Abstract

Moisture content can affect the thermo-physical properties of many materials. Thus sufficient knowledge of this parameter is required to improve product shelf life and quality, reduce waste or enhance process efficiency. The traditional loss on drying methods are still the go-to methods due to their robustness and simplicity. However, their inherent lack of selectivity imposes restrictions. These are overcome with newer techniques such as vaporization coulometric Karl Fischer titration (vap-C-KFT) and evolved water vapor analysis (EWV). The former is a well-established method, but the latter was more recently introduced and the literature available on it is scarce. This work aims to bridge this gap in knowledge and demonstrate the comparability of the EWV to the more established vap-C-KFT. Multiple samples were studied and the data are analyzed along the principles reported recently by INRiM with a few modifications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Moisture content is a parameter that expresses the “wetness” of a substance. Changes in this “wetness” can lead to alterations in the physical properties of a vast range of materials and their mixtures. For example, the tensile strength, porosity and surface area of tablets, the tensile and yield strength of glass fiber-reinforced polyamide and the optical transparency of paper are all affected by moisture content [1,2,3]. The most common technique for moisture content determination (loss on drying, LoD) is based on the loss of mass due to heating. The sample is weighted before and after heating, with the difference attributed to the amount of moisture [4]. Using heat to access the water bound within the material is simple and robust. However, besides water other sample components can evaporate as well, thus leading to possibly erroneous results [5].

Recognizing the advantages and drawbacks of the LoD method, hyphenated techniques have been developed—for example vaporization coulometric Karl Fischer titration (vap-C-KFT) and evolved water vapor analysis (EWV). These techniques differ from LoD by selectivity, as they can discriminate between water and other volatiles. For this reason, their results are reported as water content, instead of moisture content—often reported with LoD methods and it covers both water and volatile organic compounds (VOCs). Because the LoD and vap-C-KFT techniques measure different quantities, it is difficult to use the former for validating the latter. This is where evolved water vapor analysis (EWV) can be used. While there is limited literature available regarding this method [6], its working principle and intended use are similar to that of vap-C-KFT, making it a more suitable technique to compare with the vap-C-KFT method.

This work aimed to demonstrate the comparability of vap-C-KFT and EWV techniques in their intended working ranges. Firstly, two reference samples (oven water standard 1 % and α-d-lactose monohydrate) were analyzed, in order to compare the intrinsic (i.e., determined by the instruments rather than samples) characteristics of the techniques. To demonstrate the robustness of the chosen techniques, two additional samples of economic interest were analyzed: kaolinite clay and wood pellets. Kaolinite clay is used in a multitude of fields from paper industry to medical research [7, 8], while wood pellets are widely used as a fuel. Moisture content affects the properties of both materials, related to their use and storage [9, 10]. The calibration method was adopted from a previous study published by INRiM [6], combining it with a calculation tool previously developed for Collège Français de Métrologie [11]. Further inputs were drawn from validation guidelines [12, 13].

2 Materials and Methods

2.1 Vaporization Coulometric Karl Fischer Titration

The first method, vap-C-KFT, is a variety of the Karl Fischer (KF) titration method. The core of the method remains the Karl Fischer reaction [14]—for each iodine molecule, a molecule of water is consumed (Fig. 1b). In the case of coulometric titration, the iodine is generated within the measurement cell with a generator electrode and its quantity is measured via integration of electric current over time. The end-point is detected by a pair of electrodes. A constant alternating current is maintained between these electrodes, excess of iodine is indicated by the decrease in the measured voltage required for maintaining the current.

In the case of vap-C-KFT, the KF titrator is coupled with an oven, which heats a headspace vial containing the sample, which can be either solids or liquids. The evolved components are carried by a constant flux of dry gas to the titration cell (Fig. 1a). This step eliminates the need to dissolve solid samples in a suitable solvent beforehand, as in the classical application, and facilitates the analysis of more complex samples [15].

For this work, an 831 KF Coulometer (Metrohm AG, Switzerland) coulometric KF titrator was combined with an 874 OSP oven sample processor (Metrohm AG, Switzerland). The standard uncertainty of the 831 KF coulometer as reported in its documentation was 3 μg of water [16]. The OSP allows automated analysis and should reduce variability between operators. The samples were weighed into vials, which were sealed to prevent the loss or gain of water from the ambient air. Both instruments were operated via Tiamo 2.4 full software (Metrohm AG, Switzerland). The generator electrode with a diaphragm was used to reduce the probability of iodine reaching the cathode and avoid introducing a bias to the measurement. The anolyte, HYDRANAL Coulomat AG Oil and the catholyte, HYDRANAL Coulomat CG, were both obtained from Sigma-Aldrich.

2.2 Evolved Water Vapor Analysis

The instrument used was an easyH2O (Berghof Products + Instruments GmbH, Germany) evolved water vapor analyzer, controlled by Aqualys software (Berghof Products + Instruments GmbH, Germany). This type of instrument is commonly referred to as “evolved water vapor analyzer”, which will be used in this work. The manufacturer has named it thermo-coulometric water detection [6].

Although P2O5 sensors have been used in hygrometry for a while, coupling them with an oven to analyze solid samples is a recent development. The sensors were invented in the end of 1950s for the natural gas industry [17]. These sensors were integrated into a bench-top device for water determination in solids nearly 50 years later at the end of the 1990s [18], made possible by improvements in sensor and gas diffuser design. The system heats the sample in an oven and the released water is carried by a stream of dried air to the sensor (Fig. 2). The uncertainty of the EWV system as reported in its documentation was 2 μg of water [19]. The used EWV instrument did not have an autosampler, each sample was individually and manually loaded into the EWV oven. The samples are weighed into open sample boats.

3 Calibration Procedure

Both instruments are coulometers by their nature and water content is found by integrating current over time. This means that in principle neither of them needs calibration. Nevertheless, as was demonstrated recently [6], calibration with standard samples ensures better comparability between the obtained results. For this reason, a calibration method similar to the one described in [6] was applied in this work to both techniques.

3.1 Standards

Two standard samples with different water contents were used to make the calibration curves. The first was a reference material produced by Merck KGaA—water standard oven 1 % (hereinafter RM), with a certified water content of 0.98 g/100 g (with an expanded uncertainty (U) of ± 0.03 g/100 g, k = 2; Fig. 3). The second standard sample was α-d-lactose monohydrate (hereinafter ADL), sourced from Acros Organics. Its reference value, 5.00 g/100 g (± 0.17 g/100 g, k = 2; Fig. 3) was calculated from its molecular formula. The corresponding uncertainty is estimated from the results of an interlaboratory comparison measurement round organized within the METefnet project for the same sample [20].

3.2 Calibration

The calibration method is a modification of the approach used by INRiM [6]. The calibration curve was obtained from the measurements of both standard samples. The determinations used for calibration were spread out over the measurement day, to better account for possible changes within the instruments during the day—if they deviated more than 20 % from the expected value, the results were discarded and maintenance of the system was performed until the calibration measurements were within the acceptable range. For example, the sensor of the EWV system requires regeneration from time to time—if the performance of the system is not verified both before and after analyzing samples, it cannot be guaranteed that the system was working within the defined parameters. In the case of vap-C-KFT, the reagent has a limited lifespan as well and spreading the calibration measurements served to verify the system performance during the course of the analysis run. The calibration points were chosen to cover the working range and subsequent samples would fall within the calibration range, a similar principle is used in bioanalytical validation guidelines [12, 13]. The measurement results were processed with the “Modélisation des Résultats d’Étalonnage” tool [11]. This tool allowed for rapid and streamlined calculations of both calibration curves, coefficients and uncertainty estimation. The analysis results were thereafter calculated using the obtained slope and intercept values (Fig. 3).

4 Results and Discussion

4.1 Instrumental Performance

Cell coefficients (reference water content divided by measured water content) calculated from the calibration samples were used to compare the performance of both systems. The cell coefficients permitted the use of both standards (RM and ADL) in one calibration set, otherwise it would have been difficult as the standards had different water content. The relative standard deviation (RSD) of cell coefficients was used as an estimate for the variability of calibration points during a single measurement day. The cell coefficient “normalizes” the data from different standard samples to 1. Thus any difference in absolute water content (mg of water) or concentration (g/100 g) will not be influencing the estimate of “scatter/variability”. The results from three measurement series were used; the weighted averages are shown in Table 1.

The second measure of instrumental performance was the uncertainty estimate associated with the empty sample container analysis, so-called “tare measurement”. This is the mass of water originating from the sample container, i.e., so-called “boat” for EWV and so-called “vial” for vap-C-KFT, and the value is subtracted from the sample results, thus serving as an offset. The pooled standard deviation of tare measurements from several measurement series was used as the standard uncertainty estimate (uc) for tare measurement (Table 1).

Both systems have similar performance. The spread of standard measurements is slightly larger for the EWV, but still close to the value obtained with vap-C-KFT. This difference may be attributed to vap-C-KFT using an autosampler and EWV relying on manual sample insertion. The combined standard uncertainty estimates for empty sample vessels (tare measurement) were similar as well—3 μg and 4 μg of water for EWV and vap-C-KFT, respectively. Because the average sample is smaller for EWV (see sample mass range, Table 1), the impact of tare measurement uncertainty is proportionally larger. However, both methods display comparable capabilities and thus may be used to validate each other’s results.

4.2 Case Study of Two Samples

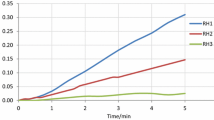

Kaolinite clay was provided in the form of a fine powder, requiring no additional sample preparation. This sample had low water content (below 1 g/100 g), increasing the danger of possible contamination with water vapor from the environment. As an inorganic sample, the possibility of water evolving due to decomposition was low. Wood pellets had to be ground before they could be analyzed by either system, to both homogenize and reduce the size of individual particulates. Because there was a risk of additional water being released during decomposition at high temperatures, a suitable temperature program was first developed. First a small sample, necessary to avoid saturating the system if the water content of the sample was unknown, was analyzed using a temperature gradient method. This analysis was used to find the temperature at which water was released and if there was further water released during, for example, decomposition. Although it was a qualitative analysis, it also provided a measure of the approximate water content of the sample. These results were then used to select the optimal temperature and sample size for a given sample type. A larger amount of wood pellets was prepared (ground to a fine powder) and stored for subsequent analysis, to reduce variability from sample preparation. The wood pellets had higher water content (nearly 10 times larger) than kaolinite clay, necessitating the use of different sample sizes. It is important to optimize sample size because: (i) the measurement system should not become saturated; (ii) the total amount of water measured in the sample needs to be sufficiently high (e.g., 1000 μg for vap-C-KFT and 500 μg for EWV); (iii) the mass of the sample needs to be large enough to ensure reliable weighing. The masses of the kaolinite clay samples used for measurements were approximately 100 mg for vap-C-KFT and 54 mg for EWV, the masses of wood pellet samples were and 16 mg and 13 mg, respectively. On both instruments, both samples were analyzed on three separate days (k = 3; covering at least 1 week), each measurement series consisted of three replicates (n = 9).

The measurement uncertainty estimate was the result of pooling the uncertainty estimates of all measurement series together. The uncertainty estimate of a single measurement series was composed of the repeatability of the sample measurement and the uncertainty coming from the calibration of the instrument. The latter combines the uncertainty coming from the “tare measurement” and the measurement of calibration samples. The results are presented in Fig. 4.

Both analytical methods yielded comparable results. For kaolinite clay, the methods displayed good agreement (|En| = 0.17; En is the normalized error according to ISO 13528) and both results fall within the uncertainty range of the each other. For wood pellets the agreement was not as good (|En| = 0.95), but remained within respective uncertainty limits. The larger disparity of wood pellet results could be attributed to a more complex and hygroscopic matrix and possible issues with sample handling and preparation, which was not the case with the clay sample. The vap-C-KFT method resulted in somewhat smaller uncertainty estimates. This can be credited to better repeatability, possible due to the autosampler.

5 Conclusions

The work presents a comparison of two coulometric methods for the determination of water content in solids. It was experimentally demonstrated, that both instruments have similar performance limitations in terms of the repeatability of their standard sample measurements and the uncertainty associated with the tare/blank value determinations. In the case of EWV any outside influence has a larger relative impact, because of smaller sample size used with this technique (in comparison with vap-C-KFT). Additionally, better repeatability may be achieved if an automatic sample introduction system would be developed for the EWV device. The water content of kaolinite clay and wood pellet samples was determined with the corresponding uncertainty evaluations. These samples are of economic interest and the presented uncertainty evaluation method offers a rapid method for doing so.

These results provide evidence that EWV and vap-C-KFT results are comparable with each other. While vap-C-KFT is the more established technique, EWV was useful for studying differently bound forms of water has additional capabilities (due to the fast reaction time of the sensor)—allowing to investigate the relation between free and bound water in solid samples [21].

References

P. Thapa, A.R. Lee, D.H. Choi, S.H. Jeong, Powder Technol. 310, 92 (2017)

J. Chaichanawong, C. Thongchuea, S. Areerat, Adv. Powder Technol. 27, 898 (2016)

A.F. Forughi, S.I. Green, B. Stoeber, Rev. Sci. Instrum. 87, 023706 (2016)

Y. Pomeranz, C.E. Meloan, Food analysis (Springer, Boston, 1994), pp. 575–601

R.E. Sturgeon, J.W. Lam, A. Windust, P. Grinberg, R. Zeisler, R. Oflaz, R.L. Paul, B.E. Lang, J.A. Fagan, B. Simard, C.T. Kingston, Anal. Bioanal. Chem. 402, 429 (2012)

F. Rolle, G. Beltramino, V. Fernicola, M. Sega, A. Verdoja, Int. J. Thermophys. 38, 36 (2017)

W. M. Bundy and J. N. Ishley, Appl. Clay Sci. 5, 397 (1991)

J. Frederick, S. Boysen, C. Wagg, S. Chalhoub, Can. J. Vet. Res. 81, 41 (2017)

N. Striūgas, L. Vorotinskienė, R. Paulauskas, R. Navakas, A. Džiugys, L. Narbutas, Energy Convers. Manag. 149, 937 (2017)

J. Sjöström, P. Blomqvist, Fuel 134, 460 (2014)

Modélisation des résultats d’étalonnage. (Collège Français de Métrologie, 2012), http://www.cfmetrologie.com/fr/modelisation-des-resultats-d-etalonnage. Accessed 31 May 2020

Bioanalytical Method Validation. (U.S. Food and Drug Administration, 2018), https://www.fda.gov/files/drugs/published/Bioanalytical-Method-Validation-Guidance-for-Industry.pdf. Accessed 31 May 2020

Guideline on bioanalytical method validation (European Medicines Agency, 2011), https://www.ema.europa.eu/en/documents/scientific-guideline/guideline-bioanalytical-method-validation_en.pdf. Accessed 31 May 2020

K. Fischer, Angew. Chem. 48, 394 (1935)

V. Kestens, P. Conneely, A. Bernreuther, Food Chem. 106, 1454 (2008)

Instructions for Use 756/831 KF Coulometer, english (english), (Metrohm AG, 2003), https://www.metrohm.com/en/products/karl-fischer-titration/kf-titrino-coulometers/28310010. Accessed 31 May 2020

F. A. Keidel, US2830945 (A) (15 April 1958)

U. Klas and R. Ganter, DE19635203 (A1) (5 March 1998)

Water determination Simplified water detection (Berghof Products + Instruments GmbH, 2004), https://www.lambda-at.com/pdf/easyH2O.pdf. Accessed 31 May 2020

M. Heinonen, S. Bell, B.I. Choi, G. Cortellessa, V. Fernicola, E. Georgin, D. Hudoklin, G.V. Ionescu, N. Ismail, T. Keawprasert, M. Krasheninina, R. Aro, J. Nielsen, S.O.G. Aytekin, P. Osterberg, J. Skabar, R. Strnad, Int. J. Thermophys. 39, 20 (2018)

M.W. Ben Ayoub, E. Georgin, J.F. Rochas, S. Hubert, R. Aro, L. Neves, P. Sabouroux, Meas. Sci. Technol. 29, 241 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aro, R., Ben Ayoub, M.W., Leito, I. et al. Moisture in Solids: Comparison Between Evolved Water Vapor and Vaporization Coulometric Karl Fischer Methods. Int J Thermophys 41, 113 (2020). https://doi.org/10.1007/s10765-020-02697-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-020-02697-6