Abstract

The objective of this study was to investigate the volatile organic compounds (VOCs) produced from heterotrophic cultivation of the cyanobacterium Phormidium autumnale with different sources of monosaccharides. The volatiles were isolated by headspace solid-phase micro-extraction in different residence times, separated by gas chromatography, and identified by mass spectrometry (SPME-GC/MS). The profile of volatiles contained a total of 44 volatile compounds when P. autumnale was grown heterotrophically on glucose and 35 when grown on fructose. A combined total of 68 compounds was identified and 11 volatiles were common to both extracts. The compound 3-methyl-butanol was identified among the major volatile compounds formed, reaching a concentration of 141.5 μg mg−1 dry weight for the glucose-grown cultures and 69.5 μg mg−1 for the fructose-grown cultures after 144 h. Many of the compounds detected during heterotrophic cultivation originated from terpenoids (β-ionone, β-cyclocitral, and 5,6-epoxy-β-ionone), fatty acids (hexanol, hexanal), or the 2-keto acid pathway (3-methyl-butanol, propanol, butanol).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The continual growth of the commercial application of primary and secondary biotechnology metabolites and more strict environmental legislations have led to interest in developing renewable forms to produce these compounds to apply in fine chemistry (Havel and Weuster-Botz 2006; Rastogi and Sinha 2009). Microalgae and cyanobacteria are considered some of the most promising feedstocks for sustainable supply of food and non-food industries (Draaisma et al. 2013; Borowitzka 2013).

Volatile organic compounds (VOCs) are secondary metabolites obtained from microalgae and cyanobacteria that could be used as an important alternative source of pharmaceutical products, aromas, and fragrances at a low cost (Havel and Weuster-Botz 2006). However, many undesirable taste and odor outbreaks have been associated with volatile organic compounds such as geosmin and 2-methylborneol, produced by microalgae and cyanobacteria, and these are typical off-flavor compounds (Fujise et al. 2010). The exploration of knowledge about the volatile profile of microalgae without off-flavor compounds is a possibility, and a scientific challenge is to apply these metabolites as chemical fine feedstocks.

Volatile organic compounds from microorganisms with commercial appeal include propanol, butanol, 3-methyl-butanol, hexanol, hexanal, β-cyclocitral, β-ionone, and 5,6-epoxy-β-damascenone (Berger 2009; Smith et al. 2010). Flavors from microorganisms compete with traditional agricultural sources. Elucidation of metabolic pathways and precursors and application of bioengineering have resulted in a set of more than 100 commercial chemical aromas derived from biotechnology (Berger 2009).

Biosynthesis of VOCs depends on the availability of building blocks such as carbon and nitrogen as energy provided by primary metabolism. Therefore, the availability and the kind of chemical structure of these building blocks have a major impact on the concentration of volatile organic compounds. Based on their biosynthetic origin, VOCs are classified into several classes, including terpenoids, fatty acid derivatives, and 2-keto acid pathway products (Dudareva et al. 2013).

The characterization of the volatile fraction of bioreactors can contribute to the establishment of bioconversion routes of substrates and enable the identification of potential applications of the bio-products formed (Jacob-Lopes et al. 2010; Jacob-Lopes and Franco 2013). The full use of the volatile fraction of microalgal/cyanobacterial biomass may represent an improvement in the supply of a large volume of inputs to many different types of industry. Clearly, there is a need for prospective studies on the volatile fraction of microalgal bioreactors, as well as the elucidation of metabolic pathways of formation of these compounds. Therefore, the aim of this study was to evaluate the volatile organic compound profile produced in heterotrophic cultures of the cyanobacterium Phormidium autumnale, using glucose and fructose as exogenous carbon source.

Materials and methods

Standards

The standards 2-butanone, 3-methy-2-butanone, 2-propanol, 2-methyl-1-propanol, 1-butanol, 2-heptanone, 3-hydroxy-2-butanone, 6-methyl-5-hepten-2-one, and β-ionone, as well as 3-octanol which was employed as an internal standard, were from Sigma-Aldrich (USA). The identities of volatile compounds were confirmed with retention indices and comparison with the MS spectral database.

Microorganism and culture conditions

Axenic cultures of P. autumnale were originally isolated from the Cuatro Cienegas desert (26° 59′ N, 102° 03′, W. Mexico). Stock cultures were propagated and maintained in solidified agar-agar (20 g L−1) containing BG11 medium (Rippka et al. 1979). The cultures were illuminated with 20-W fluorescent daylight-type tubes (Osram Sylvania, Brazil), located in a photoperiod chamber at a photon flux density of 15 μmol photons m−2 s−1 and a photoperiod of 12/12 h light/dark at 25 °C.. The photon flux density was adjusted and controlled by using a digital photometer (Spectronics, model XRP3000).

To obtain the inocula in liquid form, 1 mL of sterile medium was transferred to slants, and the colonies were scraped off and then homogenized with the aid of mixer tubes. The entire procedure was performed aseptically.

The cultivations were performed in a bubble column bioreactor (Francisco et al. 2014) operating under a batch regime, in 2.0 L of culture medium. The bioreactor including filtering units was sterilized by autoclaving at 121 °C for 40 min and then for 30 min containing the medium. The experimental conditions were as follows: initial concentration of inoculum 100 mg L−1, temperature 26 °C, pH adjusted to 7.6, and aeration of 0.1 volume of air per volume of culture per minute and absence of light. The culture medium consisted of BG11 medium supplemented with either glucose or fructose (12.5 g L−1) as exogenous carbon source.

Biomass concentration

Cell biomass was determined gravimetrically by filtering a known volume of culture through a 0.45-μm membrane filter (Millepore) and drying at 60 °C for 24 h before weighing.

Samples were collected over 7 days at 0, 24, 48, 72, 96, 120, and 144 h. The experiments were performed twice and in duplicate for each substrate. Therefore, data refer to the mean value of four repetitions.

Isolation of the volatile organic compounds

The volatile compounds were isolated using headspace solid-phase micro-extraction (HS-SPME) with a 50/30-μm divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber (Supelco, USA). Sample preparation was performed using 20 mL of culture medium, equally separated into two portions. These two portions were analysed by HS-SPME coupled with GC/MS for the quantitative determination of the volatile compounds. The aliquot was placed in a headspace septum vial containing 3 g of NaCl and 10 μL of an internal standard solution. The SPME fiber was inserted into the headspace of the vial containing the sample for 45 min at 40 °C, with agitation provided by a magnetic stir bar. After this period, the fiber was removed from the vial and immediately desorbed into the injector of the GC. The analytical procedure was performed twice and in duplicate. Therefore, data refer to the mean value of four repetitions.

GC/MS analysis

The volatile compounds were separated on a DB-Wax fused silica capillary column, 60 m in length, 0.25 mm id, and 0.25 μm film thickness (Chrompack Wax 52-CB) in a Shimadzu QP 2010 Plus gas chromatograph mass spectrometer. The initial oven temperature for the DB-Wax column was set at 35 °C for 5 min, followed by a linear increase at 5 °C min−1 to 220 °C, and this temperature was held for 5 min. For identification, an electron-impact ionization voltage of 70 eV was applied, and helium was used as the carrier gas.

The volatile compounds were identified by a comparison of their MS spectra with those provided by the computerized library (NIST MS Search). In addition, to assist with identification, each volatile linear retention index (LRI) was calculated using the retention times of a standard mixture of paraffin homologues prepared in hexane and compared with the LRI values published in the literature for columns with the same polarity (Acree and Arn 2015). Co-injection of the sample and the standard mixture provided experimental LRIs for the compounds, which were compared with those of standards analyzed under similar conditions.

Results and discussion

Table 1 shows the volatile organic compounds identified in all experiments. The cultivations with glucose had a total of 44 compounds, and those with fructose had 35 compounds. A combined total of 68 compounds was identified, and 11 volatiles were common to both experiments. The 68 compounds include 23 alcohols, 15 ketones, 10 aldehydes, 8 esters, 5 miscellaneous, 4 acids, and 3 hydrocarbons.

Figure 1 and Table 2 show the impact of the metabolic transformation as a function of time on the composition of volatile compounds in the heterotrophic bioreactor supplemented with glucose. Between 24 and 72 h of cultivation, there was a clear change in the volatile profile of the heterotrophic P. autumnale; all of the 24 news compounds were formed in this period.

One of the most abundant volatile groups produced in the experiment was ketones. Both 2,3-butanedione and dehydro-2-methyl-furanone were found in relatively high amounts, 180.6 and 146.8 μg mg−1, respectively, between 24 until 72 h of cultivation (Table 2). Ketones can be formed in many ways; aliphatic ketones might be products of lipid oxidation or degradation and methyl ketones (C3–C17), such as 6-methyl-5-hepten-2-one, could be formed from the oxidative cleavage of carotenoids. Rodrigues et al. (2014) identified β-carotene and echinenone as the major carotenoids in P. autumnale biomass, observing that these compounds have in common a neutral planar polyene chain. Acree and Arn (2015) reported the odor descriptors for ketones identified in P. autumnale cultivation: 2-butanone and 3-methyl-butanone (camphor), 2,3-butanedione (butter), 4-methyl-2-pentanone (fruity), 2-heptanone (soap), and β-ionone (violet, flowers).

As expected, a few aldehydes were formed (Table 2). These aldehydes can provide several notes to food matrices depending on the number of carbon atoms and the degree of saturation. The structures formed were C2 and C4 compounds; the short chain linear aldehydes are often derived from chemical lipid oxidation and feature a green-like, fruit-like, and malt-like odor (Durme et al. 2013). Decanal (peak 40) is the second major compound in 0 h of residence time (229.80 μg mg−1). Losses of 99.1 % of this compound are evidenced throughout cultivation. The primary barrier to overproduction of aldehydes in microorganisms is the rapid conversion of the desired aldehydes into alcohols by numerous endogenous enzymes (Kunjapur et al. 2014).

All alcohols formed are short chain linear (C3–C5) compounds. These compounds are a chemical signature of cyanobacteria and have been confirmed in studies involving the identification of organic volatiles in these microorganisms (Ozaki et al. 2008; Sun et al. 2012; Durme et al. 2013; ). The biosynthesis of peaks 13 and 26 is known to be generated from 2-keto acid; these keto acids are intermediates in the amino acid biosynthesis pathways and can be converted into alcohol by alcohol dehydrogenases (Dickinson 1996).

All esters identified in the volatile profile of P. autumnale have sweet fruity flavors (Table 1). These compounds are widely applied in food industries (Berger 2009; Sun et al. 2012). Although it has been reported in the literature that Phormidium produces dibutyl-phthalate, regarded as a toxic component, this compound was not detected in this study, which enhances the commercial potential of this technological route (Sun et al. 2012).

Acetic acid was the most abundant of the acid compounds identified, followed by butanoic acid (29.9 μg mg−1 at 72 h), isobutyric acid (21.1 μg mg−1 at 24 h), and isovaleric acid (8.7 μg mg−1 at 72 h).

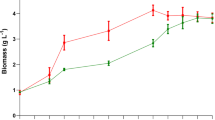

Figure 2 and Table 3 show the volatile profile of the cultivations with fructose. Between 48 and 96 h of cultivation, 20 new compounds were formed. The cultivations with fructose need more time to convert organic carbon into volatile compounds, compared to glucose. These results are in agreement with Francisco et al. (2014), who reported maximum specific growth rates of 0.76 and 0.57 day−1 for glucose and fructose, respectively, in the same experimental conditions.

Based on their biosynthetic origin, several unquestionable volatile organic compounds identified in P. autumnale were derived from different classes, including 2-keto acid derivatives, fatty acid derivatives, and terpenoids.

Almost all alcohols identified in the culture with fructose were formed between 48 and 96 h of the experiment. The compounds 2-propanol (peak 13), 1-butanol (peak 24), and 3-methyl-1-butanol (peak 26) are formed by deamination followed by decarboxylation of the branched-chain amino acid, such as l-leucine and l-isoleucine (Fujise et al. 2010; Ouchi et al. 1980) leading to the formation of a correspondent 2-ketocid (Fig. 3).

The alcohol 1-hexanol (peak 34) shows an increase in concentration until 96 h (45.1 μg mg−1), in the same period that the aldehyde hexanal (peak 18) was consumed. Volatile organic compounds like hexanol and hexanal are fatty acid derivates from the C18 unsaturated fatty acids, linoleic or linolenic acid (Fig. 3). Biosynthesis of these compounds is based on acetyl-CoA, which is generated from pyruvate, the final product of the penthose phosphate pathway. The lipoxygenase pathway forms 9-hydroperoxy and 13-hydroperoxy intermediates. The hydroperoxide lyase branch converts both hydroperoxides into C6 and C9 aldehydes, which are reduced to alcohols by dehydrogenases (Gigot et al. 2010).

The other aldehyde formed (3-methylbutanal) also has been found in other microalgae species (Sun et al. 2012; Durme et al. 2013), and the major aldehyde produced was acetaldehyde (41.8 μg mg−1) at 48 h; this compound shows an attractive odor description (fruit) for the food industry.

β-cyclocitral (peak 49), β-ionone (peak 61), and 5,6-epoxy-β-ionone (peak 66) seem to be important volatile organic compounds in some microalgae such as Chlorella vulgaris and Scenedesmus sp. (Rzama et al. 1995; Durme et al. 2013). β-cyclocitral was formed until 96 h (2 μg mg−1) and disappeared in 144 h, while β-ionone decreased and 5,6-epoxy-β-ionone was formed during the whole experiment. These compounds are produced by the terpenoid biosynthetic pathway. β-cyclocitral can be formed from the enzymatic cleavage of the double bond between carbons 7 and 8 of β-carotene (Fig. 3). β-ionone is produced by enzymatic cleavage of the double bond between carbons 9 and 10 of the same carotenoid (Donadio et al. 2011; Dudareva et al. 2013). Ketone 5,6-epoxy-β-ionone is a product from the oxidative reaction of another ketone, β-ionone, and this explains the decrease in concentration of β-ionone while there is an increase of 5,6-epoxy-β-ionone over the experimental time (Table 3).

The experiment with fructose produced fewer esters than glucose—just isobutyl acetate (peak 23), with the highest formation at 96 h (1.2 μg mg−1) and odor description pungent and fruity.

Finally, the descriptor odor of the compounds detected in experiments with glucose or fructose was mainly classified as fruity, spice, and floral compounds, and no compound off-flavor compound was identified in heterotrophic cultivation of P. autumnale.

The cultivation on glucose produced more kinds of volatile compounds in less time when compared with the cultivation with fructose. This information could be correlated with the carbon balance of the system, considered in terms of conversion of organic carbon into biomass (Francisco et al. 2014).

Conclusion

Phormidium autumnale can produce a variety of industrially interesting volatile compounds, and the knowledge about the biosynthesis of these structures from microalgae/cyanobacteria might prove useful to help elucidated ways to the application of these biobased feedstocks for both food and non-food industries.

References

Acree T, Arn H (2015) Flavornet and human odor space. Last accessed on 22 February 2015, http://www.flavornet.org

Berger RG (2009) Biotechnology of flavours—the next generation. Biotech Lett 31:1651–1659

Borowitzka MA (2013) High-value products from microalgae—their development and commercialisation. J Appl Phycol 25:743–756

Dickinson JR (1996) ‘Fusel’ alcohols induce hyphal-like extensions and pseudohyphal formation in yeasts. Microbiology 142:1391–1397

Donadio C, Bialecki A, Valla A, Dufossé L (2011) Carotenoid-derived aroma compounds detected and identified in brines and speciality sea salts (fleur de sel) produced in solar salterns from Saint-Armel (France). J Food Comp Anal 24:801–810

Draaisma RB, Wijffels RH, Slegers PM, Brentner LB, Roy A, Barbosa MJ (2013) Food commodities from microalgae. Curr Opin Biotech 24:169–177

Dudareva N, Klempien A, Muhlemann JK, Kaplan I (2013) Biosynthesis, function and metabolic engineering of plant volatile organic compounds. New Phytol 198:16–32

Durme JV, Goiris K, Winne A, De Cooman L, Muylaert K (2013) Evaluation of the volatile composition and sensory properties of five species of microalgae. J Agric Food Chem 61:10881–10890

Francisco EC, Franco TT, Wagner R, Jacob-Lopes E (2014) Assessment of different carbohydrates as exogenous carbon source in cultivation of cyanobacteria. Bioproc Biosyst Eng 1:2–11

Fujise D, Tsuji K, Fukushima N, Kawai K, Harada K (2010) Analytical aspects of cyanobacterial volatile organic compounds for investigation of their production behavior. J Chromatogr A 1217:6122–6125

Gigot C, Ongena M, Fauconnier ML, Wathelet JP, Jardin PD, Thonart P (2010) The lipoxygenase metabolic pathway in plants: potential for industrial production of natural green leaf volatiles. Biotechnol Agron Soc Environ 14:451–460

Havel J, Weuster-Botz D (2006) Comparative study of cyanobacteria as biocatalysts for the asymmetric synthesis of chiral building blocks. Eng Life Sci 6:175–179

Jacob-Lopes E, Franco TT (2013) From oil refinery to microalgal biorefinery. J CO2 Utilization 2:1–7

Jacob-Lopes E, Scoparo CHG, Queiroz MI, Franco TT (2010) Biotransformations of carbon dioxide in photobioreactors. Energ Convers Manag 51:894–900

Kunjapur AM, Tarasova Y, Prather LJ (2014) Synthesis and accumulation of aromatic aldehydes in an engineered strain of Escherichia coli. J Am Chem Soc 136:11644–11654

Ouchi K, Yamamoto Y, Takagishi M, Akiyama H (1980) Regulation of isoamyl alcohol formation via Ehrlich pathway in Saccharomyces cerevisiae. J Ferment Technol Japan 58:301–309

Ozaki K, Ohta A, Iwata C, Horikawa A, Tsuji A, Ito E, Yoshitomo I, Harada KI (2008) Lysis of cyanobacteria with volatile organic compounds. Chemosphere 71:1531–1538

Rastogi RR, Sinha RP (2009) Biotechnological and industrial significance of cyanobacterial secondary metabolites. Biotechnol Adv 27:521–539

Rippka R, Deruelles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Rodrigues DB, Flores EMM, Barin JS, Mercadante AZ, Jacob-Lopes E, Zepka LQ (2014) Production of carotenoids from microalgae cultivated using agroindustrial wastes. Food Res Int 65:144–148

Rzama A, Benharref A, Arrreguy B, Dufourc EJ (1995) Volatile compounds of green microalgae grown on reused wastewater. Phytochemistry 38:1375–1379

Smith KM, Cho KM, Liao JC (2010) Engineering Corynebacterium glutamicum for isobutanol production. Appl Microbiol Biotechnol 87:1045–1055

Sun SM, Chung GH, Shin TS (2012) Volatile compounds of the green alga, Capsosiphon fulvescens. J Appl Phycol 24:1003–1013

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santos, A.B., Fernandes, A.S., Wagner, R. et al. Biogeneration of volatile organic compounds produced by Phormidium autumnale in heterotrophic bioreactor. J Appl Phycol 28, 1561–1570 (2016). https://doi.org/10.1007/s10811-015-0740-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-015-0740-0