The effect of immersion in a coffee drink solution on the color stability of two CAD/CAM ceramic restorations was investigated in this in vitro study. To this end, zirconia-reinforced lithium silicate (ZLS) and lithium disilicate (LDS) glass-ceramic blocks were surface-treated using mechanical polishing and glazing techniques. In addition, their color was examined before and after immersion in a coffee solution using a spectrophotometer, and the color changes were evaluated. A two-way analysis of variance (ANOVA) was used to examine the color changes. The material type significantly influenced color changes (P < 0.001). After glazing and mechanical polishing, LDS exhibited considerably less color change in both groups than ZLS. In both types of ceramics, the glazed group experienced less color variation than the mechanically polished group. Color changes were clinically acceptable across all groups. The glazing surface treatment produced superior color stability than the mechanical polishing technique. LDS exhibited more color stability than ZLS in both surface treatments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

CAD/CAM-manufactured monolithic dental restorations have become increasingly popular in recent years due to their superior mechanical properties, biocompatibility, polishability, and favorable esthetic appearance [1]. There are various types of monolithic restorations, such as monolithic zirconia restorations, lithium disilicate (LDS), zirconia-reinforced lithium silicate (ZLS), and feldspathic, leucite-based ceramics, which are used to fabricate a variety of restorations, such as inlays, onlays, partial crowns, veneers, and anterior and posterior crowns [2,3,4].

Due to their silicate content and crystallization, LDS and ZLS exhibit superior esthetic results compared to the rest of these materials, and they appear similar to natural teeth. Therefore, they are commonly used to restore anterior and esthetic zone teeth [5]. ZLS is produced by reinforcing LDS with 10 wt.% ZrO2; consequently, it possesses the advantageous mechanical properties of zirconia and the beneficial esthetic appearance of glass-ceramic [3, 6].

Numerous factors influence the final color of ceramic restorations created with CAD/CAM technology, including the restoration’s crystalline structure, the smoothness of the ceramic’s surface, the reflection of light beams from the restoration’s surface, the thickness and translucency of the restoration, and the type of cement beneath the restoration. In addition, after the restoration has been delivered, its lack of adequate color stability and staining over time can cause color changes that compromise its quality and longevity, which are considered reasons for replacing the restoration [1, 7,8,9,10,11].

According to Sarikaya, et al. [12], coffee beverages cause the greatest staining of hybrid ceramics and nano-ceramic resins among all coloring agents. Saba, et al. demonstrated that coffee violates the aesthetic appearance of Vita Enamic and Vita Block Mark II porcelains by altering their color and microhardness [13]. Therefore, a proper surface treatment method that can improve surface characteristics will benefit the restoration’s color stability and aesthetic appearance [5].

Different surface treatment protocols can be utilized to reduce color changes and increase the restoration’s translucency. Glazing a ceramic surface is one of the best techniques for creating a smooth surface. However, due to the increased number of chairside restorations fabricated using CAD/CAM technology, mechanical polishing techniques are used more frequently than glazing approaches because they are a more rapid procedure [14].

Although the manufacturers of these ceramics recommend both glazing and mechanical polishing to obtain a smooth surface, there is insufficient data to determine whether these two ceramic types’ color stability and mechanical properties are comparable due to these two processes. Manufacturers market different kits and polishing pastes to create a smooth and glazed surface, but it is unknown which method is the most effective [14].

On the other hand, glazing the ceramic surface before restorations are cemented decreases surface roughness, fills porosities on the restoration surface, increases ceramic strength, and plays a significant role in color stability and prevention of restoration staining [15,16,17]. However, it is often necessary to adjust the restoration in the dental office (chairside) during the delivery session regarding the final occlusion and cervical contour. Such adjustments are typically performed by fine-grain diamond burs [3].

Although these adjustments are required to correct the contour or improve the aesthetic appearance of restorations, they may damage or destroy the restoration’s surface glaze, resulting in a rough surface that collects plaque, stains, and a discolored surface. Furthermore, these surfaces cause dental caries and periodontal disease. Therefore, these surfaces should be considered for a second round of mechanical polishing and glazing [3].

Although polishing provides the desired mechanical properties, studies have produced contradictory findings regarding the effect of various surface polishing procedures on the color stability of ceramic restorations. Alp, et al. demonstrated that the material type significantly influenced color changes, except for the polished LDS group, where color changes were discernible in all of the ZLS and LDS groups that were polished or viewed [5].

Kanat-Ertuk, et al. reported that glazing alone produced superior color stability in LDS and ZLS restorations than mechanical polishing and external coloring. The color stability of LDS restorations was superior to that of ZLS restorations. Moreover, polishing pastes reduced restoration color changes to clinically acceptable levels [14]. Therefore, although manufacturers recommend glazing and polishing the surface to improve aesthetic appeal, it is unclear which procedure yields the most favorable color stability results [5].

In the present study, LDS and ZLS monolithic ceramics with favorable physical properties and aesthetic appearance were evaluated in light of the significance of color stability in new CAD/CAM ceramic restorations. ZLS is a relatively new ceramic introduced in 2013 under the brand names Suprinity (Vita) and Celtra (Dentsply Sirona). However, limited research has been conducted to evaluate its characteristics and how to enhance its properties. Although ZLS and LDS ceramics manufacturers believe that glazing and mechanical polishing methods can be used interchangeably to achieve optimal optical properties, it is unclear which method ensures longer-lasting color stability. Therefore, additional research is required. Consequently, this in-vitro study was conducted to determine the effect of two different surface treatment procedures (glazing and mechanical polishing) on the color stability of lithium disilicate (LDS) and zirconia-reinforced lithium silicate (ZLS) monolithic restorations.

EXPERIMENTAL SECTION

Sample Preparation

Two distinct types of CAD/CAM blocks were selected in the present study:

1. ZLS (zirconia-reinforced lithium silicate) (Celtra Duo, Dentsply);

2. LDS (lithium disilicate glass-ceramic) (IPS e.max CAD, Ivoclar Vivadent AG).

Twenty rectangular samples measuring 1.5 ± 0.03 mm in thickness were cut from two distinct types of ceramic blocks, namely ZLS (n = 10) and LDS (n = 10) of the A2 shade, measuring 1.5 × 7 × 12 mm, using a sectioning machine (MeCatome T210, France) under low speed and continuous cold water irrigation to prevent microcrack formation [5, 15]. The samples were then placed in an ultrasonic device (Eurosonic 4D, Euronda, Vicenza, Italy) to eliminate any remaining particles and surface contamination. The samples were subsequently sintered and completely crystallized in an Ivoclar Vivadent AG porcelain oven according to the manufacturer’s instructions [3, 5].

To standardize the polishing procedure, samples were polished using a low-speed handpiece cooled by water and ultra-fine (600 grit) silicon carbide sandpaper [3]. The samples were then submerged in distilled water for 10 min, dried with an air syringe, and stored at room temperature [18]. Photographs of LDS and ZLS samples prepared for this study are shown in Fig. 1.

Surface Treatments

The samples of both ceramics were randomly assigned to two groups (n = 5) based on the surface treatments (polishing or glazing). The ZLS group samples (n = 5) were polished using a low-speed handpiece and a polishing kit (ZLS polishing set; Vita Zahnfabrik) per the manufacturer’s instructions. The samples were initially polished with pink diamond instruments at 10,000 rpm, followed by grey diamond instruments at 6,000 rpm [5].

In the glazed ZLS group (n = 5), sample surfaces were coated with a thin layer of glaze material (Celtra Duo Universal Glaze; Dentsply Sirona). The samples were then heated in an oven at 820°C for 60 sec [5, 19]. In the polished LDS group (n = 5), samples were polished using a low-speed handpiece and a polishing kit (Ivoclar Vivadent OptraFine Assortment) per the manufacturer’s instructions. The surfaces of the samples were initially polished with light blue instruments at 10,000 rpm, followed by polishing with dark blue instruments at 10,000 rpm while cooled with water. The samples were then polished at 8000 rpm with a diamond polishing paste [5].

In the glazed LDS group (n = 5), sample surfaces were coated with a thin layer of glazing material (IPS e.max Ceram; Ivoclar Vivadent) and subsequently placed in an oven at 770°C for 90 sec [5]. Afterward, the polished samples were placed in an ultrasonic device with a suitable irrigation solution to eliminate residual materials and contamination [20]. Before determining the baseline color of the samples, they were submerged for 24 h at 37°C in distilled water.

Sample Baseline Color

A spectrophotometer was used to determine the baseline color of the surface-treated samples (Spectroshade, Italy). The baseline color of all samples was determined using a dental spectrophotometer in the colored environment of CIELAB against a white background. Color intensity was determined using the Commission Internationale D’Eclairage (CIE) LAB color environment as follows [1, 14]:

L indicates lightness (i.e., a grayscale from black to white);

A indicates chromaticity from green (negative) to red (positive);

B indicates chromaticity from blue (negative) to yellow (positive).

Before measuring the color of the samples, the spectrophotometer was calibrated according to the manufacturer’s instructions [14]. Each sample was measured twice, and the mean was calculated to reduce potential chromaticity determination deviations. One operator was responsible for all measurements [5]. The operator was blinded during chromaticity measurements with the spectrophotometer to prevent any possible biases.

Coffee Immersion

After establishing the baseline color of the samples, they were submerged in a coffee solution for two weeks (Nescafe; Nestle, Brazil) [14]. To prepare the coffee beverage, 2 g of coffee powder was combined with 200 ml of hot water. The temperature of the solution was measured with a thermometer until it reached 37°C. The samples were subsequently submerged in coffee. Afterward, the samples were mounted vertically on the container floor to prevent their contact. Finally, the samples were incubated at 37°C for 24 h, and the coffee beverage was replaced daily for two weeks.

According to a study by Guler, et al., 24 h of coffee consumption is nearly equivalent to 30 days of regular coffee consumption. Immersing samples in coffee at 37°C was equivalent to almost 1.25 years of coffee consumption [21, 22].

Sample Final Color

After two weeks, the surface color of the samples that had received surface treatments was determined using a spectrophotometer. The samples’ final color after being immersed in the coffee drink for two weeks was reported and compared with the baseline (before immersion in the coffee drink) to calculate ΔE (color change) for each group given in Eq. (1):

where b1, a1, and L1 denote baseline values before coffee immersion, and b2, a2, and L2 represent values after coffee immersion. An ΔE < 3.3 was considered clinically acceptable [1, 14, 23].

RESULTS AND DISCUSSION

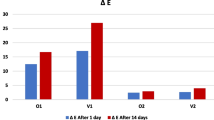

The results of descriptive analyses were expressed as mean ± standard deviation (SD) and minimum and maximum values. Table 1 and Fig. 2 display the variation of color change examined parameters for ZLS and LDS ceramic materials with glazed and mechanically polished surfaces. The Shapiro–Wilk test was used to evaluate the normality of data. Two-way analysis of variance (ANOVA) was used to analyze the effect of glazing or mechanical polishing surface treatments on the color stability of two distinct types of CAD/CAM ceramic materials because the color change data for the study groups were normally distributed. In all tests, a significance level of 0.05 was deemed statistically significant. Statistical analyses were performed using SPSS 26.0. The results of a two-way ANOVA are summarized in Table 2 to compare the color changes resulting from glazing or mechanical polishing surface treatments in the two ceramic materials.

The results indicated that the mean color changes in the ZLS and LDs ceramic materials were significantly different (P < 0.001), with greater color changes in the ZLS group (with both surface treatments) than in the LDS group. In addition, the mean color changes significantly differed between glazing and mechanical polishing (P < 0.001). To this end, these changes were more significant with mechanical polishing (in both the ZLS and LDS groups) than with the glazing method. The cumulative effect of ceramic material type and surface treatment on color changes was insignificant (P = 0.090).

Figure 3 plots the mean color changes resulting from the glazing or mechanical polishing of the surfaces of two ceramic materials.

DISCUSSION

Considerable differences in color changes were observed between ZLS and LDS ceramic materials, with more color changes occurring in the ZLS group (both with surface glazing and mechanical polishing) than in the LDS group. In addition, the mean color changes were significantly different between the two surface treatment methods (glazing and mechanical polishing), with mechanical polishing producing more color changes than glazing in both the ZLS and LDS groups. All groups exhibited color changes within the clinically acceptable range (ΔE < 3.3) [1, 14, 23].

Previous research has demonstrated that surface treatment and surface roughness impact color stability [7, 14, 24]. Motro, et al. evaluated the effects of various surface treatments, such as glazing, re-glazing, and mechanical polishing, on the color stability and surface roughness of IPS e.max Ceram ceramic after twelve days of immersion in coffee. The glazed group showed the highest color stability and the lowest surface roughness. All groups exhibited color changes within the clinically acceptable range [24]. Yilmaz, et al. reported more color stability in glazed ceramic samples than in polished ceramic samples after immersion in methylene blue using polishing kits and pastes [7].

Consistent with the two studies by Motro, et al. and Yilmaz, et al., the glazed groups of both ceramic types exhibited more color stability than the mechanically polished groups. This could be attributed to the glazing liquid’s capacity to fill the pores and reduce the depths of surface irregularities. In addition, the high temperature during the thermal cycles of glazing causes the viscous flow of the glass content to bridge the cracks [25].

Ren, et al. and Choi, et al. evidenced that zirconia-containing composite resins exhibited more color changes due to their porous structure and pigment penetration into these spaces. Based on the findings of these two studies, zirconia- reinforced lithium silicate ceramics may exhibit greater color changes than lithium disilicate ceramics. However, additional research is required to substantiate this argument [26, 27].

Consistent with the findings of the two studies cited above, lithium disilicate ceramic (IPS e.max CAD) demonstrated superior color stability to zirconia-reinforced lithium silicate (Celtra Duo) with both surface treatment techniques in the present study. The structure of the ceramics could account for these color differences between the two ceramics. LDS is more homogeneous and has a higher crystal content. In contrast, incorporating ZrO2 into the ZLS ceramic increases its viscosity and reduces crystal growth [28].

Kanat-Erturk, et al. evaluated the effect of glazing and mechanical polishing surface treatments on the color stability of lithium disilicate (IPS e.max CAD) and zirconia-reinforced lithium silicate (Vita Suprinity CAD) following immersion in coffee at four different time intervals over two weeks. In line with the present study, the glazed groups of both ceramics exhibited more color stability than the mechanically polished groups. All groups exhibited color changes within the clinically acceptable range. In contrast to the present study, the ZLS group demonstrated superior color stability at the two-week interval compared to the polished LDS group. This difference may be attributable to the variation in mechanical polishing kits. In addition, differences between Celtra Duo and Vita Suprinity ceramics may have contributed to the observed differences, as these two zirconia-reinforced lithium silicate ceramics are manufactured differently: Vita Suprinity requires crystallization, whereas Celtra Duo is pre-crystallized. Notably, in the study by Kanat-Erturk, LDS exhibited improved color stability compared to ZLS after polishing paste application in both the glazing and mechanical polishing groups [14].

Eldwakhly, et al. evaluated the color stability of various ceramics, such as ZLS (Celtra Duo), LDS (IPS e.max CAD), nano-ceramics (Lava TM Ultimate), hybrid ceramics (Vita ENAMIC), and high-translucency ceramic (Lava TM Plus), under the influence of various coloring agents. Among the evaluated ceramics, LDS (IPS e.max CAD) demonstrated the highest color stability [29].

Bukhari investigated the effects of various surface finishing processes and the number of oven rounds on the color stability of four distinct ceramics, namely IPS e.max CAD, IPS e.max Press, Celtra Duo, and Celtra Press. The results showed that glazing reduced surface roughness and improved optical properties more than mechanical polishing and finishing in all evaluated ceramics [30]. The present study’s findings are consistent with those of the two studies listed above.

Alp, et al. assessed the influence of surface treatments and thermocycling on the staining of IPS e.max CAD and vita Suprinity ceramics. Consistent with the present study, color changes in all glazed and mechanically polished LDS and ZLS groups fell within the clinically acceptable range. The glazed groups exhibited superior color stability than the mechanically polished groups in both ceramics. In contrast to the present study, color changes in the LDS ceramic were greater than in the ZLS ceramic, with the LDS group experiencing more color changes. This discrepancy in results may be attributable to differences between the two materials and the methods employed. The ZLS ceramic used by Alp, et al. differed from that used in the current study. Conversely, the procedures differed between the two studies (thermocycling versus immersion in coffee) [5].

CONCLUSIONS

In conclusion, the current study’s significant findings are as follows:

1. Glazing produced superior color stability than mechanical polishing in zirconia-reinforced lithium disilicate and silicate ceramics.

2. Lithium disilicate ceramic demonstrated more color stability than zirconia-reinforced lithium silicate ceramic during glazing and mechanical polishing.

3. As a coloring agent, coffee negatively affected the color stability of CAD/CAM ceramics.

4. All groups exhibited color changes within the clinically acceptable range.

References

A. Abu-Obaid, A. AlMawash, N. Alyabis, and N. Alzaaqi, “An in vitro evaluation of the effect of polishing on the stainability of different CAD/CAM ceramic materials,” Saudi Dent. J., 32(3), 135 – 141 (2020).

H. K. Kim and S. H. Kim, “Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia,” Dent. Mater. J., 30(9), e229 – e237 (2014).

F. Firouz, F. Vafaee, Z. Khamverdi, S. Khazaei, S. G. Gholiabad, and M. Mohajeri, “Effect of three commonly consumed beverages on surface roughness of polished and glazed zirconia-reinforced lithium silicate glass ceramics,” Front Dent., 16(4), 296 – 302 (2019).

T. Traini, B. Sinjari, R. Pascetta, N. Serafini, G. Perfetti, P. Trisi, et al. “The zirconia-reinforced lithium silicate ceramic: lights and shadows of a new material,” Dent. Mater. J., 35(5), 748 – 755 (2016).

G. Alp, M. G. Subasi,W. M. Johnston, and B. Yilmaz, “Effect of surface treatments and coffee thermocycling on the color and translucency of CAD-CAM monolithic glass-ceramic,” J. Prosthet. Dent., 120(2), 263 – 268 (2018). https://doi.org/10.1016/j.prosdent.2017.10.024

S. E. Elsaka and A. M. Elnaghy, “Mechanical properties of zirconia reinforced lithium silicate glass-ceramic,” Dent. Mater., 32(7), 908 – 914 (2016).

C. Yılmaz, T. Korkmaz, H. Demirköprülü, G. Ergün, and Y. Özkan, “Color stability of glazed and polished dental porcelains”, J. Prosthodont., 17(1), 20 – 24 (2008).

D. Sarac, Y. S. Sarac, S. Kulunk, C. Ural, and T. Kulunk, “The effect of polishing techniques on the surface roughness and color change of composite resins,” J. Prosthet. Dent., 96(1), 33 – 40 (2006).

I. J. Kim, Y. K. Lee, B. S.Lim, and C.W. Kim, “Effect of surface topography on the color of dental porcelain,” J. Mater. Sci. Mater. Med., 14(5), 405 – 409 (2003).

Y. K. Lee, B. S. Lim, and C. W. Kim, “Effect of surface conditions on the color of dental resin composites,” J. Biomed. Mater. Res., 63(5), 657 – 663 (2002).

A. R. Tuncdemir, E. Dilber, H. B. Kara, and A. N. Ozturk, “The effects of porcelain polishing techniques on the color and surface texture of different porcelain systems,” Mater. Sci. Appl., 3(5), 294 – 300 (2012).

I. B. Sarıkaya, K. Yerliyurt, and Y. Hayran, “Effect of surface finishing on the colour stability and translucency of dental ceramics,” BMC Oral Health, 18(1), 40 (2018).

D. A. Saba, R. A. Salama, and R. Haridy, “Effect of different beverages on the color stability and microhardness of CAD/CAM hybrid versus feldspathic ceramic blocks: An in-vitro study,” Future Dent. J., 3(2), 61 – 66 (2017).

B. Kanat-Ertürk, “Color stability of CAD/CAM ceramics prepared with different surface finishing procedures,” J. Prosthodont., 29(2), 166 – 72 (2020).

N. Vasilic, R. Henderson, T. Jorgenson, E. Sutherl, and R. Carson, “The use of bovine porous bone mineral in combination with collagen membrane or autologous fibrinogen/fibronectin system for ridge preservation following tooth extraction,” J. Okla. Dent. Assoc., 93(4), 33 – 38 (2003).

M. D.Wright, R. Masri, C. F. Driscoll, E. Romberg, G. A. Thompson, and D. A. Runyan, “Comparison of three systems for the polishing of an ultra-low fusing dental porcelain,” J. Prosthet. Dent., 92(5), 486 – 490 (2004).

M. Colombo, C. Poggio, A. Lasagna, M. Chiesa, and A. Scribante, “Vickers micro-hardness of new restorative CAD/CAM dental materials: Evaluation and comparison after exposure to acidic drink,” Materials (Basel), 12(8), 1246 (2019).

M. Alnasser, M. Finkelman, A. Papathanasiou, M. Suzuki, R. Ghaffari, and A. Ali, “Effect of acidic pH on surface roughness of esthetic dental materials” J. Prosthet. Dent., 122(6), 567e1 – e8 (2019).

M. Zimmermann, G. Egli, M. Zaruba, and A. Mehl, “Influence of material thickness on fractural strength of CAD/CAM fabricated ceramic crowns,” Dent. Mater. J., 36(6), 778 – 783 (2017).

D. Awad, B. Stawarczyk, A. Liebermann, and N. Ilie, “Translucency of esthetic, dental restorative CAD/CAM materials and composite resins with respect to, thickness and surface roughness,” J. Prosthet. Dent., 113(6), 534 – 540 (2015).

N. Aydın, S. Karaoğlanoğlu, E. A. Oktay, and M. A. Kılıçarslan, “Investigating the color changes on resin-based CAD/CAM Blocks,” J. Esthet. Restor. Dent., 32(2), 251 – 256 (2020).

A. U. Guler, F. Yilmaz, T. Kulunk, E. Guler, and S. Kurt, “Effects of different drinks on stainability of resin composite provisional restorative materials,” J. Prosthet. Dent., 94(2), 118 – 124 (2005).

S. Ardu, V. Braut, D. Gutemberg, I. Krejci, D. Dietschi, and A. J. Feilzer, “A longterm laboratory test on staining susceptibility of esthetic composite resin materials,” Quintessence Int., 41(8), 695 – 702 (2010).

P. F. K. Motro, P. Kursoglu, and E. Kazazoglu, “Effects of different surface treatments on stainability of ceramics,” J. Prosthet. Dent., 108(4), 231 – 7 (2012).

A. J. Raigrodski, “Contemporary all-ceramic fixed partial dentures: a review,” Dent. Clin. North Am., 48(2), 531 – 544 (2004).

Y. F. Ren, L. Feng, D. Serban, and H. S. Malmstrom, “Effects of common beverage colorants on color stability of dental composite resins: the utility of a thermocycling stain challenge model in vitro”, J. Dent., 40, e48 – e56 (2012).

M. S. Choi, Y. K. Lee, B. S. Lim, S. H. Rhee, and H. C. Yang, “Changes in surface characteristics of dental resin composites after polishing,” J. Mater. Sci., 16(4), 347 – 353 (2005).

G. W. Ho and J. P. Matinlinna, “Insights on ceramics as dental materials. Part II: chemical surface treatments”, Silicon, 3(3), 117 – 123 (2011).

E. Eldwakhly, D. R. M. Ahmed, M. Soliman, M. M. Abbas, and W. Badrawy, “Color and translucency stability of novel restorative CAD/CAM materials”, Dent. Med. Probl., 56(4), 349 – 356 (2019).

S. F. Bukhari, Mechanical and Optical Properties of Machinable and Pressable Glass Ceramic, Boston University Theses & Dissertations, Boston (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 9, pp. 60 – 62, September, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghazaee, S., Moslehifard, E., Ghaffari, T. et al. Effect of Surface Glaze Treatment and Mechanical Polishing on the Color Stability of Two Types of Cad/Cam Ceramics. Glass Ceram 80, 396–401 (2024). https://doi.org/10.1007/s10717-023-00621-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-023-00621-6