Abstract

The recycling and remanufacturing of used electronic products are the great significance to environmental governance and resource management. From the demand perspective of remanufactured products, this paper proposes a demand-oriented recycling model of used electronic products based on the reverse supply chain and cooperative game theory. Taking cost–benefit analysis as the basis of the benefits model of the participants in the electronic waste product recycling system, a static multi-stage game model and a dynamic cooperative game model are established, there is an optimal strategy at each stage which may not be unique, depending on the decision model constructed. In the static multi-stage recycling mode, the strategic decisions at all stages are all based on the same demand for remanufactured products, the strategy decision at each stage of the recycling mode of waste electronic products is based on the multi-stage demand prediction of remanufactured products. The cost optimization of each link in the static multi-stage is to realize the optimal strategy combination of participants in each link. The study concluded that by setting demand as the main goal, both recycling and remanufacturing companies can improve their own benefits by realizing an optimal cost combination.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the technological innovation and its frequent updating and upgrading, the high consumption of electronic and electrical equipment has brought about a high output of used electronic products. The rapid expansion of manufacturing techniques, innovation and consumer demand has led to improvements in various electronic equipment, and the increased production exhibits a positive relationship with the quantity of waste electrical and electronic equipment (Zlamparet et al., 2017). Recycling and reusing waste electrical and electronic equipment has thus become a global social issue (Zhu, 2017).

Used electronic products not only include abundant resources but also contain various toxic substances, which can adversely affect the environment and human health. (Kiddee et al., 2013). Without proper recycling, e-waste can generate critical environmental pollution (Qu et al., 2013). Owing to the improved environmental awareness of people and the constraints of government legislation, the industry is aiming for development supplemented with environmental protection and is striving to integrate the green capabilities of the companies in both the forward and reverse supply chains (Kumar & Dixit, 2019). The Waste Electrical and Electronic Equipment Directive provided by the European Union mandates recycling obligations of the manufacturers; however, most manufacturers are still in the preliminary stage of environmental considerations (Messmann et al., 2019). In India, a developing country, studies have shown that consumers prefer to benefit from recycling, which to some extent reflects that India is increasingly attaching importance to the study of electronic wastes recycling and economic circulation. In order to promote the amount of recycling by producers and recyclers, government policies are needed to restrict the dismantlers in the secondary market. (Dasgupta et al., 2017).

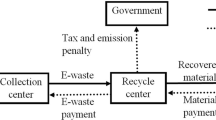

In the recycling link of the entire closed-loop supply chain, the main parties are recyclers, remanufacturers, and consumers involved in recycling. Among them, recyclers are mainly in charge of recovering waste electrical and electronic products from consumers using certain remuneration payments, and then transferring the recovered electrical and electronic products to remanufacturers. Then, the remanufacturer classifies those waste electrical and electronic products according to its degree of damage. If the damage does not affect normal use, latter can be resold as second-hand goods. This process is called "Reuse". In addition, waste electrical and electronic products that are severely damaged and difficult to repair can only be used to excavate their residual value by using their ingredients. This process is called "Recycle". In general, the disposal of waste electrical and electronic products is mainly composed of the above three parts, namely "3R". The above subjects and links together constitute the entire reverse recycling supply chain.

Recycling and remanufacturing of used electronic products is an important component of supply chain management both locally and globally. As an important part of closed-loop supply chain management, the research on the recycling and remanufacturing of used electronic products plays a great role in improving resource utilization, reducing enterprise costs and improving supply chain management. The existing supply chain management research mainly focuses on how to improve the product recovery rate and how to carry out the product remanufacturing process, and there is less systematic analysis of the decision-making process of the whole closed-loop supply chain. The recycling strategy of used electronic products recycling enterprises is mainly formulated from the perspective of product supply, but there is a knowledge gap in the analysis of the demand for remanufactured products. Therefore, it is extremely necessary to study the recycling mode of used electronic products under the demand orientation. This paper aims to address the lack of research in this area and develops a demand-oriented recycling model of used electronic products.

This study takes the recycling of used electronic products as the main research subject, discusses and summarizes the supply chain management theory of used electronic products, and considers the construction of the product recycling mode through the whole process of the whole closed-loop supply chain under the demand orientation. From the perspective of economics, the game competition and cooperation theory and system analysis theory are applied to integrate the demand orientation into all links of the whole recycling and remanufacturing, and the whole recycling and resale process of products is studied in stages, that is, the formulation of recycling channels and recycling strategies, recycling and classification for Remanufacturing The remanufactured products are analyzed in multiple stages of sales. At the same time, the system analysis method and the combination of qualitative and quantitative methods are used to construct the strategic decision-making and benefit model of participants in each stage. Finally, by connecting the strategic decision-making results of different stages, the decision-making model of optimized product recycling mode is established, which provides a theoretical basis for improving the recycling efficiency of used electronic products, the sales rate of remanufactured products, and the benefits of product recycling and remanufacturing enterprises.

This paper is organized as follows. In the next section, we provide a summary of the literature related to recycling and remanufacturing. This is followed by the development of the Demand-oriented electronic waste product recycling model in two scenarios—dynamic and static recycling models. Next, we carry out numerical simulations that describe the benefits’ changes in a graphic way and the results from the different scenarios are presented. Finally, we provide managerial insights and concluding remarks.

2 Literature review

As possessors of waste electrical and electronic equipment, consumers significantly influence the recycling process. Thus, focusing on the impact of consumers’ behavior during the recycling process can help achieve more efficient recycling of waste electrical and electronic equipment (Zhu, 2017). It has been reported that consumers tend to retain waste products for a long time, and this tendency is related to the recycling behavior characteristics and lifestyles of the consumers. In addition, the technological evolution, design characteristics, and market value of the product, along with the environmental stimulus are factors that affect a consumer’s recycling behavior (Sabbaghi et al., 2015). When two types of products, that is, traditional and environmental friendly products exist in the market, the environmental differential quality influences the demand for the respective products; however, the production capacity or scale of the manufacturer is not a limiting factor that affects the demand for these two types of products. (L. Zhang et al., 2015). Research supports the decision of environmentally conscious consumers to buy new and used products, and it also supports the scrapping decisions in the case of collection points and separation of reusable equipment (Boldoczki et al., 2020). Furthermore, the demand for remanufactured products influences the development of environmental protection strategies for remanufacture and reuse enterprises. Therefore, the strategies of remanufacturers are highly influenced by the potential consumer groups of remanufactured products (Jiménez-Parra et al., 2014). When consumers are sensitive to recycling prices, recyclers' profits decrease, but manufacturers' and supply chain systems' profits increase. Only when a large proportion of recycled WEEE is used for remanufacturing can it benefit all members of the supply chain (Liu et al., 2021).

In the recycling process of waste products, government policies considerably influence the development of sustainable industrial clusters (Jiao & Boons, 2017). The existing recycling process of waste home appliances in China presents an unbalanced situation of high technology cost and low effect (Zhou et al., 2017). The government is thus intervening in the electrical and electronic equipment recycling market by providing subsidies and regulations (Fu et al., 2020).

Although green production strategies are not extremely profitable for manufacturers, government subsidies can help facilitate the change in manufacturer theories due to the corresponding shift in consumer awareness (Yu et al., 2016). The provision of government subsidies does not only increase the remanufacturing activity but also encourages the manufacturers to design products that are more suitable for remanufacturing (Mitra & Webster, 2008). Nowadays, many states and countries have passed legislation that makes producers responsible for the proper disposal of products (Tian et al., 2019). By implementing a series of policies and regulations pertaining to the extension of corporate responsibility to improve the self-financing subsidy program of enterprises, the environmental performance can be improved. At this point, the total profit of the manufacturers and recyclers may decrease, but not necessarily the consumer surplus (Zhou et al., 2017). When motivating retailers, the impact of different incentive strategies on the retailers' net profit changes is different. When the value of the incentive utility is low, the price discount incentive strategy allows the retailers to obtain the maximum profit. However, when the value of the incentive utility increases to a certain extent, the retailer can obtain the maximum profit under the cash incentive strategy (T. Zhang et al., 2020). A comparison of the government regulations and subsidies for formal recycling channels with the informal channels without regulation and subsidies indicated that both the channels favor high-quality waste products. However, the government's marginal benefit is low when recycling high-quality used products, and thus the government subsidy strategies need to consider the quality competition of recycled products (Liu et al., 2016).

Corporate social responsibility also plays a key role in supply chain management (M. Zhang et al., 2018). The manifestation of corporate social responsibility is strongly related to the behavior of corporate managers, and managers' high awareness regarding environmental protection can promote the realization of corporate social responsibility (Qu et al., 2015). It has been reported that the supplier CSR has a moderating effect on the pressure between the environment and corporate performance; however, this effect has not appeared in the financial domain (Haleem et al., 2017). Cash flow is the key to maintaining the production operations of manufacturing companies. In particular, changing the cost structure and cost rate of the manufacturing companies in the supply chain management can adjust the risk of the cash flow (Tsai, 2017). In addition, the life of an electronic product can be extended by identifying the short-term opportunities and risks in product lifecycle management (Althaf et al., 2019). In the research of supply chain management, reducing the interval between recycling and reuse is the main challenge for manufacturers and distributors (Kadambala et al., 2017). Realizing product inventory increases the manufacturers’ cost input, and at the same time, the value of the product inventory is likely to decrease due to the short life cycle of the product. Consequently, research on the product reverse logistics inventory is critical to optimize the supply chain management (Calmon & Graves, 2017).

As an emerging recycling method, the use of online recycling can effectively solve the problems of difficult recycling of electronic waste and irregular recycling channels (Wang et al., 2019). Diversifying the recycling methods can help improve the recycling efficiency of waste products. A comparison of the different recycling channels indicated that the dual-channel recycling method is better (Feng et al., 2017). The recycling companies can enhance their own interests by improving the efficiency and benefits of recycling waste products. Enterprises can formulate different recycling prices and strategies to improve the number of recycled used products (Hu et al., 2016). Manufacturers can recycle waste products in the form of a single product transaction with a retailer. Retailers can adopt direct recycling and trade-in methods to recycle products. Furthermore, it has been observed that the game equilibrium results under different recycling modes depend on the consumers’ incentive strategy (Maiti & Giri, 2017).

The difference between this article and the above research is the construction of a product recycling model that runs through the entire closed-loop supply chain under the consideration of demand orientation. Finally, by linking the results of strategic decision-making at different stages, a decision-making model for an optimized product recycling model is established, which provides a theoretical basis for improving the recycling efficiency of used electronic products and the sales rate of remanufactured products, and for improving the efficiency of product recycling and remanufacturing enterprises.

What game theory wants to study is the optimal decision of each participant and the possibility of these optimal decisions result among members of the supply chain (including closed-loop supply chain). The relationship between supply chain management is the relationship between cooperation and competition. The goal of supply chain management is to cooperate with each member of the chain.

Cooperative game studies system benefit and cost-sharing. It is like two sides of the same coin for a problem with non-cooperative game. For the disharmony of supply chain channels caused by double margins, or the contradiction between individual rationality and collective rationality, cooperative game is an analysis means. However, the focus of cooperative game does not focus on how to achieve the coordination of supply chain channels, but instead looks at how to distribute the benefits of the alliance when the supply chain members cooperate, that is, when the supply chain channels can achieve coordination. Some scholars use the sharply value, Owen value and consistent license value in cooperative game to solve the problem of benefit distribution in supply chain alliances.

Fair and reasonable benefit distribution mechanism is an important basis for the existence of a supply chain alliance and the key to the stable development of supply chain alliance. In reality, the collapse of many supply chain alliances is caused by the unreasonable benefit distribution mechanism. How to establish a reasonable benefit distribution mechanism is the key to successfully maintaining the cooperative relationship of supply chain alliance, and it is an important issue affecting the operation efficiency and development ability of the alliance.

Most of the existing studies study the decision-making of stakeholders of remanufactured products from the perspective of supply. Moreover, only single-phase supply chain decision is usually considered, and the dynamic multi-period coordination is lacking. This article starts from the perspective of product demand in the reverse supply chain and considers the demand forecast of multi-period products’ change with time, which can effectively alleviate the impact of time and the recycling quantity on decision-making, which can provide a reference for recycling enterprises and remanufacturing enterprises.

3 Model development

Game theory has been widely used in the research of closed-loop supply chain. Based on the game theory and the benefits model of cost–benefit analysis, this paper constructs the demand-oriented recycling game model: the static multi-stage game and the dynamic cooperation game model. Depending on the existing research results and experience, the form of cooperation is the strategy to optimize the long-term interests of the game players. Therefore, the game consequences for the participants in each link should satisfy the Pareto optimality. For recycling and remanufacturing product sales links, the balance of the product supply is ensured, which also provides a theoretical basis for the subsequent model construction.

Based on the existing research results of recycling strategy of used electronic products, remanufacturing production strategy and sales strategy of remanufactured products, this chapter takes cost–benefit analysis as the benefit model of participants in the used electronic product recycling system, and uses the relevant knowledge of game theory as the analysis tool, Build a recycling model of used electronic products in a closed-loop supply chain based on demand. The establishment of decision-making model can provide a theoretical basis for improving the recovery efficiency of used electronic products, the sales rate of remanufactured products, and the benefits of product recovery and remanufacturing enterprises.

3.1 Model description

When constructing a demand-based recycling model of used electronic products, the basic requirements must satisfy the actual situation as much as possible. Thus, the current analysis only considers the three links (Sales of the remanufactured products, remanufacture of the used electronics and recycling of the electronic wastes) in the closed-loop supply chain and the benefit models of the four types of participants (Consumer, remanufacturer, retailer and recycler). In addition, the following assumptions are made to ensure the simplicity of the model construction and solution:

Assumption 1: The participants in the closed loop supply chain have a positive attitude toward the recycling of the used electronic products, and different parties exhibit a cooperative attitude in each link of recycling and remanufacturing;

Assumption 2: The strategy of each participant in the closed-loop supply chain is based on the demand of the remanufactured products in the market as the main strategic basis, and the benefit model of each participant is constructed considering the cost benefit model;

Assumption 3: The benefit model of the participants in the entire closed-loop supply chain is a function related to the number of used electronic products or remanufactured products. The decisions of each participant are expressed as quantitative decisions.

Assumption 4: The interesting relationship among the different parties in the different links in the closed-loop supply chain is based on the realization of the Pareto optimality. Therefore, the solution of all the strategic results is based on the supply and demand balance of the products at different stages. (Table 1)

3.2 Static multistage game model

The static multistage electronic waste recycling model includes three parts: sales of the remanufactured products, remanufacture of the used electronics, and recycling of the electronic wastes. The strategy of each link is mainly to achieve the demand for the remanufactured products in the market. In reality, since the leading party in each link is different, if each leading party is taken as the starting point, the allocation can be made according to each link, and the optimal strategy for each link can be calculated separately to provide relevant stakeholders with suggestions. This is more in line with the actual situation.

(1) Strategic and benefit models for the remanufacturing product sales.

The supply of remanufactured products in the sales link is used to meet the needs of the remanufactured products in the market, and the sales strategy is based on the predicted market demand. At this time, the sales price established can achieve the dual results of zero inventory and consumer demand.

There exist three types of demands for the remanufactured products on the market: used products that are directly put on the market, products that have been put on the market through simple maintenance, and brand new products. The demand forecast models for different products can be represented as

When the demand forecasts for the different types of remanufactured products in the market are \(Q_{i} \left( {i = 1,2,3} \right)\), the main strategy of the sales process is to select the sales channels. Assume that two sales channels are present: direct sales and commission sales. When a product with a ratio of \(\alpha_{i} \left( {0 < \alpha_{i} \le 1,i = 1,2,3} \right)\) for product \(i\) is sold through direct channels, the cost of remanufacturing sales can be expressed as

When the remanufactured product price on the market is \(P_{i} \left( {i = 1,2,3} \right)\), the expected benefit model of the remanufacturing link is

The main goal of the remanufacturing and sales process strategy is to achieve profit: When the price of the products in the market is stable, the main purpose of the sales strategy is to achieve the lowest cost, that is \(\min C\left[ {{\text{Sale}}} \right]\). When the market price changes, the main goal of the sales strategy is to achieve the optimal benefits, that is \(\max E\left[ {{\text{Sale}}} \right]\).

(2) Remanufacturing and recycling strategy models.

The strategy of remanufacturing production is based on the product demand in the market, and at the same time, this strategy is limited by the remanufacturing technology and cost. The used electronic products with different quality conditions correspond to different production processes. If the rate of conversion of the used products to the remanufactured products is \(\mu_{i} \left( {0 < \mu_{i} \le 1,i = 1,2,3} \right)\), \(\mu_{i}\) is limited based on the product quality, remanufacturing capacity, and production technology, and the conversion rate of the different remanufactured products does not satisfy the constraint. Therefore, the scale of the used electronic products required for the production of different remanufactured products is

Assuming that the quality level of different used electronic products is \(\beta_{j} \in \left[ {0,1} \right]\), the quantity function of the used electronic products under different quality levels is

where \(q_{j} \left( {j = 1,2, \cdots } \right)\) denotes the model parameters. It is assumed that when the quality level is divided according to the quality level, the two standards \(\beta_{1} ,\beta_{2}\) satisfy \(0 \le \beta_{1} \le \beta_{2} \le 1\). Under these standards, the requirements for the production of different remanufactured products are realized, that is,

The cost of the resulting remanufacturing process is:

The remanufacturing process pays for the production of products that meet the market demand at the lowest cost; consequently, the strategy can be developed by achieving the minimum cost, that is, \(\min C\left[ {{\text{Rem}}} \right]\).

The strategy in the recycling of used electronic products mainly involves the formulation of the recycling channels and recycling price strategies of recycling companies. The formulation of the recycling prices depends on the number of the used electronic products required for remanufacturing. If the remanufactured product quantity for the used electronics manufacturers is \(Q_{i}^{^{\prime}} \left( {i = 1,2,3} \right)\), it is assumed that the recycling companies formulate the recycling price strategies according to the different quality levels. The recycling channels include direct and entrusted recycling. The proportion of direct recycling channels is \(\gamma \left( {0 \le \gamma \le 1} \right)\), and the entrusted recovery channel ratio is \(\left( {1 - \gamma } \right)\). The cost structure of the waste product recovery stage is

Similar to the production of remanufactured products, the recycling of waste products is also based on the strategy of achieving the lowest cost, that is, \(\min C\left[ {{\text{Rec}}} \right]\).

Based on the strategic decision model of each stage, it is possible to construct an electronic waste product recycling model that covers the entire closed-loop supply chain and the expected benefit model for the different participating groups. The static multistage used electronic product recycling model based on the demand can be defined as

Furthermore, the expected benefit model of the participants in the closed loop supply chain determined by this model can be integrated as follows:

Formulas (3–1) and (3–2) are used to solve the strategic decision results of different links and the expected benefits of various groups. The solution of the strategy results at different stages starts from the demand for the remanufactured products, and it is reversed from the sales link of the remanufactured products to the recycling of the used electronic products. The demand for the remanufactured products is used to solve the needs of the used electronic products and the strategies adopted at each stage.

3.3 Dynamic cooperative game model

Even in the case of a dynamic cooperative game, the analysis of the demand for the remanufactured products is the starting point. To facilitate the analysis and discussion of this model, the participants of the entire system are divided into two categories: recycling companies and remanufacturing companies belong to a same category, used electronic product holding groups and consumers of the manufactured products belong to another category, and the behavioral activities of the remanufacturing consumer group are completed by the remanufacturing enterprises. It is important to consider the impact of time under dynamic conditions due to the time difference between the product recycling and remanufacturing processes and the product sales. Therefore, it is necessary to consider the changes in the product demand affected by the time when performing the analysis.

Starting from the forecast of the demand for the remanufactured products on the market, as obtained by the recycling and remanufacturing companies, and aiming to enhance the profits of the recycling and remanufacturing companies in a certain period, the expected benefit models of the recycling and remanufacturing companies are established. Considering that the demand in this period is affected by the previous sales in multiple periods, the product demand forecasting model can be defined as

where,\(d_{n}\), \(r_{n}\) and \(\theta_{n}\) denote the model parameters, \(n\) is the number of data periods used in the prediction, and \(n \le t\).

When analyzing the different stages of strategy development for recycling and remanufacturing companies in period \(t\), it is necessary to consider the product demand forecast in multiple periods because the supply of the remanufactured products in period \(t\) is produced by the remanufacturing process in period \(\left( {t - 1} \right)\). The waste products required for the remanufacturing phase \(\left( {t - 1} \right)\) are obtained from the recycling process of phase \(\left( {t - 2} \right)\). Figure 1 illustrates the product recycling model in the dynamic process.

In other words, when constructing the recycling model of used electronic products in the period \(t\), it is necessary to consider the demand for the remanufactured products in the period \(\left( {t + 2} \right)\). The cost structure of the recycling and remanufacturing companies in period \(t\) needs to be obtained based on the demand for the remanufacturing products in periods \(\left( {t + 1} \right)\) and \(\left( {t + 2} \right)\).

First, we build a recycling model for the used electronic products in phase t, and it is assumed that the product conversion rate is \(\mu_{i} \left( {0 < \mu_{i} \le 1,i = 1,2,3} \right)\). The demand forecast for the remanufactured products in period \(\left( {t + 2} \right)\) is

Subsequently, the number of used electronic products that need to be recycled in period t is

It is also assumed that the number of used products at different quality levels obey a certain function distribution:

The strategy development models at different stages can be defined as

The cost structure for the recycling and remanufacturing companies in a dynamic context is

The expected benefit models for the remanufacturing and recycling companies are

The expected benefits for the consumer groups of the remanufactured products and holders of used electronic products are

The model solution in the dynamic cooperative game scenario is the same as that in the multistage static scenario, and both these solutions are based on the demand forecast of the remanufactured products. The difference is that the recovery mode strategy solution in the static scenario is mainly based on the cost analysis, and in the cooperative game, a cost constraint model and a cost revenue benefit model can be used simultaneously, and thus the multi-period product demand changes need to be considered.

The strategy of the different stages can be determined from the comprehensive benefits of remanufacturing companies and used electronic product recycling companies. Since the quantity decision is made by considering the demand forecasting model, the required solution is the allocation strategy. No absolute connection exists among the strategy formulation at different links. Here, an 'absolute connection' refers to a connection that directly affects the strategy formulation of a link. This phenomenon occurs because the strategy formulation at each stage is based on the number of used electronics or remanufactured products at this stage. The number of products at this stage is determined by the forecast of the remanufactured products and the manufacturing capabilities of the company; consequently, the strategy formulation is performed independently.

In the solution at each stage of the strategy, it is assumed that the strategies of the other stages are fixed. The sales strategy designation of the remanufactured products is considered as an example in this model as well. The electronic wastes recycling strategy and remanufactured product production strategy are \(\gamma\) and \({\beta }_{j}\left(j=\mathrm{1,2}\right)\), respectively. The manufacturing product sales strategy solution method is

Similarly, the remanufacturing strategy and used electronic product recycling strategy can be solved through the following process. When the remanufacturing product sales strategy is \(\alpha_{i}^{*} \left( {i = 1,2,3} \right)\), and the used electronic product recycling strategy is \(\gamma\), the strategic decision of the remanufacturing product manufacturer is

When the remanufactured-product sales strategy is \(\alpha_{i}^{*} \left( {i = 1,2,3} \right)\), and the strategic decision of the remanufacturing-product manufacturer is \(\beta_{j}^{*} \left( {j = 1,2} \right)\), the recycling strategy of the used electronic product recycling company is

The optimal recycling strategy for the used electronic products is \(\gamma^{*}\).

From the above analysis, the optimal equilibrium strategy in different stages of the dynamic cooperative game situation can be obtained. The equilibrium refers to the prediction of the demand for the remanufactured products in the market when the remanufacturers and recyclers in the closed-loop supply chain adopt this strategy. This state is used to ensure that the strategy can obtain the expected profit benefits, while ensuring that the benefits of the other participants are optimal.

The strategy formulation of the closed-loop supply chain under the dynamic cooperative game is based on the prediction of the product demand in the market by the recycling and remanufacturing companies and the remanufacturing, sales, and product recycling of the current period based on the multi-period product demand forecasts. When the used electronic product recycling company and the remanufacturing company are considered as one entity in the dynamic game model, the used electronic product recycling strategy, remanufacturing strategy, and remanufacturing product sales strategy work together on the expected benefit model.

4 Simulation and results discussion

In this section, a simple example is considered to perform a simple simulation analysis. Furthermore, this section discusses the impact of the strategy formulation and different stages of strategic decision-making on the benefits of the participants in the supply chain in the multistage static scenario in the process of recycling and reuse of used electronic products. Based on this discussion, the influence of the strategy formulation on the enterprise benefit in the recycling system of used electronic products under a dynamic situation is examined.

In the final determination of the pattern of the used electronic products, the recycling and remanufacturing companies aim at achieving optimal costs. Therefore, solving the cost composition under different strategies is the basis for the strategy formulation of the recycling and remanufacturing companies. The analysis of the participants' benefits under different strategy combinations is used to further validate the effectiveness of the model. In addition, it should be noted that this study mainly focuses on theoretical research, and the selection of numbers only plays an auxiliary role in numerical tests.

4.1 Static multistage scenario

The constructed model indicates that the three links of the recycling and reuse of used electronic products can be individually decided without affecting the other. Therefore, it can be simplified by analyzing the strategic decisions of a certain stage in the static multistage scenario. In the dynamic situation, the strategic decision of each link is made according to the demand prediction of remanufactured products. Although the strategic decision of each stage does not affect each other, all the strategies work together on the benefits of recycling enterprises and remanufacturing enterprises. Therefore, in the multistage static situation, the strategic decision of a certain stage and benefit analysis of the participants in that stage are assigned priority, while in the dynamic cooperative game situation, the overall benefit of recycling and remanufacturing enterprises is assigned priority.

In the analysis of the static multistage electronic waste product recycling model, the sales strategies of the different products can be formulated independently; however, the benefits of the remanufactured product sales link are affected by the combination of all the product strategies. To simplify the analysis, it is assumed that the demand and cost of the first type of the remanufactured products in the market have been determined, and we consider the changes in the benefits of the remanufacturing product sales resulting from the changes in the strategy development of the other two products.

It is assumed that the product sales price is \(P_{i1} = 10\). The cost of a product sold through the direct sales channel is \(c_{i1} = 10 - \alpha_{i} q_{i}\), the cost of the second channel is \(c_{i2} = 10 - \left( {1 - \alpha_{i} } \right)q_{i}\), and the fixed cost of selling all the products is \(c_{1} + c_{2} = 50\). The expected benefit function of the resale process can be expressed as

After the processing, the cost changes under the different strategic decisions of the remanufacturing product sales link can be obtained. Figure 2 shows the change in the expected benefit of the remanufacturing product sales process when one product is determined, and two other different types of remanufactured products are sold.

Figure 2 shows that the optimal cost strategy for the remanufacturing product sales link is jointly determined by the different types of products. Since the sales strategy of the different products can be independently determined, the cost of the remanufacturing sales link is a combination of the different strategies. The selling price of remanufactured products is determined by the actual market conditions. When the market price is stable, the sellers of remanufactured products adopt various strategies to sell. These measures can be reflected in the cost of the product, including the price of remanufactured products purchased from remanufacturers, preferential prices to promote sales, etc.

Similar analysis to the process of the remanufacturing product sales can be done for the recycling process of the used electronic products. However, the analysis of the production strategy of the remanufacturing products is different, and restrictions exist among the product quality levels, which makes the analysis of the remanufacturing strategy, recycling strategy and sales strategy differently. To simplify the analysis, this article considers the existence of two quality levels, and the cost composition is thus jointly affected by the two different levels of the products. It is assumed that the income of the transferred product is certain, and the benefit of the income depends on the cost. Here, \({P}_{i2}=3,{Q}_{i}=10\left(i=\mathrm{1,2}\right)\), and the proportion of a certain product is \(\beta\). In this case, the proportion of another product is \(\left(1-\beta \right)\), their costs are \(\left(2-\beta \right)\) and \(\left(3+\beta \right)\), and the other fixed cost is \(C_{0}^{{''}} \left( {\sum {Q_{i}^{'} } } \right) = 25\) The expected benefit can be simplified as

This aspect indicates that the expected benefits of the remanufactured product manufacturers change, and the cost change curve for the production of the different types of products with the change in \(\beta\) is as shown in Fig. 3.

The cost constraint can be considered separately in the strategy formulation of the production process of the remanufacturing products, based on the demand for the remanufactured products. At this time, the price and quantity of the transferred remanufactured products are fixed, and the formulation of their strategy depends on the lowest cost. The expected benefit of the remanufacturer shows a trend of first decline and then rise with the cost increase of strategy \({\beta }_{1}\) and the decrease of strategy \({\beta }_{2}\). When the costs of the two strategies are equal, the total strategy cost is the highest at this time, and remanufacturer's benefit reaches the lowest value.

Under different strategy formulations, the existence of discrepancies in the quantity and quality of the used electronic products used to produce different types of remanufactured products leads to a change in the cost, thereby changing the total cost. Under the optimal strategy, the total cost of remanufacturing is the lowest, which is conducive to the realization of the optimal income benefit.

The strategy for the remanufacturing product sales phase is \({\alpha }_{i}^{*}\left(i=\mathrm{1,2},3\right)\), and the number of products sold through the direct channels for different products is \({\alpha }_{i}^{*}{Q}_{i}\). At this time, the sales of the remanufactured products not only meet the demand for the products in the market but also achieve the optimal benefits expected from the remanufacturing sales link.\({\alpha }_{i}^{*}\) helps realize the sales efficiency and benefits in the remanufacturing sales.

The strategy of the remanufacturing stage includes \({\beta }_{1}^{*},{\beta }_{2}^{*}\). The formulation of this strategy is achieved under the influence of the product production capacity and other such factors. This formulation realizes the requirements of remanufacturing and reduces the cost of remanufacturing.

The strategy of the product recovery phase is \({\gamma }^{*}\), which means that the waste product recycling is performed on the scale of the waste product demand based on the remanufacturing production. When the number of products recycled through the direct recycling channel is \({\gamma }^{*}\), the cost of recycling the products can be reduced.

The strategies at different stages are individually decided; however, they are all affected by the demand for the remanufactured products in the market. The strategy formulation at different stages is based on the analysis of the cost or benefit models based on the realization of the product demand in the market. It is worth noting that the variables \({\alpha }_{i}\left(i=\mathrm{1,2},3\right)\) and \(\gamma\) are selected for the strategies of the remanufacturing product sales and waste product recycling stages because these two separate steps of the company are cost-intensive and may not meet the product demand goals.

4.2 Dynamic cooperative game scenario

In contrast with the static multistage electronic waste product recycling model, the multi-period market demand forecast is considered in the dynamic cooperative game scenario. Therefore, the dynamic change curve of the demand for the remanufactured products must be considered in the dynamic scenario. To simplify the analysis, the demand for the two types of remanufactured products is considered, assuming that the initial demand is \({Q}^{t}=[10+\mathrm{sin}t,8+\mathrm{cos}t]\), and the market prices of the remanufactured products are \(P=\left[20,15\right]\), respectively. Next, the change curve of the demand for the remanufactured products can be simply expressed as shown in Fig. 4.

With the change of time, the demand for remanufactured products and the model parameter \({q}_{1}\) basically have the same changing trends, and the changes in demand are more obvious and cyclical. It is assumed that the strategy for the remanufacturing process is \(\beta\); in other words, \(\beta\) is the proportion of the first category of the products in all the used electronic products, or the proportion of such used electronic products after quality classification. The cost of the two different types of products can be expressed as \(\left(4-\beta \right)\) and \(\left(3+\beta \right)\), and the cost of the remanufacturing process can be expressed as

The same analysis can be performed for the recycling of the used electronic products. Assuming that the recycling strategy is \(\alpha\), that is, \(\alpha\) is the proportion of the quantity of recycled products using a certain recycling channel, the cost of the recycling link can be expressed as

The benefits of the remanufacturing and recycling companies can be expressed as

Assuming that \(t = 10\), the change in the benefits under different strategic decisions can be obtained, as shown in Fig. 5.

Considering different stages in period \(t\), the benefit change curves for the recycling and remanufacturing companies in different periods can be obtained. As shown in Fig. 5, the greater the proportion of remanufacturers who produce products of the first quality level and adopt direct sales channels, the better the benefits of remanufacturers and recycling companies. With the increase of the strategy value of the sales link, the overall benefit first shows a slight downward trend, then rises and finally shows a straight upward trend with a stable slope, this is because the cost of direct sales is lower, and the decline is the result of the competition between the two sales methods. When the proportion of the first quality level products produced in the remanufacturing process gradually increases, the overall benefit shows a symmetric parabolic trend, which first decreases and then increases to the same as the initial value. This is because when the first quality level product is not produced, its cost is the lowest. With the increase of the production proportion of the first quality level product, the cost gradually reaches the highest. In the later stage, with the decrease of the second quality level product, the selling price gradually increases, showing a trend of increasing overall benefit. The efficiency of recycling enterprises and remanufacturing enterprises changes because of the change in the number of different products over time, adopting this method in a certain period of time can help achieve the benefits of the recycling and remanufacturing enterprises.

The optimal equilibrium strategy for the remanufactured product sales is \({\alpha }_{i}^{*}\left(i=\mathrm{1,2},3\right)\). Under this strategy, the product sales in this period are expected to realize supply equilibrium; however, this act has no impact on the strategy development in other stages. \({\beta }_{j}^{*}\left(i=\mathrm{1,2}\right)\) is the optimal strategy for the remanufacturing phase; in contrast with the static case, this value is not determined by the current sales volume of the remanufactured products, but by the product demand of the next period. \({\gamma }^{*}\) is the optimal decision of the used electronic product recycling strategy, which is based on the product demand after the two periods. The strategies of each stage work together to enhance the expected benefits of the remanufacturing companies and electronic wastes recycling companies.

The model can be further validated by analyzing the changes in the efficiency of the recycling and remanufacturing companies under different combinations of strategies. In particular, the model is expected to assist the recycling and remanufacturing companies make strategic decisions. This aspect can be realized by optimizing the cost under different strategies.

5 Conclusion

This paper constructs an optimized decision model of recycling strategies for used electronic products by analyzing the behavior of different participants in the closed-loop supply chain, and discusses the changes in the benefits of the participants under different decision combinations through the analysis of examples. It can provide a basis for the strategic decision-making of used electronic product recycling and remanufacturing enterprises. Through analysis, it is concluded that in the demand-oriented recycling model of used electronic products, the strategic decisions of recycling enterprises and remanufacturing enterprises can improve benefits by realizing the optimal cost combinations.

Under static multi-period, with remanufactured product demand set as goal, to achieve the optimal cost of each link is to achieve the optimal strategy combination of participant in each link. However, in the dynamic cooperative game based on the demand prediction of multi-period remanufacturing products, the cost optimization of a certain link cannot meet the strategic optimization, and the benefit optimization of both recycling enterprises and remanufacturing enterprises can only be achieved when all cost optimizations are met simultaneously. The recycling process of remanufacturer sales is similar to recycling enterprises. The cost of making decision alone is higher and cannot meet product demand. When remanufacturing is limited by product quality level and production capacity, remanufacturers should adopt direct sales in the sales link, because its cost is the lowest. With the competition of sales channels, enterprises' income will decrease, which is because channel competition increases their sales cost.

According to the model analysis, the conclusion can be drawn that under the static situation, the optimal strategy in the sales link of remanufactured products is similar to that in the recycling link, and the optimal cost strategy is determined by the sales of different products together, so the optimal strategy is the strategy combination of each product decision. However, the remanufacturing process is different, in this case, the optimal strategy depends on the lowest cost, which is influenced by the product quality level and determined by the quantity in the sales link. By contrast, in the dynamic situation, the change of multi-phase market demand needs to be considered. The supply equilibrium can be reached in the sales stage without effect on the other stages. In the remanufacturing stage, the cost is determined by the next stage of product demand; the optimal recycling strategy is determined by the product demand after two phases. Therefore, companies and governments can analyze from the following three perspectives, and make strategic choices for recycling and remanufacturing by analyzing the trend of changes in profits as the three factors. For example, there are three perspectives: the selection of e-waste recycling channels, the quality level of remanufactured products, and the selection of sales channels for remanufactured products. This can provide a good policy basis for the government and enterprises, and has important policy significance.

From the demand perspective, this paper reduces the impact of the uncertainty of recycling time and recycling quantity on recycling enterprises and remanufacturing enterprises, and the model built in this paper is in line with the current situation and recycling requirements as far as possible. Future research can further optimize the strategic decision-making model at different stages, and at the same time connects the strategic decision-making at different stages to form the recycling model of used electronic products through the closed-loop supply chain.

Data availability

The data used during the current study are available from the corresponding author on reasonable request.

References

Althaf, S., Babbitt, C. W., & Chen, R. (2019). Forecasting electronic waste flows for effective circular economy planning. Resources, Conservation and Recycling, 151, 104362.

Boldoczki, S., Thorenz, A., & Tuma, A. (2020). The environmental impacts of preparation for reuse: A case study of WEEE reuse in Germany. Journal of Cleaner Production, 252, 119736.

Calmon, A. P., & Graves, S. C. (2017). Inventory management in a consumer electronics closed-loop supply Chain. Manufacturing & Service Operations Management, 19(4), 568–585.

Dasgupta, D., Debsarkar, A., Hazra, T., Bala, B. K., Gangopadhyay, A., & Chatterjee, D. (2017). Scenario of future e-waste generation and recycle-reuse-landfill-based disposal pattern in India: A system dynamics approach. Environment, Development and Sustainability, 19, 1473–1487.

Feng, L., Govindan, K., & Li, C. (2017). Strategic planning: Design and coordination for dual-recycling channel reverse supply chain considering consumer behavior. European Journal of Operational Research, 260(2), 601–612.

Fu, J., Zhong, J., Chen, D., & Liu, Q. (2020). Urban environmental governance, government intervention, and optimal strategies: A perspective on electronic waste management in China. Resources, Conservation and Recycling, 154, 104547.

Haleem, F., Farooq, S., & Wæhrens, B. V. (2017). Supplier corporate social responsibility practices and sourcing geography. Journal of Cleaner Production, 153, 92–103.

Hu, S., Dai, Y., Ma, Z.-J., & Ye, Y.-S. (2016). Designing contracts for a reverse supply chain with strategic recycling behavior of consumers. International Journal of Production Economics, 180, 16–24.

Jiao, W., & Boons, F. (2017). Policy durability of Circular Economy in China: A process analysis of policy translation. Resources, Conservation and Recycling, 117, 12–24.

Jiménez-Parra, B., Rubio, S., & Vicente-Molina, M.-A. (2014). Key drivers in the behavior of potential consumers of remanufactured products: A study on laptops in Spain. Journal of Cleaner Production, 85, 488–496.

Kadambala, D. K., Subramanian, N., Tiwari, M. K., Abdulrahman, M., & Liu, C. (2017). Closed loop supply chain networks: Designs for energy and time value efficiency. International Journal of Production Economics, 183, 382–393.

Kiddee, P., Naidu, R., & Wong, M. H. (2013). Electronic waste management approaches: An overview. Waste Management, 33(5), 1237–1250.

Kumar, A., & Dixit, G. (2019). A novel hybrid MCDM framework for WEEE recycling partner evaluation on the basis of green competencies. Journal of Cleaner Production, 241, 118017.

Liu, H., Lei, M., Deng, H., Keong Leong, G., & Huang, T. (2016). A dual channel, quality-based price competition model for the WEEE recycling market with government subsidy. Omega, 59, 290–302.

Liu, Y., Xia, Z., Shi, Q., & Xu, Q. (2021). Pricing and coordination of waste electrical and electronic equipment under third-party recycling in a closed-loop supply chain. Environment, Development and Sustainability, 23, 12077–12094.

Maiti, T., & Giri, B. C. (2017). Two-way product recovery in a closed-loop supply chain with variable markup under price and quality dependent demand. International Journal of Production Economics, 183, 259–272.

Messmann, L., Helbig, C., Thorenz, A., & Tuma, A. (2019). Economic and environmental benefits of recovery networks for WEEE in Europe. Journal of Cleaner Production, 222, 655–668.

Mitra, S., & Webster, S. (2008). Competition in remanufacturing and the effects of government subsidies. International Journal of Production Economics, 111(2), 287–298.

Qu, Y., Liu, Y., Nayak, R. R., & Li, M. (2015). Sustainable development of eco-industrial parks in China: Effects of managers’ environmental awareness on the relationships between practice and performance. Journal of Cleaner Production, 87, 328–338.

Qu, Y., Zhu, Q., Sarkis, J., Geng, Y., & Zhong, Y. (2013). A review of developing an e-wastes collection system in Dalian, China. Journal of Cleaner Production, 52, 176–184.

Sabbaghi, M., Esmaeilian, B., RaihanianMashhadi, A., Behdad, S., & Cade, W. (2015). An investigation of used electronics return flows: A data-driven approach to capture and predict consumers storage and utilization behavior. Waste Management, 36, 305–315.

Tian, F., Sošić, G., & Debo, L. (2019). Manufacturers’ competition and cooperation in sustainability: Stable recycling alliances. Management Science, 65(10), 4733–4753.

Tsai, C.-Y. (2017). The impact of cost structure on supply chain cash flow risk. International Journal of Production Research, 55(22), 6624–6637.

Wang, B., Ren, C., Dong, X., Zhang, B., & Wang, Z. (2019). Determinants shaping willingness towards on-line recycling behaviour: An empirical study of household e-waste recycling in China. Resources, Conservation and Recycling, 143, 218–225.

Yu, Y., Han, X., & Hu, G. (2016). Optimal production for manufacturers considering consumer environmental awareness and green subsidies. International Journal of Production Economics, 182, 397–408.

Zhang, L., Wang, J., & You, J. (2015). Consumer environmental awareness and channel coordination with two substitutable products. European Journal of Operational Research, 241(1), 63–73.

Zhang, M., Tse, Y. K., Doherty, B., Li, S., & Akhtar, P. (2018). Sustainable supply chain management: Confirmation of a higher-order model. Resources, Conservation and Recycling, 128, 206–221.

Zhang, T., He, G., & Han, Y. (2020). How to optimize retailers’ recovery strategies for electronic waste. Journal of Cleaner Production, 244, 118796.

Zhou, W., Zheng, Y., & Huang, W. (2017). Competitive advantage of qualified WEEE recyclers through EPR legislation. European Journal of Operational Research, 257(2), 641–655.

Zhu, X. (2017). Recycling pricing and coordination of WEEE dual-channel closed-loop supply chain considering consumers’ Bargaining. International Journal of Environmental Research and Public Health., 14, 1578.

Zlamparet, G. I., Ijomah, W., Miao, Y., Awasthi, A. K., Zeng, X., & Li, J. (2017). Remanufacturing strategies: A solution for WEEE problem. Journal of Cleaner Production, 149, 126–136.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Xiaodong Lv is in charge of the Introduction and Theory and Hypotheses Section. Angfei Li and Tao Zhang provide the empirical results of the article, and Shuhong Wang makes the conclusions and submits the article.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Ethical approval was obtained from the National Natural Science Foundation of China.

Consent to participate

All authors of the article consent to participate.

Consent to publish

All authors of the article consent to publish.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Parameters setup.

Appendix: Parameters setup.

Notation | Definitions |

|---|---|

\(C\left[ {{\text{Sale}}} \right]\) | Total cost of sales of the remanufactured products |

\(C\left[ {{\text{Rem}}} \right]\) | Total production cost of the remanufactured product |

\(C\left[ {{\text{Rec}}} \right]\) | Total cost for recycling the waste electronics |

\(E\left[ {{\text{Rem}}\& {\text{Rec}}} \right]\) | Cost of the recovery enterprise and remanufacturing enterprise in the dynamic situation |

\(E\left[ {{\text{Sale}}} \right]\) | Expected sales benefits of the remanufactured products |

\(E\left[ {Cons} \right]\) | Expected benefits for the consumer groups of the remanufactured products |

\(E\left[ {hol} \right]\) | Expected benefits for the waste electronic product holders |

\(E\left[ {Rem\& Rec} \right]\) | Expected benefits for the recycling and remanufacturing companies |

\(E\left[ {Sale\& Hol} \right]\) | Expected benefits for the consumer groups of the remanufactured products and holders of waste electronic products |

\({\upalpha }_{i} \left( {i = 1,2,3} \right)\) | Proportion of products sold through the direct sales channel during the remanufacturing sales process in constant market demand |

\(\beta_{i} \left( {i = 1,2} \right)\) | Cost for a remanufactured product of different quality levels produced by remanufacturer when the remanufactured product demand is constant |

\({\upgamma }\) | Proportion of the direct recycling channels adopted by the recycling companies when the demand for the waste electronic products is constant |

\(1 - {\upgamma }\) | Proportion of the commissioned recycling channels adopted by the recycling companies |

\(C_{0} \left( {\sum Q_{i} } \right)\) | Fixed costs for selling all the remanufactured products, including advertising and leasing |

\(C_{1} \left( {\sum Q_{i} } \right)\) | Variable costs for selling all the remanufactured products, including discounts, cash and compensation, to promote sales |

\(C_{2} \left( {\alpha_{i} } \right)\) | Cost to be paid to the retailer when taking commission sales; this cost is related to the proportion of commission |

\(P_{i} \left( {i = 1,2,3} \right)\) | Sale price of the remanufactured product |

\(\mu_{i}\) | Conversion rate of waste electronic products to remanufactured products |

\(\beta_{j} \in \left[ {0,1} \right]\) | The quality level of different waste electronic products |

\(C_{0}^{^{\prime}} \left( {\sum Q_{i}^{^{\prime}} } \right)\) | Fixed cost of remanufacturing; this cost is related to the scale of the waste products |

\(C_{1}^{^{\prime}} \left( {\sum Q_{i}^{^{\prime}} } \right)\) | Variable costs in the remanufacturing process; this cost consists of the production costs of all the different processes \(\mathrm{k}\) of the remanufacturing process |

\(Q_{i}^{^{\prime}}\) | The quantity of waste electronic products required by remanufacturing enterprises \(Q_{i}^{^{\prime}} \left( {i = 1,2,3} \right)\) \({Q}_{i}^{^{\prime}}\left(i=\mathrm{1,2},3\right)\) \({Q}_{i}^{^{\prime}}\left(i=\mathrm{1,2},3\right)\) |

\(Q_{i}\) | The demand forecast for different remanufactured products in the market \({\mathrm{Q}}_{\mathrm{i}}\left(\mathrm{i}=\mathrm{1,2},3\right)\) \({\mathrm{Q}}_{\mathrm{i}}\left(\mathrm{i}=\mathrm{1,2},3\right)\) |

\(C_{0}^{^{\prime\prime}} \left( {\sum Q_{i}^{^{\prime}} } \right)\) | Fixed cost of recycling |

\(\mathop \smallint \limits_{0}^{1} c^{\prime\prime}\left( {\beta_{j} } \right)q^{\prime}\left( {\beta_{j} } \right)\) | Direct cost of recycling the product |

\(c^{\prime\prime}\left( {\beta_{j} } \right)\) | Product recycling prices at different quality levels |

\(C_{1}^{^{\prime\prime}} \left( \gamma \right)\) | Cost of adopting a commissioned recycling channel |

\(d_{n} \left[ {Q_{{i - }} \left( {t - n} \right)} \right]^{{r_{n} }} e^{{\theta _{n} }}\) | Changes in the product demand in the current period caused by the product sales in the period \(\left( {t - n} \right)\), where \(d_{n}\), \(r_{n}\) and \(\theta_{n}\) denote the model parameters |

\(Q_{{i - }} \left( {t - n} \right)\) | Number of products sold in \(\left( {t - n} \right)\), \(n \le t\) |

\(n\) | Number of data periods considered to generate the predictions |

\(F\left( {P_{i} ,Q_{i} } \right)\) | Benefits such as satisfaction from the remanufactured consumer groups buying remanufactured products |

\(G\left( {\sum Q_{i}^{^{\prime}} ,P_{i}^{^{\prime\prime}} } \right)\) | Cost effectiveness of the electronics products discarded by the product owners |

\(\alpha_{i}^{*} \left( {i = 1,2,3} \right)\) | Strategies for the remanufacturing product sales phase |

\(\alpha_{i}^{*} Q_{i}\) | Number of products sold through direct channels for different products |

\(\beta_{1}^{*} ,\beta_{2}^{*}\) | Strategies in the remanufacturing phase |

\(\gamma^{*}\) | Strategies for product recycling |

\(E\left[ {Rpv} \right]\) | Cost constraints in the resale process |

\(a_{m} x_{m}^{{b_{m} }} e^{{\varepsilon_{m} }}\) | Changes in the product demand caused by the factor \(\left( {t - n} \right)\) affecting the demand for remanufactured products,where \(a_{m}\), \(b_{m}\) and \(\varepsilon_{m}\) denote the model parameters |

\(x_{m}\) | Value converted by qualitative or quantitative elements according to certain rules |

\(\varepsilon_{m}\) | Number of variables that affect the demand forecast for the remanufactured products |

\(P_{i}\) | Remanufactured product prices in the market |

\(q^{\prime}\left( {\beta_{j} } \right)\) | Number of used electronic products at different quality levels |

\(Q_{{i - }} \left( {t + 2} \right)\) | Forecast of the remanufacturing product demand in the period (t + 2) |

\(Q_{{i - }}^{'} \left( t \right)\) | Number of waste electronic products to be recycled in the period t |

Rights and permissions

About this article

Cite this article

Lv, X., Li, A., Wang, S. et al. Building a demand-oriented optimal model for the recycling of used electronic products. Environ Dev Sustain 25, 5949–5971 (2023). https://doi.org/10.1007/s10668-022-02287-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02287-6