Abstract

Due to increasing environmental problems, the reuse of waste materials has become essential, and ground-granulated blast furnace slag is one of these materials. This study investigated the effects of ground granulated blast furnace slag, lime, and sodium silicate as alternative additives on soft clay. Forty-five unconfined compressive strength tests were conducted using five different percentages of ground granulated blast furnace slag (2%, 4%, 6%, 8%, and 10% of the total dry weight), three different percentages of sodium silicate (1%, 1.5%, and 2.5% of the total dry weight), and a constant percentage of 6% lime (by total dry weight). The specimens were cured for 7, 28, and 90 days. Also, three consolidation tests were conducted on improved samples with optimal percentages of lime and ground granulated blast furnace slag and 1%, 1.5%, and 2.5% sodium silicate by total dry weight. The results showed that using a mixture of ground granulated blast furnace slag, lime, and sodium silicate improved the soil’s unconfined compressive strength, and this stabilizing effect increased over time. Furthermore, the settlement of the improved samples increased, and simultaneously, the void ratio decreased. Additionally, scanning electron microscopy and energy-dispersive X-ray analysis were performed on specimens. The results showed that the presence of additives increased the soil samples’ strength due to increased hydration reactions and porosity reduction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, with population growth, urban expansion and the lack of adequate soil, improving and stabilizing problematic soils has become more important. Soft clay is a problematic soil, which, due to its high softness and insufficient resistance, can cause serious damage to civil engineering projects. Soil stabilization includes techniques and methods to increase resistance, reduce permeability, or provide a specific soil parameter. One of these methods is the use of chemical additives. Commonly used additives that have long been used for soil stabilization are: Cement (Bouras et al. 2022; Zidan 2020), Lime (Aldaood et al. 2021; Bouras et al. 2022), Nanomaterials (Parsaei et al 2023; Abbasi et al. 2018), and so on. However, using lime and cement can cause a great deal of damage to the environment. In other words, the most crucial environmental concerns regarding lime and cement are its high energy consumption and air pollution. Additionally, the lime and cement manufacturing process emits greenhouse gases into the atmosphere annually (Salimi and Ghorbani 2020; Amran et al. 2020). Therefore, many researchers are considering using waste materials as alternative additives instead of or in conjunction with lime and cement. Ground granulated blast furnace slag (GGBFS) is one such industrial waste material. It is a subsidiary and lateral product made from the impurities in iron ore, produced during the process of separating iron from iron ore. GGBFS is a mixture of silicates and complex metal oxides that remain after the impurities cool. This compound takes a solid shape and is used in various contexts, including slag cement, refractory materials, slag wool, rail ballast, road substructure materials, asphalt, and concrete aggregates.

The use of other chemical additives with the GGBFS, such as sodium silicate, and lime, can enhance and improve the pozzolanic reactions, thus helping to improve the properties of soil. The addition of lime to clay in the presence of water after cation exchange dissolves the clay surfaces (release of SiO2 and Al2O3 in the medium). Then, as Eqs. 1 and 2 show, the presence of free calcium ions (Ca2+) in the system causes the formation of cementitious compounds such as hydrated calcium silicate (CSH) gel and calcium aluminate hydrate (CAH) gel with pozzolanic reactions (Akbari et al. 2020; Bell 1996). These two substances play the most important role in soil stabilization, which is called hydration products.

The use of GGBFS with lime and other additives has been investigated by several researchers. Zheng et al. (2023) investigated the effect of lime-GGBFS on Phosphogypsum soil and Phosphogypsum free soil. They conducted fatigue, compaction, and unconfined compressive strength (UCS) tests on specimens and concluded that lime-GGBFS had a better effect on Phosphogypsum soil and the strength and the dynamic elastic modulus in both types of soils increased. Ebailila et al. (2022) studied The effect of lime–GGBFS on non-sulfate and sulfate-dosed soil. In this study, a multi-scale investigation including UCS and linear expansion was performed to assess their performance. The tests indicated that the binary blends of lime–GGBS are effective on the UCS of non-sulfate and sulfate-dosed soil. Darsi et al. (2021); Keramatikerman et al. (2016) conducted UCS tests to demonstrate that the addition of GGBFS containing lime to clay leads to a significant increase in compressive strength at all time periods. They also found that the maximum soaked California Bearing Ratio (CBR) and UCS values were significantly increased after stabilization with GGBFS and lime and Microstructural analysis using scanning electron microscopy (SEM) and X-ray diffraction (XRD) on clay modified by a mixture of GGBFS and lime indicated that GGBFS enhances pozzolanic reactions and consequently increases resistance. Yi et al. (2015) examined the mechanical and microstructural characteristics of soft marine clay stabilized with lime and activated GGBFS. It concluded that the combination of lime and GGBFS yielded better performance than cement alone. Review studies by researchers Nidzam and Kinuthia (2010); Abdila et al. (2022) explored the details and mechanism of soil stabilization using GGBFS. They concluded that GGBFS could be highly effective in soil stabilization, particularly in sulphate soils, where the traditional use of Portland cement and lime may result in further infiltration. Wild et al. (1998) substituted lime with GGBFS in lime-stabilized clay soils in the presence of gypsum to evaluate its strength for substructure layers. Their findings revealed that replacing lime with GGBFS led to a significant increase in resistance. Behera and Senapati (2021) concluded that addition of GGBFS and stone dust to expansive soil can improve unsoaked CBR and UCS of expansives soil.

Sodium silicate is a widely available and non-contaminating additive that, in the presence of water, forms a colloid state that acts as a gel and connects particles (Chien et al. 2014; Houlsby 1990) This improves reaction conditions. Bibak et al. (2020) studied the effect of sodium silicate as a facilitating agent of the reactions in soil stabilization, lime, and waste material on soft clay. They conducted Compaction and UCS tests on the specimens and concluded that the best function of the stabilized soil was achieved when there was 6% lime, 6% industrial waste, and 1.5% sodium silicate. with this percentage of additives, the optimum moisture content of specimens decreased, and dry unit weight and UCS increased. Vakili et al. (2016) investigated improving cement clay shear strength by adding varying percentages of sodium silicate and GGBFS. They determined the optimum percentages of sodium silicate and GGBFS under vertical loading.

As previously stated, the use of lime in soil stabilization is not eco-friendly. Toxic gases are generated as part of the production process and consume a lot of energy. Many researchers have studied other additives to replace lime. Therefore, the main purpose of this study is to replace some of the lime with GGBFS and sodium silicate and study the effect of these additives on soft clay soil.

2 Materials and Procedures

2.1 Lime

The quicklime was prepared, placed in water as hydrated lime, and then used as a powder after drying. Table 1 presents the chemical properties of lime.

2.2 Sodium Silicate

The sodium silicate used in this study has the chemical formula of \({\mathrm{Na}}_{2}{\mathrm{SiO}}_{3}\). It is a powder and is added to the soil after being dissolved in water. Table 2 shows the properties of sodium silicate.

2.3 GGBFS

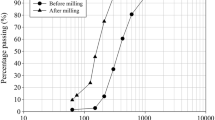

The GGBFS used in this study is from the Isfahan Steel Company in Iran. Table 3 shows GGBFS compounds. GGBFS, as shown in Fig. 1, is a grey powder and is used in its dry form. At least 90% of the GGBFS aggregates measured between 0 and 3 mm and were used after being ground and sieved.

2.4 Soil Properties

The clay studied in this paper is from Kermanshah city, Iran, and was taken at a depth of one meter. Figure 2 shows the grains of this clay. Table 4 reveals the geotechnical properties of the clay used. These values were obtained using standard laboratory tests. XRD analysis of the soil is illustrated in Fig. 3.

2.5 Sample Preparation

First, the soil was placed in an oven at a temperature of 110 °C for 24 h to dry completely. Then, to determine the optimum percentage of lime for this type of clay, 2%, 4%, 6%, 8%, and 10% of lime by dry weight was added to the soil and mixed with the optimum moisture content. The mixture was cured for 7 and 28 days in a glass insulated box, with the temperature maintained at 25 °C and the humidity of the sample's water content. After determining lime optimum percentage, dry GGBFS powder with 2%, 4%, 6%, 8%, and 10% by dry weight was added to the dry soil and completely mixed. It should be noted that to achieve a better mixture and higher hydration activity, the GGBFS powder was passed through sieve no. 200. Then, this mixture added to the dry soil step by step. It is important to note that in each step of the mixing process, the soil was mixed properly with the GGBFS powder until the mixture became a brownish colour entirely. Then, dry sodium silicate at 1%, 1.5%, and 2.5% by dry weight, along with lime at the optimum percentage, was dissolved in water and added to the mixture step by step until the mixing was complete and the colour of the mixture became light brown. To prepare UCS specimens, an apparatus was used to compress the consolidated soil into a 4-inch density mold. Then, by using a pull-out jack, the UCS specimens were extracted. Finally, two plastics were placed around the samples, and they were cured at three different times: 7, 28, and 90 days in a glass insulated box at 25 °C under optimal moisture content. After determining GGBFS optimum percentage, sodium silicate at 1%, 1.5%, and 2.5% by dry weight with optimum percentage of lime and GGBFS added to soil just as mentioned before and compacted in consolidation ring then consolidation test was conducted on samples.

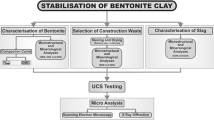

3 Methodology

The UCS tests were carried out according to ASTM D 2166 (2010) standard. The sample size used was 3.8 mm × 76 mm. In this test, the limiting pressure is set to zero and an axial load is applied rapidly until the sample collapses. The UCS device strain rate was set to 1 mm/min. Figure 4 shows the UCS device and a sample while testing.

Initially, UCS tests were conducted on soil samples with varying lime percentages to determine the lime optimum percentage. Then, UCS tests were conducted on soil samples when GGBFS and sodium silicate were added to the soil, while keeping the lime percentage constant. Afterward, to determine the effective parameters in predicting the rate of settlement, the consolidation test was performed using a consolidometer apparatus in accordance with the ASTM D2435 (2011) standard. In this test, the effect of sodium silicate ratio on test results was investigated by keeping lime and GGBFS at a constant amount by optimum percentage. The specimens were prepared using a ring having a diameter of 75 mm and a height of 20 mm. The samples were subjected to vertical stresses of 0.25, 0.5, 1, 2, 4, and 8 kg/cm2, and each loading step took 24 h.

Considering that curing time has a significant effect on specimen strength and can enhance pozzolanic reactions in the samples, curing times of 7, 28, and 90 days were selected for the UCS tests.

4 Results and Discussion

In this research, 58 UCS tests and 4 consolidation tests were planned and conducted. Some tests were carried out for identification purposes as basic tests. 10 UCS tests were performed to determine the optimal percentage of lime, 45 UCS tests involved different percentages of additives, and three Tests were conducted solely on untreated base soil. Also, one consolidation test was performed on base soil and three consolidation tests involved different percentages of sodium silicate while keeping lime and GGBFS at a constant amount by the optimum percentage. According to the results, the highest UCS was achieved in a soil sample containing 2.5% sodium silicate, 8% GGBFS, and 6% lime. Also, with this amount of additives highest settlement and lowest void ratio achieved. The results of the consolidation tests after applying the final vertical stress (8 kg/cm2) and UCS tests are presented in Table 5.

4.1 Optimum Percentage of Lime

As previously stated, to reduce the number of main samples, the optimal percentage of lime for the soil was first determined using the UCS test. The proportion of soil and lime, as well as the results of the UCS tests for curing times of 7 and 28 days, are given in Table 6.

Considering the results, it can be concluded that the optimal percentage of lime for the soil is 6% (Fig. 5). With presence of this percentage, the strength of the 7 and 28 days' soil specimens increased by 11.65 and 8.7 times, respectively, compared to the untreated soil.

4.2 The Effect of GGBFS, Sodium Silicate and Lime on UCS Strength

To investigate the effect of GGBFS with sodium silicate and lime on the improved samples, the strength of samples was analysed (the lime content was constant across all samples). As shown in Figs. 6, 7, and 8, increasing the percentage of GGBFS from 2 to 8% caused the strength of the samples to increase. This was more noticeable in the samples containing between 6 and 8% GGBFS. However, when the percentage of GGBFS was raised from 8 to 10%, the strength of the samples decreased. Figure 9 shows that the highest and lowest strength values were obtained for specimens containing 8% and 2% GGBFS, respectively. Also presence of sodium silicate with 2.5% by dry weight, along with other additives, has a positive effect on the increase rate of soil sample strength. for example, at curing times of 7, 28 and 90 days, the UCS value increased by 57.5, 66.2 and 74.4 times, respectively. Accordingly, the optimal amount of GGBFS and sodium silicate for this type of soil, along with lime, is 8% and 2.5%, respectively. Unlike in previous studies, which revealed that about 75% of the sample’s strength was obtained during the first 14 days when using GGBFS and construction waste in clay stabilization (Hasan et al. 2016), this study shows that increasing curing time has a profound impact on the strength of specimens. As shown in Fig. 9, The strength of the samples after 90 days was impressive, indicating that long-term curing time has a profound impact on improving soil strength.

4.3 The Effect of GGBFS, Sodium Silicate and Lime on Consolidation

Consolidation tests were performed on samples containing 8% GGBFS, 6% lime, and 1, 1.5, and 2.5% sodium silicate. These samples exhibited the highest UCS values than other specimens. The results of the consolidation tests are presented in Figs. 10 and 11, which show settlement and void ratio (e) versus log p (pressure) curves, respectively.

Based on the results presented in Fig. 10, samples mixed with additives experienced more settlement than samples without additives (final settlement increased from 0.075 to 0.117 cm at 6%lime, 8% GGBFS and, 2.5% sodium silicate). Additionally, an increase in the amount of sodium silicate resulted in higher settlement. Therefore, using these additives with mentioned percentages leads to an increase in settlement. However, to draw more accurate conclusions, different percentages of these additives should be further investigated.

Figure 11 demonstrates that the void ratio of the samples decreased with increasing settlement as well as increasing the percentage of sodium silicate (final void ratio decreased from 0.58 to 0.47 at 6% lime, 8% GGBFS and, 2.5% sodium silicate). In other words, as pressure increases, the settlement also increases, and consequently, the void ratio of the sample decreases. Furthermore, Fig. 11 reveals that the presence of these additives in the soil changes its behaviour from normally consolidated to overconsolidated.

4.4 The Effect of GGBFS, Lime and Sodium Silicate on Atterberg Limits

The results of the Atterberg Limits tests show that the addition of these three materials to the clay soil changes it to a silty texture. As a result, the Atterberg limits cannot be determined by using the Casagrande test in the laboratory.

4.5 Result of Microstructure Analysis

To further complete the results and accurately examine the changes in the specimens, SEM imaging, and energy-dispersive X-ray (EDX) analysis were conducted. For this purpose, SEM and EDX analyses were performed on untreated soil and sample treated with 2.5% sodium silicate, 8% GGBFS and 6% lime after a 90-day curing period.

In order to take SEM images, the most uniform part of the samples was selected, and images were taken at different scales. Figure 12a and c show pores (red circles) and seams that could be due to water evaporation. Yi et al. (2015) remarked that the porosity rate of a clayey soil sample stabilized with GGBFS and lime was lower than soil stabilized with cement. It could be due to the difference in materials' nature and hydration reactions. In fact, in a soil sample mixed with GGBFS and lime, hydration reactions cause larger pores to be filled and converted into smaller pores. It can be seen by examining the number and size of pores on the surface of the samples (Fig. 12b and d). Furthermore, Fig. 12b and d determined that the distribution of pores is steadier in the stabilized specimen. However, the pores in the untreated sample are concentrated in one place, leading to failure in those areas. Additionally, the size of these pores in the stabilized sample is small and almost uniform, whereas, in the untreated sample, the dimensions of these pores vary, and the specimen has large pores.

SEM micrograph after 90 days’ curing time a SE of soil sample with 200 μm magnification b SE of soil and 8% GGBFS, 6% lime and 2.5% sodium silicate mixture with 200 μm magnification c BSE of soil sample with 200 μm magnification d BSE of soil and 8% GGBFS, 6% lime and 2.5% sodium silicate mixture with 200 μm magnification e SE of soil sample with 20 μm magnification f SE of soil and 8% GGBFS, 6% lime and 2.5% sodium silicate mixture with 20 μm magnification

Furthermore, Fig. 12b and d represent a continuous surface on which particles are distributed in such a way that no separation is perceived on the surface, whereas in Fig. 12a and c, there is a visible lower level of continuity. Additionally, as shown in Fig. 12e, untreated soil particles have a flat surface before stabilization, which changes into a needle shape after stabilization (Fig. 12f). This needle-shaped morphology, during particle contact, causes particles to lock and stabilize together, greatly increasing the stability of the specimens. This result may be attributed to the formation of gel C-S-H by calcium in lime and silicate in sodium silicate.

The results of the EDX analysis are presented in Fig. 13. By comparing Fig. 13a and b, which were taken from untreated and treated samples, it observed that the amount of iron (Fe) in the stabilized sample increased due to the presence of GGBFS. Therefore, the presence of iron (Fe) could be the reason for the creation of a uniform surface in the stabilized sample, as iron (Fe) is a flexible oxide. Additionally, the EDX analysis of the stabilized sample demonstrates that silicon (Si) and calcium (Ca) are their main constituents and are present in large percentages (Fig. 13b). These elements are abundant in both the soil and the GGBFS (Table 3). On the other hand, calcium hydroxide is one of lime's main constituents. Therefore, according to Eqs. 1 and 2, and since calcium is one of the main elements in hydration reactions, increased amounts of these elements lead to increased hydration reactions, and consequently, the strength of the specimen's increases. Slight traces of potassium (K), aluminum (Al), magnesium (Mg), and oxygen (O) were also observed in EDX analyses.

5 Conclusion

The current study conducted to investigates the effect of GGBFS, sodium silicate, and lime on UCS and consolidation of soft clay. Many parameters were considered when selecting the additives used in this research, including environmental contamination, material availability, cost, etc. Generally, GGBFS is a waste material produced on a large scale, making it available as an additive for stabilization. Sodium silicate and lime are also inexpensive and accessible, making this stabilization method applicable and affordable on a large scale. Ultimately, the optimal percentages of each additive were determined. The following results were obtained:

-

1)

Lime had a positive effect on the unconfined compressive strength of the soil, and the optimum percentage of lime was 6% (total dry weight). Using this percentage, the soil strength of the 7 and 28 day’s soil specimens increased by 11.65 and 8.7 times, respectively, compared to the untreated soil.

-

2)

The presence of GGBFS as the main additive had a significant effect on soil strength, particularly compared to untreated soil. This effect was more noticeable at 6% and 8% GGBFS, and when the GGBFS percentage was increased from 8 to 10%, the strength of the samples decreased. Thus, the optimum GGBFS percentage was determined to be around 8% (total dry weight).

-

3)

The presence of sodium silicate to 2.5% by total dry weight increased the UCS of soil. As a result, Sodium silicate is a suitable catalyst for increasing and accelerating hydration reactions. However, the effects of higher amounts of sodium silicate should also be examined.

-

4)

Since pozolanic reactions increase over time, the curing time had a significant effect on the strength of samples. Therefore, the highest strength of the treated samples at 7, 28, and 90 days was 57.5, 66.2 and 74.4 times greater, respectively, compared to the untreated soil.

-

5)

The presence of Lime, GGBFS, and sodium silicate in soil resulted in higher settlement and lower void ratio (e). Also, with increasing the percentage of sodium silicate the void ratio (e) decreased and the settlement increased.

-

6)

The SEM images confirmed that the additives fill and convert larger pores into smaller ones, creating a continuous surface by increasing the formation of gel C–S–H through the presence of calcium in the lime and the GGBFS, as well as silicate in the sodium silicate. Additionally, the particles' surface morphology changes into a needle shape. This needle-shaped morphology, when particles come into contact with each other, locks and stabilizes the particles together, greatly increasing the stability of the stabilized specimens.

-

7)

The EDX analysis revealed an increase in iron (Fe) in the stabilized sample due to the presence of GGBFS, which creates a uniform surface in the stabilized sample. Additionally, silicon (Si) and calcium (Ca) significantly increased after stabilization, leading to increased hydration reactions and subsequently enhancing the strength of the specimens.

Data Availability

Enquiries about data availability should be directed to the authors.

References

Abbasi N, Farjad A, Sepehri S (2018) The use of nanoclay particles for stabilization of dispersive clayey soils. Geotech Geol Eng 36:327–335. https://doi.org/10.1007/s10706-017-0330-9

Abdila SR, Abdullah MMAB, Ahmad R, Burduhos Nergis DD, Rahim SZA, Omar MF, Sandu AV, Vizureanu P (2022) Syafwandi potential of soil stabilization using ground granulated blast furnace slag (GGBFS) and fly ash via geopolymerization method: a review. Materials 15(1):375. https://doi.org/10.3390/ma15010375

Akbari HR, Sharafi H, Goodarzi AR (2020) Effect of polypropylene fber inclusion in kaolin clay stabilized with lime and nano-zeolite considering temperatures of 20 and 40 °C. Bull Eng Geol Environ 80:1841–1855. https://doi.org/10.1007/s10064-020-02028-x

Aldaood A, Bouasker M, Al-Mukhtar M (2021) Mechanical behavior of gypseous soil treated with lime. Geotech Geol Eng 39:719–733. https://doi.org/10.1007/s10706-020-01517-w

Amran YM, Alyousef R, Alabduljabbar H, El-Zeadani M (2020) Clean production and properties of geopolymer concrete: a review. J Cleaner Prod 251:119679. https://doi.org/10.1016/j.jclepro.2019.119679

ASTM Standard D 2166 (2010) Standard test method for unconfined compressive strength of cohesive soil. American Society of Testing and Materials, West Conshohocken, Pennsylvania. https://doi.org/10.1520/D2166-06

ASTM Standard D 2435 (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. American Society of Testing and Materials, West Conshohocken, Pennsylvania. https://doi.org/10.1520/D2435-04

Behera CK, Senapati S (2021) Soil stabilization by industrial waste (GGBS and Stone Dust). Int J Eng Res Tech 10(9):409–415. https://doi.org/10.17577/IJERTV10IS090154

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237. https://doi.org/10.1016/0013-7952(96)00028-2

Bibak H, Khazaei J, Moayedi H (2020) Investigating the effect of a new industrial waste on strengthening the soft clayey soil. Geotech Geol Eng 38:1165–1183. https://doi.org/10.1007/s10706-019-01079-6

Bouras F, Al-Mukhtar M, Tapsoba N, Belayachi N, Sabio S, Beck K, Martin M (2022) Geotechnical behavior and physico-chemical changes of lime-treated and cement-treated silty soil. Geotech Geol Eng 40:2033–2049. https://doi.org/10.1007/s10706-021-02008-2

Chien SC, Teng FC, Ou CY (2014) Soil improvement of electroosmosis with the chemical treatment using the suitable operation process. Acta Geotech 10(6):813–820. https://doi.org/10.1007/s11440-014-0319-y

Darsi BP, Molugaram K, Madiraju SVH (2021) Subgrade black cotton soil stabilization using ground granulated blast-furnace slag (GGBFS) and lime, an inorganic mineral. Environ Sci Proc. https://doi.org/10.3390/iecms2021-09390

Ebailila M, Kinuthia J, Oti J, Al-Waked Q (2022) Sulfate soil stabilisation with binary blends of lime–silica fume and lime–ground granulated blast furnace slag. Transport Geotech 37:100888. https://doi.org/10.1016/j.trgeo.2022.100888

Hasan U, Chegenizadeh A, Budihardjo MA, Nikraz H (2016) Experimental evaluation of construction waste and ground granulated blast furnace slag as alternative soil stabilisers. Geotech Geol Eng 34(6):1707–1722. https://doi.org/10.1007/s10706-016-9983-z

Houlsby AC (1990) Construction and design of cement grouting. Wiley, New York

Keramatikerman M, Chegenizade A, Nikraz H (2016) Effect of GGBFS and lime binders on the engineering properties of clay. Appl Clay Sci 132–133:722–730. https://doi.org/10.1016/j.clay.2016.08.029

Nidzam RM, Kinuthia JM (2010) Sustainable soil stabilisation with blastfurnace slag–a review. Proc Ins Civ Eng Constr Master 163(3):157–165. https://doi.org/10.1680/coma.2010.163.3.157

Parsaei M, Rojhani M, Seyedahmadian S (2023) Effect of the addition of nano alumina on the mechanical properties of clay. Geotech Geol Eng 41:3767–3779. https://doi.org/10.1007/s10706-023-02488-4

Salimi M, Ghorbani A (2020) Mechanical and compressibility characteristics of a soft clay stabilized by slag-based mixtures and geopolymers. Appl Clay Sci 184:105390. https://doi.org/10.1016/j.clay.2019.105390

Vakili MV, Chegenizadeh A, Nikraz H, Keramatikerman M (2016) Investigation on shear strength of stabilised clay using cement, sodium silicate and slag. Appl Clay Sci 124:243–251. https://doi.org/10.1016/j.clay.2016.02.019

Wild S, Kinuthia JM, Jones GI, Higgins DD (1998) Effects of partial substitution of lime with ground granulated blast furnace slag (GGBS) on the strength properties of limestabilised sulphate-bearing clay soils. Eng Geol 51(1):37–53. https://doi.org/10.1016/S0013-7952(98)00039-8

Yi Y, Gu L, Liu S (2015) Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl Clay Sci 103(1):71–76. https://doi.org/10.1016/j.clay.2014.11.005

Zheng P, Li W, Ma Q, Xi L (2023) Mechanical properties of phosphogypsum-soil stabilized by lime activated ground granulated blast-furnace slag. Constr Build Mater 402:132994. https://doi.org/10.1016/j.conbuildmat.2023.132994

Zidan AF (2020) Strength and consolidation characteristics for cement stabilized cohesive soil considering consistency index. Geotech Geol Eng 38:5341–5353. https://doi.org/10.1007/s10706-020-01367-6

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Beygi, L., Khazaei, J. Soft Clay Eco-Friendly Improvement by Ground Granulated Blast Furnace Slag and Quicklime. Geotech Geol Eng 42, 2061–2074 (2024). https://doi.org/10.1007/s10706-023-02661-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02661-9