Abstract

In view of asymmetric deformation of a roadway in structural complex area, in situ investigation, theoretical analysis, numerical simulation and industrial test were carried out to deeply research the mechanism of asymmetric deformation and control method. Results show that large and unsymmetrical deformation with differential distribution along the axial direction of the roadway is the deformation characteristic of its surrounding rock. Also, complex ground stress, easily weakened rock properties, asymmetric rock structure and uniform supporting structure are primary reasons that the roadway is asymmetrically deformed, whose key regions are upper sidewall corner and lower sidewall shoulder of the roadway. On this basis, an asymmetrically-control strategy is proposed, which includes homogenizing the surrounding rock, strengthening rock masses and coupled supporting of key regions, along with the control method. Industrial test result shows that the roadway has been in a stable deformation stage after repairation within about 20 days, with the deformation of surrounding rock well controlled within 100 mm, and asymmetric deformation has also been effectively controlled. This study can be used as a reference for the control of asymmetric and large deformation of roadway in other similar complex conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the increase of coal mining intensity, and complexity of the mining conditions, the roadway design often fails to avoid the area with complex structure, resulting in the diversification of the surrounding rock structure (Yuan et al. 2011; Yang et al. 2017; Zhang 2017). Due to different factors influencing the stability of surrounding rock, such as the bedding angle, strength characteristics and softening characteristics of the surrounding rock, the roadway inevitably suffers irregular forms of tunnel damage. Due to the influence of complex in-situ stress, etc., the weak surface of the irregular angle rock layer of the surrounding rock is more likely to concentrate stress and produce slip deformation. The symmetrical support structure of the roadway produces an asymmetrical squeezing effect, which quickly loses its stability and leads to the instability of the full-section deformation of the roadway. It has become one of the important problems eager to be solved under the current coal mining conditions (Ma et al. 2013).

Some researches on the asymmetric deformation of the roadway have been carried out. Chen et al. (2016) studied the problem of large asymmetric deformation and difficult support in the east general return airway of Hemei No. 9 Coal Mine, and proposed “anchor mesh cable spraying + bottom angle bolt + full-section grouting + reverse bottom arch” "Asymmetric coupling control strategy. Li et al. (2006) comprehensively analyzed the mechanism of deformation, failure and instability of dynamic pressure soft rock roadway, and put forward a new technology of “non-uniform support” based on anchor grouting reinforcement and strengthening key parts. Scholars combined different geological conditions to carry out targeted analysis, aiming to strengthen the asymmetric support method of key parts (Chen et al. 2016; Li et al. 2006; Wang et al. 2014; Zhang et al. 2011a, b, 2013). Qin et al. (2019) used the method of theoretical analysis and numerical simulation to systematically study the distribution characteristics of the roof bearing structure of the deep soft rock roadway, finally proposed and successfully applied the roof reinforcement scheme of the deep dynamic soft rock roadway. Yang et al. (2020) studied the high effective and long anchoring mechanism of deep high stress roadway roof and put forward the long high-performance sustainable bolt technology, which effectively controlled the deformation of deep high stress roadway. Qi and Ma (2019) studied the influence of roof presplitting and rock mass filling on the stability of roadway surrounding rock of deep high stress roadway. Yang et al. (2019) studied the deformation failure mechanism of the deep goaf-side roadway under the mining disturbance of adjacent coal working face in underground mine and put forward the integrated control technology of pressure relief and anchorage, the surrounding rock of roadway is well controlled. The deformation and destruction of the roadway is full of universality and particularity, with reasons vary differently, and specific research expected to conducted according to special geological conditions. In this paper, with the repaired mine − 415 belt roadway as the research object, the influencing factors such as in-situ stress, occurrence characteristics, mechanical properties of surrounding rock and other factors in the roadway with complex structure are analyzed. The law of asymmetric deformation and failure of surrounding rock is revealed by numerical simulation, and the corresponding control countermeasures and methods are put forward, so as to promote the safe and efficient mining.

2 Asymmetric Deformation Characteristics of Roadway in Complex Structure Area

2.1 Project Overview

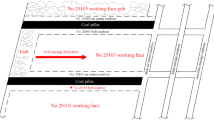

A coal mine mainly mines the 7th coal seam of Shanxi Formation, the coal thickness is 1.0–4.5 m, the average is 3.2 m, and the seam inclination angle is 20°–30°.The layout of the roadway is shown in Fig. 1. It penetrates the two wings of the 7-seam roof syncline at 6°–30°. The roadway is a straight-wall semicircular arch with a size of 3600 mm × 2900 mm. It is dominated by mudstone, and the layered distribution of the stratum is extremely uneven. The dip angle of the stratum in the tunnel section is 9°–20°. During roadway excavation, 23 faults with a fall of less than 3 m were revealed. The total length falls into the complex stress area generated by syncline structure. The surrounding rock cracks around the roadway are rich in pore water and fissure water, which needs to be pumped out when serious. The roadway adopts a method of scaffolding support, which has been repaired due to serious damage. The repair then adopts a new method of anchor cable net support as an alternative. As a result, the deformation and damage are still serious within six months after the repair, which can no longer meet the cross-sectional size requirements.

2.2 Asymmetric Deformation and Failure Characteristics of Roadway

The characteristics of regional in-situ stress, the deformation of surrounding rock in, and the difference in occurrence space have important effects on the irregular deformation and destruction of the roadway. The research data shows that (Chen et al. 2016; Huang et al. 2018; Sun et al. 2009) the roadway with high stress and inclined rock layers show asymmetric deformation trend to varying degrees generally. It can be concluded that the horizontal tectonic stress and mining stress of the inclined rock layers under high stress are playing more important roles. What is more, the complex surrounding rock structure shows the soft rock characteristics with large, nonlinear deformation. The roadway generally adopts non-targeted symmetrical support form, which makes key parts easily become unstable. In addition, it has the characteristics of complex in-situ stress field, segmented difference in lithology of surrounding rock, upper and lower lithology and structural asymmetry, and irregular intersection of roadway and bedding, which triggers the phenomena of asymmetric deformation and failure to varying degrees throughout the entire length of the roadway. On-site investigation and analysis of the deformation of the − 415 belt roadway revealed that the deformation characteristics are as follows:

(1) Large deformation of surrounding rock in roadway.

The − 415 belt roadway showed little deformation of surrounding rock in the early stage of roadway excavation, and no obvious deformation of the supporting structure. However, with the time of maintenance, the floor of roadway first appears floor heave deformation (Fig. 2a), then the shoulders at the diagonal began to produce different degrees of damage (Fig. 2b). As a result, the whole section shows a rapid creep state, with maximum deformation value exceeds 1000 mm.

(2) Asymmetrical effect of roadway deformation.

The whole length of − 415 belt roadway shows the deformation of floor heave, most of which show that the maximum floor heave point deviates from the center line of the roadway and the floor of the roadway is inclined. After several times of maintenance, the measured value is still more than 600 mm, which is inclined to one side of sidewalk at the same time. The deformation of floor heave drives the surrounding rock under the side wall to squeeze into the tunnel space plastic, which makes the overall bottom angle show large deformation and damage. The deformation sketch of the surrounding rock of the roadway is shown in Fig. 2. During the early maintenance, the 1800 m range of the sidewalk side of the bottom slab is pulled to 400 mm, and only about 200 mm height difference remains now. Besides, the damage and deformation degree of the right shoulder angle is more serious than the left, which shows obvious asymmetric deformation phenomenon.

3 Analysis of Key Influencing Factors of Asymmetric Deformation

(1) Complex in-situ stress field.

The most direct influencing factor of the surrounding rock stability of the roadway is the stress characteristics around the roadway, but it basically depends on the state of the in-situ stress field. The in-situ stress field is the main content of the roadway occurrence environment. As the main content of roadway occurrence environment, the in-situ stress field has a great influence on the mechanical properties of surrounding rock, the distribution law of surrounding stress field, the deformation and failure evolution law of support structure, which finally affects the stability of roadway support system (He et al. 2008; Zhang et al. 2019). The − 415 belt roadway is located in the syncline structure, and the in-situ stress environment is extremely complex due to the influence of faults and associated small folds. The direction of the maximum horizontal principal stress is generally vertical to the tunnel axis, and the magnitude varies in different regions, which is far greater than the vertical stress. Differing from the typical pre-failure form of layer peeling along the contour of the general roadway, the − 415 belt roadway is first caused by the squeezing stress concentration, which cause the structural surface to fracture and slip, then the floor and shoulder are plastically squeezed to break, and finally cause different degrees of deformed bottom drum and shoulder angle.

(2) Properties of surrounding rock.

The surrounding rock of − 415 belt roadway is mainly composed of siltstone, fine sandstone and a few carbonaceous mudstones, which are rich in pore and fissure water and belong to aquifer. The microstructure and composition of the surrounding rock of the roadway were tested by scanning electron microscope and X-ray diffractometer, the research indicates: the content of argillaceous matrix in the rock block is 46.6%, which is mainly composed of illite and smectite mixed layer that are easy to soften and expand. The internal fracture is developed and the connectivity is good. The pore volume and pore surface area in the natural state are 0.02 cm3/g and 2.86 cm2/g, respectively. There is no obvious change of pore volume in the water saturated state, but the pore surface area is increased by 20%. Under the weathering, they are increased by 72.5% and 70%, respectively. After several times of maintenance, the cracks on the surface of the surrounding rock provide a channel for the air in the roadway space to enter into the water bearing sandstone, which makes the rock under the water infiltration lose water and weathering. At the same time, the unbalanced tensile stress and shear stress caused by the expansion of adjacent rock structures in different water-containing states. The tensile and shear failure of the muddy cement resulted in new cracks, which caused the rocks to form a dry–wet cycle of flooding and dehydration. The surrounding rock is weakened due to the failure of mesoscopic structure, the decrease of cohesion and internal friction angle, which leads to the loss of surrounding rock foundation for the active support of surrounding rock supporting structure, and as a result, more likely to generate the large deformation.

(3) Rock structure.

In addition to the influence of the stress environment, the expansion deformation failure of the roadway is also related to the distribution and properties of the rock structure plane. The composite layered surrounding rock is the common manifestation of the coal mine roadway (He et al. 2008). When a certain angle exists between the distribution of the structural plane of the rock stratum and the roadway section, the obtuse angle is often used as a key area to become a breach of stress concentration and energy incongruity. In addition, due to the influence of the orientation of the in-situ stress and the weakening effect of the surrounding rock hydrolytic weathering, the rock blocks in this part are subject to sliding deformation and external work. The plastic failure area of the local section firstly appears (Jia et al. 2018; Zhang et al. 2011a, b), and the roadway is often asymmetrically deformed due to the destruction and development of key parts.

(4) Influence of support method.

The roadway adopts uniform support mode generally, and the pretightening moment of bolt is less than 50 N m in actual construction. Roadway excavation and support can be regarded as the contradictory and unified process of pressure relief adjustment and control constraint of surrounding rock. Different combination of support timing, prestress force and support mode play different roles on the depth of surrounding rock fracture (Xu and Zhang 2007). The release of the roadway plastic property makes the shallow surrounding rock work and converge to the tunnel space until the sum of the bolt support resistance and the surrounding rock self stability ability approaches to the convergence force. The lack of prestress of anchor rod just prolongs the duration of this process, which is equivalent to increasing the depth of surrounding rock fracture area. The homogenized support structure has higher support ability under the action of uniform load, but it is easy to drive the instability of the whole roadway due to the instability of key parts under the uneven force. A contradictory evolution process is formed between the symmetrical support form of − 415 belt roadway and the heterogeneous rock structure, asymmetrical stress field due to the uncoupled and uncoordinated inconsistency between the applied force and the stress. The stress distribution of surrounding rock changes and centralization, which leads to the failure of supporting structure and floor heave in key parts, finally shows the phenomenon of asymmetric deformation.

4 Numerical Simulation of Asymmetric Deformation and Failure

4.1 Numerical model

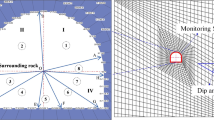

Taking the Geological Occurrence Characteristics of − 415 belt roadway at 90 m as an example, the numerical simulation of asymmetric deformation and failure process of roadway is carried out by using the UDEC, discrete element program. As shown in Fig. 3, the model size is 50 m × 50 m, and the dip angle of rock stratum is 10°. Mohr Coulomb criterion is selected, which can reflect the S_D effect of different compressive strength of geotechnical materials and the sensitivity to normal stress (He et al. 2008). The bottom boundary of the model limits the displacement in Y direction, the left and right boundaries fix the displacement in X direction, and the upper boundary is the stress boundary. According to the calculation of the self weight of the overburden of the roadway, the value is 10.8 MPa, the horizontal lateral pressure is 16.2 MPa, and the lateral pressure coefficient λ is 1.5. According to the laboratory physical and mechanical tests and similar engineering experience, the physical and mechanical parameters of rock layers in the model are shown in Table 1.

4.2 Analysis of simulation results

Through simulation, the distribution of stress and displacement around − 415 belt roadway is shown in Figs. 4 and 5, and the following rules can be obtained:

(1) Asymmetry of stress distribution around roadway.

As shown in Fig. 4a, the trend of the vertical stress isoline is roughly perpendicular to the dip angle of the rock stratum. The stress concentration area is located in the surrounding rock at the lower part of the left side, and the stress reduction area is located in the left shoulder and the right bottom corner. The stress concentration at the bottom corner of the left side is the most obvious, whose value is more than 2 times of the stress reduction area. The concentration of vertical stress causes the left side to squeeze and the left side of the floor to be asymmetrically uplifted. As shown in Fig. 4b, the horizontal stress of the roadway presents a state of concentrated roof and floor and unloading of two sides, in which the horizontal stress value at the right and left bottom corners of the roof is the largest in the shallow surrounding rock, while the stress value at the right and left bottom corners of the roof and shoulder of the left side is small. Horizontal stress concentration often leads to flexural floor heave and plastic failure of roof.

(2) Deformation asymmetry of surrounding rock.

Among the influencing factors of the roadway surrounding rock deformation, the stress field plays a decisive role, and the asymmetry of the stress distribution often leads to asymmetric deformation of the surrounding rock of the tunnel. According to the vertical displacement nephogram (Fig. 5a), the roadway is generally in the state of large displacement on the lower left and upper right sides while small displacement on the two sides. The trend is roughly perpendicular to the dip angle of the rock stratum, which is consistent with the distribution of vertical stress. It can be seen from the horizontal displacement nephogram (Fig. 5b) that both the left and right sides of the roadway are squeezed inward, with displacement of more than 40 mm, but the deformation of the left bottom corner and the right shoulder are larger than that of the right bottom corner and the left shoulder respectively. The displacement vector diagram also shows that the roadway presents the overall pressure state, but the displacement of left bottom corner and right shoulder is large while the displacement of right bottom corner and left shoulder is small. As a result, the overall deformation state presents asymmetry.

(3) Asymmetry of failure process.

After the excavation of the roadway, the bottom corner of the left side first appears plastic failure, which drives the surrounding rock of the lower part of the left side to squeeze into the roadway space. Compared with the results of numerical simulation and field investigation, it can be concluded that the failure process of the roadway is firstly the overall pressure of the roadway, secondly the failure of the bottom corner of the upper side and the bottom bulge, thirdly the failure of the bottom corner of the lower side and the mesh bag, then the internal extrusion deformation of the surrounding rock of the lower part of the upper side, and finally the deformation failure of the upper side and the deformation failure of the lower side, resulting in the overall instability of the roadway, and the failure process is asymmetric.

5 Asymmetric Deformation Control Strategy and Method

5.1 Proposal of Control Strategy

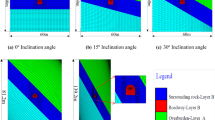

Through the above analysis, it can be concluded that the complex in-situ stress, easily weakened rock properties, asymmetric rock structure and uniform support mode are the main reasons for the asymmetric failure of the roadway, while the upper bottom angle and the lower shoulder are key areas of the deformation and failure of the roadway. − 415 belt roadway is inclined to the bedding of rock stratum at different angles in the whole length, and the asymmetric deformation is significantly different. The key failure areas are uncertain in the left and right sides, which fails to limit the early failure of key parts of the roadway through a unified asymmetric support method. It is also not feasible to detect the inclination of rock stratum intensively and accurately in the whole length of the roadway because of excessive investment cost. In view of the above problems, the control strategy of tunnel asymmetric deformation is proposed as follows:

(1) Homogenization of surrounding rock.

One of the significant influencing factors of the asymmetric deformation of the roadway is uncertainty of the dip angle of the rock and distribution of the structural plane, and the key part of early failure of the surrounding rock is also related to it, which is the bottom angle of the upper side and the shoulder of the lower side with the obtuse angle of the rock. With a reasonable depth of the surrounding rock, through the surrounding rock grouting and other engineering means to weaken the occurrence characteristics of the asymmetric surrounding rock, and then improve the isotropy of the rock mass, the influence of the weak structure on the deformation of the roadway can be effectively weakened, so as to control the asymmetric deformation. After several times of maintenance, cracks have been widely developed in the surrounding rock, which provides conditions for the slurry to penetrate into the surrounding rock.

(2) Strengthening of surrounding rock strength.

The weathering of the surrounding rock of the roadway destroys the micro structure of the rock, while the reduction of cohesion and strength, leads to the loss of self stability of the surrounding rock. The active support performance of bolt support is reflected in the interaction with surrounding rock. Through the strength strengthening of win–win situation, the balance between surrounding rock bolt support structure and external confining pressure could be achieved. Furthermore, the weakening of the surrounding rock property makes the bolt active support lose the engineering foundation, so it is necessary to strengthen the surrounding rock property by grouting and other ways. The study shows that grouting is an effective method to improve the strength of surrounding rock (Jiang et al. 2016; Zhao and Yang 2018; Yang and Lu 1997; Fang et al. 2009; Wang et al. 2007). According to literature (He et al. 2008), the residual strength of the test piece after cement grouting reinforcement can be increased by 0.7–2.0 times, and the uniaxial compressive strength of some test pieces can reach more than 50 MPa. Cement slurry can replace the loose muddy interstitial material, then exert the bonding characteristics to re-cement the matrix, and form a stable structure on the meso level, which strengthens the mechanical properties of surrounding rocks, finally improves self-stability and the active support of the roadway Engineering foundation.

(3) Coupling support.

Roadway support must be coordinated with non-linear large deformation characteristics and be coupled with the strength, rigidity and structure of surrounding rock (Sun et al. 2006; Lin and Shi 2011).As to the − 415 belt roadway which has been repaired for many times, the surrounding rock elastic energy has been fully released, and the stress concentration location has been transferred to a deeper place. The shallow support structure only needs to provide the support resistance which is greater than the sum of its own weight and the smaller expansion force of the adjacent surrounding rock to maintain the stability of the roadway. Through the combination of full section grouting strengthening, shoulder strengthening anchor cable and inclined angle anchor bolt, the coupling support is carried out in the key parts of the roadway, so that the support structure corresponds to the asymmetric trend of the roadway. Moreover, it can also effectively inhibit the early damage of the key parts, realize the closure of the support structure, the integration of the roadway surrounding rock, and the homogenization of the support load, and finally achieve the stability of the roadway.

5.2 Control method of roadway

Based on the existing materials and construction technology, the asymmetric control method of surrounding rock grouting + high prestressed bolt + small aperture prestressed anchor cable support is developed.

(1) Construction parameters of surrounding rock grouting.

The groutability, adhesion and mechanical properties of grouting materials are the key to determine the effect of grouting reinforcement (Li et al. 2006), while the key to ensure the effect of grouting is reasonable grouting pressure, spacing between grouting and the end standard of grouting (Fang et al. 2009).Considering the economic and technical conditions, cement water glass slurry is selected as the grouting material. The water cement ratio is 0.8:1–1:1, the proportion of slurry and water glass is 1:0.03–1:0.05, among which cement is No. 425 ordinary portland cement, the modulus of water glass is 3, Baume degree is 40 be '. The bolt support has been implemented during grouting, which can restrict the radial displacement of the surrounding rock. Therefore, the grouting pressure is selected to be 3–4 MPa. The grouting end criterion is that the single-hole slurry is filled at working pressure and cannot be refilled. Grouting equipment and parameters are shown in Table 2.

(2) Parameters of high prestressed bolt support.

Φ 20 mm × 2000 mm ordinary screw steel bolts are used for the top side of the roadway. The spacing between rows is 700 mm × 700 mm, the resin coil is lengthened for anchoring, the anchoring length is 1000 mm, the anchoring force is not less than 13t, the dish tray with thickness not less than 10 mm is used, and the drag reduction washer and bearing steel washer are matched. The bolt is not pre-tensioned at the time of installation. After the grouting is completed, use the BK30 pneumatic torque wrench to re-tighten the nut until the pre-tightening torque is not less than 300 N m.

(3) Small aperture prestressed anchor cable.

In the 700 mm position on the left and right sides of the roadway vault, Φ 15.24 mm × 6000 mm small diameter prestressed anchor cable is used to support and lengthen the anchorage. The anchorage length is 1500 mm, and the spacing between rows is 1400 mm × 1400 mm. The tensioning machine is used to ensure that the pretension force of the anchor cable is not less than 120 kN.

(4) Reinforcement and support parameters of key parts.

The 1050 mm position of the right shoulder side of the roadway adopts the reinforcement support of the same specification. The bolt at the bottom corner of the left side and the horizontal direction are set at 20°, and the grouting bolt at the left side and the floor are also inclined to the bottom corner for grouting at about 20°. The support at the two key positions of the left shoulder and the bottom corner of the right side of the roadway is strengthened to improve the stability of the roadway.

In conclusion, the roadway support section is shown in Fig. 6.

5.3 Practical Effect

The 80–100 m section of − 415 belt roadway is selected as the test site for industrial test. The construction parameters and requirements are strictly followed in the construction. The support effect of the roadway is tested by the observation results of the underground pressure of the roadway. The surface displacement curve after more than one month of roadway repair is shown in Fig. 7.

It can be seen from Fig. 7 that the surrounding rock enters into the deformation and stability stage after the roadway maintenance for more than 20 days, among which the floor heave is the largest, reaching 81 mm, the two sides move closer and the roof sinks within 45 mm, with no rheological signs of the surrounding rock. From the perspective of overall deformation trend, the deformation of roof, floor and two sides of surrounding rock is relatively harmonious. From the deformation, the deformation of surrounding rock is less than 100 mm, and the floor heave is only 57 mm more than the roof subsidence, with the uniform deformation. From the deformation degree, the deformation of the left and right sides of the roadway is also relatively symmetrical. It shows that the asymmetric control method of roadway realizes the coupling effect of the key parts of surrounding rock and supporting structure, makes both sides of the roadway coordinate deformation, effectively avoids the asymmetric failure phenomenon in the complex structure area, ensures the overall stability of the roadway, and has good supporting effect.

6 Conclusion

-

(1)

Complex in-situ stress field, easily weakened rock properties, asymmetric rock structure and uniform support mode are main reasons for the asymmetric deformation and failure damage of the roadway in the complex structure area. The upper sidewall corner and lower sidewall shoulder of the roadway are key regions for the deformation and damage of the roadway.

-

(2)

According to the special circumstance of the roadway, the asymmetric deformation control strategy of homogenization of surrounding rock, strengthening of surrounding rock strength and coupled support of key regions is proposed, and the asymmetric control method of surrounding rock grouting + high prestressed anchor + small aperture prestressed anchor cable support + reinforcement in key parts is formulated.

-

(3)

The industrial test results show that after 20 days of roadway repairation, the deformation is stable, and the deformation is controlled within 100 mm. Besides, the deformation on both sides of the roadway is relatively symmetrical, that is, the whole roadway finally achieves a coordinated, uniform and symmetrical deformation. The asymmetric control method of the roadway realizes the coupling effect between the key parts of the surrounding rock and the supporting structure, which ensure the overall stability of the roadway.

References

Chen SY, Song CS, Guo ZB et al (2016) Asymmetric deformation mechanical mechanism and control countermeasure for deep roadway affected by mining. J China Coal Soc 41(01):246–254

Fang XQ, He J, He JS (2009) Research on reinforced technology for deep soft rock and dynamic pressurized roadway under high stress. Rock Soil Mech 30(6):1693–1698

He MC, Wang XY, Liu WT et al (2008) Numerical simulation on asymmetric deformation of deep soft rock roadway in kongzhuang coal mine. Chin J Rock Mech Eng 27(4):673–678

Huang WP, Li C, Xing WB et al (2018) Asymmetric deformation mechanism and control technology of roadway with depth over 1000 meters under rheological state. J Min Saf Eng 35(03):481–488

Jia ZK, Wang JC, Dai XF (2018) Roadway surrounding rock deformation and failure mechanism and supporting research in inclined seam. Coal Sci Technol 46(s1):68–71

Jiang BY, Wang LG, Gu ST et al (2016) Damage mechanism and support design of deep composite soft rock lane in Yangcheng mine. J Min Saf Eng 33(03):452–459

Li XH, Yang HM, Liu HX et al (2006) Research on bolt-grouting reinforcement technology in dynamic pressure and soft rock roadway. J Min Saf Eng 23(2):159–163

Lin HL, Shi YK (2011) Simulation on stability of surrounding rock of large section chambers in deep structural complex areas. J China Coal Soc 36(10):1619–1623

Qin DD, Wang XF, Zhang DS et al (2019) Study on surrounding rock-bearing structure and associated control mechanism of deep soft rock roadway under dynamic pressure. Sustainability 11:18927

Qi FZ, Ma ZG (2019) Investigation of the roof presplitting and rock mass filling approach on controlling large deformations and coal bumps in deep high-stress roadways. Latin Am J Solids Struct 16(UNSP e1904)

Sun XM, He MC, Xj Y (2006) Research on nonlinear mechanics design method of bolt-net-anchor coupling support for deep soft rock tunnel. Rock Soil Mech 27(7):1061–1065

Sun XM, Zhang GF, Cai F et al (2009) Asymmetric deformation mechanism within inclined rock strata induced by excavation in deep roadway and its controlling countermeasures. Chin J Rock Mech Eng 28(6):1137–1143

Wang HP, Gao YF, Li SC (2007) Uniaxial experiment study on mechanical properties of reinforced broken rocks pre-and-post grouting. Chin J Under Ground Space Eng 3(1):27–31

Wang J, Guo ZB, Cai F et al (2014) Study on the asymmetric deformation mechanism and control countermeasures of deep layers roadway. J Min Saf Eng 31(1):28–33

Xu XL, Zhang N (2007) Study of control process deformation behavior and of soft rock drift under rich water condition. J China Univ Min Technol 36(3):298–302

Yang HQ, Han CL, Zhang N et al (2019) Stability control of a goaf-side roadway under the mining disturbance of an adjacent coal working face in an underground mine. Sustainability 11:6398

Yang HQ, Han CL, Zhang N et al (2020) Long high-performance sustainable bolt technology for the deep coal roadway roof: a case study. Sustainability 12:1375

Yang SQ, Chen M, Jing HW et al (2017) A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng Geol 217:89–101

Yang XA, Lu SL (1997) Mechanism and technique of roof-bolting and grouting in weak rock tunnels. J China Coal Soc 22(1):32–36

Yuan L, Xue JH, Liu QS et al (2011) Surrounding rock stability control theory and support technique in deep rock roadway for coal mine. J China Coal Soc 36(4):535–543

Zhang B, Cao SG, Wang LG et al (2011a) Deformation failure mechanism and support measurements in roadway of steeply inclined coal seam. J Min Saf Eng 28(2):214–219

Zhang GF, Zeng KH, Zhang C et al (2011b) Failure mechanism and support design of interclated roadway surrounding inclined coal seam in Qishan coal mine. J Min Saf Eng 28(1):22–27

Zhang HJ, Li HY, Zhang TP et al (2019) Research and engineering application of high pre-stressed resistance enhancement large deformation bolt in deep soft rock roadway. J China Coal Soc 44(02):409–418

Zhang KX (2017) Mechanism study of coal bump under tectonic and ultra-thick conglomerate coupling conditions in mining roadway. Chin J Rock Mech Eng 4:266

Zhang N, Li BY, Li GC et al (2013) Inhomogeneous damage and sealing support of roadways through thin bedded coal-rock crossovers. J Min Saf Eng 30(1):1–6

Zhao WL, Yang ZB (2018) A study on the technique of strong bolting and injection support in deep soft rock roadway. Coal Sci Technol 46(12):92–97

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gu, C., Xu, Q., Yang, H. et al. Asymmetric Deformation Mechanism and Control of Roadway in Structural Complex Area. Geotech Geol Eng 39, 145–155 (2021). https://doi.org/10.1007/s10706-020-01479-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01479-z