Abstract

Experiments in fields and micro-plots were conducted to investigate the optimal cropping system and nitrogen (N) fertilizer application rate and timing. The treatments consisted of Chinese milk vetch–rice (CMV–R) rotation with five N fertilizer application rates (0, 120, 180, 240, 300 kg N ha−1) during the rice-growing season, and fallow–rice (F–R) and wheat–rice (W–R) rotations with only one N application rate (240 kg N ha−1) each. Rice yield increased with increasing N fertilizer application rate under CMV–R rotation, and achieved highest yield under CMV–R180. There is a decreasing trend when N application rate exceeded 180 kg N ha−1. Rice yield was always higher under CMV–R240 compared to W–R240 and F–R240. During the 2012 rice season, the fertilizer N-use efficiency, residual N fertilizer in soil and N fertilizer recovery efficiency of CMV–R180 reached largest under CMV–R rotation with different N treatments. Furthermore, the fertilizer N-use and recovery efficiencies of CMV–R240 and F–R240 were far higher than those of W–R240. In 2013, fertilizer N-use efficiency was the highest (> 50%) at the heading stage, which was nearly twice as much as the efficiencies during the basal and tillering stages. The N fertilizer loss rate during the basal stage was significantly higher than that at the tillering and heading stages, which was up to 60%. CMV–R rotation with 180 kg N ha−1 achieved the highest rice yield of 9454 kg ha−1 and high fertilizer N-use efficiency (40.6%) under a relatively lower N application rate. Therefore, Chinese milk vetch–rice cropping system could be a promising approach for decreasing fertilizer inputs to prevent N pollution problems and increasing rice yield, especially for the intensive rice-based cropping systems in southern China.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rice (Oryza sativa), as one of the most important and stable food crops especially in Asia, feeds nearly half of the world’s population (Muthayya et al. 2014). With the continuous increase in world population, rice production plays a more important role in food security (Jing et al. 2008). As the primary limited nutrient factor in agriculture, nitrogen (N) is extremely important for maintaining crop yields and improving grain qualities (Fageria and Baligar 2005; Ladha and Chakraborty 2016; Mohammed et al. 2013). However, many farmers apply N fertilizer more than necessary to ensure high rice production. Excessive N fertilizer and improper application methods not only increase input costs, but also result in low N-use efficiency, high fertilizer losses through nitrate leaching and surface runoff, and atmosphere breakup through ammonia (NH3) volatilization and nitrous oxide (N2O) emission (De Datta and Buresh 1989; Min et al. 2012; Shang et al. 2014; Vlek and Byrnes 1986; Xing and Zhu 2000). Such N losses eventually lead to nitrate pollution of groundwater, eutrophication of water systems, and rise of greenhouse gas concentrations in atmosphere. Therefore, both environmental and economic factors must be simultaneously considered to ensure efficient utilization of N fertilizers for sustainable crop production (Delin et al. 2008; Stevens et al. 2005).

Rice is the predominant crop in the Taihu Lake region of southern China, which is often grown from June to November. The subsequent wheat season starts from November to the following May. The rice–wheat rotation system is the most important and prevailing rice-based agroecosystem in this region, which has high N fertilizer inputs (240–300 kg N ha−1 for rice and 200–250 kg N ha−1 for wheat) (Zhao et al. 2015). However, the economic benefit of planting wheat is very low in winter, and leaching loss of N is higher than that during the rice season (Zhao et al. 2012; Zhu 2008). There are many labor-intensive businesses in the Taihu Lake region, which results in a labor shortage in agricultural production. Recently, fallow farmland has become an increasingly common phenomenon in this area during the winter (Yu et al. 2014).

In China, cereal grain yields increased by 65% from 1980 to 2010, but at the same period, the utilization of chemical fertilizers also increased by 512% (Zhang et al. 2011). The Taihu Lake region is one of the most important rice-producing areas in southern China. To ensure production, a large amount of N fertilizer is put into paddy fields. However, rice yields have barely increased from excessive application of fertilizer N, and fertilizer N-use efficiency has significantly decreased. Most farmers have applied topdressing fertilizer based on their experiences, regardless of the appropriate amount and optimal timing of topdressing fertilizer as well as the inherent capacity of soil to supply N in such rice production systems.

Native soil N supply capacity declines rapidly with continuous rice cultivation unless it is restored by biological nitrogen fixation (BNF) (Fageria et al. 2003). Legumes have been proved to be beneficial for stable soil fertility and crop production (Mazzoncini et al. 2011; Shafi et al. 2007). Green manure crops can offer abundant organic matter, which improves soil physical, chemical and biological properties, maintains soil nutrients and productivity, and eventually sustains crop yields (Douglas et al. 1998; Fageria et al. 2005). Substituting winter legumes for wheat not only decreases ammonia volatilization and N loss due to runoff, but also improves rice yield and soil N supply (Yu et al. 2014; Zhao et al. 2015). Moreover, growing legumes in fallow fields after harvesting main crops can increase solar energy capture and C flux into soil, and thereby supply soil macro- or micro-organisms with food (Dabney et al. 2001).

The present study was established on a long-term field trial, where field micro-plot (labeled 15N fertilizer) experiments were also conducted. The objectives of our study were to investigate, (1) What are the effects of the preceding phases (Chinese milk vetch, fallow and wheat) on rice yields, the fertilizer N-use and recovery efficiencies in rice season?; (2) how does the timing of N fertilizer application (basal, tillering and heading stages) affect rice fertilizer N use and recovery efficiencies under different rice-based cropping systems? The results of our study will play an important role in guiding comprehensive promotion and application of legumes as substitutes for wheat and fallow under rice-based cropping systems in southern China.

Materials and methods

Experimental site information

Experiments were conducted at the Changshu Agricultural Ecology Experiment Station, Jiangsu, China (120°42′E, 31°33′N). The station is located in the Taihu Lake region in the humid subtropical climate zone of southern China. The location has an average annual precipitation of 1200 mm and average temperature of 16.0 °C over the past 10 years. The soil is a Hydragric Anthrosol (IUSS Working Group WRB 2007) developed from lacustrine deposits. Right before the long-term field experiment (2007), soil samples from the top 0.15 m of surface soil contained 2.17 g kg−1 of total nitrogen (Kjeldahl method), 0.82 g kg−1 of total phosphorus (Mo–Sb colorimetry after digested by H2SO4 and HClO4), 38.2 g kg−1 of organic matter (K2Cr2O7-volumetric method), 13.1 mg kg−1 of plant available P (Mo–Sb colorimetry after NaHCO3 extraction), 174 mg kg−1 of plant available K (Flame spectrometry after NH4OAc extraction), and had a pH of 7.6 (tested in a sample containing a 1:2.5 ratio of soil to water).

Field experiments

Chinese milk vetch (Astragalus sinicus L.)-rice (CMV–R) rotation is cultivated for the long-term experiment that has been under way since 2007, which includes five N treatments: 0 kg N ha−1 (CMV–R0), 120 kg N ha−1 (CMV–R120), 180 kg N ha−1 (CMV–R180), 240 kg N ha−1 (CMV–R240) and 300 kg N ha−1 (CMV–R300). The two control treatments consist of a fallow–rice (F–R) rotation with 240 kg N ha−1 (F–R240), and a wheat–rice (W–R) rotation with 240 kg N ha−1 (W–R240). In the past, 240 kg N ha−1 was the recommended N fertilizer application rate to guarantee high rice yield in the Taihu Lake region. The plots (25.76 m2) were completely randomized in the experimental field with three replications. For rice cultivation, N fertilizer was applied based on above treatments, and both P and K fertilizers were supplied 20 and 60 kg ha−1, respectively. For wheat cultivation, N, P and K fertilizers were applied at 225, 30 and 60 kg ha−1, respectively. For Chinese milk vetch cultivation, N, P and K fertilizers were applied at 0, 30 and 60 kg ha−1, respectively. No fertilizers were applied into winter fallow plots. N fertilizer was separately applied at basal, tillering and heading stages (4:2:4) in rice season. The N fertilizers were applied on 19 June, 5 July, and 13 August in 2012, and on 22 June, 7 July and 14 August in 2013. The P fertilizer was completely applied at the basal stage. The K fertilizer was applied twice, half at the basal stage and half at the heading stage. The fertilizers applied at the basal stage were thoroughly incorporated into the soil by ploughing, and topdressings were applied through surface broadcast by hand. Approximately 40 days before transplanting rice seedlings, the above-ground parts of Chinese milk vetch were chopped into about 0.1 m pieces and incorporated into the paddy soils by ploughing. The rice seedlings were transplanted on 20 June in 2012 and 23 June in 2013. The winter crops were sowed on 8 November in 2012 and 13 November in 2013.

Micro-plot experiments

After plowing in 2012, single polyvinyl chloride (PVC) tubes were installed as micro-plots within field plots on 5 June in 2012 (except G-R0). The lower ends of these tubes were hammered vertically into the soil to a depth of 0.45 m, and the upper ends extended approximately 0.15 m above the soil surface. Twelve rice seedlings were planted in each of these PVC tube micro-plots. The mineral fertilizers application rates of micro-plots were converted according to the field experiments, but 15N-labeled urea (10.15 atom% 15N) was supplied as N fertilizer. On 9 June in 2013, we installed three PVC tubes randomly into each of the G-R180, G-R240, F–R240 and W–R240 field plots at different locations compared to 2012. 15N-labeled urea with 20.12 atom% 15N was used in 2013. Table 1 provides the specific details of applying N fertilizer in the three PVC tubes of each field plot. The topdressing periods of micro-plots were consistent with the field experiments. Consistent with the local practice, the paddy fields were continuously flooded with water to a depth of 0.03–0.05 m, and then drained midseason for 1 week, followed by intermittent irrigation until harvest. Before the winter crop season, drainage ditches were dug to protect winter crops from waterlogging damage.

Sample collection and measurement

Rice yield determination in the field experiment: After rice matured, it was harvested manually from each field plot. The grains were separated from rice straws using a thresher and air-dried at about 25 °C in the sunshine for 10 days. Rice yield of each plot was weighted and recorded. About 500 g grains sampled from each plot were further air-dried for 15 days and the rice yields were calculated by deducting the moisture content.

Collection of rice samples from micro-plots: the above-ground parts of the rice plants were sampled during late October 2012, then the first 0–0.2 m of surface soil was dug out and the roots were manually collected. Previous research indicated that 90% roots of a rice plant are distributed in the top 0–0.2 m soil layer in rice paddies (Zhang et al. 2003). In 2012, the plants were washed to remove soil, separated into roots, straws and grains. In 2013, washed plants were divided into roots, straws, leaves and grains. All samples were dried at 70 °C, weighed and ground to powder.

Collection of soil samples from micro-plots: According to previous results, N fertilizer infiltration (leaching) depth cannot exceed 0.4 m in the present trial area (Tian et al. 2009). Therefore, we collected soil samples from 0 to 0.1, 0.1 to 0.2, 0.2 to 0.3 and 0.3 to 0.4 m soil depths after rice harvest in 2013. Soil samples were collected using a hollow auger with scale. Each sample represented a mixture of samples taken from five locations in each micro-plot. The soil samples were air-dried in the shade and ground to pass through a 0.149-mm sieve prior to analysis. The 15N-labeled soil and plant samples were then analyzed for soil total N content and atom% 15N using a mass spectrometer (Flash EA-Delta V, Thermo Fisher, USA).

Statistical calculations and analysis

Fertilizer N-use efficiency (%) was calculated as

Residual N fertilizer in soil (%) was calculated as

Fertilizer N recovery efficiency (%) was calculated as = a + b.

The data were analyzed using SPSS 20.0 (2011, IBM, New York, USA). Data are means of three repetitions. Differences between relative distribution proportion of 15N fertilizer in plant and its fate in 2013 were examined by a two-way analysis of variance (ANOVA; Tables 6, 7), which were affected by the timing of N application, rotations and their interaction. Following the one-way analysis of variance (ANOVA) for other experimental treatments, differences between means were compared using Fisher’s least significant difference (LSD) test.

Results

Rice yields under different rotation systems

Rice yields under different rotation systems and N application rates greatly increased from 2008 to 2011 except for G-R0 (Table 2). From 2011 to 2013, rice yields of CMV–R0 and CMV–R120 continued to increase, while which barely increased for CMV–R180, CMV–R240, CMV–R300 as well as W–R240 and F–R240. For the CMV–R rotation system, no N fertilizer application resulted in the lowest rice yields, and rice yield increased with increasing N fertilizer application. There were no significant differences among CMV–R180, CMV–R240 and CMV–R300, but eventually the CMV-180 achieved the highest rice yield in 2013. Moreover, the highest rice yield increased by 31.2% when comparing yield of CMV–R180 in 2013 with that of CMV–R240 in 2008.

Among three rotation systems with 240 kg N ha−1, rice yield under CMV–R240 was always higher than those under W–R240 and F–R240, and rice yields between W–R240 and F–R240 had no significant differences. After long-term rotations, the total soil N content already exceeded the initial value (2.17 g kg−1) (Table 3). The soil N content gradually increased with the increase of N application. The soil N content of CMV–R300 was highest. There were no significant differences between CMV–R0 and CMV–R120, or between CMV–R180 and CMV–R240. The total N content of soil under CMV–R240 and W–R240 was higher than that of F–R240.

Fate of labeled 15N fertilizer in 2012

Fertilizer 15N-use efficiency, residual N fertilizer in soil and total N recovery efficiency all increased at first and then decreased from 120 to 300 kg N ha−1 under the CMV–R rotation (Table 4). CMV–R180 resulted in the highest fertilizer 15N-use efficiency, residual N fertilizer in soil and total N recovery efficiency, which under CMV–R300 were significantly lowest among CMV–R rotation with different N application rates.

Different rotation systems with 240 kg N ha−1 had great effects on the 15N fertilizer use efficiency, residual N fertilizer in soil, and total N recovery efficiency (Table 4). The fertilizer N-use efficiencies under CMV–R240 and F–R240 exceeded that under W–R240 by 55.6 and 58.8%, and the N recovery efficiencies under CMV–R 240 and F–R240 exceeded that under W–R240 by 66.0 and 44.3%. Residual N fertilizer in soil under CMV–R240 was the highest (24.6%), and there was no difference between W–R240 and F–R240.

Comparisons of N content and 15N content in rice

Under CMV–R240, the N contents of rice roots, straws, leaves, grains and total N content were higher than those under CMV–R180, W–R240 and F–R240 in most cases (Table 5). Almost 50% N assimilated by rice plants was distributed in rice grains. The 15N content derived from fertilizer in rice under F–R240 was higher than those under CMV–R180, CMV–R240 and W–R240, and that under CMV–R180 was the lowest. The proportion of the 15N content accounted for total N content in rice was in the following order: F–R240 > W–R240 > CMV–R240 > CMV–R180.

Relative distribution proportions of 15N fertilizer in rice under different N application periods

The fertilizer 15N distribution in different rice organs was significantly affected by the timing of N application or rotation systems, but not by the interaction between these two factors except for the straws (Table 6). There was almost twice as much 15N fertilizer in the roots or leaves during the basal and tillering stages compared to that at the heading stage. The fertilizer 15N in straws under CMV–R240 was higher than that under W–R240 or F–R240 at the basal fertilizer stage. However, more 15N fertilizer was distributed in straws under W–R240 than those under CMV–R240 and F–R240 at tillering and heading stages. The 15N fertilizer distributed in grains accounted for more than 40% of total 15N fertilizer in rice during the basal and tillering stages. Fertilizer 15N contributed relatively more to the rice grains at the heading stage than at the basal and tillering stages. Furthermore, fertilizer 15N distributed in rice grains under CMV–R240 and F–R240 was higher than that under W–R240 at the heading stage.

Fate of 15N fertilizer under different N application periods in 2013

The 15N fertilizer use efficiency, residual 15N fertilizer in soil and total 15N fertilizer recovery efficiency were significantly influenced by the timing of N application or rotation systems and the interaction between them (Table 7). Fertilizer 15N-use efficiency reached more than 50% at the heading stage, and which was twice higher than those at basal and tillering stages. Residual 15N fertilizer in soil under CMV–R240 exceeded that under F–R240 by 30.6 and 43.6% at the tillering and heading stages, respectively. It was 95.3 and 23.5% higher than that under W–R240 at the tillering and heading stages, respectively. The total 15N fertilizer recovery efficiency was lowest at the basal fertilizer stage. However, applying N fertilizer at the heading stage resulted in the highest 15N fertilizer recovery efficiency. The total 15N recovery efficiencies under W–R240 were lower than those under CMV–R240 and F–R240 at basal and tillering stages.

Comparisons of distribution in rice and fate of 15N fertilizer between CMV–R180 and CMV–R240 in 2013

The 15N fertilizer distributed in rice roots, straws, leaves and grains had no differences between CMV–R180 and CMV–R240 no matter which N application stage (Table 8). The 15N fertilizer distributed in rice roots and leaves was significantly higher at basal and tillering stages than at the heading stage. The 15N fertilizer was distributed in grains at the heading stage more than that at the basal and tillering stages. There were no significant differences among fertilizer 15N-use efficiency, residual 15N fertilizer in soil and total 15N fertilizer recovery efficiency between CMV–R180 and CMV–R240 at basal and tillering stages. However, at the heading stage, they were significantly higher under CMV–R180 than that under CMV–R240. The fertilizer 15N-use and recovery efficiencies reached the highest at the heading stage. Residual 15N fertilizer in soil was highest at the tillering stage.

Discussion

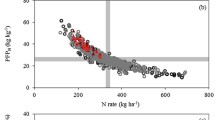

Using Chinese milk vetch as a cover crop to improve paddy soils, rice yield increased substantially under different N levels through a long-term incorporation of CMV, even without added N fertilizer (Table 2). The highest rice yield was achieved under a relatively lower N fertilizer application rate. A curvilinear relationship was found between the N application rates and rice yields under CMV–R rotation in different years (Fig. 1). According to the fitting equation, the optimum N application rates resulting in the highest yield were 220, 243, 234 and 220 kg N ha−1 in the year 2008, 2011, 2012 and 2013, respectively. Actually, the highest rice yield was achieved by CMV–R180 in 2011 and 2013 (Table 2). There were no significant differences among CMV–R180, CMV–R240 and CMV–R300 for rice yield. However, the fertilizer N-use efficiency, residual N fertilizer in soil and total N fertilizer recovery efficiency began to decrease under CMV–R240 and CMV–R300 (Table 4). Among the three rotation systems with 240 kg N ha−1 tested here, rice yield was always ranked in the following order: CMV–R > W–R > F–R. Many studies have confirmed the beneficial effects of winter legumes on the subsequent rice crop, such as higher rice yield, lower N fertilizer requirements and environmental risks (Dalal et al. 2011; Kim et al. 2012; Yu et al. 2014; Zhao et al. 2015; Zhu et al. 2012). Legumes fix substantial amounts of atmospheric N2, and the subsequent incorporation of legume residues into the soil replenishes soil N pools and makes a significant amount of N available to the succeeding main crops (Ibewiro et al. 2000; Mazzoncini et al. 2011; Zentner et al. 2006; Zhu et al. 2012). However, Chinese milk vetch alone was far from sufficient to satisfy N demands for high rice yield. In the present study, rice yield of CMV–R120 was significantly higher than that of CMV–R0, and even had achieved comparable yields with W–R240 and F–R240, with only half N fertilizer application rate. On the other hand, the total soil N content of CMV–R120 was similar to F–R240, and even less than W–R240 (Table 3). These results suggested the total N content of soil was an important reference of soil fertility and productivity, but not the only criteria. Based on the above results, the use of CMV should be combined with 180 kg N ha−1 to reduce N fertilizer inputs and underlying environmental risks while maintaining high rice yields.

The wheat–rice double-cropping system is a typical modern intensive system with high input and high output, but also with very high resource and environmental costs due to the large amounts of mineral N fertilizers inputs during the past three decades (Cui et al. 2014; Xie et al. 2017). This rotation system resulted in high background level of N in the soil (Table 3). Furthermore, continuous cultivation and fertilization have caused many problems in soils, such as soil acidification, destruction of soil structure, reduced soil quality and productivity, as well as harm to the population and activities of soil microbes (Guo et al. 2010; Liu et al. 2010, 2013a, b). Such processes are severely damaging the ecological functions and sustainability of soils and limiting their ability to self-repair. Understandably, the fertilizer N-use and recovery efficiencies under the W–R240 rotation were much lower than that under the CMV–R240 and F–R240 rotations (Table 4). The fertilizer N-use and recovery efficiencies had no differences between CMV–R240 and F–R240, but the rice yield under CMV–R240 was higher than that under F–R240 (Tables 2, 4). According to the results of fertilizer 15N content in rice, N content under F–R rotation was derived from fertilizer N more than CMV–R rotations (Table 5). The application of organic matter enhances the amount of microbial biomass N as well as the supply of soil-derived mineralized N to the plant (Nishio and Oka 2003). Thus, the rice yield of F–R240 may depend more on the mineral N fertilizer. These results suggest that high rice yield depended not only on fertilizer N-use efficiency, but could be affected by soil structure, soil organic matter and soil microbe populations and activities as well as interactions between native soil N and fertilizer N. Furthermore, the residual N fertilizer in soil under CMV–R rotation was higher than that under W–R and F–R rotations (Table 4). One possible reason is that soil organic N sources can be assimilated by plant more than inorganic N fertilizer (Motior et al. 2011). Incorporation of legume residues provides large amount of organic N sources into soil, resulting in N fertilizer retention in the soil microbial biomass, and thus the residual N fertilizer in soil was higher under CMV–R rotation system (Rahman et al. 2009).

Based on the results in 2013, the fertilizer N recovery efficiency was highest at basal fertilizer stage (Table 7). The low N fertilizer recovery efficiency could be attributable to two factors in the present study. On the one hand, rice roots are not yet fully developed during the seedling growth period and have relatively weak capacity to uptake N and other nutrients. On the other hand, excessive N fertilizer applied at early stages of rice growth would increase the proportion of ineffective tillers. The subsequent death of ineffective tillers may waste a large amount of fertilizer N (Ding et al. 2004; Jiang and Cao 2001; Qiao et al. 2013). The fertilizer N-use efficiency and total N recovery efficiency were highest at the heading stage (Table 7). Many studies have shown that N fertilizers applied at the heading stage are most effective for increasing N uptake and grain yield (Ghaley 2012; Ling et al. 2007; Zhang et al. 2013). The N fertilizer applied at the heading stage was absorbed into the grain more than that at the basal and tillering stages. These results suggest that the N fertilizer application rate can be increased at heading stage and decreased at the early growth stage of rice, which would be very important for improving fertilizer N-use efficiency and increasing N uptake. The fertilizer N-use efficiency, residual N fertilizer in soil and total N fertilizer recovery efficiency had no differences between CMV–R180 and CMV–R240 at the basal and tillering stages, and which of CMV–R180 performed even better than CMV–R240 at the heading stage (Table 8).

Conclusions

Rice yield greatly increased through long-term CMV–R rotation and reached highest at a relatively lower N fertilizer application rate (CMV–R180). Among different rotation systems with 240 kg N ha−1, the rice yield of CMV–R rotation was always higher than F–R and W–R rotations. The fertilizer N-use efficiency between CMV–R240 and F–R240 had no significant differences, but both were higher than W–R240. Further studies suggested topdressing N fertilizer at the heading stage was the most effective for increasing fertilizer N-use efficiency and absorption by rice grains. Nevertheless, the loss rate of the basal N fertilizer was highest among three N application stages. The present study showed that CMV–R rotation can be recommended as an environmental-friendly and sustainable rice-based cropping system for southern China. Further long-term studies should focus on exploring lower N fertilizer input through optimizing the application rates of N fertilizer at basal, tillering and heading stages under CMV–R rotation system.

References

Cui ZL, Dou ZX, Chen XP, Ju XT, Zhang FS (2014) Managing agricultural nutrients for food security in China: past, present, and future. Agron J 106:191–198

Dabney SM, Delgado JA, Reeves DW (2001) Using winter cover crops to improve soil and water quality. Commun Soil Sci Plan 32:1221–1250

Dalal RC, Allen DE, Wang WJ, Reeves S, Gibson I (2011) Organic carbon and total nitrogen stocks in a Vertisol following 40 years of no-tillage, crop residue retention and nitrogen fertilisation. Soil Tillage Res 112:133–139

De Datta SK, Buresh RJ (1989) Integrated nitrogen management in irrigated rice. Adv Soil Sci 10:143–169

Delin S, Nyberg A, Lindén B, Ferm M, Torstensson G, Lerenius C, Gruvaeus I (2008) Impact of crop protection on nitrogen utilisation and losses in winter wheat production. Eur J Agron 28:361–370

Ding YF, Liu SH, Wang SH, Wang CS, Huang PS, Ling QH (2004) Effects of amount of basic and tillering nitrogen applied on absorption and utilization of nitrogen in rice. Acta Agron Sin 30:762–767 (in Chinese)

Douglas CL, King KA, Zuzel JF (1998) Nitrogen and phosphorus in surface runoff and sediment from a wheat–pea rotation in Northeastern Oregon. J Environ Qual 27:1170–1177

Fageria NK, Baligar VC (2005) Enhancing nitrogen use efficiency in crop plants. Adv Agron 88:97–185

Fageria NK, Slaton NA, Baligar VC (2003) Nutrient management for improving lowland rice productivity and sustainability. Adv Agron 80:63–152

Fageria NK, Baligar VC, Bailey BA (2005) Role of cover crops in improving soil and row crop productivity. Commun Soil Sci Plan 36:2733–2757

Ghaley BB (2012) Uptake and utilization of 5-split nitrogen topdressing in an improved and a traditional rice cultivar in the Bhutan Highlands. Exp Agric 48:536–550

Guo JH, Liu XJ, Zhang Y, Shen JL, Han WX, Zhang WF, Christie P, Goulding KWT, Vitousek PM, Zhang FS (2010) Significant acidification in major Chinese croplands. Science 327:1008–1010

Ibewiro B, Sanginga N, Vanlauwe B, Merckx R (2000) Transformations and recovery of residue and fertilizer nitrogen-15 in a sandy Lixisol of West Africa. Biol Fertil Soils 31:261–269

IUSS Working Group WRB (2007) World reference base for soil resources 2006, first update 2007. World soil resources reports no. 103. FAO, Rome

Jiang LG, Cao WX (2001) Physiological mechanism and approaches for efficient nitrogen utilization in rice. Chin J Rice Sci 16:261–264 (in Chinese)

Jing Q, Bouman B, van Keulen H, Hengsdijk H, Cao WX, Dai TB (2008) Disentangling the effect of environmental factors on yield and nitrogen uptake of irrigated rice in Asia. Agric Syst 98:177–188

Kim SY, Gutierrez J, Kim PJ (2012) Considering winter cover crop selection as green manure to control methane emission during rice cultivation in paddy soil. Agric Ecosyst Environ 161:130–136

Ladha JK, Chakraborty D (2016) Nitrogen and cereal production: opportunities for enhanced efficiency and reduced N losses. In: Proceedings of the 2016 international nitrogen initiative conference, solutions to improve nitrogen use efficiency for the world, 4–8 December 2016, Melbourne, Australia

Ling Q, Zhang H, Ding Y, Dai Q, Ling L, Wang S, Yang J, Zhu Q, Su Z (2007) Theory and technology of precise and quantitative cultivation in rice. China Agricultural Press, Beijing (in Chinese)

Liu EK, Yan CR, Mei XR, He WQ, Bing SH, Ding LP, Liu Q, Liu S, Fan TL (2010) Long-term effect of chemical fertilizer, straw, and manure on soil chemical and biological properties in northwest China. Geoderma 158:173–180

Liu CA, Li FR, Zhou LM, Zhang RH, Lin SL, Wang LJ, Siddique KHM, Li FM (2013a) Effect of organic manure and fertilizer on soil water and crop yields in newly-built terraces with loess soils in a semi-arid environment. Agric Water Manag 117:123–132

Liu XJ, Zhang Y, Han WX, Tang AH, Shen JL, Cui ZL, Vitousek P, Erisman JW, Goulding K, Christie P, Fangmeier A, Zhang FS (2013b) Enhanced nitrogen deposition over China. Nature 494:459–462

Mazzoncini M, Sapkota TB, Bàrberi P, Antichi D, Risaliti R (2011) Long-term effect of tillage, nitrogen fertilization and cover crops on soil organic carbon and total nitrogen content. Soil Tillage Res 114:165–174

Min J, Shi WM, Xing GX, Powlson D, Zhu ZL (2012) Nitrous oxide emissions from vegetables grown in a polytunnel treated with high rates of applied nitrogen fertilizers in Southern China. Soil Use Manag 28:70–77

Mohammed YA, Kelly J, Chim BK, Rutto E, Waldschmidt K, Mullock J, Torres G, Desta KG, Raun W (2013) Nitrogen fertilizer management for improved grain quality and yield in winter wheat in Oklahoma. J Plant Nutr 36:749–761

Motior MR, Amano T, Inoue H, Matsumoto Y, Shiraiwa T (2011) Nitrogen uptake and recovery from N fertilizer and legume crops in wetland rice measured by 15N and non-isotope techniques. J Plant Nutr 34:402–426

Muthayya S, Sugimoto JD, Montgomery S, Maberly GF (2014) An overview of global rice production, supply, trade, and consumption. Ann NY Acad Sci 1324:7–14

Nishio T, Oka N (2003) Effect of organic matter application on the fate of 15N-labeled ammonium fertilizer in an upland soil. Soil Sci Plant Nutr 49:397–403

Qiao J, Yang LZ, Yan TM, Xue F, Zhao D (2013) Rice dry matter and nitrogen accumulation, soil mineral N around root and N leaching, with increasing application rates of fertilizer. Eur J Agron 49:93–103

Rahman MM, Amano T, Shiraiwa T (2009) Nitrogen use efficiency and recovery from N fertilizer under rice-based cropping systems. Aust J Crop Sci 3:336–351

Shafi M, Bakht J, Jan MT, Shah Z (2007) Soil C and N dynamics and maize (Zea may L.) yield as affected by cropping systems and residue management in North-western Pakistan. Soil Tillage Res 94:520–529

Shang QY, Gao CM, Yang XX, Wu PP, Ling N, Shen QR, Guo SW (2014) Ammonia volatilization in Chinese double rice-cropping systems: a 3-year field measurement in long-term fertilizer experiments. Biol Fertil Soils 50:715–725

Stevens WB, Hoeft RG, Mulvaney RL (2005) Fate of nitrogen-15 in a long-term nitrogen rate study. Agron J 97:1046–1053

Tian YH, Yin B, He FY, Zhu ZL (2009) Recovery by crop and loss of nitrogen fertilizer applied in rice season in Taihu Lake region. Plant Nutr Fertil Sci 15:55–61 (in Chinese)

Vlek PLG, Byrnes BH (1986) The efficacy and loss of fertilizer N in lowland rice. Fertil Res 9:131–147

Xie ZJ, He YQ, Tu SX, Xu CX, Liu GR, Wang HM, Cao WD, Liu H (2017) Chinese milk vetch improves plant growth, development and 15 N recovery in the rice-based rotation system of South China. Sci Rep 7:3577

Xing GX, Zhu ZL (2000) An assessment of N loss from agricultural fields to the environment in China. Nutr Cycl Agroecosyst 57:67–73

Yu YL, Xue HL, Yang LZ (2014) Winter legumes in rice crop rotations reduces nitrogen loss, and improves rice yield and soil nitrogen supply. Agron Sustain Dev 34:633–640

Zentner RP, Campbell CA, Selles F, Jefferson PG, Lemke R (2006) Effect of fallow frequency, flexible rotations, legume green manure, and wheat class on the economics of wheat production in the Brown soil zone. Can J Plant Sci 86:413–423

Zhang YP, Zhu DF, Lin XQ, Jiao GA, Huang Q (2003) Roots distribution of rice in field and its relation to soil bulk density. Chin J Rice Sci 17:141–144 (in Chinese)

Zhang FS, Cui ZL, Fan MS, Zhang WF, Chen XP, Jiang RF (2011) Integrated soil–crop system management: reducing environmental risk while increasing crop productivity and improving nutrient use efficiency in China. J Environ Qual 40:1051–1057

Zhang ZJ, Chu G, Liu LJ, Wang ZQ, Wang XM, Zhang H, Yang JC, Zhang JH (2013) Mid-season nitrogen application strategies for rice varieties differing in panicle size. Field Crop Res 150:9–18

Zhao X, Zhou Y, Wang SQ, Xing GX, Shi WM, Xu RK, Zhu ZL (2012) Nitrogen balance in a highly fertilized rice–wheat double-cropping system in southern China. Soil Sci Soc Am J 76:1068–1078

Zhao X, Wang SQ, Xing GX (2015) Maintaining rice yield and reducing N pollution by substituting winter legume for wheat in a heavily-fertilized rice-based cropping system of southeast China. Agric Ecosyst Environ 202:79–89

Zhu ZL (2008) Research on soil nitrogen in China. Acta Pedol Sin 45:778–783 (in Chinese)

Zhu B, Yi LX, Guo LM, Chen G, Hu YG, Tang HM, Xiao CF, Xiao XP, Yang GL, Acharya SN, Zeng ZH (2012) Performance of two winter cover crops and their impacts on soil properties and two subsequent rice crops in Dongting Lake Plain, Hunan, China. Soil Tillage Res 124:95–101

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 41271208), and the Key Projects in the National Science and Technology Pillar Program during the Twelfth Five-year Plan Period (2013BAD11B00). Financial support also came from the Special Fund for Agro-scientific Research in the Public Interest of China (201203030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hu, A., Tang, T. & Liu, Q. Nitrogen use efficiency in different rice-based rotations in southern China. Nutr Cycl Agroecosyst 112, 75–86 (2018). https://doi.org/10.1007/s10705-018-9930-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10705-018-9930-x