Abstract

The different crystallinity states of high density polyethylene (PE-HD) are investigated using THz time-domain spectroscopy by exploiting the complex permittivity at a frequency range from 0.5 up to 3.5 THz. We found that samples with different crystallinity can be distinguished by comparing the material specific refractive index (n) or rather the linked complex part of the permittivity (∈ ′ ′). Correlating the calorimetrically determined degrees of crystallinity with the absolute values of the refractive index and the specific absorption peak at 2.18 THz, respectively, suggests in both cases a linear correlation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

THz time-domain spectroscopy (THz-TDS) has proven to be a particularly well-suited technique to investigate the morphology of many non-polar materials [1, 2]. By exploiting absolute values of distinct absorption lines, it is possible to distinguish between different crystalline forms of a given material, to observe polymorphism, and to investigate phase changes [3]. Polymers typically show a very low absorption in the THz frequency range, which is the reason for their widespread use as base material for windows, lenses, and other optical parts for THz systems [4]. Although the absorption spectra of many polymers have therefore been extensively studied [5, 6], and often the corresponding weak absorption features have been assigned to corresponding molecular vibrations [7], the absolute values of these features are typically so low that the complex part of the complex permittivity ∈ ′ ′ is often the better suited parameter for morphological investigations in polymers [8,9]. Only in some few cases, mainly for highly crystalline polymers, attempts have been made to exploit these features, to obtain an estimation of the degree of crystallinity of the sample [8, 9]. Earlier work focuses on the variable absorption features during isothermal crystallization of natural existing polyester [10].

Also pharmaceutical and chemical science focuses on the crystallinity of various materials [11–13].

One of the most widespread used, petrochemical synthesized polymeric materials for THz applications is high density polyethylene (PE-HD). Thus, PE-HD has been extensively investigated at THz frequencies, and different absorption features were assigned to corresponding molecular motions [14].

The advantage of THz technologies, compared to commonly used technique to determine the degree of crystallinity, like DSC-analysis, is its suitability for contact-free, non-destructive testing of polymers, and their vibration modes [15, 16]. Therefore, changes in the crystallinity, which might occur on a rather longer time frame, can be easily determined, even if the sample is integrated in bigger dimensions.

2 Background

Polymers consist of macromolecular chains of covalently bonded atoms. As well as metals and ceramics also polymers have the potential to crystallize, provided that they have a linear or only lightly crosslinked/branched architecture and regular chemical constitution [17, 18]. However, polymers cannot fully crystallize, but form two phase materials with crystalline regions embedded in an amorphous matrix. Especially when the amorphous phase is in the rubbery state, the mechanical properties strongly depend on the crystal fraction. The degree of crystallization of a semi-crystalline polymer depends initially on the amount of constitutional imperfections and entanglements, but is also affected significantly by its thermal history (e.g., crystallization temperature, cooling rate, etc.). Therefore, it is necessary to control the degree of crystallinity after polymer processing. Degrees of crystallinity typically range between 5 and 80 % and are routinely evaluated by density measurement, differential scanning calorimetry (DSC), X-ray diffraction (XRD), infrared spectroscopy, or nuclear magnetic resonance (NMR). All the mentioned techniques have disadvantages. Some, like DSC, destroy the sample; others are only surface-sensitive (IR-spectroscopy) or use hazardous x-ray to determine the degree of crystallinity. All techniques have in common that they are time consuming.

One of the simplest polymers is polyethylene (PE), which consists of long chains of CH2-repeating units [19]. PE exhibits three types of crystal unit cells, of which the orthorhombic cell (a = 0.417 nm, b = 0.4945 nm, c = 0.2547 nm) is the most common. The physical properties of PE depend on amount and length of branches along the macromolecular backbone and molecular weight. High density polyethylene (PE-HD) has a molecular weight of an average 35,000 g mol−1 and contains only few branches. Thus, it is the most crystalline PE with degrees of crystallization, varying between 50 and 80 % depending on the crystallization conditions.

Especially, PE-HD, with its low absorption coefficient in the THz frequency range, represents an important polymer material, because commonly used THz optics, like lenses or special cuvettes for investigating the THz-properties of inserted liquids, are made of PE-HD. So, it is important to study the changes in THz-properties of PE-HD originate from different degrees of crystallinity.

2.1 THz Data Extraction

In this study, we compare minor changes in the absolute value of the optical parameters, that is way it is important to determine precisely and accurately the values of the frequency-dependent refractive index. Therefore, the quasi space algorithm, described in [20], is used for the data analysis: we used the improved algorithm of the commercial available TeraLyzer software [21], which exploits the Fabry-Perot oscillations in plane-parallel samples, to determine the precise thickness of the sample, and thus, accurate values for the complex permittivity \( \underline{\in}=\in^{\prime }-i\in^{\prime\prime } \), and the linked complex refractive index \( \underline{n}=n-i\kappa =\sqrt{\underline{\in}} \). This well-known complex algorithm fits a theoretical transfer function with the unknown parameters n, α, and the thicknesses to the transfer function of the recorded THz signal and minimizes the difference by a multitude of iterations [22–24].

The absorption coefficient \( \alpha \) and the extinction coefficient \( \kappa \), respectively, can be determined by using the imaginary part ∈ ′ ′ of the permittivity, considering the frequency \( f \) and the speed of light \( {c}_0 \):

The frequency-dependent error bars, based on the algorithm described in [25], are achieved by using the TeraLyzer software. The sample thickness, obtained by the TeraLyzer software, is in good agreement with the mechanical measured thickness with a micrometer screw, so the general uncertainty is about ±2 μm.

In general, the absorption coefficient \( \alpha \) increases in a rough approximation with f 2 for amorphous materials [26, 27], as the extinction coefficient κ (or the related imaginary part of the permittivity, ∈ ′ ′) is linearly related to the frequency. For semi-crystalline polymers, like PE-HD, the absorption effects, depending on the amorphous and crystalline phase, both contribute to the absorption spectra [28]. Thus, spectral features that are characteristic for crystalline samples, like distinct absorption peaks resulting from lattice vibrations of the polymer backbone in a crystal structure, are easier to identify in the spectra of κ or ∈ ′ ′, respectively. As different definitions of \( \kappa \) can be typically found in literature, it might not be the best suited candidate for a comprehensive study. Hence, for the following analysis, we restrict ourselves to n- and ∈ ′ ′-spectra.

3 Experimental Methods

3.1 Sample Preparation

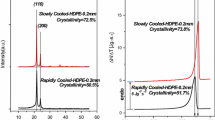

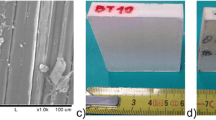

As the spectroscopic features, investigated in this study, are generally very weak, it is of outmost importance, to avoid any artifacts resulting from different fabrication processes in different material samples. Thus, Lupolen 6021D, a high density polyethylene kindly supplied by Basell Polyolefine GmbH, was exclusively used for sample preparation. The polyethylene pellets were heated to a temperature of 160 °C, pressed to sheets of about 1 mm thickness, and subsequently crystallized under certain crystallization conditions, to gain samples having different degrees of crystallinity. The samples PE-HD 0 and PE-HD 1 were quenched from melt in water at 20 and 0 °C, respectively, whereby, the sample PE-HD 2 was isothermally crystallized at 100 °C and the sample PE-HD 3 was exponentially cooled from melt to 20 °C.

3.2 Terahertz Time-Domain Spectrometer Setup

A standard free-space THz-TDS system, purged with dry air, was used in transmission geometry to investigate the PE-HD samples. A TiSa with 60 fs pulses at 800 nm was used to drive and gate LT-GaAs stripline-dipole antennas. For a detailed description of such a spectrometer, see e.g., [29]. The four PE-HD samples were measured in the focal point of the THz-TDS system in transmission geometry. Each sample was measured six times, alternating between sample and reference (air) measurement, respectively. The recorded THz traces were averaged in order to reduce the influence of laser instability or environmental impact.

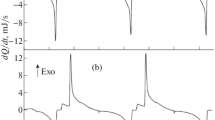

3.3 Thermal Analysis

Melting temperature T m and degree of crystallinity α cryst of the afore THz-measured samples were determined by a differential-scanning calorimeter DSC 2910 (TA Instruments, Inc.) using a temperature ramp of 10 K min−1. To this end, DSC samples with weights ranging from 10 to 20 mg were prepared from the THz spot area. Melting point T m was obtained from the peak minimum of the heat flow (exo-up). The degree of crystallinity was calculated from the heat of fusion ΔH f , as determined by integration of the melting peak, by putting into relation to the equilibrium heat of fusion ΔH 0 f = 289 J g−1of 100 % crystalline polyethylene [30, 31]:

The absolute uncertainty of a cryst is about 1.25 %, basing on the standard deviation of the measurement. The preparation-specific properties of the as-prepared samples are listed in Table 1.

4 Results and Discussion

The extracted values of the refractive index n are shown in Fig. 1 for all four samples. In general, only a low dispersion of the refractive index, with respect to frequency, can be observed, i.e., the refractive index is almost constant in the frequency range between 0.5 and 3.5 THz.

The PE-HD sample with the lowest degree of crystallinity (54.3 %) shows the lowest refractive index, and the refractive index of the other samples increases accordingly to their degree of crystallinity. The PE-HD sample with a crystallinity of 69.1 % shows the highest value for the index of refraction. Commonly, the crystallinity directly correlates with the density and thus with the refractive index. Effects caused by impurities or additives, which could lead to a higher refractive index, can be neglected, because all samples were produced of the same raw material. As well influences of air bubbles could be excepted, because these would lead to an increase in scattering, which would then be visible in the spectra by its characteristic features, but none obvious evidences could be observed in the spectra.

For evaluating the correlation between the refractive index and the crystallinity, the frequency-dependent values are averaged over the range from 0.5 up to 3.0 THz. These absolute values are shown in Table 2.

Graphing these averaged values of refractive index against the degree of crystallinity suggests a linear correlation between the absolute values of the refractive index and the crystallinity. Figure 2 illustrates the data points and the dashed line shows the linear fit, performed by using the commercial software Matlab with the included curve fitting toolbox for linear regression. The fit matches with a coefficient of determination (R-square parameter) of 0.97 to the data.

Linear approximation of the averaged refractive index values listed in Table 2

By measuring the accurate absolute value of the refractive index in the THz frequency range, it is possible to obtain a first preliminary indication of the degree of crystallinity of a sample, by comparing the results to an entry in a database for a sample with comparable fabrication conditions.

In the representation of the frequency-depending imaginary part of the permittivity ∈ ′ ′ (see Fig. 3), which is directly linked to the absorption coefficient, a characteristic absorption peak at 2.23 THz is observed. This peak appears more or less distinct in the spectrum of each of the four samples. The molecular origin of this feature has been assigned in literature as lattice vibration of the PE-HD molecules [32, 33].

In contrast to the data for the refractive index, no general trend, relating the absolute values with the degree of crystallinity, can be observed. This is also in contrast to earlier work, where the absolute value of a dominant absorption line had been exploited to determine the crystallinity of the highly crystalline polybutylene terephthalate (PBT) [9]. However, the morphology of PBT and PE-HD is different. The lattice vibration strongly depends on the spatial conformation of the PE-HD crystals. Size, orientation, and morphology of the lamellae seem to influence both the quantity and the width of the peak. However, there are clear differences in the morphological structure of the PBT and PE-HD, which are mainly due to the thermal treatment during the crystallization process. Whereas in PBT, the crystallization is obtained by tempering the samples at temperatures above the specific glass-transition temperature, the dominating effect for achieving different crystallinity states in PE-HD is the thermal treatment of the polymer melt during the cool down process.

These processes lead to different morphologies of the sample. In particular, there can be a formation of many small crystalline domains or just a few large domains. In this case, most established methods would still measure the same amount of crystallinity, not taking into account these differences in the supramolecular structure. By just exploiting the information of the absolute value of the peak maximum of the absorption line, seen in Fig. 3 for PE-HD sample 2, the spectral response of other morphological characteristics, such as peak broadening, is neglected.

Respecting to the fact that neither the peak maxima nor the FWHM of all peaks seems to correlate alone with the degree of crystallinity, our new approach uses a peak-integration, which is well known in electronic signal processing.

Peak-integration can be an attempt to consider both, the quantity and width of the peak in the ∈ ′ ′-spectra in full. Therefore, we propose integrating the peak using a zero-baseline in order to compare the absorption effects of all samples by taking into account all different absorption phenomena caused by different molecule structures. The integration limits are given by the points of inflection left and right of the central peak at about 2.2 THz. These points are determined by numerical calculation the zeroing of the second derivation with the software Matlab. Afterwards, the integration was performed with the peak-analyzer tool. For clarification, Fig. 3 points out the presented analysis method, and visualizes the integrated range of the ∈ ′ ′-peak, exemplarily for PE-HD sample 2.

The resulting peak-area-values show a linear correlation between area and degree of crystallinity as it had been seen in the case of the refractive index. Figure 4 shows the total values of the peak area with respect to the degree of crystallinity of all samples. The quality of regression is optimized by considering the standard derivation of the area-values. The R-square parameter is about 0.92, so there is a good agreement between the peak-integration results and the degree of crystallinity.

5 Summary and Outlook

We have shown that the index of refraction can be used to distinguish samples of PE-HD with differences in the degree of crystallinity. If the samples have been prepared of the same batch of raw material, it is even possible to use the refractive index as a parameter to obtain an estimate of the value of the degree of crystallinity. Whereas the local maxima of the complex part of the permittivity, \( \epsilon^{\prime\prime } \), which originates from lattice vibration of the crystalline parts of the polymer has previously been used to differentiate between samples of different crystallinity, we observe that in the case of PE-HD, this is not possible. However, by considering not only the maximum value of the peak in the ∈ ′ ′-spectrum, but also the signal area using a peak-integration, the linear correlation, which had been seen for the refractive index, can be confirmed.

In the future, it will be interesting to evaluate the impact of the crystalline domains and their influence to the spectral features. Likewise, THz-TDS imaging combined with the here presented correlations could be a suitable approach to investigate the spatial intra-sample variability of the crystallinity.

References

B. M. Fischer, S. Wietzke, M. Reuter, O. Peters, R. Gente, C. Jansen, N. Vieweg, M. Koch, “Investigating Material Characteristics and Morphology of Polymers Using Terahertz Technologies”, IEEE Transactions in Terahertz Science and Technology, Vol. 3, Issue 3 (2013).

J. A. Zeitler, D. A. Newnham, P. F. Taday, T. L. Threlfall, R. W. Lancaster, R. W. Berg, C. J. Strachan, M. Pepper, K. C. Gordon, T. Rades, “Characterization of temperature-induced phase transitions in five polymorphic forms of sulfathiazole by terahertz pulsed spectroscopy and differential scanning calorimetry”, J. of Pharmaceutical Science, Vol. 95, No. 11 (2006).

M. Franz, B. M. Fischer, M. Walther, “Probing structure and phase-transitions in molecular crystals by terahertz time-domain spectroscopy“, J. of Molecular Structure, 1006, 34-40 (2011).

B. Scherger, M. Scheller, C. Jansen, M. Koch, K. Wiesauer, “Terahertz lenses made by compression molding of micropowders“, Applied Optics, Vol. 50, Issue 15, 2256-2262 (2011).

D. R. Smith, E. V. Loewenstein, “Optical constants of far infrared materials. 3: plastics”, J. of Applied Optics, Vol. 14, No. 6 (1975).

M. N. Afsar, “Precision Millimeter-Wave Measurements of Complex Refractive Index, Complex Dielectric Permittivity, and Loss Tangent of Common Polymers”, IEEE Transactions on Instrumentation and Measurement, Vol. IM-36, No. 2 (1987).

S. Krimm, C. Y. Liang, G. B. B. M. Sutherland, “Infrared spectra of High Polymers. II. Polyethylene”, J. of chemical physics, Vol. 25, No. 3 (1956).

H. Hiromichi, Y. Morisawa, H. Sato, A. Kamiya, I. Noda, Y. Ozaki, C. Otani, “Higher order conformation of poly(3-hydroxyalkanoates) studied by terahertz time-domain spectroscopy”, Appl. Phys. Lett. 96, 101904 (2010).

S. Wietzke, M. Reuter, N. Nestle, E. Klimov, U. Zadok, B. M. Fischer, M. Koch, “Analyzing Morphology and Thermal History of Polybutylene Terephthalate by THz Time-domain Spectroscopy”, J. Infrared, Millimeter and Terahertz Waves, 32, 952-959, (2011).

H. Hoshina, S. Ischii, S. Yamamoto, Y. Morisawa, H. Sato, T. Uchiyama, Y. Ozaki, C. Otani, “Terahertz Spectroscopy in Polymer Research: Assignment of Intermolecular Vibrational Modes and Structural Characterization of Poly(3-Hydroxybutyrate)”, IEEE Transactions on Terahertz Science and Technology, Vol. 3, Issue 3 (2013).

C. J. Strachan, T. Rades, D. A. Newnham, K. C. Gordon, M. Pepper, P. F. Taday, “Using terahertz pulsed spectroscopy to study crystallinity of pharmaceutical materials”, Chemical Physics Letters, Vol. 390, Issue 1-3, 20-24 (2004).

Yao-Chun Shen, “Terahertz pulsed spectroscopy and imaging for pharmaceutical applications: A review, Int. J. of Pharmaceutics, Vol. 417, 48-60 (2011).

I. Ermolina, J. Darkwah, G. Smith, “Characterisation of Crystalline-Amorphous Blends of Sucrose with Terahertz-Pulsed Spectroscopy: the Development of a Prediction Technique for Estimating the Degree of Crystallinity with Partial Least Squares Regression”, American Association of Pharmaceitical Scientists, Vol 15, No. 2 (2014).

M. I. Bank, S. Krimm, “Lattice‐frequency studies of crystalline and fold structure in polyethylene”, J. of Applied Physics, 39, 4951 (1968).

K. Yamamoto, M. Yamaguchi, M. Tani, M. Hangyo, S. Teramura, T. Isu, N. Tomita, “Degradation diagnosis of ultrahigh-molecular weight polyethylene with terahertz-time-domain-spectroscopy”, Appl. Phys. Lett. 85(22), 5194-5196 (2004).

H. Hoshina, S. Ishii, S. Yamamoto, Y. Morisawa, H. Sato, T. Uchiyama, Y. Ozaki, C. Otani, “Terahertz Spectroscopy in Polymer Research: Assignment of Intermolecular Vibrational Modes and Structural Characterization of Poly(3-Hydroxybutyrate)”, IEEE Transactions on Terahertz Science and Technology, Vol. 3, Issue 3 (2013).

B. Heuwers, A. Beckel, A. Krieger, F. Katzenberg, J. C. Tiller, “Shape Memory Natural Rubber: An Exceptional Material for Strain and Energy Storage”, Macromolecular Chemistry and Physics 214, 912-923 (2013).

T. Raidt, R. Hoeher, F. Katzenberg, J. C. Tiller, “Chemical Cross-linking of Polypropylenes Towards New Shape Memory Polymers”, Macromolecular Communications 36, 744-749 (2015).

A. J. Peacock, “Handbook of Polyethylene: Structures: Properties, and Applications”, Marcel Dekker, Inc. New York (2000).

M. Scheller, “Data extraction from terahertz time domain spectroscopy measurement”, J. Infrared, Millimeter and Terahertz Waves, 35, 638–648 (2014).

TeraLyzer Data Extraction Suite, Lytera UG (haftungsbeschränkt), http://www.lytera.com

I. Pupeza, R. Wilk, M. Koch, “Highly accurate optical material parameter determination with THz time-domain spectroscopy”, Optics Express, Vol. 15, Issue 7, 1598-1609 (2007).

P. Jepsen, B. Fischer, “Dynamic range in terahertz time-domain transmission and reflection spectroscopy”, Optics Letters, Vol. 30, No. 1 (2005).

M. Scheller, C. Jansen, M. Koch, “Analyzing sub-100μm samples with transmission terahertzs time domain spectroscopy”, Optics Communication, Vol. 282, Issue 7, 1304-1306 (2009).

W. Withayachumnankul, B. Fischer, D. Abbot, “Material thickness optimization for transmission-mode terahertz time-domain spectroscopy”, Optics Express, Vol. 16, No. 10, 7382-7396 (2008).

M. Naftaly, R. E. Miles, “Terahertz Time-Domain spectroscopy for material characterization”, Proceedings of the IEEE, Vol. 95, No. 8 (2007).

G. W. Chantry, J. W. Fleming, P. M. Smith, “Far infared and millimeter-wave absorption spectra of some low-loss polymers”, Chemical Physics Letters, Vol. 10, No. 4 (1971).

M. N. Afsar, “Precision Dielectric Measurements of Nonpolar Polymers in the Millimeter Wavelength Range”, IEEE Transactions on Microwave Theory and Techniques, Vol. 33, Issue 12 (1985).

S. Hunsche, D. M. Mittleman, M. Koch, M. C. Nuss, “New Dimensions in T-Ray Imaging“, IEICE TRANSACTIONS on Electronics, Vol.E81-C, No.2, 269-276 (1998).

R. Hoeher, T. Raidt, M. Rose, F. Katzenberg, J.C. Tiller, “Recoverable Strain Storage Capacity of Shape Memory Polyethylene”, J. of Polymer Science Part B: Polymer Physics 51 (13) 1033-1040 (2013).

R. Hoeher, T. Raidt, C. Krumm, M. Meuris, F. Katzenberg, J.C. Tiller, “Tunable Multiple-Shape Memory Polyethylene Blends”, Macromolecular Chemistry and Physics 214 (23), 2725-2732 (2013).

S. Wietzke, C. Jansen, M. Reuter, T. Jung, D. Kraft, S. Chatterjee, B. M. Fischer, M. Koch, “Terahertz spectroscopy on polymers: A review of morphological studies,” J. Mol. Struct. 1006, 41–51 (2011).

S. Wietzke, C. Jansen, M. Reuter, T. Jung, J. Hehl, D. Kraft, S. Chatterjee, A. Greiner, M. Koch, “Thermomorphological of the terahertz lattice modes in polyvinylidene fluoride ad high-density polyethylene”, Applied Physics letters 97, 022901 (2010).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sommer, S., Raidt, T., Fischer, B.M. et al. THz-Spectroscopy on High Density Polyethylene with Different Crystallinity. J Infrared Milli Terahz Waves 37, 189–197 (2016). https://doi.org/10.1007/s10762-015-0219-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10762-015-0219-8