Abstract

Estimation of rock load is very important parameter to design the support system because it is a function of many parameters such as stress magnitude, rock mass behavior, excavation method and etc. Several methods are used to estimate this parameter such as experimental, empirical and numerical methods. In this study based on the actual collected data from five tunnels in non squeezing ground condition, a new empirical method is proposed to estimate the rock load with considering the post failure behavior of rock mass and it is estimated using the drop to deformation modulus ratio (was named η). Finally the relation between the rock load and the drop to deformation modulus ratio, η, in non squeezing ground condition is estimated. Based on the statistical analysis, the maximum correlation between both parameters is achieved using of Eqs. 9–11 to estimate the drop modulus. It is cleared that the amplitude of η, is high and to increase the correlation between mentioned parameters, the classification of data is performed in two methods, in the first method, all data is classified in two classes such as \(\eta \le 0.1\) and \(\eta > 0.1\) and in the second method, all data is classified in five classes [according to the proposed classification by Hoek and Brown (1997) and Osgoui and Ünal (2009)] as very weak (GSI < 30, ICR < 25, without filling and η < 0.01) to very good classes (10 ≤ η < 10,000 and 65 ≤ GSI < 90). Also a statistical analysis is performed to estimate the rock load using the mentioned parameter (η) in any class. The result shows that there is an inverse relation between both parameters and the best correlation is achieved using of logarithmic equations to estimate the rock load. Also the correlation of first equations obtained from the first method (including two classes such as \(\eta \le 0.1\) and η > 0.1) is higher than other equations (including five classes) so it is proposed that the mentioned equations are used to estimate the rock load.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The possible collapses of a tunnel is a complex problem because it is strongly affected by the several parameters such as rock mass behavior, properties of intact rock and discontinuities, number of joint sets and etc. (Langfor and Diederichs 2013). Geotechnical analysis performed by Szwedzicki (2008) shows that collapses do not happen at random and can be predicted by warning signs such as indicators and precursors. Terzaghi (1946) was one of the first practitioners to propose a rock mass classification system that could be used directly as a basis for identifying rock support requirements. Terzaghi’s rock load concept was shown in Fig. 1. The limitations of Terzaghi’s theory are that it may not be applicable for tunnels wider than 6 m (Singh et al. 1992, 1995, 2007) and provided no quantitative information regarding the rock mass properties (Cecil 1970). Deere et al. (1970) modified Terzaghi’s classification system by introducing the RQD as the lone measure of rock quality (Rose 1982). They have proposed guidelines for selection of rock supports for 6–12 m diameter tunnels in rock mass and distinguished between blasted and machine excavated tunnels. Barton et al. (1974, 1975) and Verman (1993) believed that the support pressure is independent of opening width in rock. Goel et al. (1996) also studied this aspect of effect of tunnel size on support pressure and found that there is a negligible effect of tunnel size on support pressure in non-squeezing ground condition, but the tunnel size could have considerable influence on the support pressure in squeezing ground condition. For a deep tunnel, Unal (1983), proposed correlation to estimate the support pressure using RMR for openings with a flat roof. Goel and Jethwa (1991) have evaluated unal’s equation for application to rock tunnels with arched roof by comparing the measured support pressures with estimates from unal’s equation. The comparison shows that it is not applicable to rock tunnels with arched roof. Bieniawski (1984) proposed guidelines for selection of tunnel supports. This is applicable to tunnels excavated with conventional drilling and blasting method.

Terzaghi’s rock-load concept in tunnels (Terzaghi 1946)

Osgoui and Ünal (2009) suggested a new equation to predict of support pressure by using of GSI. Based on this method the support pressure function depends on the following parameters:

where GSI, is the Geological Strength Index; D, is the disturbance factor; γ, is the unit weight of rock mass; Cs, is the correction factor for the horizontal to vertical field stress ratio (k), and Sq, is the correction factor for the squeezing ground condition. It should be noted that in the aforementioned equations, De is the equivalent diameter of the excavation and it is used for any tunnel shape. It can easily be obtained from:

where A is the cross-section area of the excavation.

\(\sigma_{cr}\) is the residual compressive strength of rock mass in the broken zone around the tunnel where \(\sigma_{cr} = S_{r} \cdot \sigma_{ci}\), S r = post-peak strength reduction factor as explained follow.

The parameter S r characterizes the brittleness of the rock material: ductile, softening, or brittle. By definition, S r will fall within the range 0 < S r < 1, where S r = 1 implies no loss of strength and the rock material is ductile, or perfectly plastic. In contrast, if S r tends to 0, the rock is brittle (elastic–brittle plastic) with the minimum possible value for the residual strength as highlighted in Fig. 2.

Different post-peak strength models of rocks (Osgoui and Ünal 2009)

Limitations and defects of proposed methods to estimate the rock load was described in Table 1.

Numerical methods are employed to predict the rock load but the empirical methods are still widely used due to their simplicity (Fraldi and Guarracino 2010).

The main aim of this work is to propose a new empirical equation to estimate the rock load based on the drop to deformation modulus ratio using the collected actual data from five tunnels in non-squeezing ground condition.

2 Projects Description and Geology

All data used in this paper is collected from five tunnels including Emamzade Hashem, Roodbar, Kaka Reza, Bakhtiary and Karaj in Iran. General specifications of tunnels and geological properties of rock mass are mentioned In Table 2. The collected data including all types conditions of rock mass such as weak (GSI < 25), fair (25 < GSI < 75) and good rock masses (GSI > 75) (according to Fig. 3, Alejano et al. 2009, 2010), that Rock mass of Emamzade Hashem and Roodbar tunnels (except headrace tunnel) is classified as weak to fair classes but Bakhtiary and Kaka Reza rock mass of tunnels is classified as fair condition, also rock masses of headrace tunnel of Roodbar dam and Karaj water conveyance tunnel are classified as fair to good rock mass. The location of tunnels was shown in Fig. 4 and geomechanical properties of rock masses were shown in Table 3.

3 Concept of Drop Modulus

Hoek and Brown (1997) suggested guidelines to estimate the post failure behavior types of rock mass according to rock mass quality. These guidelines are based on rock types: for very good quality hard rock masses, with a high GSI value (70 < GSI < 90), the rock mass behavior is elastic brittle; for averagely jointed rock (50 < GSI < 65), moderate stress levels result in a failure of joint systems and the rock becoming gravely; for heavily jointed rock (40 < GSI < 50), strain softening is assumed; and for very weak rock (GSI < 30), the rock mass behaves in an elastic perfectly plastic manner and no dilation are assumed. The original GSI charts are not capable of characterizing poor and very poor rock mass as denoted by N/A in the relevant parts. By adding measurable quantitative input in N/A parts of existing GSI charts, they will be enhanced in characterizing poor rock mass while maintaining its overall simplicity. Further, the new Modified-GSI chart is considered as a supplementary means for its counterparts (Fig. 5). The modified-GSI chart is valid for poor and very poor rock mass with GSI ranging between 6 and 27. In the case of GSI greater than 27, the existing GSI charts mentioned earlier should be used (Osgoui and Ünal 2009). The strain softening behavior can accommodate purely brittle behavior and elastic perfectly plastic behavior, so brittle and elastic perfectly plastic behaviors are special cases of the strain softening behavior (Alejano et al. 2009, 2010).

Modified-GSI chart suggested to be used in proposed approach (GSI < 27: poor to very poor rock mass), (Osgoui and Ünal 2009)

Strain-softening behavior is characterized by a gradual transition from a peak to a residual failure criterion that is governed by the softening parameter η. In this model when the softening parameter is null, an elastic regime exists, whenever 0 < η < η*, the softening regime occurs and the residual state takes place when η > η*, with η*, defined as the value of the softening parameter controlling the transition between the softening and residual stages. This model is illustrated in Fig. 6. It is obvious that perfectly brittle or elastic–brittle–plastic and perfectly plastic models are special cases of the strain-softening model. The following information is needed to characterize a strain-softening rock mass: (1) Peak and residual failure criteria, (2) elastic parameters (Young’s modulus and Poisson’s ratio), and (3) post-failure deformability parameters. Joints, micro-cracks, and groundwater reduce strength of rock mass. The GSI, as a scaling parameter is used to provide an estimate of the decreased rock mass strength based on the Hoek–Brown criterion. The GSI is an empirically dimensionless number that varies over a range between 10 and 100. By definition, GSI values close to 10 correspond to very-poor-quality rock mass while GSI values close to 100 correspond to excellent-quality rock masses (Hoek and Brown 1997; Marinos and Hoek 2000; Hoek et al. 2002; Cai et al. 2004). When the GSI scale factor is introduced, the Hoek–Brown failure criterion for the rock mass is given as follows (RocScience, RocLab 2002):

The parameter \(m_{b}\), in Eq. 3 depends on the following: the intact rock parameter, \(m_{i}\), the value of GSI, and disturbance factor D, as defined by the equation:

D is a factor which depends upon the degree of disturbance to which the rock mass has been subjected by blast damage and stress relaxation. According to Table 4, it varies from 0 for undisturbed in situ rock masses to 1 for very disturbed rock masses in tunnels (Hoek and Brown 1997; Hoek et al. 2002, 2008). The parameter, s, depends empirically on the value of GSI and D as follows,

The parameter, a, also depends empirically on the value of GSI, as follows:

Determining the appropriate value of \(\sigma_{3}\) for use in Eq. 3 is very important. It is estimated based on Eq. 7:

where \(\sigma_{cm}\), is the rock mass strength, defined by Eq. 8, \(\gamma\), is the unit weight of the rock mass and H, is the depth of the tunnel below surface. In case the horizontal stress is higher than the vertical stress, the horizontal stress value should be used in place of \(\gamma \cdot H\) (Hoek et al. 2002).

where C is the cohesion of rock mass and Φ is the friction angle of rock mass.

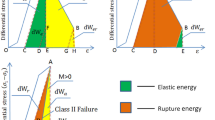

The slope for the softening stage or drop modulus is denoted by M. if the drop modulus approach to infinity, perfectly brittle behavior appears, whereas perfectly plastic behavior is obtained if this modulus approaches to zero (Alejano et al. 2010).

One of the most important parameters effect on drop modulus is confinement stress as with increasing this parameter, the rock mass behaviors become more and more ductile and finally behave ideally plastic (Rummel and Fairhurst 1970) and drop modulus tend to zero and with decreasing the confinement pressure, the rock mass behavior tend to brittle and the drop modulus increases to infinite. The conclusion of Seeber Carranza-Torres and Fairhurst (2000) showed that ideally plastic behavior, without strain softening post failure, may be expected when the confinement pressure σ 3, is equal to or greater than one-fifth of the axial stress at failure (Fig. 7).

Dependence of the post-failure behavior of granite samples on the confinement pressure. a Results of a numerical simulation of the 3-axial tests. b Schematic behavior (Egger 2000)

Assuming the failure criterion of Hoek and Brown, based on Seeber’s condition, the relation between the confinement pressure and the uniaxial compressive strength \(\sigma_{c}\), of the intact rock can be obtained (Egger 2000). This relation can be approximated by:

where, \(m_{b}\), is the product of a parameter m depending on the lithology, with a reduction factor depending on the degree of fracturing of the rock.

As mentioned above it has been observed in the field that the deformability post-failure behavior of rock masses is highly dependent on rock mass quality and confinement stress. Based on these observations, the following values proposed by Alejano et al. (2009, 2010) to estimate the drop modulus of the rock mass according to the peak rock mass quality given by GSI peak and to the level of confinement stress expressed in terms of the rock mass compressive strength given by \(\sqrt {s^{peak} } \cdot \sigma_{ci}\). The values obtained thus take into account the assumption of a continuous trend, from brittle behavior in high-quality rock masses subjected to unconfined conditions, to pure ductile behavior in poor-quality rock masses for extremely high confinement stresses. The value of the drop modulus depends on the deformation’s modulus E rm , according to:

The value of the ratio \(\omega\), depends on the GSI peak and confinement-stress level and can be estimated according to:

The deformation modulus Erm can be obtained by following Hoek and Diederichs approach (2006) because more effective factors on deformability such as the elastic modulus of intact rock Ei, disturbance factor D and GSI were used in this equation.

If confinement stresses is not considered in calculation, the drop modulus can be estimated according to Eq. 13:

A more complex approach to estimate of drop modulus, including the effect of \(\sigma_{ci}\), is:

The following equation is used as a first approach to estimate the drop modulus, if one uses more complex strain softening models with confinement stress dependent drop modulus (Alejano et al. 2009, 2010):

The most complex equation to estimate the drop modulus is defined as:

The Eq. 17 is used for GSI ranges from 20 to 75 and more effective factors such as GSI, confinement stress, \(\sigma_{3}\), unixial strength of intact rock \(\sigma_{ci}\), are applied in this equation (Alejano et al. 2009, 2010).

All mentioned equations were used to estimate the drop modulus in this paper.

4 Estimating of Rock Load in Non-squeezing Ground Condition

In this section based on actual collected data from five tunnels (140 data, Soleiman Dehkordi et al. 2011, 2013, 2014) the absolute value of the drop to deformation modulus ratio (η) was estimated according to the next equation:

The drop modulus was estimated using the mentioned equations in previous section.

the maximum and minimum of \(\eta\), varied between 0.004711–9995.03 and it depend on quality of rock mass and confinement stress so that an increase the confinement stress and a decrease quality of rock mass can cause to decrease of \(\eta\), and it can be true inversely.

Finally the relation between the rock load and the drop to deformation modulus ratio, η, in non squeezing ground condition is estimated according to the next equation (Fig. 8).

Based on the statistical analysis, the maximum correlation between both parameters is achieved using of Eqs. 9–11 to estimate the drop modulus. It is cleared that the amplitude of \(\eta\), is high and to increase the correlation between mentioned parameters, the classification of data based on mentioned parameter is adopted in two classes including \(\eta \le 0.1\) and \(\eta > 0.1\). It is shown in Figs. 9 and 10. Based on the regression analysis, there is an inversely relation between both parameters and the best correlation is achieved by logarithmic equations. The Eqs. (20) and (21) are proposed to estimate the rock load:

In the next section, the classification of rock mass with considering the geological strength index [proposed Hoek and Brown (1997) and Osgoui and Ünal (2009)] is performed based on the drop to deformation modulus ratio (\(\eta\)) and all data is classified in five classes as very weak (GSI < 30, ICR < 25, without filling and \(\eta\) < 0.01) to very good classes (65 ≤ GSI < 90 and 10 ≤ \(\eta\) < 10,000) and the statistical analysis to estimate the rock load is performed in any class and at the end, estimation of the rock load by using of proposed equations of two methods including without considering the classification based on the geological strength index (GSI) and with considering the classification based on the mentioned parameter is performed and the result of two methods is compared. The data frequency of the drop to deformation modulus ratio is shown in Fig. 11.

4.1 Estimating of Rock Load in Very Weak Rock Mass Condition (GSI < 30, ICR < 25, Without Filling and \(\eta\) < 0.01)

As mentioned above with decreasing the quality of rock mass and increasing the confinement stress, the drop to deformation modulus ratio intended to zero and the behavior of rock mass changed to elastic–plastic. In this class (GSI < 30, ICR < 25, without filling and \(\eta\) < 0.01), the quality of rock mass was very weak and the rock mass behavior was elastic–perfectly plastic and the rock load was very high. Based on the regression analysis, there was an inversely relation between both parameters and the best correlation was achieved by logarithmic equation. It was shown in Fig. 12. The following equation was achieved to estimate the rock load:

4.2 Estimating of Rock Load in Weak Rock Mass Condition (GSI < 30, ICR < 25, with Filling and 0.01 ≤ \(\eta\) < 0.05)

In this class (GSI < 30, ICR < 25, with filling and 0.01 ≤ \(\eta\) < 0.05), the quality of rock mass was weak and the rock load was high and the rock mass behavior tend to elastic–strain softening slowly. Based on the regression analysis, there was an inversely relation between both parameters and the best correlation was achieved by logarithmic equation. It was shown in Fig. 13. The Eq. (23) was proposed to estimate the rock load:

4.3 Estimating of Rock Load in Favorable Rock Mass (\(0.05 \le \eta < 0.1\) and 30 ≤ GSI < 50)

In this class (\(0.05 \le \eta < 0.1\;{\text{and}}\;30 < GSI < 50\)), the condition of rock mass was favor and the rock mass behavior was elastic–strain softening and the rock load decreased. Based on the regression analysis, there was an inversely relation between both parameters and the logarithmic equation was proposed to estimate the rock load (according to Fig. 14). The next equation was achieved to estimate the rock load:

4.4 Estimating of Rock Load in Good Rock Mass (\(0.1 \le \eta < 10\;{\text{and}}\;50 \le GSI < 65\))

The rock mass condition of this class was good and the rock mass behavior tends to elastic–brittle and the rock load was low. According to Fig. 15, there was an inversely relation between the drop to deformation modulus ratio and rock load and the logarithmic equation was proposed to estimate the rock load. The Eq. 25 was achieved to estimate the rock load:

4.5 Estimating of Rock Load in Very Good Rock Mass Condition (\(10 \le \eta < 10{,}000\;{\text{and}}\,65 \le GSI < 90\))

It is cleared that increasing the quality of rock mass and decreasing the confinement stress, caused to the drop to deformation modulus ratio tend to infinity and the behavior of rock mass changes to elastic–brittle. In this class (\(10 \le \eta < 10{,}000\;{\text{and}}\;65 \le GSI < 90\)), the quality of rock mass was very good and the rock mass behavior was elastic–perfectly brittle and the rock load intended to zero. Based on the regression analysis, there was an inversely relation between both parameters and the best correlation was achieved by logarithmic equation. It was shown in Fig. 16. The following equation was proposed to estimate the rock load:

4.6 Validation of Proposed Method to Estimate the Rock Load

Validation of proposed method is adopted using of the diversion tunnel information of the Sulakyurt dam of Turkey. The Sulakyurt dam site constructed on the Taretözü stream, in the central part of Turkey (Fig. 17, Basarir 2006). The length of the diversion tunnel is 260 m and the tunnel diameter is 3 m (Basarir 2006). It is located within Sulakyurt magmatic, consisting of the granite and diorite rock masses of Palaeocene and Quaternary deposits. Granites and diorites are moderately to highly weathered (Basarir 2006). Geology longitudinal profile of Sulakyurt tunnel is given in Fig. 18 (Basarir 2006). The properties of rock mass surrounding the tunnel is shown in Table 5.

Location map of Guledar dam site (Basarir 2006)

Geology longitudinal profile of Sulakyurt tunnel (Basarir 2006)

The radius of plastic zone in granite and diorite sections of Sulakyurt tunnel obtained from the convergence–confinement and finite element methods (calculated by Basarir) is shown in Table 6. The drop to deformation modulus ratio in granite and diorite sections of tunnel is respectively 0.0495 and 0.0266 and the rock load estimated based on the Eqs. 19 and 22 are respectively 3.85, 5.84 and 3.9, 5.7 m. The results show that there is good accordance between the obtained results of the proposed methods with the convergence–confinement and finite element methods (calculated by Basarir 2006). Also the correlation of Eqs. 19 and 20 is higher than other equations (estimated based on proposed method with considering the classification based on GSI) so it is proposed that the mentioned equations are used to estimate the rock load.

5 Conclusion

Strain-softening behavior was used to model of rock mass in this paper because perfectly brittle or elastic–brittle–plastic and perfectly plastic models are special cases of this behavior. By reason it is strongly capable to represent the macroscopic results commonly observed in practice. The results of model showed that increasing the quality of rock mass and decreasing the minimum principal stress can cause to increase the drop to deformation modulus ratio (η) and decrease the rock load, H p , inversely, because the rock mass behavior changes from elastic plastic to elastic brittle and drop modulus intended to infinite and it can be true inversely. Based on the statistical analysis, the maximum correlation between both parameters was achieved using of Eqs. 9–11 to estimate the drop modulus. Finally the relation between the rock load and the drop to deformation modulus ratio, η, in non squeezing ground condition is estimated. It is cleared that the amplitude of \(\eta\), is high and to increase the correlation between mentioned parameters, the classification of data is performed in two methods, in the first method, all data is classified in two classes such as \(\eta \le 0.1\) and \(\eta > 0.1\) and in the second method, all data is classified in five classes [according to the proposed classification by Hoek and Brown (1997) and Osgoui and Ünal (2009)] as very weak (GSI < 30, ICR < 25, without filling and \(10 \le \eta < 0.01\)) to very good classes (\(\eta < 10{,}000\;{\text{and}}\;65 \le GSI < 90\)). Also a statistical analysis is performed to estimate the rock load using the mentioned parameter (\(\eta\)) in any class. The result shows that there is an inverse relation between both parameters and the best correlation is achieved using of logarithmic equations to estimate the rock load. Also the correlation of first equations obtained from the first method (including two classes such as \(\eta \le 0.1\) and \(\eta > 0.1\)) is higher than other equations (including five classes) so it is proposed that the mentioned equations are used to estimate the rock load. Finally, it is emphasized that the empirical relation should not be used alone for design purpose.

References

Alejano LR, Alonso E, Rodriguez-Dono A, Fernandez-Manin G (2010) Application of the convergence-confinement method to tunnels in rock masses exhibiting Hoek–Brown strain-softening behavior. Int J Rock Mech Min Sci 47(1):150–160

Alejano LR, Rodriguez-Dono A, Alonso E, Fdez-Manin G (2009) Ground reaction curves for tunnels excavated in different quality rock masses showing several types of post-failure behavior. Tunnel Undergr Space Technol 24(6):689–705

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. In: NGI publication no. 106, Oslo, p 48

Barton N, Lien R, Lunde J (1975) Estimation of support requirements for underground excavations. In: XVIth symposium on rock mechanics, University of Minnesota, Minneapolis, pp 163–177

Basarir H (2006) Engineering geological studies and tunnel support design at Sulakyurt dam site, Turkey. Eng Geol 86:225–237

Bieniawski ZT (1984) Rock mechanics design in mining and tunnelling. A.A. Balkema, Rotterdam, pp 97–133

Cai M, Kaiser PK, Uno H, Tasaka Y, Minamic M (2004) Estimation of rock mass deformation modulus and strength of jointed rock masses using the GSI system. Int J Rock Mech Min Sci 41(1):3–19

Carranza-Torres C, Fairhurst C (2000) Application of the convergence-confinement method of tunnel design to rock masses that satisfy the Hoek Brown failure criterion. Tunn Undergr Space Technol 15(2):187–213

Cecil OS (1970) Correlation of rock bolts—shotcrete support and rock quality parameters in Scandinavian tunnels. PhD thesis, University of Illinois, Urbana, p 414

Deere DU, Peck RB, Parker H, Monsees JE, Schmidt B (1970) Design of tunnel support systems. High Res Rec 339:26–33

Egger P (2000) Design and construction aspects of deep tunnels (with particular emphasis on strain softening rocks). In: Published in tunnels under pressure, the proceedings of the AITES-ITA 2000 world tunnel congress

Fraldi M, Guarracino F (2010) Analytical solutions for collapse mechanisms in tunnels with arbitrary cross sections. Int J Solids Struct 47:216–223

Goel RK, Jethwa JL (1991) Prediction of support pressure using RMR classification. In: Proceedings of Indian Geotechnical conference, Surat, pp 203–205

Goel RK, Jethwa JL, Dhar BB (1996) Effect of tunnel size on support pressure. Int J Rock Mech Min Sci Geomech Abstr Pergamon 33(7):749–755

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Sci Geomech Abstr 34(8):1165–1187

Hoek E, Diederichs MS (2006) Empirical estimates of rock mass modulus. Int J Rock Mech Min Sci 43:203–215

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek–Brown failure criterion—2002 ed. In: Proceedings of the NARMS-TAC 2002, Mining Innovation and Technology. Toronto, pp 267–273

Hoek E, Carranza-Torres C, Diederichs MS, Corkum B (2008) Kersten Lecture Integration of geotechnical and structural design in tunnelling. In: 56th annual geotechnical engineering conference, University of Minnesota

Langfor JC, Diederichs MS (2013) Reliability based approach to tunnel lining design using a modified point estimate method. Int J Rock Mech Min Sci 60:263–276

Marinos P, Hoek E (2000) GSI—a geologically friendly tool for rock mass strength estimation. In: Proceedings of GeoEng 2000 conference, Melbourne

Osgoui RR, Ünal E (2009) An empirical method for design of grouted bolts in rock tunnels based on the Geological Strength Index (GSI). J Eng Geol 107:154–166

RocScience, RocLab (2002) Rocscience Inc., Toronto

Rose D (1982) Revising Terzaghi’s tunnel rock load coefficients. In: Proceedings of 23rd U.S. symposium rock mechanics, AIME, New York, pp 953–960

Rummel F, Fairhurst G (1970) Determination of the post-failure behaviour of brittle rock using a servo-controlled testing machine. Rock Mech 2:189–204

Singh B, Jethwa JL, Dube AK, Singh M (1992) Correlation between observed support pressure and rock mass quality. Int J Tunnel Undergr Space Technol Pergamon 7(1):59–74

Singh B, Jethwa JL, Dube AK (1995) A classification system for support pressure in tunnels and caverns. J Rock Mech Tunnel Technol India 1(1):13–24

Singh M, Singh B, Choudhari J (2007) Critical strain and squeezing of rock mass in tunnels. Tunnel Undergr Space Technol 343–350

Soleiman Dehkordi M, Shahriar K, Maarefvand P, Gharouninik M (2011) Application of the strain energy to estimate the rock load in non-squeezing ground condition. Arch Min Sci 56(3):551–566

Soleiman Dehkordi M, Shahriar K, Maarefvand P, Gharouninik M (2013) Application of the strain energy to estimate the rock load in squeezing ground condition of Emamzade Hashem tunnel in Iran. Arab J Geosci 6(4):1241–1248

Soleiman Dehkordi M, Lazemi HA, Shahriar K (2014) Application of the strain energy ratio and the equivalent thrust per cutter to predict the penetration rate of TBM, case study: Karaj-Tehran water conveyance tunnel of Iran. Arab J Geosci. doi:10.1007/S12517-014-1495-7

Szwedzicki T (2008) Precursors to rock mass failure in underground mines. Arch Min Sci 53(3):449–465

Terzaghi K (1946) Rock defects and loads on tunnel support. In: Proctor RV, White TL (eds) Introduction to rock tunnelling with steel supports. Commercial Sheering & Stamping Co., Youngstown, p 271

Unal E (1983) Design guidelines and roof control standards for coal mine roofs. PhD thesis, Pennsylvania State University, University Park, p 355

Verman MK (1993) Rock mass—tunnel support interaction analysis. PhD thesis, IIT Roorkee, Roorkee, p 258

Acknowledgments

The authors are indebted to staff of all consulting engineers, contractors and employers to offer data to us and to any people who help to us to preparation this paper. The authors are also indebted to Reviewers, whose comments lead to a hopefully more accurate estimation of rock load.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soleiman Dehkordi, M., Lazemi, H.A., Shahriar, K. et al. Estimation of the Rock Load in Non-squeezing Ground Condition Using the Post Failure Properties of Rock Mass. Geotech Geol Eng 33, 1115–1128 (2015). https://doi.org/10.1007/s10706-015-9891-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-015-9891-7