Abstract

High extraction of phosphate reserves and low phosphorus utilization efficiency in the food chain in China result in large P losses and serious environmental pollution. The P fertilizer industry, soil P surplus, livestock manure P and wastewater P recycling have been identified as the priority sectors based on summarizing several systemic and in-depth reviews of P flows analysis. Mineral P fertilizer production has reached 7.4 Mt P in 2012, which is more than seven times the value in 1980. The large P surpluses in arable land resulted in soil P accumulation of up to 64 Mt during the period 1951–2010. Livestock numbers have increased dramatically (more than ten times) during the period 1949–2012 in China, especially pigs and poultry, and so has the quantity of manure that they produce. The average loading of manure P on arable land in China has increased significantly from 9.5 kg P ha−1 in 1980 to 20.4 kg P ha−1 in 2010. Up to 0.49 Mt of wastewater P discharged without treatment also exerted great pressure on the environment in 2012. Based on an understanding of P interactions in these key sectors, an integrated set of policy options and technical measures is proposed. Taking P flows in China in 2010 as an example, if all of the strategies recommended in this study are adopted in P management, about 4.3, 2.5, 1.6 and 0.3 Mt of P resources, respectively, will be saved in the P fertilizer industry, arable land production, livestock manure and wastewater sectors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phosphorus (P) is a finite natural resource and is a major limiting nutrient in agriculture in many parts of the world (Sattari et al. 2012; MacDonald et al. 2011; Syers et al. 2011). The growing consumption of P fertilizers from mining of nonrenewable phosphate rock has contributed to the production of food for the nearly seven billion people on earth (Tilman et al. 2002; Lott et al. 2011). Because P is a major essential nutrient for plants with no substitute in food production (Epstein 1972), the rapidly depleting world P reserves are increasingly considered to be a new global sustainability challenge of the twenty-first century (Cordell et al. 2009; Cordell and Neset 2014). However, large P losses and environmental pollution due to high extraction of phosphate rock and low P utilization efficiency (PUE—see “Materials and methods” section for a precise definition) have recently become a prevalent problem in many countries (Vaccari 2009; Sun et al. 2012; Zhang et al. 2004). Hence, a more efficient utilization of P reserves is needed to delay the impact of dwindling amounts of extractable P and increasing costs of P fertilizer production on food security.

Currently, material flow analysis (MFA), a complete, systematic and in-depth approach, is widely used to understand the nature and magnitude of P flows through different systems at different geographical scales (Liu et al. 2008; Villalba et al. 2008; Cordell et al. 2009, 2013; Ott and Rechberger 2012; Antikainen et al. 2005; Belevi 2002; Chen et al. 2008; Cooper and Carliell-Marquet 2013; Cordell and White 2013, 2014; Jeong et al. 2009; Matsubae-Yokoyama et al. 2009; Senthilkumar et al. 2012; Suh and Yee 2011; Wu et al. 2014; Qiao et al. 2011; Schmid Neset et al. 2008; Yuan et al. 2011a, b; Bi et al. 2013; Li et al. 2010). A holistic MFA of all sectors from rock mining to food consumption at country scale is described in Fig. 1 according to a comprehensive understanding of anthropogenic flows of P.

Key sectors of P flows through the food chain and the intersectoral interactions in terms of P flows indicate P usage, stocks, losses and recycling at each sector of the process. The green boxes in the diagram represent the different key sectors which are inter-related through P flows. The industry sector describes mainly the upstream processes of P mining and fertilizer production. The agricultural sector describes the P processes in arable land, grassland and livestock production systems. The consumption sector describes mainly the food processing and household consumption. (Color figure online)

The MFA approach has often successfully traced P pathways and identified the key sectors causing environmental pollution based on the P flows structure shown in Fig. 1 (Cordell et al. 2013; Chen et al. 2010). Most of the research results have demonstrated that low PUE in the food chain, especially in agricultural and livestock production systems, results in a massive P surplus in some agricultural soils and in manure P losses. Both of these act as drivers of eutrophication in freshwater and coastal systems (Bennett et al. 2001; MacDonald et al. 2011; Rabalais et al. 2010). Suh and Yee (2011) found that P run-off from livestock waste and crop land are the two largest contributors to total life-cycle P loss in the US food production-consumption chain. Based on our rough recalculation of data in the literature, PUE in the P flow chain analyzed by the MFA approach at different geographical scales was about 13 % in Europe as a whole (Ott and Rechberger 2012), 10 % in France (Senthilkumar et al. 2012), 11 % in Finland (Antikainen et al. 2005), 19 % in Japan (Matsubae-Yokoyama et al. 2009), 12 % in the UK (Cooper and Carliell-Marquet 2013), 21 % in South Korea (Jeong et al. 2009), and 7 % in China (Ma et al. 2010). Common trends in these studies were relatively low PUE values of livestock production and crop cultivation and a lower ratio of P recycling from wastewater, resulting in very large losses of P to the environment. These sectors are considered to be the key sectors where some additional management measures will lead to a significant improvement in the PUE of the food production-consumption chain.

China is a large agricultural country feeding 22 % of the global population (1.3 billion) with <7 % of the global arable land (arable + permanent crops) (130 million ha) (Li et al. 2011) and is playing a critical role in global P production and consumption trends (Sattari et al. 2014). For national food security reasons, the mineral fertilizer-intensive agriculture has developed enormously in China. Mineral P fertilizers in China are mined from native P rock phosphate reserves, and this mining has increased greatly during the last two decades. However, about 70 % of P rock phosphate resources are classified as low grade and the low PUE of P rock mining and processing in the P fertilizer industry sector have aggravated the depletion of native P rock reserves and the associated environmental pollution (Zhang et al. 2008). Also, the inappropriate and spatial imbalance of P fertilizer application has led to massive soil P surplus in arable land and a much lower PUE (about 7 %) in the P flow chain compared with other counties as described above, resulting in an increasing risk of P loss from agricultural land to ground water and surface waters (Liu et al. 2007; Sheng et al. 2003). Concomitantly, huge amounts of nutrient losses from animal housing facilities and a shortage of sewage treatment facilities has resulted in insufficient recycling of P in manures and wastewaters with the result of immense pressure on the environment.

As one of the most important countries in the utilization of global P resources, an improvement in the PUE in the food chain in China will have an important impact on the worldwide use efficiency of P resources. Instead of providing another comprehensive analysis of P flows in China’s food chain, we think that a focus on the key sectors with respect to low PUE and environmental pollution could provide more insight in alternative management and policy options. Therefore, in the present study we analyze the key sectors, including the P fertilizer industry, soil P surplus, manures and wastewater P in China to identify the potential options for improved P resource management. Through an in-depth understanding of P flows, we recommend integrated systemic strategies for these key sectors which can be useful for production managers, politicians and policy makers. In summary, the objectives of the study were to quantify the P situation in the key sectors in the Chinese food chain, to identify the potential strategies in these key sectors for sustainable management of P resources, and to evaluate the potential savings of P resources with adoption of the recommended technologies in the key sectors.

Materials and methods

We investigated the developments in P fertilizer industry, manure P, soil P surplus and wastewater P for China. For the P fertilizer industry, the phosphate reserves, the production, consumption, imports and exports of P fertilizers and the structure of mineral P fertilizer products were determined for the period 1980–2013. For manure P, the changes (1949–2012) in the animal stocks and manure P loadings in arable land were investigated. For soil P surplus, the changes (1951–2010) in soil P budget and PUE in arable land were calculated. Finally, for wastewater P, the amount of wastewater P discharged to the environment in 2012 was estimated.

Data sources

Data on phosphate rock reserves were obtained from USGS Phosphate Rock Mineral Commodity Summaries 1995–2012 (http://minerals.usgs.gov/minerals/pubs/commodity/phosphate_rock) and data on P fertilizer production and consumption in China during the period 1980–2012 were taken from the governmental statistical data (http://www.china-npk.org/cn/index.html). Data on P fertilizer imports and exports were derived from China Chemical Information Center (http://www.china-fertinfo.com.cn/hyxx.aspx).

Information on crop yields, arable land areas, wastewater P discharged and number of animals during the period 1950–2012 was derived from authoritative statistical sources (MOA 1949–2012; NBSC 1949–2013; ECCEY 2012). The concentrations of P in harvested crops and crop residues, the crop residue factors (RF), and the ratios of crop residue recycling to P excretion values per animal category were derived from literature (Wang et al. 2006, 2012; Ma et al. 2010; Gao et al. 2009).

Calculation methods

The total amount of P in harvested crops (comprising 16 types of crops, vegetables and fruits) was calculated using Eq. (1);

where ‘C yields (i)’ is the concentration of P in crop yields.

The total amount of P in crop residues recycled to arable land was calculated using Eq. (2);

where ‘RF(i)’ is the crop residues factor = weight of crop residues/weight of crop yields); ‘C residues (i)’ is the concentration of P in crop residues; and ‘R(i)’ is the recycling ratio of crop residues.

Total P inputs in crop production were estimated from the amounts of P in mineral P fertilizers, crop residues recycled to arable land, and manures and the fertilizers (both livestock manures and human excreta), Eq. (3);

Total P outputs in crop production were estimated from the amounts of P in harvested crops and crop residues taken away from arable land for other uses, Eq. (4);

where ‘\(\sum\nolimits_{1}^{16} {P\,in\,residues\,taken\,away}\)’ is calculated based on Eq. (2).

The P utilization efficiency in crop production (PUEc) and soil P surplus in arable land were calculated as in Eqs. (5) and (6), respectively.

The loading of animal manure P in different Chinese provinces was calculated as in Eq. (7);

where ‘P load ’ is the animal manure P loading in arable land, ‘TP animal manure ’ is the total amount of animal manure P in a specific province, and ‘S arable land ’ is the total area of arable land in the same province.

P fertilizer industry

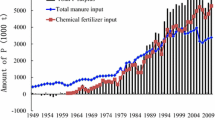

Until the end of the 1950s arable soil fertility replenishment in China was largely based on the recycling of animal manures and human feces, as well as household wastes and cereal-straw ash. Since then the mineral P fertilizer industry has expanded. The production and consumption of P fertilizers in China have increased greatly, especially from the 1980s (Fig. 2), driven mainly by massive government subsidies to the fertilizer industry [the total subsidy for fertilizer industry was $18.8 billion in 2010, which translates in $283 per ton nutrient (N + P + K)] (Li et al. 2013). The production of mineral P fertilizers has increased from 1.0 Mt P in 1980 to 7.4 Mt P in 2012, compared with a consumption increase from 1.0 Mt to 5.2 Mt P at a rate of about 5 % increase per year. Due to restrictions in the industrial production capacity of mineral P fertilizers during 1980–2006, the production of mineral P fertilizers in China could not satisfy the increasing fertilizer consumption demands at home. The gap of millions of tonnes of fertilizers was filled mainly by imports through international trade. For example, the maximum gap of mineral P fertilizers was 3.0 Mt P2O5 (1.3 Mt P) in 1995 and about 1.2 Mt P was imported from the US and Russia to fill the gap (Fig. 2).

After entering the twenty-first century the fertilizer enterprises continued to introduce advanced mining equipment and modern production management technologies from abroad, resulting in an increase in P fertilizer production at an average rate of 10.7 % from 2001 to 2007. Consequently, in 2006 China had already become a net exporting country and since then export volumes have increased significantly (Fig. 2). China has now become the largest global consumer and producer of P fertilizers.

With the development of seismic exploration technology the known reserves of phosphate rock deposits have increased from 92 Mt P in 1995 to 1615 Mt P in 2012 (Fig. 2). China has now the second largest phosphate rock deposits in the world, accounting for an estimated 5.5 % of world deposits (USGS 2014). However, about 80 % of the deposits in China are of sedimentary origin, low in quality, and only 7 % has been classified as high-grade P rock resources (30 % P2O5) (Zhang et al. 2005, 2008). Figure 2 shows a dramatic increase of phosphate rock reserves in China since 2002. Prior to 2003, due to few available official data, China was thought to be a relatively small phosphate rock reserve holder. However, the Chinese government released its first official phosphate rock deposit data in 2003. Since that time, their reserve estimates have been revised upward by the USGS (Van Kauwenbergh et al. 2013).

About 87.3 % of phosphate rock in China is used for agriculture, 78.3 % as P fertilizer, and 9.0 % as a direct supplement in animal feeds. The remaining 12.7 % is used for yellow P which is normally used in detergents, fire retardants, and food additives (Junfa 2009). Usually, the high-grade phosphate rock (P2O5 content >30 % after processing) is used to produce high-quality P fertilizers such as ammonium phosphate. In contrast, low-grade phosphate rock with an average P2O5 content of 16 % is used to produce low-grade P fertilizers such as single superphosphate. The production of high-grade P fertilizers has increased dramatically since 1995 as illustrated in Fig. 3, and this has promoted a steep increase in phosphate rock mining and resulted in large amounts of low-grade phosphate rock discharge (Zhang et al. 2008). In 1980 single superphosphate accounted for about 72.4 % of P fertilizer products and the remaining 27.6 % comprised calcium magnesium phosphate products. The quality of Chinese P fertilizer products has improved greatly owing to the great progress achieved by the P fertilizer industry in recent decades. In 2012 the national total P fertilizer production had multiplied by more than seven times the 1980 figure and reached more than 7.4 Mt P, 83.5 % of which consisted of high-grade fertilizers including ammonium phosphate and compound fertilizers (Fig. 3).

The massive increase in phosphate rock mining and P fertilizer production has resulted in severe environmental pollution because of the lack of effective legal controls. It was reported that the PUE of the Chinese P fertilizer industry had decreased from 71 % before 1995 to 39 % in 2003 with 56 % of the residues discarded at the mining sites and 5 % lost as wastes during manufacturing (Zhang et al. 2008). Currently, phosphogypsum (PG) is a by-product generated in the phosphoric acid process for manufacturing fertilizers and is also a large contributor to the environmental problems and land deterioration. The quantity of PG generated is enormous: for each tonne of phosphoric acid made about 4–5 tonnes of PG are created (Smadi et al. 1999; Canut et al. 2008). Until 2011 the total cumulative amount of PG generated in the country was estimated at 250 Mt. The annual production of this material was estimated to be about 70 Mt at the end of the 12th Five-Year Plan (Wang 2013). Because this by-product is composed mainly of high levels of gypsum, phosphates, fluorides, sulphates, heavy metals, and other trace elements, it cannot be reused and is largely disposed without any treatment, by dumping in large stockpiles occupying large areas of land and causing severe environmental damage (Tayibi et al. 2009). In addition, a massive amount of low-grade phosphate rock is also discharged in large stockpiles due to the high costs of remediation processes. It was estimated that these large stocks occupied and deteriorated about 475 km2 land, and the consumption of ground water was 1.8 billion m3 per year (Zhang et al. 2008).

Currently, the average PUE of phosphate rock in the Chinese P fertilizer industry is about 61 %, much lower than the 98 % in the USA (Zhang et al. 2008). On the one hand China is suffering from the depletion of its high-quality phosphate rock resource and on the other hand there is severe environmental damage caused by the low utilization efficiency of phosphate rock deposits and the irrational management of byproducts. Therefore, increasing the PUE of phosphate rock by new technologies, a better re-utilization of the by-product and developing new and more efficient P fertilizer products by the P fertilizer industry are the potential options for a more sustainable use of this essential resource.

Manure P

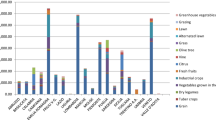

Rapid economic growth in China and increasing incomes and changes in dietary structure from cereal-based to more meat-based diets have stimulated the intensive production of livestock in industrial and specialized enterprises in peri-urban areas. Animal stocks in China have been growing substantially since the early 1950s (Fig. 4). For example, the number of pig slaughtered has increased by more than tenfold from 66 million heads in 1952 to 698 million heads in 2012, and the number of other livestock such as poultry and sheep also show similar growth trends (Fig. 4). There are several periods without any poultry stocks due to no available data. The dramatic increase in livestock numbers has led to the generation of large amounts of livestock manures. In this study, the percentage of manure P excretion per animal category in captivity that was recycled to arable land was determined according to data in literature (Ma et al. 2010), while the remainder of manure P was considered to be discarded or lost to the environment. In contrast, manure P excreted by grazing animals was considered to be recycled in grasslands completely. The amount of animal manure P recycled to arable land was considered in the construction of the cropping budgets. From 1952 to 2012, the total amount of manure P excreted by pigs, large animals and sheep has increased by 1066, 158 and 461 %, respectively. The amounts of manure P excreted by poultry and rabbits have also increased by 765 and 676 %, respectively, in 2012 compared with 1986. In 2012 the total amounts of manure P excreted by pigs, large animals, sheep and poultry were estimated at about 1179, 574, 285 and 242 (×103 t), respectively (data not shown). More than 48 % of total P in pig manures, 87 % of total P in dairy manures and 69 % of total P in poultry manures was in water-soluble forms which are plant-available and readily lost to the environment (Li et al. 2014).

At the national level the average loading of livestock manure P in arable land (amount of animal manure P excreted divided by the total cropland area) has increased gradually, i.e. 9.5 kg P ha−1 in 1980, 14.8 kg P ha−1 in 1990, 17.8 kg P ha−1 in 2000 and 20.4 kg P ha−1 in 2010 (Fig. 5). There is a wide range of livestock manure P loadings in arable land in different provinces. Across all decades the highest manure P loading occurs in Xinjiang and Qinghai provinces at more than 40 kg P ha−1. One possible explanation is that there is less arable land in these two provinces but with large numbers of animals. In the 1980s and 1990s the leading region of Chinese livestock breeding was in the southwest, mainly in Sichuan, Yunnan and Guizhou provinces in which the manure P loading was 20–30 kg P ha−1 (Fig. 5a, b). As economic development accelerated on the east coastal region in the 2000s and 2010s, livestock breeding developed dramatically in this region (Fig. 5c, d). The average loading of manure P in Hunan, Guangdong and Fujian provinces was about 30–40 kg P ha−1. In Beijing, livestock manure P loading in arable land was even higher than 40 kg P ha−1. Clearly, the regions with higher manure P loading are facing the highest environmental risk of P losses arising from livestock manure.

Due to the low environmental awareness of farmers and the lack of national waste discharge standards, there are no or inadequate disposal and treatment facilities (such as machines used for direct manure injection or incorporation into the soil to reduce surface P losses and urine—faeces segregation facilities) on 90 % of Chinese livestock farms resulting in very large amounts of manure P lost to the environment (Zheng et al. 2013; Wang et al. 2011; Sun et al. 2012). Increasing labor costs and the relatively low price of mineral P fertilizers through government subsidies encourage farmers to use mineral fertilizers instead of collecting and recycling livestock manures. This has gradually resulted in a situation in which crop and livestock production systems are no longer integrated and interdependent (Morse 1995). Consequently, livestock manures are no longer in demand for their fertilizer value, and these results in a decreasing utilization rate of manures, currently only 44 % (Cao 2006). This value is much lower than the average value of 89 % in the Netherlands (Smit et al. 2010). It was estimated that the proportion of animal wastes directly discharged to water bodies was about 2–8 % for solid wastes and about 50 % for liquid wastes in 2002 in China (ECCEY 2003). Not surprisingly, about 75 % of the lakes are polluted due to manure P losses and soil P erosion (Jin et al. 2005). With increasing urbanization, increasing numbers of livestock enterprises are developing around population centers and major markets where there is limited availability of arable land for manure disposal, thus exacerbating the risk of manure P losses (Zheng et al. 2013; Giller et al. 2002; Burton and Turner 2003). The P discharged from livestock manure and human excreta was larger than that from mineral P fertilizer applications and was the main contributor to environmental pollution in China in 2007, accounting for 56 % of P discharges (MEP 2010; Sun et al. 2012). Thus, improved management of livestock manures in China is an urgent task at present. Reducing excess P in animal diets and increasing the recycling of P in manure and organic wastes are the potential alternatives for a better utilization of P resources.

Soil P surplus

As demand increases for food production, Chinese agriculture is facing tremendous challenges to feed 22 % of the global population (1.3 billion) with <7 % of the global arable land. Seen as a cheap insurance policy due to the massive fertilizer subsidies from government, farmers tend to overuse mineral P fertilizers to ensure high productivity. Chinese farmers have successfully managed to increase the total amount of cereal production from 305 Mt in 1978 to 531 Mt in 2009. To achieve this, however, large amounts of mineral P fertilizers have been applied to arable land as shown in Fig. 2. Moreover, P inputs from other sources such as recycling of manure and waste P resulted in total P inputs to arable land substantially exceeding the quantity of P in harvested crops, leading to large surpluses of P in soils.

Due to soil P surplus, fertilizer use efficiency has been decreasing since 1951. The recovery ratio of P input by crops has decreased from 133 % in 1951–1955 to 44 % in 2006–2010 (Fig. 6). During 1951–1960, the balance of soil P inputs minus P outputs in agriculture was negative resulting in soil P depletion during this period, implying a PUE of more than 100 % (Fig. 6). With a dramatic increase in total P inputs compared with a slowly rising total P output since 1961, more and more P has accumulated in soils. During 2006–2010 about 16.3 Mt P accumulated in soils. It has been estimated that the total soil P surplus in arable land between 1951 and 2010 was up to 64 Mt. Many studies have also identified the substantial accumulation of soil P. Li et al. (2011) estimated that an average of 242 kg P ha−1 accumulated in soils from 1980 to 2007, resulting in the average soil Olsen-P value increasing from 7.4 to 24.7 mg P kg−1. It was also reported that the average phosphate content in soils has nearly tripled between 1980 and today (Qiu 2010).

Past trends in the amount of manure P recycled, mineral fertilizer P input, soil P balance, total P input, total P output and PUE in crop production during the period 1951–2010 in China. PUE was calculated by Eq. 5 in “Materials and methods” section

While some soil P surplus may be generally desirable from an agricultural perspective, the increased accumulation of soil P in arable land is closely related to freshwater eutrophication. Clearly, substantial P surpluses in soil result in an increased risk of P losses in surface and subsurface runoff from agricultural soils to the environment. The national survey of pollution sources in 2010 showed that the total amount of P losses from cropland was about 108,000 t, and is the second highest contributor to non-point environmental pollution (MEP 2010). This environmental problem in China is perhaps similar to or even more severe than that in Europe 10–20 years ago (Barberis et al. 1995; Djodjic et al. 2005). An evaluation of environmental sustainability among 142 countries demonstrated that China is facing greater environmental challenges than other major countries due to environmental degradation (Liu and Diamond 2005). As illustrated in Fig. 6, the average PUE in arable land in China is as low as about 44 % due to excessive P fertilization, much lower than the average values of 64 % in the European Union (Ott and Rechberger 2012) and 62 % in the United States (Suh and Yee 2011). With still increasing P fertilizer application and soil P surplus in arable soils, the contribution of P from non-point agricultural sources is predicted to increase. Therefore, a balanced fertilization for a higher PUE in cropping systems and new fertilization techniques to reduce soil P losses is potential options for a more sustainable agriculture.

Wastewater P

China’s urbanization has increased from 23.0 % in 1984 to 47.5 % in 2010, driven by economic growth since its reform and opening-up to the outside world. The net increase in the urban population has inevitably led to a high demand on water resources and an increase in municipal wastewater production. The total amount of wastewater discharged has increased from 37.3 billion tonnes (with 15.1 billion tonnes from municipal sources) in 1995 to 68.5 billion tonnes (with 46.3 billion tonnes from municipal sources) in 2012 (ECCEY 1995, 2012). However, the development of wastewater treatment plants has not kept pace with the urban sprawl in most cities. It was reported that about 14 % of urban sewage was treated whereas the remaining 86 % of urban sewage discharged into rivers and lakes without adequate treatment in 1997 (Oyang and Wang 2000). At present, although the number of urban sewage treatment plants has increased rapidly, a very large amount of sewage is still discharged without treatment. Generally, municipal wastewaters may contain 5–20 mg l−1 of total P, of which 1–5 mg l−1 is organic and the remainder inorganic, both of which are key sources of nutrients stimulating the rapid growth of marine algae (eutrophication).

Large quantities of wastewater P (ca. 0.49 Mt) were discharged in 2012 without any treatment (Fig. 7). In the populous provinces Shandong, Henan and Hebei the total amounts of wastewater P discharged to the environment were 61, 48 and 39 kilotonnes (kt) per year, respectively. Intermediate levels of wastewater P discharge occurred in Liaoning, Sichuan, Guangdong, Hunan, Heilongjiang, Hubei, Inner Mongolia and Anhui provinces where the average loadings ranged from 20 to 30 kt per year. At present there are at least three factors affecting the claimed treatment capacity in China. Firstly, there are too few wastewater treatment facilities in most cities and almost none in rural areas, resulting in the discharge of untreated sewage into the environment. Secondly, because of inefficient wastewater treatment technologies, the wastewater is not of a satisfactory standard after treatment. Thirdly, flushing toilets in urban areas mix human excreta with other (industrial) wastewater streams containing high levels of heavy metals and other toxic wastes and this greatly reduces the feasibility of nutrient recovery. A combination of these factors leads to a low wastewater P recycling ratio of about 70 % which is much lower than the average value of 90 % in the European Union (Ott and Rechberger 2012). Thus, the recovery of P from municipal and other wastewater by new technologies and developing new sanitation service infrastructure are the major opportunities for increasing the life expectancy of P resource.

Outlook on future management strategies

Based on the understanding of P intersectoral interactions along with the P flow chain, it is possible to develop targeted management strategies to diminish P losses to the environment and to increase P utilization efficiency (Fig. 8).

Strategy 1 for the industrial sector: phosphate rock reserves and P fertilizer production

-

1.

New technologies at the mining stage

-

The quality of remaining phosphate rock around the world is declining with the depletion of high grade phosphate rock. The average grade of mined phosphate rock has declined from 15 % P in the 1970s to <13 % P in 1996 (Stewart et al. 2005; Cordell et al. 2009). The costs of mineral P fertilizer production will increase over time. How to use the remaining high grade phosphate rock more efficiently is a major challenge for the industry. New technologies may be the key to solve this problem. For instance, the average recovery rate of phosphate rock in small mining enterprises with simple picking and shoveling equipment, which select high-grade phosphate rock only, are usually below 30 % in China. This inevitably leads to a serious waste of finite P resources. In contrast, in large and medium sized mining enterprises with advanced mining equipment and modern production management technologies, the average recovery rate is up to 82 % taking open-pit and underground mines into account (Ma et al. 2012; Zhang et al. 2008). Thus, adopting new technologies for phosphate rock mining, processing and ore dressing is a crucial step to improve the PUE throughout the entire food chain.

-

-

2.

Better management of by-products

-

Developing new technologies to promote the comprehensive utilization of the by-products including PG and low-grade phosphate rock, and prevent P losses, is a potential solution. For example, about 19 Mt of PG accounting for 27 % of annual production in China is used to make cement retarder, construction gypsum powder and gypsum brick and soil conditioner. At the same time, building impermeable bases at the storage sites of PG and low-grade phosphate rock is an efficient way to prevent contamination by leachate from diffusion into the groundwater.

-

-

3.

Developing new P fertilizer products

-

The majority of P fertilizers applied to arable land are adsorbed by soil particles or lost in runoff after rainfall because of the high concentrations of water-soluble P in high-grade fertilizers and this finally decreases the P utilization ratio to as low as 10–20 %. Therefore, developing new P fertilizer products such as slow (controlled)-release exclusive prescriptive fertilizer (LREPF) may be an efficient way to lower fertilizer use and reduce loss of P resources. It was reported that the application of LREPF can reduce chemical fertilizer pollution, save mineral fertilizers by 20 % and raise fertilizer efficiency from 35 to 60–70 % (Qi and Gao 2008).

-

Strategy 2 for the agricultural sector: livestock production and arable land

-

4.

Reducing mineral feed P additives

-

Phosphorus is an essential component of feed required by pigs, poultry and cattle. Therefore, adequate dietary P supply is important to meet animal daily requirements in order to maintain P homeostasis (Schröder et al. 1996). Large amounts of mineral feed P additives, consuming 9.0 % of phosphate rock in China, are commonly used in the livestock industry, usually resulting in an excess of P in the diets. It was reported that as total P in animal manure increases from the increase in dietary P, so does the proportion of inorganic P (Dou et al. 2002). Thus, reducing mineral feed P additives is a critical step to decrease manure P excretion, which in turn will minimize subsequent P losses to the environment.

-

Addition of enzyme additives such as microbial phytases to nonruminant (pig/poultry) diets is currently considered to be an alternative mineral feed P additive to enhance the efficiency of P recovery from phytin in grain feed. Numerous animal experiments have also indicated that adding phytase additives to animal diets at 500–1000 units (FTU) kg−1 may replace mineral P additives for pigs and poultry and reduce their P excretion by approximately 50 % (Augspurger et al. 2003; Lei and Stahl 2001; Kim et al. 2006).

-

-

5.

Higher PUE in cropping systems

-

First, we must recognize the importance of balanced fertilization and take it as a basic principle in cropping systems. The build-up and maintenance approach which was fully developed by Zhang et al. (2008) has successfully maintained soil Olsen-P at the optimum level for maximum economic efficiency and lower environmental risk of P losses (Li et al. 2011). Secondly, the activation and utilization of the ‘P legacies’ in soils by crops is a critical step to increase the PUE in cropping systems because fertilizer P continues to react with soil particles after application as a result of which added P gradually becomes unavailable to plants (Khasawneh et al. 1980; Sattari et al. 2012). Plant breeding and genetic modification to introduce new properties provides an effective shortcut to increase the uptake of unavailable P in soils. For example, both morphological adaptation (such as an altered root hair structure and higher fungal colonization) and physiological adaptation (such as an enhanced ability of roots to release protons, exudation of carboxylates and secretion of phosphatases) by plant breeding and genetic modification may significantly increase the PUE in cropping systems. Adjustment of cropping structure is also an efficient way to increase the PUE in cropping systems. For instance, in maize/faba bean intercropping systems the intercropped maize and faba bean had a 28–29 % higher P uptake compared with monocropped plants which has been attributed to rhizosphere interactions between intercropped maize and faba bean (Li et al. 2003).

-

-

6.

Recycling organic fertilizers

-

The percentage of manure recycled has decreased from 100 % in 1949 to <50 % in 2005 because of the increasing application of readily available cheap and subsidized mineral fertilizers and the dramatic development of intensive animal feeding operations without enough cropland for the disposal of livestock manures (Ju et al. 2005). Thus, in agricultural production systems the recycling of organic fertilizers such as livestock manures, crop residues, household residues and other organic products should be the general norm in the future. To increase the recycling rate of organic fertilizers current financial subsidies for mineral fertilizers should be switched to organic fertilizers. At the same time, new recycling technologies for the more efficient use of organic fertilizers should also be developed. Meanwhile, a closer intensive integration of crop production and livestock systems is considered as an alternative to improve productivity, which could occur within a farm or among farms. In some regions, a relative proportion of farm land should be converted from annual cropping to rotations that include perennial forages.

-

-

7.

Reducing soil P losses

-

In many areas excessive soil P surplus has enriched surface runoff with P due to too high a P fertilizer input. Thus, controlling the transport of soil P and preventing soil P losses to water bodies after the application of P fertilizers and manures are needed to relieve the environmental pressure caused by eutrophication.

-

Band-placement or localized application of P fertilizers rather than broadcasting can increase the PUE in an intensive farming system in north China and also reduce significantly soil P surface runoff (Jing et al. 2010). Other methods such as minimum- and zero-tillage, buffer zones and constructed wetlands are also useful in the minimization of soil P losses.

-

-

8.

Reducing manure P losses

-

‘Best management practices’ (BMPs) for livestock manure used as fertilizer including manure collection, treatment, storage, and application are necessary to reduce manure P losses because livestock manure losses have become one of the largest contributors to runoff pollution in China.

-

For manure collection technologies, solid waste is collected manually and liquid waste flows along canals or pipes. The separate collection of feces and urine is important to avoid generating a large volume of dilute wastes. The solid and liquid wastes are stored in bulk in concrete/lined tanks for months before application to land and the relative importance for manure management is 20–30 % (Oenema et al. 2007). Composting is a management tool to increase the P concentration and reduce the volume of manure in an efficient way to decrease the long distance transport costs of livestock manures. Many livestock farms also use organic materials such as straw and rice hull on the ground to absorb feces and urine, which can reduce manure P losses and also provide clean and comfortable breeding houses. Commercially available chemical amendments such as alum and slaked lime are sometimes added to manure and litter to decrease P solubility and this is also a potential way to reduce the dissolved P concentration in surface runoff (Moore et al. 2000). For manure application incorporation or subsurface injection into the soil based on the local crop P requirements can significantly reduce surface P losses (Sharpley et al. 2007).

-

Strategy 3 for the consumption sector: households and wastewater

-

9.

Changes in diets

-

The dramatic economic development and urbanization in past decades in China has promoted a meat-based diet and this is a major driver for changes in food production systems and for efficiency improvement throughout the food chain (Bai et al. 2014; Hou et al. 2013; Ma et al. 2013; Metson et al. 2012). However, through calculating backwards from human excreta to mineral P fertilizer application in arable land, it has been demonstrated that a meat-based diet per person and year requires about 11.8 kg of phosphate rock which is significantly more than the 4.2 kg requirement of a vegetarian diet (Cordell et al. 2009). Ma et al. (2013) found, based on the Chinese food dietary guidelines, that a dietary change from more meat-based diets to more cereal-based diets can significantly reduce the requirement for arable land, water, mineral P fertilizer and reduce P losses. Metson et al. (2012) also reported that meat consumption is the largest contributor to ‘dietary P footprints’. Therefore, decreasing future meat consumption could play an important role in sustainable P management strategies. Though changing dietary habits is a great challenge which is related closely to increased urbanization and higher incomes, a dietary change toward less meat and a reduction of milk consumption versus more vegetables and cereals is considered a promising way to reduce wastage of P resources.

-

-

10.

New technologies for wastewater treatment and (11) reducing wastewater P losses

-

A large quantity of P in discharged wastewater with more than 0.03 mg P l−1 is one of the main causes of eutrophication that has exerted great pressure on the environment in China (Gachter and Imboden 1985). Currently, urban wastewater infrastructure is basically designed for public health but is increasingly focusing on P recovery from both urban and industrial wastewaters (Reindl 2007). Total removal or at least a significant reduction in P concentrations in wastewaters is now a legal obligation in many countries.

-

According to the types of wastewater and operational costs, many different P-removal technologies are available to treat wastewaters. Based on the different mechanisms for removing P, the technologies include chemical metal precipitation, absorbing materials, physical heat treatment and biological immobilization by bacteria, microalgae and plants (De-Bashan and Bashan 2004). These processes essentially transfer P from the liquid to the sludge phase. The P removal efficiency of these technologies ranges from 39 % to 100 %. For example, some metal oxides such as iron oxide, Al(OH)3, calcite, and Mg(OH)2 are often used as reagents in metal precipitation technology to react chemically with P in wastewater, generating insoluble crystalline compounds (Baker et al. 1998; Donnert and Salecker 1999; Moriyama et al. 2001; Shin and Lee 1998; Wu et al. 2001). Depending on the characteristics of the P removal technologies being used, the P recovered from wastewaters can be reused either directly as a fertilizer applied to arable land or as a raw material for the fertilizer industry. Phosphorus recovery from wastewaters is not only a sustainable way to prevent P losses but also provides an alternative source of phosphate fertilizer for agricultural production. Meanwhile, more stringent legislation to reduce the concentration of P in municipal wastewaters before discharge into the environment is an efficient way to reduce wastewater P losses. Reuse of residential wastewaters composed mainly of human urine and fecal matter to irrigate crops is also an alternative way to reduce wastewater P losses. It was reported that more than 25 % of urban vegetables are being fertilized with wastewaters from cities (Ensink et al. 2004). However, this direct reuse of wastewaters requires a sanitation service infrastructure that avoids the mixing of human excreta with other wastewater streams containing heavy metals and other toxic wastes.

-

If all of the strategies described above were adopted in P management in China, PUE in different parts of the P flow chain would be increased significantly and large amounts of P resources would be saved (Table 1). We reviewed most of the P flow studies at national scale around the world, and determined the maximum PUEs in different sectors, which were considered as the attainable PUEs in China (Table 1). For example, the maximum recycling ratio of manure P reported in literature was about 89 % in the Netherlands (Smit et al. 2010). Thus, the increase in recycling ratio of manure P from 44 to 89 % in China is actually possible if the manure management technologies could achieve the standards of the Netherlands. Based on the PUEs and the size of P flows in different parts in China in 2010, the optimized size of P flows and the amount of P resource saved after adopting technologies were determined.

If in P fertilizer production new technologies are introduced at the phosphate rock mining stage, the PUE will increase from 61 % to the attainable value of 98 % as in the United States. This would not be hard to achieve by investing massively in the advanced mining equipment and staff skills training. If the mineral P fertilizer production in 2010 in China is continued, about 4.3 Mt P in phosphate rock will be saved which equals to 32.9 Mt phosphate rock (average P2O5 content = 30 %). In arable land production, after adopting new technologies the PUE may increase from 44 % to the attainable value of 64 % in the European Union and about 2.5 Mt P fertilizers will be saved to produce the same crop yield as in 2010. This is eminently possible if China invests in a set of integrated soil-crop management practices based on a modern understanding of crop ecophysiology and soil biogeochemistry and makes it viable for farmers (Chen et al. 2014). If new technologies are applied in manure and wastewater P management, about 1.6 and 0.3 Mt P will be recycled and used as P fertilizer sources, respectively. An investment in the municipal and sanitation service infrastructure is essential for the recovery of P from wastewater, especially in rural areas. However, manure P recycling through incorporation or subsurface injection with large machines on 100s of millions of small parcels of land will be a huge challenge in China.

The attainable maximum PUE in the whole chain was about 21 % in South Korea (Jeong et al. 2009), which is much higher than the 6 % in China. If the PUE in the whole chain could increase from 6 to 21 % with new technologies, about 8.1 Mt P resources will be saved in China (Table 1). In order to achieve this, a concerted effort by all entities along the whole P flow chain towards efficient use of P resource is needed in China.

The way forward

Phosphorus is a finite, yet essential, resource for agriculture and thus food production and China is the world’s largest consumer (30 % on just 7 % of the world’s arable land) and an important producer (37.5 % of the global total). In this paper we identified China’s P fertilizer industry, soil P surplus, livestock manure P and wastewater P recycling as the priority sectors that need attention to mitigate P use and thereby improve PUE. China can learn from other countries with intensive agriculture that have been dealing with large nutrient surpluses (i.e. in Europe) such as innovation of technology and policy to reduce over-application of P fertilizers in intensive agriculture by at least 30 %, in vegetable, fruit and high value cash crop production systems. China also needs the appropriate incentives and regulations from the government to promote the large-scale and effective re-use of P resources from all wastes and by-products. Most important is to develop a novel knowledge transfer and technology extension system for millions of small-holder farmers in order to realize the new governmental policies of zero-increase in chemical fertilizer input in crop production by 2020 and transformation of high input and high output agriculture to efficient and sustainable intensification. This requires an integrated effort of scientists, policy makers, farmers and other stakeholders by working together and inducing fundamental changes in P utilization.

References

Antikainen R, Lemola R, Nousiainen JI, Sokka L, Esala M, Huhtanen P, Rekolainen S (2005) Stocks and flows of nitrogen and phosphorus in the Finnish food production and consumption system. Agric Ecosyst Environ 107(2–3):287–305. doi:10.1016/j.agee.2004.10.025

Augspurger N, Webel D, Lei X, Baker D (2003) Efficacy of an E. coli phytase expressed in yeast for releasing phytate-bound phosphorus in young chicks and pigs. J Anim Sci 81(2):474–483

Bai ZH, Ma L, Qin W, Chen Q, Oenema O, Zhang FS (2014) Changes in pig production in China and their effects on nitrogen and phosphorus use and losses. Environ Sci Technol 48:12742–12749

Baker MJ, Blowes DW, Ptacek CJ (1998) Laboratory development of permeable reactive mixtures for the removal of phosphorus from onsite wastewater disposal systems. Environ Sci Technol 32(15):2308–2316

Barberis E, Marsan FA, Scalenghe R, Lammers A, Schwertmann U, Edwards A, Maguire R, Wilson M, Delgado A, Torrent J (1995) European soils overfertilized with phosphorus: part 1. Basic properties. Fertil Res 45(3):199–207

Belevi H (2002) Material flow analysis as a strategic planning tool for regional waste water and solid waste management. In: Proceedings of the workshop in “Globale Zukunft: Kreislaufwirtschaftskonzepte im kommunalen Abwasser-und Fäkalienmanagement”. GTZ/BMZ and ATV-DVWK workshop during the IFAT, pp 13–15

Bennett EM, Carpenter SR, Caraco NF (2001) Human impact on erodable phosphorus and eutrophication: a global perspective. BioScience 51(3):227–234

Bi J, Chen Q, Zhang L, Yuan Z (2013) Quantifying phosphorus flow pathways through socioeconomic systems at the county level in China. J Ind Ecol 17(3):452–460

Burton CH, Turner C (2003) Manure management: treatment strategies for sustainable agriculture. Editions Quae, Flitwick

Canut MMC, Jacomino VMF, Bråtveit K, Gomes AM, Yoshida MI (2008) Microstructural analyses of phosphogypsum generated by Brazilian fertilizer industries. Mater Charact 59(4):365–373

Cao N (2006) Phosphorus management in Chinese agroecosystem based on forecasting the change of soil phosphorus fertility. Ph.D. thesis (in Chinese)

Chen M, Chen J, Sun F (2008) Agricultural phosphorus flow and its environmental impacts in China. Sci Total Environ 405(1):140–152

Chen M, Chen J, Sun F (2010) Estimating nutrient releases from agriculture in China: an extended substance flow analysis framework and a modeling tool. Sci Total Environ 408(21):5123–5136. doi:10.1016/j.scitotenv.2010.07.030

Chen XP, Cui ZL, Fan MS, Vitousek P, Zhao M, Ma WQ, Wang ZL, Zhang WJ, Yan XY, Yang JC, Deng XP, Gao Q, Zhang Q, Guo SW, Ren J, Li SQ, Ye YL, Wang ZH, Huang JL, Tang QY, Sun YX, Peng XL, Zhang JW, He MR, Zhu YJ, Xue JQ, Wang GL, Wu L, An N, Wu LQ, Ma L, Zhang WF, Zhang FS (2014) Producing more grain with lower environmental costs. Nature 514(7523):486–489

Cooper J, Carliell-Marquet C (2013) A substance flow analysis of phosphorus in the UK food production and consumption system. Resour Conserv Recycl 74:82–100

Cordell D, Neset T-S (2014) Phosphorus vulnerability: a qualitative framework for assessing the vulnerability of national and regional food systems to the multi-dimensional stressors of phosphorus scarcity. Glob Environ Chang 24:108–122

Cordell D, White S (2013) Sustainable phosphorus measures: strategies and technologies for achieving phosphorus security. Agronomy 3(1):86–116

Cordell D, White S (2014) Life’s bottleneck: sustaining the world’s phosphorus for a food secure future. Annu Rev Environ Resour 39:161–188

Cordell D, Drangert J-O, White S (2009) The story of phosphorus: global food security and food for thought. Glob Environ Chang 19(2):292–305. doi:10.1016/j.gloenvcha.2008.10.009

Cordell D, Jackson M, White S (2013) Phosphorus flows through the Australian food system: identifying intervention points as a roadmap to phosphorus security. Environ Sci Policy 29:87–102

De-Bashan LE, Bashan Y (2004) Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997–2003). Water Res 38(19):4222–4246

Djodjic F, Bergström L, Grant C (2005) Phosphorus management in balanced agricultural systems. Soil Use Manag 21(1):94–101

Donnert D, Salecker M (1999) Elimination of phosphorus from waste water by crystallization. Environ Technol 20(7):735–742

Dou Z, Knowlton KF, Kohn RA, Wu Z, Satter LD, Zhang G, Toth JD, Ferguson JD (2002) Phosphorus characteristics of dairy feces affected by diets. J Environ Qual 31(6):2058–2065

ECCEY (1995) China environment yearbook. China Environment Yearbook Press, Beijing (in Chinese)

ECCEY (2003) China environment yearbook. China Environment Yearbook Press, Beijing (in Chinese)

ECCEY (2012) China environment yearbook. China Environment Yearbook Press, Beijing (in Chinese)

Ensink JH, Mahmood T, van der Hoek W, Raschid-Sally L, Amerasinghe FP (2004) A nationwide assessment of wastewater use in Pakistan: an obscure activity or a vitally important one? Water Policy 6(3):197–206

Epstein E (1972) Mineral nutrition of plants: principles and perspectives, Wiley, New York, p 142

Gachter R, Imboden D (1985) Lake restoration. Chemical processes in lakes. Wiley, New York, pp 365–388

Gao L, Ma L, Zhang W, Wang F, Ma W, Zhang F (2009) Estimation of nutrient resource quantity of crop straw and its utilization situation in China. Trans Chin Soc Agric Eng 25(7):173–179

Giller KE, Cadisch G, Palm C (2002) The north–south divide! organic wastes, or resources for nutrient management? Agronomie 22(7–8):703–709

Hou Y, Ma L, Gao Z, Wang F, Sims J, Ma W, Zhang F (2013) The driving forces for nitrogen and phosphorus flows in the food chain of China, 1980–2010. J Environ Qual 42(4):962–971

Jeong Y-S, Matsubae-Yokoyama K, Kubo H, Pak J-J, Nagasaka T (2009) Substance flow analysis of phosphorus and manganese correlated with South Korean steel industry. Resour Conserv Recycl 53(9):479–489

Jin X, Xu Q, Huang C (2005) Current status and future tendency of lake eutrophication in China. Sci China Ser C Life Sci 48(2):948–954

Jing J, Rui Y, Zhang F, Rengel Z, Shen J (2010) Localized application of phosphorus and ammonium improves growth of maize seedlings by stimulating root proliferation and rhizosphere acidification. Field Crops Res 119(2):355–364

Ju X, Zhang F, Bao X, Römheld V, Roelcke M (2005) Utilization and management of organic wastes in Chinese agriculture: past, present and perspectives. Sci China Ser C Life Sci 48(2):965–979

Junfa T (2009) Locate correctly the present status and outlook for phosphate rock resources reserves of China-analysis on serve life of phosphate rock reserves in China. Phosphorus Compd Fertil 24(3):6–8 (in Chinese)

Khasawneh F, Sample E, Kamprath E (1980) Evaluation and utilization of residual phosphorus in soils. ASA, CSSA, and SSSA, Madison

Kim T, Mullaney EJ, Porres JM, Roneker KR, Crowe S, Rice S, Ko T, Ullah AH, Daly CB, Welch R (2006) Shifting the pH profile of Aspergillus niger PhyA phytase to match the stomach pH enhances its effectiveness as an animal feed additive. Appl Environ Microbiol 72(6):4397–4403

Lei X, Stahl C (2001) Biotechnological development of effective phytases for mineral nutrition and environmental protection. Appl Microbiol Biotechnol 57(4):474–481

Li L, Zhang F, Li X, Christie P, Sun J, Yang S, Tang C (2003) Interspecific facilitation of nutrient uptake by intercropped maize and faba bean. Nutr Cycl Agroecosyst 65(1):61–71

Li S, Yuan Z, Bi J, Wu H (2010) Anthropogenic phosphorus flow analysis of Hefei City, China. Sci. Total Environ 408(23):5715–5722. doi:10.1016/j.scitotenv.2010.08.052

Li H, Huang G, Meng Q, Ma L, Yuan L, Wang F, Zhang W, Cui Z, Shen J, Chen X, Jiang R, Zhang F (2011) Integrated soil and plant phosphorus management for crop and environment in China. A review. Plant Soil 349(1–2):157–167. doi:10.1007/s11104-011-0909-5

Li YX, Zhang WF, Ma L, Huang GQ, Oenema O, Zhang FS, Dou ZX (2013) An analysis of China’s fertilizer policies: impacts on the industry, food security, and the environment. J Environ Qual 42:972–981

Li G, Li H, Leffelaar PA, Shen J, Zhang F (2014) Characterization of phosphorus in animal manures collected from three (dairy, swine, and broiler) farms in China. PLoS One 9(7):e102698. doi:10.1371/journal.pone.0102698

Liu J, Diamond J (2005) China’s environment in a globalizing world. Nature 435(7046):1179–1186

Liu J, Liao W, Zhang Z, Zhang H, Wang X, Meng N (2007) The response of vegetable yield to phosphate fertilizer and organic manure and environmental risk assessment of phosphorus accumulated in soil. Sci Agric Sin 40(5):959–965

Liu Y, Villalba G, Ayres RU, Schroder H (2008) Global phosphorus flows and environmental impacts from a consumption perspective. J Ind Ecol 12(2):229–247

Lott JN, Kolasa J, Batten GD, Campbell LC (2011) The critical role of phosphorus in world production of cereal grains and legume seeds. Food Secur 3(4):451–462

Ma L, Ma WQ, Velthof GL, Wang FH, Qin W, Zhang FS, Oenema O (2010) Modeling nutrient flows in the food chain of China. J Environ Qual 39(4):1279. doi:10.2134/jeq2009.0403

Ma D, Hu S, Chen D, Li Y (2012) Substance flow analysis as a tool for the elucidation of anthropogenic phosphorus metabolism in China. J Clean Prod 29–30:188–198. doi:10.1016/j.jclepro.2012.01.033

Ma L, Wang F, Zhang W, Ma W, Velthof G, Qin W, Oenema O, Zhang F (2013) Environmental assessment of management options for nutrient flows in the food chain in China. Environ Sci Technol 47(13):7260–7268. doi:10.1021/es400456u

MacDonald GK, Bennett EM, Potter PA, Ramankutty N (2011) Agronomic phosphorus imbalances across the world’s croplands. Proc Natl Acad Sci USA 108(7):3086–3091. doi:10.1073/pnas.1010808108

Matsubae-Yokoyama K, Kubo H, Nakajima K, Nagasaka T (2009) A material flow analysis of phosphorus in Japan. J Ind Ecol 13(5):687–705. doi:10.1111/j.1530-9290.2009.00162.x

MEP (2010) The first national pollution census bulletin. The Ministry of Environmental Protection, Beijing

Metson GS, Bennett EM, Elser JJ (2012) The role of diet in phosphorus demand. Environ Res Lett 7(4):044043

MOA (Minister of Agriculture) (1949–2012) Chinese animal husbandry yearbook. China Statistics Press, Beijing (in Chinese)

Moore P, Daniel T, Edwards D (2000) Reducing phosphorus runoff and inhibiting ammonia loss from poultry manure with aluminum sulfate. J Environ Qual 29(1):37–49

Moriyama K, Kojima T, Minawa Y, Matsumoto S, Nakamachi K (2001) Development of artificial seed crystal for crystallization of calcium phosphate. Environ Technol 22(11):1245–1252

Morse D (1995) Environmental considerations of livestock producers. J Anim Sci 73(9):2733–2740

NBSC (National Bureau of Statistics of China) (1949–2013) China statistic yearbook. China Statistics Press, Beijing

Oenema O, Oudendag D, Velthof GL (2007) Nutrient losses from manure management in the European Union. Livest Sci 112(3):261–272

Ott C, Rechberger H (2012) The European phosphorus balance. Resour Conserv Recycl 60:159–172. doi:10.1016/j.resconrec.2011.12.007

Oyang Z, Wang R (2000) Water environmental problems and ecological options in China. In: China water vision: meeting the water challenge in rapid transition. The 2nd world water forum, The Hague, pp 17–22

Qi G, Gao C (2008) Application of the controlled-release fertilizer in agriculture. Mod Agric Sci 11:022

Qiao M, Zheng Y-M, Zhu Y-G (2011) Material flow analysis of phosphorus through food consumption in two megacities in northern China. Chemosphere 84(6):773–778. doi:10.1016/j.chemosphere.2011.01.050

Qiu J (2010) Phosphate fertilizer warning for China. Nat News 10:498

Rabalais N, Diaz R, Levin L, Turner R, Gilbert D, Zhang J (2010) Dynamics and distribution of natural and human-caused hypoxia. Biogeosciences 7(2):585–619

Reindl J (2007) Phosphorus removal from wastewater and manure through struvite formation: An annotated bibliography. Dane County Dept of Highway. Transportation and Public Works, Wisconsin

Sattari SZ, Bouwman AF, Giller KE, van Ittersum MK (2012) Residual soil phosphorus as the missing piece in the global phosphorus crisis puzzle. Proc Natl Acad Sci 109(16):6348–6353

Sattari S, van Ittersum M, Giller K, Zhang F, Bouwman A (2014) Key role of China and its agriculture in global sustainable phosphorus management. Environ Res Lett 9(5):054003

Schmid Neset T-S, Bader H-P, Scheidegger R, Lohm U (2008) The flow of phosphorus in food production and consumption—Linköping, Sweden, 1870–2000. Sci Total Environ 396(2–3):111–120. doi:10.1016/j.scitotenv.2008.02.010

Schröder B, Breves G, Rodehutscord M (1996) Mechanisms of intestinal phosphorus absorption and availability of dietary phosphorus in pigs. Dtsch Tierarztl Wochenschr 103(6):209–214

Senthilkumar K, Nesme T, Mollier A, Pellerin S (2012) Conceptual design and quantification of phosphorus flows and balances at the country scale: the case of France. Glob Biogeochem, Cycles 26

Sharpley AN, Herron S, Daniel T (2007) Overcoming the challenges of phosphorus-based management in poultry farming. J Soil Water Conserv 62(6):375

Sheng H, Xia X, Yang L, Zhao H, Luan S, Feng K (2003) Effects of phosphorus application on soil available P and different P form in runoff. Acta Ecol Sin 24(12):2837–2840

Shin H, Lee S (1998) Removal of nutrients in wastewater by using magnesium salts. Environ Technol 19(3):283–290

Smadi MM, Haddad RH, Akour AM (1999) Potential use of phosphogypsum in concrete. Cem Concr Res 29(9):1419–1425

Smit B, Middelkoop JC, Dijk W, Reuler H, Buck AJ, Sanden P (2010) A quantification of phosphorus flows in the Netherlands through agricultural production, industrial processing and households. Plant Research International, Business Unit Agrosysteemkunde, Wageningen

Stewart W, Hammond L, Kauwenbergh S (2005) Phosphorus as a natural resource. Phosphorus: agriculture and the environment, agronomy monograph no. 46. American Society of Agronomy, Madison

Suh S, Yee S (2011) Phosphorus use-efficiency of agriculture and food system in the US. Chemosphere 84(6):806–813. doi:10.1016/j.chemosphere.2011.01.051

Sun B, Zhang L, Yang L, Zhang F, Norse D, Zhu Z (2012) Agricultural non-point source pollution in China: causes and mitigation measures. Ambio 41(4):370–379

Syers K, Bekunda M, Cordell D, Corman J, Johnston J, Rosemarin A, Salcedo I (2011) Phosphorus and food production. UNEP year book, United Nations Environmental Program, Nairobi, pp 34–45

Tayibi H, Choura M, López FA, Alguacil FJ, López-Delgado A (2009) Environmental impact and management of phosphogypsum. J Environ Manag 90(8):2377–2386

Tilman D, Cassman KG, Matson PA, Naylor R, Polasky S (2002) Agricultural sustainability and intensive production practices. Nature 418(6898):671–677

USGS (2014) Mineral commodity summaries. http://minerals.usgs.gov/minerals/pubs/commodity/phosphate_rock/mcs-2014-phosp.pdf

Vaccari DA (2009) Phosphorus: a looming crisis. Sci Am 300(6):54–59

Van Kauwenbergh SJ, Stewart M, Mikkelsen R (2013) World reserves of phosphate rock a dynamic and unfolding story. Better Crops 97:18–20

Villalba G, Liu Y, Schroder H, Ayres RU (2008) Global phosphorus flows in the industrial economy from a production perspective. J Ind Ecol 12(4):557–569. doi:10.1111/j.1530-9290.2008.00050.x

Wang J (2013) Sulphur phosphorus and bulk materials handling related engineering. SP BMH Rel Eng 1:7–12 (in Chinese)

Wang F-H, Ma W-Q, Dou Z-X, Ma L, Liu X-L, Xu J-X, Zhang F-S (2006) The estimation of the production amount of animal manure and its environmental effect in China. China Environ Sci 26(5):614–617

Wang F, Sims JT, Ma L, Ma W, Dou Z, Zhang F (2011) The phosphorus footprint of China’s food chain: implications for food security, natural resource management, and environmental quality. J Environ Qual 40(4):1081. doi:10.2134/jeq2010.0444

Wang X, Xue S, Xie G (2012) Value-taking for residue factor as a parameter to assess the field residue of field crops. J China Agric Univ 17:1–8

Wu Q, Bishop P, Keener T, Stallard J, Stile L (2001) Sludge digestion enhancement and nutrient removal from anaerobic supernatant by Mg(OH)2 application. Water Sci Technol 44(1):161–166

Wu H, Yuan Z, Zhang Y, Gao L, Liu S (2014) Life-cycle phosphorus use efficiency of the farming system in Anhui Province, Central China. Resour Conserv Recycl 83:1–14. doi:10.1016/j.resconrec.2013.12.002

Yuan Z, Liu X, Wu H, Zhang L, Bi J (2011a) Anthropogenic phosphorus flow analysis of Lujiang County, Anhui Province, Central China. Ecol Model 222(8):1534–1543. doi:10.1016/j.ecolmodel.2011.01.016

Yuan Z, Shi J, Wu H, Zhang L, Bi J (2011b) Understanding the anthropogenic phosphorus pathway with substance flow analysis at the city level. J Environ Manag 92(8):2021–2028. doi:10.1016/j.jenvman.2011.03.025

Zhang W, Wu S, Ji H, Kolbe H (2004) Estimation of agricultural non-point source pollution in China and the alleviating strategies. I. Estimation of agricultural non-point source pollution in China in early 21 century. Sci Agric Sin 37(7):1008–1017

Zhang W, Ma W, Zhang F, Ma J (2005) Comparing the superiority of Chinese phosphate rock and the using strategy with that of United States and Morocco. J Nat Resour 20:378–386 (Chinese with English abstract)

Zhang W, Ma W, Ji Y, Fan M, Oenema O, Zhang F (2008) Efficiency, economics, and environmental implications of phosphorus resource use and the fertilizer industry in China. Nutr Cycl Agroecosyst 80(2):131–144

Zheng C, Bluemling B, Liu Y, Mol AP, Chen J (2013) Managing manure from China’s pigs and poultry: the influence of ecological rationality 43(5):661–672

Acknowledgments

This study was supported by the National Basic Research Program (973-2015CB150405) and the Innovative Group Grant of the National Science Foundation of China (31421092). We also thank Dr. Peter Christie from Agri-Food and Biosciences Institute, Belfast, UK for his linguistic revision.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, G., Huang, G., Li, H. et al. Identifying potential strategies in the key sectors of China’s food chain to implement sustainable phosphorus management: a review. Nutr Cycl Agroecosyst 104, 341–359 (2016). https://doi.org/10.1007/s10705-015-9736-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10705-015-9736-z