Abstract

Life cycle assessment (LCA) had proven to be an appropriate assessment tool for analysis of agro-ecosystems by identifying, quantifying, and evaluating the resources consumed and released into the environment. In order to assess the relevant environmental impacts of rice agro-ecosystems due to a specific process, using LCA method, two factors concerned with resource utilization and contaminant emissions were calculated in north of Iran during 2016 and 2017. All the management practices/inputs were monitored and recorded with the help of local experts without interference in farmer’s practices. After preliminary evaluation, 100 paddy fields were selected in three planting systems (low input, conventional, and high input) which were predicted in two planting methods (semi-mechanized and traditional) in small, medium, and large farm size levels. Functional unit was considered as one ton paddy yield. The finding revealed that in both regions, all the impact categories and environmental pollutant were almost same and farmer’s management practices are close to each other. Also, climate change (CC) in Amol and Rasht regions was 277.21 and 275.79 kg CO2 eq., respectively. The most CC, global warming potential (GWP 100a), and cumulative energy demand (CED) in both regions were observed in high-input system for semi-mechanized method. Furthermore, the result for the impact categories of terrestrial acidification (TA), freshwater eutrophication (FE), marine eutrophication (ME), agricultural land occupation (ALO), water depletion (WD), metal depletion (MD), and fossil depletion (FD) was similar to the CC, GWP, and CED where the highest amounts in both regions statistically went to high-input system, traditional planting method, and small farms. Moreover, in both regions, high-input and conventional systems emitted higher heavy metals than low-input system. Furthermore, the most heavy metal emission in the air was achieved in small farm, and medium farm got the next rank. Additionally, the high consumption of chemical inputs, such as fossil fuels and fertilizers, in the high-input and conventional systems led to an increase of environmental pollutant in comparison with low-input systems. Therefore, to increase the sustainability of agro-ecosystems, as well as to reduce the environmental impacts of pollutant, reforming the pattern of chemical input consumption and reducing the use of non-renewable energy sources are essential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, agricultural parts play a major role in environmental pollution and knowledge regarding reducing the input utilization in such systems can help us to decrease the limited input resources and the consequent greenhouse gas (GHG) emissions and environmental impacts (Dalgaard et al. 2001). In addition, agricultural parts, especially rice production, are considered as the main cause of GHG emission and environmental pollution in developing countries (Smith et al. 2007). Hence, it is of great necessity to evaluate the life cycle of rice and its products to determine energy consumption as well as GHG emissions in rice production in order to reduce environmental pollutant. Therefore, right decision-making process is one of the most important options for good management practice of paddy fields by considering conventional planting system and other opportunities. Moreover, environmental impacts caused by rice cultivation are the most important factors for selecting the best paddy field systems in long-term decisions (Nabavi-Pelesaraei et al. 2018).

Rice is known as staple food source of the world, especially in Iran (Pishgar-Komleh et al. 2011). The worldwide area under rice cultivation has increased from 145 to over 161.1 million ha from 1995 to 2017 (FAO 2018). According to the FAO, the global paddy and rice production were 742 and 492.2 million tons in 2014, respectively (FAO 2016). Rice production in Iran has increased, and it equals 2 × 106 tons from 550 × 103 ha in 2014 (FAO 2016). About 75% of the paddy fields are located in the north of Iran (consisting of Guilan and Mazandaran provinces) (Ministry of Jihad-e-Agriculture of Iran 2016). Thus, rice production plays a key role in food security in Iran, but concerns regarding GHG emission and environmental pollutant related to rice cultivation are avoidable (Zhang et al. 2006). Therefore, efforts to identify pathways to mitigate environmental risk of rice production are necessary.

Environmental assessment is one of the accepted ways for achieving sustainable agricultural goals. Hence, life cycle assessment (LCA) is an appropriate way to study the environmental impact of a crop plant producing in its whole life cycle in production systems (Iriarte et al. 2010). LCA, used in crop-planting systems, is an attempt to estimate all GHG emission and environmental assessment of the production chain of life cycle (Goossens et al. 2017; ISO 2006). Moreover, LCA is considered as the best method to obtain an appropriate way to quantify environmental impact related to different planting systems (Biswas et al. 2008; Cherubini 2010).

LCA has been used as a method to assess environmental profile of agricultural products, such as wheat (Brentrup et al. 2004), sugar beet (Tzilivakis et al. 2005), and rice (Hokazono and Hayashi 2012; Roy et al. 2005; Roy et al. 2007). Various studies have been found in this regard. Nabavi-Pelesaraei et al. (2018) assessed 240 rice production farms in Guilan province, Iran. LCA finding demonstrated that rice production leads to 1166.09 kg CO2 eq. emission per ton. They found that rice production is hotspot in terms of energy consumption, global warming, acidification, and eutrophication impact categories. Mohammadi et al. (2015) assessed 82 paddy fields for spring and summer growing seasons in northern Iran by LCA method. They announced that rice cultivation in spring had lower environmental impact in terms of global warming, acidification, eutrophication, non-renewable energy demand, and water depletion.

Yodkhum et al. (2017), by using LCA methodology for organic rice production in Thailand, reported that GHG emission equals 0.58 kg CO2 eq. per kg of paddy which the main share was related to farm emission (83% of total GHG emission), followed by land preparation (9%), harvesting (5%), and other stages (3%). Moreover, He et al. (2018) showed that organic rice production system had lower environmental impact compared to conventional system in sub-tropical China throughout the life cycle. They announced that chemical fertilizer and pesticide consumption were the main factors causing higher non-renewable energy depletion, GWP, soil toxicity, eutrophication potential, land occupation, acidification potential, water depletion, human toxicity potential, and aquatic toxicity potential in organic rice production system.

Moreover, literature interview indicated that there are numerous studies about the environmental assessment for rice production in countries, such as USA (Linquist et al. 2012), Japan (Koga and Tajima 2011; Hokazono and Hayashi 2012), China (Zhang et al. 2010), Italy (Blengini and Busto 2009), and Taiwan (Yang et al. 2009). But, in Iran, very little attention has been paid to the life cycle assessment of rice production systems in the Guilan province (Khoshnevisan et al. 2014; Mohammadi et al. 2015; Nabavi-Pelesaraei et al. 2018; Nabavi-Pelesaraei et al. 2017). However, to the best of our knowledge, LCA has not been applied so far to specifically assess the environmental impact of rice production systems and planting methods in different paddy field size levels in Iran, especially compared to the highest rice cultivation area in the north of Iran.

Paddy fields are one of the major sources of environmental impact. Iran has about 550,000 ha of rice cultivation area, equivalent to 0.4% of the world’s rice cultivation and production (Ministry of Jihad-e-Agriculture of Iran 2016). Most of them (about 75%) are located in the Mazandaran and Guilan provinces. Furthermore, paddy field area in the Amol and Rasht regions is about 38,000 and 62,000 ha, equivalent to 16 and 26% of the total paddy field area in Mazandaran and Guilan provinces (Ministry of Jihad-e-Agriculture of Iran 2016). Hence, Amol and Rasht regions have a high share of rice production area in Iran, which requires optimization of input consumption and identification of the best production systems in order to reduce the environmental impacts. Moreover, in recent years, agricultural systems, especially rice cultivation, have undergone major changes due to the application of high level of chemical inputs, machinery, and non-renewable input resources. The occurrence of these changes has led to variance in the environmental pollution in the agricultural sector and its strong dependence on high input consumption in the farming systems. Furthermore, it is required to compare the state of all input consumptions and the life cycle assessment for rice production systems in terms of input optimization. Therefore, this study was conducted with the aim of carrying out the life cycle assessment of rice production systems in different size levels in the north of Iran.

Materials and methods

Description of the region

Mazandaran and Guilan provinces are located in the northern part of the Alborz Mountains range and south of the Caspian Sea in northern Iran, west of the Mediterranean. This survey was conducted in the Amol region (in the western part of the Mazandaran province) and Rasht region (in the central part of the Guilan province) during 2016 and 2017. Rasht region is geographically situated at 37°, 30′ to 37°, 27′ N latitude and 49°, 27′ to 49°, 55′ E longitude. In addition, the Amol region is geographically situated at 26°, 14′ to 26°, 29′ N latitude and 52°, 21′ to 52°, 38′ E longitude.

According to the climatic parameters, and topography of the region, these provinces are divided into two climates which included the Caspian humid weather and the mountain mild weather. This research covers the Caspian humid climates. Local climate data during the rice growing period were collected daily from the synoptic meteorological station nearest to the paddy fields. Climatic parameters of the survey regions are presented in Table 1. Srad_calc and PP_calc programs can also be downloaded from “https://sites.google.com/site/cropmodeling/home”. Harvest period of rice in the north of Iran is usually during September, after which clover, canola, or wheat is sown in a double-cropping system. Some farmers, after harvesting their rice product, transplant rice again or manage the residue for ratooning harvest.

Description of rice production systems and data collection

The paddy fields were selected with the help of local experts of the Rice Research Institute of Iran (RRII) to ensure that they are diverse, which is necessary for the success of the analysis. All the management practices/inputs (variables) were monitored and recorded without interference in the farmer’s practices. After the preliminary evaluation, 100 paddy fields were selected in each region. After recording the data, in each region, 100 paddy fields were converted into three planting systems based on agricultural management practices and input consumption (low-input, conventional, and high-input systems). Each planting system was converted into two planting methods (traditional and semi-mechanized). Paddy fields were classified into three size categories as small (< 0.5 ha), medium (between 0.5 and 1 ha), and large (> 1 ha). More detail and definition of selected planting systems are presented in Table 2.

In semi-mechanized planting method, the agricultural practices (puddling, irrigation regimes, fertilization, weed control, and plant protection) were carried out traditionally by farmers and the planting operations (using seedling box and mechanized transplanting) and harvesting practice (by combine and harvester machine) were mechanized. In the traditional planting methods, all the agricultural operations/practices except harvesting were carried out by farmers without machine. All the paddy field cases pertain to local rice cultivars.

The surveyed paddy fields were identified and/or selected according to the Cochran formula, which tried to cover all major production methods in each region. Then, paddy field features and additional information were recorded in the farm observations during monitoring. For data collection, first, agricultural practices were separated into seven parts, including puddling, planting, fertilization, plant protection, weed control, irrigation, and harvesting. After that, with the start of each practice, according to the temperature changes, the variety of production methods and the different amounts of inputs by the farmers were recorded. Some important management measures were seeding rate, seedling age, frequency, and the amount of nitrogen fertilizer, the amount of phosphorus (P2O5) and potassium (K2O) fertilizers, irrigation, and the amounts of herbicides, fungicides, and insecticides. At the end of the growing season, the actual harvested yield amount was registered.

In the paddy fields of Amol and Rasht, urea (46% N), triple super phosphate (48% P2O5), sulfate potassium (48% K2O), complete macro fertilizer (15% N, 8% P2O5, and 15% K2O) and foliar application of complete macronutrient and micronutrients were utilized. In addition, several pesticides, such as insecticide, fungicide, and herbicide, were used.

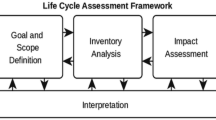

LCA methodology

LCA is a technique used to assess environmental impacts associated with all the stages of a product’s life from raw material extraction through material processing, manufacturing, transportation, use, and disposal or recycling. In order to assess the relevant environmental impacts of rice agro-ecosystems due to a specific process, using the LCA method, two factors concerned with resource utilization and contaminant emissions were calculated. This was based on this fact that LCA is a target process to investigate the environmental capacity of production, energy used in different processes, resource consumption, and residuals in the environment (Roy et al. 2009). This study was conducted using the LCA methodology in compliance with ISO14044 (ISO 2006; Brentrup et al. 2004). In this regard, four phases which are goal and scope definition, inventory analysis, impact assessment, and interpretation, were designed to assess the life cycle index (Fig. 1).

Goal and scope

The goal of this LCA study was to evaluate and compare the environmental impact of producing transgenic and non-transgenic rice genotypes. The functional unit was one ton of paddy (with moisture content of 12%). Considering this fact that straw is a co-product of paddy farms, the economic allocation of the environmental impacts was done (Rebitzer et al. 2004). Based on the economic allocation, about 90 and 10% of the environmental impacts of experimental farms belong to paddy and straw, respectively.

Life cycle inventory

The system was investigated in the paddy field systems with main functions to produce rice. In the subsequent life cycle inventory (LCI), the resource utilization (inputs) and emissions (outputs) connected to the system are compiled using the Ecoinvent 3.1 database. To make the various inputs and outputs comparable, it is necessary to relate these data to a common functional unit, which shall represent the main function of the system (Brentrup et al. 2004). Therefore, the functional unit was considered as one ton of paddy yield. Then, all inputs (resources) and outputs (emissions) per ton of paddy yield were quantified.

Items that have been considered include (a) infrastructures, comprising construction, maintenance, and depreciation of machinery and buildings (shelters for machinery); (b) all agricultural operations, including bed preparation, cultivation, fertilization, protection, irrigation, harvest, transportation supply, and consumption of fuel for the operations; (c) production of fertilizers and pesticides; and (d) transportation of all inputs.

Life cycle impact assessment

The life cycle impact assessment (LCIA) aims to evaluate the environmental impacts based on the inventory analysis within the framework of the goal and scope of the study. The third step (LCIA) must be done in order to evaluate the inventory data. Within the LCIA, the different inputs and outputs are summarized into environmental effect (Brentrup et al. 2004). Based on ISO instruction, the impacts included contamination emission to atmosphere, soil, and water (Finkbeiner et al. 2006). In this step, the inventory results are assigned into different impact categories. Impact assessment consists of characterization, normalization, and weighting.

Characterization is the first step of LCIA. Characterization is the assessment of environmental impacts of each inventory flow (e.g., modeling the potential impact of carbon dioxide and methane on global warming). Characterization provides the possibility to compare the LCI results within each category. For instance, carbon dioxide (CO2), nitrous oxide (N2O), and methane (CH4) have different environmental impacts on global warming. The global warming potential of CO2, N2O, and CH4 is 1, 265, and 28 kg CO2-eq, respectively (IPCC 2013). There are different classifications for impact categories due to the methods used. The most important impact categories in this study were global warming potential, terrestrial acidification, freshwater eutrophication, marine eutrophication, water depletion, and cumulative non-renewable energy demand. Emissions of gases with specific radiative characteristics, like CO2 and N2O, lead to an unnatural warming to the earth’s surface, which in turn will cause global and regional climatic change. This environmental impact is commonly described as “global warming.” The term “climate change” indicates that the possible consequences of global warming concern more elements of the global climate than only the temperature (Brentrup et al. 2004). Moreover, to carryout in-depth analysis, the amount of heavy metal emission in the air (Pb, Cd, Zn, and Hg) and water (Cr, Zn, Cu, Cd, Hg, Pb, Ni) is reported separately. For each impact category, corresponding characterization factors were used based on IPCC (2013) GWP 100a, cumulative energy demand, ReCiPe 2016, and Ecopoint 97 methods in SimaPro8.2.3 software.

Interpretation

One of the aims of LCA is providing comprehensive information for the decision makers. To achieve this goal, interpretation of the LCA results of a study plays an important role. In this step, the LCA results of different systems are evaluated and compared.

Results

Documenting process of rice production systems

Data analysis of different production systems, including low-input, conventional, and high-input, in both planting methods which included traditional and semi-mechanized with three paddy field size levels (small, medium, and large) in Amol and Rasht regions is described in this part.

According to the finding, the cultivation area of the three planting systems in both regions was almost the same (from 30 to 33%), but a significant difference was observed in the type of inputs used and outputs between the three planting systems. Moreover, agricultural practices and input consumption and outputs were different in the three paddy field size groups, but, in planting methods, labor, machinery, and diesel consumption varied (mean data not shown). Based on the findings, it can be stated that farmers in both regions consider more economic efficiency in rice production and pay less attention to environmental sustainability and energy efficiency. All input consumption in the high-input system was higher, and conventional system was ranked second. The low-input system shows lower input consumption and outputs. Moreover, paddy yield and straw yield in the high-input system were more than the two other systems, and the low-input system was ranked third (mean data not shown). Production systems related to the semi-mechanized planting method in both regions showed lower consumption of labor and seed than the traditional method, but diesel and machinery utilization in the semi-mechanized method was higher than the traditional method. Furthermore, in both regions, input consumption and outputs for small farms were higher than the medium- and large-size levels (mean data not shown). The most fuel consumed and the use of machinery and implements were reported in the semi-mechanized planting in different farm size levels, while the lowest fuel consumption and the use of implements and machinery were reported in the traditional planting method for the three farm size levels. In contrast to the fuel consumption and application of machinery, seed consumption and human labor in all planting systems of traditional method were higher than all the planting systems of the semi-mechanized method. In total, based on the average data of the two regions, it was concluded that farmers in the Rasht region consumed non-significantly higher input and achieved slightly higher output (mean data not shown).

Interpretation of LCA results

Data analyses of LCA carried out by ReCiPe method for both regions are presented in Tables 3, 4, and 5. Figures 2 to 5 displayed non-renewable cumulative energy demand (CED) and GWP 100a which were investigated by CED and IPCC GWP 100a, respectively. Moreover, Fig. 5 demonstrated ozone layer depletion impact category which was calculated by Ecopoint 97. Furthermore, heavy metal emission in the air (Pb, Cd, Zn, Hg) and water (Cr, Zn, Cu, Cd, Hg, Pb, Ni) was calculated by Ecopoint 97 which was demonstrated in Tables 6, 7, and 8. In the ReCiPe method, we focus on the eight impact categories which included climate change (CC), terrestrial acidification (TA), freshwater eutrophication (FE), marine eutrophication (ME), agricultural land occupation (ALO), water depletion (WD), metal depletion (MD), and fossil depletion (FD).

Contribution of non-renewable cumulative energy demand (CED) of three rice production systems in two planting methods in the Amol (a) and Rasht (b) regions. LI, C, and HI are low-input, conventional, and high-input planting systems, respectively. T and M are traditional and semi-mechanized planting methods, respectively

Cumulative non-renewable energy demand

The results of rice production system in different farm size ranking based on CED demonstrated that the most CED consumption in both regions was observed in the high-input system for the semi-mechanized method. In terms of CED utilization, in both regions, the high-input system with traditional planting method and the conventional system with both methods got ranked next. The least CED consumption was observed in the low-input system with traditional and semi-mechanized method, respectively. In addition, in the Amol region, small farms showed the highest CED utilization, after that, the medium and large farms ranked next with 6.74 and 16.11% differences, respectiely. Moreover, in the Rasht region, small farms with 12.23 and 21.76% higher CED consumption ranked first compared to medium and large farms, respectively (Fig. 2).

Furthermore, the results of different input shares on CED demonstrated that in both regions, diesel, nitrogen, and machinery utilization in three farm sizes have the highest share of CED consumption. After that, pesticides, potassium, and electricity got ranked next. Seed usage, phosphorous, and other inputs had the least share on CED utilization (Fig. 3).

Climate change

Climate change impact category was estimated based on the mass emission of N2O, CH4, and CO2. These emissions are transferred into kg CO2 eq. In the Amol and Rasht regions, the average CC was 277.21 and 275.79 kg CO2 eq. (Tables 3 and 4).

The finding revealed that CC in both regions is almost the same and farmer’s management practices are close to each other. In both regions, the highest CC was estimated in the high-input system and conventional system was ranked next. The low-input system showed the lowest CC in both regions. In fact, CC in the Amol and Rasht regions in the high-input system was 6.59 and 2.62% higher than the conventional system. Moreover, this impact category in both regions for the high-input system was 24.30 and 22.89% higher than the low-input system (Table 5). This impact category in both regions for traditional planting method was slightly more than the semi-mechanized method that equals 2.09 and 7.76% (Table 5). Furthermore, in both regions, CC in small farms was higher than medium and large farms, in which medium farm ranked second and large farm ranked third. In addition, in the Amol region, CC in small farms was 7.21 and 16.99% higher than the medium and large farms. Moreover, in the Rasht region, this impact category for small farms was 12.05 and 21.40% higher than the medium and large farms, respectively (Table 5).

IPCC GWP 100a

In relation to CC impact category, the results of Fig. 4 show that GWP 100a in both regions for the high-input system was higher than the two other systems, in which the conventional system ranked second and the low-input system ranked last. In both regions, GWP 100a for the two planting methods in different systems and farm size was changeable (Fig. 4). Moreover, in terms of input impact on the GWP 100a in the two regions, it was observed that machinery and nitrogen consumption had the highest share. Furthermore, seed, potassium, and electricity ranked next, respectively. Pesticide consumption and diesel ranked next. The lowest share for GWP belongs to inputs including zinc and sulfur consumption (Fig. 5). The result of GWP 100a was almost the same with CC impact category in different planting systems and farm sizes.

Terrestrial acidification

The result for the impact category of terrestrial acidification was similar to those for climate change where the highest amounts in both regions statistically went to high-input system, traditional planting method, and small farms (Tables 3, 4 and 5). The average TA in the Amol and Rasht regions was equal to 1.55 kg SO2 eq. (Tables 3 and 4). Based on the results, TA in the high-input system for the Amol and Rasht regions was 10.76 and 4.94% higher than the conventional system, as well as, TA of the high-input system was 32.58 and 29.77% higher than the low-input system (Table 5). Moreover, in both regions, TA for planting method was not statistically significant, in which the traditional method was slightly more than the semi-mechanized method.

In terms of farm size level, TA in small farms was statistically higher than the two other farm size levels, in which the medium farm ranked next and the large farm ranked third. TA for small farms was 7.05 and 12.5% higher than the medium farm and was 17.61 and 21.28%, respectively (Table 5).

Eutrophication

As shown in Tables 3 and 4, the average FE in the Amol and Rasht regions was 0.0406 and 0.0958 kg P eq. Moreover, the impact category of ME in the Amol and Rasht regions was equal to 0.272 and 0.286 kg N eq. The impact category of FE in the low-input system was significantly higher than the conventional and high-input systems in the Amol region, but in the Rasht region, this result was vice versa. Both impact categories in each region for the traditional method were slightly more than the semi-mechanized method. Based on the finding for farm size results, FE and ME impact categories in both regions for small farms were statistically higher than medium and large farms. In the Amol region, FE and ME for small farms were 37.63 and 8.89% higher than the medium farm size, but FE and ME in small farms compared to large farms showed 52.84 and 24.67% greater amount (Table 5).

Agricultural land occupation

As shown in Tables 3 and 4, the average ALO in the Amol and Rasht regions was 39.40 and 39.20 m2a. This result showed that ALO in the two regions is almost the same. But, in terms of planting systems, finding showed that the most amount of ALO in both regions belongs to the high-input system, and the conventional system ranked next, and the low-input system ranked third. ALO amount in the high-input and conventional systems was statistically same, but, in the low-input system, it was significantly lower than the two other systems. ALO of small farms in both regions was 26.51 and 19.12% higher than the large farms (Table 5).

Water depletion

Regarding the net impact category, the findings of the research showed that the average amount of water depletion in the Amol and Rasht regions was 17.1 m3 (Tables 3 and 4). In the planting system level, the maximum WD for both regions was achieved in the conventional and high-input systems and the low-input system ranked next (Table 5). In both regions, WD of traditional method was statistically 34.91 and 41.91%, respectively. Furthermore, in both regions, WD of small and medium farms was highest with statistically same ranked, but the least WD in both regions belongs to large farms with 15.27 and 15.67 m3 (Table 5).

Metal and fossil depletion

According to the results of Tables 3 and 4, the average metal depletion in the Amol and Rasht regions equals 49.08 and 48.13 kg Fe eq.; moreover, fossil depletion in these regions equals 99.13 and 102.41 kg oil eq., respectively. In terms of MD and FD impact categories, the low-input system showed the lowest amount and the conventional and high-input systems got the next rank. In the Amol region, MD and FD for the semi-mechanized method were slightly higher than the traditional method, but, in the Rasht region, these impact categories were the same in the two planting methods. In the Amol region, MD for the semi-mechanized method was 9.39% higher than the traditional method, but, in the Rasht region, this impact category was not significant statistically. Moreover, FD in both regions for both methods was almost the same. In terms of farm size, in both regions, the most MD and FD were observed in small farms, and medium farms got ranked next. The least MD and FD were obtained in large farms in both regions (Table 5).

Ozone layer depletion

Regarding the net impact category, the findings of the research showed that the OLD in both regions for the high-input system was more than the conventional and low-input systems, in which the low-input system ranked last. Moreover, in both regions, OLD of the semi-mechanized method was slightly higher than the traditional method. In terms of farm size effect, small farms showed the highest OLD, medium farm size ranked second, and large farms ranked third (Fig. 6). Furthermore, in both regions, diesel and nitrogen had a maximum share of OLD impact category. Machinery ranked third for OLD. Moreover, pesticides and potassium consumption ranked next. After these inputs, seed, phosphorous, and zinc consumption showed fewer OLD. The share of other inputs was insignificant (data not shown).

Contribution of ozone layer depletion (OLD) of three rice production systems in two planting methods. LTS, LTM, LTL, LMS, LMM, and LML are low-input system with small, medium, and large farm sizes in traditional and semi-mechanized methods. CTS, CTM, CTL, CMS, CMM, and CML are conventional system with small, medium, and large farm sizes in traditional and semi-mechanized methods. HTS, HTM, HTL, HMS, HMM, and HML are high-input system with small, medium, and large farm sizes in traditional and semi-mechanized methods

Heavy metal emission in the air

The results of heavy metal emission in the air (Pb, Cd, Zn, and Hg) are presented in Tables 6, 7 and 8.

According to the findings, the average heavy metal emission in the air in the two regions was almost the same statistically (Tables 6 and 7). The finding about heavy metal emission in the air demonstrated that in both regions, high-input and conventional systems emitted higher than the low-input system. But, in both regions, this emission was changeable in semi-mechanized and traditional methods. Furthermore, in both regions, the most heavy metal emission in the air was achieved in small farms; medium farms got the next rank. The least heavy metal emission was achieved in large farms (Table 8).

Heavy metal emission in water

Regarding the heavy metal emission in water (Cr, Zn, Cu, Cd, Hg, Pb, and Ni), the results of Tables 6 and 7 show that the amounts of Cr emitted in the Amol and Rasht regions were 0.82 and 2.01 g; moreover, Zn emission in these regions was 11.64 and 19.88 g. Cu emission for both regions was almost the same, but Cd and Ni emission in the Amol region was more than the Rasht region; however, Hg and Pb emission in the Rasht region was higher than the Amol region (Tables 6 and 7). The results showed that Cr emission in the Amol region for the low-input system was higher than the two other methods, but in the Rasht region, Cr emission in the high-input system was higher than the conventional and low-input systems. Moreover, Cr emission in both regions for the traditional method was slightly higher than the semi-mechanized system. Furthermore, in both regions, small farms emitted less Cr than the medium and large farms (Table 8). In terms of Zn emission in water, in the Amol region, conventional system displayed lower amount than the other systems, but, in the Rasht region, low-input system showed less emission compared to the other systems. Moreover, small farms in both regions showed lower Zn emission than medium and large farms. Cu emission in both regions for high-input system was higher than the conventional and low-input systems, in which the low-input ranked last. Also, small farms in both regions showed higher Cu emission than the other farms. In both regions, Cd, Hg, and Ni emission for the high-input system was higher than the other systems, in which the conventional system ranked second and the low-input ranked third, but Pb emission in the low-input and high-input systems was almost the same and higher than the conventional system (Table 8). Furthermore, the most Cd, Hg, Pb, and Ni emission in both regions was observed for small farms, as medium and large farms ranked next, respectively (Table 8).

Discussion

The input consumption in different farm size levels in both regions demonstrated that input usage in large paddy fields was significantly higher than the medium and small paddy fields due to better management in input utilization and agricultural practices. The results were similar to Shahin et al. (2008) and Sefeedpari et al. (2013) studies which found that large farms in wheat production have lower input consumption and more productivity. Pishgar-Komleh et al. (2011), by investigating energy and economic analysis of rice production under different farm levels in the Guilan province of Iran, demonstrated that fertilizer consumption and output in farm size larger than 1 ha were more than farms lower than 1 ha, but other input consumptions in farm size lower than 1 ha were higher than farm size with more than 1 ha. Nassiri and Singh (2009) announced that larger farms required the use of proper machine size and suitable tractor by considering farm size. In total, in the researchers’ opinion, in larger paddy fields, improved management by farmers was easier; however, output in small paddy field was slightly higher but not statistically significant. Other researchers confirm our finding about the input–output in different farm size levels (Pishgar-Komleh et al. 2011, 2012; Chauhan et al. 2006; Iqbal 2008).

The reason for higher energy consumption and global warming in the high-input system and small farms can be attributed to their high dependence on inputs and higher energy consumption for production, and these inputs are used without any regard to environmental issues. In fact, the correct management of the farm in the large farms and the higher input consumption in the other production systems were responsible for the obtained result. This result demonstrated that the semi-mechanized method had a more favorable effect on the energy balance in the paddy field ecosystems. Moreover, the use of energy resources with more efficiency by optimizing the use of different types of inputs used by choosing the correct type, amount, method, and time of input consumption, such as chemical fertilizers and pesticides, play important roles in reducing energy consumption. In other studies, energy efficiency in rice-planting systems in Australia and India was similar to this result (Iqbal 2008; Khan et al. 2010). Therefore, by analyzing the input energy in planting systems, one can ascertain the amount of all forms of energy consumption and be protected from limited resources, such as land, water, and biological resources, for future generations.

The results for comparing the input energies and global warming potential caused by it showed that there was a direct correlation between input energies and global warming potential caused by it. In fact, non-renewable energies are ecologically very important, as the source of non-renewable energies is mainly fossil fuels and relying on this resource in the future brings many risks. In this regard, other researchers have stated that the greenhouse gas emission occurs during different agricultural activities either directly through consuming fossil fuels during agricultural operations (planting to harvesting) or indirectly during the production and transfer of the field’s needed inputs (herbicides, pesticides, and chemical fertilizers) (Wood and Cowie 2004). It was also stated in another study that agricultural and non-agricultural operations (the production and transfer of fertilizers and pesticides) in rice production play roles in global warming by producing 80–98 and 16–91 kg CO2 eq. per hectare, respectively (Pathak and Wassmann 2007). Different natural and human causes make global warming, but global warming is mostly considered to be due to the increase in greenhouse gas emission because of human activities (Bare 2011), which makes a lot of changes in global climate patterns. In order to report the amount of the produced greenhouse gases, all the produced gases with the equivalent of CO2, which state the global warming potential, are reported. Nabavi-Pelesaraei et al. (2018) demonstrated that diesel with 44.34% has the highest share of energy utilization in paddy rice production in the Guilan province; moreover, total energy input was equal to 51,585 MJ ha−1. In another study, in rice production related to diesel in Iran, diesel accounted for about 46.41% of the total energy utilization in the Guilan province and 29.67% of total energy consumption in the Mazandaran province (Kazemi et al. 2015). Pishgar-Komleh et al. (2011) showed that the largest energy consumption in rice production was related to fuel (46% of total energy utilization) which included diesel gasoline, natural gas, and electricity.

In another research, GWP impact category in farming section was reported to be 119.5 kg CO2 eq. for wheat production (Wang et al. 2007), 1484–1847 kg CO2 eq. for rice in Rasht, Iran (Nabavi-Pelesaraei et al. 2014), 340 kg CO2 eq. for wheat in Marvdasht, Iran (Nabavi-Pelesaraei et al. 2016), and 381 kg CO2 eq. for wheat in Switzerland (Charles et al. 2006). The demand for non-renewable energy for wheat production per ton in Gorgan was reported to be 6641 MJ (Soltani et al. 2013). The total energy consumed depending on the type of soil and field operations and production systems was reported to be 274 to 557 MJ in England (Tzilivakis et al. 2005) and 521 MJ for sugar beet production per ton in Japan (Koga 2008). The most important substances with acidification potential in ecosystems were SO2 and nitrogen oxides, which are produced through consuming fossil fuels in the process of agricultural production. NH3, caused by the consumption of chemical fertilizers in the field, is also an important factor of acidification (Engstrom et al. 2007). These emissions cause acidification through the complex processes of atmospheric and chemical transfer, which damages the ecosystems, plants, and animal populations (Bare et al. 2003). In other research studies, the characterization index of the impact category of acidification was obtained to be 4 kg SO2 eq. (Wang et al. 2007). In another research in Chile, the impact category of acidification for canola and sunflower production was calculated to be 19 and 23 kg SO2 eq. (Iriarte et al. 2010).

Based on findings, it was observed that low-input system and large farms have less emission of heavy metals into water and air compared to high-input system and small farms in both regions; the reason was less input consumption. In fact, the amount of heavy metals into water and air was calculated based on the annual estimation of these elements’ deposit and, also, their entrance into soil through fertilizers, pesticides, seeds, and deposit and their separation from the soil by product harvest, leaching, and soil erosion. The main reasons for these results are different input consumption, different paddy yield production, and agricultural practices. It is believed that emissions, such as CFC and halogen gases, damage the ozone layer in the stratosphere (Bare et al. 2003). Eutrophication is commonly dependent on the environmental impacts of releasing excessive amounts of nutrients, which changes the species combination of ecosystems and increases the production of biomass. This is followed by damaging consequences, such as decreased biodiversity, and chemical toxic compound production for humans, livestock, and other mammals (Bare et al. 2003). Nemecek and Kagi (2007) reported the volume of eutrophication section leaching to be 0.59 kg N per ton of sugar beet in Switzerland. Other researchers reported that the characterization index of eutrophication for producing canola and sunflowers was 7.2 and 9 kg PO4 eq., respectively, in Chile (Iriarte et al. 2010). Also, in this research, the characterization index of the acidification impact category for producing canola and sunflowers was estimated to be 19 and 23 kg PO4 eq. (Iriarte et al. 2010).

In the study on rice in China, it was observed that depleting the fossil resources for diesel fuel consumption was 106 MJ per ton and its final eco-index was obtained to be 0.008 (Wang et al. 2010). The results of other researchers indicated that for producing a ton of canola in Turkey, 25.63 L diesel fuel (Unakitan et al. 2010), for a ton of soybean 87.78 L fuel (Ramedani et al. 2011), and for producing a ton of rice in Guilan, 25.08 L diesel fuel (Pishgar-Komleh et al. 2011) were consumed. In a study on rice in China, it was found out that the water consumption of rice production was 379 cm per ton, and the final index was obtained as 0.14 for the reduction of water resources (Wang et al. 2010). For the reduction of fossil resources, the fossil fuel consumption was 106 MJ per ton of rice production, and its final eco-index was obtained to be 0.008. In another study in north China, the final index for the reduction of fossil resources was obtained as 0.02 for a ton of wheat production and 0.009 for a ton of corn production (Wang et al. 2007). Besides, in another study in Germany, it was observed that in producing a ton of wheat, acidification and global warming were the main environmental impacts (Brentrup et al. 2004). For wheat, energy depletion with the final index of 0.14 and acidification with 0.13 were the most important eco-indices (Wang et al. 2007). For producing sunflowers and canola, the highest environmental impacts were reported to be global warming and eutrophication (Iriarte et al. 2010). Photochemical oxidation potential (smog) is mainly due to the formation of ozone at the ground level, which is itself influenced by the reactions between nitrogen oxides and volatile organic compounds in sunlight (Bare 2011).

The findings about all impact categories in both regions showed that the low-input systems in both methods for the three farms had a significant advantage in terms of lower emission of heavy metals and all the environmental pollution. Dastan et al. (2016), with a life cycle assessment of conservation, conventional, and improved system, concluded that only CO2 emissions showed high amounts as N2O emission ranked second. Moreover, the conventional production system showed the same values for heavy metal emission in water (cadmium, copper, zinc, lead, and chromium). However, the emission of all heavy metal in water for the conservation system was much lower than in the other two systems (Dastan et al. 2016). In the conservation production system, the emission of all heavy metals in the soil except for lead (cadmium, copper, zinc, nickel, chromium, and mercury) showed a negative value. In the conventional and intensive production system, the emission of copper, zinc, and mercury showed negative amount in the soil (Dastan et al. 2016). Other researchers compared the group of transgenic and non-transgenic rice cultivars, which stated that in terms of heavy metal emission in water (cadmium, copper, zinc, lead, and chromium), all rice cultivars were approximately equal, the main reason being equal inputs in this section (Dastan et al. 2017).

Conclusion

In this study, different impact categories of life cycle assessment were evaluated in three rice production systems in the two semi-mechanized and traditional planting methods with three farm size levels in the Amol and Rasht regions. Thus far, no report has been shown on various production systems with different planting methods and farm size level in the largest Iranian rice production area. Hence, the findings of this study can be very effective in increasing the rice ecosystem’s sustainability, as well as reducing the environmental impacts resulting from the use of chemical inputs and the achievement of sustainable agricultural objectives. The findings of this study indicate that the share of inputs and outputs was different in each rice production scenario. The main reason for the observed difference was the amount of input and output, diversity of farm management practice, and input consumption. According to the findings, the share of non-renewable energy demand, CC, and GWP 100a in both regions was low for low-input system, which could increase the share of renewable energy by incorporating conservation planting approaches. This issue is of great importance from the ecological point of view, because the source of non-renewable energies, which is mostly fossil fuels, and the reliance on these resources in the future, are fraught with great risks.

In general, the findings show that for rice cultivation in the region, the highest inputs and energy consumption were related to the nitrogen fertilizer, fuel, machinery utilization, and seed consumption, the main reason for which was the traditional method and high-input systems of rice production by farmers in both regions, especially in small farms. According to the findings, farmers in the conventional and high-input systems and small farms used a lot of chemical fertilizers in an irregular manner to improve the field and did not pay attention to organic materials and biological resources, and this increased the use of non-renewable energy, increased the emissions of greenhouse gases, and consequently decreased the index of sustainability. Hence, the proper management of nitrogen fertilizer usage and other input energies will have a significant impact on reducing energy consumption and will be effective in reducing CO2 emissions and global warming potential. Moreover, by using organic fertilizers and biological crop protection, it is possible to reduce the share of CC, GWP 100a, TA, FE, ME, OLD, ALO, WD, MD, and FD which is desirable for the sustainability of the rice production ecosystem in the region. According to the results, it is possible to improve productivity by reducing the nitrogen and fuel consumption as well as mechanization of agricultural crop. Based on the findings, it can be argued that farmers in the region consider economic efficiency in rice production and are less likely to pay attention to environmental sustainability. It seems that by reducing the government subsidies related to chemical inputs and promoting conservation planting systems, the gap created could be offset to increase economic and environmental productivity in rice cultivation in the region.

References

Bare, J. (2011). TRACI 2.0: the tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technologies & Environmental Policy, 13(5), 687–696. https://doi.org/10.1007/s10098-010-0338-9.

Bare, J. C., Norris, G. A., Pennington, D. W., & Mc Kone, T. (2003). TRACI: the tool for the reduction and assessment of chemical and other environmental impacts. Journal of Industrial Ecology, 6, 49–78. https://doi.org/10.1162/108819802766269539.

Biswas, W. K., Barton, L., & Carter, D. (2008). Global warming potential of wheat production in Western Australia: a life cycle assessment. Water & Environmental Journal, 22, 206–216. https://doi.org/10.1111/j.1747-6593.2008.00127.x.

Blengini, G. A., & Busto, M. (2009). The life cycle of rice. LCA of alternative agri-food chain management systems in Vercelli (Italy). Journal of Environmental Management, 90(3), 1512–1522. https://doi.org/10.1016/j.jenvman.2008.10.006.

Brentrup, F., Kusters, J., Lammel, J., Barraclough, P., & Kuhlmann, H. (2004). Environmental impact assessment of agricultural production systems using the life cycle assessment (LCA) methodology: II. The application of N fertilizer use in winter wheat production systems. European Journal of Agronomy, 20(3), 265–279. https://doi.org/10.1016/S1161-0301(03)00039-X.

Charles, R., Jolliet, O., Gaillard, G., & Pellet, D. (2006). Environmental analysis of intensity level in wheat crop production using life cycle assessment. Agriculture, Ecosystems & Environment, 113(1/4), 216–225. https://doi.org/10.1016/j.agee.2005.09.014.

Chauhan, N. S., Mohapatra, P. K. J., & Pandey, K. P. (2006). Improving energy productivity in paddy production through bench marking and application of data envelopment analysis. Energy Conversation & Management, 47(9/10), 1063–1085. https://doi.org/10.1016/j.enconman.2005.07.004.

Cherubini, F. (2010). GHG balance of bioenergy systems overview of key steps in the production chain and methodological concerns. Renewable Energy, 35(7), 1565–1573. https://doi.org/10.1016/j.renene.2009.11.035.

Dalgaard, T., Halberg, N., & Porter, J. R. (2001). A model for fossil energy use in Danish agriculture used to compare organic and conventional farming. Agriculture, Ecosystems & Environment, 87(1), 51–65. https://doi.org/10.1016/S0167-8809(00)00297-8.

Dastan, S., Ghareyazie, B., Mortazavi, E., Mohsenpour, M., & Abdollahi, S., (2017). The environmental life cycle assessment (LCA) of transgenic and non-transgenic rice cultivars. 2nd International and 10th National Biotechnology Congress of Islamic Republic of Iran. Aug. 29–31. Seed and Plant Improvement Institute, Karaj, Iran.

Dastan, S., Ghareyazie, B., Soltani, A., & Omidi, M., (2016). The life cycle assessment (LCA) of rice in conventional, intensive and conservation systems. 2nd International and 14th National Iranian Crop Science Congress. Aug. 30–Sep. 1. University of Guilan, Rasht, Iran.

Engstrom, R., Wadeskog, A., & Finnveden, G. (2007). Environmental assessment of Swedish agriculture. Ecological Economics, 60(3), 550–563. https://doi.org/10.1016/j.ecolecon.2005.12.013.

FAO, (2018). FAO rice market monitor (RMM). http://www.fao.org/economic/est/publications/rice-publications/rice-market-monitor-rmm/en/.

FAO, (2016) FAOSTAT—trade/crops and livestock products, available in http://faostat3.fao.org/browse/T/TP/E[15 April 2016].

Finkbeiner, M., Inaba, A., Tan, R. B. H., Christiansen, K., & Kluppel, H. J. (2006). The new international standards for life cycle assessment: ISO 14040 and ISO 14044. International Journal of Life Cycle Assessment, 11(2), 80–85. https://doi.org/10.1065/lca2006.02.002.

Goossens, Y., Geerared, A., Keulemans, W., Annaret, B., Mathijs, E., & De Tavernier, J. (2017). Life cycle assessment (LCA) for apple orchard production systems including low and high productive years in conventional, integrated and organic farms. Agricultural Systems, 153, 81–93. https://doi.org/10.1016/j.agsy.2017.01.007.

He, X., Qiao, Y., Liang, L., Knudsen, M. T., & Martin, F. (2018). Environmental life cycle assessment of long-term organic rice production in sub-tropical China. Journal of Cleaner Production, 176, 880–888. https://doi.org/10.1016/j.jclepro.2017.12.045.

Hokazono, S., & Hayashi, K. (2012). Variability in environmental impacts during conversion from conventional to organic farming: a comparison among three rice production system in Japan. Journal of Cleaner Production, 28, 101–112. https://doi.org/10.1016/j.jclepro.2011.12.005.

IPCC. (2013). Summary for policymakers. In Climate change 2013: the physical science basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. T.F. Stocker, D. Qin, G.-K. Plattner, M. Tignor, S.K. Allen, J. Doschung, A. Nauels, Y. Xia, V. Bex, and P.M. Midgley, Eds. Cambridge University Press, pp. 3–29. doi:https://doi.org/10.1017/CBO9781107415324.004

Iqbal, M. D. T. (2008). Energy input and output for production of Boro rice in Bangladesh. Electronic Journal of Environment, Agriculture & Food Chemistry, 7(3), 2717–2722.

Iriarte, A., Rieradevall, J., & Gabarrel, H. (2010). Life cycle assessment of sunflower and rapeseed as energy crops under Chilean condition. Journal of Cleaner Production, 18(4), 336–345. https://doi.org/10.1016/j.jclepro.2009.11.004.

ISO, (2006). 14040 International standard. Environmental management—life cycle assessment—principles and framework. International Organisation for Standardization, Geneva, Switzerland.

Kazemi, H., Kamkar, B., Lakzaei, S., Badsar, M., & Shahbyki, M. (2015). Energy flow analysis for rice production in different geographical regions of Iran. Energy, 84, 390–396. https://doi.org/10.1016/j.energy.2015.03.005.

Khan, S., Khan, M. A., & Latif, N. (2010). Energy requirement and economic analysis of wheat, rice and barley production in Australia. Soil & Environment, 29(1), 61–68.

Khoshnevisan, B., Rajaeifar, M. A., Clark, S., Shamshirband, M. A., Bardul Anuar, N., Mohd Shuib, N. L., & Gani, A. (2014). Evaluation of traditional and consolidated rice farms in Guilan province, Iran, using life cycle assessment and fuzzy modeling. Science of the Total Environment, 481, 242–251. https://doi.org/10.1016/j.scitotenv.2014.02.052.

Koga, N. (2008). An energy balance under a conventional crop rotation system in northern Japan: perspectives on fuel ethanol production from sugar beet. Agriculture, Ecosystems & Environment, 125(1/4), 101–110. https://doi.org/10.1016/j.agee.2007.12.002.

Koga, N., & Tajima, R. (2011). Assessing energy efficiencies and greenhouse gas emissions under bioethanol-oriented paddy rice production in northern Japan. Journal of Environmental Management, 92(3), 967–973. https://doi.org/10.1016/j.jenvman.2010.11.008.

Linquist, B. A., van Groenigen, K. J., Adviento-Borbe, M. A., Pittelkow, C. M., & van Kessel, C. (2012). An agronomic assessment of greenhouse gas emissions from major cereal crops. Global Change Biology, 18(1), 194–209. https://doi.org/10.1111/j.1365-2486.2011.02502.x.

Ministry of Jihad-e-Agriculture of Iran, (2016) Annual agricultural statics. www.maj.ir

Mohammadi, A., Rafiee, S., Jafari, A., Keyhani, A., Dalgaard, T., Trydeman Knudsen, M., Nguyen, T. L. T., Borek, R., & Hermansen, J. E. (2015). Joint life cycle assessment and data envelopment analysis for the benchmarking of environmental impacts in rice paddy production. Journal of Cleaner Production, 106, 521–532. https://doi.org/10.1016/j.jclepro.2014.05.008.

Nabavi-Pelesaraei, A., Abdi, R., Rafiee, S., & Taromi, K. (2014). Applying data envelopment analysis approach to improve energy efficiency and reduce greenhouse gas emission of rice production. Engineering in Agriculture, Environment & Food, 7(4), 155–162. https://doi.org/10.1016/j.eaef.2014.06.001.

Nabavi-Pelesaraei, A., Hoseinzadeh-Bandbafha, B., Qasemi-Kordkheili, P., Kouchaki-Penchah, H., & Riahi-Dorcheh, F. (2016). Applying optimization techniques to improve of energy efficiency and GHG (greenhouse gas) emissions of wheat production. Energy, 103, 672–678. https://doi.org/10.1016/j.energy.2016.03.003.

Nabavi-Pelesaraei, A., Rafiee, S., Mohtasebi, S. S., Hosseinzadeh-Bandbafha, H., & Chau, K. W. (2017). Energy consumption enhancement and environmental life cycle assessment in paddy production using optimization techniques. Journal of Cleaner Production, 162, 571–586. https://doi.org/10.1016/j.jclepro.2017.06.071.

Nabavi-Pelesaraei, A., Rafiee, S., Mohtasebi, S. S., Hoseinzadeh-Bandbafha, H., & Chau, K. (2018). Integration of artificial intelligence methods and life cycle assessment to predict energy output and environmental impacts of paddy production. Science of the Total Environment, 631/632, 1279–1294. https://doi.org/10.1016/j.scitotenv.2018.03.088.

Nassiri, S. M., & Singh, S. (2009). Study on energy use efficiency for paddy crop using data envelopment analysis (DEA) technique. Applied Energy, 86(7/8), 132–135. https://doi.org/10.1016/j.apenergy.2008.10.007.

Nemecek, T., & Kagi, T., (2007). Life cycle inventories of Swiss and European agricultural production systems. Final report Eco invent V2.0 No. 15a. Agroscope Reckenholz—Taenikon Research Station ARTM, Swiss Centre for Life Cycle Inventories, Zurich and Dubendorf, CH.

Pathak, H., & Wassmann, R. (2007). Introducing greenhouse gas mitigation as a development objective in rice-based agriculture: I. Generation of technical coefficients. Agricultural Systems, 94(3), 807–825. https://doi.org/10.1016/j.agsy.2006.11.015.

Pishgar-Komleh, S. H., Sedeedpari, P., & Rafiee, S. (2011). Energy and economic analysis of rice production under different farm levels in Guilan province of Iran. Energy, 36(10), 5824–5831. https://doi.org/10.1016/j.energy.2011.08.044.

Pishgar-Komleh, S. H., Ghahderijani, M., & Sefeedpari, P. (2012). Energy consumption and CO2 emissions analysis of potato production based on different farm size levels in Iran. Journal of Cleaner Production, 33, 183–191. https://doi.org/10.1016/j.jclepro.2012.04.008.

Ramedani, Z., Rafiee, S., & Heidari, M. D. (2011). An investigation on energy consumption and sensitive analysis of soybean production farms. Energy, 36(11), 6340–6344. https://doi.org/10.1016/j.energy.2011.09.042.

Rebitzer, G., Ekvall, T., Frischknecht, R., Hunkeler, D., Norris, G., Rydberg, T., Schmidt, W., Suh, S., Weidema, B. P., & Pennington, D. W. (2004). Life cycle assessment. Part 1: framework, goal and scope definition, inventory analysis, and applications. Environmental International, 30(5), 701–720. https://doi.org/10.1016/j.envint.2003.11.005.

Roy, P., Nei, D., Orikasa, T., Xu, Q., Okadome, H., Nakamura, N., & Shiina, T. (2009). A review of life cycle assessment (LCA) on some food products. Journal of Food Engineering, 90(1), 1–10. https://doi.org/10.1016/j.jfoodeng.2008.06.016.

Roy, P., Shimizu, N., & Kimura, T. (2005). Life cycle inventory analysis of rice production by local process. The Japanese Society of Agricultural Machinery, 67(1), 61–67.

Roy, P., Shimizu, N., Okadome, H., Shiina, T., & Kimura, T. (2007). Life cycle of rice: challenges and choices for Bangladesh. Journal of Food Engineering, 79(4), 1250–1255. https://doi.org/10.1016/j.jfoodeng.2006.04.017.

Sefeedpari, P., Ghahderijani, M., & Pishgar-Komleh, S. H. (2013). Assessment the effect of wheat farm sizes on energy consumption and CO2 emission. Journal of Renewable Sustainable Energy, 5, 1–15.

Shahin, S., Jafari, A., Mobli, A., Rafiee, S., & Karimi, M. (2008). Effect of farm size on energy ratio for wheat production: a case study from Ardabil province of Iran. American–Eurasian Journal of Agricultural & Environment Science, 3(4), 604–608.

Smith, P., Martino, D., Cai, Z., Gwary, D., Janzen, H., Kumar, P., McCarl, B., Ogle, S., O’Mara, F., Rice, C., Scholes, B., & Sirotenko, O., (2007). Agriculture. In: Metz, B., O. R. Davidson, P. R. Bosch, R. Dave, L. A. Meyer (eds) Climate change 2007: mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, pp. 497–540.

Soltani, A., Rajabi, M. H., Zeinali, E., & Soltani, E. (2013). Energy inputs and greenhouse gases emissions in wheat production in Gorgan, Iran. Energy, 50, 54–61. https://doi.org/10.1016/j.energy.2012.12.022.

Tzilivakis, J., Warner, D. J., May, M., Lewis, K. A., & Jaggard, K. (2005). An assessment of the energy inputs and greenhouse gas emissions in sugar beet (Beta vulgaris L.) production in the UK. Agricultural Systems, 85(1), 101–119. https://doi.org/10.1016/j.agsy.2004.07.015.

Unakitan, G., Hurma, H., & Yilmaz, F. (2010). An analysis of energy use efficiency of canola production in Turkey. Energy, 35(9), 3623–3627. https://doi.org/10.1016/j.energy.2010.05.005.

Wang, M., Wu, W., Liu, W., & Bao, Y. (2007). Life cycle assessment of the winter wheat-summer maize production system on the North China Plain. International Journal of Sustainable Development and World Ecology, 14(4), 400–407. https://doi.org/10.1080/13504500709469740.

Wang, M., Xia, X., Zhang, Q., & Liu, J. (2010). Life cycle assessment of a rice production system in Taihu region, China. International Journal of Sustainable Development and World Ecology, 17(2), 157–161. https://doi.org/10.1080/13504501003594224.

Zhang, W., Qi, Y., & Zhang, Z. (2006). A long-term forecast analysis on worldwide land uses. Environmental Monitoring & Assessment, 119, 609–620. https://doi.org/10.1007/s10661-005-9046-z.

Wood, S., & Cowie, A., (2004). A review of greenhouse gas emission factors for fertilizer production. Research and Development Division, State Forests of New South Wales. Cooperative Research Center for Greenhouse Accounting.

Yang, S. S., Lai, C. M., Chang, H. L., Chang, E. H., & Wei, C. B. (2009). Estimation of methane and nitrous oxide emissions from paddy fields in Taiwan. Renewable Energy, 34(8), 1916–1922. https://doi.org/10.1016/j.renene.2008.12.016.

Yodkhum, S., Gheewala, S. H., & Sampattagul, S. (2017). Life cycle GHG evaluation of organic rice production in northern Thailand. Journal of Environment Management, 196, 217–223. https://doi.org/10.1016/j.jenvman.2017.03.004.

Zhang, A., Cui, L., Pan, G., Li, L., Hussain, Q., Zhang, X., Zheng, J., & Crowley, D. (2010). Effect of biochar amendment on yield and methane and nitrous oxide emissions from a rice paddy from Tai Lake plain, China. Agriculture, Ecosystems & Environment, 139(4), 469–475. https://doi.org/10.1016/j.agee.2010.09.003.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Habibi, E., Niknejad, Y., Fallah, H. et al. Life cycle assessment of rice production systems in different paddy field size levels in north of Iran. Environ Monit Assess 191, 202 (2019). https://doi.org/10.1007/s10661-019-7344-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-019-7344-0