Abstract

Among the main challenges over the past few years has been to capture and analyze the progress made towards the transition to circular economy (CE), since ensuring that the transition is successful requires monitoring progress. As a result of the enormous amount of harmful waste produced by the olive oil industry in the Mediterranean region, monitoring and evaluating circularity has become the basis for economic development measures. An understanding of the degree of circularity is crucial to improving extraction processes. Additionally, this type of measurement could prove useful for driving policies on the topic and improving sustainability, since CE is often used as a potential tool to support sustainable development. This research provides a consistent review of the CE indicators used in agro-industry sector, based on the scientific literature and practice, identifying those who could assess circularity in the olive oil industry. Circularity refers to reducing waste and using by-products in the olive oil industry and in general in the food supply chain. The purpose of this review is to assess the success of CE strategies and to remove some of the ambiguity surrounding CE in practice. Despite the fact that the indicators of circular economy have aroused substantial attention globally, there is not much conceptual and empirical research focusing on the development of indicators in practice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the era of global crisis, humanity not only has to deal with numerous challenges that threaten its survival and prosperity, including the financial downturn, health pandemic, migration flows, climate change, energy sufficiency and food security, but also faces the challenge of ensuring the sustainability of the planet. Therefore, the war between Ukraine and Russia has intensified the energy crisis on the one hand, and put the food security on peril on the other. As a result of their exports of wheat, corn and sunflower oil, which are used in food processing, Ukraine and Russia account for 30 percent of global exports. The threat to Ukrainian farms and the closure of Black Sea harbors have restricted food supplies at a time when prices are at their highest since 2011, and food shortages have already hit some countries (Tank 2022).

Concurrently, there has been a significant impact on the global economy due to the Covid-19 pandemic. In response to the virus rapid spread, governments around the world have taken extraordinary measures to eliminate it, including temporary closures of businesses and companies that have affected economic markets (Chiaraluce 2021).

In addition to these burdens, many countries have sought innovative policies to address the concerns associated with resource scarcity and global warming (Geng et al. 2012). Directly and indirectly, this situation seems to have influenced the agri-food sector, even though there is an anticipated increase in agricultural demand at a rate of 1.1 percent per year over the period 2010–2050 (Alexandratos & Bruinsma 2012; Berbel & Posadillo 2018). Human societies benefit from agri-food systems (AFS) in multiple ways (food, animal feed, animal traction, clothing, bio-energy, construction materials, etc.). In contrast, they alter nutrient cycles and deplete limited resources, specifically phosphorus (P) from mines, which has negative impacts on the environment. Also, the use of non-renewable fossil energy generates greenhouse gases (GHGs) (CO2), which are responsible for climate change, and release of reactive nitrogen (N) into the atmosphere, causing a cascade of N emissions, increasing greenhouse gas emissions (N2O), and increasing atmospheric deposition (NOx and NH3). This leads to a global acidification of the environment, decreased productivity, inefficient functioning, and eutrophication of natural and cultivated ecosystems (NO3−) (Kleinpeter et., al 2023). A number of initiatives have been undertaken recently in the food sector to address perpetual concerns such as food safety, product quality, food loss, waste production, and environmental degradation (Esposito et al. 2020). In this scenario, CE provides avenues for reducing food waste and augmenting valorization of it (Ciccullo et al. 2021). It has become increasingly important to implement CE principles in the food sector, particularly in developing countries, since the food sector is vital for their economic growth (Fukase & Martin, 2020). Considering that the agri-food sector is one of those with the highest environmental footprint, increasing its sustainability is a crucial issue, in order to ensure the sustainability of the planet in general (Ncube et al. 2022). In addition, the agri-food sector, as it seems to be the greater contributor to the production of biomass in a large percentage, is considered the largest biological sector and is therefore one of the main sectors that must focus indispensably on the adoption of the principles of the CE (Duque-Acevedo et al. 2020; Atanasovska et al. 2022). Introducing by-products into the system or creating new processing steps through recycling and reusing would substantially improve the sustainability of the food system (Focker et al. 2022).

The transition to a CE is usually directly associated with stimulating innovation, increasing jobs and investments, as well as added value (Chobanova 2020). For instance, according to an analysis of the Circular Economy and Resource Efficiency Agency of the UK, conducted in 2015, it is estimated that CE has the potential to reduce unemployment rate in EU, since it could create 3 million extra jobs (Kristensen & Mosgaard 2020). While at the same time, according to a IPPC (2014) report, globally, CE could reduce carbon dioxide emissions by 550 Mt CO2 equivalent (approximately 33%), or 3/5ths of the projected reduction target for limiting global warming to 2 °C by 2050 (Robaina et al. 2020).

The CE model is the basis for most sustainable development policies and instruments (Yang et al. 2023). In the food sector, CE is considered an idea that can contribute to sustainability goals by supporting regenerative patterns of consumption and production (Friant et al. 2020). According to the UN, CE is associated directly and indirectly with the Sustainable Development Goals (SDGs). Sustainability in agriculture is a key to achieving zero hunger under SDG 2, cleaner, renewable energy sources are key to SDG 7, sustainable consumption is key to SDG 12. As well as it is specifically emphasized that by reusing and recycling products, food loss can be reduced and resource utilization efficiency can be improved, and climate change is addressed by SDG 13 (Barros et al. 2020; Zhang et al. 2022).

To the best of the authors’ knowledge, there have been no comprehensive studies aimed at filling the gaps and addressing the existing lack of an assessment tool to measure and monitoring the CE in olive oil industry. In light of that, the purpose in this review paper is to describe sources of CE indicators for monitoring progress of the agriculture and food industry, by illuminating the case of olive mills, subject to disruption caused for instance by the Ukraine conflict, pandemic, and other stressors. Due to the lack of consensus regarding the CE indicators in the agri-food industry, especially the olive oil industry, an original feature of this paper is that it reorganizes the CE indicators groups, as well as adapts the indicators to fit the olive oil industry. Since the agri-food, and specifically the olive oil industry, has a key role towards sustainable development (Espadas-Aldana et al. 2023), the development of the indicators for measuring or/and monitoring CE in olive oil industry is of great significance in order to detect the level of implementation of CE principles and check the effectiveness of the current policy. To clarify and reach desired outcomes, indicators are generally designed to provide decision-makers with objective, credible information about the state of the olive oil industry. Providing a framework for measuring and/or monitoring the system and ensuring that it evolves towards circularity is an essential component of this paper.

The remaining of this paper has the following structure: Sect. 2 is dedicated to summarize the theoretical background regarding the importance of measuring and monitoring CE in general, as well as to present existing methods and indicators. As a final note, this section gives prominence to implementing CE practices in the olive oil industry sector, and to highlighting the significance of finding indicators and methods that could be used to measure circularity in olive mills. Section 3 is a reference to the methodology this article used to achieve its objectives. A discussion and suggestions of the indicators that could be used in olive mill measurements are then presented in Sect. 4, followed by conclusions in Sect. 5.

2 Theoretical background

2.1 2.1. Measuring and monitoring of CE

As Peter Drucker describes, “you can’t manage what you can’t measure”, unless success is defined and tracked, it is not possible for someone to know whether he is successful (World Bank 2014). The CE is a political goal, which evolves a global one, aimed at combining sustainability with economic growth. The transition from a linear to a CE economy also implies the challenge of assessing this new economy type (Reich et al 2023).Therefore, a fundamental issue in the transition to sustainability is the measurement of CE performance at several levels (Janik & Ryszko 2019), since measuring and reporting progress is essential for a successful CE transition. Nevertheless, there is a lack of detailed understanding of how to assess and monitor progress, particularly at company or product level, making it difficult for producers who want to provide circular products and services in the market, as well as for consumers who wish to compare products and make their decisions considering product circularity (Kristensen & Mosgaard 2020). Since there are a variety of actions, activities, and projects that could be considered “circular,” measuring the “circularity” of a product or service is challenging. Currently, there is no widespread accepted framework for assessing and reporting an organization's “circularity”. In the CE, this lack of framework represents one of the utmost needs, as well as an opportunity (USCCF, 2022).

It is a complicated task to measure how well a country’s economy or a sector adheres to the principles of the CE, or degree of circularity (EEA, 2016). As part of the monitoring process, key areas of circularity will be identified (sustainable resource management, societal behavior, business operations) and the available indicators will be defined (Chobanova 2020).

Achieving results and targets should inspire action throughout industry and society as well. This requires the development of harmonized, measurable, relevant, and diagnostic indicators (Oswald 2013). As circularity isn't necessarily synonymous with environmental sustainability (despite often being assumed to be the case), these metrics should also measure environmental performance in addition to circularity. For instance, high recycling rates may result in drastic increases in energy demands, which may offset any environmental gains that are gained from second-hand material recovery (Haupt & Hellweg 2019).

The number of case studies whose primary aim is to evaluate the industrial symbiotic relationship towards CE has increased over the last few years. Such studies could, however, provide insight to those specializing in similar production or business activities or supply chain management processes. These researches use a variety of variables, including economic growth, recycling rates, patents related to SD and CE etc., among others (Cautisanu et al. 2018).

Achieving a circular economy requires providing organizations with tools that measure, monitor, and communicate their progress (Valls-Val et al. 2022). According to several studies in the literature, the lack of a common measurement and monitoring reference point is causing a barrier in CE development (Poponi et al. 2022). Currently, academia is most concerned with analyzing the transition towards CE, so suitable methods, tools, and indicators are required to gauge the progress (Pavlovic et al. 2020).

2.2 Indicators of CE

It has been noted that numerous CE indicators have been developed over the past few years, but there is a lack of consistency regarding their purposes, scopes, and intended applications (Janik & Ryszko 2019). The indicators are typically variables or functions of variables that provide information about circularity (technology cycles) or effects (cause-and-effect models), based on a composite data set of quantitative and qualitative information (Moraga et al. 2019).When designing new products, these indicators allow circularity to be taken into account as a criterion and input for design decisions, as well as allow companies to compare the circularity of different versions ('what if' scenarios) of the product.By defining a minimum threshold for their products, the organizations could use the CE indicators to make purchasing decisions (EMF, 2019).

Using the resource productivity (RP) indicator (EEA 2016), which correlates gross domestic product with raw material consumption or domestic material consumption, economic progress can be measured toward a more sustainable economy. The RP measures the overall wellbeing in relative to the resource consumption. A CE transition requires understanding what factors contribute to the different performances of countries in terms of their RP and how they determine a good or poor performance in utilizing resources (Robaina et al. 2020).

CE indicators are typically categorized into micro-level, meso-level, and macro-level, for organizations and products, eco-industrial parks, and cities, provinces, regions and countries, respectively (Pauliuk 2018). A good indicator in CE allows the organization's performance to be quantified and is a source of relevant decision-making information for managers and entrepreneurs (Walker et al. 2018). Due to the wide variety of sustainability indicators that have been developed, managers were increasingly having trouble grasping their meaning and significance when making decisions and computing the influence of the indicator on their efficiency level. For both company managers and researchers, the assessment of aspects such as environmental footprint, recycling quotas, or environmental impacts of waste management can be challenging, due to its great complexity (Sanchez-Ortiz et al. 2020).

Measurement and monitoring progress towards a circular economy (CE) has been highlighted by a variety of sources, and research into CE indicators has increased (Yang et al. 2023). Table 1 depicts some of the attempts that have already been made during the last decade in order to identify the indicators that are measuring the circularity level of companies, organizations etc.

Despite the numerous indicators for measuring the environmental impact or the efficient use of resources, it is relatively rare to find studies that address how to assess circularity in products and supply chains effectively. Currently, there is no generally acceptable method for measuring circularity at a micro-level (Kristensen & Mosgaard 2020). The majority of indicators considered in the literature are based on just one aspect, usually inputs and outputs in the production system, or include just some aspects of CE, despite some attempts to indicate the way to measure CE (Moraga et al. 2019).

With this understanding, the Ellen MacArthur Foundation (EMF) formulated and made available the first-ever “Circularity indicators” project in 2015 in response to the problem of the absence of measuring and monitoring tools of circularity. A major objective of this project was to identify missing indicators in CE and formulate a methodology for evaluating the transition of organizations to circular business models (Pavlovic et al. 2020).

The same year Di Maio & Rem (2015) created the “Circular Economy Index (CEI)”, which encompassed both economic and environmental factors, centered in recycling of materials but not include their recovery. A year later, Scheepens et al. (2016), using LCA, recommended a measurement for evaluating circularity for products, but this method focuses on reducing externalities and not on determining circularity levels.

Banaite &Tamosiuniene (2016) analyze the factors should be considered setting circular economy indicators. In terms of industry-level the following proposal have been drawn:

-

•

Environmental perspectives

-

•

Natural resource use in production: preserving natural resources and making efficient use of water, raw materials and energy

-

•

Level of emissions—both direct and indirect;

-

•

Recycling, reusing, and reclaiming products and materials: reduce waste generation, incineration, and landfilling, and increase material and energy efficiency

-

•

Economic perspectives

-

•

Industrial scale and quality both contribute to the economic benefit of industry

-

•

Social perspectives

-

•

Industry provides social benefits, such as increasing employment and revenue

An analysis of business models based on CE and its effect on efficiency levels by Urbinati et al. (2017) identify two dimensions to measure efficiency: the value network and the customer value proposition and interface.

Elia et al. (2017) show that materials and substance flow analysis and life cycle assessment are the two most promising assessment methodologies for covering four out of five CE dimensions. Moreover, a number of indicators and methodologies based on European Environmental Agency CE characteristics were evaluated, concluding that none of them could be used to monitor all the characteristics independently (Moraga et al. 2019).

A review on the methods for assessing resource recovery from waste in order to implement principles of CE, by Iakovidou et al. (2017) demonstrate that no single method could explain the retention of value in waste resources. So, a comprehensive assessment of CE was needed in order to take into its environmental, economic, social and technical dimensions (Moraga et al. 2019).

Although there are many resources available, Park and Kremer (2017) seek to establish sustainable indicators that could quantify CE's impact on mining efficiency. They organize and categorize the existing sustainability indicators in categories to elucidate their usage and ease their implementation in micro-level: (1) environmental (chemical and release), (2) pollution stemming from waste and emissions due to chemicals' end-of-life and use, and raw material and facility management indicators (Sanchez-Ortiz et al. 2020).

Based on the british standard institute’s (BSI) BS 8001:2017 standard, Pauliuk (2018) recommends a group of indicators. In spite of its intention to ease CE adoption in organizations and production systems, this standard do not contain mandatory specifications. For assessing the five characteristics promoted by the BSI standard (restoring, regeneration, maintaining utility, maintaining financial value, and maintaining nonfinancial value), existing indicators (climate, resource efficiency, energy and sufficiency) are used along with indicators for complementary characteristics (Moraga et al. 2019).

Along with Mayer et al. (2018), material flow analysis can be used to develop indicators for the EU that will contribute to reducing pressures on the environment caused by resource use. According to EU policy, waste (food waste and waste production) and recycling (Materials recycled and their contribution to raw material demand) should be monitored, as well as economic and social indicators (EC, 2018; Helander et al. 2019).

In the study of Parchomenko et al. (2019), three categories of CE indicators are identified, namely resource efficiencies, stock flows and product-centric indicators. A typical CE metric includes waste disposal, the use of primary versus secondary resources, recycling efficiency, while very few measure value change, value maintenance, and longevity.

According to Haupt and Hellweg (2019), an indicatoris designed to measure the environmental impact of value retention in a system, incorporating product life cycle impacts, value retention processes, and impacts on use phases.

For the practical implementation of CE in companies, Janik and Ryszko (2019) identify 19 micro-level indicators. From a managerial perspective, each metric was evaluated to determine how well it could facilitate CE decision-making. Using technical cycles, Moraga et al. (2019) indicate three types of indicators: indicators of physical properties, indicators of effects, and indicators of ecological, economic, and/or social properties.

Taking a closer look at 30 CE assessment indicators for organizations, Kristensen and Mosgaard (2020) determine extending useful life examined dismantling, maximizing resource efficiency or reusing as less used topics, while recycling, end-of-life management, and regeneration are identified as trending topics. To further improve the contribution of waste management to a CE, governments, industries, and researchers typically use mass-based recycling and reuse goals (Moraga et al. 2019; Haupt & Hellweg 2019).

Assessing an organization's level of compliance with CE requires innovative approaches. For measuring the progress of organizations toward the CE, the EU emphasizes the need to obtain CE indicators. Nevertheless, the EU institutes indicators (Eurostat 2021) at the territorial level, but those for organizations have not yet been developed. Hence, Vinante et al. (2021) argue that the organizational level is particularly important. In order to assess their progress with the CE, organizations must develop their own CE indicators and tools, which make it easier for them to assess and, as a result, improve the transition (Valls-Val et al. 2022).

In their review of CE indicators developed and employed in the academic literature and in industrial practice, Calzonari et al. (2022) provide an overview of supply chain-based CE indicators. As a result, a subset of frequently employed metrics across all sustainability pillars is identified, as well as two prototype composite indicators (CIs) are proposed.

In the meantime, a total of 10 indicators are formulated for sustainable development by UN Environment, while 17 indicators are developed by UNDP, OECD create 25–30 indicators to measure green growth, over 50 indicators are developed by the World Bank regarding sustainable development and environmental protection, and 32 indicators are developed by Eurostat for measuring resource efficiency (Cautisanu et al. 2018). Furthermore, a monitoring framework for CE has is proposed by the European Commission (EC) (EC, 2018). In private consulting, Ellen MacArthur Foundation (EMF) is at the forefront of the CE concept formulation (Ghisellini et al. 2016). However, no common concept of CE has emerged despite these actions (Moraga et al. 2019).

2.3 The case of olive oil industry

2.3.1 Olive oil industry

Over the past few decades, the production of olive oil has increased steadily due to its high antioxidant and essential fatty acid content (Fig. 1). Olive oil accounts for a substantial portion of the world's trade, and it is widely considered one of the most important trends in dietary trends. Over 3 million tons of olive oil is produced worldwide each year, contributing significantly to the economy and providing employment opportunities. In terms of production volume, Spain accounts for almost one-third of the world's olive oil production. Among the other countries that contribute to the global olive oil production are Italy, Greece, Tunisia, Turkey, and Morocco (Donner & Radic 2021).

Total Olive Oil Production (1000 tones) (Based on Data received from International Olive Oil Council in December 2021)

In these regions, this food product is highly valued because of its economic importance; however, its adverse effects on the environment have been documented. The cultivation practices followed, as well as the olive oil production practices used, cause adverse environmental effects in the areas where this activity is carried out, related to the disposal of waste, air pollution, the depletion and degradation of natural resources and the degradation of soils (Ncube et al. 2022).

2.3.2 Olive mill waste (OMW)

The olive mill waste (OMW) is a solid or liquid by-product of the oil extraction process. It varies in amount and composition, due to the fruit-related factors, production year, microbial treatment, as well as the method of extraction (traditional, three-phase, two-phase). Depending on the extraction process used, the products and by-products are shown in Fig. 2.

Products and by-products generated depending the oil extraction process (Khdair & Abu-Rumman 2020)

The main OMW, aside from olive leaves and olive stones (obtained from separating pulp before or after oil extraction), are the following:

-

1.

Semi-solid waste or Solid (OMSW) from olive mills consists of crushed olive peels, skins, stones, water, and phenolic compounds, including uronic acids and residual oil (Cecchi et al. 2018).

-

2.

Olive mill wastewater (OMWW), a dark-brown liquid composed of 83–92% water (vegetative and process water) and the remainder consisting of a heterogeneous complex of organic matter (pulp and oil residues) (Sciubba et al. 2020). Using a three-phase extraction method, this by-product is generated at the greatest rate, while a two-phase extraction method produces it at much lower rates (Table 2) (Stempfle et al. 2021).

It is especially important to note that, as shown in the Table, the extraction methods differ not only in quantity and quality of extracted oil, but also in the quantity and quality of by-products. While, 3-phase methods use five times as much water as 2-phase methods. Additionally, the Chemical Oxygen Demand (COD) concentration in 2-phase method is 4–6 g/l, while it is 30–200 g/l in 3-phase method. Hence, 2-phase method is widely believed to be less polluting than other methods (Gholamzadeh et al. 2016).

Aside from the valuable minerals and bioactive molecules contained in OMWW, it also has a high phytotoxicity, a significant pollutant charge, and low biodegradability (Stempfle et al. 2021). There is considerable environmental concern about untreated olive oil waste in the agri-food industry (Table 3), because of its high toxic load, a PH of less than 7, high COD 110 g/l and a Biological Oxygen Demand (BOD) greater than 170 g per liter. Despite the obvious necessity of waste management-treatment, finding the most efficient and effective method is much more significant (Stasinakis et al., 2008).

OMW also adversely affects the environment, contaminating ground and surface waters, changing the quality of soil, coloring natural water, and causing odors (Danellakis et al. 2011; Gholamzadeh et al. 2016).The proper treatment of by-products is therefore vital for avoiding negative externalities on the environment and maintaining local resources (energy, water, soil, raw materials).

2.3.3 OMW Management-treatment

Over the past few years, researchers have been increasingly concerned about OMW. During the months of October and February, most of the olive oil produced in the world (98%) is produced in Mediterranean countries. The result is more than 30 million m3 of waste being generated each year (Doula et al. 2017) with a high environmental impact (Donner & Radic 2021). Due to the lack of technical and economic solutions for OMW treatment, some mills illegally throw away their waste into the natural environment. Consequently, planning the utilization of natural resources and managing waste efficiently are crucial to reducing the environmental impact of olive oil mills (Khdair et al. 2019). Since most olive oil mills are small or medium sized, implementing the majority of management, remediation, and valuation techniques currently available is often too expensive (Doula et al. 2021).

There is a tendency for olive oil mill effluents to end up in evaporation ponds, but they are often discharged into natural creeks and cause soil contamination (Komnitsas et al. 2016; Donner & Radic 2021). However, this process creates significant odor problems in the area (Zagklis et al. 2015). In this context, it refers to a number of volatile organic acids as well as other low-boiling organic compounds responsible for foul odors. Due to the evaporation of these gases, methane and other pollutants are released into the atmosphere, aggravating air pollution. As well, OMW retains the same organic content and toxicity as before. OMW flooding may also occur if the evaporation ponds fail due to heavy rain. Moreover, their oil content can make the soil more hydrophobic, reducing its ability to retain and filter water (Abu-Rumman 2016), influencing natural phenols, microbial activity, acidity, lipid concentration, nitrogen immobilization, nutrient leaching, salinity and organic acids (Doula et al. 2017). A thick film of OMWW may form on the surface of water bodies and create anoxic conditions, posing a threat to the aquatic ecosystem. However, solid waste discharge has the effect of increasing saturation, water retention, and capillary lift in soil (Khdair et al. 2019). Long-term uncontrolled disposal of raw OMW on soil could adversely influence soil characteristics and lead to contamination of groundwater (Chatzistathis & Koutsos 2017).

A number of studies have been conducted in the last decade on filtration for treating OMW (microfiltration ultrafiltration, nanofiltration and reverse osmosis), which are all effective for recovering antioxidants and phenolic compounds.Before these technologies are widely implemented, however, there are still numerous drawbacks, including membrane fouling, a high cost of energy, and the disposal of concentrates has yet to be addressed (Ioannou et al. 2013; Galliou et al. 2018).

In addition to this, OMW treatment has extensively explored advanced oxidation processes (ozonation, photo-Fenton oxidation etc.). In spite of their effectiveness, these treatment methods presented financial and environmental challenges, such as the production of more toxic compounds. In the case of wastewater with a high organic content, anaerobic digestion is should be considered. It has been shown that phenolic compounds inhibit methanogenic bacteria in the case of OMW (Galliou et al. 2018).

There has been a proposal to co-digest organic residues with phenols to mitigate their effect on the anaerobic digestion process (Dareioti et al. 2010). Despite its promising potential, this technique requires centralized treatment and other feedstocks in the area, such as dung. In general, olive oil production is the primary (or only) farming activity, and therefore the amount of olive oil produced is significantly greater than that produced by other feedstocks (Galliou et al. 2018). As a result, only a relatively small portion of the OMW is suitable for co-digestion. Additionally, infrastructures for storing are needed to mitigate the seasonality of OMW production (Chatzistathis & Koutsos 2017).

Except all the aforementioned, Table 4 proposes some methodologies for valuing the OMW indicatively.

A series of circular paths can be created by recovering and transforming by-products of the olive oil production chain. These paths can prevent new impacts on disposal or provide new products. The proposed circular solutions should also be thoroughly assessed and quantified in order to avoid miscalculations while pursuing sustainability. In spite of the fact that olive oil by-products offer several circular opportunities, very little work has been done to assess their sustainability or compare linear with circular processes (Harris et al. 2021).

2.3.3.1 CE in olive oil industry

CE has become increasingly popular in recent years, and practices for immediate integration are being sought. As part of the European Commission's efforts to prevent the uncontrolled disposal of olive mill waste from affecting soil and water resources, PROSODOL, a LIFE project (LIFE07 ENV/GR/000280), was funded in 2009.This project aimed to demonstrate methods for restoring polluted areas and to propose legislative frameworks for countries in the EU to adopt. According to the results of the project, uncontrolled disposal of OMW affects most chemical and physical parameters of soil, permanently or not (Doula et al. 2017).

European Commission created TANNOW project in 2016. As part of the innovation, OMW would be converted from waste into raw material by stabilizing it, promoting the enrichment of highly antioxidant phenols, to be used in tanning steps as a medium in place of water and tannin chemicals, and as a reaction medium to produce antioxidant tanning resins.

In addition, a number of researchers and academics are interested in the topic of implementing CE and sustainability principles. Among the main waste-to-energy conversion pathways of OMSW, Christoforou and Fokaides (2016) also present a basic pretreatment technique for upgrading solid fuels. Several sorts of OMSW were utilized for energy-related purposes in their research, which focused on characterization and utilization of these wastes. Cepo et al. (2018) evaluate the antioxidant activity of dried olive pomace extracts in different food and biological model systems and analyzed the effects of different cyclodextrins. In addition, they outlin how cyclodextrin-encapsulation can improve the functionality of complex natural extracts in a simple and cost-effective way. In order to promote a CE in olive oil production, Abu Tayeh et al. (2020) suggest microwave pretreatment as a method of converting OMSW into ethanol and heavy metal sorbents. In Silvestri et al’s (2021) study, OMWW is incorporated into the brick-making process and proven to be a promising solution, which can reduce greenhouse gas emissions and reduce heat requirements during the ceramic manufacturing process by avoiding impacts related to its disposal. In comparison with conventional bricks, OMWW-based bricks reduce global warming potential by up to 3.1%, as well as abiotic depletion of fossil fuel by 4.3% (Silvestri et al. 2021). Carmona et al. (2023) propose a multi-step circular process for increasing the sustainable production of olive oil by valuing OMW, eliminating waste in virgin olive oil production pipeline, and creating new products of value. Two processes were investigated in order to obtain extracts for nutraceutical purposes from fresh OMW by using natural deep eutectic solvents (NADES) and through the recycling of the dephenolyzed-OMW by vermicomposting to produce organic fertilizer that can be used to make olive oil again. An environmental assessment of olive oil production is proposed by Ncube et al. (2022). In order to evaluate environmental performance, a variety of scenarios are considered based on a life cycle perspective. To determine the degree of environmental sustainability improved, business-as-usual scenarios, modeled on the concept of biorefineries, are compared with innovative circular scenarios. In the olive oil industry, and more generally in the food supply chain, circularity refers to decreasing waste and utilizing by-products. Instead of merely disposing of food waste to landfills, valuing through recovery is an alternative option where food waste cannot be avoided (Ghisellini et al. 2023) By-products from olive oil production can be used as feedstock for other production processes in order to reduce the environmental impact associated with olive oil production. Olive oil production results in a more equitable distribution of environmental impacts by upgrading by-products into co-products. A number of obstacles limit the valorization of by-products of oil production, including bureaucratic and authorization challenges, as well as seasonality of the supply of feedstock. A more incisive phase of closing the loop in olive oil industry appears to be hampered by economic and organizational barriers (Ncube et al. 2022). Despite a great deal of attention, CE has primarily been used in manufacturing, and recently in agri-food (Atanaskova et al., 2022). However, little research has been conducted on the olive oil industry as a whole. Furthermore, little research has been conducted to determine the current level of CE implementation in the agri-food sector, particularly in olive oil production. The research conducted frequently focuses on evaluating the sustainability, as well as the circularity of various olive oil production practices, the management practices and/or utilization of olive mill wastes. Typical example is Joumri et al. (2023) presenting an overview of thirty-two LCA-related works that have been applied to various scenarios of production involving the valorization of the generated by-products, provide a descriptive review of the LCA applied to the olive oil value chain in order to fill the gaps in the literature. Furthermore, they intend to provide more information on the amounts of water consumed and how the LCA tool assessed the environmental impacts of water consumption (Joumri et al. 2023). A study by Espadas-Aldana et al. (2023) shows how to move from a linear production system to a circular olive production system that recovers materials from organic residues by using the LCA method to support waste valorization to bio-based composite materials in French olive oil circular economy (CE).

3 Methodology

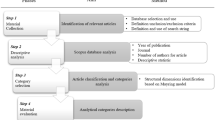

Using the last 10 years of research and review articles, a literature review was conducted focusing on olive oil industry CE indicators. The review included the following steps (Fig. 3).

-

Step 1. Scopus and Google Scholar databases were searched in the title, abstract or keywords, using the string “indicator” or “metric” or “measuring” or “monitoring” and “circular economy in olive oil industry”.

From the received result, it was ascertained that a little research on this specific issue has been conducted in order to review the specific indicators for this sector.

-

Step 2. In addition, a literature search was conducted to identify papers that propose or analyze micro-level circularity indicators. Accordingly, new keywords were added using the string “indicator” or “metric” or “measuring” or “monitoring” and “circular economy in micro-level”.

-

Step 3. Based on a screening of the title and abstract, documents that propose or discuss indicators considered that refer to the agri-food sector were selected in order to record the indicators of the sector and to propose the ones that could be used in the measurement of circularity in olive mills.

4 Discussion and proposals

In order to examine the circularity of olive oil production, it is essential that CE indicators for measuring and monitoring CE in olive oil mills (OOMs) are defined. Considering that supply chain management integrates environmental sustainability into all of its activities, CE implementation will require changes at several levels of the supply chain (Elia et al. 2020).

Though CE implementation generally involves three levels (macro, meso, and micro), the published indicators are mostly referred to macro- and meso-level. Nevertheless, the role of businesses in promoting CE cannot be underestimated (Geng et al. 2012). There have been several studies that have attempted to measure CE at the micro level by using indicators; however, a few of them have related to the agri-food sector with little reference being made to the olive oil industry (Poponi et al. 2022). While olive oil by-products provide a wealth of circular opportunities, there has not been enough effort put into assessing the viability of lateral production approaches and comparing linear ones to circular ones. Usually, efforts to assess circularity or sustainability in olive oil production focus on production processes, techniques and methods of managing and utilizing wastes and byproducts produced and often use LC methods and not circularity indicators concerning the case of the olive oil industry (Nikkhah et al. 2021; Stilitano et al. 2022; Falcone et al. 2022; Joumri et al. 2023; Espadas-Aldana et al. 2023). Since there are no specific circularity indicators to assess the implementation of the circular economy in olive oil industry, it would be useful to evaluate the existing indicators concerning the agri-food sector in general and adapt them to the olive oil mills. In OOMs, cleaner production can significantly improve the overall eco-efficiency by examining the most promising prospects for reducing internal pollution levels, incorporating processes, and managing waste (Geng et al. 2012).

In order for the olive oil industry to successfully transition to the new economic paradigm, specific CE indicators will be developed and integrated management models will be formulated (Sanchez-Ortiz et al. 2020). Despite their close relationship, sustainability and circularity indicators should view food systems through the lens of preserving functions, products, components, materials, or embodied energy (Moraga et al. 2019), utilizing a linear economy as a benchmark. When assessing CE on a micro level, such as olive oil mills, each sector should formulate a specific set of indicators according to its features, conditions, and problems. Beginning with an analysis of business model of each industry is critical, since a business model explains how it works, and can be used to analyze, evaluate, compare, manage, communicate, and innovate (Osterwalder et al. 2005). Innovation in business models plays a key role in achieving greater social and environmental sustainability. There are eight archetypes of business model recognized in CE, based on whether the innovation was technological, social, or organizational (Boken et al., 2014), most of which could be applied to olive oil mills as well. These eight archetypes were summarized by Sanchez-Ortiz et al. (2020) as follows:

Technological innovations:

-

1.

Ensure maximum material and energy efficiency;

-

2.

Make value out of waste;

-

3.

Use renewable and natural processes in place of current processes.

Social innovations:

-

4.

Focus on functionality rather than property;

-

5.

Become proactive in your role;

-

6.

Increase the level of sufficiency.

Organizational innovations:

-

7.

Maintain a socially responsible company purpose by keeping the environment and society in mind;

-

8.

Design solutions that are scalable

There have been some attempts to fill the lack of indicators gap, but no standardized indicators have been developed (Kristensen & Mosgaard 2020). Vermeyen et al (2021) attempted to provide sufficient indicators. According to the report, the food system cannot be easily analyzed or summarized due to its high number of indicators. Primary production, consumption, and waste collection and treatment were the three major food chain links examined in the study. It was therefore not possible to develop first-best indicators for all aspects of a circular economy for food. There is a need for further research to address the current gaps, like food processing, and refine the available indicators. Additionally, it is not clear which circular target should be set to achieve for local and global environmental boundaries, even though current inputs are clearly very material intensive and have significant environmental impacts (Vermeyen et al. 2021).

A modification of the material circularity indicator (MCI) (EMF, 2015), among the few tools currently available for measuring circularity, is proposed by Rocchi et al. (2021). Using modified MCI, the results of this study are integrated with life cycle assessment approaches designed for the poultry sector. According to their findings, the modified MCI can be used to evaluate the degree of circularity of a livestock rearing system and to compare different types of animal rearing systems. There is no calculation of how this nutrient contributes to closing the nutrient loop. In agricultural systems, closing the nutrient loop is an important aspect of CE. Modified MCI includes global amounts of feed expressed as quantity without considering origin. Despite its contribution to global circularity, MCI does not valorize food by-products, namely non-edible ones (Rocchi et al. 2021). Thus, such a calculation can be used to measure the circularity of the olive oil industry, but it does not provide sufficient indicators to determine if olive oil mills adhere to CE principles or how close they are to circularization.

A study by Poponi et al (2022) aim to fill this gap by identifying a possible set of indicators for measuring circularity and sustainability at various levels of application. As a result, 102 indicators are classified according to three sustainability areas (environmental, economic, and social) and spatial dimensions (macro, meso, micro) in the following eight scopes: Air, Water, Soil, Energy, Waste, Cost, Value and Productivity, Equality, and Knowledge and Innovation. According to Poponi et al. (2022) circularity cannot be assessed by monitoring individual indicator. From the indicators discussed in this research, Table 5 lists the indicators considered to be the most appropriate for evaluating circularity in olive mills (Poponi et al. 2022).

Van Schoubroeck et al. (2022) develop a framework for identifying circular economy indicators in the food industry. Using circularity as a metric, the information in this report summarizes the Flanders food system. Despite being intrinsically circular to some degrees, the food system seems to have drifted from the natural cycles underlying it because of industrial intensification and increased consumption. Therefore, there is much room to optimize the circularity of a system on all three fronts: input use, product use, and residual stream use (Van Schoubroeck et al. 2022).

In their paper, Atanaskona et al. (2022) conduct a systematic literature review on the concept of social value generated by circular economy (CE) practices in agri-food eco-industrial parks. It is found that social value associated with CE practices is under researched, providing opportunities for further investigation. Accordingly, Table 6 lists the indicators considered most appropriate for measuring circularity among olive mills based on the indicators discussed in this study.

During their study, Priyadarshini and Abhilash (2023) examine the circularity and efficiency levels in the Indian agri-food sector. Initially, they determine decoupling of energy consumption from economic growth in agriculture at the state level and then develop a Composite Agri-Food Efficiency Index (CAFEI) consisting of 38 indicators, encompassing environmental, social, economic, and governance factors (Priyadarshini and Abhilash 2023).

Based on MCI and LCA as efficient circular and environmental measurement tools, Gallo et al. (2023) aim to suggest an approach that correlates circularity with environmental impacts based on the mentioned tools. In addition, the model is tested and analyzed through the comparison of case studies in order to determine its applicability as a tool for assessing the environmental impacts of products in relation to circularity (Gallo et al. 2023).

In their study, Kleinpeter et al. (2023) develop a methodology that uses quantitative indicators to quantify the role of livestock and crops in the efficiencies and circularity of the agri-food-waste system. An analysis of nutrients flows, a detailed typology of those flows, and three groups of indicators are used to characterize the circularity between subsystems, the process efficiency of the subsystems, and the AFWS efficiency. The nitrogen metabolism of the French Reunion Island AFWS is used to illustrate the method.

According to the literature, CE indicators in the agri-food sector are still in their infancy. The circularity of agri-food is often monitored using different sustainability indicators at different levels (macro, meso, micro), but very few indicators are used to measure circularity in this sector (Poponi et al. 2022). As a consequence, it is necessary to begin measurements in practice in order to certify which of the proposed assesses the circularity effectively in olive oil mills.

5 Conclusions

Circular economies have emerged as economically balanced systems that focus on environmental, economic, and social issues, by raising the level of quality of life in overcrowded and impoverished societies due to resource scarcity. Circular economy has become an integral part of society’s strategy and policy making and has been recognized as a vital necessity. Since, CE is frequently argued to contribute to sustainable development, an examination of the alignment between the three dimensions of sustainability and the reviewed indicators specifies that economic aspects dominate the indicators, with environmental and social aspects having a lesser role. For different industrial sectors, it may be appropriate to set up specific indicators so that their concerns can be addressed appropriately. A unique and valid common group of indicators for each sector without arbitrariness could be developed to face and manage the complexity of CE transition.

As the CE evolves, the agri-food sector and olive oil industry will have a huge opportunity to manage resources efficiently, valorize and repurpose by-products and wastes, and to generate bio-energy and bio-products by adopting sustainable production practices. It is important, however, to establish strong measures and figures to guide the transition from linear to circular models. A high number of indicators are discussed throughout the literature, making it difficult to analyze or summarize the food system. Different actors in the food system emphasize circularity strategies differently. Therefore, it was not possible to come up with the first-best indicators for all aspects of a CE in the food system. The available indicators need to be fine-tuned to address current gaps, such as food processing.

The olive oil industry is one of the most significant sub-sectors of the agri-food sector, which contributes heavily to the world's biomass production. It has therefore recently emerged as a key component of the bio-economy. Despite its economic importance olive oil has adverse environmental effects, including resource depletion, land degradation, air pollution, and waste production. Circular economy principles are therefore important for the regions that host this kind of economic activity. It is necessary to determine the indicators that will be used to evaluate the degree of CE adoption and implementation in order to draw safe conclusions about the policies that need to be followed.

This study proposed some indicators in order to fills in the current need for a framework around CE for the olive oil industry. Due to the lack of studies that measure the circularity of olive mills effectively, in this paper, indicators regarding the agri-food sector in general, are proposed. Nevertheless, it is extremely important to examine their effectiveness in practice by conducting future research on measuring circularity by using these indicators. CE implementation in olive oil mills is considered a valuable opportunity, as biomass production not only reduces fossil fuel consumption and greenhouse gas emissions, but also creates new green markets and jobs by encouraging waste to be repurposed into value-added products.

Data availability

All data generated or analysed during this study are included in this published article The data have been deposited in the https://doi.org/10.1002/bse.3274, https://doi.org/10.1016/j.jclepro.2022.131753 and https://doi.org/10.1007/s11367-022-02031-2. Requests for material should be made to the corresponding authors.

References

Abu Tayeh HN, Azaizeh H, Gerchman Y (2020) Circular economy in olive oil production – Olive mill solid waste to ethanol and heavy metal sorbent using microwave pretreatment. Waste Manag 113:321–328

Abu-Rumman G (2016) Effect of Olive Mill Solid Waste on Soil Physical Properties. Int J Soil Sci 11:94–101

Alexandratos, N., Bruinsma, J. (2012). World agriculture towards 2030/2050: the 2012 revision. ESA Working paper No. 12–03. Rome, FAO.

Atanasovska I, Choudhary S, Koh L, Ketikidis PH, Solomon A (2022) Research gaps and future directions on social value stemming from circular economy practices in agri-food industrial parks: Insights from a systematic literature review. J Clean Prod 354:131753

Banaite D, Tamosiuniene R (2016) Sustainable development: the circular economy indicators’ selection model. J Secur Sustain 6:2. https://doi.org/10.9770/jssi.2016.6.2(10)

Barros MV, Salvador R, de Francisco AC, Piekarski CM (2020) Mapping of researchlines on circular economy practices in agriculture: from waste to energy. Renew Sustain Energy Rev 131:109958

Berbel J, Posadillo A (2018) Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10:237

Bocken NM, Short SW, Rana P, Evans S (2014) A literature and practice review to develop sustainable business model archetypes. J Clean Prod 65:42–56

Calzolari T, Genovese A, Brint A (2022) Circular Economy indicators for supply chains: a systematic literature review. Environ Sustain Ind 13:100160

Carmona I, Aguirre I, Griffith DMM, García-Borrego A (2023) Towards a circular economy in virgin olive oil production: Valorization of the olive mill waste (OMW) “alpeorujo” through polyphenol recovery with natural deep eutectic solvents (NADESs) and vermicomposting. Sci Total Environ 872:162198

Cautisanu C, Asandului L, Borza M, Turturean C (2018) Quantitative approach to circular economy in the OECD countries. Amfiteatru Econ 20(48):262–277

Cecchi L, Bellumori M, Cipriani C, Mocali A, Innocenti M, Mulinacci N, Giovannelli L (2018) A two-phase olive mill by-product (paté) as a convenient source of phenolic compounds: Content, stability, and antiaging properties in cultured human fibroblasts. J Funct Foods 40:751–759

Cepo DV, Radic K, Jurmanovic S, Jug M, Rajkovic MG, Pedisic S, Moslavac T, Albahari P (2018) Valorization of olive pomace-based nutraceuticals as antioxidants in chemical, food, and biological models. Molecules 23(8):2070. https://doi.org/10.3390/molecules23082070

Chatzistathis T, Koutsos T (2017) Olive mill wastewater as a source of organic matter, water and nutrients for restoration of degraded soils and for crops managed with sustainable systems. Agric Water Manag 190:55–64. https://doi.org/10.1016/j.agwat.2017.05.008

Chiaraluce G (2021) Circular Economy in the agri-food sector: a policy overview. Italian Rev Agri Econ 76(3):53–60

Chobanova R (2020) Circular Economy as a New Stage of Economic Development Circular Economy - Recent Advances. New Perspect Appl Tao Zhang Intech Open. https://doi.org/10.5772/intechopen.94403

Christoforou E, Fokaides PA (2016) A review of olive mill solid wastes to energy utilization techniques. Waste Manage 49:346–363

Ciccullo F, Cagliano R, Bartezzaghi G, Perego A (2021) Implementing the circular economy paradigm in the agri-food supply chain: The role of food waste prevention technologies, Resources. Conserv Recycl 164:105114

Danellakis D, Ntaikou I, Kornaros M, Dailianis S (2011) Olive oil mill wastewater toxicity in the marine environment: alterations of stress indices in tissues of mussel Mytilusgalloprovincialis. Aquat Toxicol 101(2):358–366

Dareioti M, Dokianakis S, Stamatelatou K, Zafiri C, Kornaros M (2010) Exploitation of olive mill wastewater and liquid cow manure for biogas production. Waste Manag 30:1841–1848

de Oliveira CT, Dantas TET, Soares SR (2021) Nano and micro level circular economy indicators: assisting decision-makers in circularity assessments. Sustain Prod Consum 26:455–468

De Pascale A, Arbolino R, Szopik-Depczynska K, Limosani M, Ioppolo G (2021) A systematic review for measuring circular economy: the 61 indicators. J Clean Prod 281:124942

Di Maio F, Rem PC (2015) A robust indicator for promoting circular economy through recycling. J Environ Protect 6(10):1095–1104

Donner M, Radic I (2021) Innovative Circular Business Models in the Olive Oil Sector for SustainableMediterraneanAgrifood Systems. Sustainability 13:2588

Doula MK, Papadopoulos AV, Zagklis G (2021) Should heavy metals be an issue of concern at olive mill waste disposal areas? The case of nickel. Curr Opinion Environ Sci Health 22:100270

Doula, M.K., Moreno-Ortego, J.L., Tinivella, F., Inglezakis, V.J., Sarris, A., Komnitsas, K. (2017)/ Chapter 2 - Olive mill waste: recent advances for the sustainable development of olive oil industry, Olive Mill Waste: Recent Advances for Sustainable Management Pages 29–56

Duque-Acevedo M, Belmonte-Urena LJ, Cortes-Garcia FJ, Camacho-Ferre F (2020) Agricultural waste: review of the evolution, approaches and perspectives on alternative uses. Global Ecology and Conservation 22:e00902

El JL, Labjar N, Dalimi M, Harti S, Dhiba D, El Messaoudi N, Bonnefille S, El Hajjaji S (2023) Life cycle assessment (LCA) in the olive oil value chain: a descriptive review. Environ Dev 45:100800

Elia V, Gnoni MG, Tornese F (2017) Measuring circular economy strategies through index methods: a critical analysis. J Clean Prod 142:2741–2751

Elia V, Gnoni MG, Tornese F (2020) Evaluating the adoption of circular economy practices in industrial supply chains: an empirical analysis. J Clean Prod 273:122966

Ellen Mc Arthur Foundation (EMF). (2015). Circularity Indicators: An Approach to Measuring Circularity: Project Overview, Available at: http://susdi.org/doc/CE/Circularity-Indicators_Project-Overview_May2015.pdf

Ellen McArthur Foundation (EMF). (2019) Circularity Indicators: An Approach to Measuring Circularity: Methodology, Available at: https://ellenmacarthurfoundation.org/material-circularity-indicator

Espadas-Aldana G, Vialle C, Belaud JP, Sablayrolles C (2023) Life cycle assessment to support waste valorisation tobiocomposite in french olive oil circular economy. Chem Eng Trans 100:523–528

Esposito B, Sessa MR, Sica D, Malandrino O (2020) Towards circular economy in the agri-food sector: a systematic literature review. Sustainability 12(18):7401

European Commission (EC). (2018). Measuring progress towards circular economy in the European Union—Key indicators for a monitoring frame-work: Accompanying the document. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on a Monitoring Framework for the Circular Economy, Strassbourg. Retrieved from: https://eur-lex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX:52018SC0017&from=EN

European Environment Agency (EEA). (2016). “More from less—material resource efficiency in Europe.” Publication 10/2016.Available at: https://www.eea.europa.eu/publications/more-from-less

Eurostat.(2021). Circular Economy Indicators, Monitoring Framework.European Commission [WWW Document].URL.Retrieved from: https://ec.europa.eu/eurostat/web/circular-economy/indicators.

Falcone G, Stillitano T, Iofrida N, Spada E, Bernardi B, Gulisano G, De Luca AI (2022) Life cycle and circularity metrics to measure the sustainability of closed-loop agri-food pathways. Front Sustain Food Syst 6:1014228. https://doi.org/10.3389/fsufs.2022.1014228

Focker M, van Asselt ED, Berendsen BJA, van de Schans MGM, van Leeuwen SPJ, Visser SM, van der Fels-Klerx HJ (2022) Review of food safety hazards in circular food systems in Europe. Food Res Int 158:111505

Friant MC, Vermeulen WJ, Salomone R (2020) A typology of circular economy dis-courses: navigating the diverse visions of a contested paradigm. Res Conserv Recycl 161:1–19

Fukase E, Martin W (2020) Economic growth convergence and world food demand and supply. World Dev 132:104954

Galliou F, Markakis N, Fountoulakis MS, Nikolaidis N, Manios T (2018) Production of organic fertilizer from olive mill wastewater by combining solar greenhouse drying and composting. Waste Manag 75:305–311

Gallo F, Manzardo A, Camana D, Fedele A, Scipioni A (2023) Integration of a circular economy metric with life cycle assessment: methodological proposal of compared agri-food products. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-022-02130-0

Geng Y, Fu J, Sarkis J, Xue B (2012) Towards a national circular economy indicator system in China: an evaluation and critical analysis. J Clean Prod 23:216–224

Ghisellini P, Cialani C, Ulgiati S (2016) A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J Clean Prod 114:11e32

Ghisellini P, Ncube A, Rotolo G, Vassillo C, Kaiser S, Passaro R, Ulgiati S (2023) Evaluating environmental and energy performance indicators of food systems, within circular economy and “farm to fork” frameworks. Energies 16:1671

Gholamzadeh N, Peyravi M, Jahanshahi M (2016) Study on Olive Oil Wastewater Treatment: Nanotechnology Impact. J Water Environ Nanotechnol 1(2):145–161

Harris S, Martin M, Diener D (2021) Circularity for circularity’s sake?Scoping review of assessment methods for environmental performance in the circular economy. Sustain Prod Consum 26:172–186. https://doi.org/10.1016/j.spc.2020.09.018

Haupt M, Hellweg S (2019) Measuring the environmental sustainability of a circular economy. Environ Sustain Ind 1–2:100005

Helander H, Petit-Boix A, Leipold S, Bringezu S (2019) How to monitor environmental pressures of a circular economy: An assessment of indicators. J Ind Ecol 23:1278–1291

Iacovidou E, Velis CA, Purnell P, Zwirner O, Brown A, Hahladakis J, MillwardHopkins J, Williams PT (2017) Metrics for optimising the multi-dimensional value of resources recovered from waste in a circular economy: a critical review. J Clean Prod 166:910–938

Ibanez-Fores V, Martínez-Sanchez V, Valls-Val K, Bovea MD (2022) Sustainability reports as a tool for measuring and monitoring the transition towards the circular economy of organisations: Proposal of indicators and metrics. J Environ Manage 15(320):115784. https://doi.org/10.1016/j.jenvman.2022.115784

Intergovernmental Panel on Climate Change (IPCC) (2014) Climate Change 2014 Mitigation of Climate Change. In: Edenhofer O, Pichs-Madruga R, Sokona Y, Farahani E, Kadner S, Seyboth K, Adler A, Baum I, Brunner S, Eickemeier P, Kriemann B, Savolainen J, Schlömer S, von Stechow C, Zwickel T, Minx JC (eds) Contribution of working Group III to the Fifth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge

International Olive Oil Council (2021) World Olive Oil. Available at: https://www.internationaloliveoil.org/what-we-do/economic-affairs-promotion-unit/#figures

Ioannou LA, Michael C, Vakondios N, Drosou K, Xekoukoulotakis NP, Diamadopoulos E, Fatta-Kassinos D (2013) Winery wastewater purification by reverse osmosis and oxidation of the concentrate by solar photo-Fenton. Sep Purif Technol 118:659–669

Janik A, Ryszko A (2019) Circular economy in companies: an analysis of selected indicators from a managerial perspective. Multidisciplinary Aspects Prod Eng 2(1):523–535

Khdair A, Abu-Rumman G (2020) Sustainable environmental management and valorization options for olive mill byproducts in the Middle East and North Africa (MENA) region. Processes 8(6):671. https://doi.org/10.3390/pr8060671

Khdair A, Abu-Rumman G, Khdair SI (2019) Pollution estimation from olive mills wastewater in Jordan. Heliyon 5:e02386

Kleinpeter V, Alvanitakis M, Vigne M, Wassenaar T, Lo Seen D, Vayssières J (2023) Assessing the roles of crops and livestock in nutrient circularity and use efficiency in the agri-food-waste system: A set of indicators applied to an isolated tropical island. Res Conserv Recycl 188:106663

Komnitsas K, Modis K, Doula M, Kavvadias V, Sideri D, Zaharaki D (2016) Geostatistical estimation of risk for soil and water in the vicinity of olive mill wastewater disposal sites. Desalination Water Treat 57:2982–2995

Kristensen HS, Mosgaard MA (2020) A review of micro level indicators for a circular economy e moving away from the three dimensions of sustainability? J Cleaner Prod 243:118531

Mayer A, Haas W, Wiedenhofer D, Krausmann F, Nuss P, Blengini GA (2018) Measuring progress towards a circular economy: A monitoring framework for economy-wide material loop closing in the EU28. J Ind Ecol 23:62–76

Moraga G, Huysveld S, Mathieux F, Blengini GA, Alaerts L, Van Acker K, de Meester S, Dewul J (2019) Circular economy indicators: What do they measure? Resour Conserv Recycl 146:452–461

Ncube A, Fiorentino G, Panfilo C, De Falco M, Ulgiati S (2022) Circular economy paths in the olive oil industry: a life cycle assessment look into environmental performance and benefits. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-022-02031-2

Nikkhah A, Firouzi S, Dadaei K, Van Haute S (2021) Measuring circularity in food supply chain using life cycle assessment; refining oil from olive kernel. Foods 10:590

Osterwalder A, Pigneur Y, Tucci CL (2005) Clarifying business models: Origins, present, and future of the concept. Commun Assoc Inf Syst 15:1–40

Oswald, I. (2013). Environmental Metrics WEEE Collection and Recycling Programs, Universitat Augsburg, Available at: https://opus.bibliothek.uniaugsburg.de/opus4/front door/index/index/docId/2312.

Parchomenko A, Nelen D, Gillabel J, Rechberger H (2019) Measuring the circular economy - a multiple correspondence analysis of 63 metrics. J Clean Prod 210:200–216

Park K, Kremer G (2017) Text mining-based categorization and user perspective analysis of environmental sustainability indicators for manufacturing and service systems. Ecol Ind 72:803–882

Pauliuk S (2018) Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour Conserv Recycl 129:81–92

Pavlovic A, Boskovic G, Jovicic N, Nestic S, Sliusar N, Stanisavljevic N (2020) Determination of circularity indicators - a case study of MB. Int Co Recycl Sustain Dev 13:9–21

Poponi S, Arcese G, Pacchera F, Martucci O (2022) Full length article Evaluating the transition to the circular economy in the agri-food sector: Selection of indicators. Resour Conserv Recycl 176:105916

Priyadarshini P, Abhilash PC (2023) An empirical analysis of resource efficiency and circularity within the agri-food sector of India. J Cleaner Prod 385:135660. https://doi.org/10.1016/j.jclepro.2022.135660

Reich RH, Vermeyen V, Alaerts L, Van Acker K (2023) How to measure a circular economy: A holistic method compiling policy monitors. Res Conserv Recycl 188:106707

Robaina M, Villar J, Pereira ET (2020) The determinants for a circular economy in Europe. Environ Sci Pollut Res 27:12566–12578

Rocchi L, Paolotti L, Cortina C, Fagioli FF, Boggia A (2021) Measuring circularity: an application of modified Material Circularity Indicator to agricultural systems. Agri Food Econ 9(9):1–13

Saidani M, Yannou B, Leroy Y, Cluzel F, Kendall A (2019) A taxonomy of circular economy indicators. J Clean Prod 207:542–559

Sanchez-Ortiz J, Rodriguez-Cornejo V, Del Rio-Sanchez R, T Garcia-Valderrama (2020) Indicators to measure efficiency in circular economies. Sustainability 12:4483. https://doi.org/10.3390/su12114483

Scheepens AE, Vogtlander JG, Brezet JC (2016) Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. case: making water tourism more sustainable. J Cleaner Prod 114:257–268

Sciubba F, Chronopoulou L, Pizzichini D, Lionetti V, Fontana C, Aromolo R, Socciarelli S, Gambelli L, Bartolacci B, Finotti E, Benedetti A, Miccheli N, U Palocci C Bellincampi D (2020) Olive mill wastes: a source of bioactive molecules for plant growth and protection against pathogens. Biology 9:450

Silvestri L, Forcina A, Di Bona G, Silvestri C (2021) Circular economy strategy of reusing olive mill wastewater in the ceramic industry: How the plant location can benefit environmental and economic performance. J Clean Prod 326:129388

Silvestri C, Silvestri L, Piccarozzi MR, A. (2022) Toward a framework for selecting indicators of measuring sustainability and circular economy in the agri-food sector: a systematic literature review. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-022-02032-1

Stasinakis AS, Elia I, Petalas AV, Halvadakis CP (2008) Removal of total phenols from olive-mill wastewater using an agricultural by-product, olive pomace. J Hazardous Mater 160(2–3):408–13

Stempfle S, Carlucci D, de Gennaro BC, Roselli L, Giannoccaro G (2021) Available pathways for operationalizing circular economy into the olive oil supply chain: mapping evidence from a scoping literature review. Sustainability 13:9789

Stillitano T, Falcone G, Iofrida N, Spada E, Gulisano G, De Luca AI (2022) A customized multi-cycle model for measuring the sustainability of circular pathways in agri-food supply chains. Sci Total Environ 844:157229

Tank A (2022) Economic Impact of Russia –Ukraine War. Int J Innov Res Sci Eng Technol 11(4):3345–3348

TANNOW (2016) Reuse of olive mill wastewater for producing new antioxidant tanning chemicals.Available at: https://cordis.europa.eu/project/id/715071.

United States Chamber of Commerce Foundation (USCCF) (2022) Measuring Circular Economy, Available at: https://www.uschamberfoundation.org/circular-economy-toolbox/about-circularity/measuring-circular-economy

Urain I, Eguren JA, Justel D (2022) Development and validation of a tool for the integration of the circular. J Clean Prod 370:133318

Urbinati A, Chiaroni D, Chiesa V (2017) Towards a new taxonomy of circular economy business models. J Cleaner Prod 168:487–498

Valls-Val K, Ibanez-Fores V, Bovea MD (2022) How can organisations measure their level of circularity? A review of available tools. J Cleaner Prod 354:131679

Valls-Val K, Ibanez-Fores V, Bovea MD (2023) Tools for assessing qualitatively the level of circularity of organisations: applicability to different sectors. Sustain Prod Consum 36:513–525

Van Schoubroeck S, Vermeyen V, Alaerts L, Van Acker K, Van Passel S (2022) How to monitor the progress towards a circular food economy: a Delphi study. Sustain Prod Consum 32:457–467

Vermeyen V, Alaerts L, Arenberg K, Van Schoubroeck S, Van Passel S, Van Acker K (2021) Circular economy indicators for the food system. CE CENTER Circular Econ Policy Res Center 20:91

Vinante C, Sacco P, Orzes G, Borgianni Y (2021) Circular economy metrics: literature review and company-level classification framework. J Clean Prod 288:125090

Vola P, Cantino G, Gelmini L (2023) Micro-level measurement of the circularity of organizations: the Italian innovative standardized approach applied to a public sector case study. Eur J Social Impact Circular Econ. https://doi.org/10.13135/2704-9906/7155

Walker S, Coleman N, Hodgson P, Collins N, Brimacombe L (2018) Evaluating the environmental dimension of material efficiency strategies relating to the circular economy. Sustainability 10:666

World Bank (2014). You Can’t Manage What You Don’t Measure, Available at: https://blogs.worldbank.org/education/you-can-t-manage-what-you-don-t-measure

Yang CK, Ma HW, Liu KH, Yuan M, H. (2023) Measuring circular economy transition potential for industrial wastes. Sustain Prod Consum 40:376–388

Zagklis DP, Vavouraki AI, Kornaros ME, Paraskeva CA (2015) Purification of olive mill wastewater phenols through membrane filtration and resin adsorption/desorption. J Hazard Mater 285:69–76

Zhang Q, Dhir A, Kaur P (2022) Circular economy and the food sector: a systematic literature review. Sustain Prod Consum 32:655–668

Funding

The authors did not receive support from any organization for the submitted work. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

AK organized the structure of the paper. AK and Ass. Prof. AP prepared “Measuring and Monitoring the Circular Economy”. AK and Prof. SA prepared the “Introduction” and “Conclusions”. AK conducted the literature review regarding the issue of olive oil mills’ waste to highlight the importance of the appropriate management for the sector. Furthermore, AK surveyed the global literature concerning the CE indicators in order to highlight the most important ones that could be used in assessing circularity in olive oil mills. The Methodology was indicated by AK and Ass. Prof. AP. AK and Ass. Prof. AP revised the manuscript based on reviewers’ comments. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kounani, A., Pavloudi, A. & Aggelopoulos, S. Performance indicators of circular economy in the agriculture and food industry. Environ Syst Decis 44, 380–397 (2024). https://doi.org/10.1007/s10669-023-09942-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10669-023-09942-x