Abstract

Sustainable development and sustainability notions are among trending topics of twenty-first century. Elevated sustainability concerns of various stakeholders have been forcing members of all industries to evolve into their more environmentally and socially responsible versions. However, a complete framework with a true sustainability and benchmarking focus is yet to be delivered. Within this study, an innovative, holistic, versatile and scalable tool was developed to assess and benchmark sustainability performance of organizations and supply chains. The proposed framework was established upon trivet structure of triple bottom line philosophy and fueled by lean, Six Sigma and life cycle analysis methodologies for accurate and effective measurement of sustainability performance. Completeness of the framework was ensured through development of first-generation key performance indicator pool with 33 indicators, a unique work environment assessment mechanism for safety and environmental protection issues in terms of 11 risk categories and by construction of an ownership structure for ease of framework deployment. Proposed framework is expected to help with true sustainability performance improvement and benchmarking objectives at a range of business levels from facility to sectoral operations. Both small- and medium-sized enterprises and large corporations could benefit from SBT Framework since it eliminates unit-based comparisons within its standardized performance measurement modules. Industries with lower profit margins could also gain competitive edge through continuous discovery of improvement opportunities. Furthermore, some manufacturing industries with unique characteristics such as wood products industries with their carbon sequestration potential and electric car manufacturers with their renewable energy-dependent final products could document their strengths more effectively through this science-based assessment mechanism.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The old planet, Earth, has always been so generous to all its occupants for countless generations since the very first traces of life. Human population on earth has been rapidly increasing and expected to continue to increase at global level despite slowing growth due to decreasing fertility rates (United Nations 2017). However, existing natural resources don’t have unlimited capacities and reserves to keep up with ongoing and increasing consumption rates of human population (Bell et al. 2012; Dyllick et al. 2002; Elkington 1994). On the other hand, global macrotrends such as increased level of globalization, climate change, resource scarcity, tighter profit margins and fiercer competition in all industries, laws and regulations, and increased awareness among people of importance of sustainability force companies to alter and re-calibrate their competitive strategies to do more with less, to comply with laws and regulations as well as to meet expectations of all stakeholders (Authry et al. 2012; Stank et al. 2013). Moreover, level of competition has shifted from “clash of companies” to “clash of supply chains” (Myerson 2012). Such an action plan that ensures survival in the long run requires increased level of collaboration and communication among business partners.

Sustainability has been named among the strongest frontiers of sixth innovation wave along with Renewable Energy Systems, Green Nanotechnology and few others (Seebode et al. 2012). Some researchers also claimed that Sustainable Manufacturing is the latest form of manufacturing strategies evolution and should be driven by true life cycle (6Rs) approach to achieve a closed-loop flow (Faulkner and Badurdeen 2014). It was also pointed out as the key for survival of future generations (WCED 1987). However, without investing in sustainability of remaining resources or revitalizing the consumed values, it does not seem feasible to ensure ability of future generations to survive. Sustainability efforts have failed to truly yield desired outcomes up until today. Therefore, further collective action plans should be developed in a timely manner and ways to achieve “true sustainability” should be intensively sought after. Global trends usually cause birth of innovations, and innovations drive the evolution of industries. If all industries are going to work toward an aligned ultimate objective, highest possible level collaboration and communication should be achieved firstly at intra- and inter-organizational levels and then at inter-sectoral levels as explained in a previous study within an Ultimate Objective Concept (Tasdemir and Gazo 2018). Increased levels of transparency and communication among business partners were also shown among future trends in supply chain management (Sweeney 2013). Therefore, top executives of sectoral leaders should demonstrate extreme devotion that will infuse from top levels to shop floor level employees and will trigger bottom-up transparency and strategic alignment of entire workforce. Only such a transformation and dedication could help with this massive scale strategic partnership.

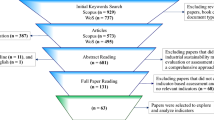

This study builds upon a previous work that evaluated current state-of-the-art for lean-driven sustainability (Tasdemir and Gazo 2018). Findings of this previous research have included but are not limited to; (1) lean could be used as a foundation for sustainability benchmarking frameworks. (2) Synergies between lean and sustainability outweigh the divergences. (3) There is still lack of frameworks and models with sufficient effectiveness to measure and benchmark true sustainability performance. Moreover, integrated and composite frameworks were pointed out among the options with high potential for effective measurement, improvement and benchmarking of sustainable performance across many sectors by many researchers (Brewer and Pojasek 2012; Rebelo et al. 2016; Wang et al. 2013). Some researchers also emphasize that reverse logistics, closed-loop supply chains and waste management practices need special attention for enhanced environmental sustainability (Singh and Trivedi 2016).

Based on these findings, the objectives of this study are (1) development and proposition of a versatile and innovative composite framework with capabilities of measuring and benchmarking true sustainability performance of organizations and supply chains in various sectors, (2) creation of first-generation key performance indicator (KPI) pools for accurate assessment of environmental, economic and social sustainability performance, (3) defining a deployment strategy and ownership model for the proposed framework and (4) pointing out the future research direction on the path to validation of the proposed framework.

1.1 Significance and novelty of the study

Transparency from the perspective of TBL has started to become a mandatory practice rather than a voluntary disclosure mechanism (Berger-Walliser and Scott 2018; McCarty et al. 2011). Therefore, organizations should make sure that sustainability is part of their corporate strategy and its principles are aligned with organization’s vision, mission and culture (Pojasek 2012a). Corporate organizations should consider whether their business activities must conform to existing or future regulations and to assess the risk of non-compliance. This involves proper evaluation of direct and indirect impact of domestic and international regulations and laws on organizations’ own operations as well as their business partners. Nowadays, such risk factor is often too high for corporate firms of sectors such as manufacturing, transportation and energy (McCarty et al. 2011). This risk factor itself could be a sufficient reason to measure and improve sustainability performance.

To further emphasize significance of the study, one important question to ask is “What happens if Sustainability is Ignored?” Steve Howard, Chief Sustainability Officer at IKEA Group, highlights potential catastrophic outcomes of such ignorance by discussing some global facts based on three numbers, 3, 6 and 12.

The first number 3 stands for three billion people coming out of poverty and joining to global middle-class by 2030. It is striking when the current number of people who belongs to global middle-class (2 billion) is considered. Second number is 6, which is the estimated Celsius Degree increase in the level of global warming by the end of this decade. The last number, 12, is the number of cities with one million or more people by end of nineteenth century. Today, the world has approximately 500 cities that exceeded threshold of one million. This growth and consumption rate created a challenge which is called resources scarcity (TEDGlobal 2013).

What Steve Howard said is a strong statement that highlights significance of climate change, increasing population and resource scarcity issues. Responsible, effective and efficient use of available resources can be a solution to foreseen catastrophic outcomes. Investing in renewable energy resources, promoting recycling activities and avoiding waste generation can help with achieving socially and environmentally responsible activities. Furthermore, several reporting mechanisms and indices were developed by various independent and government organizations in the last two decades (Svensson et al. 2016). Some of these indices have been serving as mandatory reporting mechanisms as part of regulations in place, while others have been designed for voluntary reporting purposes (Vimal et al. 2017; Wang et al. 2013). However, almost all of them were limited to computing and reporting economic, environmental and social impacts of operations and failed to offer benchmarking perspective, which incapsulated these frameworks into their self-created hard-shells that avoid enriched proposition of sustainability improvement ideas. As Ebert and Welsch stated in their study, measurability and comparability are two common characteristics of meaningful indices for environmental performance reporting, and most of the current indices are not satisfactorily meaningful (Ebert and Welsch 2004). Moreover, Dahl (2012) acknowledged, in his study, both urgency of tackling sustainability concerns and potential of values-based indicators to guide sustainability efforts of all stakeholders at the individual, national and global levels. Today, people of the Earth should act collectively to take proactive and innovative steps to avoid catastrophic outcomes of our actions that will impair well-being of future generations (Closs et al. 2011).

On the other hand, academics have focused on development of frameworks and models in the past (Ansari and Kant 2017). However, many of them highlighted environmental aspects of sustainability and, somehow ignored its trivet structure (Klewitz and Hansen 2014) and failed to address at least one pillar of triple bottom line (TBL) (see Fig. 1) during their effort to generate sustainability solutions. Any sort of misbalance in the cognitive importance placed on each pillar of sustainability would cause it to totally fall apart (Gopalakrishnan et al. 2012; Wang and Dai 2017). Ness et al. (2007) evaluated available tools for sustainability assessment from a wide perspective in detail and highlighted that a limited number of tools are capable of integrating nature-society facets and there still is a heavy bias toward environmental parameters which ignores other two pillars of TBL. The authors also stated that lack of successful integration when more than one tools are co-deployed to achieve desired assessment objectives (Ness et al. 2007). Some of the studies lacked a complete design, either from perspective of TBL or macro-to-micro business structure, for target processes or sectors. Without a holistic approach, sustainability is nothing more than a delusion in a desert. As Ness et al. (2007) stated, if scientific community is to redefine sustainability assessment, three factors, namely integration of nature-society systems, scalability and temporal aspects, should be considered (Ness et al. 2007). The originality of the study lies within its extensive, comprehensive and holistic design. Almost all of the previously proposed lean-based sustainability measurement tools have either failed to offer a solution to benchmark sustainable performance or lacked at least one of scalability, versatility and flexibility features that are critical to ensure applicability of frameworks to various levels of operations within a supply chain (Tasdemir and Gazo 2018). Some of them addressed issues at the supply chain level, while others focused on the applicability of methods to operations. With utmost acknowledgement of contributions presented in previous studies, this study tries to build on existing knowledge and to pay special attention to filling the gaps left by previous attempts to contribute to the body of knowledge in the intersection zone of Operations Management and Sustainable Development disciplines.

Another novel feature of this study is its strong practical perspective accompanying its comprehensive theoretical and methodical development phase. Sustainability could be perceived as a complex and difficult concept by executives of organizations (Pojasek 2012b). This situation could worsen when developed sustainability frameworks are full of scientific terms and notions. Proposed user interface, KPI definition and formulas and deployment methodology of the proposed framework were designed to carry feature of “Convenience” to ensure meaningfulness and practicality for all parties interested in true sustainability.

Despite existence of previous research studies, discovered portion of truly sustainable operations is still limited when compared to the whole. Authors of some past studies agreed upon beneficial impacts of simultaneous implementation of lean and sustainability on TBL pillars (Hajmohammad et al. 2013; Larson and Greenwood 2004; Poveda and Young 2015; Wiengarten et al. 2013). Although some studies tried to discover potential benefits gained through sequential and simultaneous implementation of lean and sustainability initiatives within organizations or along supply chains, they often lacked a clear conclusion on implementation and applicability procedures (Tasdemir and Gazo 2018). Therefore, it could be stated that concept of truly sustainable performance measurement still lacks availability of a versatile framework that could be conveniently applied to any industry and to any segment of operations. On the other hand, the proposed framework has been designed to ensure benchmarking and continuous improvement features through exhaustive use of lean and Six Sigma tools with a purpose of proactive elimination of economic, environmental and social wastes (Das 2018). It also avoids undesirable consequences of operations and activities at both intra- and inter-organizational levels. Use of lean, Six Sigma and life cycle analysis (LCA) tools within the proposed framework is further discussed in later sections of this study.

2 Proposal of a new sustainability performance benchmarking tool

As Maslow (1943) explained in his paper titled “A Theory of Human Motivation”, needs of humankind can be illustrated as a five-tier hierarchical model, in which fulfillment of bottom levels (basic needs) opens the door for higher level needs. Regardless of whether it is deficiency needs (water, food, warmth) or self-actualization needs (creative activities), necessities and desires of humankind have led to birth of countless industries. All these industries highly rely on natural resources, namely air, water, trees and plants, fossil energy resources and soil either to use as raw, intermediary and supplementary materials for creation and delivery of products or services. Operations of today’s industries significantly contribute to resource depletion rate through over-consumption, waste generation, contamination and pollution. All these factors have drastic impacts on both environment and society. Increased awareness of sustainability has also changed expectations of stakeholders, especially customers, from organizations engaged in various industries. Today, many customers have started to demand green, sustainable or responsibly generated products and services. Organizations and Supply Chain structures have been reshaped based on end-cast rather than forecast to ensure fully customer centric focus (Bowersox et al. 2000).

Since the very first days of industrialization, the way industries operate has continuously changed due to technological advancements and development of modern operations management techniques as functions of innovation waves. World population projection, natural resource scarcity, shrinking profit margins across many industries and innovation trends discussed in introduction have put organizations in a situation where “Doing More with Less”(Vais et al. 2006) is the new daily practice to ensure long-term economic survivability through increased competitive advantage while ensuring societal and environmental responsibilities are also fulfilled. Such an effective operations management requires significantly enhanced efficiency levels in terms of workforce and space capacity utilization, productivity, quality and materials usage. All of these could be possible with continuous and aggressive elimination of waste. Production wastes were shown to be among causes of weak environmental performance in a past study (Moreira et al. 2010). As of today, the best management technique available to academics and professionals for such purposes is lean management. Lean tries to achieve better efficiency and effectiveness through continuous elimination of 8 types of wastes (Ohno 1988). Lean philosophy also aims for engraving continuous improvement mindset into DNA of organizations through aggressive cultural transformation to ensure standardization (Wilson 2009). Lean could be used as a catalyst for development of a new assessment mechanism through its wide range of applicability spectrum. Lean is being applied to even Service, IT and Public sectors (Dadashzadeh and Wharton 2012; Rauch et al. 2016; Teeuwen 2010). Chiarini (2014) studied potential environmental benefits of lean implementation and concluded that certain lean tools such as value stream mapping (VSM) and 5S, total productive maintenance and SMED can be used to increase environmental performance. In several past studies, potential contribution of RFID technology to increase TBL performance was also investigated. Findings of those studies covering various areas of a closed-loop supply chains were in favor of cost efficiency, pollution reduction and waste reduction (Jaggi et al. 2014; Kumar and Rahman 2014; Sarac et al. 2010). This project proposes the use of Lean philosophy as a solid catalyst to establish other layers of the new tool upon it. Supportive nature of Lean philosophy toward TBL performance was already mentioned within the context of previous chapters. Therefore, strengthening this feature with other available performance measurement tools could galvanize effectiveness of the proposed framework.

Integrated implementation of triple bottom line (TBL) developed by Elkington (1994) and lean philosophy evolved from Ohno’s Toyota Production System (TPS, 1980) could play crucial role in achievement of true sustainability and open the door for a whole new level of competitive advantage within the walls of organizations and across the supply chains. An integrated approach empowers the synergies between lean and sustainability and establishes the background for the development of a new and consolidated method (Mollenkopf et al. 2010; Pampanelli et al. 2015). Tasdemir and Gazo (2018) found that synergies between lean and sustainability outweigh the divergences. Several other researchers have also highlighted complementary aspects of lean with sustainability such as reduced emission of VOCs as a function of lean initiatives (WSDE 2007), financial and work area safety performance enhancements through 5S application (Ho 2010a, b; Vieira and Cachadinha 2011), pollution prevention through Kaizen events (Soltero and Waldrip 2002), increased energy efficiency and reduced CO2 emissions with help of layout reconfiguration practices (Fahad et al. 2017), and enhanced safety in workplaces through lean transformation (Taubitz 2010). Government organizations also promote integrated implementation of lean and sustainability (US EPA 2000, 2007, 2011). EPA emphasizes synergistic nature of lean and environmental sustainability by stating that; “… one simple way to understand how your company’s lean efforts are affecting the environment is to add one or more environmental performance metrics to the metrics used to evaluate and track the success of lean implementation” (US EPA 2007). Lean could also be the low-hanging fruit in the path to Truly Sustainable Supply Chains. However, such an integrated approach may still leave some soft spots in terms of analytic tools required to conduct quantitative analysis and impact analysis required to detect emission, pollution, water and energy footprint performance at intra- or inter-organizational levels when it comes to assessment of true sustainability performance. To cover such drawbacks, Six Sigma and LCA methodologies were introduced to the design and development phases of the proposed tool.

The evolution of modern Six Sigma methodology was initiated within the walls of Motorola toward the end of 1970s and beginning of 1980s (Pepper and Spedding 2010). However, underlying methodology, sigma variation analysis, can be traced back to 1930s (Chiarini 2012). Toward mid-1990s, Six Sigma has gained more popularity once companies like Motorola, Allied Signal and General Electric (GE) revealed significant cost savings, improved quality and customer satisfaction (Hahn et al. 2000). Usefulness of Six Sigma methodology for performance benchmarking purposes was also documented in the past (Harry et al. 2010). Today, paths of lean and Six Sigma crossed with each other and often co-employed within a scope of integrated methodology called lean Six Sigma (Maleyeff et al. 2012). Applicability of quality management tools to improve environmental performance and positive correlation between environmental performance and increase in quality was also documented in a previous study (Pil and Rothenberg 2003).

In a different development path, LCA has emerged from 1960s’ energy impact analysis and rapidly gained popularity in the eyes of industry experts, academia and policy makers (McManus and Taylor 2015). LCA is one of the most commonly used tools for eco-design and eco-efficiency purposes (Cluzel et al. 2010). It is also the most commonly employed methodology for assessment of environmental impact of products and services. As defined in ISO 14044, LCA methodology comprises a four phases, namely Goal and Scope Definition, Inventory Analysis, Impact Assessment and Interpretation (Lehtinen et al. 2011). LCA is also effectively used for public policy making and strategic planning purposes (Klöpffer 2013). Necessity of looking at the entire life cycle of products and processes is becoming a common practice rather than an optional one (Curran 2004). LCA has also been successfully incorporated with lean Six Sigma-driven sustainability studies (Banawi and Bilec 2014; Cheung et al. 2017; Vinodh et al. 2016).

As could be interpreted from above scientific findings, lean philosophy, Six Sigma methodology and LCA Techniques have significant potential to contribute toward true sustainability and sustainable development purposes. Therefore, within this study, an innovative and versatile sustainability benchmarking tool, which is fueled by lean, Six Sigma and LCA, is proposed. Overall, achieving true sustainability would be a breakthrough improvement for humanity. However, metrics and methodology are not enough for breakthrough improvements (McCarty et al. 2011). That is why we need to embed a proper methodology with an innovative and comprehensive framework that also consists of an effective benchmarking feature through proactive KPIs. Definition of a proper deployment strategy is also a critical success factor. Therefore, theoretical details and conceptual structure, modules of the framework, first-generation KPI pool and deployment plan of the proposed framework are documented in detail in the following sections of the study.

2.1 Theoretical and conceptual framework of sustainability benchmarking tool (SBT)

The development phase was initiated with determination and definition of key features that the new measurement tool must carry to properly serve the purpose and to fill the gaps detected during systematic literature review. These features are:

-

Versatility—To ensure applicability to any system or sector through modifications.

-

Visual—To ensure effective transfer of information.

-

Comprehensive—To address micro and macro supply chain issues at intra- and inter-organizational level.

-

Holistic—To cover all pillars of sustainability in a bias-free fashion.

-

Convenient—To ensure user friendliness via simplistic design and user interface.

-

Innovative—To bear opportunities for further developments.

-

Scalable—To vertically and horizontally compare, align and improve measured outcomes along the supply chain (within and outside the walls).

-

Standardized—To ensure comparability of measurement results with those of other business units, organizations and supply chains.

Accommodation of each unique feature by using only one method or tool was not feasible. Therefore, the proposed tool had to be a combination of a set of methodologies and tools working toward the same goal, assessing and benchmarking true sustainability. The proposed framework incorporates use of Six Sigma and life cycle assessment (LCA) methods to fill in the gaps where synergies of lean and sustainability (TBL) cannot meet the requirements for effective environmental footprint tracking, social responsibilities evaluation and overall benchmarking of sustainable performance. Triple bottom line sets the foundation for development of the proposed framework while lean, Six Sigma and LCA principles are exhaustively employed to detect and to remedy sustainability issues throughout an organization or supply chain based on desired aggregation level. These four complex and effective methodologies were melted in the same pot and shaped into a composite framework named as “sustainability benchmarking tool (SBT)” Fig. 2.

Sustainability benchmarking tool (SBT) was designed take advantage of strengths of each methodology involved and synergies that exist among all four. Lean and Six Sigma have enormous number of tools to offer, each of which bears economic, environmental and social benefits for corporations (Langenwalter 2006; McCarty et al. 2011; Parveen et al. 2011; Vieira and Cachadinha 2011). Each of these has many proven direct or indirect contributions toward at least one of TBL pillars. The lean philosophy is used to ensure cultural change, continuous improvement, transparency and waste elimination (a TBL perspective), while LCA tools are tasked to track footprints left by business operations and to provide input for environmental performance indicator calculations. Last, but not the least, Six Sigma methodology has been extensively used for root causes, improvement opportunities and controlling existing variation in the system.

In addition to employment of lean, Six Sigma and LCA concepts, development of a “True Sustainability Index” (TSI), a rating system for “Work Environment Risks Assessment Mechanism” and creation of KPI pools comprising economic, environmental and social metrics have been key elements of the proposed methodology. A three-phase theoretical framework of the proposed tool is given in Fig. 3.

Design of the proposed tool has 6 modules, 1 Main and 5 Add-on Modules. The general structure of the tool was named “Space Shuttle Configuration” (SSC) since Add-on modules can be easily mounted or dismounted upon necessity to increase or decrease level of detail represented in the tool. Conceptual framework of the new tool is given in Fig. 4. Main module, a modified VSM, is designed to be the locomotive for other modules. It is used to map the organization or supply chain level processes or activities and to detect and report value-added and non-value-added activities. Capacity, time, material, energy, water and inventory status information as well as cost factors are documented in this module. Four of five add-on modules, namely Environmental Performance Module, Economic Performance Module (FPM), Social Performance Module (SPM) and Work Environment Risk Assessment Rating (WERAR) Modules are tasked to generate and report associated TBL performance data for processes or organizations or supply chains being analyzed. The last add-on module, TSI Module, is used to calculate and generate a quantified index score of the TBL performance of the process as of evaluation date. Assessment mechanism and sustainable performance modules of the proposed framework rely on fundamentals of Balanced Score Card technique (Kaplan and Norton 1996) to ensure alignment of sustainability perceptions and expectations of all stakeholders. In two different studies, Shaker discovered sustainable development in EU (Shaker 2015) and developed a mega index for the Americas to assess sustainability of nations (Shaker 2018) from a macro perspective. The author stated that “…A constructive sustainable development index revolution would allow sustainability scientists to streamline complex indices into simple, meaningful tools for operationalizing development planning and policymaking. (Shaker 2018).” The design of assessment mechanism of SBT Framework is complimentary with the statements of Shaker and aims to report sustainability performance at various scales with a simple yet meaningful index score. The framework combines modern management techniques and philosophies with the up-to-date technological tools to capture, evaluate and improve economic, environmental and social performance of organizations and supply chains.

a Space shuttle configuration as the inspiration source (A) (NASA 2005). b Conceptual framework of the proposed tool

Value Stream Mapping was the most critical lean tool employed since it comprises the main module of SBT Framework to capture, visualize and document the work area to be assessed. VSM is frequently preferred in scientific studies, since it can operate in harmony with LCA analyses (Cherrafi et al. 2016; Chiarini 2014; Faulkner and Badurdeen 2014; Torres Jr. and Gati 2009). Accuracy and reliability of environmental data analyses is ensured through the use of a set of LCA tools including life cycle inventory databases, computer software programs such as Sima Pro 8 and Gabi (Fu et al. 2015; Ng et al. 2015; Santero et al. 2010).

There also are some simplified LCA (S-LCA) tools such as spreadsheets, online interfaces designed to aid with life cycle assessment procedures (Hitchcock et al. 2011; McManus and Taylor 2015; Rossi et al. 2016). As documented in a previous study, depending on outcome of software selection decision, conclusions reached at the end of LCIA analysis could vary (Speck et al. 2016). Therefore, using proper software based on contingency of company/supply chain/sector is critical. These tools will be used to generate and extract material and resource consumption data as well as to determine emission values associated with supply chain operations and processes. Tools that could have potential use within this study are listed in Table 1.

Advanced software programs like SimaPro 8 and GaBi enable researchers and professionals to conduct a cradle to grave life cycle assessment by disclosing footprints of supply chain operations. Such software programs provide a science-based information and offer transparent daily operations in terms of environmental impacts to promote conscious decision-making activities. They could be effectively used for collecting, analyzing and monitoring environmental sustainability performance data for any process along the life cycle of a product or service. Creators of Sima Pro 8 state the potential application areas of the software as:

It can be used for a variety of applications, such as sustainability reporting, carbon and water foot printing, product design, generating environmental product declarations and determining key performance indicators (Pre Sustainability 2017).

Moreover, the location of the organization subject to assessment and the geographical extension of its supply chain dictate the type of LCA database and software to be used. For instance, if the SBT Framework is to be deployed in a European company, Sima Pro 8 and European Life Cycle Data Network will be better options to pick, whereas for a US-based corporation, GaBi and US Life Cycle Inventory would serve a better purpose. Furthermore, if the analysis is to be conducted on a series of supply chain operations for a global company with facilities on more than one continent, a combination of both tools and databases could be used to generate necessary emission, resource consumption and waste generation data. Within engine of SBT Framework, environmental impact assessment is conducted as an input–output-based process with help of above discussed LCA software and databases.

The framework tries to achieve a “cradle to grave” emission, energy and water footprint-based assessment as a function of aggregation of various business activities and supply chain members through “gate to gate” (Klöpffer and Grahl 2014) assessment for target business activities based on phases of LCA defined in ISO 14040 (Khasreen et al. 2009; Klöpffer 2013). Such segmentation of analysis scope is set in parallel to borderlines of work environment that is subject to assessment and helps with precise investigation of impacts of operations.

Within each of six modules, SBT Framework requires exhaustive use of various qualitative and quantitative lean, Six Sigma and LCA tools and techniques as wells as integration of technology through software programs. These programs are essential for flawless assessment and benchmarking of True Sustainability Performance. A comprehensive list of these tools, techniques and technology is provided in Table 2. All six modules of SBT Framework were explained in detail within Sect. 2.2.

2.2 Modules of SBT Framework

2.2.1 Value stream mapping (VSM) module

SBT Framework was structured around an extended-VSM that was designed to serve as a visual databank. All process information including material & information flow, inventory levels, cost functions, and emission, waste generation, water and energy footprint data is documented by VSM Module. From the perspective of a complete life cycle of a product or service, the purpose of VSM can be stated as:

Since engaging with proper technology is among primary concerns of the proposed framework, use of Minitab Companion (Minitab Inc. 2017b) is recommended for construction of VSM Module. In this module, data related to business unit subject to assessment is collected, documented and visualized within three main ladders. A similar approach to track energy, material and natural gas consumption rates of manufacturing processes was also utilized in EVSM Tool developed and presented by Litos et al. (2017). One ladder contains value-added-time (VAT), value-added-cost (VAC), while another stream is tasked with documentation of energy and water footprint for each process or step within the system. Last ladder is designed to track emission footprint and solid waste generation data. Data captured by these ladders later provide input for performance modules to calculate scores for associated KPIs. A generic example of VSM Module created in companion by Minitab can be viewed in Fig. 4 as part of SBT Framework interface.

VSM is a versatile tool by its nature that provides opportunity to detect value-added activities along with eight wastes from the perspectives of both lean and sustainability (Agustiady and Badiru 2013; Martichenko and Von Grabe 2010; Myerson 2012). Use of extended or modified versions of VSM for sustainability purposes has been validated by many researchers. Faulkner and Badurdeen (2014) developed a modified VSM and called it “Sustainable Value Stream Mapping” to determine environmental and social sustainability performance. Brown et al. (2014) tested applicability extent of the methodology developed by Faulkner and Badurdeen in different manufacturing settings and concluded that use of VSM helps with measurement of environmental and social sustainability performance of operations. In another study, Marimin et al. (2014) used Green Value Stream Concept to evaluate Green Productivity and focused on environmental and economic sustainability performances in rubber industry.

2.2.2 Economic (FPM), environmental (EPM), social (SPM) performance measurement and True Sustainability Index (TSI) modules

Economic, environmental and social performance modules are used to capture sustainability performance of operations subject to assessment for a specific review period. Within SBT Framework, quarterly and annual updates on performance assessment are recommended. Each of the three modules was designed to ensure equal-weight, accurate measurement and standardized documentation of sustainability performance data based on TBL pillars. Easy-to-interpret dashboards of the FPM, EPM and SPM modules will collectively generate True Sustainability Index (TSI) for detection of improvement opportunities and comparison across relevant business units. To generate input for these modules, value-added-time, cost, energy, material and capacity efficiency analysis, LCA-based environmental performance measurements and as well as social sustainability concepts are exhaustively used.

Product or service, process, supply chain, facility, logistics, environmental footprint and energy consumption values captured by VSM Module are fed into these engine modules to generate comprehensive and standardized economic, environmental and social performance scores. Modules were also compared to each other in terms of non-compliance rates to create an internal comparison mechanism prior to feeding of populated indices into TSI Module. Such a comparison is useful for assessing effectiveness of existing sustainability principles relative to each other. Strength and weakness identification of target functional unit/facility/organization/supply chain in the means of various sustainability KPIs is also carried out in TSI module. For any KPI score to be classified as strength or weakness, it should read an index score higher than 9.00 or 7.00, respectively.

Title of the scoring index along with those of its components was inspired by Environmental Sustainability Index System developed by Yale University and Columbia University (EPI 2005; Hsu et al. 2016). TSI places measured sustainability performance on a 10-point scale and aims to deliver a standardized and globally comparable outcome. TSI is the cumulative product of Economic Sustainability Index (FSI), Environmental Sustainability Index (ESI) and Social Sustainability Index (SSI) and can be formulated as:

Economic, environmental and social sustainability indices were designed to measure true status of sustainability performance at the time of performance measurement. Environmental and social indexes generate results considering predetermined Work Environment Risk Assessment Ratings (WERAR) and recorded incident occurrence rates in a specific period. These indexes can be formulated as:

where FI economic or financial indicator, EI environmental indicator, SI social indicator, n total number of indicators used, a number of reported environmental incidents that falls under a specific category, b number of reported social incidents that falls under an associated category, pi penalty coefficient assigned to that specific associated WERAR category.

TSI score is a strong holistic indicator of economic, environmental and social sustainability, which enable intra- and inter-organizational comparison of sustainability performance based on standardized KPIs. Improvement (if not optimization) activities are carried out to enhance and improve TSI score and are based on define-measure-analyze-improve-control (DMAIC) methodology (McCarty et al. 2011). Identified weaknesses are tackled through a science-based waste minimization and variation elimination approach driven by lean and Six Sigma principles. Summary of DMAIC steps and scientific methods is shown in Fig. 5.

Steps of DMAIC and procedures to be followed within each step (Ben Ruben et al. 2017)

2.2.2.1 SBT maturity degrees and first-generation KPI pools for SBT Framework

Within this section, classification of KPIs used to control and measure operational effectiveness and efficiency in terms of TBL were discussed and presented. For different application areas, they may take different names, acronyms and metrics; however, their main purpose, “explain and quantify performance,” remains the same (Cai et al. 2009; Cohen et al. 2014; Ness et al. 2007; Singh et al. 2012). Since measuring too much with too many indicators is counterproductive (Parmenter 2015) and measurement process itself is non-value-added by its nature (Grinsven 1993), determination of proper number of KPIs to be embedded into SBT Framework was a critical decision. Proposed benchmarking tool also involves a KPI pool that consists of a combination of standardized KPIs for pillars of sustainability at three different complexity levels. A total of 33 KPIs was assigned to each sustainability pillar based on desired assessment complexity as shown in Fig. 6.

Each of the three levels, namely bronze frontier, silver frontier and gold frontier, requires a certain level of organizational readiness and competency in terms of lean, Six Sigma and LCA concepts. Number of KPIs per pillar increases as the culture of organization matures. Therefore, bronze frontier KPI pool was designed to serve as the introductory level repository with 5 direct and 1 relative KPIs, whereas gold frontier KPI pool is the more comprehensive maturity degree with the highest number of KPIs for each of Sustainability pillars as can be seen in Fig. 6. Key competencies created or obtained in terms of lean, Six Sigma, LCA and sustainability have direct influence on decision of “Which level to consider for benchmarking purposes?”

Since TBL concepts are in relatively early stages of their evolution, environmental and social dimensions of TBL are less prevalent and more immature in terms of completeness and effectiveness of measurement mechanisms when compared to the economic dimension (Tasdemir and Gazo 2018). To simplify the classification of sustainability indicators, a taxonomy procedure was followed. Preferred taxonomy scheme consisted of two layers. In the first layer, KPIs were classified depending on their essentiality to economic, environmental and social efficiency and responsibility to create depth and maturity levels of the framework while in the second layer, TBL-oriented categorization was used to distribute indicators among sustainability pillars. Each KPI pool was created to serve unique requirements of industrial applications at company and sectoral level. First-generation KPI pool of SBT Framework was designed with enough flexibility to position the framework within the coverage area of Facility-Corporation-Sectoral level assessments on the scale of technical detail and measurement level comparison (Sarkar et al. 2011). Determination of KPIs to be used within each pillar was a tricky job. Performance measurement power and scope of each KPI had to be applicable to both intra- and inter-organizational and sectoral levels since SBT Framework was designed to enable performance measurement and benchmarkability across organizations, supply chains and sectors through aggregation of standardized True Sustainability Index as illustrated in Fig. 7. Therefore, KPIs were picked or created by using EPA (Fiksel et al. 2012; US EPA 2000), GRI (2011) and OECD (OECD 2004, 2011) publications as guidelines among those that could be strategically positioned to detect sustainability performance with required level of macro or micro business focus scalability to ensure effective measurement, comparison and aggregation.

Another important factor to consider during KPI selection and classification phase was to ensure that measures are compliant with requirements of the framework. Any KPI to be included in the pool should carry some fundamental properties. Eight commonly referred to (Eckerson 2010) and three proposed(p) properties, namely essential and accurate, interpretable, improvement-oriented, dynamic, up-to-date, useful and visual, communicative, feasible, standardized(p), proactive(p), net-impact-oriented(p), were selected.

Following creation of initial pool, each KPI was modified to calculate performance levels in a standardized manner rather than in absolute values of basic units or metrics. Performance indicators that already have standardized values were left as is. Moreover, with help of LCA analyses, Environmental and social KPIs were altered and redesigned to be “Net Impact” oriented instead of a traditional gross impact perspective. For instance, CO2 emission is picked as indicator of carbon footprint (Simons and Mason 2002; Ugarte et al. 2016; US EPA 2012). Designated KPI for this purpose is named “Net CO2 Emission Impact,” which also takes negative emissions and carbon storage potential into account. Formulation and overall structure of performance indicators also acknowledge “existence of purpose of corporate organizations as well as expectations of various stakeholders (De Ron 1998), and therefore, they generate feasible and meaningful outcomes from a holistic perspective for all associated parties. Although, in a perfect world, optimum outcome is “Zero Emissions” or “Zero Harm,” some level of emissions and harm is a phenomenon of today’s available technology and tools when ever-evolving and ever-increasing needs of humans are considered. Therefore, benchmarking the processes based on the possible best practices is the most feasible solution. Based on these facts, first-generation KPI pool for three complexity levels of SBT Framework is given in Fig. 8. Simplified formulas and corresponding reference sources of each KPI picked for sustainability measurement are given in Appendix A.

First-generation KPI pool contains specifically selected sustainability performance measures to ensure that the SBT Framework can be used for both inter- and intra-organizational assessment purposes. Calculated ESI and SSI scores are a combined product of measured KPI outcomes and detected work area safety issues and incidents. These incidents and issues are identified and documented within a module described in the following subsection.

2.2.3 Work Environment Risk Assessment Rating (WERAR) module

This mechanism has an employee, society and environmental safety focus and is complimentary with Environmental and Social Sustainability index calculations. As precedents or inspiration sources of this module, societal metrics used by (Brown et al. 2014), “Work Environment Metric” proposed by (Faulkner and Badurdeen 2014) and “EPA EHS Icon” developed by (US EPA 2007) are used. This module reaches beyond being an isolated metric and/or signaling tool through its broader perspective and by introduction of integrated control mechanism. WERAR establishes a two-layer, 5-grade risk scale of select risk categories, namely Noise (N), Electrical Systems (E), Exposure to Hazardous Materials (H), Hazardous Material Spill (S), Pressurized Systems (P), Ergonomics (ER), High-Speed Moving Machinery and Systems (V), Green Area or Biodiversity Damage (GB), Biological Hazard (BH), Fire (F), Radioactivity (RA) as well as it keeps track of 5S Housekeeping (5S). Risk categories are designed to cover Health, Safety and Environmental Protection categories defined by major organizations such as OSHA, EPA, NRC and ISO (De Oliveira Matias and Coelho 2002). F and RA categories have direct influence on both ESI and SSI scores, while S and GB only have influence on ESI. The remaining categories take place only in SSI calculations. Moreover, 5S Housekeeping activities are being investigated within this module since its effectiveness of achieving clean and organized workplaces and contribution to increased work area safety was proven and documented in the past (Chiarini 2014; Ho 2010a; Vieira and Cachadinha 2011).

Proposed mechanism assigns a risk grade called Work Environment Risk Assessment Rating (WERAR) to the work environment subject to assessment. Assignment of WERAR requires definition of probabilistic and incidental impact of identified risk as well as determination of existing control level associated with that risk within the work area. Probabilistic analyses are carried out based on past incident data whereas incidental impact risk is determined through expert opinion. WERAR mechanism also requires the use of a supplementary lean tool, Gemba Walks (Womack 2013). It involves actual observation of work environment for detection of potential safety and inefficiency problems associated with the work area under investigation. Gemba Walks will be used to determine risk grade of a certain environment in addition to identification of current control levels. Implementation of 5S and Standardized Work practices along with Kaizen events are recommended for reducing various safety risks in work environments. Audit Form created for such purposes was provided in Appendix B. Proposed module has other unique properties that encourage safer work practices and environments through implementation of a standardized risk grading and incident tracking system. This risk assessment mechanism is designed to include a risk grade matrix which issues a penalty coefficient “p” to work environment depending on severity of probabilistic and incidental impact risk with a purpose of adjusting SBT Framework’s environmental and social performance score. To achieve this objective, two scales were introduced to WERAR mechanism. Probabilistic scale defines assigned risk grade of an environment depending on occurrence frequency of environmental or social incidents, while impact scale tries to assign a grade based on devastating impact degree of a probable incident on people or environment. Incidents with high probability and expected high devastating impact are penalized the most. Risk matrix was designed to penalize increases in Impact scale more than it reacts to increases in Probabilistic Scale. Risk grade and penalty coefficient assigned within this module has direct influence on Environmental and Social Indices (EPI and SPI), while identification and assignment of control levels to risk categories highlight effectiveness of existing control mechanism. General structure, risk grade matrix and control levels scale of WERAR mechanism are shown in Table 3.

All six modules of SBT Framework, associated methodology and required technological intellectual and technological infrastructure, have been explained in detail in the previous sections. SBT Framework can be implemented by any facility/organization/supply chain that is interested in such assessment and benchmarking of true sustainability through methodical execution of steps provided in Fig. 9.

Organization-wide implementation of the proposed framework will require a high level of dedication from the entire workforce. To provide all interested parties with a complete guide, a part of the study was dedicated to present ownership of deployment and SBT Framework maturity model for a successful cultural change.

2.3 Ownership of framework deployment and engraving true sustainability into organization culture

Even the most well-thought framework will be prone to failure if its deployment and implementation phases are not managed in a rigorous fashion. Proposed framework requires an integrated and aggressive deployment plan which will infuse throughout the entire structure of the organization starting from business strategy development to shop floor level operations. However, prior to actual deployment, a small-scale pilot study is recommended to enhance level of familiarity with the framework. General structure of SBT Framework deployment plan is quite similar to that of lean and can be evaluated under two main factors, namely impact scope and organizational readiness (Weiner 2009). The impact scope of the proposed framework has two layers. First layer addresses cultural change within an organization, while second layer aims for cultural transformation of the entire supply chain by setting positive examples as a function of first layer outcomes. Past research studies documented that it pays to be environmentally and socially responsible (Li et al. 2017) and that being a sectoral leader could be a cutting edge competitive advantage (Langenwalter 2006). However, there is no one single correct model which can be applied to all organizations right away. Organizational readiness dictates the development of deployment plan depending on industry dynamics considering the contingent theory (Torbjørn H. Netland 2016). It is essential to tailor the deployment plan based on organization’s situation and realities. Economic stability, familiarity with lean, Six Sigma and sustainability (e.g., already in-place lean and sustainability initiatives or no experience at all), perspectives of highest-level executives and current culture collectively determine the organizational readiness. Moreover, the proposed framework should be integrated in correlation with other appropriate management approaches such as lean accounting, lean and green procurement, sustainable product development, etc. Such deployment of the proposed framework requires an effective leadership across the organization and high collaboration among leaders of supply chain members. Since SBT Framework is a lean Six Sigma-based assessment and benchmarking mechanism, a lean leadership model that ensures continuous improvement of sustainability would serve the purpose. Dombrowski and Mielke’s (2014) study can offer further insights into fundamental principles of lean leadership and the proposed fifteen rules of sustainable lean deployment.

Although organization-wide deployment plans are quite traditional, they are the most challenging to execute when compared to plans with narrower impact scope. Therefore, a solid leadership from top management, large infrastructural investment, customer-oriented perspective, employee involvement and establishment of an organization wide common language as well as a problem-solving methodology are required. A past study found that cross-functional executive and worker involvement increases effectiveness of lean initiatives and also helps with strategic alignment of lean activities with environmental and social sustainability objectives (Longoni and Cagliano 2015). Distribution of SBT Framework ownership can be performed in nine steps: (1) make the decision for the transformation and ensure strategic alignment throughout the organization. (2) Appoint a SBT Framework champion and establish ownership. (3) Align business strategy with true sustainability framework. (4) Gain possession of all the required resources including technology, human resources and material. (5) Create a shared vision through expansion of ownership (form a team). (6) Train the workforce. (7) Analyze current state of the organizational readiness and detect opportunities. (8) Develop tactics to tackle the issues identified. (9) Start deployment, review (monthly, annually) and adjust accordingly.

Having a dedicated team for deployment and implementation of corporate lean programs offers certain advantages (Torbjorn H. Netland et al. 2015). Therefore, the proposed deployment plan requires one SBT Framework Champion from C-Suite and 3 Sustainability Leaders for each triple bottom line (TBL) pillar. Then, the responsibility is distributed over facility level leaders who will supervise department level team leaders. Team leaders will be responsible for creating and supervising their own SBT teams as well as for collaboration with other linked teams. The size of SBT teams is dependent on scale of the organization and complexity of the product or service system. Economic Sustainability Leader will be responsible for achievement of financial goals in collaboration with other pillar leaders. Economic pillar leader will also deal with establishment of a transparent relationship with suppliers and customers to achieve desired outcomes. Environmental Sustainability Leader will ensure minimization (if not elimination) of environmental impacts of various level operations as well as creating effort to ensure compliance with environmental regulations, laws and standards. Last but not least, Social Sustainability Leader will manage relationship with worker unions and part of the society associated with the firm to achieve targeted social outcomes. Ownership of the deployment is vertically and horizontally shared among different management levels. Clear definition of roles and responsibilities is essential for a successful deployment and its governance. Hierarchical structure of dedicated implementation team with ownership distribution can be seen in Fig. 10.

Creating key competencies throughout the entire workforce is also essential for successful deployment of the proposed framework. Therefore, proper education and training opportunities should receive sufficient attention and financial allocation from SBT Framework Champion. Starting from leaders to team members, entire workforce should be trained through in-house training sessions. TSF specialized personnel should have complete understanding of lean, Six Sigma and TBL philosophies. They should also be able to educate, train and motivate the rest of the workforce to help with creation and development of a teamwork spirit as well as a common language along all organizational units. Entire workforce should be consistently provided with daily, weekly and monthly education opportunities to achieve certain level of key competencies. Such competency of team members could be achieved by setting certain requirements for TSF positions and by ensuring proper opportunity for obtaining of those credentials. An example of minimum requirements for various levels of SBT Framework deployment team positions could be as given below:

SBT True Sustainability Framework Champion

-

At least an M.S. Degree (preferably Ph.D.) with a Specialization in Sustainability (TBL)

-

Six Sigma Master Black Belt

-

Certification in Lean Management

-

Certification in Leadership Excellence

Senior Level Executives

-

At least an M.S. Degree in Business or Related Discipline

-

Certification in Lean

-

Six Sigma Black Belt

-

Highest Level Certification in Sustainability

Facility Level Leaders

-

At least a B.S. Degree in Business Related Discipline

-

Certification in Lean

-

Six Sigma Black Belt

-

Certification in Sustainability

Department Level Team Leaders

-

At least Six Sigma Green Belt

-

Well-Trained (if not Certified) in Lean and Sustainability Concepts

Existence of Work Environment Risk Assessment Mechanism (WERAR) requires audit of facilities with a purpose of risk grade assignment. Such audits can only be performed by professionals with corresponding credentials. Professionals could either be temporarily hired from third-party providers or existing personnel can be provided with opportunity for certification training to obtain necessary skill sets and credentials. Examples of such credentials are ISO 9001:2015 Internal Audit Program Certification (ASQ 2018), ISSP Sustainability Associate (ISSP-SA) (ISSP 2018), Sustainability Management Certified Professional (SMCP) (SMA 2018), or equivalent.

Furthermore, deployment of the proposed framework requires proper and detailed analyses of current state of the company structure in terms of lean and sustainability performance to discover level of organizational readiness and to prioritize areas to be improved based severity of identified weaknesses. Following business strategy decisions and establishment of required infrastructure including ownership distribution, capital allocation and identification of stakeholder expectations as well as deployment of the framework is ready to be initiated. Complete implementation of the proposed framework is not an easy-task, since it intends to transform the entire structure of the organization. It requires qualified workforce, adequate training, computer software, consultants (if needed), compliance with regulations and further technological investments (as part of lean transformation) related to infrastructure. Therefore, Return on Investment (ROI) will totally depend on success of cultural transformation, consistency of dedication, amount of investment made, size of the organization and external factors such as political, social and economic dynamics of the industry/region/world. The ROI of the proposed framework can be evaluated under two distinct titles, namely direct tangible and indirect tangible returns. Tangible returns cover gains such as increased profitability, reduced cost factors, reduced lead time, increased market share and actual ratio of ROI as well as reduced cost of compliance with regulations. On the other hand, indirect tangible returns can be summarized as increased reputation and brand value/firm image in the eyes of customers due to increased social and environmental performance. These factors are expected to boost the sales and market share in return. Moreover, increased job satisfaction and loyalty of workers can be counted among indirect tangible gains since it will contribute to overall productivity and efficiency. Both direct and indirect tangible gains could gradually be obtained starting from the first day of deployment. Successful deployment of SBT Framework is expected to be completed between 3 and 5 years similar to the maturity establishment levels documented by (Raje 2018). Simplified version of TSF Maturity Model can be seen in Fig. 11.

This study was designed to propose and document in detail a composite framework and its theoretical and conceptual models, as well as a deployment plan and ownership distribution to assess and benchmark true sustainability performance. As is the case for any model proposition, SBT Framework was also based on some assumptions and has some limitations. In the next section, these assumptions and limitations are presented.

3 Assumptions and limitations of the framework

Proposed framework was designed to operate based on seven assumptions associated with implementing organization and LCA databases. One should also consider the underlying assumptions of the proposed methodology and tools to develop a complete understanding of the concept and to deploy it on an existing system with sufficient competency. These assumptions are listed below.

Assumptions related to Implementing organization: (1) can develop a complete understanding of lean and sustainability philosophies, (2) are ready to provide required infrastructure and training for the associated staff, (3) can assign a “SBT Framework Champion” and form a “SBT team,” (4) organization itself and its supply chain partners are eager to achieve a fully transparent multi-directional information flow, (5) have appropriate vision to lead and to set an example for its supply chain partners and sectoral competitors along True Sustainability journey, and (6) product/service systems are suitable for value stream mapping. On the other hand, assumption related to LCA Software and Database: (1) has all the required process and inventory data available to determine performance within the scope of environmental impact for that specific sector.

SBT Framework also has some limitations inherent in its design. Since the proposed framework follows a lean Six Sigma Philosophy-based methodology, cost of deployment or cost of transformation can become high depending on the size of the organization/supply chain, target industry and types of the inputs associated with the target industry. This situation may quickly elevate once resource requirements of LCA studies are considered. Advanced software programs are quite expensive and require user to develop a good understanding of the program modules through a steep learning curve. Moreover, some software programs and databases could have missing environmental footprint data for certain industry segments or geographical regions. Organizations operating with limited resources may not be able to deploy the proposed framework due to such resource limitations. Next, SBT Framework is yet to be validated through different case studies from different sectors, which would enable the authors to have strong evidence on claimed applicability and versatility of the proposed framework on an industrial scale. Authors of past studies highlighted a number of limitations of LCA principles. Two most common limitations reported are insufficient transparency of the results and lack of consideration of social and economic impacts during the life cycle of a product (Lehtinen et al. 2011). On the other hand, the proposed Sustainability Benchmarking Tool (SBT) tries to compensate for this issue with help of lean philosophy and high level of collaboration among supply chain partners (Brockhaus et al. 2013). Last but not least, gains as a function of a lean transformation may start to stagnate for a while after the first year. Similar pattern could be observed for SBT Framework following its deployment. Therefore, observation and evaluation of actual benefits of SBT Framework for different application areas would require a considerable amount of time, which could delay release of next generation KPI pools and redefined deployment guidelines. Despite these limitations, a successful SBT Framework implementation is expected to accurately assess all pillars of sustainability and closely monitor and globally benchmark product’s life cycle.

Therefore, those considering employment of SBT Framework for true sustainability assessment should take assumptions and limitations of the proposed tools into account and should remember that true sustainability is not a destination, but a never-ending journey as lean and continuous improvement are.

4 Conclusive remarks and future work

This study aims to build upon previous contributions made to the field of lean-driven sustainability by proposing an innovative and versatile framework that is designed to aid with unbiased assessment of True Sustainability Performance at intra- and inter-organizational levels. Previously discovered untapped potential of lean-driven sustainability is utilized and strengthened with Six Sigma and LCA principles to ensure effective and accurate performance measurement. The outcomes of this conceptual paper are expected to contribute to both sustainability science and sustainable operations management. Both SMEs (small and medium-sized enterprises) and large corporations could benefit from SBT Framework since it eliminates unit-based comparisons with its standardized performance measurement modules. Industries with lower profit margin could also gain competitive edge through continuous discovery of improvement opportunities. Furthermore, some manufacturing industries with unique characteristics such as wood products industries with their carbon sequestration potential and electric car manufacturers with their renewable energy-dependent final products could document their strengths more effectively through this science-based assessment mechanism. To document legitimacy of the proposed framework, in parallel, the authors are also working on two different validation studies one within value-added wood products industry and one involving integration with higher education curriculum to document proven effectiveness and contribution of the proposed tool in sustainability performance. Further practical applications of the SBT Framework could include but are not limited to; optimization of transportation activities for any supply chain to reduce fossil fuel dependency through promotion of local business support and efficient transportation modes, a better documentation of earth-friendly and socially conscious practices of electronics manufacturers who deal with conflict minerals, greening and control of industries that utilize harmful chemicals, to proactively promote recycling and reuse various materials across all industries and to proactively control water utilization and wastewater treatment. It could also be used to measure and benchmark success of organizations in protecting privacy of collected customer data with help of Social Performance Module. It is also designed to effectively control and improve employee safety at any work area that may bear potential risks.

As can be easily interpreted from above implications, the proposed framework is not limited to bare features of a technical tool. It is designed to trigger organizational and consecutively inter-organizational level of cultural transformation to ensure Sustainable Operations across various sectors. This framework is also flexible by its nature to respond to growing and upcoming innovation waves as well as evolving stakeholder expectations. Therefore, future work to be also needs to be defined.

Scheduled future work for the authors includes (1) to test and validate the proposed tool in real industry settings, (2) evaluate negative impacts of SBT Framework deployment on business stability, (3) integrate SBT Framework with digital innovation and enhance user interface to make it more convenient and portable, (4) develop and publish second-generation KPI pools based on ever-changing direction of innovation and sustainability research.

References

Agustiady, T., & Badiru, A. B. (2013). Sustainability utilizing lean six sigma techniques. Boca Raton, FL: CRC Press.

Agustiady, T. K., & Cudney, E. A. (2016). Total productive maintenance: Strategies and implementation guide. Boca Raton: CRC Press.

AlJaberi, O. A., Hussain, M., & Drake, P. R. (2017). A framework for measuring sustainability in healthcare systems. International Journal of Healthcare Management. https://doi.org/10.1080/20479700.2017.1404710.

Andersen, B., & Fagerhaug, T. (2006). Root cause analysis: Simplified tools and techniques. Milwaukee: ASQ Quality Press.

Ansari, Z. N., & Kant, R. (2017). Exploring the framework development status for sustainability in supply chain management: A systematic literature synthesis and future research directions. Business Strategy and the Environment, 26(7), 873–892. https://doi.org/10.1002/bse.1945.

ASQ. (2018). ISO 9001:2015 internal auditor training (exemplar global certified). Retrieved December 5, 2018, from https://asq.org/training/iso-90012015-internal-auditor-training-exemplar-global-certified-ia2015.

Authry, C. W., Goldsby, T. J., & Bell, J. E. (2012). Global macrotrends and their impact on supply chain management: Strategies for gaining competitive advantage. London: Pearson Education.

Azevedo, S. G., Carvalho, H., & Cruz-Machado, V. (2016). LARG index: A benchmarking tool for improving the leannes, agility, resilience and greenness of the automotive supply Chain. Benchmarking: An International Journal, 23(6), 1472–1499. https://doi.org/10.1108/bij-07-2014-0072.

Azevedo, Susana G., Carvalho, H., Duarte, S., & Cruz-Machado, V. (2012). Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Transactions on Engineering Management, 59(4), 753–765. https://doi.org/10.1109/TEM.2012.2189108.

Banawi, A., & Bilec, M. M. (2014). A framework to improve construction processes: Integrating lean, green and six sigma. International Journal of Construction management, 14(1), 58–71. https://doi.org/10.1080/15623599.2013.875266.

Basu, R. (2009). Implementing six sigma and lean. Oxford: Butterworth-Heinemann.

Bell, J. E., Autry, C. W., Mollenkopf, D. A., & Thornton, L. M. (2012). A natural resource scarcity typology: Theoretical foundations and strategic implications for supply chain management. Journal of Business Logistics, 33(2), 158–166. https://doi.org/10.1111/j.0000-0000.2012.01048.x.

Ben Ruben, R., Vinodh, S., & Asokan, P. (2017). Implementation of lean six sigma framework with environmental considerations in an Indian automotive component manufacturing firm: A case study. Production Planning and Control, 28(15), 1193–1211. https://doi.org/10.1080/09537287.2017.1357215.

Berger-Walliser, G., & Scott, I. (2018). Redefining corporate social responsibility in an era of globalization and regulatory hardening. American Business Law Journal, 55(1), 167–218. https://doi.org/10.1111/ablj.12119.

BOEM. (2017). Financial terms and ratios. https://www.boem.gov/Proposed-Financial-Terms-Ratios/

Borris, S. (2006). Total productive maintenance: Proven strategies and techniques to keep equipment running at maximum efficiency. New York: McGraw-Hill Education.

Bowersox, D. J., Closs, D. J., & Stank, T. P. (2000). Ten mega-trends that will revolutionize supply chain logistics. Journal of Business Logistics, 21(2), 1–15.

Brewer, A. S., & Pojasek, R. B. (2012). Assessing environmental sustainability performance at the national level: leading indicators can help. Environmental Quality Management, 22(2), 33–47. https://doi.org/10.1002/tqem.21325.

Brockhaus, S., Kersten, W., & Knemeyer, A. M. (2013). Where do we go from here? Progressing sustainability implementation efforts across supply chains. Journal of Business Logistics, 34(2), 167–182. https://doi.org/10.1111/jbl.12017.

Brown, A., Amundson, J., & Badurdeen, F. (2014). Sustainable value stream mapping (Sus-VSM) in different manufacturing system configurations: Application case studies. Journal of Cleaner Production, 85, 164–179. https://doi.org/10.1016/j.jclepro.2014.05.101.

Cai, J., Liu, X., Xiao, Z., & Liu, J. (2009). Improving supply chain performance management: A systematic approach to analyzing iterative KPI accomplishment. Decision Support Systems, 46(2), 512–521. https://doi.org/10.1016/j.dss.2008.09.004.

Cherrafi, A., Elfezazi, S., Chiarini, A., Mokhlis, A., & Benhida, K. (2016). The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. Journal of Cleaner Production, 139, 828–846. https://doi.org/10.1016/j.jclepro.2016.08.101.

Cheung, W. M., Leong, J. T., & Vichare, P. (2017). Incorporating lean thinking and life cycle assessment to reduce environmental impacts of plastic injection moulded products. Journal of Cleaner Production, 167, 759–775. https://doi.org/10.1016/j.jclepro.2017.08.208.

Chiarini, A. (2012). From total quality control to lean six sigma (Vol. 26). Milan: Springer. https://doi.org/10.1007/978-88-470-2658-2.

Chiarini, A. (2014). Sustainable manufacturing-greening processes using specific lean production tools: An empirical observation from European motorcycle component manufacturers. Journal of Cleaner Production, 85, 226–233. https://doi.org/10.1016/j.jclepro.2014.07.080.

Closs, D. J., Speier, C., & Meacham, N. (2011). Sustainability to support end-to-end value chains: The role of supply chain management. Journal of the Academy of Marketing Science, 39(1), 101–116. https://doi.org/10.1007/s11747-010-0207-4.

Cluzel, F., Yannou, B., Afonso, D., Leroy, Y., Millet, D., & Pareau, D. (2010). Managing the complexity of environmental assessments of complex industrial systems with a lean 6 Sigma approach. In Proceedings of the 1st international conference on complex systems design and management, CSDM 2010 (pp. 279–294). https://doi.org/10.1007/978-3-642-15654-0_20.

Cohen, S., Bose, S., Guo, D., Miller, A., DeFrancia, K., Berger, O., et al. (2014). The growth of sustainability metrics - sustainability metrics white paper series: 1 of 3. In: Research program on sustainability policy and management (pp. 1–14). Earth Research Institute, Columbia University. https://doi.org/10.7916/D8RN36RW.

Cooper, J. S., & Fava, J. A. (2006). Life-cycle assessment practitioner survey summary of results. Journal of Industrial Ecology, 10(4), 12–14.

Curran, M. A. (2004). The status of life-cycle assessment as an environmental management tool. Environmental Progress, 23(4), 277–283. https://doi.org/10.1002/ep.10046.

Dadashzadeh, M. D., & Wharton, T. J. (2012). A value stream approach for greening the IT Department. International Journal of Management & Information Systems (IJMIS), 16(2), 125–136. https://doi.org/10.19030/ijmis.v16i2.6912.

Dahl, A. L. (2012). Achievements and gaps in indicators for sustainability. Ecological Indicators, 17, 14–19. https://doi.org/10.1016/j.ecolind.2011.04.032.

Darmawan, M. A., Putra, M. P. I. F., & Wiguna, B. (2014). Value chain analysis for green productivity improvement in the natural rubber supply chain: A case study. Journal of Cleaner Production, 85, 201–211. https://doi.org/10.1016/j.jclepro.2014.01.098.

Das, K. (2018). Integrating lean systems in the design of a sustainable supply chain model. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2018.01.003.

De Oliveira Matias, J. C., & Coelho, D. A. (2002). The integration of the standards systems of quality management, environmental management and occupational health and safety management. International Journal of Production Research, 40(15 SPEC.), 3857–3866. https://doi.org/10.1080/00207540210155828.

De Ron, A. J. (1998). Sustainable production: The ultimate result of a continuous improvement. International Journal on Production Economics, 5657(98), 99–110. https://doi.org/10.1016/S0925-5273(98)00005-X.

Dombrowski, U., & Mielke, T. (2014). Lean leadership-15 rules for a sustainable lean implementation. Procedia CIRP, 17, 565–570. https://doi.org/10.1016/j.procir.2014.01.146.

Dyllick, T., Hockerts, K., & Thomas Dyllick, K. H. (2002). Beyond the business case for corporate sustainability. Business Strategy and the Environment, 11(2), 130–141. https://doi.org/10.1002/bse.323.

Ebert, U., & Welsch, H. (2004). Meaningful environmental indices: A social choice approach. Journal of Environmental Economics and Management. https://doi.org/10.1016/j.jeem.2003.09.001.

Eckerson, W. (2010). 12 Characteristics of effective metrics. TDWI Blog. https://tdwi.org/Blogs/TDWI-Blog/2010/04/Effective-Metrics.aspx.