Abstract

In order to explore the influence of creep pre-damage on bursting liability of coal and rock, the creep pre-damage treatment of coal with different stress levels (0%, 30%, 45%, and 60%) was carried out, and the bursting liability index test was carried out. The variation rules of uniaxial compressive strength, impact energy index, elastic energy index, and dynamic failure time with different degrees of creep pre-damage was analyzed. The bursting liability of coal is evaluated comprehensively. The results show that with the increase of creep pre-damage degree, the uniaxial compressive strength, elastic energy index, and impact energy index of coal sample first increase and then decrease, and the dynamic failure time first decreases and then increases. The comprehensive evaluation result of coal sample bursting liability changes from weak impact to strong impact, then to weak impact, and finally to no impact. This paper provides a reference for the study of rock burst of coal under the influence of creep.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the development of China's coal industry, most of the shallow coal seams have been mined, and coal mines gradually turn into deep mining. For the safety of deep mining, rock burst is one of the problems that cannot be ignored (Zuo et al. 2020; Xu et al. 2019; Zhu et al. 2016, 2019a; Guo et al. 2019). Rock burst is a kind of dynamic disaster phenomenon caused by the instantaneous release of elastic energy accumulated in coal and rock mass, which has the characteristics of sudden and violent (He et al. 2019; Yang et al. 2020; Liu et al. 2018; Gao et al. 2020; Li et al. 2017b). With the increase of coal mining depth, the underground faces the complex mining conditions of high stress, high permeability, high ground temperature and strong mining disturbance, which makes the conditions and forms of dynamic disasters have changed significantly, and increases the frequency of dynamic disasters such as rock burst, coal and gas outburst in deep mines (Mark 2018; Zhang et al. 2020a; Cao et al. 2016; Chen et al. 2017).

The physical and mechanical properties of coal are related to the impact propensity of coal. Due to the complex geological environment of coal formation, the complex internal structure of coal, the huge differences in mineral composition and water content, these differences will affect the impact propensity of coal and rock mass. In addition, the environment and stress state of coal and rock mass, as well as the temperature and humidity of surrounding environment and the thickness ratio of coal to rock will have a greater impact on the impact propensity (Mo et al. 2020; Du et al. 2020; Yang et al. 2021). Many scholars have done a lot of research in this area. Gao et al. (2018a, b) studied the bursting liability of coal samples by gas pressure based on the research background of complex dynamic disasters in deep high gas mine. It was found that the comprehensive evaluation results of coal samples with the increase of gas pressure were the decrease of bursting liability. Mao et al. (2001) systematically measured the relationship between coal seam bursting liability and coal seam water content, coal seam water content and coal seam porosity by using an experimental analysis method. The results show that the bursting liability of coal seam is inversely proportional to the water content of coal seam, and is most sensitive to the increase of water content in the original water content state, and the saturated water content of coal seam is directly proportional to the porosity of coal seam. The "creep type" impact is also an impact phenomenon that cannot be ignored.

In addition, when mining underground, with the increase of mining time, the coal pillar will creep under the action of surrounding rock pressure (Danesh et al. 2017; Kang et al. 2015; Zhang et al. 2020b). Many scholars have done a lot of research on the creep characteristics of coal. Huang et al. (2021) studied the effect of initial damage on the deformation of coal samples by triaxial compression creep test under multistage loading. It is found that the total creep time, the deviatoric stress of creep failure, the stress threshold of accelerated creep and the start time of volume expansion decrease with the increase of initial damage. Li et al. (2017a) studied the creep behavior of coal filled with different amounts of gas, and discussed the creep constitutive model which is more suitable to reflect the test process. Yang et al. (2015) tested the short-term creep characteristics of coal under different confining pressures under triaxial compression, proposed a new damage evolution equation of coal, established a new short-term damage model of coal, and proposed a new nonlinear creep damage model of coal.

Generally, the comprehensive evaluation of coal bursting liability grade needs to be comprehensively measured according to the uniaxial compressive strength, elastic energy index, impact energy index and dynamic failure time. At present, scholars have discussed the correlation mechanism between creep and rock burst of rock and coal (Wang et al. 2020; Jiang et al. 2015,2018; Song et al. 2018; Chen et al. 2020; Zhu et al. 2019b; Yin et al. 2016), but no further study has been conducted on the change of bursting liability of coal affected by creep characteristics. Therefore, it is of great significance to carry out the test research on bursting liability index of coal under creep characteristics to evaluate the grade of bursting liability of coal under creep influence and prevent the occurrence of creep rock burst accidents. In this paper, coal is taken as the research object, the creep pre-damage of coal samples at different stress levels (0%, 30%, 45%, and 60%) is carried out, and then the bursting liability index test of all coal samples is carried out to analyze the influence of different degrees of creep pre-damage of coal samples on the bursting liability, so as to provide reference for the theoretical study of rock burst.

2 Test method and sample preparation

2.1 Test equipment

In this test, SAW-2000 microcomputer controlled electro-hydraulic servo triaxial rock testing machine is used, which can complete conventional uniaxial compression, triaxial compression, creep test and loading and unloading test.

2.2 Sample preparation

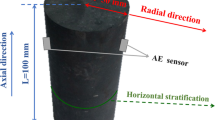

The test samples are all taken from the same mine. Due to the heterogeneity of coal and the development of more pores, in order to ensure that the collected coal samples have good contrast and less dispersion, the sampling process should be strictly in accordance with the standard "Methods for determining the physical and mechanical properties of coal and rock-Part 1: General requirements for sampling (GB/T 23,561.1 2009)". The collected coal body is processed with a core drilling machine and cutting machine to the size of Φ 50 mm × 100 mm (as shown in Fig. 1), and then wrap it with plastic wrap for storage.

2.3 Test scheme

-

(1)

The prepared samples were divided into groups A, B, C, and D. Group A was the control group. The uniaxial compressive strength, impact energy index, elastic energy index and dynamic failure time of coal samples were tested. The loading mode of uniaxial compression test is displacement control, and the loading rate is 0.05 mm/min until the coal sample is destroyed.

-

(2)

The gradient of creep pre-damage was determined by the uniaxial compressive strength of group A. 30%, 45%, and 60% of the uniaxial compressive strength of group coal samples were taken for 2 h creep pre-damage treatment, numbered as group B, C, and D. the loading mode of creep pre-treatment was also controlled by displacement, and the loading rate was the same as 0.05 min/min, and finally unloaded to 0.5 MPa at the same rate.

-

(3)

After creep pretreatment, B, C, and D three groups of coal samples also adopt the axial displacement control loading, the rate is 0.05 mm/min for uniaxial compression test, until the rock sample is damaged, and then calculate the impact propensity index, finally carry out the comprehensive evaluation of coal and rock impact propensity. The test steps are shown in Fig. 2.

In this test, the impact energy index, elastic energy index and dynamic failure time of coal samples are calculated in strict accordance with the provisions of the standard " Methods for test, monitoring and prevention of rock burst-Part 2: Classification and laboratory test method on bursting liability of coal (GB/T 25,217.2 2010)". There were 3 parallel samples in each group.

3 Results and discussion

3.1 Analysis of creep variables under creep pre-damage at different stress levels

Through the creep pre-damage test, the strain time curves of coal samples under creep action of different stress levels are obtained, as shown in Fig. 3. It can be seen from the strain time diagram of coal samples in Fig. 3 that the creep variables of group B coal samples after creep pre-damage treatment at 30% stress level are 0.27%, that of group C coal samples after creep treatment at 45% stress level is 0.42%, and that of group D coal samples after creep pre-damage treatment at 60% stress level is 0.64%.

In the creep pre-damage test of coal samples at different stress levels, the creep deformation will occur with the increase of axial load, and the instantaneous strain is relatively large. The instantaneous strain of coal samples in the loading process will show a linear law. When the load reaches a dead load with the increase of time, the deformation of coal samples decreases sharply, and the total deformation tends to be stable with the increase of time. Coal samples in different stress levels of creep test compression stage will experience decay creep stage and steady-state creep stage. In the creep pre-damage test of coal samples at different stress levels, the total amount of strain changes increases with the gradual increase of stress levels, and the instantaneous strain of coal samples is also larger.

3.2 Effect of creep pre-damage on the bursting liability index of coal sample

3.2.1 Effect of creep pre-damage on uniaxial compressive strength of coal sample

Under the condition of uniaxial compression, the internal stress of coal sample will be generated, which will increase with the increase of external load. When the internal bearing capacity of coal sample is less than the external load, the coal sample will be destroyed. The compressive strength of coal sample after creep pre-damage at different stress levels is shown in Fig. 4.

It can be seen from the Fig. 4 that the uniaxial compressive strength of coal sample decreases after creep pre-damage treatment at different stress levels. The uniaxial compressive strength of group A coal samples without any pretreatment is 25.75 MPa. After creep pre-damage treatment at 30% stress level, the uniaxial compressive strength of group B is 28.3 MPa, which is 9.9% higher than that of group A. After creep pre-damage treatment at 45% stress level, the uniaxial compressive strength of group C is 21.25 MPa, which is 17.48% lower than that of group A. After 60% stress level creep pre-damage treatment, the uniaxial compressive strength of group D is 19 MPa, which is 26.21% lower than that of group A.

This is because coal is a kind of structural medium containing various original pores and fractures. After 30% stress level creep pre-damage treatment, the internal pores of the coal sample are closed, and the internal soft minerals further fill the pores. Under the effect of redistribution, the compactness of the coal sample increases, and the compressive strength of the coal sample is enhanced. After the 45% stress level creep pre-damage treatment, the coal sample also experienced the pore closure stage in the process of producing instantaneous strain. However, under the 45% stress level creep pre-damage, some tiny cracks will appear in the coal sample, which is irreversible and leads to the deterioration of the coal sample, As a result, the uniaxial compressive strength of coal sample is lower than that of untreated coal sample. After 60% stress level creep pre-damage treatment, the micro cracks inside the coal sample are further developed and expanded. This process is also irreversible. The deterioration effect of the coal sample is strengthened, resulting in the significant reduction of the uniaxial compressive strength of the coal sample and the untreated coal sample.

3.2.2 Effect of creep pre-damage on impact energy index of coal sample

The larger the impact energy index is, the more energy accumulated before the failure is than that consumed during the failure. The excess energy will be converted into the kinetic energy and radiation energy of the broken coal sample, and the broken coal will be thrown into the roadway to produce rock burst and cause damage. The calculation diagram of the impact energy index is shown in Fig. 5. The impact energy index is calculated according to Eq. (1),

where AS is the deformation energy accumulated before the peak value. AX is the post peak deformation energy. KE is the impact energy index. The value of AS is equal to the area under the OC curve, and the value of AX is equal to the area under the CD curve. D is the initial point of residual strength.

The change trend of impact energy index of coal samples after creep pre-damage at different stress levels is shown in Fig. 6. The impact energy index of group coal without any pretreatment is 2.16. After creep pre-damage at 30% stress level, the impact energy index of group B is 3.92, which is significantly higher than that of group A by 81.48%, and the index value is close to the strong bursting liability. After creep pre-damage at 45% stress level, the impact energy index of group C is 1.86, which is 13.89% lower than that of group A. After 60% stress level creep pre-damage, the impact energy index of group D is 1.33, which is significantly lower than that of group A by 38.43%.

It shows that after the creep pre-damage of 30% stress level, the energy accumulated by the external load of the coal sample is consumed less in the failure process, and most of the energy is stored in the coal sample and released suddenly in the form of kinetic energy. After creep pre-damage at 45% and 60% stress levels, more and more energy is consumed during uniaxial compression, which further leads to the decrease of impact energy index.

3.2.3 Effect of creep pre-damage on elastic energy index of coal sample

After different degrees of creep pre-damage, as shown in Fig. 7, the elastic energy index is calculated according to Eq. (2) and Eq. (3) through loading and unloading experiments.

where WET is the elastic energy index. ΦSE is the elastic strain energy, and its value is the area under the unloading curve, as shown in the shaded part of Fig. 7. ΦC is the total strain energy, and its value is the area under the loading curve. ΦSP is plastic strain energy, and its value is the area enveloped by loading curve and unloading curve.

The change trend of elastic energy index of coal samples after creep pre-damage at different stress levels is shown in Fig. 8. It can be seen from the Fig. 8 that the elastic energy index of group A coal sample without any pretreatment is 4.24. The results show that the energy consumed by the damage and plastic deformation of the coal sample without any treatment during loading and unloading is less, and the work done by the servo testing machine on the coal sample is mostly stored in the form of elastic performance.

The elastic energy index of group B coal sample after 30% stress level creep pre-damage is 5.15, which is significantly increased by 21.46% than that of group a coal sample, indicating that the internal structure of coal sample becomes more compact after 30% stress level creep pre-damage, which increases the compressive strength of coal sample and stores more elastic strain energy.

After creep pre-damage at 45% stress level, the elastic energy index of group C is 2.22, which is 47.64% lower than that of group A. This shows that after the coal sample is treated by 45% stress level creep pre-damage, the creep action makes the coal sample germinate some new cracks, increases the energy dissipation in the plastic deformation of the coal sample in the loading and unloading test, and reduces the storage of elastic strain energy in the coal sample.

After 60% stress level creep pre-damage, the elastic energy index of coal sample is 1.1, which is 74.06% lower than that of group A. It shows that after 60% stress level creep pre-damage treatment, the creep effect makes the internal pores and cracks of the coal sample further develop and expand, the energy consumed by plastic deformation further increases, and finally leads to the decrease of the elastic energy index of the coal sample.

With the increase of creep pre-damage degree, the elastic energy index of coal sample first increases and then decreases. The reason for this phenomenon is that with the increase of creep pre-damage degree, the strength of coal sample first increases and then decreases. After creep pre-damage at low stress level, the uniaxial compressive strength of the coal sample increases, the internal pores of the coal sample close, and the result is compacted. During the loading process, the elastic energy stored in the coal sample increases, so the elastic energy index increases. The uniaxial compressive strength of coal sample decreases after creep pre-damage at medium and high stress levels, and the internal cracks of coal sample develop faster during loading, which makes the plastic deformation of coal sample larger, the damage development larger, the irreversible deformation and the energy consumed by damage more, so the elastic energy index becomes smaller.

3.2.4 Effect of creep pre-damage on dynamic failure time of coal sample

The dynamic failure time of coal is determined by the dynamic failure time curve, as shown in Fig. 9. In the figure, ED is the failure time, CD is the failure process, OC is the loading process.

The change trend of dynamic failure time of coal samples after creep pre-damage at different stress levels is shown in Fig. 10. It can be seen from the Fig. 10 that with the increase of creep pre-damage degree of coal sample, the dynamic failure time of coal sample first decreases and then increases. It shows that the time from ultimate strength to complete failure is longer and longer.

The dynamic failure time of group a coal without any pretreatment is 169 ms. After 30% stress level creep pre-damage treatment, the dynamic failure time of group B coal sample is 49 ms, which is 71% less than that of group a coal sample. The reason is that after 30% stress level creep pre-damage treatment, the micro pores and cracks in the coal sample are closed, and the internal structure of the coal sample is re adjusted and becomes dense. Macroscopically, the uniaxial compressive strength of coal sample increases, the stress–strain curve of coal sample enters the elastic stage earlier, and the coal sample tends to be brittle. With the increase of uniaxial compressive strength of coal sample, the elastic energy accumulated in coal sample increases. The greater the brittleness of coal sample, the higher the conversion efficiency of elastic energy released by coal sample into kinetic energy. Finally, the fracture time of coal sample is accelerated and the dynamic failure time is reduced.

After 45% stress level creep pre-damage treatment, the dynamic failure time of group C coal sample is 377 ms, which is 123.08% higher than that of group a coal sample. It shows that after 45% stress level creep pre-damage treatment, group C coal sample is damaged, new cracks sprout in the coal sample, the elastic energy accumulated in the coal sample is transformed into plastic deformation energy, the released elastic energy is reduced, and the efficiency of elastic energy converted into kinetic energy is reduced. Finally, the fracture velocity of coal sample is small, the time from ultimate strength to complete instability is long, and the dynamic failure time of coal sample is increased.

The dynamic failure time of group D coal sample after 60% stress level creep pre-damage treatment is 841 ms, which is 397.63% higher than that of coal sample without creep treatment. The results show that after 60% stress level creep pre-damage treatment, the internal damage degree of group D coal sample is further increased, the uniaxial compressive strength of coal sample is reduced, the internal accumulated elastic energy is reduced, and the releasable elastic energy is also reduced. Finally, the failure rate of coal sample is further reduced and the dynamic failure time of coal sample is further increased.

4 Effect of creep pre-damage on bursting liability of coal sample

The bursting liability of coal is generally evaluated according to the uniaxial compressive strength, impact energy index, elastic energy index and dynamic failure time. The classification standard of coal bursting liability is shown in Table 1.

The evaluation results of bursting liability of coal samples under creep pre-damage of different stress levels are shown in Table 2. It can be seen from Table 2 that with the increase of creep pre-damage degree, the bursting liability of coal changes from weak impact to strong impact, then to weak impact, and finally to no impact.

The impact propensity of group B coal samples after creep pre-damage treatment at 30% stress level is stronger than that of group A coal samples. This is because the impact propensity classification of elastic energy index and dynamic failure time of group B coal samples after creep pre-damage treatment at 30% stress level changes from type II to type III, The impact propensity classification of uniaxial compressive strength and impact energy index does not change, but increases in numerical value, so the impact propensity of coal sample increases after creep pre-damage treatment at 30% stress level.

After 45% stress level creep pre-damage treatment, the evaluation results of bursting liability of group C coal samples are the same as that of group A coal samples, but there are some differences in numerical value. The uniaxial compressive strength, impact energy index and elastic energy index of group C coal samples after 45% stress level creep pre-damage treatment are reduced to varying degrees, and the dynamic failure time is prolonged.

After 60% stress level creep pre-damage treatment, except for uniaxial compressive strength, the bursting liability of other impact propensity indexes of group D coal samples changed to type I, resulting in the comprehensive evaluation result of impact propensity of coal samples as no impact.

5 Conclusion

-

1.

In different degrees of creep pre-damage test, the total amount of creep change increases with the increase of the degree of creep pre-damage, and the instantaneous strain of coal sample also increases with the increase of the degree of creep pre-damage.

-

2.

With the increase of creep pre-damage degree, the uniaxial compressive strength, elastic energy index and impact energy index of coal samples first increase and then decrease. The dynamic failure time first decreases and then increases.

-

3.

With the increase of creep pre-damage degree, the comprehensive evaluation result of bursting liability of coal samples changes from type II to type III, then to type II, and finally to type I.

References

Cao A-Y, Dou L-M, Wang C-B et al (2016) Microseismic precursory characteristics of rock burst hazard in mining areas near a large residual coal pillar: a case study from Xuzhuang coal mine Xuzhou, China. Rock Mech Rock Eng 49:4407–4422

Chen G-X, Guo B-B, Hao Z (2020) Rockburst start-up condition influenced by accelerated creep of surrounding rock of circular roadway. J China Coal Soc 45:3401–3407

Chen Y-L, Lu A-H, Mao X-B, et al. (2017) Nonlinear dynamics mechanism of rock burst induced by the instability of the layer-crack plate structure in the coal wall in deep coal mining, shock and vibration, 4051967

Danesh N-N, Chen Z-W, Connell L-D et al (2017) Characterisation of creep in coal and its impact on permeability: an experimental study. Int J Coal Geol 173:200–211

Du X-L (2020) Discussion on national standard for burst tendency of combined coal and rock. Saf Coal Mines 51(229–235):242

Gao B-B, Qian Y-N, Chen L-W et al (2018a) Study on gas pressure affected to bump potential of coal sample. Coal Sci Technol 46:58–64

Gao B-B, Wang Z-G, Li H-M et al (2018b) Experimental study on the effect of outburst-proneness of coal by gas pressure. J China Coal Soc 43:140–148

Gao M-T, Song Z-Q, Duan H-Q, et al. (2020) Mechanical properties and control rockburst mechanism of coal and rock mass with bursting liability in deep mining, shock and vibration, 8833863.

GB, T 23561.1. (2009) Methods for determining the physical and mechanical properties of coal and rock-Part 1: general requirements for sampling. Standards Press of China, Beijing ((in Chinese))

GB, T 25217.2 (2010) Methods for test, monitoring and prevention of rock burst-Part 2: Classification and laboratory test method on bursting liability of coal. Standards Press of China, Beijing ((in Chinese))

Guo Z-P, Yang H-Z, Xie W-W et al (2019) Analysis of rock burst risk of roadway in lower seam “Knife Handle” type isolated working face. Geotech Geol Eng 37:1469–1481

He S-Q, Song D-Z, Li Z-L et al (2019) Precursor of spatio-temporal evolution law of MS and AE activities for rock burst warning in steeply inclined and extremely thick coal seams under caving mining conditions. Rock Mech Rock Eng 52:2415–2435

Huang P, Zhang J-X, Spearing AJS et al (2021) Experimental study of the creep properties of coal considering initial damage. Int J Rock Mech Min Sci 139:104629

Jiang F-X, Feng Y, Kouame KJA et al (2015) Mechanism of creep-induced rock burst in extra-thick coal seam under high ground stress. Chinese J Geotech Eng 37:1762–1768

Jiang P, Pan P-Z, Zhao S-K et al (2018) A coupled elasto-viscoplastic damage model based on strain energy theory of rock and application. J China Coal Soc 43:2967–2979

Kang J-H, Zhou F-B, Liu C et al (2015) A fractional non-linear creep model for coal considering damage effect and experimental validation. Int J Non-Linear Mech 76:20–28

Li X-C, Yang C-L, Ren T et al (2017a) Creep behaviour and constitutive model of coal filled with gas. Int J Min Sci Technol 27:847–851

Li X-L, Li Z-H, Wang E-Y et al (2017b) Microseismic signal spectra, energy characteristics, and fractal features prior to rock burst: a case study from the Qianqiu Coal Mine, China. J Earthquake Eng 21:891–911

Liu G-J, Mu Z-L, Chen J-J et al (2018) Rock burst risk in an island longwall coal face by stress field. Geosci J 22:609–622

Mao X-B, Chen Z-Q, Xu S-P et al (2001) Experimental study on the relation between the burst tendency and water content in coal seam. Chin J Rock Mechan Eng 1:49–52

Mark C (2018) Coal bursts that occur during development: a rock mechanics enigma. Int J Min Sci Technol 28:35–42

Mo Y-L, Li H-Y, Deng Z-G et al (2020) Initial damage effect of energy response for coal with different bump proneness. J Min Saf Eng 37:1205–1212

Song Y-F, Pan Y-S, Li Z-H et al (2018) Creep instability of isolated coal pillar under rock burst. Saf Coal Mines 49:47–50

Wang Q-Y, Liu J, Wang P-T et al (2020) Experimental investigation of accelerated failure of creep rock induced by impact disturbance. Rock Soil Mech 41(781–788):798

Xu L-M, Lu K-X, Pan Y-S, et al. (2019) Study on rock burst characteristics of coal mine roadway in China, Energy Sources, Part A: Recovery, Utilization, and Environmental Effects

Yang S-Q, Xu P, Ranjith P-G (2015) Damage model of coal under creep and triaxial compression. Int J Rock Mech Min Sci 80:337–345

Yang L, Wang X-Q, Li J-Z (2021) Energy evolution and damage characteristics of coal with different bursting liability under unlaxial compression. Coal Sci Technol 49:111–118

Yang H-Z, Guo Z-P, Chen D-Z, et al. (2020) Study on reasonable roadway position of working face under strip coal pillar in rock burst mine, Shock and Vibration, 8832791

Yin W-L, Pan Y-S, Li Z-H et al (2016) Lag time study on nonlinear creep buckling of the isolated coal pillar. Chinese J Appl Mech 33(1106–1112):1126

Zhang D-X, Guo W-Y, Zhang C-W et al (2020a) A new burst evaluation index of coal-rock combination specimen considering rebound and damage effects of rock. Geomat Nat Haz Risk 11:984–999

Zhang L, Li X-C, Ren T (2020b) A theoretical and experimental study of stress-strain, creep and failure mechanisms of intact coal. Rock Mech Rock Eng 53:5641–5658

Zhu G-A, Dou L-M, Cai W et al (2016) Case study of passive seismic velocity tomography in rock burst hazard assessment during underground coal entry excavation. Rock Mech Rock Eng 49:4945–4955

Zhu GA, Dou LM, Wang CB et al (2019a) Experimental study of rock burst in coal samples under overstress and true-triaxial unloading through passive velocity tomography. Saf Sci 117:388–403

Zhu WC, Niu LL, Li SH, Li S et al (2019b) Creep-impact test of rock: Status-of-the-art and prospect. J Min Strata Control Eng 1:77–87

Zuo J-P, Song H-Q, Jiang Y-Q, et al. (2020) Preliminary discussion on comprehensive research method for rock burst in coal mine based on Newton's Second Law, Shock and Vibration, 8861306

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Yang, H. Experimental study on bursting liability index of coal considering creep pre-damage. Geotech Geol Eng 40, 1475–1484 (2022). https://doi.org/10.1007/s10706-021-01978-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-021-01978-7