Abstract

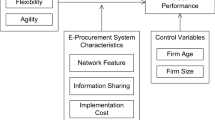

Despite extensive attention that researchers and practitioners have paid to supply chain digitalization, our understanding of how to leverage supply chain digitalization for superior supply chain performance remains limited. By adopting the theory of information processing, this research explores how supply chain digitalization affects supply chain performance through supply chain agility and how such relationships are moderated by environmental uncertainty. Using data collected from 143 companies in China, the current study finds the significant mediating role of supply chain agility and the moderating role of environmental uncertainty (environmental dynamism, munificence, and complexity). Furthermore, the mediating effect of supply chain agility on the relationship between supply chain digitalization and supply chain performance can be enhanced under high environmental dynamism and complexity. The research enhances the understanding of supply chain digitalization and provides managerial insights into how to leverage supply chain digitalization for improving supply chain performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Digitalization is considered as a significant factor in the development of supply chain into a new era [28, 29]. Supply chain digitalization refers to the process in which firm digitizes supply chain processes by using big data, cloud computing and other information technologies [9, 67]. It is a customer-centric, intelligent supply chain with global links and data driven by new technologies, so as to obtain more valuable products and services [51]. Under the condition of digitalization, firms are placed in the context of global connectivity and real-time data exchange [7], and thus facing the pressure of many uncertain factors brought by the complex market environment, which requires firms to have a faster and more efficient supply chain [71].

With the widespread application of digital technologies such as cloud computing and big data analysis, supply chain digitalization enhances the operational performance of all supply chain members and the links between them. Specifically, supply chain digitalization can help firms become more resilient and responsive, which enables them to reduce costs, improve profit margins, and ultimately improve their performance [1, 34, 58]. The intelligence and automation of the supply chain can shorten order processing lead times, reduce inventory costs, and enable joint product design and development with major suppliers, thus upgrading performance [71]. Besides, supply chain digitalization based on data-driven strategies can better understand and fulfill the changing requirements of customers, and help offer customized products and services reliably and at a cost [14]. Thus, we aim to examine whether and how supply chain digitalization influences supply chain performance.

Although most researchers have studied the direct impact of supply chain digitalization on its performance [2, 25], few studies have explored how supply chain digitalization effects its performance via specific intermediate mechanisms. Specifically, supply chain agility is the capability to adjust tactics and operations within its supply chain to respond to environmental changes, opportunities, and threats [23]. Supply chain digitalization brings tremendous opportunities which need to be seized by supply chain agility to cope with challenges in a rapidly changing market [12]. In this context, supply chain agility can share supply chain information in the process of digitalization in real time [11]. The supply chain can timely adjust the strategy according to the technical conditions to achieve the goal of improving performance [27, 62]. As such, we propose that supply chain agility might mediate the relationship between supply chain digitalization and supply chain performance.

Moreover, the supply chain is prone to external environmental interference, such as environmental uncertainty (dynamism, munificence, and complexity) [15, 55]. Information processing theory (IPT) states that an firm's information processing capabilities need to be aligned with its information requirements [38]. According to IPT, environmental uncertainty creates new information processing needs that are often difficult to address in traditional ways in digital context. However, it is unclear that whether supply chain digitalization and agility complement or substitute different external environments to influence performance. Some studies have proved that information processing capabilities should cater to the environmental needs [10, 59]. In a volatile or complex business environment, emerging digital technologies may increase the competitive pressure of firms, thereby burdening supply chain yields [35], under which supply chain agility is necessary for supply chain digitalization to improve performance. Contrarily, in stable or munificent environments, where external changes are infrequent and tend to be predictable and incremental, supply chain agility plays a minor role. Thus, we examine how the process of supply chain digitalization influencing performance through supply chain agility is moderated by environmental uncertainty.

Drawing on IPT, this study addresses the following research question: (1) how supply chain digitalization influences supply chain performance through supply chain agility, (2) how such relationships are moderated by the environmental uncertainty factors. 143 Chinese firms are surveyed by the paired survey method, and a moderated mediation model is established. Our study has the following contributions. First, we regard supply chain digitalization as a unified structure for a firm's information processing capabilities, and empirically examine a positive relationship between supply chain digitalization and its performance. While there is the ongoing debate on whether digital supply chain systems are good or bad for risk management [67], the current research contributes to confirming the importance of supply chain digitalization for improving supply chain performance. Second, our study explores the mediation mechanism of supply chain agility, which helps open the black box by explaining how supply chain digitalization impacts performance. Although there are other operational capabilities (i.e., flexibility, alignment and adaptation) [17], we examine the mediation mechanism of agility as it helps respond quickly and effectively to market changes. The results show that supply chain digitalization can improve supply chain agility, and consequently supply chain performance. Third, this study demonstrated the role of three dimensions of environmental uncertainty (environmental dynamics, environmental munificence, and environmental complexity) as a boundary condition that differently moderate the effect of supply chain digitalization on supply chain performance. Past studies have mainly examined and found different contingency effects of environmental uncertainty on relationships between supply chain integration and performance [66]. Although environmental uncertainty as a contextual factor for digital use or capabilities has received considerable attention [50, 64, 73], our research extends existing research by exploring the relationship between supply chain digitalization and supply chain performance when environmental uncertainty produces unknown and unfamiliar situations.

2 Theoretical framework

2.1 Information processing theory

Based on IPT [20], the entire supply chain can be viewed as an information-intensive process [49]. IPT shows the supply chain should improve the ability to create information processing and take steps to reduce the need for information processing [6]. Supply-chain level analysis has indicated that supply chain performance can be achieved by improving information processing capabilities and information quality [20].

Specifically, information processing capability refers to the information capability of firm in managing business operations, which is used to collect, process, and distribute information [53]. Some studies have pointed out that supply chain digitalization is the key element of information processing capability [5]. Based on IPT, some researchers propose that information processing capability can be supported by information technology [46]. In the digital era, information technology has been more widely developed, such as Internet of Things, blockchain, RFID and other digital technologies [61]. In this study, supply chain digitalization represents its information processing ability, which provides an information exchange channel for obtaining external information. Improving information capability can help firms improve performance.

Supply chain agility as an information processing intermediate mechanism can communicate with all parties of the supply chain in a timely manner through the information system to obtain real-time market data [65]. When the internal and external information of the supply chain is combined and complementary to each other, information processing capacity will be enhanced and supply chain performance will be improved. Furthermore, when a supply chain is viewed as an open socio-economic system, supply chain will face many uncertain external environmental pressures, such as environmental turbulence factors. While external environmental conditions differ significantly, they are suggested to be significant influencers of supply chain digitalization and the derived performance. IPT indicates that environmental uncertainty may lead to the extent and transparency of information sharing. Therefore, in the face of such uncertain factors, the supply chain needs to have stronger information processing capacity. Specifically, firms that operate in dynamic and complex environments are likely to require frequent adjustments to their marketing approach in order to satisfy the constantly changing customer needs. However, the motivation and willingness to use supply chain digitalization for achieving supply chain agility and performance are weakened in munificent environments. In the face of environmental uncertainty, the information processing demand of supply chain should be matched with its own information processing ability to achieve superior performance.

3 Hypotheses development

3.1 Supply chain digitalization and supply chain performance

The researchers point out that supply chain activities are considered information-intensive [31, 60]. Based on IPT, supply chain digitalization represents the information processing capability of supply chain to support firm operation management. Therefore, supply chain digitalization improves its performance through information collection and processing.

First, supply chain digitalization leverages efficient information processing capabilities to support production planning and control decisions [43], thereby improving supply chain performance. For example, firms can provide remote services of operational data in real time through cloud computing, or further analyze data and extract valuable information through big data. For example, firms can provide remote services with operational data in real time through cloud computing [8], or can further analyze data and extract valuable information through big data [24]. Moreover, supply chain digitalization supports firms demand prediction, product development decisions, thereby increasing market share [32]. On the one hand, supply chain digitalization provides firms with enough market information. On the other hand, firms can utilize supply chain digitalization for demand prediction and rapid response to customer needs [38]. In sum, we consider that supply chain digitalization be capable of improving its performance. Therefore, we propose the hypothesis is stated as follows:

H1. Supply chain digitalization is positively related to supply chain performance.

3.2 The mediating role of supply chain agility

As supply chain management is an information-intensive activity, the realization of its performance depends on a large amount of information and powerful information processing capabilities. Supply chain digitalization facilitate real-time information transfer between supply chain partners [48], demand management with customers [47], to affect performance. When the firm has strong information processing capabilities, the supply chain can grasp the external information of the supply chain in time, so as to better coordinate the relationship between the inside and outside of the supply chain [52]. Supply chain agility provides firms with timely and comprehensive information that helps them recover quickly from external shocks, thus responding rapidly when encountering various kinds of events [74]. Supply chain agility also helps firms synchronize supply and demand, thereby reducing inventory and transportation costs [19]. This can meet the changing demand patterns of the external environment and match the increasing internal and external information needs of the supply chain [41]. Thus, firms with information processing capabilities based on supply chain digitalization can improve performance through supply chain agility.

In sum, supply chain agility can grasp the external environment information in time, and accurately match the internal and external information which is needed by supply chain digitalization. Supply chain agility enables information to be rapidly disseminated, responded to and processed in the supply chain. Then, companies use its internal and external information to adjust its business strategy in time, so as to improve its performance. Therefore, the following hypothesis has been stated:

H2. Supply chain agility mediates the relationship between supply chain digitalization and supply chain performance.

3.3 The moderating role of environmental uncertainty

Consistent with previous literature [68], we view environmental uncertainty from the perspectives of dynamics, munificence and complexity. First, environmental uncertainty will lead to inconsistent internal and external information in the supply chain. In order to enhance their internal information processing capabilities, firms will invest more resources to develop supply chain digitalization. Second, a highly uncertain environment will bring various disruptions to the supply chain. Thus, we can respond to the risk of supply chain disruption by improving the agility of the supply chain. In conclusion, we predict that environmental uncertainty will have a significant influence on the relationship between supply chain digitalization and its performance via supply chain agility.

3.3.1 The moderating role of environmental dynamism

Environmental dynamics is a manifestation that the environment is not stable enough, which represents the change rate and unpredictability of the environment [42]. The more unstable the environment, the shorter the period for firm to gain a stronger competitive advantage [50]. In a highly dynamic environment, the supply chain will generate a lot of information processing requirements. Therefore, it is suggested that firms adjust information technology infrastructure, develop digital technology matching with environmental dynamics, and maintain a more lasting competitive advantage. In other words, when faced with a highly dynamic environment, firms are more inclined to extend digital technology to the whole supply chain and integrate timely upstream and downstream message consistency. When the internal information of the supply chain is integrated, there will be a greater demand for external information to ensure that the initial investment is not wasted. Therefore, we propose that the digitalization of the supply chain in a dynamic environment is beneficial to improve agility.

On the one hand, supply chains need to rely on firm’s boundaries to collect information in a dynamic environment. On the other hand, more accurate and efficient external information needs to be obtained by the supply chain. Thereby, supporting the operation and management of firms and reduce the negative impact of uncertain events. As a result, with supply chain becomes more agile, there will be more access to external information. To achieve optimal performance, firms need to have more powerful information processing ability. The powerful information processing capabilities will ensure the normal operation and management of firms in the supply chain. Therefore, when environmental dynamics become stronger, the strength of the positive impact of supply chain agility on supply chain performance will become stronger.

In short, in a dynamism environment, the supply chain will use digital technology to enhance its agility to achieve higher performance. Considering the mediating effect of supply chain agility, we believe that as environmental dynamics increase, the indirect impact of supply chain digitalization on its performance will increase. Therefore, it is hypothesized that:

H3. The indirect relationship between supply chain digitalization and supply chain performance through supply chain agility is stronger when environmental dynamism is stronger than when it is weaker.

3.3.2 The moderating role of environmental munificence

Environmental munificence refers to the degree to which the firm's environment can support its continued growth [16, 63]. The more munificence the environment is, the faster the market grows [50]. In other words, mature or shrinking market conditions are less munificent. In the munificent environment, a firm tends to obtain useful information and resources from munificent environments rather than adopt advanced digital technology to improve information processing capabilities. It will decrease the transmission of information through supply chain digitalization to improve performance through agility.

Furthermore, in the munificent environment, the market environment competition intensity is relatively low. When the environment is more munificent, supply chain agility is easier to accelerate the processing a large amount of external information. Firms are less likely to choose supply chain digitalization to improve information processing capabilities. Therefore, when considering the mediating effect of supply chain agility, we believe that the indirect impact of supply chain digitalization on its performance will decrease with the increase of environmental abundance. Therefore, it is hypothesized that:

H4. The indirect relationship between supply chain digitalization and supply chain performance through supply chain agility is stronger when environmental munificence is weaker than when it is stronger.

3.3.3 The moderating role of environmental complexity

The environmental complexity results from the diversity of inputs and outputs [16]. In other words, there is heterogeneity and scope in an firm's activities [63]. The more complexity the environment is, the more diverse the products possess, and the shorter the life cycle of the products have. To keep up with the trend of the market and ensure the timely updating of products, firms need to have more information and more powerful information processing capacity. Therefore, in a complex environment, firms tend to use more advanced digital technologies to process information. They can use the high-quality and efficient information generated by supply chain digitalization to develop more rational business strategies, thus improving supply chain agility.

Complex environments may impact the extent and transparency of information sharing. With the complexity of the environment increases, the information transparency of the supply chain will also decrease. The improvement of supply chain agility will bring more external information to it, thus enhancing information transparency. Therefore, strong information processing ability will effectively match internal and external information, develop more reasonable business strategies, and achieve higher performance. In conclusion, when the agility of the supply chain has a mediating effect, we agree that as the complexity of the environment increases, the indirect impact of the supply chain digitalization on its performance will also increase. Therefore, it is hypothesized that:

H5. The indirect relationship between supply chain digitalization and supply chain performance through supply chain agility is stronger when environmental complexity is stronger than when it is weaker.

4 Methods

4.1 Sampling and data collection

To test our hypotheses, we conducted an empirical survey of Chinese firms. This survey focused on China's Yangtze River Delta region. Because the region's economy is one of the most developed in China, firms in these regions are more inclined to develop supply chain digitalization. We obtained a representative sample by working with a market research firm. Our research sample from different industries, such as manufacturing, finance and insurance, steel industry and automobile industry. At the same time, the sample includes firms of various nature (state-owned firms, private and foreign firms).

We obtained the basic information about the surveyed firms and their managers through our partner firms. We select senior managers for the survey. First, they are more familiar with the location of the supply chain and understand the dynamics of firms. Second, they have a better understanding of the firm's IT strategies and a deeper understanding of the firm's supply chain digitalization. Third, they pay more attention to market dynamics and environmental changes. Considering that the model is not suitable for using a single respondent questionnaire, two different questionnaires were distributed to different managers of each firm. Thus, common method deviations are reduced. we sent questionnaires to each firm's operations managers on marketing-related constructs (such as environmental uncertainty and supply chain performance) and to each firm's IT managers on information technology constructs (such as supply chain digitalization).

Our survey was based on respondents who were invited for the first time. In the invitation letter, we explained the source of their contact information, as well as the purpose of our research. we selected potential respondents to send questionnaire. After eliminating the samples with low reliability, we obtained a complete response with an effective response rate of 26% (143 out of 550 firms). To test for possible non-response biases (i.e., firm location, firm ownership, industry type, firm size, and firm age), we used Chi-square and ANOVA test to examine key characteristics of the surveyed firms. Therefore, we believe that the study sample is representative. Table 1 is the demographic information of the research sample.

4.2 Measure

We obtained the construction measurements in our study from previous literature.

Our questionnaire used a Likert 7-scale, which ranged from 1 to 7 (range from “Strongly disagree” to “Strongly agree”).

Supply chain digitalization. We adopted a previous research project to measure supply chain digitalization from six indicators [67]. This scale reflects the communication and transactions between different firms through supply chain digitalization.

Supply chain agility. We adopted an existing measures from existing literature [69]. The scale reflects that in the uncertain environment, firms can respond quickly and make countermeasures in time.

Supply chain performance. Based on existing research, supply chain performance is evaluated by seven items [30]. It assesses supply chain efficiency, operation capability and service levels.

Environmental uncertainty. Based on previous studies, we divide environmental uncertainty into three dimensions: environmental dynamism, environmental munificence and environmental complexity [16, 63].

Environmental dynamism. Based on the literature, we measure environmental dynamism using eight indicators [42]. The scale reflects market instability from customer preference and technology turnover.

Environmental munificence. We adopted an existing measure from previous studies [63]. It reflects the state of the industry and the attitudes of competitors.

Environmental complexity. We measured environmental complexity by using three metrics [16]. The scale reflects the heterogeneity and scope of the firm.

Control variables. Considering supply chain digitalization and supply chain agility may be affected by control variables. We adopt dynamic measurement method of environment [54]. We set the dummy variables to the region of the business, business ownership, and industry type. Regions 1–4 were used (Anhui in Region 1, Jiangsu in Region 2, Zhejiang in Region 3, Shanghai in Region 4, and other regions as baselines). In the ownership of companies, 1 represents a state-owned firm, 2 represents a private firm, 3 represents a foreign-funded firm, and 4 represents others. In terms of industry types, 1–6 represent automobile industry, machinery and equipment manufacturing, electronics manufacturing, commodity processing industry, steel industry and table finance industry respectively. Moreover, the number of employees as the firm size, and the age of the firm as the date of establishment.

4.3 Common method bias (CMV)

During the survey period, psychometric separation was established to ensure that questionnaire participants did not have any direct understanding of these constructs. Moreover, we can guarantee that the questionnaire participants' answers are confidential. Furthermore, to reduce common method bias, we designed questionnaires for operation managers and IT managers respectively. After the investigation is over, we check whether the results of the investigation are affected by common method bias. We first used the Harman's one-factor test [44]. The results show that the first factor explains 16.49% of the variance, less than 40% [44]. This suggests that there are less common method biases in our study. Then, we assessed the fit of the model with confirmatory factor analysis (CFA). We tested and compared the measurement model and the one factor model respectively. According to the results, the fitting of our measurement model ((χ2/df = 0.702, RMSEA = 0.001, SRMR = 0.010, IFI = 1.001, TLI = 1.010, CFI = 1.000) is much better than that of one-factor model ((χ2/df = 8.678, RMSEA = 0.18, S8RMR = 0.147, IFI = 0.432, TLI = 0.401, CFI = 0.322). Therefore, we believe that CMV do not pose a significant threat to study results.

4.4 Reliability and validity

For reliability, Cronbach's alpha and compound reliability were measured for each structure. As shown in Appendix A, Cronbach's alpha ranges from 0.806 to 0.977 and compound reliability ranges from 0.884 to 0.981, both of which were not lower than 0.70 [36].

For the validity of the questionnaire, we measured convergent validity and discriminant validity. We tested convergent validity by extracting mean variance (AVE). As shown in Appendix A, all variances are not less than the recommended level of 0.5, and all factor loads are not less than 0.6 [26]. Therefore, the convergence of the measurement method is effective. Moreover, we use the square root of AVE and the shared variance to evaluate the discriminative validity [26]. In Table 2, the square root of the AVE of all constructs is greater than the correlation between the construct and other constructs [26]. This proves the discriminant validity of the constructs. Furthermore, to detect whether multicollinearity exists between constructs, we test the variance inflation factor. According to the results, the VIFS of all constructs did not exceed the threshold 10 [26]. Therefore, there is no serious multicollinearity between constructs in our study.

5 Analyses and results

To test our hypothesis, we used the SPSS macro program, PROCESS. Baron and Kenny [4] proposed a sequential test (step by step) to test mediating effects. But some researchers dispute this method. Preacher and Hayes [45] proposes that the sequential test has shortcomings, such as type I errors about mediation. Therefore, they developed a PROCESS macro program that relies on non-parametric bootstrapping [45]. PROCESS has been widely used in research to evaluate complex models containing mediating and moderating variables [56, 57, 72].

We first used "Model 4" in PROCESS to verify our hypotheses 1 and 2. Table 3 summarized the path results. Hypothesis 1 is about the direct impact of the digitalization of the supply chain to its performance. The results in Table 3 show that supply chain digitalization had a significant and positive impact on supply chain performance (β = 0.336, p < 0.001). Thus, hypothesis 1 was supported.

Hypothesis 2 examines whether supply chain agility plays a mediating effect between supply chain digitalization and its performance. The results in Table 3 show that supply chain digitalization was insignificantly related to supply chain performance when adding supply chain agility (β = 0.108, p > 0.05). Next, we tested whether the supply chain agility has a mediating effect by executing bootstrapping with 5000 resamples. Table 4 showed that the indirect impact (effect = 0.228, SE = 0.085) of supply chain digitalization on its performance through supply chain agility was positive and significant. Furthermore, the bias-corrected 95% confidence interval (CI) for total effect on supply chain performance respectively was [0.158, 0.514], which did not contain zero. It is evident that the digitalization of the supply chain has a positive and significant impact on the performance of the supply chain whether it is direct or indirect. Therefore, the hypothesis 2 was verified.

We used "Model 58" in the PROCESS program of SPSS to verify Hypotheses 3, 4 and 5. The regression results are shown in Table 5. First, the interaction items between supply chain digitalization and environmental dynamism (β = 0.146, p < 0.05) and the interaction items between supply chain digitalization and environmental complexity (β = 0.190, p < 0.05) both had a positive and significant impact on supply chain agility. However, the interaction term between supply chain digitalization and environmental munificence was not significant for supply chain agility (β = − 0.034, p > 0.05). Moreover, the interaction items between supply chain agility and environmental dynamism (β = 0.245, p < 0.001) and the interaction items between supply chain agility and environmental complexity (β = 0.115, p < 0.05) both had a positive and significant impact on supply chain performance. Contrary to our hypothesis, the environmental munificence had a positive moderating effect on the relationship between supply chain agility and supply chain performance (β = 0.088, p < 0.01).

Table 6 shows the moderated results of different levels of environmental uncertainty on the mediation model. According to the results, we found that when the dynamism of the environment was at a high level, the indirect impact of supply chain digitalization on the performance of the supply chain via supply chain agility was significantly positive (β = 0.310, SE = 0.150, 95% CI = [0.060,0.337]). But when the environmental dynamism was at a low level, this indirect impact was not significant (β = 0.076, SE = 0.061, 95% CI = [− 0.033,0.207]). Thus, Hypothesis 3 was verified. Moreover, when the complexity of the environment was at a high level, the indirect impact of the digital supply chain on the performance of the supply chain via supply chain agility was significantly positive (β = 0.276, SE = 0.115, 95% CI = [0.090,0.532]). But when the environmental complexity was at a low level, this indirect impact was not significant (β = 0.051, SE = 0.083, 95% CI = [− 0.081,0.221]). Therefore, the results confirmed hypothesis 5. However, whether environmental munificence was higher (β = 0.145, SE = 0.103, 95% CI = [− 0.024,0.374]) or lower (β = 0.105, SE = 0.073, 95% CI = [− 0.000,0.0.276]), supply chain digitalization indirectly affects its performance through supply chain agility was insignificant. Overall, hypothesis 4 was not supported.

6 Discussion

6.1 Discussion of the results

Based on IPT, this study examines how supply chain digitalization effects its performance via supply chain agility and how the mediated relationships are moderated by environment uncertainty. Through a survey of firms in the Yangtze River Delta region of China, we prove the positive relationship between supply chain digitalization and supply chain performance, and this positive effect is mediated by supply chain agility. These results are consistent with previous studies that have discovered the role of supply chain digitalization on supply chain performance [2, 25]. Besides, we find that with the increase of environmental dynamism, the indirect impact of supply chain digitalization on supply chain performance through supply chain agility will increase. Because firms obtain external information through the agility of the supply chain in a dynamic environment, and rely on the information processing capabilities of their digital technology to improve performance. With the increase of environmental complexity, the indirect impact of the digitalization of the supply chain on supply chain performance through supply chain agility will increase. Because in a complex environment, supply chain agility will increase the scope of information sharing and transparency. Thereby, obtaining more external information and ultimately achieve the purpose of improving performance. However, although environmental munificence strengthens the relationship between supply chain agility and performance, the results show that the indirect impact of the supply chain digitalization on supply chain performance through agility will not change despite it is in higher environmental munificence or lower environmental munificence. A plausible explanation is that in less munificent environments, markets are more competitive. In order to gain advantages in the fierce competition environment, the firm will invest more efforts to develop supply chain digitalization and its information processing capacity will be enhanced, thus the supply chain performance will also be improved. At the higher levels of munificent environment, the market was less competitive where information sharing is higher. When firms obtain a large amount of information, the firms still need to utilize digital links with supply chain members to achieve agility and improve the ultimate performance. Indeed, based on the moderated mediation results shown in Table 6, the mediated relationship between supply chain digitalization and performance via supply chain agility is significant when the environmental munificence is medium. In other words, in either high or low level of environmental munificence, it is not critical for firms to leverage supply chain digitalization for achieving superior performance via supply chain agility.

6.2 Theoretical implications

Our research contributes to the existing literature in two main ways. First, our research proposes and verifies the role of supply chain agility as a mediating variable between supply chain digitalization and supply chain performance. A large body of studies have primarily focused on the effects of specific digital technologies, such as big data analysis [3, 22], cloud computing [8, 13], and artificial intelligence [18, 40], on supply chain performance. From the information processing perspective, we have regarded supply chain digitalization technology as a unified structure for the information processing capabilities of the firms and have empirically tested the direct impact of supply chain digitalization on its performance. Existing discussion of whether and how supply chain digitalization affects supply chain performance is still open to debate [74]. Within a supply chain context, agility helps reconfigure firm-level and supply chain-level resources, quickly react to unexpected shifts in supply and demand, and improve supply chain’ effectiveness [23], which realizing the value of supply chain digitalization. We extend past research by exploring the mediating role of supply chain agility which promotes supply chain partners to timely identify and respond to opportunities arising from digitalization [41].

Second, in information system literature, the conditional impact of environmental uncertainty on the relationship between supply chain digitalization and performance is scarcely examined. Although there is an assumption that supply chain digitalization may be more valuable under conditions of high uncertainty [39], there is limited empirical understanding on the impact that the external environment has on leveraging supply chain digitalization for achieving supply chain performance. Our research explores how environmental uncertainty moderates the impact of supply chain digitalization on the performance of the supply chain through supply chain agility. We integrate the IPT and related literature to identify that environmental uncertainty as factors that determine firms’ SCR information processing requirements [21]. Some researchers have explored the mechanism through which dynamic capabilities influence performance under different environmental uncertainty while they mainly focused on single dimension, such as market turbulence [37, 70]. By distinguishing specific dimensions, our research provides a more comprehensive and deep understanding of the enhanced and diminished effect of supply chain digitalization on supply chain performance across different levels of environmental dynamism, environmental munificence, and environmental complexity.

6.3 Managerial implications

Our findings provide some insights into supply chain managers. First, in the digital age, supply chain digitalization is extremely important for firms to obtain competitive advantages. The powerful information processing capability of diverse digital technologies, such as big data analytics, blockchain, and intelligent manufacturing can help formulate a high level of supply chain agility for achieving superior performance. When the supply chain improves digital maturity degree and the level of adoption of digital tools, the supply chain can improve agility to quickly obtain more market information and enhance the information sharing of the whole supply chain. Supply chain agility also plays an extremely important part in the performance of the supply chain. In short, firms should not only develop and apply digital technologies, but also adopt agile supply chain strategy so as to achieve superior supply chain performance. An agile supply chain should adapt adequately to different kinds of changes through enterprise partnering, production outsourcing and component supplier networks. The whole supply chain can improve performance by develop supply chain agility to better realize the value of supply chain digitalization.

Second, managers need to be aware that in an uncertain environment, supply chain agility enables firms to perceive external information in a timely manner, so that firms can perceive and take advantage of environmental changes and enhance information processing ability. For the sustainable development of supply chain, firms should vigorously continue to digitalize their supply chain chains in the current volatile and uncertain business environment. In particularly, deploying supply chain digitalization and agility is required in highly dynamic and complex environments because in such environments the capability to obtain and manage supply and demand information accurately and timely may become more important to avoid threats and meet challenges and consequently generating superior performance.

6.4 Limitations and future research

Although this research has some contributions, there are still some limitations. First, the survey samples were mostly located in Anhui provinces in China, so there are limitations in the sample representation. Because different countries or regions have different economic environments, focusing on one location/region may limit the generalizability of our research results. Therefore future studies can collect surveys from different countries or regions to improve reliability and generalizability of our findings. Second, the sample size is relatively small to some extent in this study. Future studies can use a larger sample size to further test the robustness of our results. Third, we only used cross-sectional data in this study. In future research, we can try to use longitudinal data to study the relationship among the supply chain digitalization, supply chain agility and supply chain performance. Finally, we study supply chain performance as a whole. Some studies have proposed a "triple bottom line" approach to sustainability [33]. Therefore, future studies can divide supply chain performance into different dimensions, such as economic performance, environmental and social performance.

7 Conclusion

Prior research has been inconclusive on the value of digitalization on performance especially as environment uncertainty evolve. Our study addresses the debate derived from prior research by adopting IPT that the fit between information processing capability and information processing needs can improve performance. This study verifies the positive value of supply chain digitalization and creates a process model that demonstrates that supply chain agility has a partial mediating effect between supply chain digitalization and supply chain performance. In addition, when environmental dynamics and environmental complexity are at a higher level, partial mediating effects are stronger while environmental munificence has no contingency effect. We hope that the current research can improve the understanding of the sustainable development of the supply chain, especially in the context of the digital age.

References

Akter S, Wamba SF, Gunasekaran A, Dubey R, Childe SJ (2016) How to improve firm performance using big data analytics capability and business strategy alignment? Int J Prod Econ 182:113–131. https://doi.org/10.1016/j.ijpe.2016.08.018

AlMulhim AF (2021) Smart supply chain and firm performance: the role of digital technologies. Bus Process Manag J 27(5):1353–1372. https://doi.org/10.1108/bpmj-12-2020-0573

Bag S, Wood LC, Xu L, Dhamija P, Kayikci Y (2020) Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour Conserv Recycl 153:104559. https://doi.org/10.1016/j.resconrec.2019.104559

Baron RM, Kenny DA (1986) The moderator-mediator variable distinction in social psychological research: conceptual, strategic, and statistical considerations. J Pers Soc Psychol 51(6):1173–1182. https://doi.org/10.1037/0022-3514.51.6.1173

Belhadi A, Mani V, Kamble SS, Khan SAR, Verma S (2021) Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation. Ann Oper Res. https://doi.org/10.1007/s10479-021-03956-x

Bensaou M, Venkatraman N (1995) Configurations of inter-organizational relationships: a comparison between US and Japanese automakers. Manage Sci 41(9):1471–1492. https://doi.org/10.1287/mnsc.41.9.1471

Bienhaus F, Haddud A (2018) Procurement 4.0: factors influencing the digitisation of procurement and supply chains. Bus Process Manage J 24(4):965–984. https://doi.org/10.1108/bpmj-06-2017-0139

Bruque Cámara S, Moyano Fuentes J, Maqueira Marín JM (2015) Cloud computing, Web 2.0, and operational performance. Int J Logist Manage 26(3):426–458. https://doi.org/10.1108/ijlm-07-2013-0085

Büyüközkan G, Göçer F (2018) Digital supply chain: literature review and a proposed framework for future research. Comput Ind 97:157–177. https://doi.org/10.1016/j.compind.2018.02.010

Cadden T, Cao G, Treacy R, Yang Y, Onofrei G (2021) Dynamic capability theory as a lens to investigate big data analytics and supply chain agility responsible ai and analytics for an ethical and inclusive digitized society. Lecture notes in computer science, pp 467–480

Calatayud A, Mangan J, Christopher M (2019) The self-thinking supply chain. Supply Chain Manage Int J 24(1):22–38. https://doi.org/10.1108/SCM-03-2018-0136

Cao Q, Dowlatshahi S (2005) The impact of alignment between virtual enterprise and information technology on business performance in an agile manufacturing environment. J Oper Manag 23(5):531–550. https://doi.org/10.1016/j.jom.2004.10.010

Cao Q, Schniederjans DG, Schniederjans M (2017) Establishing the use of cloud computing in supply chain management. Oper Manag Res 10(1–2):47–63. https://doi.org/10.1007/s12063-017-0123-6

de Sousa Jabbour ABL, Jabbour CJC, Foropon C, Godinho Filho M (2018) When titans meet–Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol Forecast Soc Chang 132:18–25. https://doi.org/10.1016/j.techfore.2018.01.017

Despoudi S, Papaioannou G, Dani S (2020) Producers responding to environmental turbulence in the Greek agricultural supply chain: does buyer type matter? Prod Plan Control 32(14):1223–1236. https://doi.org/10.1080/09537287.2020.1796138

Dess GG, Beard DW (1984) Dimensions of organizational task environments. Adm Sci Q 29(1):52–73. https://doi.org/10.2307/2393080

Dubey R, Altay N, Gunasekaran A, Blome C, Papadopoulos T, Childe SJ (2018) Supply chain agility, adaptability and alignment: empirical evidence from the Indian auto components industry. Int J Oper Prod Manag 38(1):129–148

Dumitrascu O, Dumitrascu M, Dobrotǎ D (2020) Performance evaluation for a sustainable supply chain management system in the automotive industry using artificial intelligence. Processes 8(11):1384. https://doi.org/10.3390/pr8111384

Eckstein D, Goellner M, Blome C, Henke M (2014) The performance impact of supply chain agility and supply chain adaptability: the moderating effect of product complexity. Int J Prod Res 53(10):3028–3046. https://doi.org/10.1080/00207543.2014.970707

Egelhoff WG (1991) Information-processing theory and the multinational enterprise. J Int Bus Stud 22(3):341–368. https://doi.org/10.1057/palgrave.jibs.8490306

Fan H, Cheng TCE, Li G, Lee PKC (2016) The effectiveness of supply chain risk information processing capability: an information processing perspective. IEEE Trans Eng Manage 63(4):414–425. https://doi.org/10.1109/tem.2016.2598814

Fernando Y, Chidambaram RRM, Wahyuni-Td IS (2018) The impact of big data analytics and data security practices on service supply chain performance. Benchmark Int J 25(9):4009–4034. https://doi.org/10.1108/bij-07-2017-0194

Gligor DM, Esmark CL, Holcomb MC (2015) Performance outcomes of supply chain agility: when should you be agile? J Oper Manag 33–34:71–82. https://doi.org/10.1016/j.jom.2014.10.008

Gunasekaran A et al (2017) Big data and predictive analytics for supply chain and organizational performance. J Bus Res 70:308–317. https://doi.org/10.1016/j.jbusres.2016.08.004

Gupta H, Kumar S, Kusi-Sarpong S, Jabbour CJC, Agyemang M (2020) Enablers to supply chain performance on the basis of digitization technologies. Ind Manag Data Syst 121(9):1915–1938. https://doi.org/10.1108/imds-07-2020-0421

Hair JF, Ringle CM, Sarstedt M (2014) PLS-SEM: indeed a silver bullet. J Mark Theory Pract 19(2):139–152. https://doi.org/10.2753/mtp1069-6679190202

Hallikas J, Immonen M, Brax S (2021) Digitalizing procurement: the impact of data analytics on supply chain performance. Supply Chain Manage Int J 26(5):629–646. https://doi.org/10.1108/SCM-05-2020-0201

Heilig L, Voß S (2017) Status quo and innovative approaches for maritime logistics in the age of digitalization: a guest editors’ introduction. Inf Technol Manage 18(3):175–177. https://doi.org/10.1007/s10799-017-0282-z

Holmström J, Holweg M, Lawson B, Pil FK, Wagner SM (2019) The digitalization of operations and supply chain management: Theoretical and methodological implications. J Oper Manag 65(8):728–734. https://doi.org/10.1002/joom.1073

Huo B, Zhao X, Zhou H (2014) The effects of competitive environment on supply chain information sharing and performance: an empirical study in China. Prod Oper Manag 23(4):552–569. https://doi.org/10.1111/poms.12044

Jayaram J, Vickery SK, Droge C (2000) The effects of information system infrastructure and process improvements on supply-chain time performance. Int J Phys Distrib Logist Manag 30(3):313–220. https://doi.org/10.1108/09600030010326082

Joshi AD, Gupta SM (2019) Evaluation of design alternatives of end-of-life products using internet of things. Int J Prod Econ 208:281–293. https://doi.org/10.1016/j.ijpe.2018.12.010

Kamble SS, Gunasekaran A, Gawankar SA (2018) Sustainable Industry 4.0 framework: a systematic literature review identifying the current trends and future perspectives. Process Saf Environ Prot 117:408–425. https://doi.org/10.1016/j.psep.2018.05.009

Kayikci Y (2018) Sustainability impact of digitization in logistics. Proc Manuf 21:782–789. https://doi.org/10.1016/j.promfg.2018.02.184

Kiel D, Müller JM, Arnold C, Voigt K-I (2017) Sustainable industrial value creation: benefits and challenges of industry 4.0. Int J Innov Manage 21(8):1–34. https://doi.org/10.1142/S1363919617400151

Lance CE, Butts MM, Michels LC (2006) The sources of four commonly reported cutoff criteria: what did they really say? Organ Res Methods 9(2):201–220. https://doi.org/10.1177/1094428105284919

Li L (2022) Digital transformation and sustainable performance: the moderating role of market turbulence. Ind Mark Manage 104:28–37. https://doi.org/10.1016/j.indmarman.2022.04.007

Li Y, Dai J, Cui L (2020) The impact of digital technologies on economic and environmental performance in the context of industry 4.0: a moderated mediation model. Int J Prod Econ 229:107777. https://doi.org/10.1016/j.ijpe.2020.107777

Mikalef P, Boura M, Lekakos G, Krogstie J (2019) Big data analytics capabilities and innovation: the mediating role of dynamic capabilities and moderating effect of the environment. Br J Manag 30(2):272–298. https://doi.org/10.1111/1467-8551.12343

Min H (2009) Artificial intelligence in supply chain management: theory and applications. Int J Log Res Appl 13(1):13–39. https://doi.org/10.1080/13675560902736537

Nandi S, Sarkis J, Hervani AA, Helms MM (2021) Redesigning supply chains using blockchain-enabled circular economy and COVID-19 experiences. Sustain Prod Consum 27:10–22. https://doi.org/10.1016/j.spc.2020.10.019

Newkirk HE, Lederer AL (2006) The effectiveness of strategic information systems planning under environmental uncertainty. Inf Manage 43(4):481–501. https://doi.org/10.1016/j.im.2005.12.001

Nguyen T, Zhou L, Spiegler V, Ieromonachou P, Lin Y (2018) Big data analytics in supply chain management: a state-of-the-art literature review. Comput Oper Res 98:254–264. https://doi.org/10.1016/j.cor.2017.07.004

Podsakoff N (2003) Common method biases in behavioral research: a critical review of the literature and recommended remedies. J Appl Psychol 88(5):879–903. https://doi.org/10.1037/0021-9010.88.5.879

Preacher KJ, Hayes AF (2004) SPSS and SAS procedures for estimating indirect effects in simple mediation models. Behav Res Methods Instrum Comput 36(4):717–731. https://doi.org/10.3758/bf03206553

Premkumar G, Ramamurthy K, Saunders CS (2005) Information processing view of organizations: an exploratory examination of fit in the context of interorganizational relationships. J Manag Inf Syst 22(1):257–294. https://doi.org/10.1080/07421222.2003.11045841

Qrunfleh S, Tarafdar M (2014) Supply chain information systems strategy: impacts on supply chain performance and firm performance. Int J Prod Econ 147:340–350. https://doi.org/10.1016/j.ijpe.2012.09.018

Rai A, Patnayakuni R, Seth N (2006) Firm performance impacts of digitally enabled supply chain integration capabilities. MIS Quarterly, pp 225–246

Roy S, Satpathy B (2019) Strategic alliance between information intensive services and supply chain integration: impact on firm performance. Braz J Oper Prod Manage 16(2):241–260. https://doi.org/10.14488/BJOPM.2019.v16.n2.a7

Sabherwal R, Sabherwal S, Havaknor T, Steelman Z (2019) How does strategic alignment affect firm performance? The roles of information technology investment and environmental uncertainty. Mis Quart 43(2):453–474. https://doi.org/10.25300/MISQ/2019/13626

Seyedghorban Z, Tahernejad H, Meriton R, Graham G (2020) Supply chain digitalization: past, present and future. Prod Plan Control 31(2–3):96–114. https://doi.org/10.1080/09537287.2019.1631461

Shou Y, Li Y, Park YW, Kang M (2017) The impact of product complexity and variety on supply chain integration. Int J Phys Distrib Logist Manag 47(4):297–317. https://doi.org/10.1108/ijpdlm-03-2016-0080

Shou Z, Zheng X, Zhu W (2016) Contract ineffectiveness in emerging markets: an institutional theory perspective. J Oper Manag 46:38–54. https://doi.org/10.1016/j.jom.2016.07.004

Shu CL, Jin JL, Zhou KZ (2017) A contingent view of partner coopetition in international joint ventures. J Int Mark 25(3):42–60. https://doi.org/10.1509/jim.16.0075

Silvestre BS (2015) Sustainable supply chain management in emerging economies: environmental turbulence, institutional voids and sustainability trajectories. Int J Prod Econ 167:156–169. https://doi.org/10.1016/j.ijpe.2015.05.025

Su Y, Lee DKL, Xiao X, Li W, Shu W (2021) Who endorses conspiracy theories? A moderated mediation model of Chinese and international social media use, media skepticism, need for cognition, and COVID-19 conspiracy theory endorsement in China. Comput Hum Behav 120:106760. https://doi.org/10.1016/j.chb.2021.106760

Tang S, Nadkarni S, Wei LQ, Zhang SX (2021) Balancing the Yin and Yang: Tmt gender diversity, psychological safety, and firm ambidextrous strategic orientation in chinese high-tech smes. Acad Manag J 64(5):1578–1604. https://doi.org/10.5465/amj.2019.0378

Teece DJ (2018) Business models and dynamic capabilities. Long Range Plan 51(1):40–49. https://doi.org/10.1016/j.lrp.2017.06.007

Vagnoni E, Khoddami S (2016) Designing competitivity activity model through the strategic agility approach in a turbulent environment. Foresight 18(6):625–648. https://doi.org/10.1108/fs-03-2016-0012

Vanpoucke E, Boyer KK, Vereecke A (2009) Supply chain information flow strategies: an empirical taxonomy. Int J Oper Prod Manag 29(12):1213–1241. https://doi.org/10.1108/01443570911005974

Varriale V, Cammarano A, Michelino F, Caputo M (2021) Sustainable supply chains with blockchain, IoT and RFID: a simulation on order management. Sustainability 13(11):6372. https://doi.org/10.3390/su13116372

Vendrell-Herrero F, Bustinza OF, Parry G, Georgantzis N (2017) Servitization, digitization and supply chain interdependency. Ind Mark Manage 60:69–81. https://doi.org/10.1016/j.indmarman.2016.06.013

Wade M, Hulland J (2004) The resource-based view and information systems research: review, extension, and suggestions for future research. Mis Quart 28(1):107–142. https://doi.org/10.2307/25148626

Wamba SF, Dubey R, Gunasekaran A, Akter S (2020) The performance effects of big data analytics and supply chain ambidexterity: the moderating effect of environmental dynamism. Int J Prod Econ. https://doi.org/10.1016/j.ijpe.2019.09.019

White A, Daniel EM, Mohdzain M (2005) The role of emergent information technologies and systems in enabling supply chain agility. Int J Inf Manage 25(5):396–410. https://doi.org/10.1016/j.ijinfomgt.2005.06.009

Wong CY, Boon-itt S, Wong CWY (2011) The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J Oper Manag 29(6):604–615. https://doi.org/10.1016/j.jom.2011.01.003

Xue L, Zhang C, Ling H, Zhao X (2014) Risk mitigation in supply chain digitization: system modularity and information technology governance. J Manag Inf Syst 30(1):325–352. https://doi.org/10.2753/mis0742-1222300110

Yayla AA, Hu Q (2012) The impact of IT-business strategic alignment on firm performance in a developing country setting: exploring moderating roles of environmental uncertainty and strategic orientation. Eur J Inf Syst 21(4):373–387. https://doi.org/10.1057/ejis.2011.52

Ying Lu, Ramamu K (2011) Understanding the link between information technology capability and organizational agility: an empirical exam. Mis Quart 35(4):931–954. https://doi.org/10.2307/41409967

Zhou J, Mavondo FT, Saunders SG (2019) The relationship between marketing agility and financial performance under different levels of market turbulence. Ind Mark Manage 83:31–41. https://doi.org/10.1016/j.indmarman.2018.11.008

Zhou Q, Wang S (2021) Study on the relations of supply chain digitization, flexibility and sustainable development—a moderated multiple mediation model. Sustainability 13(18):10043–10062. https://doi.org/10.3390/su131810043

Zhou X, Ma J, Dong X (2018) Empowering supervision and service sabotage: a moderated mediation model based on conservation of resources theory. Tour Manage 64:170–187. https://doi.org/10.1016/j.tourman.2017.06.016

Zhu S, Dong T, Luo X (2021) A longitudinal study of the actual value of big data and analytics: the role of industry environment. Int J Inf Manage. https://doi.org/10.1016/j.ijinfomgt.2021.102389

Zouari D, Ruel S, Viale L (2020) Does digitalising the supply chain contribute to its resilience? Int J Phys Distrib Logist Manag 51(2):149–180. https://doi.org/10.1108/ijpdlm-01-2020-0038

Acknowledgements

This study was funded by the National Natural Science Foundation of China (Nos. 72071190 and 72271072), the Fundamental Research Funds for the Central Universities (JZ2023HGPA0294 and JZ2024HGTG0314), and Scientific Research Key Project of Education Department of Anhui Province (2023AH050043). Xiayu Chen is another corresponding author to this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, S., Liu, H., Xu, W. et al. The impact of supply chain digitalization on supply chain performance: a moderated mediation model. Inf Technol Manag (2024). https://doi.org/10.1007/s10799-024-00431-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s10799-024-00431-4