Abstract

This paper examines the relationships between Cerchar hardness index (CHI) and some mechanical properties of coal measure rocks in Zonguldak Hard Coal Basin. Some index properties (Cerchar hardness index, Shore scleroscope hardness, in situ Schmidt rebound hardness and point load strength) and strength (uniaxial compressive strength and Brazilian tensile strength) properties of 29 sedimentary rock samples are determined. Then, relationships between (CHI) and strength as well as and some other index values are evaluated using statistical methods. Linear relationships are found between CHI and uniaxial compressive strength, Schmidt rebound hardness. Power relationships are determined between CHI and Shore scleroscope hardness, diametral point load strength, point load strength anisotropy index. Besides, CHI tests are performed by means of bits having tip angles of 99° and 125° and excellent linear relationships are identified between them.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A dictionary description of hardness is that a body is hard if it is not easily penetrated. This definition conveys the concept that hardness is related to resistance to local compression. Hardness should be considered as an expression of material behaviour rather than a fundamental physical property of a material. Hardness of rock can be a function of many intrinsic properties of rock including mineral type, grain size, cohesion of minerals, grain boundaries, and rock strength including plasticity behaviour and modulus of elasticity, among others (Atkinson 1993).

A large number of test methods have been developed to measure rock hardness, including indentation resistance, dynamic rebound of an impacting body, and relative wear of rock with respect to other materials. Three distinct types of tests have been used to measure the hardness of rock: the scratch hardness test (Mohs hardness), the dynamic or rebound hardness test (Schmidt rebound hardness and Shore scleroscope hardness), and the indentation (Vickers, Knoop, Brinnell) test (Atkinson 1993).

Predicting performance and bit consumption of mining and tunnelling machines, including drill rigs is very important in excavation engineering. Since cutting machines used underground for mechanized excavation are the systems requiring high investments, it is necessary to predict the machine performance before selecting a suitable machine to buy (Bilgin 1989). That’s why some rock properties such as petrographic, physical and mechanical ones have great significance in predicting the performance of mechanized excavation systems. In addition, rock quality designation (RQD) properties and in situ strength tests should also be performed (Su and Akçin 2005; Yaralı et al. 2008).

Performing direct test to evaluate rock strength and deformability is mostly expensive and require considerable time, especially for preparation of rock samples for testing (Shalabi et al. 2007). For these reasons, indirect tests such as Schmidt rebound hardness, Shore scleroscope hardness, and point load strength can be used to estimate rock strength. These tests are relatively easy to perform, not expensive, and take short testing time (Yasar and Erdogan 2004).

As a consequence, in one of the previous meeting held in Montreal on the 3rd September 1987, the commission of International Society for Rock Mechanics on Rock Borabality, Cuttability, and Drillability, strongly advised the Cerchar abrasivity and Cerchar hardness index as standard rock machineability tests (Cerman 1988). Since then, Cerchar hardness index has been used at many tunneling and longwall mining projects for estimation of drillability and machine specifications (Cerman 1988; Copur and Eskikaya 1992; Bilgin et al. 1992; Guarga and Muniaini 1997; AFTES 2003; Couchard et al. 2004; Sofretu and Schwenzfeier 2005).

Voest Alpine company claimed that the prediction of excavation rate depended on Cerchar hardness index of rocks for AM50 and AM100 roadheaders. Coder (1973) in his study on tunnel boring machines showed that Cerchar hardness index of rocks played an important role on prediction of excavability of rocks (Bilgin 1989). Some roadheader manufacturers claimed that the performance prediction of machine depended on Cerchar hardness index of rocks (AFTES 2003).

Cerchar hardness index test was originally developed at the Laboratoire du Center d’Etutes et Recherches des Charbonnages (CERCHAR) de France for coal mining applications and testing results of Cerchar were published by Valantin (1974). The test is generally used for defining the strength and cuttability characteristics of coal or rock samples (Valantin 1974; Bilgin et al. 1992; AFTES 2003; Sofretu and Schwenzfeier 2005).

In this test, a tungsten carbide bit having a diameter of 8 mm and an inclusive tip angle of 99° is rotated at a speed of 190 rpm and penetrates into the rock. The bit is loaded vertically by a 200 N weight, against the test specimen. The less hard the rock, the more easily the bit penetrates. The index of hardness is chosen as the time taken in seconds to drill a hole of 1 cm deep, assuming constant rotational speed (Valantin 1974). The results are stated in Cerchar points (Table 1) on a scale from 0 to 150. In addition, for coal samples, Bilgin et al. (1992) formed a cuttability classification by using CHI values that is given in Table 2.

Valantin (1974) found a linear relationship between normal force acting on a pick and Cechar hardness index, and exponential relationship between uniaxial compressive strength and Cerchar hardness index.

Cerman (1988) investigated the effect of thrust force and rotational speed on Cerchar hardness index on marl, calcareous phosphate and carried out a statistical analysis in order to find a relationship between physical and mechanical properties. He found an exponential relationship between thrust force, rotational speed and Cerchar hardness index. He also established a poor exponential relationship between roadheader advance rate in Eyup Tunnel in Istanbul, Turkey and Cerchar hardness index. He compared uniaxial compressive strength with Cerchar hardness index and found that the relationship between Cerchar hardness index at 500 rpm and uniaxial compressive strength had nearly the same trend with Valantin’s (1974) correlation.

Bilgin et al. (1992) found out a linear relationship between uniaxial compressive strength and Cerchar hardness index for coal samples.

Bilgin and Phillips (1994) examined factors affecting the mechanical properties of coal and their testing methods, including coal petrology and strength characteristics of lithotypes; compressive strength and stress–strain characteristics of coal specimens; tensile strength, point load strength, Schmidt rebound hardness values, cone indenter hardness, impact strength index, Cerchar hardness index, Hardgrove grindability index, coal characterization through Vickers microhardness measurements, and strength classification of coal for cuttability assessment.

Bilgin and Kahraman (2003) observed rotary blast hole drills in fourteen rock types at eight open pit mines and correlated the penetration rates with rock properties. They found that the uniaxial compressive strength, the point load strength, Schmidt rebound hardness value, Cerchar hardness index and impact strength showed strong correlations with the penetration rate. The Brazilian tensile strength and cone indenter hardness exhibited quiet good correlations with the penetration rate.

Su and Akcin (2005) investigated relationships between some index tests (Shore sclerescope hardness, cone indenter value, and impact strength index) and Cerchar hardness index on coal samples and evaluated drillability or cuttability of coal samples. They found good relationships between index test results and Cerchar hardness index.

Cerchar hardness test is developed as an index test especially for coal measure rocks. But, there are limited researches between Cerchar hardness index and strength properties for coal measure rocks in literature. The researcher reported in this paper differs from the previous ones in a way that three methods of testing of hardness i.e., Schmidt rebound hardness, Shore scleroscope hardness and Cerchar hardness index are compared with each other using several coal measure rocks.

The goal of this study is to investigate the relationships between Cerchar hardness index and some other indexes as well as strength properties of coal measure rocks encountered in Hard Coal Basin. For this purpose; block samples were collected and prepared for uniaxial compressive strength, Brazilian tensile strength, Shore sclerescope hardness index, point load strength, and Cerchar hardness index tests. Moreover, Schmidt rebound hardness measurements were realized on coal face. Then, the statistical relationships between these parameters are determined. Another purpose of this study is to see whether using a standard drill bit (125°) which is commonly available in the market is suitable for this test instead of using a bit having tip angles of 99° or not.

2 Materials and Methods

The samples are obtained from different coal basins and reported in Table 3. In this study, in situ Schmidt rebound hardness measurements are carried out on twenty-four gallery faces. NX size (54 mm diameter) samples are used for testing in laboratory. The samples are prepared according to ISRM suggestions.

Schmidt rebound hardness (SRH) tests are carried out in field using N-type Schmidt hammer with 2.207 Nm impact energy. Twenty-four rebound values from single impacts separated at least a plunge diameter are recorded and the mean value of the highest 10 readings is considered as suggested by Brown (1981). Each test is repeated at least four times. SRH values are corrected based on a correction factor: C.F. = Specified standard value of the anvil/average of 10 readings taken on the calibrated anvil (Tarkoy 1975).

Uniaxial compressive strength (UCS) tests are performed on trimmed core samples having a length-to-diameter ratio of 2.0–2.5. The stress rate is applied within the limits of 1.0 MPa/s. The tests are repeated five times for each rock type and the results are averaged. The tests are carried out according to ISRM (1979) suggestions.

Brazilian tensile strength (BTS) tests are conducted on core samples having a thickness to diameter ratio of 0.5. A loading rate of 200 N/s is applied. The tests are repeated ten times for each rock type and the results are averaged. The tests are carried out according to ISRM (1978) suggestions.

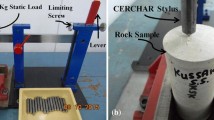

In this study, Cerchar hardness index (CHI) test device modified by Yarali and Akcin (2005) is used to determine the CHI values. The testing device is made up of four basic parts (Fig. 1). These are a bit, a digital chronometer, a vertical weight (to provide compressive force) of 200 N and a horizontal belt which can be changed for three different positions of drill bit as 190, 500 and 700 rpm to adjust rotational speed (standard belt has only position for 190 rpm). The drill distance can be fixed with a button according to demanded drill distance (standard drill distance is 1 cm) and a vertical weight can be adjusted to different weights. The digital chronometer is connected to a switch so, after the completion of drilling time, drilling operation is automatically stopped. Thus, the drilled distance is determined according to the drilling time.

The Cerchar hardness index tests are performed at 190 rpm by using NX core samples. In addition, two bits with different tip angles (99° and 125°), which were produced particularly for 8 mm diameter based on DIN 8039 standards, are used.

Initially, CHI test is applied by using the bit with a 99° tip angle without a spiral for chip removal. The specimen is placed in the clamp. The vertical scale is adjusted for 1 cm and the penetration time is recorded. Then, the bit with tip angle of 125° is attached as same as the bit with tip angle of 99°. The test is repeated at least two times for each rock type for both of the bits. Finally, the average value is determined as CHI.

The Shore sclerescope hardness (SSH) test is used in empirical equations concerning drillability and wearing of drill tools, which is also influenced by rock mineralogy, elasticity and cementation (Rabia and Brook 1978; Altindag 2002). SSH test measures the surface hardness in terms of the elasticity of the material. A diamond-tipped hammer is allowed to fall from a known height on the surface of specimen to be tested and the hardness value depending on the height to which the hammer rebounds is determined. In order to perform the tests, samples are prepared as having 54 mm diameter and 30 mm thickness. Then, the sample surfaces are polished with emery. A D-model scleroscope is used to perform the tests. SSH values are recorded for 20 times in 3 mm spacing on the surface and average value is accepted as SSH value. The tests are carried out according to ISRM (1977) suggestions.

The point load strength (PLS) tests are performed on NX size core samples of coal measure rocks. The tests are carried out diametrally with core specimens having length to diameter ratio greater than 1.0 and axially with core specimens with length/diameter ratio of 1.0. Moreover, the strength anisotropy index (Ia(50)) for each samples is defined as the ratio of mean Is(50) values measured perpendicular and parallel to planes of stratification. The tests are carried out according to ISRM (1985) suggested methods. PLS test was repeated at least ten times for each rock type and the average value is recorded as PLS.

3 Results and Discussions

The average results of all the tests are listed in Table 4. As seen, the range varies from soft to hard rocks: UCS varies from 45 to 128 MPa, BTS varies from 5.9 to 10.8 MPa, SRH varies from 35.6 to 61.5, SCH varies from 20.2 to 45.9, PLT from 2.13 to 9.13 MPa, and CHI from 23 to 250 s.

Firstly, the affect of tip angle of bit on CHI is investigated. According to Fig. 2, there is excellent linear relationship (R2 = 0.9715) between two bits with different tip angles of 99° and 125°. It is determined that the bit having 125° tip angle which is commonly available in the market can be used in CHI instead of the bit having 99° tip angle (Initially, the Cerchar hardness test is applied by using the bit with a 99° tip angle without a spiral for chip removal).

Figure 3 shows the relationship between UCS and CHI for two different bits with tip angle of 99° and 125°. It is clearly seen in Fig. 3 that linear relationships (with high determination coefficient of 0.899 and 0.8977, respectively) are found between two different bits. But the same trend is not seen for BTS and CHI (with low determination coefficients of 0.3612 and 0.3406, respectively) (Fig. 4).

As seen in Figs. 5 and 6, it is found that CHI is related to SRH and SSH with high correlation coefficients for both tip angles of 99° and 125°.

CHI values is correlated with both PLT (axial and diametral) and point load strength anisotropy index (Ia(50)) values. Power relationships are obtained between CHI (bits with tip angle of 99° and 125°) and diametral PLT values (Fig. 7). For these relationships, the determination coefficients of 0.9158 and 0.8708, are found, respectively. However, it is not found a reliable correlation between CHI and axial PLT values. In addition, negative power relationships are found between CHI (bits with tip angle of 99° and 125°) and point load strength anisotropy index values (Fig. 8). For these relationships, the determination coefficients of 0.6791 and 0.6517, are found, respectively.

Ia50 assumes values close to 1.0 for quasi-isotropic rocks and higher values when the rock is anisotropic (ISRM 1985). The Ia50 values of siltstone and mudstone are Ia50 > 1 (anisotropic), for sandstone is Ia (50) < 1 (quasi-isotropic). This situation shows that point load strength anisotropy index is affected on both CHI and drilling time (in Fig. 8).

The statistical relationships between CHI (with two different tip angles of 99° and 125°) and UCS, BTS, SRH, SSH, PLT are investigated by using regression analysis based on the method of least squares. Microsoft ExcelTM is used for the regression equations (Tab. 5). The equation of the best-fit line and coefficient of determination (R2) are determined for each regression. Equations of the best fit curves with 95% confidence limit, observed t- and F-test values at 5% significance level (Table 6), standard error and coefficient of determination (R2) values are determined for each regression. The statistical analyses indicate that the relationships between CHI and UCS, SSH, SRH, diametral PLT, point load strength anisotropy strength index are reliable.

The results of uniaxial compressive strength are compared with the results of other investigators which carried out on less strength materials (tuff, marl, etc.) in Fig. 9. This comparison shows that there is linear relationship between the strength of rock and the drill time.

4 Conclusions

The mechanical properties of coal measure rocks are the most important parameters in designing ground workings and classification of rocks for engineering purposes. Many researchers have constructed portable and easy to use test devices. They investigated the relationships between rock strength, deformation and rock hardness. Cerchar hardness index is indirect index test to be used for defining the strength and cuttability characteristics of coal measure rocks. In this study, a modified Cerchar hardness index test machine is used to determine CHI.

Some index properties (Cerchar hardness index, Shore sclerescope hardness, in situ Schmidt rebound hardness and point load strength) and strength properties (uniaxial compressive strength and Brazilian tensile strength) of 29 sedimentary rock samples are performed using samples collected from Turkish Hard Coal Enterprises, Zonguldak, Turkey, underground gallery faces. During Cerchar hardness index test two kinds of bits with tip angles of 99° and 125° are used. Then, relationships among CHI and both strength and some index test values are evaluated using regression analysis.

The effect of tip angle on Cerchar hardness index (CHI) is also investigated. A linear relationship is determined between bit with tip angle of 99° and bit with tip angle of 125°, with R2 value of 0.9715. Thus, it is found that the bit with tip angle of 125° which is easy to found in market can be used instead of the bit with tip angle of 99° in Cerchar hardness index tests.

The uniaxial compressive strength, Shore sclerescope hardness, Schmidt rebound hardness, diametral point load strength and point load strength anisotropy index exhibit strong correlations with Cerchar hardness index values (tip angle of 99° and tip angle of 125°).

References

AFTES (2003) Guidelines for characterization of rock masses useful for the design and the construction of underground structures. Tunnels et ouvrages Souterrains, France

Altindag R (2002) The evaluation of rock brittleness concept on rotary blasthole drills. J S Afr Inst Min Metall 102:61–66

Atkinson RH (1993) Hardness tests for rock characterization. In: Hudson JA (ed) Comprehensive rock engineering, Chapter 5, 3rd edn. Oxford Pergamon Press, Oxford, pp 105–117

Bilgin N (1989) Applied rock excavation for civil and mining engineering. Birsen Press, Istanbul

Bilgin N, Kahraman S (2003) Drillability prediction in rotary ballast hole drilling. In: Proceedings of the 18th international mining congress and fair of Turkey, Antalya, Turkey, pp 177–182

Bilgin N, Phillips HR (1994) Mechanical properties of coal, coal: resources, properties, utilization, pollution. Istanbul Technical University, İstanbul, pp 127–138

Bilgin N, Phillips HR, Yavuz N (1992) The cuttability classification of coal seams and an example to mechanical plough application in ELI Darkkale coal mine. In: Proceedings of the 8th coal congress of Turkey, Zonguldak, Turkey, pp 31–53

Brown ET (1981) Rock characterization testing and monitoring. Pergamon Press, Oxford

Cerman T (1988) Investigation into the application of Cerchar hardness and abrasivity tests in different rock formations of Amasra Coalfield and Eyup Tunnel. B.Sc. Thesis (unpublish), Dissertation, Istanbul Technical University

Coder M (1973) Etudes experimentales sur le comportement des roches an faurage. These de Docteur de Specialite, Dissertation, Universite Paul_Sabatier de Toulouse

Copur H, Eskikaya S (1992) Investigation into physical and mechanical properties of M2 marl of ELI Eynez Region with particular reference to mechanised excavation. In: Proceedings of the 8th coal congress of Turkey, Zonguldak, Turkey, pp 15–31

Couchard I, Cotthem A, Hick S (2004) The Belgian high-speed railway soumagne tunnel project. Eng Geol 104:475–484

Guarga RL, Muniaini FJL (1997) The Support tunnel construction. Tunnels for People, Rotterdam, Balkema, ISBN 90 5410868, pp 116–119

ISRM (1977) Suggested method for determining hardness and abrasiveness of rock. Int J Rock Mech Min Sci Geomech Abstr 15:89–97

ISRM (1978) Suggested method for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15:99–103

ISRM (1979) Suggested method for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16:135–140

ISRM (1985) Suggested method for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr 22:51–60

Rabia H, Brook N (1978) The Shore hardness of rock. Technical note. Int J Rock Mech Min Geomech Abstr 16:335–336

Shalabi FI, Cording EJ, Al-Hattamleh OH (2007) Estimation of rock engineering properties using hardness tests. Eng Geol 90:138–147

Sofretu FM, Schwenzfeier G (2005) Mechanizated excavation. AFTES Working Group No 4. http://www.aftes.asso.fr

Su O, Akçin NA (2005) Investigation of the relationships between Cerhar hardness index and some index properties of coal. In: Proceedings of the 19th international mining congress and fair of Turkey, İzmir, Turkey, pp 1–17

Tarkoy P (1975) Rock hardness index properties and geotechnical parameters for predicting tunnel boring machine performance. Ph.D. thesis Dissertation, University of Illinois

Valantin A (1974) Examen des différent procèdes classiques de la nocivité des roches vis-à-vis de l’abatage mécanique. Industrie Minérale, Mine, pp 133–140

Yaralı O, Akcin NA (2005) Investigation of relationships between Cerchar hardness index values and strength properties. In: Proceedings of the 19th international mining congress and fair of Turkey, Izmir, Turkey, pp 271–281

Yaralı O, Yasar E, Bacak G, Ranjith PG (2008) A study of rock abrasivity and tool wear in coal measures rocks. Int J Coal Geol 74:53–66

Yasar E, Erdogan Y (2004) Estimation of rock physicomechanical properties using hardness methods. Eng Geol 71:281–288

Acknowledgement

This research supported by Bülent Ecevit University (Project No: 2012-17-11-04), moreover the author wish to acknowledge to Turkish Hard Coal Enterprises due to providing facilities for site investigations, Eren Soyer (min eng, HEMA, TURKEY) for their contribution.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yaralı, O. Investigation into Relationships Between Cerchar Hardness Index and Some Mechanical Properties of Coal Measure Rocks. Geotech Geol Eng 35, 1605–1614 (2017). https://doi.org/10.1007/s10706-017-0195-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0195-y