Abstract

Gypsum-based composite is a widely used material in construction applications; it is a traditional material that is frequently used in non-structural and decoration, such as dry walls and ceilings, because to its benefits, which include environmental aspects, sound and heat insulation capabilities, and fire resistance. Brittleness, poor mechanical properties, and high water absorption are the main drawbacks of gypsum-based composites, limiting their use. Fibers have been employed to improve the performance of gypsum-based composites in a number of research investigations. Natural date palm fibers (DPF) are considered efficient candidate for natural reinforcement in composites that dedicated to various applications due to many reasons, mainly, their low cost, good thermophysical and mechanical properties compared to man-made fibers. Date palm fibers-reinforced gypsum-based composites showed good overall performance and would be more commercially viable as building materials. This paper reviews previous research on date palm fiber-reinforced gypsum-based composites. This paper summarizes, evaluates, and discusses the sources and properties of gypsum and DPFs, the influence of these fibers on the mechanical and thermal properties of the composites, and it highlights the fiber surface treatments to improve the fiber–matrix adhesion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Building and construction sectors are among the world's largest consumers of energy and non-renewable resources. Approximately a third of the world's final energy consumption and nearly 15 % of direct CO2 emissions are caused by the building and construction sectors combined; moreover, buildings and buildings construction sectors continue to use more energy as a result of increased energy access, rising heating and air conditioning demand, and the rapid increase in the area of buildings around the world [1]. The data in the residential sector has shown that the world electric energy consumption has shown an increase from 4.2 EJ in 1973 to a value of 21.9 EJ in 2019 [2]. The energy consumption growth is related to some extent to the use of inefficient insulating materials with poor thermal properties. Several efforts have been undertaken to address the construction sector's energy efficiency problem, and improving the thermal insulation qualities of building materials is critical in this regard [3]. Because good insulation minimizes energy consumption, less energy is required to cool the space in the summer and less heat is required to keep the room warm in the winter [4]. Besides, efficient thermal insulation can significantly contribute in reducing the electricity demand and provide a comfortable indoor environment in buildings [5]. By employing thermal insulators in buildings, a significant reduction in energy consumption for heating and air cooling can be achieved [4], and therefore a significant save in the electric demand of the house. However, the reduction amount in energy consumption is dependent on the climate conditions as well as the applied insulator type and thickness. In this context, thermal insulation performance in buildings has become the major topic in this area [5].

In the last few decades, a huge awareness has been dedicated into using composite building materials that have high thermal insulation efficiency for energy saving [6,7,8]. Gypsum plaster is a commonly used building material that may compete with cement because of its availability in subsoil, low cost, convenience of usage, and mechanical qualities appropriate for a wide range of applications [9]. Gypsum plaster is used in buildings, especially in walls or false ceiling [3]. However, gypsum has many disadvantageous. It is sensitive and difficult to adapt to hot and cold climatic conditions [3]. Furthermore, gypsum plaster appears to be heavy, porous, and brittle. However, by combining gypsum plaster with fiber, the heaviness and brittleness can be substantially reduced [9]. Synthetic fibers have forced researchers to develop new materials that are low cost, renewable, and environmentally friendly, such as natural fibers, which are less reliant on fossil fuels [9]. The qualities of gypsum plaster can be improved by adding fibers to generate fiber-reinforced gypsum composites to overcome the shortcomings of the net material due to the exceptional strength, toughness, and durability of natural fibers over their lifetime [10]. Natural fibers can also play a significant role in thermal insulation due to a number of advantages: low environmental impact, biodegradable, inexpensive, long-lasting, and possesses strong thermophysical features [5]. It has been believed that adding fibers to strengthen quasi-brittle matrices will greatly improve their overall behavior in a cost-effective manner [10,11,12]. Indeed, improved mechanical, thermal and acoustic properties have been reported as a result of using fibers compared to the non-fiber-reinforced gypsum-based composites [10, 13, 14].

Date palm wood waste is a natural material available in a huge quantity in MENA region (Middle East and North Africa). From this wood, natural fibers can be extracted through various processes. Many researchers were dedicated their studies on this available renewable resource, as a low cost product for reducing heat loss in buildings [15,16,17,18,19,20]. Date palm fibers (DPF) are a promising candidate for the development of energy-efficient and safe insulation materials [15]. The developed gypsum-DPF demonstrated excellent thermal and mechanical features, allowing them to be used as a thermal insulation material [18]. Similarly, Portland-cement was chosen as a binder-based matrix, and the obtained results revealed that the use of DPF is a promising choice for use as a thermal insulation material in buildings [17]. Hygric properties and durability of this composite were investigated and showed encouraging results [21, 22]. The thermal, mechanical, and acoustic properties of a lime-based matrix reinforced by DPF were investigated [23]. The results suggested that the material might be used as a good thermal insulator (thermal conductivity was as low as 0.091 W·m−1·K−1 for samples with 50 % w/w load of DPF) with good sound absorption capacity. On the other hand, the research has found that valuing local materials, particularly soil and plant waste, is a smart method to fulfill the goals of low cost building materials, thermal comfort, reduced energy use, and fewer fossil carbon dioxide emissions. In this regard, the thermophysical and mechanical properties of raw soil-based bricks mixed with date palm waste aggregates were examined [24]. The results showed that the thermal insulation has improved from net samples with 0.677 W·m−1·K−1to those mixed with 10 % DPF with 0.342 W·m−1·K−1. However, because of the poor compatibility between fiber surfaces and matrix, an increase in thermal insulation capacity was frequently followed with a decrease in mechanical properties. The fiber–matrix interfacial domain is a critical factor in fiber-reinforced ceramic matrix composites (CMCs), and the composite will be either brittle or damaged tolerant, therefore certain parameters must be met [25].

The main objectives of the present paper are the following: (a) to review and highlight the efficiency of the DPFs in the field of composites for construction applications in regard to worldwide abundance, extraction processes of fibers, thermophysical and mechanical properties compared to some fibers, and construction applications as competitive reinforcement material for insulating. (b) to review and highlight the efficiency of gypsum as an ancient building material lately received much attention in reinforcement applications with fibers, in terms of environmental friendliness and thermal isolation compared to some other commonly used matrices. (c) to review and highlight the efficiency of the combination between gypsum-based matrix with DPFs mainly in regard to thermal insulation advantages in construction and to present the benefits of surface treatment of fibers in this regard. To the best of the authors’ knowledge, no review paper has been conducted on gypsum-based composites reinforced with palm fibers in construction applications.

The editing of the present review paper has been based on many references from different types of books, book sections, conference proceedings, reports, review papers, and original research papers. The methodology of the work is in brief as follows: The first section outlines the DPFs’ renewable sources worldwide, extraction processes, properties, and applications as reinforcement. The second section summarizes the useful features of the gypsum in construction in terms of reinforcement with fibers and isolation. The third section describes the advantages of reinforcing gypsum-based matrix with DPFs in regard to thermal insulation in construction and summarizes the surface treatment processes and influences. Finally, a conclusion that summarizes the main points is mentioned.

2 Date Palm Trees (DPT) and Date Palm Fibers (DPF)

Phoenix dactylifera L., the date palm, is a member of the Palmae (Arecaceae) family [26]. The Middle East and North Africa are the traditional cultivated arid regions of this species (mostly in Algeria, Saudi Arabia, Iraq, Pakistan, Egypt, Sudan, Oman, Iran, and Tunisia [27]), although these are not the only places in the globe where it is grown (e.g. California, Peru, and Australia) [26]. The date palm is adapted to hot climates and a certain level of salinity in the soil. The date palm tree uses the thermal insulation strategy to endure hot conditions and retain its trunk at acceptable and suitable temperatures for its growth and development when temperatures in the shade exceed 50 °C [23].

Date palm can grow in single stems or in clumps with multiple stems from a single root system. The DPT trunks can grow up to 30 m tall [26], as shown in Fig. 1. Large pinnate leaves (3 m to 5 m long) with 50–130 leaflets on each side of a ligneous midrib (rachis) [26]. The male and female flowers of the date palm are born in separate individuals, making it a dioecious species [26].

2.1 DPT waste

Figure 2(a) depicts the DPT structure. At the base of the trunk, several offshoots might be generated. Persistent leaf bases (midrib base—petiole) cover the brown-colored trunk. On the top of the trunk, several leaves distributed 360° around the tree, and each leaf is a long midrib with spines and pinnate with leaflets. Each year, 10 to 20 new leaves are normally generated [27].

(a) Phoenix dactylifera L. structure [29]; (b) annual pruning by-products (photograph from El-Meghaier, Algeria)

During the harvest seasons of palm fruits (dates) every year, large quantities of agricultural wastes can be accumulated in the agricultural lands of many countries (Fig. 2(b)). However, these wastes are disposed without any economic utilization value. These valuable biomass wastes can be used as new sources of cellulosic fiber [27]. The natural fibers can be acquired from the mesh, midribs, leaflets, and spadix stems (Fig. 3) [28]. Date palm leaves are divided into three sections: (i) the midrib, (ii) the midrib base, and (iii) the leaflets. The midrib, sometimes known as the rachis, is the central section of the date palm leaf that carries the leaflets [28], while the midrib base is sometimes referred to as petiole [15]. The date palm surface is also referred as the mesh [28].

A single date palm can produce around 26 kg of waste per year from various parts of the tree [27]. The total amount of agricultural waste in MENA region (Middle East and North Africa) produced annually can vary from 2.6 to 2.8 million tones [27]. Unfortunately, the volume of these agricultural wastes is not correctly determined, and they are not used in many industrial applications as important renewable resources of cellulose, hemicelluloses, lignin, and other compounds [27].

2.2 Extraction of DPF

The interest of natural fibers has been increased due to the increasing demand for more sustainable applications. In comparison to man-made fibers, natural fibers are environmentally friendly and offer high specific properties (due to their lightweight). Because to the large number of date palm units, annual pruning creates a large amount of by-products, making date palm one of the most readily available natural fiber sources. Fibers can be extracted from four parts of palm tree: (i) mesh, (ii) spadix stems, (iii) midribs, and (iv) leaflets. Several techniques have been used to extract the natural fibers from all parts of the palm tree; i.e. extraction of fibers mechanically or by separating cellulose fibers from lignin and hemicelluloses using chemical or biological treatments. Extraction processes that produce pure, long, and fine fibers with minimal damage are considered successful [28]. The technique of fiber extraction has an impact on the physical properties of the fibers [27].

Mechanical extraction and alkaline treatment with NaOH are the two most commonly used extraction procedures mentioned in the literature [28]. Mechanical extraction often involves chopping and grinding date palm parts into small pieces without attempting to delignify the fibers, whereas mesh fibers exist in a special form that may be easily separated by hand or with water [28]. Figure 4 depicts the mechanical technique for extracting palm fibers.

DPF extraction techniques and physical and mechanical properties (d: diameter, L: length, ρ: density, σ: tensile strength, and E: modulus of elasticity) [28]

Regarding the chemical treatment, alkaline treatment (with NaOH) is the most common extraction technique, as mentioned. Different NaOH combinations were tested (NaOH concentration, treatment temperature, and treatment duration), and the most common combinations employed were 1 % NaOH at 100 °C for 1 h and 5 % NaOH at 90 °C for 3 h [28]. Many other different alkaline solutions were used in literature, such as cement solution [31], calcium hydroxide Ca(OH)2 [19], and calcium oxide CaO [32]. On the other hand, acidic chemicals were also used for treatment, such as hydrochloric acid HCl solution [33]. In the literature, an unusual extraction technique based on oxygen plasma was applied at varied plasma discharge powers and exposure times [34].

Bezazi et al. [29] extracted raw fibers from date palm rachis using two methods: (i) retting in water for 3 weeks, and (ii) boiling in water for 2.5 h. These techniques were used to facilitate the individual separation of the fibers from the gums, waxes, and pectin. The investigated mechanical behavior showed that the fibers extracted by boiling provided higher tensile strength and Young’s modulus compared to fibers retting in water (with a difference of about 12.43 MPa and 1.26 GPa, respectively). These results are in accordance with the data found in literature as the authors indicated. In this context, it is worthy to mention that retting with warm instead of cold water reduces the process time between 70 h and 100 h under controlled conditions (temperature and pH) [29, 35].

2.3 Date Palm Fibers (DPF)

One of the sources of natural fibers is DPT wood waste. The natural fibers can be extracted from the date palm tree wood waste that has been obtained by annual pruning of different parts of the plant (i.e. midribs, leaflets, spadix stems, and mesh). Natural fibers can be used in developing composites suitable for different industrial applications. Furthermore, the cost of natural fibers and their global availability are considered to be the most important parameters for their applications in many industrial sectors [27].

The number of date palms in the world is estimated at about 120 million units [36], and when taking the average of 35 kg of palm residues per tree per year, then, the estimated rawDPF s will be about 4200 metric tons yearly [37], more than 10 times the quantity of sisal fibers commercialized worldwide as shown in Table 1.

The inexpensive cost of natural fibers in comparison to synthetic materials is one of the key reasons for their adoption in industry [37]. The cost of raw natural fibers varies per kind, but DPF are considered among the most abundant and cost-effective natural fibers (NF) due to their widespread availability, according to Awad et al. [27]. Moreover, it is noted that DPF have thermal conductivity less than that of hemp and still close to sisal [23]. As mentioned in the study of Agoudjil et al. [15], the thermal conductivity values of DPF, hemp, and sisal are respectively, 0.083 W·m−1·K−1, 0.115 W·m−1·K−1, and 0.07 W·m−1·K−1. It is important to mention that there are different types of each kind of natural fiber, different structure, pore distribution make it possible to obtain significantly different results of thermal conductivity. Low thermal conductivity of DPF can be attributed to the low density that resulted from the high mean diameter (i.e. high voids) of these fibers compared to other fibers, as shown in Table 2. As a result of these advantages, DPF is unquestionably a competitive material. These facts encourage the researchers for finding new ways to valorize these abundant renewable resources. Some already implemented ideas are based on extraction of DPF from different parts of DPT (agricultural waste) using various techniques (i.e. biological, mechanical, and chemical [27]) and use the extracted natural fibers in different applications. The fibers mechanical performance can be influenced by the extraction procedure, according to Soltan et al. [38] and as shown in the review study of Elseify et al. [28].

Plant fibers cell wall is mostly made up of three major organic polymers: cellulose, hemicellulose, and lignin [37]; cellulose is surrounded by hemicelluloses and incorporated in lignin as a matrix, giving it a composite-like structure [28]. Because of their diverse molecular composition and structure, these polymers have variable mechanical and water absorption properties [37]. The majority of lignocellulosic fibers (a scientific term that also refers to plant fibers) contain 50 to 70 % cellulose [39]. Thus, cellulose is the principal constituent for all the plant fibers [40]. C, H, and O are the main elements of the cellulose with a chemical formula of C6H10O5 [39]. The cellulose affects the most characteristics of the lignocellulosic fiber [39], and because of the hydroxyl group (‒OH) in the cellulose chain, all the plant fibers are hydrophilic in nature [41]. Furthermore, as compared to other organic polymers, cellulose is a chemically stable material that cannot be dissolved by alkaline solutions and has a great resistance to acids (excluding strong acids at high concentrations) [28].

Hemicellulose and lignin are the most abundant components after cellulose. Hemicellulose is a polymer made up of sugars like glucose and glucuronic acid that can form amorphous, branched, or non-linear structures with limited strength [42]. Lignin is a complex organic polymer in which has a highly complex amorphous structure [39]. Furthermore, lignin fills the gaps between the cellulose and hemicellulose in the cell wall [43], and it is also thought to be a viable natural resource for adhesive and coating applications [44]. The three large polymers are bonded together by covalent bonds [39]. DPF cellulose and lignin mean contents are compared to those of other natural fibers in Table 3. Besides that, DPF contain mineral substances such as phosphorous, calcium, iron, and silicon [45], but in quantities depending on the date palm parts from which the fibers were extracted.

It can be seen that the cellulose content in DPF is lower than that in sisal and hemp fibers. Compared to coir fibers, this content is relatively high. This fact contributes in reducing the water absorption ability in DPF compared to sisal and hemp fibers, in addition to having better mechanical and weathering properties than coir fibers [37]. In addition, as compared to coir fibers, cellulose content in DPF is higher than lignin content, similar to sisal and hemp fibers. Low lignin/cellulose ratio (low lignin content with high cellulose content) alters the cellulose degradation pathway and leads to incomplete combustion of natural fibers [47]; this behavior can be important in the field of fire resistance.

Natural fibers are characterized also by very good mechanical properties compared to glass fibers (man-made fibers and among the most versatile industrial materials known today) in specific strength and modulus [48]. DPFs have low density (0.9 g·cm−3 to 1.2 g·cm−3) and a high elongation to brake (2 % to 19 %) which can compete with glass fibers that characterized by density of 2.5 g·cm−3 and elongation to brake (2.5 % to 3 %) [37, 48].

Finally, the origin of the plant, as well as agricultural parameters (soil quality, weathering conditions, retting procedure, and so on) can affect the chemical analysis of DPF [49], and therefore the results shown in the previous Tables. Moreover, the DPF extracted for different parts of the plant may show a difference in their contents of cellulose, hemicellulose, and lignin as shown in the study of Awad et al. [27].

Finally, DPF are considered efficient candidate for natural reinforcement in composites that dedicated to various applications.

2.4 DPF Characteristics According to Date Palm Parts and Varieties

The date palm trees are existing in different varieties, such as Deglet-noor (DN), Mech-deglet (MD), and Elghers (EG) [15]. The thermophysical properties of date palm samples cut-out from petiole or/ bunch (spadix stems) of different varieties (DN, MD, and EG) of Algeria region are shown in Table 4. At room temperature and atmospheric pressure, all of the data were attained. The thermal conductivity and density of the investigated wood samples (and hence the extracted fibers) are seen to be dependent on the date palm tree's part and variety. The influence of date palm variety and part on thermal conductivity was found to be minor when compared to the effect of other parameters [15]. Alotaibi et al. [46] showed in their study on different types of DPFs extracted from different parts of the tree that there is a noteworthy difference in the chemical composition of fibers (in regard natural polymers contents). It is worth noting that the chemical make-up of date palm wood (and thus the derived DPF) varies from country to country [27], this is due to the climate and geographic conditions, which have an impact on the structure and chemical compositions of DPF [50]. Regarding the thermal stability of DPFs, it was concluded that the natural palm fibers extracted from the fruit bunch stalk (spadix stems) is more thermally stable (higher thermal degradation temperature) with rougher fracture surface which may lead to increase isolation and bonding strength in composites [46].

The DPFs extracted from different parts of the plant showed a difference in morphology according to SEM images as shown in Table 5. The same observation was reported in the study of Djoudi et al. [51] in regard to mechanical properties and the values of X-Ray diffraction analysis.

2.5 Applications of Date Palm Fibers DPF

Date palm fibers, which are extracted from various parts of date palm trees, have just a few traditional uses. DPFs, for example, have been utilized in the past as (i) cushion material, with the leaflets shredded into coarse fibers and used as fiberfill in cushions; and (ii) cords, with the fibrous mesh enclosing the trunk opened and spun into cords [28]. DPF have been used in a variety of novel applications, including papermaking, particleboard uses, insulating panels, and, most notably, as reinforcement in a variety of matrices (polymer, cement, gypsum, etc.) [28]. DPF have shown to be quite competitive in the automotive industry when compared to other natural fibers [37].

The reinforcement efficiency of natural fibers is measured by the stress transfer between the matrix and the natural fibers. The stress transfer depends on the strength of natural fibers and as well as their length [28]. If the fibers length is less than the so-called critical stress transfer length (critical length), they are considered inclusion rather than reinforcement, hence, lowering the composite's strength [28]. Besides to the stress transfer, the microfibrillar angle (MFA) of fibers inside the composite has an influence on the overall strength of the composite, where the smaller MFA the more load the fiber could carry [28]. Because the applied load will have two components, horizontal and vertical, the inclination of fibers affects their ability to carry the entire load [28].

In the future, the demand of natural fibers (mainly the wide available ones with competitive price such as DPF) would show an increase due to the increase of urbanization and projects mainly in construction and infrastructure such as construction applications (e.g. reinforcement of concrete) and geotechnical applications (e.g. geotextiles).

In a general way, the reinforcement of the matrix with natural fibers has a positive influence on the mechanical properties and the thermal insulation behavior. As indicated by [19, 20, 28], the addition of DPF into cement improved the strength properties of the composite. The toughness improved as a consequence of using long DPF with increasing fiber weight fraction, according to the same authors. Besides that, density and ductility of mortar were improved due to the incorporation of mesh fibers [28, 52]. Moreover, the use of mesh fibers with maintaining weight fraction significantly improved the thermal insulating capacity by reducing the thermal conductivity coefficient of the composites [28, 53, 54]. Figure 5 summarizes some of the main applications of palm fibers.

3 Reinforcement with Natural Fibers

Natural fibers, as noted in the literature, are gaining a lot of attention these days due to their multiple benefits, including low cost, biodegradability, eco-friendliness, and relatively good mechanical properties [55]. As a result, natural fibers are used as reinforcement for a variety of matrices [56]. Gypsum, lime, cement, and earth are among the most used matrices for construction applications.

3.1 Gypsum

Gypsum is a commonly used building material (it is an ancient decorative material that is frequently utilized in interior linings such as walls and ceilings [57]) and that is due to its advantages, mainly, the environmental friendliness, sound and thermal isolation properties [58]. Aside from that, due to the significant latent heat associated with dehydration into hemihydrate and anhydrite, gypsum is commonly utilized to create firebreak systems (i.e. gypsum is fire resistant) [59]. Moreover, gypsum can be recycled using appropriate processes [10]. The range of gypsum applications is limited, however, because to several of its notable shortcomings, such as brittleness, heaviness, low water resistance, and shrinking during fire exposure [60,61,62,63,64]. Many strategies have been suggested to overcome the drawbacks of gypsum-based composites, as the addition of slag, fly ash, and phase change material (PCM), etc. [65, 66]. In contrast, the strategy of using fibers has been attracted the researchers because of the excellent properties of fibers (strength, toughness, and their durability over their service life), since using fibers was believed to overcome the matrix shortcomings and to improve dramatically the composites’ properties [10, 67]. In comparison to net composites (i.e. without reinforcement), gypsum-based composites reinforced with fibers have better mechanical, thermal, and acoustic properties [10, 13, 14]. In this context, glass fiber is widely used, but this use ran into many disadvantages: (i) its high cost makes it difficult to combine with a low-priced material (such as gypsum), (ii) the accepted reinforcement is usually in the form of short fibers rather than fabric [68]. As a result, the usage of glass fibers as reinforcement may pose health concerns during manufacturing, recycling, or even after an accidental break [68]. Natural fibers, with their low cost, great strength, and lack of harm to human health, are one of the conceivable options in response to the global desire to reduce environmental effect.

Many studies on natural fiber-reinforced gypsum-based composites have been published [14, 59, 69, 70]. The purpose of many of these researches is to obtain new composite materials with improved thermophysical and mechanical properties for reducing the building energy consumption. Various natural fibers were used in the literature as reinforcement to overcome some drawbacks of gypsum matrix. Among them, hemp fibers (Fig. 6a), sisal fibers, cork fibers and paper fibers were mentioned in many studies. Generally, the incorporation of fibers in gypsum matrix increased remarkably its comprehensive properties [10, 14, 71].

When comparing net gypsum to gypsum reinforced with hemp fibers, the material containing hemp fibers showed a considerable drop in heat conductivity and a significant increase in mechanical properties [70]. In a similar study, during a fire exposure (150 °C and 250 °C), hemp fibers acted as a thermo-mechanical reinforcement of gypsum panels (i.e. toughening role), and hence preventing the brittle collapse of matrix [59]. These studies encourage using hemp fibers (and in general, natural fibers) as gypsum-reinforcement in the production of materials with different applications: as false ceiling, wall material, toughened gypsum plasterboards for fire-protection. In a similar way, sisal fibers were also chosen to manufacture gypsum-fiber composites [69]. Cork fibers and paper fibers (cardboard waste) were used also as gypsum reinforcement to form an eco-friendly composite material for building thermal insulation [14].

According to Jia et al. [10], in the field of fiber-reinforced gypsum-based composites, natural gypsum (NG) and gypsum by-products [flue gas desulphurization gypsum (FGDG) and phosphogypsum (PG)] have been employed in several researches, and the characteristics of these types are given in Fig. 7.

Characteristics of some gypsum types often used with fibers [10]

Natural gypsum comes from natural minerals, whereas gypsum by-products come from various chemical processes [10]. By-products of gypsum include also fluorogypsum and red gypsum [10]. FGDG is a gypsum by-product produced in coal-fired power plants during the flue gas desulfurization process [73]. Phosphoric acid plants produce PG as a waste by-product during the processing of plant rock [74]. Gypsum by-products are often waste materials with large amount which are discarded without any treatment, and that created great hazard issues on the environment and on the human health [10, 75,76,77,78,79]. Gypsum by-products can be reused to make building gypsum (BG) and high-strength gypsum (HSG) in a cost-effective manner [10]. BG is mainly composed of β-CaSO4·0.5H2O and CaSO4, and it is obtained through calcination of gypsum by-products [10, 80,81,82,83]. The mineral composition of HSG is α-CaSO4·0.5H2O, and it can be produced by reusing of gypsum by-products [10, 84,85,86]. Besides gypsum by-products, NG also can be used to produce BG and HSG [10]. NBG and NHSG are the abbreviations for BG and HSG made from NG, respectively, and Table 6 illustrates their mechanical strength.

3.2 Lime

Besides to gypsum, lime based mortar has been used for centuries in the field of construction as a stone binder in ancient buildings [87]. However, the development of Portland cement in mid nineteenth century affected the use of lime in construction. Nevertheless, the necessity to develop environmental-friendly products increased the attention of using lime again as a building material. Nowadays, lime is frequently utilized in the manufacture of exterior plasters, mostly to protect load-bearing structures from the weather [88]. Due to the effects of temperature changes, heat expansion and shrinkage cracking, water erosion, freezing and thawing [88] as well as the brittle character of the material and relatively low mechanical properties [25], the durability of lime based binder is posed as a critical issue. Organic additions (plant extracts, rice paste, molasses, egg white, etc.) were commonly utilized as a solution in ancient constructions because they contain fats, proteins, and carbohydrates, which have a good effect on the binder by minimizing the cracking effect, as indicated by Tamas-Gavrea et al. [89]. Furthermore, using short fibers as reinforcement randomly distributed throughout the matrix is one of the most effective approaches to improve the major defect of lime-based matrix (plastic shrinkage) [88]. Besides that, with short length fibers the diameter change expected to be very small over the longitudinal direction [45]. Nowadays, the building industry encourages the use of “green materials” and therefore choosing natural fibers as reinforcement of lime plasters (Fig. 6b). In this context, many obtained results in the literature are very encouraging.

Lime plasters have been reinforced with sisal fibers and kenaf fibers of 5 mm length; the obtained results were encouraging in terms of durability compared to polymeric fibers [88]. Besides the earlier fibers, good results have been obtained in terms of thermal, mechanical and acoustical properties when using sheep wool fibers with a length of 1 mm to 10 mm as reinforcement in lime based mortar [89, 90]. According to Formisano et al. [91], raw jute fibers can be utilized to reinforce lime-based mortar as a building product in seismic zones. In bending tests, 1 % jute fibers of length 5 mm to 15 mm rendered the composite more ductile, with an average ultimate displacement roughly 15 % higher than the unreinforced samples; in compression testing, the stress was reduced by 25 % (with reference to unreinforced fibers) [91]. Depending on the kind of matrix, basalt fiber type, and fiber concentration, basalt fiber reinforcing of lime-based mortar improved post-cracking behavior and compressive strength significantly [25]. Chemical surface treatment of hemp fibers was discovered to play a significant influence in the strengthening of the lime-fibers interface as well as the overall stiffness of the composite in a study by Le Troedec et al. [87]; in the previous study, the lime reinforcement was based on hemp fibers with lengths ranged between 1 mm and 10 mm.

3.3 Cement

Besides to gypsum and lime, a new inorganic matrix has been attracted the focus of the researchers many years ago mainly due to some interesting mechanical properties. However, because Portland cement is a brittle material, introducing fibers into the cement matrix can help to improve several defects, such as toughness and the elimination of temperature and shrinkage cracks [92]. The properties of Portland-cement-based composites reinforced with natural fibers were investigated at the end of the 1970s [93]. It was concluded that natural fibers might be used to reinforce Portland-cement-based matrices, with promising results similar to those reported with maguey fiber reinforcement [94]. Unprocessed natural fibers were widely chosen to reinforce gypsum, lime, and also Portland-cement matrices, and the reason behind that being in their obtaining process at low price, their minimal carbon impact and good mechanical properties. Natural fibers reinforced cementitious composites had been widely investigated for several applications [95], for example, they can be used to strengthen masonry constructions and as sandwich panels [96]. The prepared sample, as shown in Fig. 6(c), is made up of cement mortar reinforced with DPF.

In Mexico, lechuguilla fibers (of 20 mm to 30 mm length) were used as a material of reinforcement in Portland-cement due to their wide availability [93]. Besides, the reinforcements were at a dosage of 1 % by volume using treated and untreated fibers. The results showed that using natural fiber (lechuguilla) as reinforcement leads in a composite with a ductile post-crack behavior under bending. In another study, cementitious matrix reinforcement was tested with hemp fibers and sugarcane bagasse fibers [96]. Bagasse fiber increased flexural strength, while hemp fibers increased composite toughness, according to an experimental investigation.

3.4 Soil

Among used building materials since ancient decencies, raw soil. Raw soil, like lime, has been abandoned since the invention of cement [97]. However, some African rural communities continue to live in earthen buildings. Depending on the extraction sites, natural soil contains varying quantities of clay, silt, sand, and gravel. Soil as a natural building material has received a lot of attention as a result of the increased awareness for healthy building materials. Furthermore, when compared to industrial building materials, soil requires less energy in the manufacturing process [72]. Moreover, soil is a recyclable, inexpensive, and readily available building material [72]. Raw soil was utilized in construction in many techniques such as mud brick, rammed soil, adobe, and so on [97]. The most common techniques, primarily using cement, are compacted soil bricks (CEB) and stabilized blocks [98]. CEB stands for compacted earth brick, a relatively new method that allows for flexible blocks to be integrated into a post-beam structure as filling material or as the principal material in a load-bearing wall [97]. Many studies have looked into the impact of using natural fibers as reinforcement in CEB. The impact of aggregate or fiber is widely established to be dependent on the type of plant aggregate or fiber, particle geometry, and soil composition [98]. Increased aggregate or fiber content in the soil matrix has a common impact on: (1) the physical properties: adjust the density, the shrinkage cracks, and sound insulation; (2) the mechanical properties: improve ductility, tensile and flexural strength; (3) the thermal properties: improve insulation capacity which is directly linked with the density [98]. Various types of natural fibers were used for reinforcement of soil matrix as: alfa fibers [97], diss fibers [99], straw fibers and Ocenaica seagrass fibers [100], hemp and flax fibers (Fig. 6d) [72].

4 Effect of Matrix Type and Fibers’ Dimension on DPF-Reinforced Composites

From the perspective of enhancing the thermal insulation of buildings using eco-friendly materials, a developed idea has been formulated lies in the reinforcement of matrix materials with widely available natural fibers in MENA region. Various composites using DPF have been created with the purpose of producing an insulating material that will reduce heat loss in buildings. The only reinforcement approach investigated in this work is one that relies on uniform fiber dispersion in the matrix to generate a homogeneous mixture.

4.1 Cement Mortar vs. Gypsum Plaster Reinforced with DPF—Petiole and Rachis

By using the same source of DPF (mechanical extraction technique of midrib base (petiole) and a ligneous midrib (rachis), which are the most available wood waste of the date palm trees), gypsum-based matrix [18] and cement mortar based matrix [17] were reinforced with small fibers (tiny sticks) of 3 mm or of 6 mm mean diameter (Fig. 8) with various weight ratios. The purpose of these studies is the investigation of thermal insulation and mechanical performance of the developed DPF composites. The results are discussed based on RILEM requirements for structural and/or insulating applications of lightweight concretes (Table 7).

Extraction of date palm fibers (b: [17]) from dry wood waste (a)

Hemihydrate gypsum (HG) has been reinforced with various weight ratios of DPF ranged from 1.2 % to 10 % [18]. Figure 9 summarizes the preparation process of gypsum-DPF composites. In contrast, DPF have been mixed with cement based mortar (Portland cement, sand of 5 mm maximum size, and water) with weight ratio ranged from 5 % to 15 % [17]; the preparation process of the composites is depicted in Fig. 10.

Components of gypsum composites reinforced with DPF [18]

Components of DPF-reinforced cement mortar [17]

The type and concentration of the ingredients, the mixing procedure, the curing conditions, the testing protocols, and other factors all may have an impact on the composites' mechanical and thermophysical properties.

4.1.1 Reinforcement with Fine Fibers

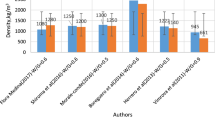

The results of thermal and mechanical tests of the studied matrix materials (i.e. gypsum and cement mortar) reinforced with fine DPF (i.e. of 3 mm size) are shown in Fig. 11.

According to RILEM (Table 7), it can be seen that net gypsum (0/G) is suitable material for thermal insulation and structural application compared to net cement mortar (0/C). Hence, adding DPF strongly improved the insulating behavior of net gypsum while maintaining a good mechanical resistance. On the other hand, the reinforcement of cement mortar with DPF strongly enhanced the thermal insulation property of the net matrix. However, this enhancement is accompanied with a huge reduction in the compressive strength. As an example, adding 5 % DPF to net gypsum material (5/G) lowered thermal conductivity by about 55 % compared to 52 % in the case of cement mortar. However, compressive strength decreased by about 14 % for gypsum matrix compared to around 92 % for cement mortar matrix. The properties of composite materials are well known to be dependent on the properties of their constituent components and their interfacial compatibility [102]. Cement mortar has a higher mechanical strength compared to gypsum, but the incorporation of DPF strongly reduced that property. This behavior can be due to the chemical incompatibilization between the fibers and the matrix. The inclusion of natural fibers in a mineral or polymer matrix can result in an interface incompatibility between the fibers and the matrix, as reported in the literature [87]. The compatibility of DPF seemed poor with cement mortar material (i.e. low interfacial bonding) and that led to create many voids between the matrix and the fibers compared to gypsum matrix. Consequently, the poor compatibility promoted low mechanical resistance. Furthermore, the roughness or smoothness of the fiber surface may affect the interfacial bond fiber–matrix and, as a result, the mechanical strength [21]. Because natural fiber is a complex heterogeneous polymer composed mostly of cellulose, hemicellulose, and lignin, polymer shape, extractive synthetics, and handling conditions have an effect on the surface [103].

Natural fibers as reinforcements in composites demand a high level of adhesion and bonding between the fibers and the matrix, regardless of the matrix utilized [103]. According to that, the reinforcement of gypsum material with DPF seems a very good choice for better thermal insulating and structural application. In the studied range of DPF content, thermal conductivity of gypsum-DPF achieved values below 0.3 W·m−1·K−1, while the compressive strength values are above 3.5 MPa. In contrast, cement mortar–DPF composites are suitable only for thermal insulating application, since the compressive strength values are very low (below 3.5 MPa). However, cement based composites can be considered pollutant materials with a high environmental impact due to effects of cement production.

4.1.2 Reinforcement with Large Fibers

A different behavior has been noticed when large size fibers have been used in the reinforcement of gypsum material. The results are compared to those reinforced with fine size fibers.

The results in Fig. 12 indicate that the use of fibers with large size has a slight influence on the thermal conductivity of gypsum material. The reduction in thermal conductivity did not exceed 16 %. Thus, the DPF size effect on thermal conductivity is less obvious. However, the reduction in compressive strength by adding large size fibers was more obvious. This reduction is in the range of 30 % to 50 %. Thermal conductivity and compressive strength are shown to have a direct relationship. Increased air gaps inside fibers (large sized fibers are more porous than the smaller sized ones) reducing thermal conductivity, and resulting in decreased mechanical strength. Moreover, fibers with high length creates a practical problem of flocculation of fibers during mixing, and this yielding a non-homogeneous mixture [104]. This indicates that finer DPF are most beneficial to fabricate homogeneous composites and therefore to achieve an optimum mechanical strength. These findings are consistent with Panesar et al. [105] for concrete containing cork waste.

Gypsum plaster reinforced with DPF of fine size (F) and large size (L): results of mechanical and thermal tests [18]

5 Gypsum-Based Composites Reinforced with DPF: Compatibility, Thermal, and Mechanical Properties

5.1 Gypsum Plaster Reinforced with DPF—Mesh Fibers

Gypsum plaster was reinforced with specific part of DPFs. Mesh fibers were extracted from the date palm tree's sheath. The sheath was spread into separate fibers with different lengths and diameters. The used mesh fibers have length ranged from 50 mm to 300 mm and diameter ranged from 0.1 mm to 2 mm. The fabrication of composites is summarized in Fig. 13.

Fabrication of the composites mesh fibers-gypsum [104]

For various w/g (water-to-gypsum) ratios and mesh fibers contents, the compressive strength of the composites mesh fibers-gypsum was examined. Figure 14 shows the results obtained when w/g = 0.6.

Compressive strength of mesh fibers–gypsum composites [104]

It can be seen from the results that net gypsum plaster (0 % DPF) has a high compressive strength compared to 8.5 MPa reported in the study of Chikhi et al. [18]; despite employing a similar water/gypsum ratio, the two studies yielded different results. This could be tied on one hand to the chemical properties of the used gypsum powder, and on the other hand to the DPF source and the fabrication process of the composites. Besides that, the study of Chikhi et al. [18] used dry fibers while the study of Al-Rifaie et al. [104] used moist fibers and this is due to the fact that dry natural fibers have a high capacity for water absorption during mixing process. The high mechanical strength results were obtained when using gypsum with high contents of silica oxide SO3 (51.52 %) and calcium oxide CaO (39.2 %), with an average setting time of 9 mm to 11 min, as indicated by Al-Rifaie et al. [104]. The reduction in the compressive strength as a result of fibers addition is very obvious in Fig. 14. It was discovered that adding fibers to concrete disturbs the mineral skeleton, generating voids within the matrix and increasing porosity while also providing it a limited strength [9]. Al-Rifaie et al. [104] found that incorporating DPF (mesh fibers) increased flexural strength. It has thus been possible to transform the fracture mode of gypsum plaster from brittle to quasi-plastic by utilizing DPF. Besides, the impact strength gave an important improvement as a result of incorporation DPF.

Currently, energy loss in buildings is a major problem worldwide, and thus, construction materials should have besides the mechanical strength a good thermal insulating property. Consequently, mechanical strength is not enough parameter to investigate the application of the composite for structural and insulating; hence, mechanical strength should be accompanied with suitable thermal properties. No results were presented by Al-Rifaie et al. [104] regarding the thermal properties of gypsum–mesh fibers composites.

In the context of reducing the building energy consumption, gypsum plaster and DPF were chosen as good candidates for such purposes. DPF (with a mean diameter of 2 mm) were mixed with natural gypsum plaster (HG with a water-to-gypsum mass ratio (w/g) of 0.6), according to the study by Braiek et al. [3]. The main reason behind chosen gypsum plaster was the low thermal conductivity (1322 kg·m−3; 0.45 W·m−1·K−1 [3]). Similarly, the reason behind chosen DPF in this study was their low thermal conductivity (276 kg·m−3 [3]; 0.083 W·m−1·K−1 [15]), which helped to the improvement of gypsum's thermal properties and, as a result, its thermal insulating capacity. The preparation process was based on mixing DPF and gypsum powder with water (w/g = 0.6), the mixture was then stirred constantly at high speed for 10 min, until it became pasty. When gypsum reinforced DPF were compared to gypsum alone, the thermophysical results demonstrated a significant improvement in thermal insulating properties. As a result, DPF-gypsum boards could be employed as a more efficient thermal insulator in buildings than plaster boards [3].

5.2 Gypsum Mortar Reinforced with DPF—Mesh Fibers

A composite material for construction has been developed by Djoudi et al. [9] consists of gypsum plaster, crushed gravel, sand, DPF and water. According to Djoudi et al. [9], The plaster concrete reinforced with DPF (mesh fibers) is made by mixing gravel, sand, and fibers first, then adding gypsum plaster and the amount of lime in water. The chosen gypsum plaster is classified as class 1 (i.e. percentage of CaSO4, 2H2O should be higher than 90 %) and characterized by best mechanical properties (compressive strength of about 33 MPa and tensile strength of 1.84 MPa). Because the gypsum plaster used had a quick setting time (7 min), 6 % of air lime was added as a setting retarder to extend the period to 30 min. Air lime has no effect on the plaster's mechanical properties, but it does reduce its solubility and lengthen its use period [9]. The used fibers have diameter ranged from 0.2 mm to 1 mm, and length ranged from 10 mm to 40 mm. Light vibration was suggested as a sufficient procedure for producing a workable and compact concrete-fiber matrix with appropriate fiber orientation [9].

Large fibers (sizes 30 mm and 40 mm) have been discovered to better enclose large granulates than fine fibers (sizes 10 mm and 20 mm), resulting in a better optimal granular composition, (S/G)Opt—sand/gravel ratio. As a result, it was suggested that granulometry be closely related to fiber dimension [9]. Furthermore, the ratio and length of fibers have an impact on the composites' workability. It was discovered that workability decreases as the ratio of fibers increases, as does the length of fibers; fibers with long lengths tend to tangle, resulting in poor workability; in addition, fiber length increases void volume and effects concrete compactness [9]. On the other hand, it was discovered in this study that the composite has the best ductility when the fiber length is increased, because the energy dissipated by the fiber will be considerably more as the fiber length increases. The density and water absorption of the composite are also affected by the DPF ratio and length. Density is inversely proportional to the increasing of fibers content [106].

The compatibility between the gypsum-based matrix and the DPF proved to be efficient, as depicted in Fig. 15. After the flexural test, there was a satisfactory transmission of loads from the matrix to the fibers, indicating strong interfacial bonding between the matrix and DPF. After the test, the fibers bridged the fracture; the load was transferred to the fiber as the fracture propagated until the interface braked, at which point the fiber began pulling out the matrix and the load began to decrease [9]. Similar behavior was detected by SEM investigations (Scanning Electron Microscopy) on DPF-gypsum composites [3]; DPF (fine fibers) were well dispersed and uniformly incorporated in the gypsum matrix, as shown by the micrograph (Fig. 15b, c). With high magnification SEM image, it was clearly observed no agglomerated particles of DPF, and this proved that DPF were well distributed and homogenized in the composite. The compatibility between gypsum plaster and natural fibers has been investigated also with hemp fibers [70]. The results indicated that gypsum showed good compatibility with hemp fibers too, because mechanical strength increased using short hemp fibers to a certain content. However, the compatibility decreased when long fibers have been used. Hence, gypsum-based matrix is considered as a very competitive candidate for the development of DPF-reinforced composites suitable for thermal insulating because of its compatibility with natural fibers and its inferior thermal conductivity of 0.424 W·m−1·K−1 [9].

According to the fiber concentration and length, the thermal and mechanical properties of a produced gypsum plaster based matrix reinforced with DPF are shown in Fig. 16. The results showed that increasing DPF percentage to 1.5 % improved compressive strength. This behavior was explained by the orientation of fibers in relation to the applied force; when the orientation of fibers is parallel to the applied force, it amplifies this effort, and thus an improvement in compressive strength can be observed [9]. There is a decrease in mechanical strength at a specific dosage of fibers (1.5 %) due to the excess of fibers and their poor distribution in the matrix (i.e. packing of fibers becomes difficult at high content), thereby increasing the porosity inside the matrix [9]. The results, however, remain within the range of load bearing concrete masonry: 10 MPa to 40 MPa [9]. The results, on the other hand, revealed that the length of DPF had an inverse relationship with the compressive strength. Similar findings have been observed by other researchers [107, 108]. According to Zuraida et al. [109], short fibers mineralize faster than long fibers because there are more end points in short fiber-reinforced composites, allowing cement hydration products to penetrate more easily.

Plaster concretes with fiber lengths of 20 mm and 40 mm: results of thermal conductivity and compressive strength [9]

The thermal conductivity reduces with increasing DPF content and it increases with increasing DPF length, as seen in Fig. 16. This pattern of behavior also noticed by Khedari et al. [108]. The thermal conductivity and the voids that result from fiber packing have an inverse relationship [9]. According to the research, short fibers are more difficult to align and pack densely than large fibers [108, 110]. Short fibers produce many voids for a given fiber ratio, resulting in a low thermal conductivity value [9, 108].

Fiber length is well known to play a significant role in the properties of fiber-reinforced composites. According to Morrissey et al. [110], there is a critical length of embedment, and when it is shorter, fibers tend to pull out, and when it is longer, fibers tend to break; the critical fiber length is determined by the possibility of the formation of strong anchor points.

The size of sand has also an impact on the material's structure. Thus, it is very important to mention that the used sand size has a non-negligible effect on the properties of the composite materials. Thermal conductivity is proportional to the size of sand, where fine sand can insert into the matrix between fibers, causing fibers to align to be far apart, resulting in large voids and low density and thermal conductivity [108]. The compressive strength seems inversely proportional to the sand size, where increasing the sand size decreases the compressive strength of the material [108]. The degree of sand size influences on thermal conductivity and compressive strength, on the other hand, it may be depending also on the length of the utilized fibers.

According to RILEM classification of lightweight concrete [101], it can be seen in Fig. 16 that the suitable concrete composites for structural and insulating applications are those reinforced with short DPF (20 mm) and with dosage above 0.5 %.

6 Reinforcement Using DPF After Surface Treatment

Natural fibers are inexpensive and plentiful, biodegradable, and have a low density [111]. However, they show some drawbacks such as their moisture uptake (i.e. their high O/C ratio which means more hydrophilic character and leads to more water absorption and vice versa), quality variations (i.e. subsequent swelling and degradation), low thermal stability, and poor chemical and fire resistance [111, 112]; as a result of insufficient adhesion between matrix and natural fibers, debonding occurs over time; these natural fiber deficiencies can be overcome by surface treatment/modification [112]. Furthermore, employing raw fibers for reinforcement frequently results in poor compatibility with diverse matrices, resulting in high water absorption and swelling property, which leads to crack formation in brittle matrices [111]. Surface treatment affects the natural fiber's surface structure as well as its surface energy [112]. Surface treatments, although, having a positive effect to overcome the problem of incompatibility [48]. Besides that, the cost of surface treatment is more or less dependent on the type of the chosen treatment process.

Natural fibers are said to generate lightweight products with low thermal conductivity when they are used [17, 18, 108]. However, these products lost their mechanical strength as a result of using discrete and randomly oriented raw natural fibers. The mechanical properties of composites are affected by the physical, chemical, or a mix of physical and chemical bonds between the natural fiber and the matrix [107]. Surface treatment can help maintaining good mechanical strength. Based on the findings from hemp fibers, it was discovered that chemical treatments (EDTA, NaOH) played a significant influence in the strengthening of lime-fibers composites [87], where EDTA is the ethylene-diamine-tetracetic acid.

In the study of Asasutjarit et al. [107], coconut fibers were subjected to three different pretreatment conditions. The first condition (i) involved utilizing raw fibers; the second condition (ii) involved washing raw fibers 10 times with 10 L of tap water until the pH of the water reached 7; The final condition (iii) was based on boiling and washing the raw fibers: it was discovered that 2 h of boiling in water was enough to reduce water soluble chemical compounds like sugar, resin, starch, and so on. The boiled fibers were then washed in tap water until the water color becomes clear. The fibers under all these conditions were followed by sun-dried for 2 days. The results revealed that pretreatment of coir fibers with boiling and washing enhanced the bending modulus of rupture (MOR) and internal bond (IB). The required fibers pretreatment was found to be boiling and washing, as this procedure improved some of the physical and mechanical properties of the natural fibers employed. Extraneous components of raw coir fibers, such as inorganic compounds (sugar, coloring matter, starches, and so on), were eliminated by boiling in water, and this could have a significant impact on the formation of the fiber–cement bond connection [107].

The paper of Khedari et al. [108] investigated the development of a new lightweight construction material made of cement, sand, and waste fiber from young coconut (Cocos nucifera) and durian (Durio zibethinus). Following a series of preliminary experiments on fruit peels in Thailand, these two previous products have the lowest thermal conductivity and bulk density [108]. The raw material was dried at 60 °C for 8 h using an oven, then, the dry raw material was grinded to obtain fibers with different sizes, then, the obtained fibers were soaked in water for 16 h, and then, the moist fibers were dried at 60 °C for 16 h, and finally, the dry fibers were obtained and they have been used in the preparation of the composite materials. The authors did not mention the reason behind using this particular fiber preparation process, but, it seems that water may help in producing pure fiber and heat may help in eliminating impurities and undesired compounds from the surface of the fiber. Thermo treatment is a physical process that alters the structural and surface properties of a natural fiber without changing its chemical composition, consequently influencing its mechanical bonding to the matrix [112].

In the study of Ali-Boucetta et al. [16], three types of treatments of DPFs mesh (fibers length of 25 mm ± 2 mm) were discussed: (i) boiling water treatment, (ii) sodium hydroxide treatment, and (iii) linseed oil treatment. DPF were boiled in a cooker for 5 min, 1 h, 2 h, and 3 h for boiling water treatment; after boiling, the fibers were drained and rinsed with water to eliminate any organic compounds; and finally, clean fibers were dried at room temperature for 2 days. The second treatment method involves soaking DPF in a NaOH solution for 2 h, then rinsing with 1 % concentrated acetic acid and distilled water until neutral pH is reached, and lastly drying the treated fibers in a 60 °C oven for 24 h. The third treatment technique is based on mixing dry fibers (50 °C for 24 h) with linseed oil; the treated fibers have been finally dried at 50 °C for several days. The results showed that both raw and treated DPF enhanced the compressive strength of cement mortar composites, with alkaline treatment providing the best resistance, followed by boiling treatment. Besides to that, these treatment techniques improved the flexural strength of the composites. Linseed oil treatment, on the other hand, did not show any improvement in mechanical strength. However, linseed oil treatment has a huge contribution in reducing the capillary absorption coefficient (69.8 % at 24 h) compared to other treatment techniques.

Chemical treatment, on the other hand, is one of the most widely utilized natural fiber treatment methods for application in natural fiber-reinforced composites. Chemical treatment alters the natural fiber's crystalline structure by removing weak components such as hemicelluloses, lignin and some impurities from the outer surface layer, and their elimination may lead in good results and more stable bonding between the fiber–matrix [45, 111]. As an example, using a water repellent agent minimizes moisture absorption and consequent swelling of natural fibers [111]. Chemical treatment can improve fiber strength in addition to enhancing adhesion between the fiber surface and the matrix [48]. Furthermore, chemical treatment of fiber surfaces minimizes water absorption and improves the mechanical properties of the fiber–matrix composites [48]. Chemical treatments are frequently used as a necessary process to increase the adhesion between the hydrophobic matrix (polymer) and the hydrophilic natural fibers [45, 48, 113, 114], such as alkaline treatment [48]. SEM micrographs of DPF (fibers surrounding the stem of the palm tree plant) in Fig. 17 illustrate the effect of chemical treatment (6 % NaOH for 3 h) on the outer layer of fibers with different average diameters. It was clear that by chemical treatment of fibers, the impurities, oil, waxes, residual hemicellulose and lignin were etched away, and therefore caused a reduction in diameter to form finer-microfibers [29, 45]. In a similar way, similar results of SEM images on DPF (date palm fruit branches) were obtained [115]. However, the results after chemical treatment are more or less dependent on the followed treatment conditions. Hence, chemical treatment can improve the surface morphology and properties of natural fibers and increase their surface roughness, as mentioned by Abdal-hay et al. [45]. Besides that, the previous study reported after treatment a decrease in O/C ratio that related to the relative decrease in the oxygen concentration while the carbon concentration remained the same. This suggests that the treated DPF reorganize their structure without causing damage to the cellulose in the fibers. Moreover, the X-RD results showed an increase in the crystallinity index of the treated fibers and that because the amorphous hemicellulose in the untreated fiber [45]. In this regard, Amroune et al. [115] showed that when the TGA-XRD results are compared to untreated fibers, the treated fibers show a higher thermal stability and higher crystallinity index.

Effect of chemical treatment (6 % NaOH at 95 °C for 3 h) on surface properties of natural palm fiber [45]

Asim et al. [116] used in their study a chemical treatment with NaOH solution (6 % NaOH concentration for 3 h), and then the DPFs (short fibers of 1 mm size) were washed with water to neutralize pH value of fibers, and finally, the treated fibers were dried under controlled conditions. In order to evaluate the effect of chemical treatment, these authors were used these fibers in their raw and treated states for reinforcement of polymer matrix. The reported results showed that the mechanical properties of the composite were improved greatly as a result of the improvement of the interfacial bonding fiber–matrix after the treatment. Similarly, important improvement in mechanical properties was reported after 3 % NaOH treatment for 2 h of DPF (date palm fruit branches) [115]. Moreover, similar results were obtained in the study of Abdal-hay et al. [45] as shown in Table 8. According to these authors, the improvement in tensile strength was attributed to the removal of impurities on the fiber surface as well as the reduction in the diameter; besides, the negative impact on Young’s modulus was attributed to the rearrangement of the fiber structure without affecting its main construction component.

Finally, it is important to mention that the treatment conditions (solution concentration, treatment time, temperature, etc.) may have more or less effect on the desired results and therefore the efficiency of fibers for better adhesion with the matrix.

7 Conclusion

DPFs are attractive because they are employed in the composites sector as a natural reinforcing material. The choice of DPF, in particular, is due to many reasons mainly the abundance at the international level of their sources as renewable waste and their distinctive thermophysical and mechanical properties. In the composites sector for construction applications, it was proven that the reinforcement with DPF has a positive influence on the mechanical properties and thermal insulation behavior of the matrix.

Despite being a considerably older material than cement, gypsum has only occasionally been employed in the building industry. Due to its properties, gypsum has lately been shown to be a remarkable material in the composites sector. Gypsum has a low thermal conductivity and a good fire resistance, which strongly contributes to reduce the need for electricity to heat and cool rooms in buildings.

The present paper has proven that for the development of cost-effective composites in construction, the employment of DPF as a natural reinforcing material with the gypsum-based matrix showed attractive results in regard to compatibility and thermal insulation issues. Besides, by utilizing DPF, it has been shown that it is possible to transform the fracture mode of gypsum plaster from brittle to quasi-plastic.

Surface treatment in the composites sector alters the DPF crystalline structure by removing weak components such as hemicelluloses, lignin, and some impurities from the outer surface layer, and their elimination lead to good results and more stable and durable bonding between the fiber–matrix.

Finally, DPF are said to generate lightweight and cost-effective products with low thermal conductivity when they are used with gypsum-based composites. In this regard, there are important conclusions that need to be taken into account for the development of this material:

-

The granulometry should be closely related to the fiber dimension. The ratio and length of fibers have an impact on the workability and the ductility of the composites. Thus, optimum fiber length and ratio are recommended.

-

DPF dimension (diameter and length) and ratio have an influence on thermal conductivity and compressive strength of gypsum-based matrix. Thus, critical fiber dimension and ratio is required to achieve optimum mechanical strength and thermal insulating capacity.

-

The sand size has a non-negligible impact on the thermal and mechanical properties of gypsum-based matrix reinforced with DPF. Thus, critical sand size is required.

-

Surface treatment of DPF is recommended using low cost techniques as alkaline treatment and boiling treatment which may provide a strong enhancement of the fibers properties and therefore their use for reinforcement with gypsum-based matrix.

Data Availability

Data analyzed in the current review research were a re-investigation of existing data, which are openly available in the published papers referenced in the current research.

References

IEA, Buildings. A source of enormous untapped efficiency potential. Report. International Energy Agency, Paris (2021)

IEA, Key World Energy Statistics 2021. Statistics Report. International Energy Agency, Paris (2021)

A. Braiek, M. Karkri, A. Adili, L. Ibos, S. Ben Nasrallah, Energy Build. 140, 268–279 (2017)

F. Eddib, M.A. Lamrani, Alex. Eng. J. 58, 937–944 (2019)

N.A. Ramlee, J. Naveen, M. Jawaid, Constr. Build. Mater. 271, 121519 (2021)

R. Zhao, H. Guo, X. Yi, W. Gao, H. Zhang, Y. Bai, T. Wang, Int. J. Thermophys. 41, 87 (2020)

F. Koçyiğit, Int. J. Thermophys. 41, 41 (2020)

F. Koçyiğit, Int. J. Thermophys. 43, 18 (2022)

A. Djoudi, M. Khenfer, A. Bali, E. Kadri, G. Debicki, Int. J. Phys. Sci. 7, 2845–2853 (2012)

R. Jia, Q. Wang, P. Feng, Composites B. Eng. 205, 108540 (2021)

L. Rovero, S. Galassi, G. Misseri, Composites B Eng. 194, 108051 (2020)

G. Xue, E. Yilmaz, W. Song, S. Cao, Composites B Eng. 172, 131–142 (2019)

Z. Du, W. She, W. Zuo, J. Hong, Y. Zhang, C. Miao, Cem. Concr. Compos. 108, 103549 (2020)

S. Sair, B. Mandili, M. Taqi, A. El Bouari, Compos. Commun. 16, 20–24 (2019)

B. Agoudjil, A. Benchabane, A. Boudenne, L. Ibos, M. Fois, Energy Build. 43, 491–497 (2011)

T. Ali-Boucetta, A. Ayat, W. Laifa, M. Behim, Constr. Build. Mater. 273, 121056 (2021)

N. Benmansour, B. Agoudjil, A. Gherabli, A. Kareche, A. Boudenne, Energy Build. 81, 98–104 (2014)

M. Chikhi, B. Agoudjil, A. Boudenne, A. Gherabli, Energy Build. 66, 267–273 (2013)

A. Kriker, A. Bali, G. Debicki, M. Bouziane, M. Chabannet, Cem. Concr. Compos. 30, 639–648 (2008)

A. Kriker, G. Debicki, A. Bali, M.M. Khenfer, M. Chabannet, Cem. Concr. Compos. 27, 554–564 (2005)

B. Haba, B. Agoudjil, A. Boudenne, K. Benzarti, Constr. Build. Mater. 154, 963–971 (2017)

A. Kareche, B. Agoudjil, B. Haba, A. Boudenne, Waste Biomass Valoriz. 11, 3801–3809 (2020)

R. Belakroum, A. Gherfi, M. Kadja, C. Maalouf, M. Lachi, N. El Wakil, T.H. Mai, Constr. Build. Mater. 184, 330–343 (2018)

D. Khoudja, B. Taallah, O. Izemmouren, S. Aggoun, O. Herihiri, A. Guettala, Constr. Build. Mater. 270, 121824 (2021)

M.L. Santarelli, F. Sbardella, M. Zuena, J. Tirillò, F. Sarasini, Mater. Des. 63, 398–406 (2014)

M. Tengberg, Date palm: origins and development, in Encyclopedia of Global Archaeology. ed. by C. Smith (Springer, New York, 2014), pp.2033–2035

S. Awad, Y. Zhou, E. Katsou, Y. Li, M. Fan, Waste Biomass Valoriz. 6, 2853 (2020)

L.A. Elseify, M. Midani, L.A. Shihata, H. El-Mously, Cellulose 26, 2209–2232 (2019)

A. Bezazi, H. Boumediri, G. Garcia del Pino, B. Bezzazi, F. Scarpa, P.N.B. Reis, A. Dufresne, J. Nat. Fibers. (2020). https://doi.org/10.1080/15440478.2020.1848726

C.S. Newhall, The Trees of northeastern America: The shrubs of northeastern America (Putnam’s Sons, New York, 1891)

H.H. Abdel-Rahman, R. Al-Juruf, F. Ahmad, I. Alam, Int. J. Cem. Compos. Lightweight Concr. 10, 175–181 (1988)

S. Abdelaziz, S. Guessasma, A. Bouaziz, R. Hamzaoui, J. Beaugrand, A.A. Souid, Constr. Build. Mater. 124, 228–236 (2016)

A. Alawar, A.M. Hamed, K. Al-Kaabi, Composites B Eng. 40, 601–606 (2009)

M. Gholami, M.S. Ahmadi, M. Tavanaie, M. Khajeh Mehrizi, Sci. Eng. Compos. (2017). https://doi.org/10.1515/secm-2017-0102

W. Konczewicz, N. Kryszak, E. Nowaczkiewicz, R. Kozlowski, J. Wojtysiak, W. Podsiedlik, Mol. Cryst. Liq. Cryst. 571, 116–131 (2013)

A. Jaradat, A. Zaid, J. Food Agric. Environ. 2, 208–217 (2004)

F.M. Al-Oqla, S.M. Sapuan, J. Clean. Prod. 66, 347–354 (2014)

D. G. Soltan, P. das Neves, A. Olvera, H. Savastano Junior, V.C. Li, Ind. Crops Prod. 103, 1–12 (2017)

L.C. Hao, S.M. Sapuan, M.R. Hassan, R.M. Sheltami, Natural fiber reinforced vinyl polymer composites, in Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites. ed. by S.M. Sapuan, H. Ismail, E.S. Zainudin (Woodhead Publishing, Duxford, 2018), pp.27–70

K.K. Chawla, Fibrous Materials (Cambridge University Press, Cambridge, 1998)

C. Baillie, Green Composites: Polymer Composites and the Environment (Woodhead Publishing Limited, Duxford, 2004)

J. Summerscales, N.P.J. Dissanayake, A.S. Virk, W. Hall, Composites Part A Appl. Sci. Manuf. 41, 1329–1335 (2010)

J.G. Speight, Non–fossil fuel feedstocks, in The Refinery of the Future, 2nd edn., ed. by J.G. Speight (Gulf Professional Publishing, Cambridge, 2020), pp.343–389

T.A. Khan, J.-H. Lee, H.-J. Kim, Lignin-based adhesives and coatings, in Lignocellulose for Future Bioeconomy. ed. by H. Ariffin, S.M. Sapuan, M.A. Hassan (Elsevier, Amsterdam, 2019), pp.153–206

A. Abdal-hay, N. Suardana, D. Jung, K.-S. Choi, J.K. Lim, Int. J. Precis. Eng. Manuf. 13, 1199–1206 (2012)

M.D. Alotaibi, B.A. Alshammari, N. Saba, O.Y. Alothman, M.R. Sanjay, Z. Almutairi, M. Jawaid, Int. J. Biol. Macromol. 135, 69–76 (2019)

G. Dorez, L. Ferry, R. Sonnier, A. Taguet, J.M. Lopez-Cuesta, J. Anal. Appl. Pyrolysis 107, 323–331 (2014)

X. Li, L.G. Tabil, S. Panigrahi, J. Polym. Environ. 15, 25–33 (2007)

A. Al-Khanbashi, K. Al-Kaabi, A. Hammami, Polym. Compos. 26, 486–497 (2005)

A. Komuraiah, N.S. Kumar, B.D. Prasad, Mech. Compos. Mater. 50, 359–376 (2014)

T. Djoudi, M. Hecini, D. Scida, Y. Djebloun, H. Djemai, J. Nat. Fibers 18, 789–802 (2021)

M. Boumhaout, L. Boukhattem, H. Hamdi, B. Benhamou, F. Ati Nouh, Constr. Build. Mater. 135, 241–250 (2017)

H. Chaib, A. Kriker, A. Mekhermeche, Energy Procedia 74, 919–925 (2015)

A. Mokhtari, A. Kriker, Y. Guemmoula, A. Boukrioua, M.M. Khenfer, Energy Procedia 74, 344–350 (2015)

A. Lotfi, H. Li, D.V. Dao, G. Prusty, J. Thermoplast. Compos. Mater. 34, 089270571984454 (2019)

Y.K. Kim, Natural fibre composites (NFCs) for construction and automotive industries, in Handbook of Natural Fibres. ed. by R.M. Kozłowski (Woodhead Publishing, Duxford, 2012), pp.254–279

S. Xie, Z. Ji, Y. Yang, G. Hou, J. Wang, Composites B Eng. 106, 10–19 (2016)

K. Suresh Babu, C. Ratnam, Mater. Today Proc. 44, 2245–2249 (2021)

F. Iucolano, B. Liguori, P. Aprea, D. Caputo, Constr. Build. Mater. 185, 256–263 (2018)

C.N. Ang, Y.C. Wang, Constr. Build. Mater. 23, 675–686 (2009)

M. Arikan, K. Sobolev, Cem. Concr. Res. 32, 1725–1728 (2002)

K. Babu, C. Ratnam, Mater. Today Proc. 44, 1988 (2021)

Y.-H. Deng, T. Furuno, J. Wood Sci. 47, 445–450 (2001)

M. Singh, M. Garg, Cem. Concr. Compos. 14, 23–32 (1992)

M. Serhat Başpınar, E. Kahraman, Constr. Build. Mater. 25, 3327–3333 (2011)

Y. Zhang, K. Wang, W. Tao, D. Li, Constr. Build. Mater. 224, 48–56 (2019)

F. Pacheco-Torgal, S. Jalali, Constr. Build. Mater. 25, 575–581 (2011)

L. Boccarusso, M. Durante, F. Iucolano, D. Mocerino, A. Langella, Constr. Build. Mater. 260, 120476 (2020)

A.W. Fonseca Coelho, R.M. da Silva Moreira Thiré, A.C. Araujo, Addit. Manuf. 29, 100789 (2019)

K. SureshBabu, C. Ratnam, Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.12.363

P. Dalmay, A. Smith, T. Chotard, P. Sahay-Turner, V. Gloaguen, P. Krausz, J. Mater. Sci. 45, 793–803 (2010)

P. Zak, T. Ashour, A. Korjenic, S. Korjenic, W. Wu, Constr. Build. Mater. 106, 179–188 (2016)

N.H. Koralegedara, P.X. Pinto, D.D. Dionysiou, S.R. Al-Abed, J. Environ. Manage. 251, 109572 (2019)

K. Kovler, Radioactive materials, in Toxicity of Building Materials. ed. by F. Pacheco-Torgal, S. Jalali, A. Fucic (Woodhead Publishing, Duxford, 2012), pp.196–240

X. Huang, M. Jiang, X. Zhao, C. Tang, Constr. Build. Mater. 127, 137–143 (2016)

X. Liu, H. Wen, T. Edil, C. Benson, Transp. Res. Rec. 2204, 102–109 (2011)

A. Rashad, J. Clean. Prod. (2017). https://doi.org/10.1016/j.jclepro.2017.08.049

J. Wang, P. Yang, Renew. Sustain. Energ. Rev. 82, 1969–1978 (2018)

D. Watts, W. Dick, J. Environ. Qual. 43, 246–252 (2014)

P. Chindaprasirt, K. Boonserm, T. Chairuangsri, W. Vichit-Vadakan, T. Eaimsin, T. Sato, K. Pimraksa, Constr. Build. Mater. 25, 3193–3203 (2011)

M. Garg, A. Pundir, R. Singh, Mater. Struct. 49, 3253–3263 (2016)

P. Tesárek, J. Drchalová, J. Kolísko, P. Rovnaníková, R. Černý, Constr. Build. Mater. 21, 1500–1509 (2007)

M. Yang, J. Qian, J. Wuhan Univ. Technol. Mater. Sci. Ed. 26, 1103–1107 (2011)

T. Feldmann, G.P. Demopoulos, Hydrometallurgy 155, 20–28 (2015)

B. Ma, W. Lu, Y. Su, Y. Li, C. Gao, X. He, J. Clean. Prod. 195, 396–405 (2018)

J.-C. Yang, H.-D. Wu, N.-C. Teng, D.-Y. Ji, S.-Y. Lee, Ceram. Int. 38, 381–387 (2012)

M. Le Troëdec, C.S. Peyratout, A. Smith, T. Chotard, J. Eur. Ceram. Soc. 29, 1861–1868 (2009)

G. Di Bella, V. Fiore, G. Galtieri, C. Borsellino, A. Valenza, Constr. Build. Mater. 58, 159–165 (2014)

D.-R. Tămaş-Gavrea, T.-O. Dénes, Procedia Manuf. 46, 402–409 (2020)

T.-O. Dénes, D.-R. Tămaş-Gavrea, Procedia Manuf. 46, 19–26 (2020)

A. Formisano, G. Chiumiento, F. Fabbrocino, in Proceedings of XXIV AIMETA Conference 2019, Cham (2020).

T.H. Panzera, A.L. Christoforo, P.H. Ribeiro Borges, High performance fibre-reinforced concrete (FRC) for civil engineering applications, in Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications. ed. by J. Bai (Woodhead Publishing, Duxford, 2013), pp.552–581

C. Juárez, A. Durán, P. Valdez, G. Fajardo, Build. Environ. 42, 1151–1157 (2007)

J. Castro, A.E. Naaman, ACI Mater. J. 78, 69 (1981)

K.M.F. Hasan, P.G. Horváth, T. Alpár, J. Nat. Fibers (2021). https://doi.org/10.1080/15440478.2021.1875380

G. Ruano, F. Bellomo, G. López, A. Bertuzzi, L. Nallim, S. Oller, Constr. Build. Mater. 240, 117856 (2020)

S. Ajouguim, S. Talibi, C. Djelal-Dantec, H. Hajjou, M. Waqif, M. Stefanidou, L. Saadi, Mater. Today Proc. 37, 4049–4057 (2021)

A. Laborel-Préneron, J.E. Aubert, C. Magniont, C. Tribout, A. Bertron, Constr. Build. Mater. 111, 719–734 (2016)

M. Benzerara, S. Guihéneuf, R. Belouettar, A. Perrot, Constr. Build. Mater. 289, 123211 (2021)

E. Olacia, A.L. Pisello, V. Chiodo, S. Maisano, A. Frazzica, L.F. Cabeza, Constr. Build. Mater. 239, 117669 (2020)