Abstract

In this work the adsorption and corrosion inhibition conduct of chalcone oxime derivatives on carbon steel in 0.5 M sulfuric acid solution at various temperatures (293, 303, 313, and 323 K) were investigated through weight loss measurements, potentiodynamic polarization, and electrochemical impedance spectroscopy. Results reveal that CO–H and CO–OMe exhibit an excellent inhibition efficiency of 95 and 96% at a concentration of 4.48 × 10−4 M and 293 K, respectively. The compounds are classified as mixed type inhibitors. Moreover, the influence of temperature and the activation parameters disclose that CO–H and CO–OMe are chemisorbed on the carbon steel surface. The adsorption of CO–H and CO–OMe follows Langmuir isotherm. The surface morphology was evaluated using scanning electron microscopy (SEM) and the adsorption behavior was analyzed by UV–visible. MD simulation data show good agreement with experimental results.

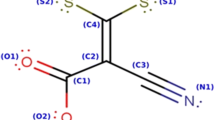

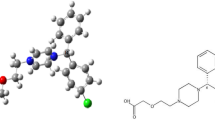

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Steel has a favorable role owing to its superior technical characteristics. Nevertheless, it has the major drawback of possessing a fairly strong reactivity with the surrounding environment, which contributes more or less to their demise [1,2,3].Metal corrosion is a phenomenon in which metals and alloys tend to return to their original state of oxide, sulfide, carbonate, or any other salt that is more stable under the influence of chemical reagents or environmental agents [4, 5]. Petroleum corrosion is certainly much more common than elsewhere, considering the complexity of the conditions faced and the manufacturing situations in which prevention is practiced [6, 7]. Petroleum sites are the key victims of corrosion phenomena, particularly when utilizing acids that are frequently used in this industry, particular H2SO4 and HCl, in steel pickling, chemical washing, and boiler decaling [8,9,10,11]. Organic inhibitors, whose mode of action usually comes from their adsorption on the metal surface, are more commonly used to solve this unfavorable tendency owing to their excellent biodegradability, easy availability, and non-toxic nature [12, 13]. Such compounds must fulfill other requirements: prevent the metal dissolution, slow the acid action, and remain stable at low concentrations [14,15,16,17].Successful organic inhibitors usually have in their structure either N, S, or O atoms and π-electrons in triple or conjugate double bonds [18,19,20].

Chalcone oxime has been used as selective retinoid receptor agonists RARγ, and tyrosinase inhibitors, and also applied to synthesize isoxazolines and isoxazoles, both of which are heterocycles very useful in organic and medicinal chemistry [21, 22]. Until now there is no research on the usage of chalcone oxime as a corrosion inhibitor, as well the cheap and straightforward synthesis of the product. Thus, in this situation, the investigation seems to be a significant study.

In this paper, chalcone was synthesized by the Claisen–Schmidt reaction and chalcone oxime derivatives via the condensation of chalcone and hydroxylamine hydrochloride (Scheme 1). The compounds inhibitory effect was inspected against the corrosion of carbon steel in 0.5 M H2SO4 solution at different temperatures (293–323 K). Various chemical and electrochemical techniques were used in this perspective. The surface morphology was examined using scanning electron microscopy to reveal the nature of the protective layer developed on carbon steel substrate. UV–visible technique was used to understand the adsorption action of the synthesized inhibitors over the carbon steel surface. To gain basic findings about interactions and surface adsorption of CO–H and CO–OMe, molecular dynamics (MD) simulation simulations were applied.

2 Materials and measurements

2.1 Preparation of chalcone 3 and chalcone oxime 4

-

Synthesis of chalcone

In a round bottom flask (50 mL), placed in an ice bath, 20 mL of EtOH, 10 mmol of acetophenone 1 (11 mmol) of benzaldehyde derivatives 2 and 15 mL of 10% NaOH solution were added. Then kept on magnetic stirring at 40 °C for 4 h. The mixture was cooled slowly and left in freezer for 48 h and filtered under vacuum. The crude product was recrystallized from ethanol [23].

-

Synthesis of chalcone oxime

A mixture of chalcone derivatives 3 (1 mmol), hydroxylamine hydrochloride (3 mmol), potassium carbonate (1 mmol), and anhydrous sodium sulfate (1.5 mmol) was refluxed in ethyl acetate (15 mL). After the reaction completion, the mixture was filtered, and the solvent was evaporated under reduced pressure. Then distilled water (15 mL) and dichloromethane (15 mL × 3) were added to extract organic compounds. The organic extracts were combined, dried over anhydrous MgSO4, filtered, and concentrated under reduced pressure. The crude mixture was obtained and purified by silica gel column chromatography eluted with a mixture of n-hexane–EtOAC (80/20, v/v) to afford pure product 4 [24].

2.2 Physical and spectroscopic data for chalcone oxime

1,3-diphenylprop-2-en-1-one oxime (CO–H); white solid, yield: 93%; mp 90–91 °C; 1H NMR (300 Hz, CDCl3): δ (ppm) 11.29 (s, 1H, OH), 7.78–7.56 (m, 4H), 7.46–7.31 (m, 6H), 7.29–6.38 (m, 2H). 13C NMR (75 Hz, CDCl3): δ (ppm) 157.74 (C=N); 139.76 (CH–CAr), 137.04 (CAr); 136.19 (Cq–CH=CH); 134.79 (Cq–C=N); 129.25–125.74 (CAr); 117.15 (CH=CH–Cq). IR (KBr) cm−1: 3590 (OH); 2985 (CH); 1620 (C=N); 1514 (C=C); 945 (N–O).

4-methoxyphenyl-1-phenylprop-2-en-1-one oxime (CO–OMe); white solid, yield: 88%; mp117–118 °C 1H NMR (300 MHz, CDCl3):δppm: 10.98 (s, 1H), 7.61–7.40 (m, 8H), 7.30–7.11 (m, 2H), 6.95–6.85 (m, 2H), 3.80 (s, 3H).13C NMR (75 MHz, CDCl3):δppm: 161.33 (Cq–O) 154.07 (C=N);136.29 (CH–CAr); 131.57 (Cq–CN), 130.85 (Cq–CH=CH); 128.62 (CAr); 128.60 (CAr); 127.24 (CAr); 123.18 (CH–CN); 114.28 (CAr); 55.31 (C–O).IR (KBr) cm−1: 3600 (OH); 2995 (CH); 1640 (C=N); 1520 (C=C); 1310 (Ar–OMe).

2.3 Materials

The chemical composition of carbon steel operated as working electrode in this study is enclosed in Table 1. The corrosive solution (0.5 M H2SO4) was prepared by diluting an analytical reagent grade 98% H2SO4 with distilled water. In the meanwhile, various concentration gradients of chalcone oxime derivatives (1.12 × 10–4, 2.24 × 10–4, 3.36 × 10–4, 4.48 × 10–4 M) at temperatures of 293 K were prepared to assess inhibition efficiency. Before each test, the electrode was polished by empery paper (200, 600, 800, and 1200), then washed with distilled water, acetone and dried.

2.4 Weight loss measurements

Weight loss was accomplished by exposing carbon steel specimens to 100 mL of 0.5 M H2SO4 solution for 6 h with differing chalcone oxime derivatives concentrations at 293 K. The surface of specimens (1 cm × 1 cm × 0.3 cm) underwent polishing pre-treatment prior to each trial. Afterward, carbon steel was washed by hot ethanol, distilled water, and acetone to remove all organic and inorganic matter, and then the samples were weighed. The corrosion rates (ν) were computed according to the following equation [25]:

where ΔW denotes the average weight loss, S represents the sample surface area (cm2), t stands for the immersion time (h), νo and νdesignate the values of corrosion rate (mg cm–2 h–1) in uninhibited and inhibited media, respectively.

2.5 Electrochemical measurements

In this study, the electrochemical measurements in this study were performed using PGZ301 electrochemical workstation with a classical three-electrode system: Pt as the counter electrode, a saturated calomel reference electrode (SCE), and carbon steel as a working electrode (0.282 cm2). The carbon steel was maintained immersed in the corrosive medium until the open-circuit potential (OCP) was stabilized (40 min) before the electrochemical measurements. The potentiodynamic polarization (PDP) curves were plotted by a scan rate of 0.5 mV s–1 and the range of OCP ± 200 mV. The electrochemical impedance spectroscopy (EIS) was recorded at various frequencies between 100 kHz and 10 mHz in the OCP with an amplitude of 10 mV. The inhibition efficiency (η) was estimated using both techniques PDP and EIS as following [26, 27]:

\(i_{corr}^{0}\) and \(i_{corr}\) denote the corrosion current densities values in absence and presence of the inhibitory molecule, respectively.

where \(R_{p}^{b}\) and \(R_{p}^{i}\) are polarization resistances obtained in the blank and the inhibited solutions, respectively.

The surface coverage, θ is expressed as:

\(\eta_{P}\) is the inhibitory efficiency determined by PDP.

2.6 Scanning electron microscopic measurement (SEM) and electrolyte analysis

The surface of carbon steel was polished with abrasive papers of different grades (200–1200) and sprayed with water and acetone, then the carbon steel was immersed for 6 h in 0.5 M H2SO4 with and without adding 4.48 × 10–4 M of synthesized inhibitory molecules. The specimens were extracted from the study solution and rinsed with distilled water and dried. The SEM images were obtained on an SEM FEI FEG 450. Weight reduction testing electrolytes are subject to an evaluation by means of UV mini-1240/UV–VIS Spectrophotometer with a view to confirming the iron-inhibitor complex formation that could happen upon dipping steel in a sulfuric acid electrolyte comprising inhibitor molecules.

2.7 Molecular dynamics (MD) simulation details

The adsorbed inhibitors CO and CO-NO2neutral and unnatural forms on the metal surface was established using the MD simulation using Forcite module implemented in Materials Studio 8.0 software [28, 29]. The study of these interactions of the molecules with the Fe (1 1 0) surfaces was carried out from a simulation box (22.34 × 22.341 × 35.13 Å3) with periodic boundary conditions. The Fe (110) surface was presented with a 6-couche slab model in each layer representing a (9 × 9) unit cell. The constructed simulation box is emptied by 20.13 Å3. This vacuum is occupied by 500H2O, 10H3O+, 5 \(SO_{4}^{2 - }\) and the inhibitory molecule. The temperature of the simulated system of 293 K was controlled by the Andersen thermostat, NVT ensemble, with a simulation time of 400 ps, and a time step of 1.0 fs, all under the COMPASS force field [30].

3 Results and discussion

3.1 Weight loss measurements

The protection performance of CO–H and CO–OMe against carbon steel corrosion in 0.5 M H2SO4 at 293 K was calculated gravimetrically. Table 2 provides the values of corrosion rate and the inhibition activity. It can be noticed that the corrosion rate decreases with increasing CO–H and CO–OMe concentration. As a result, the inhibiting efficiency increases and reaches an inhibiting power of 93% and 95% in the presence of 4.48 × 10–4 M of CO–H and CO–OMe, respectively. The maximum protection efficiency for CO–OMe was due to the presence of electron donating methoxy group[31].This indicates that CO–H and CO–OMe covered the carbon steel surface through the adsorption and from it prevent the attack by the corrosive solution on the surface[32].The inhibition activity can be explained by the following equations[33]:

The iron dissolution reaction.

The inhibition mechanism

First of all, the protonation of CO

3.2 Potentiodynamic polarization (PDP)

PDP curves were plotted for carbon steel in H2SO4 environment in with and without different concentrations of CO–H and CO–OMe at 293 K. As seen in Fig. 1, the cathodic curves are in the form of a Tafel line, indicating that the H+ reduction reaction on the steel surface takes place according to a pure activation mechanism [34]. As seen in Fig. 1, the addition of the CO–H and CO–OMe to the acid solution caused a significant reduction in the anodic and cathodic current densities. Concerning anodic polarization plots and especially in the higher concentrations for CO–H and CO–OMe inhibitors, it should be noted that one areas (1, and 2) are observed, which show the inhibited area, and uninhibited area, respectively. With augmenting anodic potentials, the anodic currents augmented with anodic Tafel slope βa1 in area 1. Next, for the rest of potential values, the desorption potential (Edsp), the anodic currents rise sharply and dissolve at βa2 slope in area 2 and stabilized until the end forming a considerable flat. This flat can be ascribed to the shift of adsorption–desorption equilibrium toward the desorption of CO–H and CO–OMe molecules on the electrode surface [35].

Examination of Table 3 leads to the conclusion that the corrosion current densities in presence of the inhibitor are lower than those found in the blank test solution. It can be suggested that the inhibitors adsorb first on the carbon steel surface before acting by simple blocking through its active sites. Furthermore, on may notice that the corrosion potential gap is less than 85 mV for all concentrations and that both the anodic and cathodic partial currents are also reduced. These outcomes demonstrate the mixed nature with an anodic predominance of the inhibitors under study [36, 37], and show that the inhibitors CO–H and CO–OMe reduces both rates of the anodic dissolution of carbon steel and the reduction of H+.

The fact that the Tafel slopes (βa and βc) do not present a defined behavior pattern with respect to the blank again support the claim that the adsorption process of CO–H and CO–OMe on carbon steel surface in 0.5 M H2SO4 solution is due to the blockage of active sites by the CO–H and CO–OMe compounds.

3.3 Electrochemical impedance spectroscopy

The study of electrochemical impedance diagrams at the corrosion potential for different concentrations was conducted to complete the understanding of the corrosion mechanisms of carbon steel and their prohibition in 0.5 M H2SO4 medium. From Fig. 2, one may see that the recorded impedance spectra consist of a unique capacitive loop that is not a perfect semicircle, which is attributed to the dispersion of the interfacial impedance frequency owed to the heterogeneity of the electrode surface [38, 39]. This heterogeneity may be the result of roughness, dislocations, impurities, adsorption, and can also be caused by the electrode's surface [40]. In general, this type of spectrum is assigned to a charge transfer mechanism taking place on a heterogeneous and irregular substrate [41].

Table 4 exhibits the data achieved following experimental results simulation with an equivalent circuit described in Fig. 2. In the 0.5 M H2SO4 alone and with 1.12 × 10–4, 2.24 × 10–4, 3.36 × 10–4, and 4.48 × 10–4 M of CO–H and CO–OMe, the circuit consisted of an electrolyte resistance (Re) in series with a polarization resistance (Rp) that is in parallel with a constant phase element (CPE), as illustrated in Fig. 2. The CPE is inserted to substitute a double layer capacitance (Cdl) to provide a more precise fit. The impedance of the CPE is established as [42]:

where A is the CPE modulus and n is a measure that reflects a deviation from the ideal behavior ranged from − 1 to 1. Besides, the CPE is linked with the double layer capacitance (Cdl) by the next relationship [42]:

The chi-squared was utilized to appraise the precision of the fitting outcomes, the small chi-squared values (Table 4) acquired for all the outcomes show that the fitted results have a great concurrence with the experimental findings. The estimation of A for the reference electrolyte is larger than that of inhibited electrolyte; this proposes that the CO–H and CO–OMe molecules interacted with the electrode surface, thus reducing the destruction of exposed sites of the electrode. The highest Rp (137.3 Ω cm2 for CO–H and 176.2 Ω cm2 for CO–OMe) have been found at 0.448 mM. Indeed, increases in Rp values and the simultaneous reduction in Cdl as CO–H and CO–OMe concentration increased demonstrates the substitution of corrosive ions and water molecules from substrate surface with the inhibitor molecules, which rise the thickness of the electrical double layer, and decreases the local dielectric constant, and it is a sign that CO–H and CO–OMe acted at the steel/acid interface [43]. However, the augments of the n value after the addition of CO–H and CO–OMe in 0.5 M H2SO4 electrolyte (0.856–0.884) relative to that achieved in reference electrolyte (0.853) can be interpreted as a certain diminution of the surface heterogeneity [44]. The corresponding values of ηEIS(%) for carbon steel in presence of CO–H are above that of CO–OMe and attaints 94% and 95% at 0.448 mM, respectively. These outcomes affirm once again that the synthesized compounds display potent inhibitive activity for carbon steel in 1/2 M H2SO4. It is worth noting that EIS trials confirm the superiority attached to the protection capacity of CO–H in relation to CO–OMe, which is consistent with the data of weight reduction and PDP measurement.

3.4 Effect of temperature

Temperature can be considered as one of the factors that likely alter both the behavior of the steel in an aggressive environment and the nature of the interaction between the metal and the inhibitory molecules. In order to analyze the temperature effect on the inhibitory efficacy of the molecules under study, the polarization curves were plotted for carbon steel in 0.5 M H2SO4 with and without the addition of the CO–H and CO–OMe, in the temperature range going from 293 to 323 K (Fig. 3). The electrochemical descriptors derived from the polarization curves and the inhibiting efficiency are given in the Table 5. It can be noted that the increase in temperature causes an increment of icorr value without and with the introduction of the inhibitors, while the values of the inhibiting efficiency are almost constant in the temperature range studied (Table 5). This reflects strong adsorption of CO–H and CO–OMe (chemisorption) [45]. To understand the adsorption ability of the examined inhibitors, a detailed investigation was done using different activation and adsorption parameters.

Activation thermodynamic parameters were assessed using Arrhenius and transition state equations [46, 47]:

where A represents a pre-exponential factor, ∆Ha designates the enthalpy, ∆Sa denotes the entropy of activation, T is the absolute temperature in Kelvin, h represents the Plank constant, N refers to the Avogadro number, and R is the molar gas constant. Figure 4 shows the Arrhenius plots of Ln icorr versus 1/T.

It can be seen that the plot yields straight lines with almost unitary regression coefficients, which reveals that the corrosion mechanism obeys to the Arrhenius equation with a slope equal to ( − Ea/R). The apparent activation energies (Ea) were computed and gathered in Table 6. The Ea values of CO–H and CO–OMe were found lower than those of the blank test solution which reveals that the adsorption occurs upon the active centers having the greatest energies, whereas the corrosion mechanism takes place on the active centers possessing the lowest energies, and form it CO–H and CO–OMe are typically chemisorbed on the carbon steel surface [48]. From Fig. 5, △Ha and △Sa values were calculated and are listed in Table 6.

The positive values of △Ha confirm that the formation of activated complex is an endothermic process, while the negative values of △Sa suggest that the order takes place, through transformation from reactants to activate complex [49, 50].

3.5 Adsorption isotherm

The action of organic inhibitors occurs generally through adsorption onto the metallic surface. This adsorption can be considered as a quasi-replacement process betwixt the organic product in the aqueous phase Org(aq) and H2O molecules following the reaction below [51]:

where x refers to the number of H2O molecules displaced by the inhibitory molecules. The investigation of the adsorption type and the determination of the thermodynamic parameters characterizing this adsorption often enable to elucidate the action mode of these inhibitory compounds. To identify the adsorption type corresponding to the inspected inhibitors, diverse forms of isotherms were tested: Langmuir, Frumkin, and Temkin. It can be noticed that the Langmuir isotherm has the correlation nearly equal to the unity (Fig. 6), which is expressed by the subsequent equation [52]:

where θ represents the surface coverage, C refers to the inhibitor’s concentration, and Kads denotes the adsorption equilibrium constant. The high values of Kads (Kads(CO–H) = 1.51 × 104 M−1and Kads(CO–OMe) = 2.12 × 104 M−1) are an indication of a stronger adsorption of CO–H and CO–OMe on the carbon steel surface [53, 54].In a way to obtain a deeper insight of the CO adsorption mechanism, the standard adsorption free energy (\(\Delta G_{ads}^{^\circ }\)) associated with Kads were estimated by this equation [55]:

where 55.5 represents the water concentration in mol/L, R denotes the universal gas constant, and T refers to the absolute temperature. The negative value of \(\Delta G_{ads}^{^\circ }\) indicates the stability of the double layer adsorbed on the metal surface [56]. According to literature, the values of \(\Delta G_{ads}^{^\circ }\) near to − 20 kJ/mol or more positive, corresponds to charged molecules/charged metal interaction (physical adsorption), whereas values close to − 40 kJ/mol or more negative implies a charge transfer between the organic molecules and the metallic substrate (chemisorption) [57, 58]. The values of \(\Delta G_{ads}^{^\circ }\) show that the studied inhibitors (\(\Delta G_{ads}^{^\circ }\)(CO–H) = − 33.2 kJ/mol and \(\Delta G_{ads}^{^\circ }\)(CO–OMe) = − 34.3 kJ/mol), is chemisorbed on the carbon steel surface and also uses the electrostatic interactions betwixt the charged molecules/charged metal interface, which points out to a mixed adsorption process [59].

3.6 Surface analysis

Scanning electron microscopy (SEM) was used to assess the morphology of the steel surface and confirm whether inhibition is owed to the development of an organic film on the surface. On one hand, the image of the electrode surface after an immersion time of 6 h at 293 K in 0.5 M H2SO4 (Fig. 7a), show that the dissolution of the metal makes the substrate very rough. While in the presence 4.48 × 10−4 M of CO–H or CO–OMe (Fig. 7a, c) the surface is covered with a platelet-shaped product reflecting the presence of an organic compound. From these observations, it seems that that the inhibition is owed to the development of an adherent and stable deposit that hinders the electrolyte's arrival to the steel surface [60, 61].

3.7 UV–visible spectroscopic studies

UV–visible spectroscopic measurements were conducted for 0.5 M H2SO4 solution in absence and presence of 4.48 × 10−4 M of either CO–H or CO–OMe before and after an immersion time of 48 h immersion of carbon steel at 293 K. The electronic absorption spectra (Fig. 8) of CO–H and CO–OMe before the steel immersion display a main visible band at 200, 238, 290, 315 nm, and 311,214 nm, respectively. The observed band can be attributed to π–π× transition related to aromatic ring and n–π× electronic transition from oxime groups. After 48 h of steel immersion, it can be seen that the UV–visible spectra of CO–H seem to change. In fact, there is a slight shift from 315 to 318 nm and disappear two bands at 238,290 nm with an appearance at 257 nm. For CO–OMe UV–visible spectra show a shift from 311 to 303 nm and an appearance band at 257 nm. These experimental findings may be assigned to the creation of a complex among Fe2+ and CO–H and/or CO–OMe in 0.5 M H2SO4 [62, 63].

3.8 MD simulation

In this last section, we have exploited molecular dynamics simulation as a very useful and efficient approach to clarify the reactivity or the action mode of the studied molecules in relation to the steel surface used in a sulfuric acid (H2SO4) environment [64,65,66]. Figures 9 and 10 give the preferred adsorption configuration of adsorbents in both neutral and protonated forms and their radial distribution functions (RDF) on the first well-ordered layer of iron. The configurations presented inform us about the adoption performance of each species on the simulated iron substrate. As visualized by each configuration (Figs. 9 and 10) that the compounds CO–H, CO–HH, CO–OMe, and CO–OMeH adsorb through all their skeletons onto the substrate, showing that these species favor the reduction of steel metal degradation of iron in H2SO4.

With respect to the overviews obtained from the RDF in Figs. 9 and 10, we can see that the values of the first peaks are lower than 3.5. These properties make it possible to reinforce the adsorption of the investigated inhibitor molecules on the surface of the metal; consequently, there is a reduction in the active sites on this area [67]. Additionally, protonation of CO–H, CO–H, and CO–OMe leads to the elongation of the studied bond lengths, which negatively influences on the rigidity of the adsorbed layer on the surface of the iron.

The interfacial interactions of species Co and CO–OMe no-charged and loaded forms with the Fe-surface were assessed using the interaction energy (E interaction) [68]:

Based on the simulation data to calculate the interaction energy (E interaction), the values of this descriptor are collected in Table 7. The negative value of E interaction confirms a large spontaneous adsorption of the selected molecules on the Fe (110) substrate [69,70,71,72]. Thus, neutral and protonated inhibitors tend to adsorb in the acid solution thermodynamically on the Fe of the steel in question. The minimum value of CO–OMe/Fe (110) shows that this molecule reacts strongly with the iron surface. This data validates the results obtained by the experiments.

Based on the MD simulation data, the neutral and protonated forms of the studied molecules adsorb in parallel on the steel surface, which shows a strong adsorption of these inhibitors. The nature of this adsorption can be chemical by the coordination bonds made between the electronic doublet of oxygen (O) of the tested inhibitors and the vacant orbitals found in the iron atoms (donation effect), the reverse effect (donation) allows the chemical adsorption to be reinforced. Physical adsorption occurs between the protonated nitrogen atom of the cationic forms (COHH and CO–OMeH) and the chlorine anions (Cl−) adsorbed on the iron surface. Therefore, if we assume that the inhibitor CO–OMe does not protonate in the acidic medium, in this case chemical adsorption will be in the majority which leads to a better inhibition against corrosion.

4 Conclusion

CO–H and CO–OMe were synthesized and characterized. Various techniques such as weight loss, PDP, and EIS were operated to evaluate the inhibitory efficacy on the carbon steel in 0.5 M H2SO4. Several conclusions are found and are summarized as follows:

-

CO–OMe has slight advantage as a good inhibitory efficacy of carbon steel in 0.5 M sulfuric acid solution than CO-H and both acts as a mixed type.

-

The temperature effect indicates the CO–H and CO–OMe is chemisorbed on the carbon steel surface.

-

The adsorption of CO–H and CO–OMe on the carbon steel surface obeys Langmuir isotherms.

-

The scanning electron microscopy (SEM) show the formation of a protective film on the surface of carbon steel.

-

UV–visible spectra shown the formation of a complex between Fe2+ and CO–H and/or CO–OMe in 0.5 M H2SO4

-

Molecular dynamics simulations reveal the strong interaction between the CO–H and CO–OMe and the iron surface.

References

Chung IM, Hemapriya V, Kim SH, Ponnusamy K, Arunadevi N, Chitra S, Prabakaran M, Gopiraman M (2021) Liriope platyphylla extract as a green inhibitor for mild steel corrosion in sulfuric acid medium. Chem Eng Commun 208(1):72–88

Elkholy AE, El-TaibHeakal F (2018) Electrochemical measurements and semi-empirical calculations for understanding adsorption of novel cationic Gemini surfactant on carbon steel in H2SO4 solution. J Mol Struct 1156:473–482

Barrahi M, Elhartiti H, El Mostaphi A, Chahboun N, Saadouni M, Salghi R, Zarrouk A, Ouhssine M (2019) Corrosion inhibition of mild steel by Fennel seeds (Foeniculum vulgare Mill) essential oil in 1 M hydrochloric acid solution. Int J Corros Scale Inhib 8(4):937–953

Abdel Nazeer A, Madkour M (2018) Potential use of smart coatings for corrosion protection of metals and alloys. J Mol Liq 253:11–22

Heusler KE, Landolt D, Trasatti S (1989) Electrochemical corrosion nomenclature. J Electroanal Chem Interfacial Electrochem 274:345–348

Soltani N, Tavakkoli N, Attaran A, Karimi B, Khayatkashani M (2020) Inhibitory effect of Pistacia khinjuk aerial part extract for carbon steel corrosion in sulfuric acid and hydrochloric acid solutions. Chem Pap 74:1799–1815

Chai C, Xu Y, Li D, Zhao X, Xu Y, Zhanga L, Wu Y (2019) Cysteamine modified polyaspartic acid as a new class of green corrosion inhibitor for mild steel in sulfuric acid medium: synthesis, electrochemical, surface study and theoretical calculation. Prog Org Coat 129:159–170

Laabaissi T, Benhiba F, Rouifi Z, Missioui M, Ourrak K, Oudda H, Ramli Y, Warad I, Allali M, Zarrouk A (2019) New quinoxaline derivative as a green corrosion inhibitor for mild steel in mild acidic medium: Electrochemical and theoretical studies. Int J Corros Scale Inhib 8(2):241–256

Nabah R, Benhiba F, Ramli Y, Ouakki M, Cherkaoui M, Oudda H, Touir R, Warad I, Zarrouk A (2018) Corrosion inhibition study of 5, 5-diphenylimidazolidine-2, 4-dione for mild steel corrosion in 1 M HCl solution: experimental, theoretical computational and Monte Carlo simulations studies. Anal Bioanal Electrochem 10(10):1375–1398

Ma X, Dang R, Kang Y, Gong Y, Luo J, Zhang Y, Fu J, Li C, Ma Y (2020) Electrochemical studies of expired drug (formoterol) as oilfield corrosion inhibitor for mild steel in H2SO4 media. Int J Electrochem Sci 15:1964–1981

Zarrok H, Zarrouk A, Salghi R, Ramli Y, Hammouti B, Assouag M, Essassi EM, Oudda H, Taleb M (2012) 3,7-Dimethylquinoxalin-2-(1H)-one for inhibition of acid corrosion of carbon steel. J Chem Pharm Res 4(12):5048–5055

Hamdani I, El Ouariachi E, Mokhtari O, Salhi A, Chahboun N, El Mahi B, Bouyanzer A, Zarrouk A, Hammouti B, Costa J (2015) Chemical constituents and corrosion inhibition of mild steel by the essential oil of thymus algeriensis in 1.0 M hydrochloric acid solution. Der Pharm Chem 7(8):252–264

El-Rabiei MM, Nady H, Zaki EG, Negem M (2019) Theoretical and experimental investigation of the synergistic infuence of tricine and iodide ions on the corrosion control of carbon steel in sulfuric acid electrolyte. J Bio Tribo Corros 5:103. https://doi.org/10.1007/s40735-019-0298-5

Rbaa M, Galai M, Abousalem AS, Lakhrissi B, EbnTouhami M, Warad I, Zarrouk A (2020) Synthetic, spectroscopic characterization, empirical and theoretical investigations on the corrosion inhibition characteristics of mild steel in molar hydrochloric acid by three novel 8-hydroxyquinoline derivatives. Ionics 26:503–522

Fergachi O, Benhiba F, Rbaa M, Ouakki M, Galai M, Touir R, Lakhrissi B, Oudda H, Ebn Touhami M (2019) Corrosion inhibition of ordinary steel in 5.0 M HCl medium by benzimidazole derivatives: electrochemical, UV–visible spectrometry, and DFT calculations. J Bio Tribo Corros 5:21. https://doi.org/10.1007/s40735-018-0215-3

El Faydy M, Rbaa M, Lakhrissi L, Lakhrissi B, Warad I, Zarrouk A, Obot IB (2019) Corrosion protection of carbon steel by two newly synthesized benzimidazol-2-ones substituted 8-hydroxyquinoline derivatives in 1 M HCl: experimental and theoretical study. Surf Interfaces 14:222–237

Guo L, Tan J, Kaya S, Leng S, Li Q, Zhang F (2020) Multidimensional insights into the corrosion inhibition of 3,3- dithiodipropionic acid on Q235 steel in H2SO4 medium: a combined experimental and in silico investigation. J Colloid Interface Sci 570:116–124

Zarrouk A, Hammouti B, Zarrok H, Salghi R, Dafali A, Bazzi Lh, Bammou L, Al-Deyab SS (2012) Electrochemical impedance spectroscopy and weight loss study for new pyridazine derivative as inhibitor for copper in nitric acid. Der Pharm Chem 4(1):337–346

Zarrok H, Al Mamari K, Zarrouk A, Salghi R, Hammouti B, Al-Deyab SS, Essassi EM, Bentiss F, Oudda H (2012) Gravimetric and electrochemical evaluation of 1-allyl-1Hindole-2,3-dione of carbon steel corrosion in hydrochloric acid. Int J Electrochem Sci 7:10338–10357

Louadi YE, Abrigach F, Bouyanzer A, Touzani R, El Assyry A, Zarrouk A, Hammouti B (2017) Theoretical and experimental studies on the corrosion inhibition potentials of two tetrakis pyrazole derivatives for mild steel in 10 M HCl. Port Electrochim Acta 35(3):159–178

Radhakrishnan S, Shimmon R, Conn C, Baker A (2015) Integrated kinetic studies and computational analysis on naphthyl chalcones as mushroom tyrosinase inhibitors. Bioorg Med Chem Lett 25(19):4085–4091

Xu X, Li J, Du C, Song Y (2011) Improved synthesis of 1,3-Diaryl-2-propen-1-one oxime in the presence of anhydrous sodium sulfate. Chin J Chem 29(12):2781–2784

Qian Y, Ma GY, Yang Y, Cheng K, Zheng QZ, Mao WJ, Shi L, Zhao J, Zhu HL (2010) Synthesis, molecular modeling and biological evaluation of dithiocarbamates as novel antitubulin agents. Bioorg Med Chem 18:4310–4316

Wang YT, Qina YJ, Zhang YL, LiY J, Rao B, Zhang YQ, Yang M, Jiang AQ, Qi JL, Zhu HL (2014) Synthesis, biological evaluation, and molecular docking studies of novel chalcone oxime derivatives as potential tubulin polymerization inhibitors. RSC Adv 4:32263–32275

Zarrok H, Zarrouk A, Salghi R, Oudda H, Hammouti B, Assouag M, Taleb M, EbnTouhami M, Bouachrine M, Boukhris S (2012) Gravimetricandquantumchemical studies of 1-[4-acetyl-2-(4- chlorophenyl)quinoxalin-1(4H)-yl]acetone as corrosion inhibitor for carbon steel in hydrochloric acid solution. J Chem Pharm Res 4(12):5056–5066

Tazouti A, Galai M, Touir R, EbnTouhami M, Zarrouk A, Ramli Y, Saraçoğlu M, Kaya S, Kandemirli F, Kaya C (2016) Experimental and theoretical studies for mild steel corrosion inhibition in 1.0 M HCl by three new quinoxalinone derivatives. J Mol Liq 221:815–832

Zarrouk A, Hammouti B, Dafali A, Zarrok H (2011) L-Cysteine methyl ester hydrochloride: a new corrosion inhibitor for copper in nitric acid. Der Pharma Chem 3(4):266–274

Echchihbi E, Nahlé A, Salim R, Benhiba F, Moussaif A, El-Hajjaji F, Oudda H, Guenbour A, Taleb M, Warad I, Zarrouk A (2020) Computational, MD simulation, SEM/EDX and experimental studies for understanding adsorption of benzimidazole derivatives as corrosion inhibitors in 10 M HCl solution. J Alloys Compd 844:155842

Accelrys (2016) Materials studio, revision 8.0. Accelrys Inc., San Diego

Andersen HC (1980) Molecular dynamics simulations at constant pressure and/or temperature. J Chem Phys 72:2384–2393

Benhiba F, Elaoufir Y, Belayachi M, Zarrok H, El Assyry A, Zarrouk A, Hammouti B, Ebenso EE, Guenbour A, Al Deyab SS, Oudda H (2014) Theoretical and experimental studies on the inhibition of 1,1’-(2-phenylquinoxaline 1,4-diyl)diethanone for the corrosion of carbon steel in 1.0 M HCl. Der Pharm Lett 6(4):306–318

Laamari MR, Benzakour J, Berrekhis F, Bakasse M, Villemin D (2012) Investigation of the effect of piperidin-1-yl-phosphonic acid on corrosion of iron in sulfuric acid. Arab J Chem 9(S2):S1218–S1224

Solmaz R, Mert ME, Kardaş G, Yazici B, Erbıl M (2008) Adsorption and corrosion inhibition effect of 1,1′-thiocarbonyldiimidazole on mild steel in H2SO4 solution and synergistic effect of iodide ion. Acta Phys Chim Sin 24:1185–1191

Derfouf H, Harek Y, Larabi L, Basirun WJ, Ladan M (2019) Corrosion inhibition activity of carbon steel in 1.0 M hydrochloric acid medium using hammada scoparia extract: gravimetric and electrochemical study. J Adhes Sci Technol 33(8):808–833

Li X, Xie X, Deng S, Du G (2014) Two phenylpyrimidine derivatives as new corrosion inhibitors for cold rolled steel in hydrochloric acid solution. Corros Sci 87:27–39

Khadraoui A, Khelifa A, Hadjmeliani M, Mehdaou R, Hachama K, Tidu A, Azari Z, Obot IB, Zarrouk A (2016) Extraction, characterization and anti-corrosion activity of Mentha pulegium oil: weight loss, electrochemical, thermodynamic and surface studies. J Mol Liq 216:724–731

Anusuya N, Saranya J, Sounthari P, Zarrouk A, Chitra S (2017) Corrosion inhibition and adsorption behaviour of some bis-pyrimidine derivatives on mild steel in acidic medium. J Mol Liq 225:406–417

Döner A, Solmaz R, Özcan M, Kardas G (2011) Experimental and theoretical studies of thiazoles as corrosion inhibitors for mild steel in sulphuric acid solution. Corros Sci 53:2902–2913

Bentiss F, Lebrini M, Vezin H, Chai F, Traisnel M, Lagrené M (2009) Enhanced corrosion resistance of carbon steel in normal sulfuric acid medium by some macrocyclic polyether compounds containing a 1,3,4-thiadiazole moiety: AC impedance and computational studies. Corros Sci 51:2165–2173

Boucherit L, Douadi T, Chafai N, Al-Noaimi M, Chafaa S (2018) The inhibition activity of 1,10–bis(2-formylphenyl)-1,4,7,10–tetraoxadecane (Ald) and its schiff base (L) on the corrosion of carbon steel in HCl: experimental and theoretical studies. Int J Electrochem Sci 13:3997–4025

Fiala A, Boukhedena W, Lemallem SE, Ladouani HB, Allal H (2019) Inhibition of carbon steel corrosion in HCl and H2SO4 solutions by ethyl 2-cyano-2-(1,3-dithian-2-ylidene) acetate. J Bio Tribo Corros 5:42. https://doi.org/10.1007/s40735-019-0237-5

Saranya J, Benhiba F, Anusuya N, Subbiah R, Zarrouk A, Chitra S (2020) Experimental and computational approaches on the pyran derivatives for acid corrosion. Colloids Surf A 603:125231

El Ouadi Y, Abrigach F, Bouyanzer A, Touzani R, Riant O, ElMahi B, El Assyry A, Radi S, Zarrouk A, Hammouti B (2015) Corrosion inhibition of mild steel by new N-heterocyclic compound in 1 M HCl: experimental and computational study. Der Pharma Chem 7(8):265–275

Mashuga ME, Olasunkanmi LO, Verma C, Sherif ESM, Ebenso EE (2020) Experimental and computational mediated illustration of effect of different substituents on adsorption tendency of phthalazinone derivatives on mild steel surface in acidic medium. J Mol Liq 305:112844

Boutouil A, Laamari MR, Elazhary I, Bahsis L, Anane H, Stiriba SE (2020) Towards a deeper understanding of the inhibition mechanism of a new 1,2,3-triazole derivative for mild steel corrosion in the hydrochloric acid solution using coupled experimental and theoretical methods. Mater Chem Phys 241:122420

El Faydy M, Galai M, EbnTouhami M, Obot IB, Lakhrissi B, Zarrouk A (2017) Anticorrosion potential of some 5-amino-8-hydroxyquinolines derivatives on carbon steel in hydrochloric acid solution: gravimetric, electrochemical, surface morphological, UV–visible, DFT and Monte Carlo simulations. J Mol Liq 248:1014–1027

Khattabi M, Benhiba F, Tabti S, Djedouani A, El Assyry A, Touzani R, Warad I, Oudda H, Zarrouk A (2019) Performance and computational studies of two soluble pyran derivatives as corrosion inhibitors for mild steel in HCl. J Mol Struct 1196:231–244

Shaban SM (2016) N-(3-(dimethyl benzyl ammonio) propyl) alkanamide chloride derivatives as corrosion inhibitors for mild steel in 1M HCl solution: experimental and theoretical investigation. RSC Adv 6:39784–39800

Shaban SM, Aiad I, El-Sukkary MM, Soliman EA, El-Awady MY (2015) Inhibition of mild steel corrosion in acidic medium by vanillin cationic surfactants. J Mol Liq 203:20–28

Kumar R, Yadav OS, Singh G (2017) Electrochemical and surface characterization of a new ecofriendly corrosion inhibitor for mild steel in acidic media: a cumulative study. J Mol Liq 237:413–427

Díaz-Cardenas MY, Valladares-Cisneros MG, Lagunas-Rivera S, Salinas-Bravo VM, Lopez-Sesenes R, Gonzalez-Rodríguez JG (2017) Peumusboldus extract as corrosion inhibitor for carbon steel in 0.5 M sulfuric acid. Green Chem Lett Rev 10(4):257–268

Zarrouk A, Hammouti B, Al-Deyab SS, Salghi R, Zarrok H, Jama C, Bentiss F (2012) Corrosion inhibition performance of 3,5-diamino-1,2,4-triazole for protection of copper in nitric acid solution. Int J Electrochem Sci 7:5997–6601

Zarrok H, Zarrouk A, Salghi R, Oudda H, Hammouti B, Ebn Touhami M, Bouachrine M, Boukhris S (2012) A combined experimental and theoretical study on the corrosion inhibition and adsorption behaviour of quinoxaline derivative during carbon steel corrosion in hydrochloric acid. Port Electrochim Acta 30(6):405–417

Rajendraprasad S, Ali S, Prasanna BM (2020) Electrochemical behavior of N1-(3-methylphenyl)piperidine-1,4-dicarboxamide as a corrosion inhibitor for soft-cast steel carbon steel in 1 M HCl. J Fail Anal Preven 20:235–241

Zarrok H, Salghi R, Zarrouk A, Hammouti B, Oudda H, Bazzi Lh, Bammou L, Al-Deyab SS (2012) Investigation of the inhibition effect of N-1-naphthylethylenediamine dihydrochloride monomethanolate on the C38 steel corrosion in 0.5M H2SO4. Der Pharma Chem 4(1):407–416

Singh A, Ansari KR, Kumar A, Liu W, Songsong C, Lin Y (2017) Electrochemical, surface and quantum chemical studies of novel imidazole derivatives as corrosion inhibitors for J55 steel in sweet corrosive environment. J Alloys Compd 712:121–133

Kharbach Y, Qachchachi FZ, Haoudi A, Tourabi M, Zarrouk A, Jama C, Olasunkanmi LO, Ebenso EE, Bentiss F (2017) Anticorrosion performance of three newly synthesized isatin derivatives on carbon steel in hydrochloric acid pickling environment: electrochemical, surface and theoretical studies. J Mol Liq 246:302–316

Salhi A, Tighadouini S, El-Massaoudi M, Elbelghiti M, Bouyanzer A, Radi S, El Barkany S, Bentiss F, Zarrouk A (2017) Keto-enol heterocycles as new compounds of corrosion inhibitors for carbon steel in 1 M HCl: weight loss, electrochemical and quantum chemical investigation. J Mol Liq 248:340–349

Solomon MM, Umoren SA (2016) In-situ preparation, characterization and anticorrosion property of polypropylene glycol/silver nanoparticles composite for mild steel corrosion in acid solution. J Colloid Interface Sci 462:29–41

Prabakarana M, Kima SH, Oha YT, Rajb V, Chung IM (2017) Anticorrosion properties of momilactone a isolated from rice hulls. J Ind Eng Chem 45:380–386

Saxena A, Prasad D, Haldhar R (2018) Use of Asparagus racemosus extract as green corrosion inhibitor for mild steel in 0.5 M H2SO4. J Mater Sci 53:8523–8535

Rbaa M, Fardioui M, Verma C, Abousalem AS, Galai M, Ebenso EE, Guedira T, Lakhrissi B, Warad I, Zarrouk A (2020) 8-Hydroxyquinoline based chitosan derived carbohydrate polymer as biodegradable and sustainable acid corrosion inhibitor for mild steel: experimental and computational analyses. Int J Biol Macromol 155:645–655

Cao S, Liu D, Zhang P, Yang L, Yang P, Lu H, Gui J (2017) Green Brönsted acid ionic liquids as novel corrosion inhibitors for carbon steel in acidic medium. Sci Rep 7:8773. https://doi.org/10.1038/s41598-017-07925-y

El Yaktini A, Lachiri A, El Faydy M, Benhiba F, Zarrok H, El Azzouzi M, Zertoubi M, Azzi M, Lakhrissi B, Zarrouk A (2018) Practical and theoretical study on the inhibitory inflences of new azomethine derivatives containing 8-hydroxyquinoline moiety for the corrosion of carbon steel in 1 M HCl. Orient J Chem 34(6):3016–3029

Cherrak K, Benhiba F, Sebbar NK, Essassi EM, Taleb M, Zarrouk A, Dafali A (2019) Corrosion inhibition of mild steel by new benzothiazine derivative in a hydrochloric acid solution: experimental evaluation and theoretical calculations. Chem Data Collect 22:100252

Rouifi Z, Benhiba F, El Faydy M, Laabaissi T, About H, Oudda H, Warad I, Guenbour A, Lakhrissi B, Zarrouk A (2019) Performance and computational studies of new soluble triazole as corrosion inhibitor for carbon steel in HCl. Chem Data Collect 22:100242

Benhiba F, Benzekri Z, Guenbour A, Tabyaoui M, Bellaouchou A, Boukhris S, Oudda H, Warad I, Zarrouk A (2020) Combined electronic/atomic level computational, surface (SEM/EDS), chemical and electrochemical studies of the mild steel surface by quinoxalines derivatives anti-corrosion properties in 1 mol. L-1 HCl solution. Chin J Chem Eng 28(5):1436–1458

Saha SK, Ghosh P, Hens A, Murmu NC, Banerjee P (2015) Density functional theory and molecular dynamics simulation study on corrosion inhibition performance of mild steel by mercapto-quinoline Schiff base corrosion inhibitor. Phys E 66:332–341

Rbaa M, Benhiba F, Dohare P, Lakhrissi L, Touir R, Lakhrissi B, Zarrouk A, Lakhrissi Y (2020) Synthesis of new epoxy glucose derivatives as a non-toxic corrosion inhibitors for carbon steel in molar HCl: experimental, DFT and MD simulation. Chem Data Collect 27:100394

Rahmani H, Alaoui KI, El Azzouzi M, Benhiba F, El Hallaoui A, Rais Z, Taleb M, Saady A, Labriti B, Aouniti A, Zarrouk A (2019) Corrosion assessement of mild steel in acid environment using novel triazole derivative as a anti-corrosion agent: a combined experimental and quantum chemical study. Chem Data Collect 24:100302

Olasunkanmi LO, Obot IB, Ebenso EE (2016) Adsorption and corrosion inhibition properties of N-{n-[1-R-5-(quinoxalin-6-yl)-4, 5-dihydropyrazol-3-yl] phenyl} methanesulfonamides on mild steel in 1 M HCl: experimental and theoretical studies. RSC Adv 6:86782–86797

Benhiba F, Hsissou R, Benzekri Z, Belghiti ME, Lamhamdi A, Bellaouchou A, Guenbour A, Boukhris S, Oudda H, Warad I, Zarrouk A (2020) Nitro substituent effect on the electronic behavior and inhibitory performance of two quinoxaline derivatives in relation to the corrosion of mild steel in 1 M HCl. J Mol Liq 312:113367

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thoume, A., Benhiba, F., Elmakssoudi, A. et al. Corrosion inhibition behavior of chalcone oxime derivatives on carbon steel in 0.5 M H2SO4. J Appl Electrochem 51, 1755–1770 (2021). https://doi.org/10.1007/s10800-021-01612-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-021-01612-7