Abstract

In underground coal mines, the connection between the water-flow fracture zone and aquifer can potentially cause massive water and sand inrush when the working face is covered with unusually thick (638.4 m) alluvium. This paper presents a case study for a method used to investigate the height of the water-flow fracture zone in the Xinjulong mine, China. The engineering geological and hydrogeological conditions of the overlying strata and aquifer were first obtained from field and laboratory studies, followed by numerical modelling. Numerical models were built using the discrete element method. The results from empirical data and actual measurements are compared in this work, from which the regularity of the water-flow fracture zone is developed. Finally, the potential for water inrush into the working face is investigated based on predictive analysis of the connectivity between the water-flow fracture zone and aquifer at the base of the alluvium that overlies the mine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of a water-flow fracture zone can be detrimental to safe mining beneath a water body such as an aquifer, and thus it is important to determine the height of the water-flow fracture zone (He et al. 2002). Many studies of such have been undertaken by engineers and technicians, such as Yin et al. (2013) who used statistical analysis software software to analyse the height of a water-flow fracture zone, and summarised the empirical formulae of the conditions for fully mechanized coal mining. Hu et al. (2012) used multiple regression analysis to obtain the nonlinear statistical relationship between the height of the water-flow fracture zone and mining height, and the length of the working face and mining depth. This was based on measured data of the water-flow fracture zone in many fully mechanized mining working faces. Wu et al. (2012) built a simulation test model to study the height of a water-flow fracture zone after the failure of overlying strata. Wang et al. (2014) studied the height of the water-flow fracture zone of the No. 16 coal seam in the Xin’an coal mine using rock failure process analysis (RFPA), while Liu et al. (2016) used a FLAC®3D numerical simulation (Itasca Consulting Group, Inc.) to predict the height of the water-flow fracture zone in the No. 16105 working face of the Wusuotun coal mine.

Xu et al. (2009, 2012) combined theoretical analysis with practical exploration to study the influence of the location of key strata on the height of a water-flow fracture zone, and developed a method for determining its height based on the location of these key strata. Other work has also achieved results in guiding safe mining production beneath water bodies (Li et al. 2012; Zhang et al. 2016a, b; Lv 2014) but only limited studies have investigated failure characteristics and the effects of regularity of overlying strata on the height of water-flow fracture zones during fully mechanized caving face mining. For coal mines beneath thick alluvium, it is important to study the development height of water-flow fracture zones to determine safe mining height and set safe coal pillar heights.

The No. 1302N working face in the Xinjulong mine, Shandong Province, China, is used in this study to conduct a discrete element method (DEM) analysis of the characteristics and regularity of overlying strata and water-flow fracture zone height. This is combined with the empirical work of Xu and Liu (2011) and field measurements of the water-flow fracture zone height. By analysing the connectivity between the water-flow fracture zone and alluvium of the basal aquifer, it is possible to predict potential water inrush during mining.

2 Engineering Background and Geological Conditions

2.1 Engineering Background

The strike length of the No. 1302N working face in Xinjulong coal mine is 1608 m, the tendency length is 270 m and the average dip angle of the No. 3 coal seam is 8°. The average thickness of Neogene alluvium that overlies the No. 1302N working face is 638.4 m. The maximum thickness of the alluvium is located above the shallow area of the working face. The average bedrock thickness is 150 m, and contains many water-bearing strata which have variable water rich content. The cut of the working face is in the thinnest bedrock.

Large mining disturbances may lead to an increase in the height of the water-flow fracture zone, even if connected with the aquifer. The increased height may lead to water inrush, which threatens safe coal production of the No. 1302N working face.

2.2 Hydrogeological Conditions

In the roof of the coal seam, the mudstone and siltstone aquifers are mainly thick and poorly permeable, which blocks water flow from the upper aquifer into the working face. Based on drilling data, the No. 1302N working face roof contains bedrock consisting of medium grained sandstone, coarse sandstone (aquifer) and an aquifuge comprising siltstone and mudstone. The names and locations of the aquifers and aquifuges are shown in Table 1 and Fig. 1.

Both Table 1 and Fig. 1 show that the aquifer and aquifuge of the roof (No. 1) are cross-deposited. Thus, the aquifuge can prevent hydraulic connection between the aquifers and the working face is mainly threatened by potential water inrush from the roof aquifer.

3 Establishment and Analysis of Numerical Model

3.1 Numerical Model Establishment

The plane strain numerical model was established according to the stratum characteristics using UDEC™ 4.0 software (Universal Distinct Element Code, Itasca Consulting Group, Inc.). The model size was set to 450 m in length and 180 m in height. Coal pillars (75 m wide) were set with fixed boundaries at both ends of the open-cut and stop-line. The thickness of the coal seam was set to 9 m, with bedrock thickness above the coal seam of 150 m and a vertical stress of 13 MPa was applied to the top interface of bedrock (u = 0, v = 0). The left and right boundary conditions were set as single constraint bounds (u = 0, v ≠ 0) and the upper boundary as a free boundary. The physical and mechanical parameters of each rock are shown in Table 2.

After initial balance of the model was achieved, an excavation was made 75 m from the left boundary of the model, with each excavation advancing 10 m into the working face. The numerical simulation of the geometric model is shown in Fig. 2.

3.2 Macroscopic Failure Characteristics

When the working face has advanced 20 m, the immediate roof of the coal seam collapses (Fig. 3a), the interlayer crack spreads upwards and the medium grained sandstone (No. 1 aquifer) nearest to the coal seam exhibits a small amount of vertical cracking. The first collapse of immediate roof occurs at about 20 m advancement, i.e. after two advancements. As the working face continues advancing to 40 m (Fig. 3b), the No. 1 aquifer appears to collapse for the first time, and the upper part of the No. 2 aquifer cracks visibly and begins to collapse. The interlayer and vertical cracks are obvious and expand upwards and vertical fracturing penetrates into the upper strata of the No. 3 aquifer. The maximum height of the caving zone is about 28 m, and the maximum height of the water-flow fracture zone is about 58 m.

Simulation of deformation and failure of strata overlying a working coal face (bright green). Note that as the working face advances 20 m, the immediate roof collapses and interlayer cracks spread upward, followed by collapse of the No. 1 aquifer at 40 m. a advancing distance of 20 m, b advancing distance of 40 m, c advancing distance of 50 m, d advancing distance of 80, e advancing distance of 130 m, f advancing distance of 200 m

The thickness and strength of the No. 1 aquifer is significant (medium sandstone is 11 m thick) and has a high carrying capacity. As a result, when the stress exceeds its carrying capacity, roof collapse occurs that results in the upper part of the thin and weak rock layer to also collapse. This is referred to as the first weighting interval of the main roof, which is at about 40 m.

When the working face has advanced 50 m, the collapse zone of the overlying strata develops into the mudstone of the lower part of the No. 3 aquifer (medium sandstone) (Fig. 3c). The height of the collapse zone reaches a maximum of 34.6 m. When the working face has advanced 80 m, the height of the collapse zone remains essentially unchanged, and the height of the water-flow fracture zone continues to develop and passes through the mudstone of No. 3 aquifer into the bottom of the siltstone (Fig. 3d). However, the growth rate decreases at this stage, and the height of the water-flow fracture zone reaches about 78 m.

When the working face has advanced 100 m, the fracture zone develops to a maximum height of 100 m and reaches the No. 4 aquifer. With continued mining (Fig. 3e, f), the maximum height of the collapse zone and water-flow fracture zone remains stable. The overlying stratum of the early mining area fully collapses as the advancing distance increases. The collapsed rock is compacted and supports the upper strata, especially in the area of greatest subsidence in which cracks are compacted and closed. Thus, saddle-shaped depressions form at both ends, elevated in the middle. This saddle shape becomes more obvious with increasing advancing distance.

At this stage, the maximum height of the collapsed zone is about 36.8 m and the ratio of collapse to mining height is 4.09. The maximum height of the water-flow fracture zone is about 100 m and the ratio of the height of the fracture zone to mining height is 11.12.

From the above analysis, it can be inferred that, during mining, the water-flow fracture zone will affect aquifers No. 1–4, but the distance between the No. 5 aquifer and coal seam is greater than the maximum height of the water-flow fracture zone, thus the No. 5 aquifer is not affected.

4 Height Analysis of the Water-Flow Fracture Zone

4.1 Empirical Calculation of Height

According to the borehole data, the average mining thickness of the No. 1302N working face is 9 m, and bedrock strength in the shallow working face area is medium-hard. The failure height of the overlying strata in the shallow working face area is calculated according to the medium-hard strength and maximum coal thickness of 9 m.

4.2 Empirical Formula Calculation

According to the regression equation of Xu and Liu (2011), the maximum height calculation for two zones (i.e. the collapsed zone and water-flow fracture zone) in a fully mechanized mining operation under medium-hard overlying strata is as follows:

where Hm is the maximum height of the collapsed zone, H Li is the maximum height of the water-flow fracture zone and M is the mining height (<12 m).

The maximum height of the collapse zone is in the 33.54–42.96 m range, and the height of the water-flow fracture zone is in the 86.1–109.1 m range when the mining height is 9 m.

According to many years of observation and statistical analysis in the Yanzhou mining area (Huang 2007), the height of the two zones can be empirically determined as follows where the height of the collapsed zone is four times the height of mining:

The relationship between the maximum height of the water-flow fracture zone and mining height is as follows:

The value of Hm determined from Eq. (3) is 36 m, and the value of H Li determined from Eq. (4) is in the 66.26–74.70 m range when the mining height is 9 m.

4.3 Measured Water-Flow Fracture Zone Height

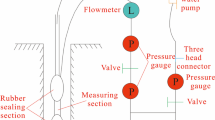

Three observation boreholes were designed to observe the height of the water-flow fracture zone (Fig. 4). The boreholes are designated as follows: #1 pre-mining hole, #2 post-mining hole and #3 post-mining hole, as shown in Table 3.

Based on the distribution of rock strata in the roof of the coal seam obtained from borehole drilling data, the leakage quantity of the three observation boreholes were quantitatively and qualitatively determined, as well as the height of the water-flow fracture zone (92.42–94.65 m).

It can be seen that the actual observation height of the water-flow fracture zone in the working face is in accordance with the results of numerical simulation and the calculations of Eq. (2), which differs from that of Eq. (4) for the Yanzhou mining area which provides results that are too low. Based on regression analysis and statistical data from the Yanzhou mining area (Table 4; Xu and Liu 2011; Table 5; Huang 2007), it is evident that the empirical calculation used in regression analysis considers a mine depth >400 m, while the Yanzhou empirical calculation only considers shallow mining depths. Thus, the empirical regression analysis is more suitable for the calculation of two zones of overlying strata in deep mining.

It is important to note that each coal mine will have its own specific geological conditions, mining methods and mining conditions. Therefore, the empirical calculations can be used as a reference, but can be used in combination with numerical results to analyse the development laws of the water-flow fracture zone. This potentially provides a better method for accurately assessing the height of the water-flow fracture zone. By comparing the simulation results with the results of empirical calculations, accurate conclusions can be made regarding the development laws of the water-flow fracture zone.

The No. 1302N working face is at a depth of about 800 m, and is overlain by more than 600 m of alluvium. As a result, the empirical regression analysis results are most comparable to the actual measurement results. However, there is still very little observational data and limited research into conditions of two zones in deep mining. The study of deformation and failure height of the 1302N working face in this paper shows that there is no obvious influence exerted by the alluvium thickness.

Nevertheless, there is an influence exerted by the presence of faults. The 2302 N working face, which is adjacent to the 1302N working face, is normally mined when the thickness of bedrock is 70 m, but when the bedrock is 160 m thick, faulting occurs followed by water and sand inrush. The sand that rushes in is located at the bottom of the thick alluvium (Fig. 5), which indicates that the characteristics of deformation and failure of the overlying strata in unusually thick alluvium need further study.

5 Conclusions

In this paper, a method for predicting the development height of the collapse zone and water-flow fracture zone during fully mechanized mining beneath unusually thick alluvium has been presented. Combined results of empirical calculations and numerical simulations based on the development laws of the water-flow fracture zone allow the following conclusions to be drawn:

-

1.

The first collapse above the No. 1302N working face occurs after about 40 m of advancement; with a maximum collapse zone height of about 36.8 m. The ratio of collapse zone to mining height is 4.09. The maximum height of the water-flow fracture zone is about 100 m, and the ratio of fracture zone height to mining height is 11.12.

-

2.

When the advancement distance is about 50 m, the collapse zone reaches its maximum, and the water-flow fracture zone develops rapidly. When the advancement distance increases to 130 m, the fracture zone develops to its maximum value. As the advancement distance increases further, the overlying strata fully collapse. Cracks within this material become compacted and close, and the collapsed rock compacts supports the upper strata. This is especially evident in the area of greatest subsidence, in which a saddle-shaped depression forms that becomes most obvious with increasing distance from the collapse.

-

3.

Considering the maximum development height of the fracture zone, failure of the strata overlying the No. 1302N working face will affect aquifers No. 1–4. However, the No. 5 aquifer will not be affected because the distance from the No. 5 aquifer to the coal seam is greater than the maximum height of the water-flow fracture zone. Therefore, during mining of the No. 1302N face, aquifers No. 1–4 will exert an influence on water inflow into the working face. At present, there are still too few observation data and research results for the overlying strata and accurate calculations are still lacking.

Therefore, the characteristics of deformation and failure development in strata overlying a coal mine beneath unusually thick alluvium are linked to the presence of aquifers, mining advancement distance and particular geological conditions, such as faults. However, further study is required to fully quantify the development and operation of water-flow fracture zones.

References

He MC, Jing HH, Sun XM (2002) Soft rock engineering mechanics. Science Press, Beijing

Hu XJ, Li WP, Cao DT et al (2012) Index of multiple factors and expected height of fully mechanized water flowing fractured zone. J China Coal Soc 37(4):613–620

Huang FC (2007) Coal control and treatment technology for fully mechanized caving mining in thick seam. Coal Industry Press, Beijing

Li PQ, Bai HY, MA MAJ et al (2012) Failure height development law of overburden thick loose strata above fully mechanized coal mining face under thin base rock. Coal Sci Technol 40(1):35–37

Liu WT, Chen ZX, Zhang MP (2016) Numerical simulation and site measurement of development height of fracture zone in overburden strata. Min Saf Environ Prot 43(1):57–60

Lv WH (2014) Measure and simulation for development height of water conducted crack zone in overburden roof[J]. J Xi’an Univ Sci Technol 34(3):309–313

Wang LL, Wanh JC, Yin HY et al (2014) The height of water flowing fracture zone of 16 coal seam in xin’an coal mine. J Shandong Univ Sci Technol Nat Sci 33(1):40–45

Wu YP, Yu S, Gao XC et al (2012) Study on height of water flow fracture zone in fully mechanized caving face [J]. Coal Eng 1(10):59–61

Xu YC, Liu SQ (2011) Study on method to set safety coal and rock pillar for fully mechanized top coal caving mining under water body. Coal Sci Technol 39(11):1–4

Xu JL, Wang XZ, Liu WT et al (2009) Effects of primary key stratum location on height of water flowing fracture zone. Chin J Rock Mech Eng 28(2):380–385

Xu JL, Zhu WB, Wang X (2012) New method to predict the height of fractured water-conducing zone by location of key strata. J China Coal Soc 37(5):762–769

Yin SX, Xu B, Xu H et al (2013) Study on height calculation of water conducted fracture zone caused by fully mechanized mining. Coal Sci Technol 41(9):138–142

Zhang WQ, Li B, Yuan JD (2016a) Detection and evaluation of crack development near the fault zone under the influence of coal mining. Electron J Geotech Eng 21(22):6841–6850

Zhang WQ, Li B, Yu HL (2016b) The correlation analysis of mine roof water inrush grade and influence factors based on Fuzzy Matter-Element. J Intell Fuzzy Syst 31(6):3163–3170

Acknowledgements

This study was supported by the Specialized Research Fund for the Doctoral Program of Higher Education of China (No. 20133718110015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, W., Li, B., Zhang, G. et al. Investigation of Water-Flow Fracture Zone Height in Fully Mechanized Cave Mining Beneath Thick Alluvium. Geotech Geol Eng 35, 1745–1753 (2017). https://doi.org/10.1007/s10706-017-0205-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0205-0