Abstract

Cultivation temperature is one of the major factors affecting the growth and lipid accumulation of microalgae. In this study, the effects of temperature on the growth, lipid content, fatty acid composition and biodiesel properties of the marine microalgae Chaetoceros sp. FIKU035, Tetraselmis suecica FIKU032 and Nannochloropsis sp. FIKU036 were investigated. These species were cultured at different temperatures (25, 30, 35 and 40 °C). The results showed that the specific growth rate, biomass and lipid content of all microalgae decreased with increasing temperature. With regards to fatty acids, the presence of saturated fatty acids (SFAs) in T. suecica FIKU032 and Nannochloropsis sp. FIKU036 decreased with increasing temperature, in contrast with polyunsaturated fatty acids (PUFAs). Moreover, Chaetoceros sp. FIKU035 was the only species that could grow at 40 °C. The highest lipid productivity was observed in Chaetoceros sp. FIKU035 when cultivated at 25 °C (66.73 ± 1.34 mg L−1 day−1) and 30 °C (61.35 ± 2.89 mg L−1 day−1). Moreover, the biodiesel properties (cetane number, cold filter plugging point, kinematic viscosity and density) of the lipids obtained from this species were in accordance with biodiesel standards. This study indicated that Chaetoceros sp. FIKU035 can be considered as a suitable species for biodiesel production in outdoor cultivation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, the majority of biodiesel production comes from oil extracted from oleaginous seed plants, such as rapeseed, soybean, sunflower and palm. However, a potentially better alternative to these crops is photosynthetic microalgae, which could provide at least 10 to 20 times higher oil yields per unit land area and have the added benefit of little competition for agricultural land (Chisti 2008). Moreover, microalgae can potentially use part of carbon dioxide produced by combustion of fossil fuels; from this point of view, the microalgae can also be seen as simple CO2 sequestrants to use for greenhouse gas emission control, thereby reducing greenhouse gas emissions (Converti et al. 2009). The demand for biofuel is extremely strong and currently rising; therefore, the production of algae for biofuel and/or CO2 capture requires extremely large-scale culturing (Borowitzka and Moheimani 2013). With this in mind, the outdoor cultivation systems seem to be the most suitable and commercialized, as they would require lower initial capital costs (Brennan and Owende 2010; Lee 2011; Acién et al. 2012; Slade and Bauen 2013). However, large-scale outdoor culture systems are subject to wide fluctuations in diurnal and seasonal temperature (Borowitzka 2016). Thus, the selection of microalgae strains adapted to a wide range of temperatures would be beneficial for microalgae cultivation in outdoor systems at different time of the year.

Temperature influences all metabolic processes, and the optimum temperature for a particular algae strain will have a pronounced effect on the achievable productivity of a culture (Borowitzka 2016). The different culture environmental conditions, such as seasonal fluctuation, result in low and high temperatures and can cause variable growth rates and lipid accumulation of microalgae (Oliveira et al. 1999; Renaud et al. 2002; Sheng et al. 2011; Markou et al. 2012; Wei et al. 2015; Ippoliti et al. 2016). The photosynthesis rate, respiration and growth of microalgae all decline when optimal temperatures are exceeded due to imbalances between adenosine triphosphate (ATP) production and energy demand, inactivation or denaturation of necessary proteins for photosynthesis (Raven and Geider 1988; Ras et al. 2013) or stress on photosystem II activity (Sheng et al. 2011). Temperature also has the effect of changing fatty acid composition. It has been reported that total unsaturated fatty acids decreased with high temperature (Montensen et al. 1988; Renaud et al. 1995; Jiang and Chen 2000; Wei et al. 2015). In microalgae, unsaturated fatty acids are necessary for the maintenance of membrane fluidity, and the degree of membrane fluidity depends on the length of fatty acid chains (Hochachka and Somero 1984; Harwood 1988; Sargent et al. 1989). Moreover, the properties of biodiesel are determined by the fatty acid profile of the microalgae. Thus, fatty acid composition of algal lipids is very important for biodiesel production. Saturated fatty acids provide a more favourable cetane number, oxidative stability, heat of combustion and viscosity (Ramos et al. 2009). A higher content of saturated fatty acids improves oxidative stability and combustion while worsening cold flow, while a higher content of unsaturated fatty acid, especially polyunsaturated fatty acid, improves cold flow but leads to poorer oxidative stability and combustion (Knothe 2013). An optimal proportion of saturated to unsaturated fatty acids in the fatty acid methyl ester (FAME) yields the best quality of biodiesel (Islam et al. 2013).

Therefore, the objectives of this study were to investigate effects of temperature (25, 30, 35 and 40 °C) on the specific growth rate, biomass and lipid productivity of marine microalgae. Their fatty acid profiles were analysed and biodiesel properties were estimated based on their fatty acid methyl esters.

Materials and methods

Strains and culture conditions

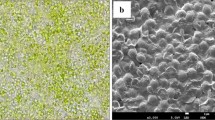

Chaetoceros sp. FIKU035, Tetraselmis suecica FIKU032 and Nannochloropsis sp. FIKU036 were obtained from the Chantaburi Coastal Fisheries Research and Development Centre, Chantaburi Province, Thailand. All species were cultured in 1 L of sterilized F/2 Medium (Guillard and Ryther 1962) with a salinity of 27 ± 1 ppt. Cultures were maintained at room temperature (25 ± 1 °C) under 50 μmol photons m−2 s−1 light intensity on a 12:12-h light/dark cycle and were aerated continuously.

The analyses of different growth temperatures were carried out by cultivation of 104 cells mL−1 of Chaetoceros sp. FIKU035 and Tetraselmis sp. FIKU032 and 106 cells mL−1of Nannochloropsis sp. FIKU036, in 250-mL cylinder tubes (OD 40 mm × 350 mm) containing 200 mL of sterilized F/2 medium with salinity of 27 ± 1 ppt. Experiments were performed at a constant temperature of 25, 30, 35 or 40 °C under 100 μmol photons m−2 s−1 light intensity with 12:12-h L/D cycle in a growth chamber (LGS-5201, Labtech, Korea). The growth rate of each species was characterized based on cell counts using a haemocytometer or via optical density measurements at 680 nm (UV-1700 Pharma Spec, Shimadzu, Japan). All experiments were carried out in triplicate.

The specific growth rate (μ) was calculated from the slope of the linear regression of time (days) and cell density (cell mL−1) according to eq. (1) (Wood et al. 2005):

where μ (day−1) is the specific growth rate in log phase, N 0 is the cell density at the beginning of log phase and N t is the cell density at late log phase.

Biomass and biomass productivity

Microalgae at late log phase were harvested by centrifugation at 1520×g for 10 min. The pellet was dried at 60 °C for dry weight measurement. The biomass productivity was calculated according to eq. (2) (Song et al. 2013). In addition, algal biomass was stored at −20 °C until chemical analysis.

Total lipid and fatty acid analysis

Lipids of marine microalgae were extracted following Bligh and Dyer (1959). Briefly, dried microalgae were extracted with chloroform/methanol/water (1:2:0.8) for 3 h and then filtered through Whatman No. 2 filter paper and rinsed with the same solvent mixture. This process was repeated a second time. The filtrates were pooled in a separation funnel, and then, chloroform and water were added to produce a 1:1:0.9 solvent ratio. The separation funnel was shaken and left to stand overnight, and then, the lower chloroform lipid layer was collected. The solvent was removed under a vacuum at 40 ± 1 °C using a rotary evaporator. Total lipid in the form of a viscous green residue was weighed, redissolved in methanol and stored at −20 °C until further analysis. Total lipids and lipid productivity were calculated according to eqs. (3–4) (Song et al. 2013).

Transesterification and fatty acid analysis

FAMEs of algal lipids were prepared following the method of Prevot and Mordret (1976). Briefly, an aliquot of lipid (~9–12 mg) was added to 2 mL of 0.5 M CH3ONa and was incubated at 55 °C for 30 min. Then, 2 mL of distilled water and n-hexane were added and gently mixed to recover the upper n-hexane layer containing FAMEs, which was neutralized by washing with distilled water many times and was finally purified by silica gel column chromatography using a 5% mixture of diethyl ether in hexane. The resulting FAMEs were analysed by GC-FID (7890 A, Agilent Technologies, USA) equipped with a DB-Wax column (127-2012, Agilent Technologies, USA). The oven temperature was set at and held at 170 °C for 2 min, then was raised 5 °C min−1 to 240 °C where it was held for 14 min. The injector and detector temperatures were set at 250 °C. FAME components were identified by comparisons with retention times of FAME standards (37 FAME standards C4-C24, Supelco, USA).

Estimation of biodiesel properties

The essential biodiesel parameters were estimated with a mathematical model based on FAME molecular structure, carbon chain size and the number and/or position of double bonds, as follows:

The cetane number (CN) of fatty acid methyl esters was calculated using eq. (5) (Krisnangkura 1986):

The saponification value (SV) in mg KOH g−1 and the iodine value (IV) in g I2 (100 g)−1 of fatty acid were estimated by eqs. (6–7) (Kalayasiri et al. 1996):

where N i is the percentage of each FAME and D i is the number of double bonds of each FAME.

The degree of unsaturation (DU) was calculated based on the total of MUFA and PUFA using eq. (8) (Ramos et al. 2009):

The long chain saturation factor (LCSF) and the cold filter plugging point (CFPP) were calculated according to eqs. (9–10) (Ramos et al. 2009):

The kinematic viscosity (υ, mm2 s−1) at 40 °C, density (ρ, g cm−3) at 20 °C and higher heating value (HHV) of biodiesel were calculated by eqs. (11, 12, 13) (Ramírez-Verduzco et al. 2012):

where Mw i is the molecular weight of a fatty acid, N i is its percentage of the fatty acid composition and D i is the number of double bonds in the fatty acid.

Statistical analysis

The results were expressed as the mean values ± standard deviation. Comparisons of the means were conducted by one-way analysis of variance (ANOVA), followed by a Duncan’s multiple range test to determine significance. In all cases, comparisons that showed a p value <0.05 were considered significant.

Results

Effect of temperature on growth and biomass

The growth rate of microalgae is highly variable under different temperature, and the results of our studies of this phenomenon are given in Table 1. In Chaetoceros sp. FIKU035, the highest specific growth rate was observed in culture at 25 °C (0.537 ± 0.027 day−1). However, there were no significant change (p > 0.05) in culture growth rates at 25, 30 and 35 °C. The growth rate of Chaetoceros sp. FIKU035 was decreased at 40 °C. This result shows that this species is adaptable to growth at a wide temperature range (25–40 °C). Growth temperatures above 30 °C were lethal for T. suecica FIKU032, with the highest specific growth rate of 0.378 ± 0.012 day−1 observed at 25 °C. In addition, Nannochloropsis sp. FIKU036 grew at 25° and up to 35 °C, the specific growth rate of this microalga decreased with increasing temperature and the optimal temperature was 25 °C with specific growth rate of 0.331 ± 0.006 day−1 at this temperature. Among the three species investigated, Chaetoceros sp. FIKU035 was the most eurythermal species, exhibiting a significantly higher specific growth rate than the other two species.

Biomass and biomass productivity are shown in Fig. 1. The highest biomass and biomass productivity of Chaetoceros sp. FIKU035 (777.93 ± 58.33 mg L−1, 388.97 ± 49.13 mg L−1 day−1) and T. suecica FIKU032 (978.43 ± 25.58 mg L−1, 369.84 ± 9.67 mg L−1 day−1) was found at 30 °C. The highest biomass and biomass productivity of Nannochloropsis sp. FIKU036 (885.35 ± 64.78 mg L−1, 293.05 ± 21.44 mg L−1 day−1) were found at 25 °C and decreased with increasing temperature. Among the three species, the highest biomass was observed for T. suecica FIKU032, while the highest biomass productivity was observed for Chaetoceros sp. FIKU035.

Effect of temperature on lipid content and fatty acid composition

Total lipid content and productivity at different temperatures are shown in Fig. 2. At its optimum growth temperature of 25 °C, the lipid content of Chaetoceros sp. FIKU035 was 20.42 ± 0.41%. However, the lipid content of this microalga decreased about two-fold at 35 °C (10.82 ± 0.68%) and two and a half fold at 40 °C (8.03 ± 0.01%). Similarly, the lipid productivity of Chaetoceros sp. FIKU035 decreased about two-fold from 25 to 35 °C (66.73 ± 1.34 to 29.98 ± 1.82 mg L−1 day−1) and by four-fold at 40 °C (15.92 ± 1.09 mg L−1 day−1). Moreover, Chaetoceros sp. FIKU035 had significantly higher lipid content and lipid productivity than the other assayed species.

The effect of temperature on fatty acid composition is shown in Fig. 3. The content of saturated fatty acids (SFAs) and monounsaturated fatty acids (MUFAs) for T. suecica FIKU032 and Nannochloropsis sp. FIKU036 decreased with increasing temperature. Conversely, polyunsaturated fatty acids (PUFAs) of these two species increased with increasing temperature. The content of SFAs and PUFAs in Chaetoceros sp. FIKU035 did not change significantly with temperature. Moreover, the MUFA content of Chaetoceros sp. FIKU035 seemed to decrease with increasing temperature.

Table 2 shows the change of the fatty acid profile of microalgae under different growth temperatures. The major fatty acids of Chaetoceros sp. FIKU035 were C14:0, C16:0 and C16:1, while T. suecica FIKU032 and Nannochloropsis sp. FIKU036 mainly contained C16:0 and C18:1n9. The contents of SFAs and MUFAs were highest in Chaetoceros sp. FIKU035 cultured at 25–30 °C, which represented approximately 80% of total FAMEs. Moreover, the content of C16:0, C18:0 and C18:1n9 decreased with increasing temperature for all species. Chaetoceros sp. FIKU035 showed higher C16:1 and lower C18:2n6 and C18:3n3 contents than the other two species assayed. The content of C18:3n3 in Nannochloropsis sp. FIKU036 increased with increasing temperature.

Effects of temperature on biodiesel properties

The essential biodiesel properties of microalgae cultured at different temperatures are shown in Table 3. The results showed that FAMEs of all species had biodiesel properties, including iodine value, cetane number, kinematic viscosity and density in accordance with European (EN14214) and American (ASTM D6751) standards. However, the cold plugging point of Chaetoceros sp. FIKU035 at 40 °C and of Nannochloropsis sp. FIKU036 at 30 and 35 °C were not in accordance with the European standard.

Discussion

Many researchers have reported on the importance of temperature on microalgae cultivation for biodiesel production (Wigmosta et al. 2011; Ras et al. 2013; Slade and Bauen 2013). Cultivation temperature is a very important factor, especially in a tropical country such as Thailand. In Thailand, the average temperature is approximately 30 °C, while the highest temperature is nearly 40 °C in summer (Meteorological Department 2015). In selecting a suitable microalgae strain for biodiesel production, factors such as lipid content, fatty acid composition and biomass production of the particular strain under different growth temperatures must be considered. Using strains adapted to wide range of temperature would be beneficial for microalgae cultivation at different time of the year.

In the present study, Chaetoceros sp. FIKU035 was found to be able to grow in a wide range of temperatures, from 25 to 40 °C (Eurythermal species) similar to findings of a previous study by Ras et al. (2013). Growth of T. suecica FIKU032 and Nannochloropsis sp. FIKU036 did not occur above 35 and 30 °C, respectively. These results were in accordance with previous reports of Nannochloropsis salina, which cannot grow at temperatures above 35 °C (Wagenen et al. 2012), Tetraselmis chui, which can grow between 15 and 30 °C (Chen et al. 2012), and Tetraselmis subcordiformis and Nannochloropsis oculata, which can grow between the ranges of 15–30 and 20–35 °C, respectively (Wei et al. 2015). In addition, temperature was observed to have effects on specific growth rate and biomass. The specific growth rate and biomass of Chaetoceros sp. FIKU035 and Nannochloropsis sp. FIKU036 both decreased with increasing temperature. The biomass productivity of T. suecica FIKU032 was lower than Chaetoceros sp. FIKU035 at 30 °C. The best biomass productivity was found for Chaetoceros sp. FIKU035 cultured at 25–30 °C. However, these results were not significantly different from T. suecica FIKU032 cultured at 30 °C. Temperature affects microalgae growth due to changes of cell metabolic activities and activity of important enzymes, such as ribulose-1,5-bisphosphate carboxylase/oxygenase (Rubisco), an essential enzyme in photosynthesis (Feller et al. 1998; Leggat et al. 2004; Wei et al. 2015). Fogg and Thake (1987) reported that the specific growth rate of microalgae declined when cultured at high temperature, due to increasing respiration.

It has been reported that lipid content and productivity of microalgae are dependent on growth conditions such as growth phase, medium composition, irradiance and temperature. In this study, the lipid content of Chaetoceros sp. FIKU035 and Nannochloropsis sp. FIKU036 significantly decreased with increasing temperature. This was in agreement with previous reports that lipid content of microalgae decreased when cultured at extremely low or high temperatures (Aaroson 1973; Opute 1974; Renaud et al. 1995). There have also been reports that the lipid contents of Chaetoceros sp., C. calcitrans and C. simplex decreased with increasing temperature (Renaud et al. 2002). In contrast, Wei et al. (2015) reported that the lipid content of N. oculata and T. subcordiformis increased with increasing temperature. However, beyond the optimal temperature, lipids of microalgae are known to decrease due to stress on photosystem II activity (Sheng et al. 2011). Thus, it can be said that the effect of temperature on growth rate, lipid content and lipid productivity of microalgae is species-specific.

Temperature also has an effect on fatty acid composition and biodiesel properties (Converti et al. 2009; Ramos et al. 2009; Islam et al. 2013; Knothe 2013). In this study, the PUFA content of T. suecica FIKU032 and Nannochloropsis sp. FIKU036 increased with increasing temperature. These results contrast those of a previous study that reported that some microalgae respond to a decrease in temperature by increasing the ratio of unsaturated fatty acids. Enhanced stability and fluidity of cellular membranes, particularly thylakoid membranes (through increased levels of unsaturated fatty acid in membrane lipids), protect the photosynthetic machinery from photoinhibition at low temperatures. Conversely, the microalgae cultured at a high temperature contained a lower content of unsaturated fatty acid (Renaud et al. 2002; Hu 2003). In addition, there was no significant difference in PUFA content in Chaetoceros sp. FIKU035 over the experimental temperature range.

In an assessment of general biodiesel properties, the fatty acid composition of microalgae is an important parameter that has to be considered. Commonly, palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1), linoleic acid (C18:2) and linolenic acid (C18:3) are strong candidates for suitable biodiesel production (Knothe 2008). In this study, Chaetoceros sp. FIKU035 cultured at 25 and 30 °C showed fatty acid profiles that are suitable for biodiesel production due to high content SFAs and MUFAs (more than 80% of FAMEs). MUFAs (i.e., C16:1 and C18:1) are advantageous over SFAs and PUFAs for their desirable oxidative stability, cold flow and combustion properties (Knothe 2009). A certain amount of PUFA can have positive impact on the biodiesel flow properties, especially during cold weather, but can have adverse effects on oxidative stability (Knothe 2008). However, Chaetoceros sp. FIKU035 exhibited a low content of PUFAs (~10–14% of total FAMEs). The fatty acid composition of Chaetoceros sp. FIKU035 was in accordance with a previous report by Wang et al. (2014) in that the dominant fatty acid of Chaetoceros muelleri were C14:0, C16:0 and C16:1, while the PUFA content was only 10–16% of total FAMEs. This predominance of short chain fatty acid (C14-C18) and low percentage of PUFAs are very significant for the potential of Chaetoceros sp. FIKU035 for the biodiesel production.

These findings support previous reports that short chain fatty acids, which contain high SFAs and MUFAs, are suitable for biodiesel production by having increased energy yield, oxidative and thermal stability and higher cetane number (Monyem et al. 2000; Knothe 2007, 2008, 2009). However, lipids dominated by these fatty acids are prone to solidify at low temperature. Lipids with high PUFA content provide a poor cetane number and oxidative stability (Ramos et al. 2009; Hoekman et al. 2012). A low cetane number causes longer ignition delay time (Gopinath et al. 2009). In addition, poor oxidative stability increases viscosity, as well as gum formation and sediment in biodiesel (Knothe 2005). In this study, the cold filter plugging points of Chaetoceros sp. FIKU035 at 40 °C and of Nannochloropsis sp. FIKU036 at 30 and 35 °C were not in accordance with accepted standards due to accumulated long chain saturated fatty acids. Too high of a cold filter plugging point in biodiesel leads to wax formation and engine starving due to reduced fuel flow (Hoekman et al. 2012).

This study revealed that the specific growth rate, biomass and lipid productivity, fatty acid composition and biodiesel properties of Chaetoceros sp. FIKU035, T. suecica FIKU032 and Nannochloropsis sp. FIKU036 varied with the temperature of cultivation. The highest specific growth rate, biomass and lipid productivity values were found for Chaetoceros sp. FIKU035. Moreover, the fatty acid profiles produced by this strain were suitable for biodiesel production. In addition, the biodiesel parameters were in accordance with European (EN14214) and American (ASTM D6751) standards. These finding suggest that Chaetoceros sp. FIKU035 can be considered as suitable species for outdoor cultivation for biodiesel production, as it can grow in wide range temperatures, up to 40 °C. Thus, it is suitable for the environment of Thailand and other tropical countries.

References

Aaroson S (1973) Effect of incubation temperature on the macromolecular and lipid content of the phytoflagellate Ochromonas danica. J Phycol 9:111–113

Acién FG, Fernández JM, Magán JJ, Molina E (2012) Production cost of real microalgae production plant and strategies to reduce it. Biotechnol Adv 30:1344–1353

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Borowitzka MA (2016) Algal physiology and large-scale outdoor cultures of microalgae. In: Borowitzka MA, Beardall J, Raven JA (eds) The physiology of microalgae. Springer, Dordrecht, pp 601–652

Borowitzka MA, Moheimani NR (2013) Sustainable biofuels from algae. Mitig Adapt Strat Glob Chang 18:13–25

Brennan L, Owende P (2010) Biofuels from microalgae – a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energy Rev 14:557–577

Chen SY, Pan LY, Hong MJ, Lee AC (2012) the effects of temperature on the growth of and ammonia uptake by marine microalgae. Bot Stud 53:125–133

Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26:126–131

Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M (2009) Effect of temperature and nitrogen concentration on growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process 48:1146–1151

Feller U, Crafts-Brandner SJ, Salvucci ME (1998) Moderately high temperatures inhibit ribulose-1, 5-bisphosphate carboxylase/oxygenase (Rubisco) activase-mediated activation of Rubisco. Plant Physiol 116:539–546

Fogg GE, Thake B (1987) Algae cultures and phytoplankton ecology. 3rd Edn, University of Wisconsin Press, Madison. 269 pp.

Gopinath A, Puhan S, Nagarajan G (2009) Relating the cetane number of biodiesel fuels to their fatty acid composition: a critical study. Proc Inst Mech Eng Part D J Automob Eng 223:565–583

Guillard RRL, Ryther JH (1962) Studies of marine planktonic diatoms. I. Cyclotella nana Hustedt, and Detonula confervacea (Cleve) Gran. Can J Microbiol 18:229–239

Harwood JL (1988) Fatty acid metabolism. Annu Rev Plant Physiol 39:101–138

Hochachka PW, Somero GN (1984) Biochemical adaptation. Princeton Univ Press, Princeton 560 pp

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M (2012) Review of biodiesel composition, properties and specifications. Renew Sust Energ Rev 16:143–169

Hu Q (2003) Environmental effects on cell composition. In: Richmond A (ed) Handbook of Microalgal culture: biotechnology and applied phycology. Wiley-Blackwell, Hoboken, pp 83–93

Ippoliti D, González A, Martín I, Sevilla JMF, Pistocchi R, Acién FG (2016) Outdoor production of Tisochrysis lutea in pilot-scale tubular photobioreactors. J Appl Phycol 28:3159–3166

Islam MA, Magnusson M, Brown RJ, Ayoko GA, Nabi Md N, Heimann K (2013) Microalgal species selection for biodiesel production based on fuel properties derived from fatty acid profiles. Energies 6:5676–5702

Jiang Y, Chen F (2000) Effects of temperature and temperature shift on docosahexaenoic acid production by the marine microalge Crypthecodinium cohnii. JAOCS 77:613–617

Kalayasiri P, Jeyashoke N, Krisnangkura K (1996) Survey of seed oils for use as diesel fuels. J Am Oil Chem Soc 73:471–474

Knothe G (2005) Oxidative stability of biodiesel: literature overview. In: Knothe G, Van Gerpen J, Krahl J (eds) The biodiesel handbook. AOCS Press, Urbana, pp 122–126

Knothe G (2007) Some aspects of biodiesel oxidative stability. Fuel Process Technol 88:669–677

Knothe G (2008) “Designer” biodiesel: optimizing fatty ester composition to improve fuel properites. Energy Fuel 22:1358–1364

Knothe G (2009) Improving biodiesel fuel properties by modifying fatty ester composition. Energy Environ Sci 2:759–766

Knothe G (2013) Production and properties of biodiesel from algal oils. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 207–221

Krisnangkura K (1986) A simple method for estimation of cetane index of vegetable oil methyl esters. J Am Oil Chem Soc 63:553–553

Lee DH (2011) Algal biodiesel economy and competition among bio-fuels. Bioresour Technol 102:43–49

Leggat W, Whitney SM, Yellowlees D (2004) Is coral bleaching due to the instability of the zooxanthellae dark reactions? Symbiosis 37:137–153

Markou G, Angelidaki I, Georgakakis D (2012) Microalgal carbohydrates: an overview of the factors influencing carbohydrates production and of main bioconversion technologies for production of biofuels. Appl Microbiol Biot 96:631–645

Meteorological Department (2015) The Climate of Thailand. Retrieved from https://www.tmd.go.th/en/archive/thailand_climate.pdf on 21 December 2016.

Montensen SH, Borsheim KY, Rainuzzo JR, Knutsen G (1988) Fatty acid and elemental composition of the marine diatom Chaetoceros gracills Shutt. Effects of silicate deprivation, temperature and light intensity. J Exp Mar Biol Ecol 122:173–185

Monyem A, Canakci M, Van Gerpen JH (2000) Investigation of biodiesel thermal stability under simulated in-use conditions. Appl Eng Agric 16:373–378

Oliveira MACL, Monteiro MPC, Robbs PG, Leite SGF (1999) Growth and chemical composition of Spirulina maxima and Spirulina platensis biomass at different temperatures. Aquacult Int 7:261–275

Opute FI (1974) Studies on fat accumulation in Nitzschia palea Kütz. Ann Bot 38:889–902

Prevot AF, Mordret FX (1976) Utilisation des Colonnes Capillaries de Verre Pour l’Analyse des Corps Gras par Chromotographie en Phase Gazeuse. Rev France Corps Gras 23:409–423

Ramírez-Verduzco LF, Rodríguez-Rodríguez JE, Jaramillo-Jacob AR (2012) Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 91:102–111

Ramos MJ, Fernandez CM, Casas A, Rodriguez L, Perez A (2009) Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour Technol 100:261–268

Ras M, Steyer J-P, Bernard O (2013) Temperature effect on microalgae: a crucial factor for outdoor production. Rev Environ Sci Bio/Tech 12:153–164

Raven JA, Geider RJ (1988) Temperature and algal growth. New Phytol 110:441–461

Renaud SM, Zhou HC, Parry DL, Think LV, Wao KC (1995) Effect of temperature on the growth, total lipid content and fatty acid composition of recently isolate tropical micro algae Isochrysis sp., Nitzshia closterium, N. paleacea and commercial species Isochrysis sp. (clone T.ISO). J Appl Phycol 7:595–602

Renaud SM, Thinh LV, Lambrinidis G, Parry DL (2002) Effect of temperature on growth, chemical composition and fatty acid composition of tropical Austalian microalgae grown in batch culture. Aquaculture 211:195–214

Sargent JR, Hederson RJ, Tocher DR (1989) The lipids. In: Halver J (ed) Fish nutrition, vol 2. Academic Press, London, pp 153–218

Sheng J, Kim HW, Badalamenti JP, Zhou C, Sridharakrishnan S, Krajimalnik-Brown R, Rittmann BE, Vannela R (2011) Effects of temperature shifts on growth rate and lipid characteristics of Synechocystis sp. PCC6803 in a bench-top photobioreactor. Bioresour Technol 102:11218–11225

Slade R, Bauen A (2013) Micro-algae cultivation for biofuels: cost, energy balance, environmental impacts and future prospects. Biomass Bioenergy 53:29–38

Song M, Pei H, Hu W, Ma G (2013) Evaluation of the potential of 10 microalgae strains for biodiesel production. Bioresour Technol 141:245–251

Wagenen JV, Miller TW, Hobbs S, Hook P, Crowe B, Huesemann M (2012) Effects of light and temperature on fatty acid production in Nannochloropsis salina. Energies 5:731–740

Wang XW, Liang JR, Luo CS, Chen CP, Gao YH (2014) Biomass, total lipid production, and fatty acid composition of the marine diatom Chaetoceros muelleri in response to different CO2 levels. Bioresour Technol 161:124–130

Wei L, Huang X, Huang Z (2015) Temperature effects on lipid properties of microalgae Tetraselmis subcordiformis and Nannochloropsis oculata as biofuel resources. Chin J Oceanol Limnol 33:99–106

Wigmosta MS, Coleman AM, Skaggs RJ, Huesemann MH, Lane LJ (2011) National microalgae biofuel production potential and resource demand. Water Resour Res 47:1–13

Wood AM, Everroad RC, Wingard LM (2005) Measuring growth rate. In: Andersen RA (ed) Algal culturing techniques. Elsevier Academic Press, NY, pp 269–285

Acknowledgements

This work was partially supported by the Center for Advanced Studies for Agriculture and Food, Institute for Advanced Studies, Kasetsart University, under the Higher Education Research Promotion and National Research University Project of Thailand, Office of the Higher Education Commission, Ministry of Education, Thailand (Grant No. CASAF170).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chaisutyakorn, P., Praiboon, J. & Kaewsuralikhit, C. The effect of temperature on growth and lipid and fatty acid composition on marine microalgae used for biodiesel production. J Appl Phycol 30, 37–45 (2018). https://doi.org/10.1007/s10811-017-1186-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-017-1186-3