Abstract

This paper describes the results of an investigation on the effect of two readily-available materials, namely granite and dolerite dusts on the properties of a tropical expansive soil from southeast Nigeria. The aim was to evaluate their use as potential stabilizing agents. Standard compaction, California bearing ratio (CBR), and Atterberg limit tests were performed on the natural expansive soil and on samples treated with varying percentages of granite or dolerite dust. Noticeable reduction in shrinkage and plasticity as well as an increase in CBR were observed in the treated soil samples. The improved clayey soil measured up to the Nigerian standards for materials used in general filling, embankment and sub-base materials, but they fall below the standards set for use as base materials. Based on the strength development, it seems that the cheap rock-dusts can be used as partial replacement for the other more expensive materials been used in treatment of expansive soils. Therefore their use may not only become an efficient method for the utilization of materials that are abundant in the terrain, but may also contribute to the development of the nation’s solid minerals sector.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Engineering construction is quite challenging in southeast Nigeria because of the occurrence of soils with low bearing capacity and high swelling or shrinkage potential. The alternating periods of six months of dry season (mild to zero rainfall) and six months of heavy rain (annual mean > 2000 mm) in a terrain characterized by shallow water table (<5 m in some places) play significant role in the failure of engineering structures constructed on the problematic soils. Moisture-sensitive soils do not only exhibit large deterioration in strength properties (Phanikumar and Sharma 2007; Li et al. 2008; Mohamedzein and Al-Rawas 2011), but also are subject to heave and settlement which are widely-recognized problems in civil engineering construction (Sharma and Phanikumar 2005; Mir and Sridharan 2013). For poor quality soils to be suitable for highway and pavement design, they must meet existing index and strength requirements usually achieved by stabilization. Stabilization of soils is carried out primarily to improve strength and durability properties and has often relied on conventional additives such as cement and lime (Al-Rawas et al. 2005; Buhler and Cerato 2007; Phanikumar 2009). However, industrial stabilizing substances like lime, quick lime and Portland cement are most often expensive which warrants the researching into alternative cheaper source of stabilizers. The use of alternative source of lime such as; wood ash, fly ash, rice husk ash, and limestone ash to stabilize expansive soil have be assessed by various authors (Okagbue and Yakubu 2000; Cokca 2001; Ji-ru and Xing 2002; Kumar and Sharma 2004; Okagbue 2007; Brooks 2009; Wong 2015; Emeh and Igwe 2016) and their results suggested an improvement in the geotechnical properties of the natural soils after stabilization. They also noted that the degree of improvement achieved is proportional to the calcium oxide (CaO) content of the stabilizer. Though these alternatives are cheap, their quantity is not enough to stabilize the numerous road network which lies under the problematic expansive soils in Nigeria; hence there is need to explore more alternative cheaper source of stabilizers. To solve this problem, Okagbue and Onyeobi (1999) and Ene and Okagbue (2009) have assessed the use of marble dust and pyroclastic dust respectively to stabilize expansive soils within Nigeria. Though the result of both rock dusts improved the quality of the expansive soils, the soil treated with pyroclastic dust was not durable for a long period of time while marble dust is not available in large quantity within the country. Recently, there have been increase in the quantity of granite and dolerite dust generated by quarry companies within the country, and this has necessitated the need to assess their use as a stabilizing material for expansive soils. Not only because these materials are cheap and easily available in most of the basement complexes in Nigeria (Fig. 1) (Obaje 2009), but also because of their chemical composition which have been shown to contain appreciable amount of lime (CaO) and Alumina (Imasuen et al. 2013; Talabi 2013) which serves as a source of pozzolans for the stabilizing processes. Application of dusts from abundant intrusive rocks with significant quantity of calcium oxide as clay stabilizers will not only provide an innovative stabilization method, but may also be a positive contribution to a growing economy.

Outline map of Nigeria showing its geology (After Obaje 2009)

2 Materials and Methods

The clay soil used for this investigation was obtained from Enyigba, a mining district in Ebonyi State, south-eastern Nigeria. The granite dust and dolerite dust were obtained from a local quarry in Akwanga, Nasarawa State, Nigeria, and was then mechanically sieved. Particles passing through American standard of testing material (ASTM) sieve #200 (<75 µm) were used for the stabilization processes. Atterberg limits, standard compaction (West African standard), triaxial and unsoaked California bearing ratio (British standard) tests were carried out to determine the geotechnical properties of the clay both in its natural state and when mixed with varying percentages (10, 15 and 20%) of granite dust or dolerite dust. The results of these tests were used to evaluate the efficacy of the dusts as additives for the improvement of the engineering properties of clay soil to enable its use as an engineering construction material. The aforementioned analyses were carried out using standard laboratory procedures and equipment. Details of these analyses are highlighted in (Cokca 2001; PhaniKumar and Sharma 2004; Punmia et al. 2005; Arora 2009; Mohamedzein and Al-Rawas 2011; Mir and Sridharan 2013).

3 Results and Discussion

3.1 Effect of the Additives on the Consistency Limits of the Soil

There was a general reduction in the liquid limit (LL) and plastic limit (PL) of the natural soil [which was classified as an organic clay of medium plasticity (CL) (Table 1)] on addition of both granite dust and dolerite dust; hence a reduction in its plasticity. Figure 2 revealed that the addition of 20% granite dust resulted to a 6.7% decrease in the plasticity index (PI) of the natural soil, while 6.8% decrease in the plasticity index of the natural soil was achieved on addition of 10% dolerite dust (Fig. 3). This result showed that double the quantity of granite dust will be required to reduce the plasticity of the natural soil compared to using dolerite dust. This difference could be as a result of the chemical composition of both stabilizers (Table 2), noting that the calcium oxide (CaO) content of dolerite dust (6–14%) is higher than that of granite dust (1%). Calcium oxide content of unconventional expansive soil stabilizers have shown to be directly proportional to its immediate stabilizing ability (Kumar and Sharma 2004; Ismaiel 2006; Ji-ru and Xing 2002; Ene and Okogbue 2009; Wong 2015; Emeh and Igwe 2016).

3.2 Effect of the Additives on the Compaction Properties of the Soil

The maximum dry density (MDD) and optimum moisture content (OMC) values of the natural soil sample and samples with varying percentages of rock dust are presented in Figs. 4 and 5. Figure 4 revealed that the value of MDD of the natural soil reduced on addition of 10% of both granite and dolerite dust, but increase on addition of 15% of the rock dusts. The increment continued on addition of 20% dolerite dust but decreased when the same percentage of granite dust was added. The decrease and subsequent increase in the value of the MDD on addition of the dolerite dust was also observed and explained by Okagbue and Yakubu (2000) and Emeh and Igwe (2016), to have been caused by flocculation and agglomeration of the clay particles as result of the chemical reaction between lime and clay minerals. The flocculated particles caused increase in the void ratio of the admixture; hence a reduction in the MDD. Meanwhile further increase in the quantity of rock dust resulted to gradual decrease in the void ratio; thus subsequent increase the MDD. Since the MDD is affected by the chemical reaction between lime and clay minerals (Kezdi 1979), the fluctuating phenomenon observed on addition of granite dust could be as a result of variation in the mineralogical composition of the natural expansive soils, noting that the mineralogical composition of the soil used was not predetermined. Again comparing the two rock dusts, the highest MDD (1935 kg/m3) was achieved on addition of 15% granite dust compared to 1880 kg/m3 that was achieved on addition of 20% dolerite dust.

Similarly, Fig. 5 revealed that there was a gradual decrease in the OMC of the natural soil on addition of the rock dust till up to 15%, but on addition of 20% of the rock dusts, the OMC of the granite dust stabilized soil gradually increased while that of the dolerite dust sharply increased. Again this behaviour could be as a result of reaction between lime and clay minerals. At lower content of rock dust, the lime-clay reaction could not be initiated, thus at this point the grain size distribution of the clay soils changes to a coarser configuration of silty to sandy soil (Drnevich et al. 2009); hence reduction in the OMC. But as the rock dust is increased, the reaction between lime and clay is initiated, this cation exchange reaction which is an exothermic reaction normally leads to the drying of soil, thus more water is been required for the subsequent reaction, which is disassociation of the calcium hydroxide into Ca2+ and OH- ions (Okagbue and Yakubu, 2000; National lime association 2004), therefore leading to increase in the OMC. Again the lowest reduction in the OMC (14%) of the natural soil was achieved by the addition of 15% of both rock dusts.

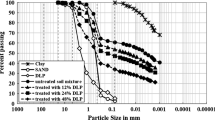

3.3 Effect of the Additives on the California Bearing Ratio (CBR) of the Soil

Figure 6 shows the result of the California bearing ratio (CBR) tests conducted on the natural expansive soil and on clay-rock dust admixtures. There is a steady increase in CBR values with increasing percentages of granite and dolerite dusts in the modified clay, though on addition of 20% dolerite dust, the CBR value tends to gradually reduce while that of granite dust continued with the steady increase. Various explanations have been put forward by different authors for the increase in CBR values. Thompson (1965) explained that the increase in CBR is as a result of the cation exchange and agglomeration reactions that occur on addition of rock dust to clay soils. Croft (1967) noted that the development and hardening of gelatinous reaction products and intergrowths of crystalline, hydrous calcium silicates and aluminates are responsible for cementation in clay-soils stabilized with lime, lime-flyash and cement. While Ene and Okogbue (2009) attributed it to the formation of bonds of calcium alumina hydrate and silicate hydrate on addition of rock dust to clay soils. It is however widely believed that the additives results in structural arrangements of reaction products and soil elements which contribute to rigidity of stabilized soils.

The geotechnical properties of granite-fortified and dolerite-fortified clays were compared to the Nigerian standards and presented in Tables 3 and 4. Analyses of the dolerite dust–clay mixture and the granite dust–clay mixture (at varying percentages) with reference to the Nigerian standards revealed that the granite dust and dolerite dust were potentially effective stabilizing agents for expansive soil. Generally, natural soils with up to 20% of the rock dusts measured up to the Nigerian standards for materials used in general filling and embankment, and as a sub-base material. It was however noticed that the stabilized soils (even at percentage of rock dust content up to 20%) fell below the standards set for base materials and thus cannot be used for road construction. Although the granite and dolerite clay mixtures fell short of the Nigerian standard for road construction, the new procedure will enable poor quality materials to be employed in the construction of other important engineering structures that would have otherwise been unsuitable for use. Decisions to establish strategic engineering structures require designers to take into consideration local economic factors, environmental and climatic conditions as well as project location during planning and execution stages. Excessive heave associated with swelling of expansive soils can cause considerable distress to civil engineering structures (Çokça 2001). Stabilization procedures using locally available material is therefore desirable. The rock dust- stabilized clay met some of the Nigerian standards but increased moisture content during the six months of heavy rains remains a serious concern. Kumar et al. (2007), Kamruzzaman et al. (2009) and Jongpradist et al. (2010) reported that the gains of cement-stabilized soils were better preserved if provision for adequate protection against increase in moisture content were made. A study on the impact of cyclic wetting and drying (Guney et al. 2007) showed that the initial gain of lime stabilization was lost after the first cycle and swelling potential increased at subsequent cycles. The results obtained from the granite and dolerite dust-stabilized samples indicate that the pozzolanic products that account for strength gain do not differ much for both types of agents. While the stabilized materials fell short of the standard as a base material, they may be suitable for various other engineering applications.

4 Conclusions

An experimental program was undertaken to assess the effects of locally abundant granite and dolerite dusts on the geotechnical characteristics of expansive clays obtained from a mining district in southeast Nigeria. The conclusion drawn from the results obtained are summarized as follows:

-

1.

The granite and dolerite dust can be used to reduce the plasticity index of expansive soils; hence it’s heaving potential, but double the quantity of granite dust will be required to reduce the plasticity of the natural soil compared to using dolerite.

-

2.

The compaction properties of expansive soils can be significantly improved by stabilizing the natural soils with about 15% of either dolerite dust or granite dust, but further increase in the quantity of the rock dust will give negative results.

-

3.

The California bearing ration of expansive soils of medium plasticity can be significantly improved by adding about 20% by weight of either granite dust or dolerite dust to it, though granite dust appears to improve the CBR better.

-

4.

Although, the addition of the rock dust mixtures up to 20% did not improve their usage as base materials for road construction, they may still be useful in various other engineering applications. This in our view will not only provide easy access to clay stabilizing agents but will also make significant contributions to the growth of a developing economy through the solid mineral sector.

References

Al-Rawasa AA, Hagoa AW, Al-Sarmib H (2005) Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build Environ 40:681–687

Arora KR (2009) Soil mechanics and foundation engineering. Standard Publishers Distributors, Delhi

Brooks RM (2009) Soil stabilization with fly ash and rice husk ash. Int J Res Rev Appl Sci 1(3):209–217

Buhler RL, Cerato AB (2007) Stabilization of Oklahoma Expansive Soils using Lime and Class C Fly Ash. Problematic Soils and Rocks and In Situ Characterization. American Society of Civil Engineers, Reston VA, pp. 1–10. http://ascelibrary.org/doi/abs/10.1061/40906%28225%291. Accessed 11 Mar 2017

Çokça E (2001) Use of class C fly ashes for the stabilization of an expansive soil. J Geotech Geoenviron Eng 127(7):568–573

Croft JB (1967) The structures of soils stabilized with cementitious agents. Eng Geol 2(2):63–80

Drnevich VP, Daita RK, Kim D (2009) Family of compaction curves for chemically modified soils, Final report joint transportation research program (FHWA/IN/JTRP-2005/7) File No. SPR- 2850

Emeh C, Igwe O (2016) The combined effect of wood ash and lime on the engineering properties of expansive soils. Int J Geotech Eng 10(3):246–256

Ene E, Okogbue CO (2009) Some basic geotechnical properties of expansive soil modified using pyroclastic dust. Eng Geol 107:61–65. doi:10.1016/J.Enggeo.2009.03.007

Guney Y, Sari D, Cetin M, Tuncan M (2007) Impact of cyclic wetting–drying on swelling behavior of lime-stabilized soil. Build Environ 42(2):681–688

Hermes OD (1964) A quantitative petrographic study of dolerite in deep river basin North Carolina. Am Mineral 49(11–1): 1718

Imasuen OI, Olatunji JA, Onyenubi TUS (2013) Geological observation of basement rocks around Gangu, Kogi state. Int Res J Geol Min 3(2):57

Ismaiel HAH (2006) Treatment and improvement of the geotechnical properties of different soft fine grained soils using chemical stabilization. PhD. thesis, Institute of Geology, Martin Luther Halle-Wittenberg University, Germany

Ji-ru Z, Xing C (2002) Stabilization of expansive soils by lime and fly ash. J Wuhan Univ Technol 17(4):73–78

Jongpradist P, Jumlongrach N, Youwai S, Chucheepsakul S (2010) Influence of fly ash on unconfined compressive strength of cement-admixed clay at high water content. J Mater Civ Eng 22(1):49–58

Kamruzzaman A, Chew S, Lee F (2009) Structuration and destructuration behavior of cement-treated Singapore marine clay. J Geotech Geoenviron Eng 135(4):573–589

Kézdi Á (1979) Stabilized earth roads. Elsevier, Amsterdam, p 327p

Kumar BRP, Sharma RS (2004) Effect of fly ash on engineering properties of expansive soils. J Geotech Geoenviron Eng 130(4):764–767

Kumar A, Walia B, Bajaj A (2007) Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J Mater Civ Eng 19(3):242–248

Li L, Benson C, Edil T, Hatipoglu B (2008) Sustainable construction case history: fly ash stabilization of recycled asphalt pavement material. Geotech Geol Eng 26(2):177–187

Mir BA, Sridharan A (2013) Physical and compaction behavior of clay soil-fly ash mixtures. Geotech Geol Eng 31(4):1059–1072

Mohamedzein YEA, Al-Rawas AA (2011) Cement-stabilization of sabkha soils from Al-Auzayba, Sultanate of Oman. Geotech Geol Eng 29(6):999–1008

National Lime Association (2004) Lime-treated soil construction manual, lime stabilization and lime modification, vol 326. National Lime Association, Bulletin, Arlington, pp 1–41

Obaje NG (2009) Geology and mineral resources of Nigeria. Lect Notes Earth Sci. doi:10.1007/978-3-540-92685-69

Okagbue CO (2007) Stabilization of clay using woodash. J Mater Sci Civ Eng: ASCE 19(1):14–18

Okogbue CO, Onyeobi TUS (1999) Potential of marble dust to stabilize red tropical soils for road construction. Eng Geol 53:371–380

Okogbue CO, Yakubu JA (2000) Limestone ash waste as a substitute for lime in soil improvement for engineering construction. Eng Geol 58:107–113

Phanikumar B (2009) Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: a comparative study. Geomech Geoengin 4(2):175–181

PhaniKumar B, Sharma R (2004) Effect of fly ash on engineering properties of expansive soils. J Geotech Geoenviron Eng 130(7):764–767

Phanikumar B, Sharma R (2007) Volume change behavior of fly ash-stabilized clays. J Mater Civ Eng 19(1):67–74

Punmia BC, Ashok KJ, Arun KJ (2005) Soil mechanics and foundations. Laxmi Publications (P) Ltd, New Delhi

Sharma R, Phanikumar B (2005) Laboratory study of heave behavior of expansive clay reinforced with geopiles. J Geotech Geoenviron Eng 131(4):512–520

Talabi AO (2013) Mineralogical and chemical characterization of major basement rocks in Ekiti State, SW-Nigeria. RMZ Mater Geoenviron 60:73–86

Thompson MR (1965) Lime treated soils for pavement construction. J Highw Div 94(2):59–67

Wong LS (2015) Formulation of an optimal mix design of stabilized peat columns with fly ash as a pozzolan. Arab J Sci Eng 40(4):1015–1025

Acknowledgements

The authors are grateful to Engineer Anyanwu of the Civil Engineering Soil Mechanics Laboratory, University of Nigeria, Nsukka for his assistance during laboratory testing. The insightful contributions of Mr. I. C. Agbodike, Ms. O. Onyiuke, Mr. L. Ohuoba, Mr. D. Ekwem (who died while doing this work) and Mr. A. Kapi are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Igwe, O., Adepehin, E.J. Alternative Approach to Clay Stabilization Using Granite and Dolerite Dusts. Geotech Geol Eng 35, 1657–1664 (2017). https://doi.org/10.1007/s10706-017-0200-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0200-5