Samples of carboxymethyl chitosan have been synthesized with different extents of substitution by changing the reaction conditions. Carboxymethyl chitosan completely dissolves in water when the extent of substitution exceeds 90%. The theological properties were studied for 4% aqueous solutions of carboxymethyl chitosan with CaCl2 and Ca(OH)2 as additives as well as for a mixture of carboxymethyl chitosan and polyethylene oxide with added CaCl2. The introduction of additives to aqueous solutions of carboxymethyl chitosan leads to enhanced viscosity and gel formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Natural polymers remain in demand and will continue to find common use because of a number of reasons such as their renewability in nature, capacity to undergo biodecomposition, and biocompatibility [1,2,3]. Chitin is the second-most common natural polymer after cellulose and its derivatives are finding increasing use in many areas [4,5,6]. Chitin dissolves in a limited number of solvents convenient for practical application, while chitosan (CTS) dissolves in acidified aqueous media. This polymer is finding increasing use in agriculture, the food industry, pharmaceuticals, biomedicine, and cosmetics. The insolubility of chitin and chitosan in water limits their use.

Chitin and CTS are chemically modified to impart water solubility. Water-soluble derivatives of CTS have been obtained containing hydroxypropyl, carboxymethyl, carboxyethyl, sulfate, and phosphate groups. Water-soluble copolymers of CTS have also been obtained In Themost convenient method for obtaining water-soluble CTS derivatives is the synthesis of carboxymethyl chitosan (CM-CTS). The conditions for the synthesis of CM-CTS are similar to the conditions for commonly used carboxymethyl cellulose. Carboxymethylated derivatives of chitin and CTS have also been obtained and studied [8, 9].

By adjusting the conditions for the synthesis of CM-CTS, we may obtain samples completely soluble in aqueous solutions at different pH and samples, which are insoluble in water in a certain pH range [10, 11]. Aqueous solutions of CM-CTS have found use in cosmetics and biomedicine [12,13,14]. Both scientific and practical interest is found for gel-like systems obtained from aqueous solutions of CM-CTS, which may be used for the preparation of creams and ointments.

In the present work we obtained water-soluble CM-CTS and studied the theological properties of aqueous solutions of this material with various additives. The starting material was chitosan isolated from the outer skeletons of crabs (obtained from Bioprogress, Russia) with deacetylation (DA) of 88% and molecular mass 1.15·105 as well as polyethylene oxide (PEO) with molecular mass 3.5·104 obtained from Sigma Aldrich, USA.

The sample of CM-CTS was synthesized by a procedure similar to the reaction conditions described by Chen and Park [10]. A weighed sample of 10 g chitosan was taken in all cases. The ratio of the reagents in the reaction medium [NaOH and monochloroacetic acid (MCAA)], the composition of the reaction mixture (water/isopropyl alcohol), temperature, and reaction duration were all varied. The extent of substitution (ES) and DA of the CM-CTS samples were determined conductometrically using reported methods [15, 16]. The characteristic viscosity of the chitosan and CM-CTS samples was determined according to the recommendations of Pogodina et al. [17].

The solubility of the samples was determined relative to the preparation of 1% solutions of the polymers. Weighed samples (1 g) were placed into 99 g distilled water. We also used 2% solutions of acetic acid (AA) and NaOH. The mixtures were stirred for 4 h. The solutions were then centrifuged for 0.5 h at 4500 rpm to separate the insoluble part. The resultant precipitate was washed on the filter with ethanol, dried in vacuum at 50°C, and weighed. The solubility (in %) was calculated using the formula

where M1 is the mass of the weighed sample and M2 is the mass of the insoluble part of the sample.

The study of the theological properties of moderately concentrated (4%) aqueous solutions was carried out using a Rheotest-2.1 rheoviscosimeter in the shear stress range 3-600 Pa. Calculated amounts of concentrated aqueous solutions of CaCl2 and Ca(OH)2 were added to the 4% aqueous solutions. These solutions were mechanically stirred for 1 h prior to studying the theological properties of the prepared mixtures.

Table 1 shows the conditions for the synthesis of CM-CTS and the values of their DA, ES, and [η], while Table 2 gives the values for solubility of the samples obtained in water and 2% aqueous AA and NaOH. CTS-CM with high ES could not be obtained using a reaction mixture with an excess of water (80/20 water/IPA) (Table 1, samples CM-CTS-1—CM-CTS-6). These results are in good accord with the data of other workers [10, 11]. Increasing the reaction time (τ) from 1 to 4 h at 40°C leads to an increase in ES to 34%. In this case, a decrease in the DA of the samples from 83 to 70% is observed, indicating that the carboxymethylation reaction proceeds mainly at the polysaccharide hydroxyl groups. However, there is also partial addition of carboxymethyl groups at the amino groups. Since the reaction is carried out in an aqueous alkaline medium, there is oxidative destruction of the chitosan molecules, as indicated by the decrease in the values of [η] for the CM-CTS samples. Increasing the reaction temperature (t) and the amount of MCAA in the reaction medium did not lead to a significant increase in ES when using 80/20 water/isopropyl alcohol (IPA) (samples CM-CTS-5 and CM-CTS-6).

CM-CTS samples with high ES (see CM-CTS-7–CM-CTS-9) were obtained only using a reaction mixture with excess isopropyl alcohol (20/80 water/IPA), which is also in good accord with the results of other workers [10, 11]. The greatest ES value was obtained carrying out the reaction at room temperature (CM-CTS-9) but with a very long reaction time, which is inconvenient for the industrial production of chitosan ether.

The data given in Table 2 show good solubility in water for CM-CTS with ES > 70%. Since CM-CTS is a polyampholite containing amino and carboxyl groups, we should expect its solubility in both acidic and alkaline media. CM-CTS samples with low ES (up to 50%) are insoluble or only partially soluble in aqueous NaOH but, similar to chitosan. highly soluble in acidic aqueous solutions. Good solubility of CM-CTS in aqueous NaOH is observed only for ES > 70%. Complete solubility of CM-CTS in alkaline media occurs when ES = 90%.

In order to raise the viscosity of aqueous solutions of CM-CTS or obtain gel-like systems, we use additives of the salts of polyvalent metals, synthesize copolymers with CM-CTS as a component [7, 18,19,20,21], or mix with other polymers [22,23,24]. In order to investigate the intermolecular interactions in concentrated solutions, we studied the theological properties of 4% aqueous solutions of CM-CTS with ES = 70% with added CaCl2 and Ca(OH)2. Chitosan is partially compatible with polyethylene oxide [25]. Thus, we studied the Theological properties of 4% aqueous solutions of 85/15 CM-CTS/PEO with added CaCl2.

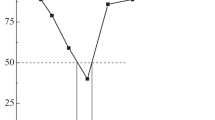

The flow curves of all the systems studied represent incomplete Bow curves of non-Newtonian liquids (Figs. 1-3). The structural viscosity branch appears at log τ> 2.5. For convenience of comparison, the curves for the dependence of the viscosity of the mixtures studied on the amount of additive are shown in Fig. 4. The introduction of CaCl2 into a solution of CM-CTS leads to a greater increase in viscosity than upon the introduction of Ca(OH)2 (Fig. 4, curves 1 and 2). Mixing a solution of CM-CTS with a solutions of PEO (curve 3) reduces the viscosity due to the lower viscosity of the PEO solution. (PEO with a low molecular mass). However, the trend for increasing viscosity of CM-CTS/PEO with added CaCl2 remains similar as in the case of the solution of CM-CTS with added CaCl2, the viscosity is considerably enhanced. Thus, the viscosity of aqueous solutions of CM-CTS may be varied in a rather broad range up to the formation of gels by introducing Ca2+ ions as aqueous solutions of CaCl2 or Ca(OH)2 into solutions of chitosan ether.

This work was carried out with the financial support of the Federal Agency of Scientific Organizations (FANO) (Theme No. 0096-2016-0004, State Registration No. AAAA-A 16-116071450050-6).

References

I. Simkovich, Carbohydr. Polymers, 95, No. 2, 697-715 (2013).

J. Liu, S. Willfor, and C. Xu, Bioactive Carbohydr. A. Dietary Fibers, 5, 31-61 (2015).

A. M. Bochek, Fibre Chemistry. 40, No. 3, 192-197 (2008).

M. Rinaudo, Prog. Polymer Sci., 31, No. 7, 603-632 (2036).

R. K. Shukla and A. Tiwari, Carbohydr. Polymers, 88, No. 2, 399-416 (2012).

I. Younes and M. Rinaudo, Mat: Drugs. 13, No. 3, 1133-1174 (2015).

V. K. Mourya, N. N. Inamdar, and A. Tiwari, Adv. Mat. Lett., 1, No. 1, 11-33 (2010).

F. S. Kittur, K. V. H. Prashanth, et al., Carbohydr. Polymers, 49, No. 2, 185-193 (2002).

A. Anitha, V. V. Divya Rani, et al., Carbohydr. Polymers, 78, No. 4, 672-677 (2009).

X.-G. Chen and H. J. Park, Canbohydr. Polymers, 53, No. 4.355-359 (2033).

N. K. Patel and V. K. Sinha. Intern. J. Polymeric Mater., 58, No. 11, 548-560 (2009).

D. Narayanan, R. Jayakumar, and K. P. Chennazhi, WIREs Hammed. Nanobioterhnot., 6, No. 6.574-598 (2014).

A. Jimtaisong and N. Saewan, Int. J. Cosmetic Sci., 36, No. 1, 12-21 (2014).

D. Tzaneva, M. Djivoderova, et al., J. Pharm. Sci. & Res., 9, No. 8, 1383-1387 (2017).

F. R. De Abreu and S. P. Campana-Filho, Polimeros: Ciência e Tecnol., 15, No. 2, 79-83 (2005).

S. S. Vaghani, M. M. Patel, et al., Bull. Mater. Sci., 35, No.7, 1133-1142 (2012).

N. V. Pogodina, G. M. Pavlov, et al., Polymer Sci. U. S. S. R., 28, No. 2, 251-259 (1986).

T. Matsumoto and H. Zenkoh, Chem. Soc. Faraday Trans., 87, No. 24, 3841-3846 (1991).

Y. F. Poon, Y. B. Zhu, et al., Adv. Funct. Mater., 17, No. 13, 2139-2150 (2007).

G. Fan, R. Lyu, et al., Appl. Polymer Sci., 135, No. 7, 1-10 (2018).

L.-G. Yang, Y.-G. Lan, et al., Acta Phamtacol. Sinica, 31, No. 12, 1625-1634 (2010).

G.-Q. Zhu, F.-G. Wang, et al., Asian. J. Chem., 26, No. 1, 33-35 (2014).

F. O. M. S. Abreu, C. Bianchini, et al., Polymer Int., 58, No. 11, 1267-1274 (2009).

W. E. G. Müller, M. Neufurth, et al., Europ. Cells a. Mater., 31, 174-190 (2016).

E. S. Sashina, A. V. Vnuchkin, and N. P Novoselov, Russ. J. Appl. Chem., 79, No. 10, 1643-1646 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna. Vol. 50. No. 3. pp.52-55. May-June. 2018

Rights and permissions

About this article

Cite this article

Bochek, A.M., Shevchuk, I.L. Properties of Aqeous Solutions of O,N-Carboxymethyl Chitosan with Various Additives. Fibre Chem 50, 193–196 (2018). https://doi.org/10.1007/s10692-018-9958-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-018-9958-3