Abstract

In the context of the food supply chain, the UN sustainable goals of 2030 aim at reducing food wastage by fifty percent. Developed countries have started taking steps, but there is little or no sign of progress toward reaching the goal for emerging economies. One such sustainable approach is incorporating circular practices in the food supply chain. A total of 15 barriers to the closed-loop food supply chain were identified through extensive literature review and expert opinions. Further ranking of barriers was done, and a causal relationship among them was built using the Grey DEMATEL methodology. It was found that traceability issues, limited expertise in information and technology, poor logistic network design, and high installation and operational cost of updated facilities were the most influential factors. Sensitivity analysis was also performed to check the robustness of the framework. This study will assist managers in forming the policies and looking after the factors ranked higher. While modeling the framework for their company, they can implement the changes to overcome the challenges of closing the loop. It will also help government regulations in setting regulations for the organization with the aim of encouraging clean practices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It is forecasted that the world’s population will mark 9 billion by 2050 and 10.1 billion by the end of the twenty first century (Bastein et al., 2013). The population rise will result in increasing demands worldwide and will put stupendous pressure on the earth to match those specific demands (Franklin-Johnson et al., 2016). The demands for natural resources are ever-increasing, and by 2030, it will require resources equivalent to two to three planets by 2050 (UN Sustainable Development Goals, 2015). As the resources are limited, the current linear economy model will not work for so long and the world is heading toward the CE model. The CE model integrates reverse logistics, design innovation, collaborative ecosystem, and business model innovation, thus focusing on management and alignment of resource flows across the closed chain (Goyal et al., 2018). It is driven by various drivers like creative minds, winning entrepreneurs, updated technologies and friendly ecosystem management at zonal, regional, and country levels. However, CE has not been studied much and still is unexplored due to the primary focus on the linear model (Goyal et al., 2021; Ungerman & Dědková, 2020). Few of the CE practices are being followed by a few firms. For instance, Attero Recycling Pvt. Ltd. has designed a setup for systematically collecting, processing, and distributing recycled products generated from e-waste in India. Another example is that Haathichaap Company has created a distinctive setup by using elephant poop for paper making, thus reducing the burden on trees.

Over the past few years, technological advancements in the Indian market go along with stress factors, including overpopulation, political conflicts, urbanization, food, and water insufficiency, and climate shifts (El Bilali, 2020). As per the reports of 2016, the population in urban areas in India accounts for 377 million people and generates approximately 62 MT of municipal solid waste every year (Fiksel et al., 2021). Due to the inefficient services, only 70% of the total waste is collected from which only 20% got treated, and the rest 50% is left in open landfills untreated. As per the patterns of rapid urbanization and consumption, it is forecasted that by 2030 waste generation will reach 165 million MT (India Environment Portal, 2016). The GDP of India has a direct relation to the consumption of resources which is directly proportional to the population. Thus choosing sustainable practices within economic models and framing the policies by opting for efficient strategies will positively impact the economy (Priyadarshini & Abhilash, 2020). The present model implies that $697bn of the Indian economy is insecure under Business-as-Usual (BaU) scenario, which is expected to lower down to $382bn by opting for corrected technology and circular economy practices (www.ficcices.in; www.esds.teriin.org). As per The World Economic Forum, circular economy practices could benefit $ 1 trillion/yr worldwide due to reduced ecological footprint, reducing dependency on limited resources (WEF, 2013). The study carried out by Accenture in 2019 reported that by 2030 India can unlock $0.5 trillion of economic value by adopting Circular Economy strategies (Fiksel et al., 2021). The idea of CE is novel; the basic principles of CE are closely analogous to sustainability approaches like industrial symbiosis (IS) and industrial ecology (IE), which aims at closing the loops of linear supply chains (Fraccascia et al., 2021; Morseletto, 2020). Further, Morseletto (2020) has clarified the concept of CE that it is an economic model which targets the productive use of resources by minimizing waste, lowering primary resources, and closing the loops of the value chains without causing harm to the environment and availing socioeconomic advantages.

According to the Global Hunger Index (2020), India ranks at 94th position out of 107 countries behind its neighboring countries i.e. Sri Lanka (64th), Nepal (73rd), Bangladesh (75th), Myanmar (78th), and Pakistan (88th). According to reports from the Global Hunger Index (2019), climate change and hunger are the two significant challenges the world faces today. Wastage of food in developed countries is seen in the consumption stage (NRDC, 2013), whereas in emerging economies, it is seen in the production (Gustavsson et al., 2011) and post-harvest phase, due to poor handling and storage facilities (Kummu et al., 2012). Due to the increasing competition and awareness among the consumers, organizations are shifting toward zero waste or opting for sustainable production methods (Ageron et al., 2012). Whitehair et al. (2013) in their study stated that raising awareness among consumers regarding food waste may lead to sustainability. FLW is also responsible for climate change and shares 8% of worldwide GHG emissions (FAO, 2015). Approximately 800 million people are starving and do not have sufficient food to eat (FAO, 2015). According to the report of the World Bank (2013) in the African region reducing post-harvest losses to 1% could wave off $40 million every year (Vilariño et al., 2017). Looking at the current position of India, it is of utmost importance to incorporate CE practices in the food supply chain to lower the losses incurred in the various phases of the value chain (Govindan & Hasanagic, 2018).

When and how food is wasted or lost is of great concern as it affects the efficiency of food systems. Food wastage in developed countries is seen in the consumption stage (NRDC, 2013). In contrast, in developing countries, it is seen in the production phase (Gustavsson et al., 2011) and this replicates the poor harvesting techniques used in developing countries. In terms of food wastage, developed countries organize campaigns and awareness programs to minimize food wastage. In contrast, developing countries face food loss issues as no or minimal such programs are conducted. According to present estimates, by 2028, India’s population will reach up to 1.45 billion, equal to China’s, and by 2050 it will be 1.7 billion nearly identical to the combined population of China and the USA. As per the FAO (2020) report, 189.2 million individuals are undernourished resulting in 14% of the population in India and approximately 25% of the world’s undernourished individuals belonging to India.

Further 33% of the total malnourished infants are from India. According to the Department of Agriculture, Cooperation and Farmers Welfare, India 2018–2019 sets a record farm output of 285.21 million tons of food grain. It implies that food production is not the primary issue. The part of food produced on farms never reaches the end consumer which the policymakers have ignored for since long. According to UN reports about 40% of the total production value is wasted which accounts for a whopping amount of ₹92,000 crores per annum. Much research has been done in developed countries concerning food loss management, and there is a dearth of study in developing countries (Mangla et al., 2018a). Due to practical issues, implementation of a circular economy in the food supply chain is quite challenging. The need of the hour is to identify the barriers to implementing circular economy practices in the food supply chain and determine the causal relation between them which are most important in the context of emerging economies like India.

Keeping this in mind, the following research questions are being raised:

-

What are the top barriers to implementing circular practices in emerging economies’ food supply chain industry?

-

How can decision-makers assess the importance of identified barriers?

-

How can decision-makers determine the inter-relationships (if any persist) among identified barriers?

To answer the above research questions, the present study has the following objectives:

-

Identification of barriers/factors to implementing circular practices in the food supply chain.

-

Prioritizing the factors of circular practices in the food supply chain for the case company.

-

Building causal relationships between the factors and finding out cause and effect groups of the barriers.

The rest of the paper is structured in the following manner. Section 2 illustrates the “Literature review” of possible barriers followed by “Methodology” in Sect. 3, which justifies the suitability of the research method chosen and elaborates steps involved in the Grey DEMATEL methodology. Section 4 includes “Case of the present model” which discusses the case study of the proposed framework. Section 5 elaborates on “Results and discussion,” which discusses the results obtained from the analysis. Section 6 includes “Sensitivity analysis,” which tests the consistency of the results obtained. Section 7 discusses the “Policy and managerial implications,” which draws out the important policy and managerial implications. Lastly, Sect. 8 lists down the “Conclusions, limitations and recommendations for future research,” which presents the outcomes, shortcomings and future opportunities of the study, respectively.

2 Literature review

This section of the article covers the literature review on implementing the concept of CE in the food supply chain. It also helps to identify the issues that impede the application of CE and calls attention to the research gaps.

Stahel and Reday firstly introduced the term CE in (1976). The CE was founded on the analogy of the earth as a closed economic system, interlinking surroundings and economy in a circular manner (Jackson et al., 2014). Further, the concept of CE was introduced by Pearce and Turner in “Economics of Natural Resources and the Environment” in 1990 (Pearce & Turner, 1990). Ellen MacArthur Foundation has successfully developed CE practices in various fields like waste management, sustainable development, food management, etc. (EMF, 2017). The methodology of CE is applied in Finland for transitioning the food supply chain into a circular food chain (Jurgilevich et al., 2016). It helps to draw out the maximum value from the system, thus leaving zero or minimum waste to the surroundings (Bag et al., 2019). It is one of the sustainable practices concerned with maintaining a balance between society, finance, and the environment to reduce, reuse and recycle waste. It helps make the supply chain efficient by reviving the product properties instead of discarding them and returning them to the market (Moktadir et al., 2018). According to Lieder & Rashid, 2016 the concept behind the CE practices is that it allows shifting of epicenter from limited natural resources to recovery of these resources thus leading to economic, social, and environmental assistance. In the linear supply chain at each step, waste is generated from the production to consumption phase but none of them is treated for revival (MacArthur, 2013). Thus, the circular economy overcomes the drawbacks of the take-make-dispose philosophy (Shi et al., 2006). Through its proper closed channels at each step, all the leftovers which were discarded earlier are now collected at the recycling center and properties are revived to be used again (Yuan et al., 2006). Some of the processes belonging to CE are remanufacturing where the used or defective product is manufactured again making it defect-free, and introducing them back to the market providing a guarantee period for the product to run (Moktadir et al., 2018). Take-back is also a CE practice where the product, after use, is taken back by the remanufacturer through its reverse logistic channel and thus recycling the product (Andrews, 2015). Su et al. (2013) suggest that products can be designed waste-free by connecting them to recyclable loops, thus shifting the system from cradle-to-grave to cradle-to-cradle. CE takes waste as a secondary resource. The philosophy of CE has a vision of a zero-waste economy recovering value by collaborating within the same sector or with different sectors (Weetman, 2016). Prieto-Sandoval et al. (2018) reviewed various approaches and applications regarding the CE concept, and its association with eco-innovation was advanced. The concept of CE lacks in framework and strategies for the practical implementation of CE practices in specific sectors (Kakwani & Kalbar, 2020).

Majorly, food loss and food waste are treated as the same to focus on the waste component of the food loss. However, according to Food and Agriculture Organization, food waste is an integral part of food loss. Food loss (FL) calls attention to a decrease in edible food mass that covers stages of production, post-harvest and processing in the food supply chain (FSC) before they reach the consumer (Lipinski et al., 2013; Parfitt et al., 2010). Food waste (FW) refers to the one which is of good quality and fit to be eaten by humans but does not get consumed because it is discarded at the distribution and consumption stage (Lipinski et al., 2013; Parfitt et al., 2010). As per the European Union-funded project FUSIONS (2014), pre-harvest waste (not mature) does not account for food waste and it is calculated as agricultural waste. Food loss and waste (FLW) protocol will be used in this paper further, and it is defined as the weight of food and/or associated edible parts removed from the supply chain (Hanson et al., 2016).

Research on food waste management has taken a steep rise over the past ten years focusing mainly on quantifying the food wastage along the food supply chains along with finding the factors which contribute more to the problem. According to the literature, in fear of overcoming shortage costs or to fulfill undetermined demand food industries produce in excess which leads to food wastage (Gustavsson et al., 2011). Food waste is large in supply chains where there is a lack of communication and coordination between the actors. Also, perishable food products with shorter shelf life are more prone to get wasted due to improper storage conditions and poor handling (Corrado & Sala, 2018). Studies have suggested that avoiding excess food generation throughout the supply chain from production to consumption is one of the most efficient strategies (Papargyropoulou et al., 2014). Many preventive measures are suggested in the studies to manage food waste which include redistribution of food for human consumption and animal feed, spreading awareness among consumers to prevent food waste, enhancing supply chain efficiency, and government strategies and frameworks to prevent food waste (FUSIONS, 2016). However, for factual information and to improve supply chain efficiency, new concepts like circular economy must be incorporated along with digital technologies such as block-chain technology, Internet of Things (IoT), Etc. (Cane & Parra, 2020). Implementing CE practices in the processes needs up-gradation of digital technologies which can help in communicating better between the supply chain partners and also improves traceability (Corallo et al., 2020; Annosi et al., 2021).

In the context of food, United Nations food and agriculture organization reported that one-third of food is wasted along different stages of the food supply chain (Gustavsson et al., 2011). It has been reported that the execution of production techniques has not been green and reported as the main reason for the depletion of resources (Foley et al., 2011). When it comes to the food supply chain, it is more prone to losses in comparison with the service or manufacturing supply chain, as food items are liable to rot (Singh et al., 2018). Food waste (FW) has been identified as a universal problem due to its impacts on the environment (UNEP, 2014), economy (Garrone et al., 2014), and society (Evans, 2012), which demands a change in political actions (Searchinger et al., 2019) to lower down the consequences. Under the sustainable development goal 2030, United Nations aims to halve food waste globally. According to the D and B report, in 2015, nearly 40–50% of fruits and vegetables were wasted, followed by 35% of milk products and 21% of meat (Singh et al., 2019). For efficient functioning of the food supply chain, traceability of food products is of utmost importance (Hobbs et al., 2005). India’s 98% of food is sold in the unorganized market, due to which India fails to integrate its supply chain with ICT tools. Circular Economy is the concept that can help to make supply chains more sustainable (Kirchherr et al., 2017). It has a limitation and provides a scope of research as implementation concepts of the circular economy within the supply chain field are limited (Govindan & Hasanagic, 2018).

Many authors have implemented the CE concept in their past studies, as can be seen in Table 1. Chaudhary and Vrat (2020) developed a circular flow model of gold content in cell phones from manufacturing to the recycling phase using a system dynamics approach. Moktadir et al. (2018) analyzed the drivers of sustainable manufacturing practices and circular economy in the context of the leather industry. Mangla et al., (2018a, 2018b) carried out work on identifying the barriers to implementing CE practices in the automotive industry of India. Yazdani et al. (2019) worked on implementing CE practices in the agriculture sector. Farooque et al. 2019) analyzed the barriers to implementing CE practices in the food supply chain in China. Likewise, other authors like Principato et al. (2019), Meherishi et al. (2019), Yadav et al. (2020), Sharma et al. (2020a, 2020b), Campos et al. (2020), Khandelwal and Barua (2020) and Gupta et al. (2021) have demonstrated their work for promoting CE practices in the agro-food industry, sustainable packaging, automotive industry, e-waste management, fruit industry, plastic industry and manufacturing industry, respectively.

The studies done in the area of the food supply chain are as follows:

In the context of developed countries, Papargyropoulou et al. (2014) modeled the framework. They examined those factors that led to food wastage and provided practical solutions to tackle the issue of food waste. Genovese et al. (2017) chose chemical and food industries for study and compared the performance of the traditional supply chain with the noble circular system. They concluded that a circular system is environmentally friendly to the former supply chain. Brancoli et al. (2017) focused on the impact of food wastage at a supermarket in Sweden. Diaz-Ruiz et al. (2019) identified factors that lead to food wastage using the Delphi technique and provided multiple solutions. Principato et al. (2019) studied the Italian pasta case and adopted the CE approach for reducing food wastage.

Considering emerging economies like India, Balaji and Arshinder (2016) modeled the food supply chain and explained the causes of food wastage using the TISM approach. Gardas et al. (2018) modeled causal factors of post-harvesting losses in the fruit and vegetable supply chain using the ISM approach. Gokarn and Kuthambalayan (2017) analyzed challenges for reducing food wastage in the food supply chain using the ISM approach. Vrat et al. (2018) reviewed an article on the sustainable cold chain for perishable food products. Sharma et al. (2019) analyzed the issues impeding CE practices in the food supply chain using ISM-MICMAC analysis. Sharma et al. (2020a, 2020b) reviewed the food supply chain and analyzed the problems in integrating the supply chain with Industry 4.0. Krishnan et al. (2020) studied the mango food supply chain. They found the factors that inhibit the CE practices in the supply chain and also measured the life cycle assessment for environmental impact. Many other studies have been successfully recorded on the circular systems. However, very little research has been done considering the food supply chain, which provides a cushion to find out the barriers to making the food supply chain circular in a developing nation like India. To identify the issues for incorporating CE practices in FSC, a systematic literature review was done. A total of 18 barriers were chosen after the review of the literature and discussion from the experts. Barrier codes are listed as CFC which stands for challenges for the circular food chain and is listed with its serial number as 1, 2, 3, … and so on. 15 barriers were finalized and are listed in Table 2.

3 Research gaps and highlights

Research on the sustainable supply chain is still at an early stage regarding how to update supply chain policies and theories and successfully implement circular practices in the supply chain. Many studies have focused on the issues of food wastage and its prevention, but none of them included circular flows and factors that can make the supply chain efficient (Gharfalkar et al., 2015; Mourad, 2016). Implementation of circular practices is different in developing countries as compared to the developed countries due to the difference in specific government laws, technology, infrastructure, and social conditions that exist. Many studies have been carried out in various other fields like the automotive sector, leather industry, plastic industry, etc., incorporating circular practices, but none of them is done considering the food industries in the Indian context to the best of the author’s knowledge. A few of the essential studies are listed in Table 1. Practically, the implementation of the circular economy concept is not clear and is in the nascent stage. To apply successfully the concept of circular economy in supply chains, primarily, challenges that obstruct the application of circular flows need to be studied. There is a dearth of studies examining barriers to circular supply chain management (Govindan & Hasanagic, 2018). Yazdani et al. (2019), Principato et al. (2019), and Campos et al. (2020) carried out work on a circular supply chain based on the food industry, but the work was carried out in developed countries. There is a need for developing countries like India to model the challenges/barriers to the circular food supply chain as food is a perishable item and sustainable practices need to be implemented.

3.1 Problem description

The literature review reveals that previous studies focused on sustainability in the supply chain, the adoption of a circular economy, and possible threats to the food supply chain (Khan et al., 2021; Mangla et al., 2018b; Sharma et al., 2019; Yazdani et al., 2019). There is a need to have a thorough analysis of CE adoption barriers explicitly in FSC in developing economies. The shift in the food production and consumption patterns due to the rapid rise in population (~ 9 billion by 2050) leads to the exploitation of natural resources (Gedam et al., 2021; Govindan & Hasanagic, 2018; Yazdani et al., 2019). The unsustainable practices used in the food sector result in environmental pollution, food wastage, and food shortage, which need to be controlled by adopting a few green recovery practices. It is estimated that one-third of the food goes wasted from production to the consumption phase which results in the loss of limited and valuable natural resources (Gustavsson et al., 2011).

Elimination of food waste is not feasible because some causes are inevitable. However, the prevention of food waste can be done effectively by opting for correct programs, policies, and human attitudes toward the issue (Joshi & Visvanathan, 2019; Moraes et al., 2021; Nayak & Bhushan, 2019). In India, conventional practices have been practiced and inefficiencies in the food sector result in food wastage, which finally leads to the loss of the country’s finances. Nowadays, novel technology needs to be applied to leave behind traditional approaches. It is estimated that the Indian economy will lose half a trillion-dollar worth of the country’s GDP by 2030, which can be prevented by adopting CE business models (FICCI, 2018). For adopting the CE culture in the FSC, it is important to study the CE barriers so as to make a shift from linear to circular practices. CE is an exhaustive idea, which has several challenges due to which transition to a circular economy is difficult (Parida et al., 2019). For the country's sustainable growth, concepts like reduce, reuse and recycle need to be implemented in the process. For fulfilling the objective and modeling the framework, initially barriers to circular approaches to the food supply chain need to be identified. Thus, this study focuses on finalizing the barriers through an extensive review of the literature and incorporating experts’ opinions, and finally, the causal relationship among the barriers was obtained using the Grey DEMATEL methodology for a case company.

4 Research methods

Present research work implements a two-stage methodology, where the first stage is associated with the finalization of the barriers that are relevant to the study. Delphi technique proposed by Dalkey and Helmer (1963) was used in the first stage. Primarily all the factors which were relevant to the study were collected through a rigorous review of the literature, and expert interviews were carried out till they finalized the crucial factors. In this study, initially, 18 barriers were figured out from the literature and expert opinion was taken on every factor. After multiple sessions of a discussion carried out on the factors finally, 15 barriers were selected for further study using the Grey DEMATEL approach. DEMATEL is a constructive tool to build a mutual interaction between factors by developing causal relationships and helps in decision-making for complex problems (Fontela & Gabus, 1976; Gabus & Fontela, 1973). DEMATEL was firstly proposed by Battelle Memorial Institute in Geneva and was successfully applied to get a solution for complex problems. For getting the solutions to multi-criteria complex problems, the MCDM techniques are preferred. Many authors have applied different MCDM techniques to get solutions to practical problems. The main advantage of using DEMATEL over other MCDM techniques like ISM and AHP is that DEMATEL helps in examining the causal relationship among the criteria and also helps in determining the strength of the effects, whereas ISM methodology examines the inter-relationship among the criteria with the help of driving and dependence power but unable to find the strength of the criteria. Moreover, AHP also does not consider the indirect effect of the criteria, and the assumption is made that they are independent (Khurana et al., 2010; Lin et al., 2011; Luthra et al., 2013; Mani et al., 2014). The DEMATEL approach is used by several researchers to examine the interrelationships among the barriers in the multi-criteria decision-making problems (Bacudio et al., 2016; Jalalifar et al., 2013; Gandhi et al., 2015; Mangla et al., 2014).

DEMATEL makes the complex model simpler as it relies upon the basics of digraph, which divides the various factors into different zones of cause and effect, thus making it more straightforward for decision making (Falatoonitoosi et al., 2013). However, the main disadvantage of using DEMATEL separately is that in real-life problems, it does not account for human biases and uncertainties in the environment (Tseng, 2009). To overcome the errors due to ambiguities fuzzy technique with the decision-making tool was used by the researchers (Patil & Kant, 2014). But it has some bar with fuzziness. To overcome the limitations, this study integrated the grey technique with DEMATEL as it considers the condition of fuzziness (Julong, 1989; Li et al., 2007). The Grey approach is suitable for conditions with certain uncertainties and is suited in the case with a small sample size (Liu & Qiao, 2014). To change the grey number into crisp numbers, modified fuzzy values into crisp scores (CFCS) are used (Fu et al., 2012). Many other researchers have applied the grey approach with DEMATEL methodology in different fields successfully like third-party logistics selection criteria (Govindan et al, 2016), automotive parts remanufacturing (Xia et al, 2015), analyzing enablers of green innovation (Gupta & Barua, 2018), identifying critical factors of construction and demolition waste management (Liu et al, 2020), reverse logistics (Garg, 2020).

This research work utilizes Grey and DEMATEL methodology for identifying challenges impeding the circular approach in the food supply chain in the Indian context. The following are the steps for grey DEMATEL methodology:

Step 1 Building initial influence matrix for each evaluator.

Let there be a “t” number of barriers to the circular food supply chain and “s” be the number of evaluators taken for the case study. Every evaluator is asked to allocate the direct influence of factor i over factor j on the scale of 0, 1, 2, 3, and 4 based on the strength of the influence where 0 represents “no influence,” 1 represents “very low influence,” 2 represents “low influence,” 3 represents “high influence,” and 4 represents “very high influence” for the t number of finalized factors. For “s” the number of experts “s” initial influence matrix was obtained.

Step 2 Obtaining grey matrix.

For the matrices obtained in step 1, corresponding grey numbers are assigned by using Table 3 (Xia et al., 2015), i.e.

where 1 ≤ 1 ≤ s; 1 ≤ i ≤ t; 1 ≤ j ≤ t.

Step 3 Calculating the average grey influence matrix.

Average grey matrix [⊗ \(\check{F}_{ij}\)] is obtained by taking the mean of “s” grey matrices,

Step 4 Obtaining crisp matrix from average grey influence matrix.

For obtaining the crisp matrix, three steps are to be followed in a modified-CFCS methodology (Gupta & Barua, 2018; Rajesh & Ravi, 2015):

-

(i)

Lower and upper normalized values.

where \(\underline { \otimes } \dot{F}_{ij}\) denotes the lower normalized value of the grey number \(\underline { \otimes } \check{F}_{ij}\).

where \(\overline{ \otimes }\dot{F}_{ij}\) denotes the upper normalized value of the grey number \(\overline{ \otimes }\check{F}_{ij}\)

-

(ii)

Obtaining total normalized crisp value

$$M_{ij} = \left( {\frac{{\left( {\underline { \otimes } \dot{F}ij \left( {1 - \underline { \otimes } \dot{F}ij } \right) + \left( {\overline{ \otimes }\dot{F}ij \times \overline{ \otimes }\dot{F}ij } \right) } \right.}}{{\left( {1 - \underline { \otimes } \dot{F}ij + \overline{ \otimes }\dot{F}ij } \right.}}} \right)$$(6)

-

(iii)

Obtaining final crisp values

$$M_{ij}^{*} = \left( {\min \underline { \otimes } \dot{F}_{ij} + \left( {M_{ij} \times \Delta_{\min }^{\max } } \right)} \right)$$(7)and

$$M = \left[ {M_{ij}^{*} } \right]$$(8)

Step 5 Developing normalized direct-influence matrix “P.”

The normalized direct influence matrix “P” is determined by using Eqs. (9) and (10). The values of all the elements of this matrix will fall between 0 and 1.

where P denotes normalized direct influence matrix, E denotes normalization factor, and M denotes crisp influence matrix.

Step 6 Obtaining total influence matrix Q

where I denotes an identity matrix.

Step 7 Finding causal factors.

The Sum of rows, Ri and sum of columns, Cj are obtained by using Eqs. (12) and (13):

Step 8 Set a threshold value (α).

Calculate a threshold value (α) by taking the average of elements from matrix S using Eq. (14)

Step 9 Draw a causal relationship digraph.

It is obtained by using Eqs. (12) and (13), where the x-axis denotes the (Ri + Cj) values, and the y-axis denotes the (Ri − Cj) values. The values of qij greater than α, are chosen for digraph (Yang et al., 2008).

5 Case of the proposed model

To test the validity of the proposed model and research methodology, a food retail company is selected which deals with farm-fresh fruits and vegetables and is situated in over 65 cities in India. The case company is in operation for 20 years and is one of the leading retailers of farm-fresh fruits and vegetables in India. The case company favors recycling methods way from the past to increase the efficiency and effectiveness of the processes, thus converting a portion of waste into useful energy. As per the UN sustainable goals of 2030 to reduce food wastage by half, company is looking for applying sustainable methods to their processes like keeping a check on their supply chain, tracking ineffective processes, collecting used or expired products for energy generation, and such similar policies so that they can set up the benchmark in the market and can be cost-effective as compared to their competitors.

We approached 22 experts from different domains including government officials, managers from different domains of the case company, and professors from reputed institutes for operational and educational roles, respectively. The decision experts were chosen as those having in-depth knowledge of the green recovery mechanisms with a minimum experience of 07 years. Out of 22 experts, 10 of them accepted the invitation, resulting in an approximately 46% of response rate. The details of the experts are shown in Table 4.

Step 1 In the grey DEMATEL methodology, the first step is to obtain the direct relationship matrix for all the factors considered in the study. For this study, ten experts were selected from different domains with relevant knowledge and experience of at least 07 years in the food supply chain. They were requested to rate the factors of circular economy practices on a linguistic scale as shown in Table 3. Five-point Likert scale is selected as taken in the past paper for grey theory by Xia et al. (2015), Luthra et al. (2017) and Liu et al. (2020).

Step 2 For each initial direct influence matrix, grey matrix is formed using Eq. (1) and linguistic greyscale for the ten different experts. For expert 1, it is presented in Table 5.

Step 3 In the following step, the average grey relation matrix is obtained by using Eq. (2). All ten experts are experienced, and relevant to the area, and to confirm uniformity equal weights are assigned. The average matrix is shown in Table 6.

Step 4 Final crisp relation matrix (M) is calculated by using equations from (3)–(8), as given in Table 7.

Step 5 For obtaining normalized direct relation matrix (P), Eqs. (9) and (10) are used, as presented in Table 8.

Step 6 Eq. (11) is used to determine the total relation matrix (Q), which is shown in Table 9.

Step 7 For obtaining causal relationship parameters, some of the rows and some of the columns for the total relation matrix are obtained by using Eqs. (12) and (13) and are denoted as R 15 × 1 and C 1 × 15 vectors, respectively. The values for i = j are presented in Table 10.

Step 8 For plotting the causal relationship between the factors of the closed-loop food supply chain, a threshold value (α) was set by taking the average of elements from matrix S using Eq. (14). (α = 61.473/225 = 0.273). Values greater than the threshold value are used to plot the causal relation digraph. A solid arrow is used in the direction of cause to effect enabler and for a two-way relationship, a dotted arrow is being used which is shown in Fig. 1.

6 Results and discussion

This research provides inputs for integrating the circular economy practices in the food supply chain in the Indian context. Before applying the concept to the practical problem, its theoretical framework is of utmost importance. Thus this study helps to develop the theoretical framework, which is not only based on a literature review but also supported and validated by the experts in the field of the food supply chain.

For a complex practical problem, when the decision is to be made among the factors, which factor influences the case study (cause group) or by which factor it gets influenced (effect group). In such kinds of problems, changing one or two factors alone cannot solve the purpose as other factors are interdependent. Thus to improve the whole system, causal groups need to be identified and worked upon to enhance the effect group factors. Thus, by improving the cause and effect factors, the whole system can be improved.

The present study combines the one-round Delphi approach with a modified grey DEMATEL approach focusing on the challenges that hinder the application of circular economy practices in the food supply chain. Initially, with the help of literature review and expert opinions, a total of 15 challenges were finalized followed by a modified DEMATEL approach, thus combining DEMATEL with grey system theory to develop the cause and effect relationship between factors to transform the food supply chain in a closed-loop food supply chain. Thus, grey DEMATEL is used to overcome the biases of an evaluator, thus overcoming the human judgmental error and helping unveil the hidden interdependence among factors. This study provides crucial outcomes and helps in decision-making for officials of the company taken for study. (In the revised manuscript this change can be found on page no. 5, line no. 230).

Taking into consideration values of (Ri + Cj), the barriers are ranked as follows: CFC12 > CFC1 > CFC3 > CFC5 > CFC2 > CFC9 > CFC7 > CFC10 > CFC14 > CFC15 > CFC6 > CFC11 > CFC13 > CFC4 > CFC8. Following the rankings, the traceability issue (CFC12) is the most important challenge in closing the loop. In the traditional food supply chain, there is little information about the product. Tracking and keeping an eye on the food supply chain is of utmost importance as food is a perishable item with a time value. From production to the consumption phase and finally, toward zero waste, sustainable tracking plays an important role (Gokarn & Kuthambalayan, 2017; Gardas et al., 2018). Limited expertise in information and technology (CFC1) is the second most important challenge, which proves to be a stumbling block in closing the loops of the food supply chain. This is in line with the results of Kumar et al. (2022), Silva et al. (2020), Kamilaris et al. (2019), as they have also confirmed that for the successful implementation of circular practices in making the food supply chain sustainable technological immaturity turns out to be the crucial barrier. It is the reason why Industry 4.0 revolution is lacking in India. Many organizations follow traditional production techniques, and no additional scientific tools are updated in the system (Adebayo & Kirikkaleli, 2021). If some are updated, then there is limited knowledge about the tool and thus is not accepted. To make a system circular, organizations should opt for the best practices. The use of ICT tools and Industry 4.0 eases the information flow through the network, thus improving the sustainability of the food supply chain (Routroy & Behera, 2017). Hussain et al. (2021) explain that there is a significant link between updated technologies (social networking platforms) with sustainable practices. Thus, in order to have a sustainable food supply chain smart technologies and social networking apps need to be installed.

As per the study, poor logistic network design (CFC3) holds the third most crucial challenge for making the food supply chain circular. For the system to be circular, there is a need for a systematic forward and reverse logistic network, but India lacks a road network. Due to the perishable nature of food, with time quality of food and food products decreases. Poor process controls in the network lead to food loss and waste, especially in the case of the cold supply chain (Bicket et al., 2014; Mena et al., 2014). To improve the logistic network and maintain the quality of food products, closer linkages should be made by opening new marketing channels between producers and consumers (Priefer et al., 2016). High installation and operational cost of updated facilities (CFC2) is the next most important challenge in transforming the food supply chain. As suggested by Mangla et al. (2021), the cost of updating the facilities is too high so that the small and medium-sized firms fail to do due to the high cost of new technologies. Due to this, they stick to the conventional practices which is a reason for losses in the food supply chain. Moreover, limited cold chain and storage facilities (CFC2) is the next crucial barrier that results in huge losses due to degradation in the quality of the perishable product as its freshness is temperature-controlled. This result is in line with the previous studies of Joshi et al. (2009) and Mena et al. (2014). In developing economies, there is a lack of cold storage facilities due to the high cost of installation. Also, there is a shortage of temperature-controlled food carriers which results in food losses while transportation. Thus, these challenges need to be carefully looked upon by the supply chain actors and firms need to take all possible action in overcoming these challenges.

Moreover, after prioritizing the challenges the cause and effect groups were identified. The barriers of the causal group are examined and ranked as per the (Ri − Cj) values for every value of i = j. Identifying and ranking causal groups helps determine the barriers that need to be taken care of with priority as they do not move easily. They can further move the effect group barriers if they are managed and looked upon systematically (Lin et al., 2011). The causal barriers are ranked as follows CFC1 > CFC7 > CFC15 > CFC12 > CFC5 > CFC14 > CFC3. Rankings suggest that limited expertise in information and technology (CFC1), poor government policies (CFC7), insufficient focus on quality and safety standards (CFC15) and traceability issues (CFC12) are the major driving challenges with high positive (Ri − Cj) values. Amid all the driving barriers, limited expertise in information and technology (CFC1) has the maximum Ri value (6.734), thus confirming its high driving power as discussed earlier. The government aims to halve food waste, but the policies are not friendly to applying circular practices in India. So policies should be framed to promote zero waste and should also provide tax rebates to those who practice circular practices in their system. Digraph suggests that limited expertise in information and technology (CFC1) and traceability issues (CFC12) are the root cause of implementing a circular approach in the food supply chain as it drives major barriers.

Similarly, those barriers that are affected by the cause factors, i.e. limited cold chain and storage facilities (CFC2), poor logistic network design (CFC3), a large number of intermediaries (CFC10), and lack of backward-forward integration from farm to market (CFC9) are the important driven factors as can also be inferred from the digraph. Limited cold chain and storage facilities (CFC2) can be driven by limited expertise in information and technology (CFC1), poor logistic network design (CFC3), high installation and operational cost of updated facilities (CFC5), poor government policies and enforcements and traceability issues (CFC12). Traceability issues (CFC12) and high installation and operational cost of updated facilities (CFC5) behave dually and have a two-way relationship which is shown by dotted curves with a double-headed arrow.

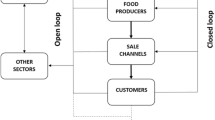

Moreover, few more inferences can be drawn out by portioning barriers into four different zones where factors above the x-axis are denoted as a causal group and factors below the x-axis are denoted as the effect group as they rely on the causal group and are also named as dysfunctional group barriers. As depicted in Fig. 2, zone 1 consists of barriers with the least power of relations or can be said as barriers with the least significance. Improper food labeling (CFC4), poor packaging efficiency (CFC8), lack of awareness regarding food wastage (CFC13), inefficient recovery centers (CFC11), limited integration between the partners (CFC6) and a large number of intermediaries (CFC10) come under this group. Zone 2 consists of causal barriers that drive other barriers, but the strength is weaker, ineffective demand management (CFC14) and Insufficient focus on quality and safety standards (CFC15) fall under this zone. Further, zone 3 constitutes barriers of the causal group that are most important and should be looked upon with priority, as overcoming these barriers can help in transforming the linear food supply chain into a circular one. Limited expertise in information and technology (CFC1), traceability issues (CFC12), poor logistic network (CFC3), high installation and operational cost of updated facilities (CFC5) and poor government policies (CFC7) are in this zone. Zone 4 covers the barriers of the effect group with high significance and should be looked upon by the management officials for implementing a circular approach in the food sector. Limited cold chain and storage facilities (CFC2) and lack of backward-forward integration from farm to market (CFC9) come under this zone.

7 Sensitivity analysis

To test the consistency and validity of the methodology, sensitivity analysis is done. This helps in validating decision-making by the experts for this study. Many methods are used for sensitivity analysis; in this study, weights of one expert are changed, thus keeping the weights of other experts similar to check the effect of one expert over the whole system (Garg, 2020; Gupta & Barua, 2018). Earlier equal weights were assigned to the experts as the minimum experience was 07 years. To check the robustness of the approach, here weights for one expert are assigned higher (0.28) and to other remaining experts, equal weights are assigned (0.08) and results are calculated. Same as the above, ten different sensitivity runs are being performed by assigning a higher weight to experts individually, as shown in Table 11.

For different sensitivity runs, separate total influence matrices were computed, and all (Ri − Cj) and (Ri + Cj) values were calculated, respectively. Based on this, Tables 12 and 13 were constructed, where the comparison of all ten sensitivity runs with the one when equal weights were assigned to all the experts is done.

It can be seen that there is no such variation in results based on (Ri + Cj) values; the same rankings are obtained with minimal accepted disparity; thus rankings show CFC12, CFC1 and CFC3 taking all first three positions, respectively, in importance factor. Furthermore, (Ri − Cj) values show that CFC1, CFC7 and CFC15 are the critical causal factors and similarly, CFC2, CFC3, CFC10, and CFC9 are the noticeable effects factors that are being affected by the causal factors, respectively. Thus, no such bias is noted in ratings provided by the decision-makers.

8 Policy and managerial implications

Based on the findings, it is necessary to introduce cleaner practices in the food supply chain in developing economies like India. However, India has managed to frame the policies and laws on sustainable practices but still faces challenges while in practice. Therefore, this study will help policymakers, practitioners, and managers carefully look at the major issues which inhibit the closing of the loop of the food supply chain. The present research work presents notable implications for academicians and policymakers. The following are the implications of the study:

-

The functionality of the circular economy practices is still in the early stages. This study will help academicians to further figure out the possibilities and will help them in overcoming these challenges.

-

Traceability issues, limited expertise in information and technology, poor logistic network design, and high installation and operational cost of updated facilities were the most influential factors. This study will help the practitioners to look into the most influential challenges and find possible ways to overcome those challenges.

-

This is the preliminary study in the view of implementing circular economy practices, and thus, this study will help researchers to further develop the framework and improve the food supply chain.

-

The present study will help policymakers and government regulatory bodies in framing the policies in favor of circular economy practices to promote sustainability in the supply chains.

-

With the growing complexity of the food supply chain and increasing food wastages, this study will help managers to introduce the circular economy principles and will help them in the decision-making process.

-

This study promotes green practices and will help in reducing food wastage which will result in reducing growing health concerns and will keep the environment clean.

9 Conclusions, limitations and recommendations for future research

Due to the growing population throughout the globe, the demands are ever-increasing and thus putting pressure on the environment as waste is also increased in a similar proportion. In this competitive market, the organization tries to come up with new ideas and solutions that are cost-effective and environmentally friendly, as the food industry has perishable items with short or limited periods, fit for consumption. Hence, the supply chain of food is to be kept tighter as compared to others. Likewise in dynamic environments like COVID-19 situations where the food supply chain was completely disrupted due to the conventional approach followed by the supply chain partners. The novel sustainability principles need to be implemented for the smooth functioning of the supply chain and may respond well to changing environments. To reduce food wastage, circular economy practices should be incorporated into the food supply chain. Keeping this perspective in mind, firstly, barriers to implementing a circular approach in the food supply chain are listed from an extensive review of literature further ranked by the experts, followed by using grey DEMATEL methodology to draw interrelationship between the factors and thus separating causal and effect factors. A study was carried out on an Indian food processing company, ABC.

The challenges of incorporating the circular approach in the food supply chain are co-related to each other, and their relationship is obtained by using the DEMATEL technique. Rankings based on importance are done and further, by studying the cause and effect factors separately, managers can implement a circular approach in the food supply chain with ease.

Taking into account this particular study, 15 barriers to implementing the circular approach in the food supply chain are found. With the help of DEMATEL methodology, prioritization factors are identified and cause and effect interdependencies are found. This research study is a novel research work in which barriers to the circular food supply chain in the Indian context are identified. In India, linear approach is much more familiar and there is a major non-acceptance of reduce, recycle, and reuse approach. To implement circular practices and promote green practices for generating energy from waste this study was carried out. From the study, it was found that the traceability issue is the most critical factor in closing the loop.

The advisory committee of a case company should keep a systematic check on the whole supply chain keeping in mind when and where a particular food item should be at a particular time and thus it will help in collecting back the waste for recycling to generate energy from waste. Followed by limited expertise in information and technology, as per updating the new approach in the system which is completely technology-driven, the manager of a company should have a look at improving skills of its labors and thus introducing new technologies in the company and making its system friendly. Adebayo et al. (2021a, 2021b) suggest that technological innovation improves the quality of the environment by eliminating inefficient ways of production. After the production of food items, the crucial part is the supply of the material. Thus the company should optimize the route to overcome the poor logistic network, thus killing inefficient stations which can save much energy. Furthermore, to successfully implement the circular approach and modify the whole food supply chain, the factors which are driving other factors should be kept in mind thus causal factors ranked up should be improved by the manager of the case company which includes expertizing its employees with updated tools and techniques, creating awareness regarding the acceptance of refurbished products. The government can also improve its policies for promoting green practices, and thus tax rebates can attract investors to implement green practices in their companies. The public–private partnership is of utmost importance in making the shift from conventional ways to cleaner ways of production (Adebayo et al., 2021a, 2021b).With the help of the DEMATEL methodology, managers could classify the cause and effect group separately which can be looked upon accordingly. The factors which were affected most by the causal factors are the large number of intermediaries which should be minimized and one should try to move toward a single-window system followed by proper linkages between producer, supplier and consumer so that from consumer it can go back in the treatment plant with ease. Thus improving causal factors will help to improve other factors thus successful implementation toward circularity can be achieved.

In continuation with this, to check the robustness of the approach, a sensitivity analysis was performed and confirmed that no severe biases in the decision-making process were found. It will help the company manager look after the factors ranked higher. While forming policies and modeling the framework for their company, they can implement the changes to overcome the challenges of closing the loop. The digraph showing the causal relationship between the factors can be looked from Fig. 1, and the managers of other food processing companies in India can use them in updating their policies and framework to confirm the validity of the study, thus will save a lot of money, time and resources for an organization.

The present research work comes up with certain limitations, which include: Firstly, this study was done keeping the food sector in mind and thus the result may vary in replicating for other sectors. Future studies can be carried out by taking different sectors into account considering the same or different factors to assess the validity of the research work. Secondly, only challenges were identified which hinder the application of circular practices in the food supply chain. Furthermore, drivers can also be listed and looked upon to promote the circular approach. Thirdly, this study is limited to ten experts. In the future, large sample of experts could be chosen, and the robustness of the model can be validated. Results obtained through DEMATEL can also be validated by using other MCDM techniques like ANP, VIKOR, AHP, etc., and results obtained from them can be compared to the one obtained from this study. Last but not least, mathematical modeling can be done to optimize the results obtained from this study. Thus, in future research work, it can be incorporated.

References

Adebayo, T. S., Adedoyin, F. F., & Kirikkaleli, D. (2021a). Toward a sustainable environment: Nexus between consumption-based carbon emissions, economic growth, renewable energy and technological innovation in Brazil. Environmental Science and Pollution Research, 28(37), 52272–52282.

Adebayo, T. S., Awosusi, A. A., Odugbesan, J. A., Akinsola, G. D., Wong, W. K., & Rjoub, H. (2021b). Sustainability of energy-induced growth nexus in Brazil: Do carbon emissions and urbanization matter? Sustainability, 13(8), 4371.

Adebayo, T. S., & Kirikkaleli, D. (2021). Impact of renewable energy consumption, globalization, and technological innovation on environmental degradation in Japan: Application of wavelet tools. Environment, Development and Sustainability, 23(11), 16057–16082.

Ageron, B., Gunasekaran, A., & Spalanzani, A. (2012). Sustainable supply management: An empirical study. International Journal of Production Economics, 140(1), 168–182.

Andrews, D. (2015). The circular economy, design thinking and education for sustainability. Local Economy, 30(3), 305–315.

Annosi, M. C., Brunetta, F., Bimbo, F., & Kostoula, M. (2021). Digitalization within food supply chains to prevent food waste. Drivers, barriers and collaboration practices. Industrial Marketing Management, 93, 208–220.

Bacudio, L. R., Benjamin, M. F. D., Eusebio, R. C. P., Holaysan, S. A. K., Promentilla, M. A. B., Yu, K. D. S., & Aviso, K. B. (2016). Analyzing barriers to implementing industrial symbiosis networks using DEMATEL. Sustainable Production and Consumption, 7, 57–65.

Bag, S., Gupta, S., & Foropon, C. (2019). Examining the role of dynamic remanufacturing capability on supply chain resilience in circular economy. Management Decision, 57, 863–885.

Balaji, M., & Arshinder, K. (2016). Modeling the causes of food wastage in Indian perishable food supply chain. Resources, Conservation and Recycling, 114, 153–167.

Bastein, A. G. T. M., Roelofs, E., Rietveld, E., & Hoogendoorn, A. (2013). Opportunities for a circular economy in the Netherlands (pp. 1–13). TNO.

Bicket, M., Guilcher, S., Hestin, M., Hudson, C., Razzini, P., Tan, A., Ten Brink, P., Van Dijl, E., Vanner, R., & Watkins, E. (2014). Scoping study to identify potential circular economy actions, priority sectors, material flows and value chains.

Bosona, T., & Gebresenbet, G. (2013). Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control, 33(1), 32–48.

Bouzon, M., Govindan, K., & Rodriguez, C. M. T. (2018). Evaluating barriers for reverse logistics implementation under a multiple stakeholders’ perspective analysis using grey decision making approach. Resources, Conservation and Recycling, 128, 315–335.

Brancoli, P., Rousta, K., & Bolton, K. (2017). Life cycle assessment of supermarket food waste. Resources, Conservation and Recycling, 118, 39–46.

Bressanelli, G., Adrodegari, F., Perona, M., & Saccani, N. (2018). The role of digital technologies to overcome Circular Economy challenges in PSS Business Models: An exploratory case study. Procedia Cirp, 73, 216–221.

Campos, D. A., Gómez-García, R., Vilas-Boas, A. A., Madureira, A. R., & Pintado, M. M. (2020). Management of fruit industrial by-products—A case study on circular economy approach. Molecules, 25(2), 320.

Cane, M., & Parra, C. (2020). Digital platforms: Mapping the territory of new technologies to fight food waste. British Food Journal.

Chaudhary, K., & Vrat, P. (2020). Circular economy model of gold recovery from cell phones using system dynamics approach: A case study of India. Environment, Development and Sustainability, 22(1), 173–200.

Corallo, A., Latino, M. E., Menegoli, M., & Striani, F. (2020). What factors impact on technological traceability systems diffusion in the agrifood industry? An Italian survey. Journal of Rural Studies, 75, 30–47.

Corrado, S., & Sala, S. (2018). Food waste accounting along global and European food supply chains: State of the art and outlook. Waste Management, 79, 120–131.

Dalkey, N., & Helmer, O. (1963). An experimental application of the Delphi method to the use of experts. Management Science, 9(3), 458–467.

Department of Agriculture, Cooperation & Farmers Welfare. (2018–2019). https://agricoop.nic.in/sites/default/files/AR_2018-19_Final_for_Print.pdf

Diaz-Ruiz, R., Costa-Font, M., López-i-Gelats, F., & Gil, J. M. (2019). Food waste prevention along the food supply chain: A multi-actor approach to identify effective solutions. Resources, Conservation and Recycling, 149, 249–260.

El Bilali, H. (2020). Transition heuristic frameworks in research on agro-food sustainability transitions. Environment, Development and Sustainability, 22(3), 1693–1728.

EMF (Ellen MacArthur Foundation). (2017). Our mission is to accelerate the transition to a circular economy. https://www.ellenmacarthurfoundation.org

Evans, D. (2012). Beyond the throwaway society: Ordinary domestic practice and a sociological approach to household food waste. Sociology, 46(1), 41–56.

Falatoonitoosi, E., Leman, Z., & Sorooshian, S. (2013). Modeling for green supply chain evaluation. Mathematical Problems in Engineering, 2013.

Farooque, M., Zhang, A., & Liu, Y. (2019). Barriers to circular food supply chains in China. Supply Chain Management: An International Journal, 24(5), 677–696.

Ficci, Circular Economy Symposium. (2018). Accelerating India’s circular economy shift A half-trillion USD opportunity future-proofing growth in a resource-scarce world. http://ficci.in/spdocument/22977/FICCI-Circular-Economy.pdf

Fiksel, J., Sanjay, P., & Raman, K. (2021). Steps toward a resilient circular economy in India. Clean Technologies and Environmental Policy, 23(1), 203–218.

Foley, J. A., Ramankutty, N., Brauman, K. A., Cassidy, E. S., Gerber, J. S., Johnston, M., Mueller, N. D., O’Connell, C., Ray, D. K., West, P. C., Balzer, C., & Zaks, D. P. (2011). Solutions for a cultivated planet. Nature, 478(7369), 337–342.

Fontela, E., & Gabus, A. (1976). The DEMATEL observer, DEMATEL 1976. Report. Attele Geneva Research Center.

Food and Agriculture Organization of the United Nations. (2015). http://www.fao.org/3/i5056e/i5056e.pdf

Food and Agriculture Organization of the United Nations. (2020). http://www.fao.org/3/ca7988en/CA7988EN.pdf

Fraccascia, L., Yazdanpanah, V., van Capelleveen, G., & Yazan, D. M. (2021). Energy-based industrial symbiosis: A literature review for circular energy transition. Environment, Development and Sustainability, 23(4), 4791–4825.

Franklin-Johnson, E., Figge, F., & Canning, L. (2016). Resource duration as a managerial indicator for Circular Economy performance. Journal of Cleaner Production, 133, 589–598.

Fu, X., Zhu, Q., & Sarkis, J. (2012). Evaluating green supplier development programs at a telecommunications systems provider. International Journal of Production Economics, 140(1), 357–367.

FUSIONS Definitional Framework for Food Waste. (2014). https://www.eu-fusions.org/phocadownload/Publications/FUSIONS%20Definitional%20Framework%20for%20Food%20Waste%202014.pdf

FUSIONS. (2016). Estimates of European food waste levels. European Union.

Gabus, A., & Fontela, E. (1973). Perceptions of the world problematique: Communication procedure, communicating with those bearing collective responsibility. Battelle Geneva Research Centre.

Gandhi, S., Mangla, S. K., Kumar, P., & Kumar, D. (2015). Evaluating factors in implementation of successful green supply chain management using DEMATEL: A case study. International Strategic Management Review, 3(1–2), 96–109.

Gardas, B. B., Raut, R. D., & Narkhede, B. (2018). Evaluating critical causal factors for post-harvest losses (PHL) in the fruit and vegetables supply chain in India using the DEMATEL approach. Journal of Cleaner Production, 199, 47–61.

Garg, C. P. (2020). A robust hybrid decision model to evaluate critical factors of reverse logistics implementation using Grey-DEMATEL framework. Opsearch, 57, 837–873.

Garrone, P., Melacini, M., & Perego, A. (2014). Opening the black box of food waste reduction. Food Policy, 46, 129–139.

Gedam, V. V., Raut, R. D., de Sousa Jabbour, A. B. L., Tanksale, A. N., & Narkhede, B. E. (2021). Circular economy practices in a developing economy: Barriers to be defeated. Journal of Cleaner Production, 311, 127670.

Genovese, A., Acquaye, A. A., Figueroa, A., & Koh, S. L. (2017). Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega, 66, 344–357.

Gharfalkar, M., Court, R., Campbell, C., Ali, Z., & Hillier, G. (2015). Analysis of waste hierarchy in the European waste directive 2008/98/EC. Waste Management, 39, 305–313.

Gligor, D., Tan, A., & Nguyen, T. N. T. (2018). The obstacles to cold chain implementation in developing countries: Insights from Vietnam. The International Journal of Logistics Management, 29(3), 942–958.

Global Hunger Index. (2019). The challenger of hunger and climate change. https://www.globalhungerindex.org/pdf/en/2019.pdf

Global Hunger Index. (2020). One decade to zero hunger. Linking health and sustainable food systems. https://www.globalhungerindex.org/pdf/en/2020.pdf

Gokarn, S., & Kuthambalayan, T. S. (2017). Analysis of challenges inhibiting the reduction of waste in food supply chain. Journal of Cleaner Production, 168, 595–604.

Govindan, K., & Hasanagic, M. (2018). A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. International Journal of Production Research, 56(1–2), 278–311.

Govindan, K., Khodaverdi, R., & Vafadarnikjoo, A. (2016). A grey DEMATEL approach to develop third-party logistics provider selection criteria. Industrial Management & Data Systems, 116(4), 690–722.

Goyal, S., Esposito, M., & Kapoor, A. (2018). Circular economy business models in developing economies: Lessons from India on reduce, recycle, and reuse paradigms. Thunderbird International Business Review, 60(5), 729–740.

Goyal, S., Garg, D., & Luthra, S. (2021). Analyzing critical success factors to adopt sustainable consumption and production linked with circular economy. Environment, Development and Sustainability, 1–30.

Gupta, H., & Barua, M. K. (2018). A grey DEMATEL-based approach for modeling enablers of green innovation in manufacturing organizations. Environmental Science and Pollution Research, 25(10), 9556–9578.

Gupta, H., Kumar, A., & Wasan, P. (2021). Industry 4.0, cleaner production and circular economy: An integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. Journal of Cleaner Production, 295, 126253.

Gustavsson, J., Cederberg, C., Sonesson, U., Van Otterdijk, R., & Meybeck, A. (2011). Global food losses and food waste.

Hanson, C., Lipinski, B., Robertson, K., Dias, D., Gavilan, I., Gréverath, P., Ritter, S., Fonseca, J., VanOtterdijk, R., Timmermans, T., Lomax, J. & Quested, T. (2016). Food loss and waste accounting and reporting standard.

Hegde, R. N., & Madhuri, N. V. (2013). A study on marketing infrastructure for fruits and vegetables in India. Research Reports Series–91. National Institute of Rural Development, Government of India, Hyderabad.

Hobbs, J. E., Bailey, D., Dickinson, D. L., & Haghiri, M. (2005). Traceability in the Canadian red meat sector: Do consumers care? Canadian Journal of Agricultural Economics/revue Canadienne D’agroeconomie, 53(1), 47–65.

Hussain, I., Nazir, M., Hashmi, S. B., Di Vaio, A., Shaheen, I., Waseem, M. A., & Arshad, A. (2021). Green and sustainable entrepreneurial intentions: A mediation-moderation perspective. Sustainability, 13(15), 8627.

India Environment Portal. (2016). Solid waste management rules. https://www.indiaenvironmentportal.org.in/content/427824/solid-waste-management-rules-2016/

Jackson, M., Lederwasch, A., & Giurco, D. (2014). Transitions in theory and practice: Managing metals in the circular economy. Resources, 3(3), 516–543.

Jalalifar, S., Hafshejani, K. F., & Movahedi, M. M. (2013). Evaluation of the effective barriers in GSCM implementation using DEMATEL method. Natural Science, 11, 95–102.

Joshi, R., Banwet, D. K., & Shankar, R. (2009). Indian cold chain: Modeling the inhibitors. British Food Journal, 111(11), 1260–1283.

Joshi, P., & Visvanathan, C. (2019). Sustainable management practices of food waste in Asia: Technological and policy drivers. Journal of Environmental Management, 247, 538–550.

Julong, D. (1989). Introduction to grey system theory. The Journal of Grey System, 1(1), 1–24.

Jurgilevich, A., Birge, T., Kentala-Lehtonen, J., Korhonen-Kurki, K., Pietikäinen, J., Saikku, L., & Schösler, H. (2016). Transition towards circular economy in the food system. Sustainability, 8(1), 69.

Kakwani, N. S., & Kalbar, P. P. (2020). Review of circular economy in urban water sector: Challenges and opportunities in India. Journal of Environmental Management, 271, 111010.

Kamilaris, A., Fonts, A., & Prenafeta-Boldύ, F. X. (2019). The rise of blockchain technology in agriculture and food supply chains. Trends in Food Science & Technology, 91, 640–652.

Khan, S. A. R., Zkik, K., Belhadi, A., & Kamble, S. S. (2021). Evaluating barriers and solutions for social sustainability adoption in multi-tier supply chains. International Journal of Production Research, 59(11), 3378–3397.

Khandelwal, C., & Barua, M. K. (2020). Prioritizing Circular Supply Chain Management Barriers Using Fuzzy AHP: Case of the Indian Plastic Industry. Global Business Review, 0972150920948818.

Khurana, M. K., Mishra, P. K., Jain, R., & Singh, A. R. (2010). Modeling of information sharing enablers for building trust in Indian manufacturing industry: An integrated ISM and fuzzy MICMAC approach. International Journal of Engineering Science and Technology, 2(6), 1651–1669.

Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling, 127, 221–232.

Krishnan, R., Agarwal, R., Bajada, C., & Arshinder, K. (2020). Redesigning a food supply chain for environmental sustainability—An analysis of resource use and recovery. Journal of Cleaner Production, 242, 118374.

Kumar, A., Mangla, S. K., & Kumar, P. (2022). Barriers for adoption of Industry 4.0 in sustainable food supply chain: A circular economy perspective. International Journal of Productivity and Performance Management.

Kumar, A., Mangla, S. K., Kumar, P., & Karamperidis, S. (2020). Challenges in perishable food supply chains for sustainability management: A developing economy perspective. Business Strategy and the Environment, 29(5), 1809–1831.

Kummu, M., De Moel, H., Porkka, M., Siebert, S., Varis, O., & Ward, P. J. (2012). Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Science of the Total Environment, 438, 477–489.

Li, G. D., Yamaguchi, D., & Nagai, M. (2007). A grey-based decision-making approach to the supplier selection problem. Mathematical and Computer Modelling, 46(3–4), 573–581.

Lieder, M., & Rashid, A. (2016). Towards circular economy implementation: A comprehensive review in context of manufacturing industry. Journal of Cleaner Production, 115, 36–51.

Lin, Y. T., Yang, Y. H., Kang, J. S., & Yu, H. C. (2011). Using DEMATEL method to explore the core competences and causal effect of the IC design service company: An empirical case study. Expert Systems with Applications, 38(5), 6262–6268.

Lipinski, B., Hanson, C., Waite, R., Searchinger, T., Lomax, J., & Kitinoja, L. (2013). Reducing food loss and waste.

Liu, J., & Qiao, J. Z. (2014). A grey rough set model for evaluation and selection of software cost estimation methods. Grey Systems: Theory and Application, 4(1), 3–12.

Liu, H., Long, H., & Li, X. (2020). Identification of critical factors in construction and demolition waste recycling by the grey-DEMATEL approach: A Chinese perspective. Environmental Science and Pollution Research, 27(8), 8507–8525.

Luthra, S., Garg, D., & Haleem, A. (2013). Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using analytical hierarchy process. Journal of Industrial Engineering and Management, 6(4), 930–962.

Luthra, S., Govindan, K., & Mangla, S. K. (2017). Structural model for sustainable consumption and production adoption—A grey-DEMATEL based approach. Resources, Conservation and Recycling, 125, 198–207.

MacArthur, E. (2013). Towards the circular economy, economic and business rationale for an accelerated transition (pp. 21–34). Cowes, UK: Ellen MacArthur Foundation.

Mangla, S. K., Bhattacharya, A., Yadav, A. K., Sharma, Y. K., Ishizaka, A., Luthra, S., & Chakraborty, R. (2021). A framework to assess the challenges to food safety initiatives in an emerging economy. Journal of Cleaner Production, 284, 124709.

Mangla, S., Kumar, P., & Barua, M. K. (2014). An evaluation of attribute for improving the green supply chain performance via DEMATEL method. International Journal of Mechanical Engineering & Robotics Research, 1(1), 30–35.

Mangla, S. K., Luthra, S., Mishra, N., Singh, A., Rana, N. P., Dora, M., & Dwivedi, Y. (2018a). Barriers to effective circular supply chain management in a developing country context. Production Planning & Control, 29(6), 551–569.

Mangla, S. K., Luthra, S., Rich, N., Kumar, D., Rana, N. P., & Dwivedi, Y. K. (2018b). Enablers to implement sustainable initiatives in agri-food supply chains. International Journal of Production Economics, 203, 379–393.

Mani, V., Agrawal, R., & Sharma, V. (2014). Supplier selection using social sustainability: AHP based approach in India. International Strategic Management Review, 2(2), 98–112.

Meherishi, L., Narayana, S. A., & Ranjani, K. S. (2019). Sustainable packaging for supply chain management in the circular economy: A review. Journal of Cleaner Production, 237, 117582.

Mena, C., Terry, L. A., Williams, A., & Ellram, L. (2014). Causes of waste across multi-tier supply networks: Cases in the UK food sector. International Journal of Production Economics, 152, 144–158.

Ministry of food processing industries. Government of India. Annual report 2019–2020. https://mofpi.nic.in/sites/default/files/english_2019-20_1.pdf

Moktadir, M. A., Rahman, T., Rahman, M. H., Ali, S. M., & Paul, S. K. (2018). Drivers to sustainable manufacturing practices and circular economy: A perspective of leather industries in Bangladesh. Journal of Cleaner Production, 174, 1366–1380.

Moraes, N. V., Lermen, F. H., & Echeveste, M. E. S. (2021). A systematic literature review on food waste/loss prevention and minimization methods. Journal of Environmental Management, 286, 112268.

Morseletto, P. (2020). Targets for a circular economy. Resources, Conservation and Recycling, 153, 104553.

Mourad, M. (2016). Recycling, recovering and preventing “food waste”: Competing solutions for food systems sustainability in the United States and France. Journal of Cleaner Production, 126, 461–477.

Nayak, A., & Bhushan, B. (2019). An overview of the recent trends on the waste valorization techniques for food wastes. Journal of Environmental Management, 233, 352–370.

NRDC Report. (2013). The dating game: How confusing food data labels lead to food waste in America. https://www.nrdc.org/sites/default/files/dating-game-report.pdf

Papargyropoulou, E., Lozano, R., Steinberger, J. K., Wright, N., & bin Ujang, Z. (2014). The food waste hierarchy as a framework for the management of food surplus and food waste. Journal of Cleaner Production, 76, 106–115.

Parfitt, J., Barthel, M., & Macnaughton, S. (2010). Food waste within food supply chains: Quantification and potential for change to 2050. Philosophical Transactions of the Royal Society B: Biological Sciences, 365(1554), 3065–3081.

Parida, V., Burström, T., Visnjic, I., & Wincent, J. (2019). Orchestrating industrial ecosystem in circular economy: A two-stage transformation model for large manufacturing companies. Journal of Business Research, 101, 715–725.

Patil, S. K., & Kant, R. (2014). A hybrid approach based on fuzzy DEMATEL and FMCDM to predict success of knowledge management adoption in supply chain. Applied Soft Computing, 18, 126–135.

Pearce, D. W., & Turner, R. K. (1990). Economics of natural resources and the environment. JHU Press.

Priefer, C., Jörissen, J., & Bräutigam, K. R. (2016). Food waste prevention in Europe—A cause-driven approach to identify the most relevant leverage points for action. Resources, Conservation and Recycling, 109, 155–165.

Prieto-Sandoval, V., Jaca, C., & Ormazabal, M. (2018). Towards a consensus on the circular economy. Journal of Cleaner Production, 179, 605–615.

Principato, L., Ruini, L., Guidi, M., & Secondi, L. (2019). Adopting the circular economy approach on food loss and waste: The case of Italian pasta production. Resources, Conservation and Recycling, 144, 82–89.

Priyadarshini, P., & Abhilash, P. C. (2020). Circular economy practices within energy and waste management sectors of India: A meta-analysis. Bioresource Technology, 304, 123018.

Rajesh, R., & Ravi, V. (2015). Modeling enablers of supply chain risk mitigation in electronic supply chains: A Grey–DEMATEL approach. Computers & Industrial Engineering, 87, 126–139.

Routroy, S., & Behera, A. (2017). Agriculture supply chain: A systematic review of literature and implications for future research. Journal of Agribusiness in Developing and Emerging Economies, 7(3), 275–302.

Sachan, A., Sahay, B. S., & Sharma, D. (2005). Developing Indian grain supply chain cost model: A system dynamics approach. International Journal of Productivity and Performance Management, 54(3), 187–205.

Searchinger, T., Waite, R., Hanson, C., Ranganathan, J., Dumas, P., Matthews, E., & Klirs, C. (2019). Creating a sustainable food future: A menu of solutions to feed nearly 10 billion people by 2050. Final report. WRI.

Sharma, J., Tyagi, M., & Bhardwaj, A. (2020a). Parametric review of food supply chain performance implications under different aspects. Journal of Advances in Management Research, 17(3), 421–453.

Sharma, M., Joshi, S., & Kumar, A. (2020b). Assessing enablers of e-waste management in circular economy using DEMATEL method: An Indian perspective. Environmental Science and Pollution Research, 27(12), 13325–13338.