Abstract

Experimental studies of the thermal expansion, heat capacity and thermal conductivity of the eutectic magnesium–lithium alloy (with composition of 23.0 at.% lithium) were performed in the temperature range of 80 K to 400 K. The relative elongation and thermal expansion coefficient of this ultralight magnesium–lithium alloy were measured by the dilatometric method using a DIL-402C setup. Measurements of the heat capacity were carried out by the differential scanning calorimetry using a DSC 404 F1 setup. Investigation of the thermal conductivity was performed by the hot-disk technique using a Hot-Disk TPS 2500S setup. The temperature dependences were constructed and tables of recommended values of the investigated properties were presented. It was found that in Mg77Li23 alloy a phase transition occurs in the range of 223 K to 253 K, where the heat capacity and the linear thermal expansion coefficient change abruptly. This transition is presumably related to the martensitic transformation of the lithium-rich bcc magnesium–lithium alloys to the hcp structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of portable electronics, automotive and aerospace industries increases the requirements for lightness of the considered structural and engineering materials. In these areas of industry, light magnesium alloys, primarily with the addition of lithium, are of great interest. Firstly, this is due to their low density. According to Ref. [1], the density of the magnesium–lithium eutectic alloy containing 23 at.% Li is lower than the density of magnesium by about 13 % and 1.8 times less than the density of aluminum. Secondly, the addition of lithium can optimize the mechanical properties of the magnesium alloy. According to Refs. [2, 3], the magnesium–lithium eutectic is a mixture of (Mg)-phase (lithium solution in magnesium with hcp structure) and (Li)-phase (magnesium solution in lithium with bcc structure), combining the advantages of both phases [4,5,6,7], namely plasticity and ductility of (Li)-phase, and high specific strength and stiffness of (Mg)-phase. The availability of reliable experimental data on the physical properties of magnesium–lithium alloys in a wide temperature range is necessary for an adequate analysis of the prospects for their application as ultralight structural materials.

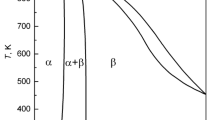

One of the factors hindering the implementation of magnesium–lithium alloys as structural and engineering materials is the paucity of data available in the literature on the behavior of their properties at temperatures below room temperature. For example, we couldn't find any information on experimental studies of the thermal expansion, heat capacity and thermal conductivity below 293 K. Moreover, according to the review [2], the phase diagram of the Mg–Li system at temperatures below 298 K remains unknown. There are no experimental data on the solubility of solid lithium in magnesium and magnesium in lithium, and on the form of phase equilibrium lines between (Mg)-phase, (Li)-phase and their solid-state mixture (Mg) + (Li) below 298 K. It is only known [2, 8, 9] that in the cryogenic temperature range a spontaneous martensitic transformation from bcc to hcp crystal structure occurs in Mg–Li alloys with a content of 83.6 at.% to 100 at.% Li. It is clear that the lack of information about phase equilibria and possible solid-state phase transitions in the eutectic composition region of the Mg–Li system does not allow one to reliably estimate the values of thermophysical properties and their change upon cooling below 298 K.

The aim of this work was to experimentally study the thermal expansion, heat capacity, and thermal conductivity of the magnesium–lithium eutectic alloy in the temperature range from 80 K to 293 K. These results will make it possible to expand the Mg77Li23 alloy thermophysical properties polytherms constructed by us earlier [1, 10].

2 Experimental Details

The heat capacity cP of the Mg77Li23 alloy was measured by the differential scanning calorimetry on a DSC 404 F1 setup [11] in the temperature range of 187 K to 374 K. An ingot with a mass of 31.48 mg and a lithium content of 23.03 ± 0.02 at.% was used as a sample, the heat capacity of which was studied by us earlier in the range of 300 K to 781 K [1]. The Mg77Li23 pellet was placed in a platinum crucible with corundum inserts under a platinum lid. The weight of the standard sapphire sample was 85.28 mg. The experiments were carried out in the heating mode at a rate of 2 K·min−1 in a dynamic argon atmosphere (99.992 vol%) with an argon flow rate of 20 ml·min−1. The relative uncertainty of the measured cP values is about 3 %.

The thermal expansion of the magnesium–lithium Mg77Li23 alloy was investigated by the dilatometric method on a DIL-402C setup [12, 13]. Low-temperature measurements of the relative elongation ε and the linear thermal expansion coefficient α were carried out in the temperature range of 100 K to 400 K, in pure helium atmosphere (99.995 vol.%), and in the heating mode at a rate of 2 K·min−1. The elongation ε(T) of the sample was calculated from the relative change in its length L from room temperature Tr = 293.15 K to temperature T:

Numerical differentiation was used to calculate the linear thermal expansion coefficient α:

The α uncertainty is generally between 1 % and 3 % [13, 14]. As an object of the thermal expansion investigation the sample of an eutectic alloy with a lithium content of 23.03 ± 0.02 at.% was used, the volumetric properties of which were previously studied by us in the range of 300 K to 759 K [1]. The reproducibility of the results of this work on the heat capacity and thermal expansion coefficients with the corresponding temperature dependences cP(T) [1] and α(T) [1] in the range of 300 K to 400 K confirmed that the purity of the Mg77Li23 alloy samples had not changed after experiments [1].

To study the thermal conductivity of Mg77Li23 alloy in the temperature range from 80 K to 293 K, a Hot-Disk TPS 2500 S setup [15] was used, which implements the transient plane source method [16, 17]. The preparation of magnesium–lithium eutectic alloy samples to measure its thermal conductivity λ was carried out according to the procedure described earlier in Refs. [10, 18]. Magnesium and lithium ingots with a purity of 99.95 wt% were used. The magnesium was supplied by JSC “Solikamsk Magnesium Works”. The natural lithium was supplied by JSC “Novosibirsk Chemical Concentrates Plant”. The same metal components were used earlier [1] in the preparation of the magnesium–lithium eutectic alloy samples. Additional purification of lithium pieces from films of oxides and nitrides, preparation of magnesium and lithium weighings in the required proportion, and sealing of weighings in a molybdenum ampoule were carried out in a glove box filled with pure argon (99.992 vol%). The lid and crucible of the ampoule were machined from a molybdenum rod 40 mm in diameter (MChVP molybdenum grade with a purity of at least 99.94 wt%) and preliminarily annealed in vacuum (at a pressure of no more than 1 mPa) for 1 h in the temperature range of 1000 K to 1200 K. It is known that magnesium does not interact with molybdenum up to 2600 K [19], and liquid lithium practically does not dissolve molybdenum up to 1000 K [19]. Fusion and homogenization of the Mg–Li sample containing 23.00 ± 0.02 at.% Li in a molybdenum ampoule were carried out in a GP-2 scanning gamma-densitometer [10, 13, 20] furnace at a temperature of 970 K. The uniformity and homogeneity of the prepared Mg77Li23 ingot in the solid and liquid states were controlled by scanning with gamma radiation in the furnace of the GP-2 setup. Further, two plane-parallel cylindrical samples 36 mm in diameter and 18 mm high with carefully polished ends were machined from the defect-free part of the resulting ingot. Transiently heated plane sensor of the Hot-Disk TPS 2500 S setup (Kapton sensor K5501 12.8 mm in diameter) was clamped in the center between two disks of the eutectic alloy. The finished assembly with an S type thermocouple was immersed in a sealed stainless steel container, which was then evacuated and filled with an argon (99.992 vol%). A LAUDA KRYOMAT RUL 80 cryostat was used to cool the samples container to 200 K. Also, three measurements of the thermal conductivity were carried out near the boiling point of nitrogen. The instrumental uncertainty of the thermal conductivity measurements carried out on the Hot-Disk TPS 2500 S is 5 % [15].

3 Results and Discussion

The relative elongation ε and the linear thermal expansion coefficient α of the magnesium–lithium eutectic alloy were measured during four experiments in the heating mode. The ε results for different heating modes almost completely coincided with each other. Figure 1 shows the experimental data of the Mg77Li23 relative elongation studied in this work, as well as our previous ε data [1] obtained on the same sample and the ε(T) dependence for pure magnesium [10]. It can be seen from Fig. 1 that the results of the present and previous [1] works on the eutectic elongation overlap in the range of 293 K to 400 K and deviate noticeably from the magnesium ε(T) dependence [10] both above and below room temperature. Attention should also be paid to a sharp change in the slope of the Mg77Li23 alloy ε(T) dependence in the vicinity of 240 K (see Fig. 1).

Figure 2 compares the eutectic magnesium–lithium alloy linear thermal expansion coefficient α experimental data of this paper (smoothed with the Savitzky–Golay method) with the results of previous studies [1, 21] and with α(T) for pure magnesium [10]. It can be seen that the α(T) dependences for all heating modes are in good agreement with each other and smoothly transition to α(T) [1] obtained earlier by the dilatometric method on the same sample. According to our data, α(T) of the Mg77Li23 alloy exceeds the corresponding dependence for magnesium [10] by about 9 % in the range of 100 K to 228 K. Further, as can be seen from Fig. 2, the thermal expansion coefficient of the eutectic alloy experiences an abrupt increase by about 25 % in the range of 228 K to 248 K (significantly exceeds the uncertainty of dilatometric measurements), exceeding magnesium α by about 35 %. Further heating of the sample to 550 K does not lead to a significant change in the thermal expansion coefficient of the eutectic alloy (see Fig. 2). In this case, the Mg77Li23 alloy α values approach α(T) of pure magnesium. This result is inconsistent with the form of the Mg–Li phase diagram [3], according to which heating above room temperature leads to a gradual increase in the fraction of the (Li)-phase and, accordingly, a decrease in the fraction of the (Mg)-phase in the volume of the eutectic sample. Approximation of this work results in the range of 100 K to 228 K by the least squares method gave the following dependence:

where T in K, α(T) in 10−6 K−1. In the range of 248 K to 568 K, the data of this work and Ref. [1] were approximated jointly by the following dependence:

where T in K, α(T) in 10−6 K−1.

The linear thermal expansion coefficient experimental data of solid magnesium–lithium eutectic alloy: 1, 1st heating; 2, 2nd heating; 3, 3rd heating; 4, 4th heating; 5, α(T) for Mg77Li23 [1]; 6, α(T) for pure Mg [10]; 7, α(T) for Mg77Li23 [21]. The expanded uncertainties are given for the 95 % confidence interval

The investigation of the magnesium–lithium eutectic alloy heat capacity cP in the range of 190 K to 374 K was carried out during two experiments in the heating mode. Figure 3 shows the experimental data on the molar heat capacity CP and their comparison with the results [1] obtained by DSC on the same sample. It can be seen that the CP(T) dependences obtained in this work for both regimes agree well with each other and are well described by CP(T) from Ref. [1] above room temperature. To compare the results for the eutectic alloy with the heat capacity of pure Mg at 200 K to 300 K, the CP(T) of a magnesium sample [22] (with a purity of 99.95 wt%) was studied by the DSC method in this work in the corresponding temperature range. Approximation of the experimental data obtained for magnesium gave the following dependence in the temperature interval of 190 K to 300 K:

where T in K, cP(T) in J·(g·K)−1. The Mg77Li23 alloy heat capacity lies below CP(T) for magnesium in the range of 200 K to 223 K and increases almost linearly with temperature (see Fig. 3). Further, in the range of 223 K to 253 K, where peculiarities on ε(T) and α(T) were observed, the eutectic alloy heat capacity experiences an abrupt increase by about 12 % (which significantly exceeds the uncertainty of DSC measurements), approaching the CP values of magnesium. At the same time, no thermal effects were recorded on the obtained DSC signal in the vicinity of 240 K, due to their possible smallness and stretching in temperature. Above 260 K, the heat capacity of the eutectic alloy increases linearly with temperature and, as noted earlier [1], can be estimated from the CP(T) of pure magnesium. The results of this work in the range of 200 K to 223 K were approximated by a linear dependence:

where T in K, cP(T) in J·(g·K)−1. And in the range of 260 K to 616 K, the joint approximation of the present work results and Ref. [1] gave the following linear dependence:

where T in K, cP(T) in J·(g·K)−1.

Figure 4 shows the results of the magnesium–lithium eutectic alloy thermal conductivity λ measurements by the transient plane source method. The measurements were carried out after holding Mg77Li23 samples for three hours at a constant temperature, wherein two or three experiments were performed for each temperature. As can be seen from Fig. 4, the results of present work lie above the data of Ref. [1] by 5 % to 8 % in the vicinity of 293 K to 300 K, which does not exceed the total uncertainties of the laser flash method and the transient plane source method. Samples were cooled to 200 K using a LAUDA KRYOMAT RUL 80 cryostat. Figure 4 shows that, in contrast to the relative elongation, thermal expansion coefficient, and heat capacity of the Mg77Li23 alloy, the temperature dependence λ(T) does not show any features in the range of 200 K to 293 K. The thermal conductivity of the eutectic alloy increases continuously and without breaks with increasing temperature (see Fig. 4). Additionally, three measurements of λ were carried out in the vicinity of the nitrogen boiling point. Figure 4 shows that the results of these experiments are in good agreement with the dependence λ(T) obtained using the cryostat. Therefore, taking into account the absence of peculiarities on ε(T) and α(T) in the range of 100 to 200 (see Figs. 1, 2), all results of the hot-disk technique measurements are approximated by a single dependence:

where T in K, λ(T) in W·(m·K)−1. A comparison with pure magnesium λ(T) [23] showed that, in the studied temperature range, the ratio of the Mg thermal conductivity to the Mg77Li23 alloy thermal conductivity varies from about 30 (in the vicinity of 78 K) to about 3 (at room temperature).

We couldn't find any information in the literature on phase transitions in the magnesium–lithium eutectic alloy at temperatures below room temperature. It is known that pure magnesium retains its hcp crystal structure at atmospheric pressure over the entire temperature range of solid-state existence [2, 24]. It can be assumed that solid lithium solutions in magnesium (up to 17 at.% Li [2]) also have only one structure, hcp. Lithium, however, upon cooling to about 78 K, undergoes a spontaneous martensitic phase transformation from bcc to hcp phase [25]. It is also known [2, 8, 9] that martensitic transitions occur in solutions of magnesium in lithium, with a content of up to 24 at.% Mg. For example, the Mg12.4Li87.6 alloy phase transformation temperature lies in the vicinity of 125 K [8]. And, according to Ref. [2], the bcc → hcp transition temperature increases with an increase in the magnesium content. If we assume the presence of this martensitic transformation for all magnesium solutions in lithium ((Li)-phase), then the observations [8, 9] make it possible to clarify the nature of abrupt changes in the heat capacity (see Fig. 3) and the thermal expansion coefficient (see Fig. 2) of the eutectic alloy, since the alloy contains the (Li)-phase in its volume. The absence of peculiarities in λ(T) (see Fig. 4), as well as the absence of abrupt changes in relative elongation (see Fig. 1) and enthalpy, indicates the partial nature of the assumed martensitic transition of the bcc (Li)-phase to the hcp structure and insufficient sensitivity of the used methods for studying thermophysical properties. As the Mg77Li23 alloy martensitic phase transformation temperature we chose TM = 238 ± 10 K, which is the average between the temperatures of the onset and end of features on CP(T) and α(T) (see Figs. 2, 3).

The values of magnesium–lithium eutectic alloy thermal diffusivity a were calculated using the dependences λ(T), cP(T), ε(T) constructed in this work, the density at room temperature [1] and the relation λ = a∙cP∙ρ. Figure 5 shows the dependence a(T) calculated at 200 K to 300 K and its comparison with the results of the previous study [1] and the recommended data for pure magnesium [26]. It can be seen that the Mg77Li23 alloy thermal diffusivity changes abruptly by approximately 10 % in the vicinity of 238 K. Further heating of the eutectic alloy leads to a continuous increase in thermal diffusivity. The deviation of this work calculations from the results of Ref. [1] near room temperature is about 7 %, which does not exceed the total uncertainties of calculations and measurements by the laser flash method [1].

Tables 1, 2 and 3 summarize the smoothed and consistent values of the thermophysical properties of the Mg77Li23 eutectic alloy in the solid and liquid states investigated in the present work and [1, 10]. The expanded uncertainty of the relative elongation U(ε), the relative expanded uncertainties of the density Ur(ρ), the thermal expansion coefficients Ur(α, β), the heat capacity Ur(cP), the thermal conductivity Ur(λ), and the thermal diffusivity Ur(a) in Tables 1, 2 and 3 are given for the 95 % confidence band.

4 Conclusion

A complex experimental study of a number of thermophysical properties (thermal expansion, heat capacity, thermal conductivity) of the magnesium–lithium eutectic alloy containing 23 at.% Li carried out at low temperatures. The obtained results are compared with the data for pure magnesium and previous experimental data [1, 10]. The performed measurements made it possible to expand the temperature range investigated earlier [1, 10] and to construct the corresponding tables of recommended data. A phase transition was found in the vicinity of 238 K, accompanied by abrupt changes on the temperature dependences of the heat capacity and the linear thermal expansion coefficient. Presumably, during heating above this temperature, the (Li)-phase in the Mg77Li23 alloy undergoes a martensitic transformation from the hcp crystal structure to bcc. Apparently, the bcc (Li) phase is stable above 238 K, while below 238 K only a fraction of the (Li) phase volume passes to the hcp structure, as indicated by the absence of observed thermal effects and a relative density changes in this work. These assumptions are put forward on the basis of observations [8, 9, 25] and, of course, require direct experimental confirmation. Nevertheless, the obtained results indicate the need for a comprehensive study of the phase composition, phase equilibria, and other properties of magnesium–lithium alloys below room temperature in order to adequately analyze the prospects for their use as the basis for ultralight structural and engineering materials.

Data Availability

Data presented in this article are available upon request from the corresponding author.

References

ASh. Agazhanov, R.N. Abdullaev, D.A. Samoshkin, Yu.M. Kozlovskii, Thermophys. Aeromech. 29, 623 (2022). https://doi.org/10.1134/S086986432204014X

A.A. Nayeb-Hashemi, J.B. Clark, A.D. Pelton, Bull. Alloy Phase Diagr. 5, 365 (1984). https://doi.org/10.1007/BF02872951

W. Gasior, Z. Moser, W. Zakulski, G. Schwitzgebel, Metall. Mater. Trans. A 27, 2419 (1996). https://doi.org/10.1007/BF02652335

H. Haferkamp, M. Niemeyer, R. Boehm, U. Holzkamp, C. Jaschik, V. Kaese, Mater. Sci. Forum 350, 31 (2000). https://doi.org/10.4028/www.scientific.net/MSF.350-351.31

R.Z. Wu, Y.D. Yan, G.X. Wang, L.E. Murr, W. Han, Z.W. Zhang, M.L. Zhang, Int. Mater. Rev. 60, 65 (2015). https://doi.org/10.1179/1743280414Y.0000000044

X. Peng, W. Liu, G. Wu, H. Ji, W. Ding, J. Mater. Sci. Technol. 99, 193 (2022). https://doi.org/10.1016/j.jmst.2021.04.072

C.P. Liang, H.R. Gong, J. Alloys Compd. 489, 130 (2010). https://doi.org/10.1016/j.jallcom.2009.09.032

C.S. Barrett, D.F. Clifton, JOM 2, 1329 (1950). https://doi.org/10.1007/BF03399158

C.S. Barrett, Acta Metall. 4, 528 (1956). https://doi.org/10.1016/0001-6160(56)90049-9

R.N. Abdullaev, R.A. Khairulin, Yu.M. Kozlovskii, ASh. Agazhanov, S.V. Stankus, Trans. Nonferr. Met. Soc. China 29, 507 (2019). https://doi.org/10.1016/S1003-6326(19)64959-9

DSC 404 F1 Pegasus. https://analyzing-testing.netzsch.com/en-US/products/differential-scanning-calorimeter-dsc-differential-thermal-analyzer-dta/dsc-404-f1-pegasus. Accessed 19 April 2023

DIL 402 Expedis Classic. https://analyzing-testing.netzsch.com/ru/pribory-resheniya/dilatometriya-dil/dil-402-expedis-classic. Accessed 19 April 2023

R.N. Abdullaev, Yu.M. Kozlovskii, R.A. Khairulin, S.V. Stankus, Int. J. Thermophys. 36, 603 (2015). https://doi.org/10.1007/s10765-015-1839-x

Yu.M. Kozlovskii, S.V. Stankus, High Temp. 52, 536 (2014). https://doi.org/10.1134/S0018151X1403016X

Hot Disk TPS 2500 S. https://www.hotdiskinstruments.com/products-services/instruments/tps-2500-s/. Accessed 19 April 2023

S.E. Gustafsson, Rev. Sci. Instrum. 62, 797 (1991). https://doi.org/10.1063/1.1142087

L.M. Heisig, R. Wulf, T.M. Fieback, Int. J. Thermophys. 44, 82 (2023). https://doi.org/10.1007/s10765-023-03190-6

R.N. Abdullaev, R.A. Khairulin, Yu.M. Kozlovskii, S.V. Stankus, ASh. Agazhanov, Int. J. Thermophys. 44, 74 (2023). https://doi.org/10.1007/s10765-023-03187-1

Springer Materials—Properties of Materials (Springer, 2023). https://materials.bibliotecabuap.elogim.com/. Accessed 19 April 2023

S.V. Stankus, R.A. Khairulin, High Temp. 30, 386 (1992). https://www.mathnet.ru/eng/tvt3390. Accessed 19 April 2023

A. Rudajevová, S. Kúdela, M. Staněk, P. Lukáč, Mater. Sci. Technol. 19, 1097 (2003). https://doi.org/10.1179/026708303225004648

R.N. Abdullaev, D.A. Samoshkin, ASh. Agazhanov, S.V. Stankus, J. Eng. Thermophys. 30, 207 (2021). https://doi.org/10.1134/S1810232821020041

C.Y. Ho, R.W. Powell, P.E. Liley, J. Phys. Chem. Ref. Data 3, 1 (1974)

G.W. Stinton, S.G. MacLeod, H. Cynn, D. Errandonea, W.J. Evans, J.E. Proctor, Y. Meng, M.I. McMahon, Phys. Rev. B 90, 134105 (2014). https://doi.org/10.1103/PhysRevB.90.134105

C.S. Barrett, Phys. Rev. 72, 245 (1947). https://doi.org/10.1103/PhysRev.72.245

Y.S. Touloukian, R.W. Powell, C.Y. Ho, M.C. Nicolaou, Thermophysical Properties of Matter, vol. 10 (Plenum Press, New York, 1973)

Acknowledgements

This work was supported by the Russian Science Foundation (Grant No. 20-79-10025). Link to the project information: https://rscf.ru/en/project/20-79-10025/.

Author information

Authors and Affiliations

Contributions

RNA, writing; YMK, dilatometric and hot-disk measurements; DAS, DSC and hot-disk measurements; SVS, supervision; AShA, samples preparation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdullaev, R.N., Kozlovskii, Y.M., Samoshkin, D.A. et al. Peculiarities of the Eutectic Mg–Li Alloy Thermal Expansion, Heat Capacity and Thermal Conductivity Behavior in the Temperature Range of 80 K to 293 K. Int J Thermophys 44, 104 (2023). https://doi.org/10.1007/s10765-023-03212-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-023-03212-3