. These studies are now in progress in our laboratory.

References

Agregán R, Munekata PE, Domínguez R, Carballo J, Franco D, Lorenzo JM (2016) Proximate composition, phenolic content and in vitro antioxidant activity of aqueous extracts of the seaweeds Ascophyllum nodosum, Bifurcaria bifurcata and Fucus vesiculosus. Effect of addition of the extracts on the oxidative stability of canola oil under accelerated storage conditions. Food Res Int. doi:10.1016/j.foodres.2016.11.009

Ahmad-Qasem MH, Barrajon-Catalan E, Micol V, Cárcel JA, García-Pérez JV (2013) Influence of air temperature on drying kinetics and antioxidant potential of olive pomace. J Food Eng 119:516–524

Ait Mohamed L, Kane CSE, Kouhila M, Jamali A, Mahrouz M, Kechaou N (2008) Thin layer modelling of Gelidium sesquipedale solar drying process. Energy Convers Manag 49:940–946

Ait Mohamed L, Kouhila M, Lahsasni S, Jamali A, Idlimam A, Rhazi M, Aghfir M, Mahrouz M (2005) Equilibrium moisture content and heat of sorption of Gelidium sesquipedale. J Stored Prod Res 41:199–209

AOAC (1990) Official method of analysis. Association of official analytical chemists, 15th ed. Washington. DC. USA: Association of Official Analytical Chemists

Astorga-España MS, Mansilla A (2014) Sub-Antarctic macroalgae: opportunities for gastronomic tourism and local fisheries in the Region of Magallanes and Chilean Antarctic Territory. J Appl Phycol 26:973–978

Astorga-España MS, Rodríguez-Galdón B, Rodríguez-Rodríguez EM, Díaz-Romero C (2016) Amino acid content in seaweeds from the Magellan Straits (Chile). J Food Comp Anal 53:77–84

Beer S, Eshel A (1985) Determining phycoerythrin and phycocyanin concentrations in aqueous crude extracts of red algae. Aust J Mar Freshw Res 36:785–792

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT–Food Sci Technol 28:25–30

Brown E, Allsopp P, Magee P, Gill C, Nitecki S, Strain C, McSorley E (2014) Seaweed and human health. Nutr Rev 72:205–216

Chan PT, Matanjun P (2017) Chemical composition and physicochemical properties of tropical red seaweed, Gracilaria changii. Food Chem 221:302–310

Chuah AM, Lee Y-C, Yamaguchi T, Takamura H, Yin L-J, Matoba T (2008) Effect of cooking on the antioxidant properties of coloured peppers. Food Chem 111:20–28

Cian RE, Caballero MS, Sabbag N, González RJ, Drago SR (2014b) Bio-accessibility of bioactive compounds (ACE inhibitors and antioxidants) from extruded maize products added with a red seaweed Porphyra columbina. LWT–Food Sci Technol 55:51–58

Cian RE, Fajardo MA, Alaiz M, Vioque J, González RJ, Drago SR (2014a) Chemical composition, nutritional and antioxidant properties of the red edible seaweed Porphyra columbina. Int J Food Sci Nutr 65:299–305

Cian RE, Garzón AG, Ancona DB, Guerrero LC, Drago SR (2015) Hydrolyzates from Pyropia columbina seaweed have antiplatelet aggregation, antioxidant and ACE I inhibitory peptides which maintain bioactivity after simulated gastrointestinal digestion. LWT–Food Sci Technol 64:881–888

Cian RE, Martínez-Augustin O, Drago SR (2012) Bioactive properties of peptides obtained by enzymatic hydrolysis from protein byproducts of Porphyra columbina. Food Res Int 49:364–372

Contreras-Porcia L, López-Cristoffanini C, Lovazzano C, Flores-Molina MR, Thomas D, Núñez A, Fierro C, Guajardo E, Correa JA, Kube M, Reinhardt R (2013) Differential gene expression in Pyropia columbina (Bangiales, Rhodophyta) under natural hydration and desiccation conditions. Lat Am J Aquat Res 41(5):933–958

Corzo O, Bracho N, Pereira A, Vásquez A (2008) Weibull distribution for modeling air drying of coroba slices. LWT–Food Sci Technol 41:2023–2028

Cox S, Gupta S, Abu-Ghannam N (2011) Application of response surface methodology to study the influence of hydrothermal processing on phytochemical constituents of the Irish edible brown seaweed Himanthalia elongata. Bot Mar 54:471–480

Cox S, Gupta S, Abu-Ghannam N (2012) Effect of different rehydration temperatures on the moisture, content of phenolic compounds, antioxidant capacity and textural properties of edible Irish brown seaweed. LWT–Food Sci Technol 47:300–307

Dawczynski C, Schubert R, Jahreis G (2007) Amino acids, fatty acids, and dietary fibre in edible seaweed products. Food Chem 103:891–899

El-Din SMM, El-Ahwany AMD (2016) Bioactivity and phytochemical constituents of marine red seaweeds (Jania rubens, Corallina mediterranea and Pterocladia capillacea). J Taibah Univ Sci 10:471–484

Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H (2011) Dietary fibre and fibre rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem 124:411–421

Farvin KHS, Jacobsen C (2013) Phenolic compounds and antioxidant activities of selected species of seaweeds from Danish coast. Food Chem 138:1670–1681

Fernández-Rojas B, Medina-Campos O, Hernández-Pando R, Negrette-Guzmán M, Huerta-Yepez S, Pedraza-Chaverri J (2014) C-Phycocyanin prevents cisplatin-induced nephrotoxicity through inhibition of oxidative stress. Food Funct 5:480–490

Ferraces-Casais P, Lage-Yusty MA, Rodríguez-Bernaldo de Quirós A, López-Hernández J (2012) Evaluation of bioactive compounds in fresh edible seaweeds. Food Anal Meth 5:828–834

Gómez-Ordóñez E, Jiménez-Escrig A, Rupérez P (2010) Dietary fibre and physicochemical properties of several edible seaweeds from the northwestern Spanish coast. Food Res Int 43:2289–2294

Gong M, Bassi A (2016) Carotenoids from microalgae: a review of recent developments. Biotechnol Adv 34:1396–1412

Gupta S, Cox S, Abu-Ghannam N (2011) Effect of different drying temperatures on the moisture and phytochemical constituents of edible Irish brown seaweed. LWT–Food Sci Technol 44:1266–1272

Hayashi L, Bulboa C, Kradolfer P, Soriano G, Robledo D (2014) Cultivation of red seaweeds: a Latin American perspective. J Appl Phycol 26:719–727

Hwang E-S, Do Thi N (2014) Effects of extraction and processing methods on antioxidant compound contents and radical scavenging activities of laver (Porphyra tenera). Prev Nutr Food Sci 19:40–48

Jeffrey SW, Humphrey GF (1975) New spectrophotometric equation for determining chlorophyll a, b, c 1 and c 2 in higher plants, algae and natural phytoplankton. Biochem Physiol Pflanz 167:194–204

Kadam S, Tiwari B, O’Donnell C (2015) Effect of ultrasound pre-treatment on the drying kinetics of brown seaweed Ascophyllum nodosum. Ultrason Sonochem 23:302–307

Lajili S, Deghrigue M, Bel Haj Amor H, Muller C, Bouraoui A (2016) In vitro immunomodulatory activity and in vivo anti-inflammatory and analgesic potential with gastroprotective effect of the Mediterranean red alga Laurencia obtusa. Pharm Biol 54:2486–2495

Lemus R, Pérez M, Andrés A, Roco T, Tello C, Vega A (2008) Kinetic study of dehydration and desorption isotherms of red alga Gracilaria. LWT–Food Sci Technol 41:1592–1599

Makkar H, Tran G, Heuzé V, Giger-Reverdin S, Lessiree M, Lebasf F, Ankers P (2016) Seaweeds for livestock diets: a review. Anim Feed Sci Technol 212:1–17

Matanjun P, Mohamed S, Mustapha NM, Muhammad K (2009) Nutrient content of tropical edible seaweeds, Eucheuma cottoni, Caulerpa lentillifera and Sargassum polycystum. J Appl Phycol 21:75–80

Michalska A, Wojdyło A, Lech K, Łysiak G, Figiel A (2016) Physicochemical properties of whole fruit plum powders obtained using different drying technologies. Food Chem 207:223–232

Mohamed S, Hashim SN, Rahman HA (2012) Seaweeds: a sustainable functional food for complementary and alternative therapy. Trends Food Sci Tech 23:83–96

Moreira R, Chenlo F, Sineiro J, Arufe S, Sexto S (2016b) Water sorption isotherms and air drying kinetics of Fucus vesiculosus brown seaweed. J Food Process Preserv. doi:10.1111/jfpp.12997

Moreira R, Chenlo F, Sineiro J, Sánchez M, Arufe S (2016a) Water sorption isotherms and air drying kinetics modeling of the brown seaweed Bifurcaria bifurcata. J Appl Phycol 28:609–618

Munier M, Moranҫais M, Dumay J, Jaouen P, Fleurence J (2015) One-step purification of R-phycoerythrin from the red edible seaweed Grateloupia turuturu. J Chromatogr B 992:23–29

Nakagawa K, Ritcharoen W, Sri-Uam P, Pavasant P, Adachi S (2016) Antioxidant properties of convective-air-dried Spirulina maxima: evaluation of phycocyanin retention by a simple mathematical model of air-drying. Food Bioprod Process 100:292–302

Neoh YY, Matanjun P, Lee JS (2016) Comparative study of drying methods on chemical constituents of Malaysian red seaweed. Dry Technol 34:1745–1751

Nguyen VT, Ueng J-P, Tsai G-J (2011) Proximate composition, total phenolic content, and antioxidant activity of seagrape (Caulerpa lentillifera). J Food Sci 76:C950–C958

Olivares-Molina A, Fernández K (2016) Comparison of different extraction techniques for obtaining extracts from brown seaweeds and their potential effects as angiotensin I-converting enzyme (ACE) inhibitors. J Appl Phycol 28:1295–1302

Ou B, Huang D, Hampsch-Woodill M, Flanagan JA, Deemer EK (2002) Analysis of antioxidant activies of common vegetables employing oxygen radical absorbance capacity (ORAC) and ferric reducing antioxidant power (FRAP) assays: a comparative study. J Agric Food Chem 50:3122–3128

Pérez AA, Farías SS, Strobl AM, Pérez CM, Piñeiro A, Roses O, Fajardo MA (2007) Levels of essential and toxic elements in Porphyra columbina and Ulva sp. from San Jorge Gulf, Patagonia Argentina. Sci Total Environ 376(1–3):51–59

Pina AL, Costa AR, Lage-Yusty MA, López-Hernández J (2014) An evaluation of edible red seaweed (Chondrus crispus) components and their modification during the cooking process. LWT–Food Sci Technol 56:175–180

Rajauria G, Jaiswal AK, Abu-Gannam N, Gupta S (2013) Antimicrobial, antioxidant and free radical-scavenging capacity of brown seaweed Himanthalia elongata from western coast of Ireland. J Food Biochem 37:322–335

Ramírez ME, Contreras-Porcia L, Guillemin M-L, Brodie J, Valdivia C, Flores-Molina MR, Núñez A, Contador CB, Lovazzano C (2014) Pyropia orbicularis sp. nov. (Rhodophyta, Bangiaceae) based on a population previously known as Porphyra columbina from the central coast of Chile. Phytotaxa 158(2):133–153

Roohinejad S, Koubaa M, Barba FJ, Saljoughian S, Amid M, Greiner R (2016) Application of seaweeds to develop new food products with enhanced shelf-life, quality and health-related beneficial properties. Food Res Int http://dx.doi.org/10.1016/j.foodres.2016.08.016

Rupérez P, Saura-Calixto F (2001) Dietary fibre and physicochemical properties of edible Spanish seaweeds. Eur Food Res Technol 212:349–354

Tello-Ireland C, Lemus-Mondaca R, Vega-Gálvez A, López J, Di Scala K (2011) Influence of hot-air temperature on drying kinetics, functional properties, colour, phycobiliproteins, antioxidant capacity, texture and agar yield of alga Gracilaria chilensis. LWT–Food Sci Technol 44:2112–2118

Uribe E, Marin D, Vega-Galvez A, Quispe-Fuentes I, Rodriguez A (2016) Assessment of vacuum-dried peppermint (Mentha piperita L.) as a source of natural antioxidants. Food Chem 190:559–565

Vimala B, Thushara R, Nambisan B, Sreekumar J (2011) Effect of processing on the retention of carotenoids in yellow-fleshed cassava (Manihot esculenta Crantz) roots. Int J Food Sci Technol 46:166–169

Yaich H, Garna H, Bchir B, Besbes S, Paquot M, Richel A, Blecker C, Attia H (2015) Chemical composition and functional properties of dietary fibre extracted by Englyst and Prosky methods from the alga Ulva lactuca collected in Tunisia. Algal Res 9:65–73

Zhang L, Li J, Hogan S, Chung H, Welbaum GE, Zhou K (2010) Inhibitory effect of raspberries on starch digestive enzyme and their antioxidant properties and phenolic composition. Food Chem 119:592–599

Zhao Y, Jiang Y, Zheng B, Zhuang W, Zheng Y, Tian Y (2017) Influence of microwave vacuum drying on glass transition temperature, gelatinization temperature, physical and chemical qualities of lotus seeds. Food Chem 228:167–176

Acknowledgments

The authors gratefully acknowledge the Project FONDECYT 1160597 for providing financial support for the publication of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Uribe, E., Vega-Gálvez, A., Heredia, V. et al. An edible red seaweed (Pyropia orbicularis): influence of vacuum drying on physicochemical composition, bioactive compounds, antioxidant capacity, and pigments. J Appl Phycol 30, 673–683 (2018). https://doi.org/10.1007/s10811-017-1240-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-017-1240-1