Abstract

Several studies in swine feed composition have demonstrated that protein levels may be modified without significant changes in meat quality in terms of carcass, lean and back fat yield. However, this variation may change certain technical indicators, such as daily weight gain. The aim of this study was to calculate the carbon footprint of the finishing stage in swine production considering four scenarios of feed composition (P18, P16, P15 and P13). The life cycle assessment methodology was applied with a life cycle inventory based on reports in the literature. The feed composition used in P18 (no soybean hulls or maize starch) had the best environmental performance for global warming per kilogram of feed. However, when evaluating the life cycle of finishing swine, P16 (containing soybean hulls, maize starch and synthetic amino acids) exhibited better environmental results; the feed used in this scenario had better technical indicators (in terms of daily weight gain), thereby reducing the feed amount for finishing swine. Using the feed composition for swine P16, the impact may be reduced by an average of 12 % compared with P13 (a high level of soybean hulls, maize starch and synthetic amino acids).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Brazilian swine production in 2013 had an average herd of 38.578 million pigs, making it the fourth largest swine producer (and exporter) in the world, as reported by the United States Department of Agriculture (USDA 2013). In this context, the state of Santa Catarina has greater prominence, as it is the largest Brazilian swine producer. This southern state has approximately one-fifth of the national herd, concentrated mainly in the western region (Brasil 2011).

Generally, swine production has a poor image in society (Basset-Mens and van der Werf 2005) due to environmental risks associated with the high density of swine per square meter and impacts that have influences on the quality of life around population centers, such as odors and disease vectors. As with any other human activity, livestock generates environmental impacts, and this particular activity is a potential impact concentrator (Dalla Costa et al. 2008; Oliveira 2004). The origin of this impact and its meaning to the environment are not always easily understood; examples include eutrophication of aquatic ecosystems as a consequence of the manure management system and global warming due to the emission of greenhouse gases (GHG) from the production chain.

In the state of Santa Catarina, due to the large production of swine, great efforts have been directed by the government to control and decrease the environmental impacts of this activity. The Brazilian government body that performs agricultural and livestock research (EMBRAPA) has developed projects that aim to mitigate these impacts and ensure that swine producers comply with current environmental laws. Despite of EMBRAPA efforts, however, one may say that the process of impact generation should be further discussed.

Life cycle assessment (LCA) was developed to quantify environmental impacts from product systems through several stages and has been shown to feasibly analyze the impacts of agricultural systems (van der Werf and Petit 2002). This methodology allows the evaluation of environmental performances of scenarios of interest, identification of hotspots in the production chain and comparison of alternatives, all in an effort to improve the production system (Baumann and Tillman 2004; Wenzel et al. 2001). LCA enables a clear understanding of the life cycle of the analyzed system, providing a basis for strategic and sustainable decisions and meeting the requirements of domestic and foreign markets.

Previous LCA research on swine production demonstrated that feed is a critical point in the production chain, especially as it relates to crop cultivation (Basset-Mens and van der Werf 2005; Dalgaard 2007; Elferink et al. 2008; Kingston et al. 2009; Kool et al. 2009; Nguyen et al. 2011; Spies 2003; Williams et al. 2006). Diet therefore has a direct influence on impact generation, where each component has a unique production chain and different method of assimilation by the animals in the finishing stage. Due to this influence on the period required for the animal to reach its final weight, feed composition may change the quantity of feed required by the animals, modifying the characteristics of the manure and consequently the emissions produced. The search for new alternatives in animal diets therefore has an extremely important role in sustainable development in the sector. Several authors (Eriksson et al. 2005; Ferreira et al. 2005; Oliveira et al. 2006; Orlando et al. 2001, 2007; Vidal et al. 2010) have already conducted studies varying feed composition in several stages of swine production and concluded that it is technically possible to change the content of crude protein (CP) without significantly altering meat quality in terms of carcass yield, lean yield and thickness of back fat.

The aim of this study was to calculate the carbon footprint (CF) of the finishing stage in swine production considering four scenarios of feed composition (P18, P16, P15 and P13), where animal diet varied according to the level and source of protein.

2 Materials and methods

This study was conducted in accordance with LCA standards issued by the International Organization for Standardization (ISO), NBR ISO 14040 (2009a) and NBR ISO 14044 (2009b).

2.1 Goal and scope definitions

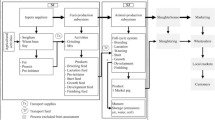

We define as a functional unit (FU) 30 kg of live weight gain in the finishing stage. The boundaries begins with the grain production, drying and processing into feed, while for animal rearing, we consider a swine with an initial weight of 70 kg in the finishing stage and end at the slaughterhouse gate, piglet production and the weaning-to-growing stage was excluded, as shown by the dotted lines in Fig. 1. The concept of ‘growing-finishing’ pigs describes the increase in weight from 25 kg to market weight (between 100 and 120 kg in Brazil). The age range is from approximately 8 to 22–26 weeks, with pigs spending approximately 8–10 weeks in a growing unit until they reached approximately 70 kg and the last 8–10 weeks in a finishing unit. In terms of outputs, the boundary comprises animal emissions to the air, manure management and manure soil application (counted as avoided fertilizer, see Fig. 1). Within these boundaries, we used background process from the ecoinvent® database for fertilizer production, electricity and transport.

We assume a farm located in Concordia, a major swine-producing city in Santa Catarina, with animal rearing in a building with a concrete floor. During the finishing period, the consumption of electricity, water, food and building materials for the facility were based on (Brazilian Agroindustry; Hörndahl 2008; Tavares 2012; Vidal et al. 2010). The construction aspects were based on data collected by the swine farming industry, including building materials.

For manure management, a system was considered in which manure was stored in downspouts outside the building and then transferred by gravity to open tanks. After 120 days of storage, stabilized manure was applied to soil as organic fertilizer. This approach considers manure as a by-product of the ‘finished swine’ system and would imply an allocation of environmental impacts. To avoid this procedure, we considered the substitution method, which represents the environmental benefits of avoiding the manufacture of the product replaced by use of manure (Dalgaard 2007), as oriented by the standard (ABNT 2009b). In this case, manure avoids the production and use of chemical fertilizer. The same approach was used by several authors (Basset-Mens and van der Werf 2005; Dalgaard 2007; Kingston et al. 2009; Kool et al. 2009; Nguyen et al. 2011; Williams et al. 2006).

The avoided fertilizer was modeled considering an average combination of urea, triple superphosphate and potassium chloride equivalent to the fertilizing potential of manure (urea contains 45 % N, triple superphosphate 42 % P2O5 and KCl has 60 % K2O). To estimate the amount of NPK fertilizer avoided, we used efficiency rates of 0.8, 1 and 1 for NPK, for urea, triple superphosphate and KCl, respectively. These indices are used because the concentrations and subsequent release of nutrients in the soil from organic fertilizers are highly variable. Therefore, the amount of these nutrients that will actually be available in the first crop after manure application must be calculated (SBCS 2004). In mathematical terms, the avoided fertilizer (F) is calculated using the following expression (Eq. 1):

where q i is the amount of the ith nutrient (i.e., N, P2O5 and K2O—Table 4).

A comparative LCA was used to quantify the environmental performance of the scenarios, labeled P18, P16, P15 and P13, which differ only by the compositions of feed involved in the finishing period (source and protein levels) and their influences on animal production. The labels refer to the protein percentage of each feed, as shown in Table 2. Feed composition and technical indicators such as daily feed consumption, daily weight gain, feed conversion rate, carcass yield and meat quality were based on Vidal et al. (2010), as shown in Table 3.

2.2 Inventory

2.2.1 Inputs

For soybean and maize production, we used data from Prudêncio da Silva et al. (2010)and Alvarenga et al. (2012). Soybean processing was based on Prudêncio da Silva et al. (2010), modified to include the production of by-product ‘soybean hulls.’ Economic allocation was used with values described by Moreira et al. (2009), which were in accordance with the Cooperativa Agroindustrial Capal, May 2012. Maize starch was based on Nguyen et al. (2012).

Diet P18, with the highest level of CP, did not include supplemental synthetic amino acid (SAA) The required amino acids for this diet were from maize and soybeans. For the remaining diets (P16, P15 and P13), the protein levels were progressively reduced and supplemented with SAA (l-lysine, d l-methionine, l-threonine, l-tryptophan and l-valine, Table 1). Hence, the nutritional value of the ileal digestible lysine was constant in the four diets (0.810), while the others SAA varied (Vidal et al. 2010) as displayed in Table 2. Data for the life cycle inventory (LCI) of lysine, threonine and methionine were based on Nguyen et al. (2012). For tryptophan and valine, we assume the same LCI as from lysine production.

Distances for the major feed components described in Table 1, such as maize and soybeans, were based on the real cities involved in the construction of scenarios based on Spies (2003), reflecting the reality in the western state of Santa Catarina. Thus, it considered 850 km of transportation by lorry truck from the grain producer to the feed factory and then 35 km from the feed factory to the swine producer. Feed was packed in raffia bags with a capacity of 50 kg, consisting of 0.2 kg of polypropylene per package.

On farm, the feed intake that is directly influenced by the finishing period and required for the animal to reach 100 kg was estimated through feed conversion rates and varied according to the feed applied (differences in weight gain and finishing periods can be found in Table 3).

With regard to water used for animal consumption, pen cleaning, nebulization, production and manure composition, we used data from Tavares (2012), which represent the reality of swine farms in Concordia-SC, while energy consumption during the process was based on data from Hörndahl (2008).

Data for on-farm buildings were estimated by considering a lifespan of 30 years, based on data by the agroindustry. The LCI is listed in Table 4.

2.2.2 Outputs

Methane (CH4) and nitrous oxide (N2O) emissions generated from animal rearing (including manure management) were calculated according to IPCC (2006). For enteric fermentation emissions, 1.50 kg of CH4 pig−1 year−1 was assumed, which represents the emissions in developed countries (IPCC 2006). The genetic source of animals produced in vertically integrated production systems in Brazil is from European companies. As they have controlled feeding strategies, Brazilian swine show similar enteric fermentation rates to European ones.

For CH4 emissions from manure storage, we used ‘Tier 2’ from IPCC, with a methane-producing capacity (B0) of 0.29 m3 CH4 (kg VS)−1, considering a methane conversion factor of 0.42. Regarding the N-related emissions, we assume no direct N2O emissions because we considered a slurry tank without natural crust cover. Indirect N2O emissions due to NH3 and NOx volatilization (both in storage and manure application) and NO3 leaching (specific for manure application) were calculated considering the default emission factors and N losses from IPCC (2006). For manure, besides the amount produced for each feed (based on the period of weight gain), we also considered manure independently from feed composition, with constant characteristics with values from Tavares (2012). In this sense, the volatile solids (VS) were 0.21 kg VS animal−1 day−1, while values for nitrogen excretion are shown in Table 4.

Other emissions derived from the animal manure management system, such as ammonia, zinc and copper, were calculated based on emission factors according to Gac et al. (2006) and Tavares (2012). Avoided fertilizer was estimated using Eq. (1) and values from Table 4. Finally, for the main product, we assumed a transport distance to the slaughterhouse of 50 km with a diesel truck. LCI for the finishing swine stage are listed in Table 4.

2.3 Life cycle impact assessment

The impact assessment method was the CML-IA, using a midpoint approach to facilitate the understanding and identification of impact origins without adding subjectivity to the final values. Although the method allows the evaluation of up to 12 impact categories, we chose to assess only the global warming potential (GWP100), which identifies GHG emissions using the IPCC characterization model in kg CO2 equivalent, also known as the CF. The characterization factors were according to the fifth report of IPCC (2013), considering 30 and 28 kg of CO2 equivalent per kg of fossil and biogenic methane (CH4), respectively, and 265 kg CO2 equivalent per kg of nitrous oxide (N2O).

3 Results and discussion

For interpretation, we first analyzed the CF of 1 kg of each feed composition and subsequently emissions from only enteric fermentation and waste management (animal production), which is known in this study as emissions from livestock during the finishing period (i.e., on-farm emissions); finally, we assessed the entire system (FU analysis) with a final comparison between the scenarios.

3.1 Feed carbon footprint

Analysis of the impact from the production of 1 kg of each feed indicates that the feed applied in P13 has the highest emission of GHG, while feed P18 showed the best environmental performance, decreasing by 9.3 % or 0.06 kilograms of CO2 equivalent in comparison with P13, as shown in Fig. 2. In absolute value of CO2 equivalent, 1 kg of feed P13 emits 0.64 kg after production and delivery on the farm (Concórdia), while P15, P16 and P18 emit 0.62, 0.60 and 0.58 kg, respectively.

Analysis of feed components indicates that maize is the main hotspot due to its high abundance in all compositions (Table 1), with a contribution of 0.293 kg CO2 eq. per kg of feed for all evaluated scenarios, as it has the same proportion in all four diets. Soybean meal emits 0.097, 0.083, 0.068 and 0.054 kg CO2 eq. for P18, P16, P15 and P13, respectively, following the share of soybean meal in the compositions: 26.7 % for P18, 22.9 % for P16, 18.9 % for P15 and 14.9 % for P13. Maize starch is the third largest source of the CF among the feed ingredients, equivalent to 0.025 kg of CO2 in P16, 0.051 kg in P15 and 0.070 kg in P13; feed P18 does not contain maize starch. Synthetic amino acids and other ingredients have a CF of 0.018, 0.026, 0.039 and 0.053 kg of CO2 eq. for P18, P16, P15 and P13, respectively.

The other two inputs of feeds are non-food components. Packaging showed little contribution, with 1.3 % of CO2 eq. on average for the four diets. The same is not true for transport, which has a significant share in the CF, with 26.9 % on average per kilogram of feed. Thus, transport becomes the second largest source of GHG emissions in the feed after maize cultivation and processing (due to the large amount consumed).

Although scenario P18 uses a higher amount of soybean meal (3.8 % more than the second largest consumer of this ingredient, P16) and therefore results in higher GHG emissions, these are outweighed by the use of maize starch and SAA in the other scenarios. Eriksson et al. (2005), evaluating three different feed compositions, reported similar results, where the scenario utilizing synthetic amino acids (scenario SAA) represented slightly more GWP than the scenario with no amino acids and peas as an alternative to wheat (scenario PEA). The authors concluded that more GHG could be saved if amino acids were excluded. In our study, SAA represented an emission approximately 5.0 kg CO2 eq. kg−1 of lysine, threonine, tryptophan and valine and 3.0 kg CO2 eq. kg−1 of methionine, while in Eriksson et al. (2005), this value was 3.6 kg CO2 eq. kg−1. All values were very close despite the high level of uncertainly associated with the SAA data.

GHG emissions from grain and its derivatives are generated by fossil fuel usage in the agricultural phase and direct and indirect N2O emissions due to the urea application as a nitrogen source used in maize production and its volatilization as NH3 or NOx and N leaching as NO3 −, as noted by Prudêncio da Silva (2011) when assessing the feed used for the production of chickens in Brazil. The emission of CO2 from fossil fuel combustion contributes an average of 68.6 % of the total CF for the production of one kilogram of feed, whereas N2O is responsible for 27.0 %.

3.2 Livestock carbon footprint

Analyzing the CF of livestock during the finishing period, we highlight the greater contribution of CH4 emissions from the enteric fermentation of animals and manure storage (Fig. 3).

Enteric fermentation contributes approximately 16.2 % on average (3.27 kg of CO2 eq.) of total emissions in animal production (20.22 kg of CO2 eq.). Manure storage is responsible for the largest share in this phase, reaching 73.7 % of total livestock emissions (13.45 kg on average for the scenarios, Table 5), considering CH4 and N2O emissions. Due to the period required to stabilize the organic matter in manure (120 days), manure storage in open tanks is primarily responsible for GHG emissions in this step. Eriksson et al. (2005) reached a similar conclusion, where the hotspot, apart from feed production, was manure storage, mainly due to methane emissions.

Soil application showed lower emission, with N2O being the only source. Field emission participates with 10.1 % of the total emission in livestock or 2.04 kg CO2 eq. (Fig. 3).

Livestock emission estimates were directly dependent on the amount of time that swine were housed in growing-finishing; therefore, the feed highly influences the estimates. As shown in Table 5 and Fig. 3, the swine in P13 are fed with feed that results in a lower daily weight gain (1.02 kg—Table 3), thereby requiring more time to reach the FU (29.41 days) and resulting in higher emissions for enteric fermentation and manure management with 20.94 kg CO2 eq. The swine fed with P15, however, have an average daily gain of 1.12 kg (highest of the four scenarios), requiring only 26.79 days to achieve FU. Therefore, P15 has the best environmental performance in animal rearing (total of 19.07 kg CO2 eq. emitted).

3.3 Finishing carbon footprint

Evaluating the entire finishing step (including feed consumption, livestock emissions and other inputs) to increase in weight from 70.00 to 100.00 kg, all scenarios reveal that feed intake is the greatest contributor of CO2 eq., with an average of 74.5 % of total emissions. Similar results were obtained by other authors (Basset-Mens and van der Werf 2005; Baumgartner et al. 2008; Dalgaard 2007; Eriksson et al. 2005; Kingston et al. 2009; Kool et al. 2009; Nguyen et al. 2011), all of whom highlighted the contribution of feed and emphasized this step as the most impactful on the swine production chain. The high impact of this step is associated with grain cultivation (mainly maize) and transport, as shown in Fig. 2.

Table 5 quantifies the total GHG emissions for each scenario. The results were directly influenced by the feed performance in terms of mass gain to swine (feed conversion rate and daily weight gain). Scenarios with higher feed consumption during the period also had higher emissions. P18 requires 90.30 kg of feed to meet the FU proposed, followed by P13 with 89.70 kg. These values converted into CO2 equivalent emissions represent 52.45 and 57.46 kg for P18 and P13, respectively.

Despite the small difference in consumption between P18 and P13 (P18 consumes 0.6 kg more than P13), feed composition in P13 has 9.3 % more emissions than P18, as shown in the comparison for each feed kilogram (Fig. 2). Thus, P13 has the highest emissions associated with feed, although it is not the largest consumer among the scenarios.

The swine in P15 is the third largest feed consumer, with 82.80 kg, followed by P16, which is the scenario that requires the least amount of feed, 81.60 kg. Feed emissions associated with scenarios P15 and P16 are 51.60 and 48.92 kg of CO2 eq., respectively. Both have lower GHG emissions than P18 and P13 due to their superior feed conversion rates. The difference in GHG emissions between P15 and P16 is due to the quantity and quality of each composition. P15 has a higher consumption (more than 1.20 kg) and a higher emission per kilogram of feed, 0.024 kg CO2 eq.

Feed consumptions in P18 and P15 have nearly equal CF emissions (differing by 0.85 kg CO2 eq.). Although P18’s feed has a considerably lower CF per kg of feed than P15 (as displayed in Fig. 2), the higher consumption due to its high feed conversion rate makes both results similar when assessed over the whole system.

The second largest CF was from livestock, reaching an average of 28.7 % of the total GHG emitted and corresponding to 20.22 kg CO2 eq. CH4 emissions (enteric fermentation and manure management) are most responsible for the CF, with an average of 16.71 kg (23.7 % of total), while N2O corresponds to 5.0 % of the total (3.50 kg of CO2 eq. on average). Although N2O has a higher GWP, CH4 accounted for a much higher volume of CO2 equivalent, due to the larger quantities emitted compared with N2O in the manure management system.

Other emissions do not appear to be significant, as the sum of the impacts associated with feed and livestock achieved an average share of 96.9 % of the total. The buildings in which the animals were housed have an average CF of 0.16 kg of CO2 eq. (Table 5), <0.2 % of the total emitted. The gases are mainly related to materials such as cement and limestone, which contribute approximately 52 % of the impact of the facility. Electricity consumption in animal housing was evaluated separately from construction, accounting on average for 1.7 % of GHG emissions. The difference in performance between the scenarios is related to the time of animal rearing, which is dependent on the feed conversion rate for each diet (Table 3).

Swine transport to slaughter is responsible for an emission of 0.96 kg CO2 eq. for all scenarios. This amount corresponds to a small share of the total GHG emissions (approximately 1.4 %). Although the transport (truck) consumes diesel, the short distance and low amount of mass transported (related to FU) resulted in this small share.

The avoided impact by the application of manure as an organic fertilizer is shown as a positive impact in the results (or environmental benefits), attenuating the negative impacts on the balance. This application results in the ‘non-use’ of approximately 2.02 kg of chemical fertilizer. This non-consumption represents a positive impact of 6.5 % (average) of the total emission, as shown by the negative values of Table 5. This ‘credit’ is equivalent to 4.60 kg CO2 eq. avoided on average for the scenarios evaluated. Slight differences in avoided fertilizer between the scenarios are explained by the different amounts of manure generated in each one.

3.4 Comparative assessment

The comparison of scenarios, simulating the consumption of four different diets in the same process (finishing swine), shows that P16 has the best environmental performance with respect to GHG emissions. Although the feed in this scenario does not have the lowest CF (status attributed to feed in P18, Fig. 2) and has the second largest CF associated with manure management (Fig. 3), P16 has the lowest CO2 eq. This low amount is due to the high feed conversion rate in swine P16 that results in a lower amount of feed required to reach the 100.00 kg slaughter weight.

Swine in P15 showed similar values to those in P16. Although P15 is fed with a greater CO2 eq. emitter, the shorter amount of time required to achieve 30.00 kg (26.8 days—Table 3) influences the amount of manure managed. This difference of almost 2 days generates less waste and hence a lower emission of CO2 eq., as shown in Table 5.

Regarding the P18 scenario, although its diet composition had the lower CF per kg of feed, this scenario has the second highest emission of CO2 eq. because of its low feed efficiency (3.01—Table 3), resulting in a higher daily feed and longer period of time needed to reach the final body weight.

Swine in the P13 scenario have the greatest final emission. In addition to consuming the worst performance diet (Fig. 2), they also have the lowest daily weight gain and therefore require a longer amount of time to reach the FU.

Improvement options for feed production were evaluated by Baumgartner et al. (2008) and Eriksson et al. (2005) in studies with different diet compositions for swine production in Germany and Sweden, respectively, by replacing the soybean meal (current practice) with European grain legumes (peas and faba beans), a feed with higher levels of SAA, or grain produced on the farm (Baumgartner et al. 2008). The results showed that feeding the swine with European grain legumes or SAA was able to reduce the GHG emissions per kg of swine by 5–6 %, respectively, when compared to current scenario with the use of soybean meal (Baumgartner et al. 2008). Eriksson et al. (2005) reached similar results by replacing a feed based on soybean meal with a feed containing peas, rapeseed meal and SAA, saving approximately 7 % of the GWP. Comparing to our results, swine fed with P13 (feed with high levels of SAA) showed the highest impacts when compared to the scenario with no use of SAA and a high content of CP (P18). Nevertheless, it is important to highlight that the slight reduction in the GHG emissions in SAA (Baumgartner et al. 2008; Eriksson et al. 2005) was associated with no use of soybeans from deforested areas, while in our study, this impact was not considered because we assumed the use of grains from southern Brazil (see Prudêncio da Silva et al. 2010). If we had considered these impacts in soybean production, the CF of P18 would probably have been increased. Using grain produced on farm (Baumgartner et al. 2008) resulted in a decrease in the CF due to less grain transportation, which represented on average 26.9 % of the total GHG from feed production in our study.

Similar to our results, Meul et al. (2012), evaluating four diets for fattening swine, found that by decreasing the CP content (N-LOW) and increasing the levels of SAA, it was not possible to reduce the CO2 eq. emissions. However, the authors only evaluated the emissions per kg of feed produced. Although the diets were nutritionally equivalent with no expected consequences in the finishing stage (Meul et al. 2012), as we showed in our study, it is important to consider that the feed diet can change the performance in promoting daily weight gain, and the need for more feed consumption increases the environmental impact.

4 Conclusions

LCA can be used as a basis for evaluating various scenarios of animal production with the ability to specify paths for better environmental performance within the methodological specifications of the analysis. In this specific case study, P16 obtained a reduction in up to 11.7 % of the CF (global warming potential) compared with P13, with changes in only one of the stages of the swine life cycle (feed composition).

Due to the superior environmental performance through LCA of P16 and the technical feasibility of the diets described by Vidal et al. (2010), this scenario was shown to be the most favorable. Nevertheless, to ensure the complete viability of P16, further analysis is recommended to assess the economic factors and, especially with regard to the production and transport of feed. In addition, an uncertainty analysis should be conducted since the parameter uncertainties in LCA studies can be high. Moreover, it should further be considered that the LCA considers fractions of a day in animal rearing to estimate the net environmental impacts, while in practice farmers do not make use of such precision.

This study demonstrates that small changes in an already consolidated system, such as feed protein origin and variation of its content, may generate significant reductions in environmental impacts. Extrapolating these results, which are modeled around a FU of one swine, for annual production, for example, or values of a production region (such as the west of Santa Catarina), the reduction becomes much more significant, many times justifying a choice that otherwise would be discarded.

Due to the high impact generation related to feed production (73 % of the total emitted), this step is the main hotspot in the finishing stage of swine production and should therefore be the main focus of attention and improvement. Issues related to the efficiency and productivity of crops, feed conversion and transport of feed components become key parameters when the goal is the reduction in the CF of swine farming.

Finally, products should be analyzed in their overall context. As demonstrated in this study, the consumption of better performance feed does not necessarily mean less environmental impact because it may have inferior performance in promoting weight gain in finishing swine.

For further recommendations, we suggest conducting an LCA of Brazilian swine production considering the earlier steps of the swine supply chain, from piglet production to the end of the weaning-to-growing (25–70 kg) stage. In addition, the influence of CP content on manure characteristics and consequently on N2O emissions should be evaluated. The use of food residues for animal feed is an alternative feed strategy that has not yet been studied by Brazilian researchers.

References

Alvarenga, R. A. F., Silva Junior, V. P., & Soares, S. R. (2012). Comparison of the ecological footprint and a life cycle impact assessment method for a case study on Brazilian broiler feed production reference. Journal of Cleaner Production, 28, 25–32. doi:10.1016/j.jclepro.2011.06.023.

Associação Brasileira de Normas Técnicas (ABNT). (2009a). NBR ISO 14040: Gestão Ambiental—Avaliação do ciclo de vida—Princípios e Estrutura. Rio de Janeiro, 21 pp.

Associação Brasileira de Normas Técnicas (ABNT). (2009b). NBR ISO 14044: Gestão Ambiental—Avaliação do ciclo de vida—Requisitos e Orientações. Rio de Janeiro, 46 pp.

Baumann, H., & Tillman, A.-M. (2004). The Hitch Hiker’s guide to LCA: An orientation in life cycle assessment methodology and application (1st ed. 543 pp.). Studentlitteratur, EUA.

Baumgartner, D. U., de Baan, L., & Nemecek, T. (2008). European grain legumes—environment-friendly animal feed? Life cycle assessment of pork, chicken meat, egg and milk production. In Federal Department of Economic Affairs DEA. Zürich: Agroscope Reckenholz-Tänikon Research Station ART.

Brasil (2011). Produção Pecuária Municipal 2011. Ministério do Planejamento, Orçamento e Gestão. Instituto Brasileiro de Geografia e Estatística. Accessed February 1, 2013 from ftp://ibge.gov.br/Producao_Pecuaria/Producao_da_Pecuaria_Municipal/2011/ppm2011.pdf.

Dalgaard, R. (2007). The environmental impact of pork production from a life cycle perspective. Ph. D. Thesis, Faculty of Agricultural Sciences, University of Aarhus and Department of Development and Planning, Aalborg University, p. 143. Accessed August 28, 2011 from http://www.lcafood.dk/Afhandling36.pdf.

Dalla Costa, O. A., Amaral, A. L., Ludke, J. V., Coldebella, A., & Figueiredo, E. A. P. (2008). Desempenho, características de carcaça, qualidade da carne e condição sanitária de suínos criados nas fases de crescimento e terminação nos sistemas confinado convencional e de cama sobreposta. Ciência Rural, 38(8), 2307–2313. doi:10.1590/S0103-84782008000800033.

Elferink, E. V., Nonhebel, S., & Moll, H. C. (2008). Feeding livestock food residue and the consequences for the environmental impact of meat. Journal of Cleaner Production, 16(12), 1227–1233. doi:10.1016/j.jclepro.2007.06.008.

Eriksson, I. S., Elmquist, H., Stern, S., & Nybrant, T. (2005). Environmental system analysis of pig production e the impact of feed choice. International Journal of Life Cycle Assessment, 10(2), 143–154. doi:10.1065/lca2004.06.160.

Ferreira, R. A., de Oliveira, R. F. M., Donzele, J. L., Araújo, C. V., Silva, F. C. O., Fontes, D. O., & Saraiva, E. P. (2005). Redução do nível de proteína bruta e suplementação de aminoácidos em rações para suínos machos castrados mantidos em ambiente termoneutro dos 30 aos 60 kg. Revista Brasileira de Zootecnia, 34(2), 548–556. doi:10.1590/S1516-35982005000200024.

Gac, A., Béline, T., & Bioteau, T. (2006). Flux de gaz à effet de serre (CH4, N2O) et d’ammoniac (NH3) liés à la gestion des déjections animales: Synthèse bibliographique et élaboration d’une base de données. Rapport final. Département Milieux aquatiques, Unité de Recherche, Gestion environnementale et traitement biologique des déchets. Rennes.

Hörndahl, T. (2008). Energy use in farm buildings: A study of 16 farms with diferent enterprises. Revised and translated second edition. Swedish University of Agricultural Sciences, Faculty of Landscape Planning, Horticulture and Agricultural Science. Report, 8.

van der Basset-Mens, C., & Werf, H. M. G. (2005). Scenario-based environmental assessment of farming systems: The case of pig production in France. Agriculture, Ecosystems and Environment, 105(1–2), 127–144. doi:10.1016/j.agee.2004.05.007.

Intergovernmental Panel on Climate Change, IPCC. (2006). IPCC Guidelines for National Greenhouse Gas Inventories: Volume 4, Agriculture, Forestry and Other Land Use. Chapter 10, In Dong, H., Mangino, J., Mcallister, T. A., Hatfield, J. L., Johnson, D. E., Lassey, K. R., de Lima, M. A., Romanovskaya, A. Emissions from Livestock and Manure Management. Accessed September 9, 2011 from www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/.pdf.

IPCC. (2013). Climate change 2013: the physical science basis. In T. F. Stocker, D. Qin, G.-K. Plattner, M. Tignor, S. K. Allen, J. Boschung, A. Nauels, Y. Xia, V. Bex, & P. M. Midgley (Eds.), Contribution of working group I to the fifth assessment report of the Intergovernmental Panel on Climate Change (p. 1535). Cambridge: Cambridge University Press.

Kingston, C., Fry, J. M., & Aumonier, S. (2009). Life cycle assessment of Pork. Final report, environmental resources management, agriculture and horticulture development board meat services: AHDBMS.

Kool, A., Blonk, H., Ponsioen, T., Sukkel, W., Vermeer, H., de Vries, J., et al. (2009). Carbon footprints of conventional and organic pork: Assessment of typical production systems in the Netherlands, Denmark, England and Germany. Gouda: Blonk Milieu Advies BV.

Meul, M., Ginneberge, C., van Middelaar, C. E., de Boer, I. J. M., Fremaut, D., & Haesaert, G. (2012). Carbon footprint of five pig diets using three land use change accounting methods. Livestock Science, 149, 215–223. doi:10.1016/j.livsci.2012.07.012.

Moreira, I., Mourinho, F. L., Carvalho, P. L. O., Paiano, D., Piano, L. M., & Kuroda, I. S, Jr. (2009). Avaliação nutricional da casca de soja com ou sem complexo enzimático na alimentação de leitões na fase inicial. Revista Brasileira de Zootecnia, 38(12), 2408–2416. doi:10.1590/S1516-35982009001200017.

Nguyen, T. T. H., Bouvarel, I., Ponchant, P., & van der Werf, H. M. G. (2012). Using environmental constraints to formulate low-impact poultry feeds. Journal of Cleaner Production, 28, 215–224. doi:10.1016/j.jclepro.2011.06.029.

Nguyen, T. L. T., Hermansen, J. E., & Mogensen, L. (2011). Environmental assessment of Danish pork. Aarhus University, Department of Agroecology. Denmark, Report no 103, April. Accessed December 10, 2011 from www.agrsci.au.dk.

Oliveira, P. A. V. (2004). Tecnologias para o manejo de resíduos na produção de suínos: Manual de boas práticas. Programa Nacional do Meio Ambiente—PNMA II (p. 109). Concórdia: Embrapa Suínos e Aves.

Oliveira, V., Fialho, E. T., Lima, J. A. F., Freitas, R. T. F., de Sousa, R. V., & Bertechini, A. G. (2006). Desempenho e composição corporal de suínos alimentados com rações com baixos teores de proteína bruta. Pesquisa Agropecuária Brasileira, 41(12), 1775–1780. doi:10.1590/S0100-204X2006001200012.

Orlando, U. A. D., Oliveira, R. F. M., de Donzele, J. L., Ferreira, R. A., & Vaz, R. G. M. V. (2007). Níveis de proteína bruta e suplementação de aminoácidos em dietas para leitoas mantidas em ambiente de alta temperatura dos 60 aos 100 kg. Revista Brasileira de Zootecnia, 36(4), 1069–1075. doi:10.1590/S1516-35982007000500012.

Orlando, U. A. D., Oliveira, R. F. M., de Donzele, J. L., Lopes, D. C., Silva, F. C. O., & Generoso, R. A. R. (2001). Níveis de proteína bruta para leitoas dos 30 aos 60 kg mantidas em ambientes de alta temperatura (31 °C). Revista Brasileira de Zootecnia, 30(5), 1536–1543. doi:10.1590/S1516-35982001000600022.

Prudêncio da Silva Jr, V. (2011). Effects of intensity and scale of production on environmental impacts of poultry meat production chains. LCA of French and Brazilian poultry production scenarios. Tese (Doutorado)—Universidade Federal de Santa Catarina, Programa de Pós Graduação em Engenharia Ambiental, Florianópolis. Accessed February 5, 2012 from http://www.ciclodevida.ufsc.br/publicacoes.php.

Prudêncio da Silva, V, Jr, van der Werf, H. M. G., Soares, S. R., & Spies, A. (2010). Variability in environmental impacts of Brazilian soybean according to crop production and transport scenarios. Journal of Environmental Management, 91(9), 1831–1839. doi:10.1016/j.jenvman.2010.04.001.

Sociedade Brasileira de Ciência do Solo, SBCS. (2004). Manual de adubação e de calagem para os Estados do Rio Grande do Sul e de Santa Catarina (10th ed., p. 400). Porto Alegre: Sociedade Brasileira de Ciência do Solo. Comissão de Química e Fertilidade do Solo.

Spies, A. (2003). The sustainability of the pig and poultry industries in Santa Catarina, Brazil: A framework for change. A Thesis Submitted for the Degree of Doctor of Philosophy. School of Natural and Rural Systems Management, University of Queensland, Brisbane.

Tavares, J. M. R. (2012). Medição do consumo de água e da produção de dejetos na suinocultura. Dissertação (Mestrado), Universidade Federal de Santa Catarina, Programa de Pós Graduação em Engenharia Ambiental, Florianópolis, p. 241.

United States Department of Agriculture, USDA. (2013). Foreign Agricultural Service. Livestock and poultry: World markets and trade. 2014: Record Global Meat Trade, Accessed March 19, 2014 from http://apps.fas.usda.gov/psdonline/circulars/livestock_poultry.pdf.

van der Werf, H. M. G., & Petit, J. (2002). Evaluation of the environmental impact of agriculture at the farm level: a comparison and analysis of 12 indicator-based methods. Agriculture, Ecosystems & Environment, 93(1–3), 131–145. doi:10.1016/S0167-8809(01)00354-1.

Vidal, T. Z. B., Fontes, D. O., Silva, F. C. O., Vasconcellos, C. H. F., Silva, M. A., Kill, J. L., & Souza, L. P. O. (2010). Efeito da redução da proteína bruta e da suplementação de aminoácidos para suínos machos castrados, dos 70 aos 100 kg. Arquivo Brasileiro de Medicina Veterinária e Zootécnica, 62(4), 914–920. doi:10.1590/S0102-09352010000400022.

Wenzel, H., Hauschild, M., & Alting, L. (2001). Environmental assessment of products: Volume 1: Methodology, tools and case studies in product development (3rd ed., p. 539). Massachusetts: Kluwer Academic Publishers.

Williams, A. G., Audsley, E., & Sandars, D. L. (2006) Determining the environmental burdens and resource use in the production of agricultural and horticultural commodities. Main Report. Defra Research Project IS0205. Bedford: Cranfield University and Defra.www.silsoe.cranfield.ac.uk, and www.defra.gov.uk.

Acknowledgments

We would like to thank the National Council of Technological and Scientific Development (CNPq) for the financial support and to the anonymous reviewers for the important suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cherubini, E., Zanghelini, G.M., Tavares, J.M.R. et al. The finishing stage in swine production: influences of feed composition on carbon footprint. Environ Dev Sustain 17, 1313–1328 (2015). https://doi.org/10.1007/s10668-014-9607-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-014-9607-9