Abstract

Corrosion deposits formed within drinking water distribution systems deteriorate drinking water quality and resultantly cause public health consequences. In the present study, an attempt was made to investigate the concurrent conditions of corrosion scales and the drinking water quality in selected water supply schemes (WSS) in districts Chitral, Peshawar, and Abbottabad, northern Pakistan. Characterization analyses of the corrosion by-products revealed the presence of α-FeOOH, γ-FeOOH, Fe3O4, and SiO2 as major constituents with different proportions. The constituents of all the representative XRD peaks of Peshawar WSS were found insignificant as compared to other WSS, and the reason could be the variation of source water quality. Well-crystallized particles in SEM images indicated the formation of dense oxide layer on corrosion by-products. A wider asymmetric vibration peak of SiO2 appeared only in Chitral and Abbottabad WSS, which demonstrated higher siltation in the water source. One-way ANOVA analysis showed significant variations in pH, turbidity, TDS, K, Mg, PO4, Cl, and SO4 values, which revealed that these parameters differently contributed to the source water quality. Findings from this study suggested the implementation of proper corrosion prevention measures and the establishment of international collaboration for best corrosion practices, expertise, and developing standards.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The presence of centralized drinking water distribution systems (DWDSs) is often an indicator of improved drinking water supply in developing countries, but it should not be assumed that the quality of drinking water is always fit for human consumption (Lee and Schwab 2005). Metallic pipes in DWDSs develop extensive internal corrosion scales in a due course of time and has become one of the most critical public health concerns. These corrosion deposits in DWDSs resulted in the destruction of pipe’s materials, reduction of hydraulic capacity, and deterioration of drinking water quality by increasing microbial growth and sinks for toxic contaminants (Peng et al. 2012; Yang et al. 2012). The availability of “colored water” or “red water” at consumer’s point often causes the increase of communal concerns about the water quality and the cost for safe drinking water provision. In addition, iron pipes’ corrosion favors unwanted chemical and biochemical reaction in DWDSs (Sun et al. 2014). In the past years, many serious red water episodes have been reported in many cities across China, America, and Europe (Tang et al. 2006; Yang et al. 2012; Świetlik et al. 2012). Thus, the internal corrosion of metallic pipes is ubiquitous in DWDSs worldwide.

Physico-chemical characteristics of corrosion by-products depend on several parameters, including metallic properties of iron pipes, source water quality, hydraulic retention time, and so on (Ray et al. 2010). However, variations of water quality could disturb the solid-liquid equilibrium and resultantly the adverse effect on the quality of drinking water (Yang et al. 2012). Generally, unlined cast iron pipes in DWDSs are highly susceptible to non-uniform corrosion deposits. According to the established literature, corrosion by-products are composed of magnetite (Fe3O4), hematite (Fe2O3), iron oxyhydroxides (goethite (α-FeOOH) and lepidcrocite (γ-FeOOH)), ferrous hydroxide (Fe(OH)2), ferric-hydroxide (Fe(OH)3), siderite (FeCO3), and green rusts (Benjamin et al. 1996). Due to the intermittent water flow in DWDS, the corrosion by-products could release toxic metals into the water and cause colored water episodes and pose adverse consequences on public health.

Provision of safe drinking water is a basic human right, and according to Pakistan’s drinking water policy, its provision to the entire population comes under the responsibility of the state. The Government of Pakistan is committed for the provision of safe drinking water to the entire citizens by 2025 with an affordable cost. Presently, over 92% of Pakistan’s population has access to clean drinking water (GoP 2009; Mahmood et al. 2011; Baig et al. 2012). However, it does not mean that the water quality in all the operational sources is safe for human consumption and mostly the drinking water is distributed by using unlined cast iron pipes. The distribution systems in many cities are decades old. Also, water quality monitoring and pipe replacement systems are either not exit or not properly functional. Numerous water contaminants have been reported in many cities across the country, which could be the result of decade-old cast iron pipes and the mixing of sewerage water with portable water in poorly managed DWDSs (Khan and Bangash 2001; Muhammad et al. 2011; Baig et al. 2012; Khan et al. 2013). The condition of decade-old pipe corrosion scales and the quality of water are seldom reported in literature from any developing country, especially in Pakistan. Thus, in this study, concurrent characteristics of corrosion scales and the water quality conditions have been reported.

The aim of this study was to investigate the characteristics of iron pipe’s corrosion scales by using different characterization techniques (X-rays diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive spectrometry (EDS), Fourier transform infrared spectroscopy (FTIR)) and some selected water quality parameters. For this purpose, three districts (Chitral, Peshawar, and Abbottabad) in northern Pakistan were selected to explore the level and compositions of corrosion scale and the concurrent water quality situation by analyzing parameters like temperature, pH, electrical conductivity (EC), total dissolved solids (TDS), turbidity, K, Na, Mg, Fe, PO4, NO3, Cl, and SO4.

Materials and methods

Study area

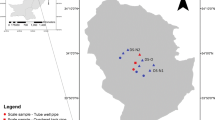

Figure 1 presents the location map of the three districts (Chitral, Peshawar, and Abbottabad) in northern Pakistan. One water supply scheme (WSS) in each of the three districts was selected for the collection of corrosion scales and water quality analyses. The three WSS were selected on the basis of their different geographical settings and water source conditions, while having almost similar distribution system, pipe diameter, and the quality of metallic pipes. A brief description of WSS in each district is given below. Green Lasht WSS was selected from the high altitude mountain district (Chitral) in northern Pakistan (Fig. 1). The WSS consist of spring catchment, storage tank, and approximately a 3-km main distribution line. Nothiya WSS was selected from district Peshawar, which is located in the low-lying plain area in northern Pakistan. In this WSS, water from underground source is pumped into the overhead storage tank and supplied to the community using nearly 3–5-km-long main distribution pipes. Mirpur WSS was selected from Abbottabad district, and the water is supplied to the community from spring water source by using 4–8-km-long main distribution pipe by gravity flow. Abbottabad is located in the north-eastern part of the country and bound by low-lying hills. All the three WSS were approximately 20–30 years old.

Corrosion scales collection

The main distribution lines were excavated at the center area of WSS and the cast iron pipes corrosion’s sample was carefully collected in union joints. Inner view pictures of the iron pipe sections were taken after bi-section of the joints. Typical corrosion scales of different color sections were carefully collected from the freshly obtained iron pipe section and dried. The freshly obtained corrosion scales were stored in closed box, grinded, and passed through a 150-μm mesh sieve. Pretreatment under aerobic or anaerobic conditions was not within the scope of this study; however, a recent study (Yang et al. 2012) extensively studied the effects of such environments on corrosion by-products composition.

Physico-chemical analyses of water samples

Water samples for physico-chemical analyses were collected in triplicates from the water tap at the center of the main distribution lines through “grab sampling” procedure. Cleaned polyethylene bottles were used to transport the water samples from the selected WSS to the laboratory and preserved as per standard methods for water quality analysis (APHA 1999; WHO 2011). All the reagents used in this study were of analytical grade and purchased from E. Merck, LTD, Pakistan. Water quality parameters including pH, temperature, turbidity, and EC were measured in the field. Water pH values were recorded using calibrated pH meter (model MP220), and the pH meter’s electrode was washed several times after each test. Electrical conductivity meter (Model Inolab Cond Level 1) was used to measure EC of water samples. Turbidity (suspended particle load) was measured as nephlometric turbidity units (NTU) using turbidity meter. Combo meter (HANNA, HI 98129) was used to measure TDS. Water samples were filtered to analyze for some selected parameters, like K, Na, Mg, Fe, PO4, NO3, Cl, and SO4 using standard procedures (APHA 1999; WHO 2011), as applied by other researchers (Mahmood et al. 2011; Muhammad et al. 2011; Khan et al. 2013; Ahmed et al. 2015). Briefly, a flame photometer was used to measure the concentration of Na and K at a wavelength of 589 and 768 nm, respectively. Calibration curves were prepared using a series of concentration (0–100 mg/L) of various standard solutions for the respective parameters. For the determination of phosphate, 1 mL ammonium molybdate and 0.4 mL SnCl2 were added into 20-mL filtered water sample and then left for some times for blue color to develop. Afterward, the color was compared with the reagent blank solution at 680 nm. To determine nitrate concentration in water samples, a series of dilution were prepared using 0.2 to 2 mL of standard potassium nitrate solution and diluted to make up to 100 mL. Then the solutions were evaporated and subsequently added 2-mL phenoldisulphonic acid to residue and further diluted up to 50 mL. An optical density was taken after 5 min at 410 nm and obtained nitrate concentration from the standard curve. Atomic absorption spectrometer (Perkin Elemr-AAnalyst-700) was used for the detection of Fe in water samples under the standard operating condition with r > 0.999. Potassium chromate indicator was used to determine chloride content in water samples while titrating against silver nitrate solution, as per standard titration procedure (APHA 1999). For data quality assurance, each sample was analyzed in triplicate and the mean value was presented.

Corrosion scale characterizations

Various characterization techniques were employed to study mineralogical, morphological, and elemental compositions of iron corrosion by-products collected from the three selected DWDSs. FTIR (IR Prestige-21, Japan) was measured as wave number (cm−1) and performed using KBr disc method. Sample XRD (X’pert PRO analytical B.V., Netherlands) patterns were recorded at 2-Theta (deg). SEM (Hitachi S-3000N, Japan) was used to investigate the morphological compositions. EDS (model: ESM-5800, GEOL, Japan) was employed to measure the elemental compositions in corrosion by-products.

Statistical analyses

Description statistics (simple statistics) were calculated for the tabulated data by using Excel 2007 (MS Office). One-way ANOVA procedure was performed by using SPSS software ver. 17. Crystalline phase of all the three samples was identified using the Jade XRD software and co-related.

Results and discussion

Results

Characterization of corrosion by-products

The corroded and precipitated layer of corrosion by-products of the three samples harvested from different WSS was quantitatively investigated by XRD technique and presented in Fig. 2a–c. Mineralogical composition of the three samples varied from each other significantly, and elemental compositions of the three WSS are presented in Table 1. Corrosion by-product from high mountain district (Chitral) was mainly composed of Fe3O4, α-FeOOH, and γ-FeOOH and SiO2 as the major constituents, while dolomite and calcite were found in trace amounts, as shown in Fig. 2a. The composition’s variation was supported by the elemental analysis, where the Wt% of calcium in Chitral and Abbottabad WSS was higher (3.8 and 5.8%, respectively) compared to Peshawar WSS (0.2%), as given in Table 1. Interestingly, quite similar constituent’s peaks appeared in district Abbottabad WSS corrosion by-product; however, the composition of SiO2 was found higher than the other WSS. The reason of higher SiO2 amount in Chitral and Abbottabad WSS corrosion by-products could be of elevated siltation or the deposition of silt on the inner surface of pipes, which, during corrosion, is mixed with the iron oxy-hydroxides. This justification can also be supported by higher turbidity level in respective water samples (Table 2) and the elevated silicon content measured in EDS analysis (Table 1). However, lower peaks were appeared in the corrosion by-product harvested from Peshawar WSS (Fig. 2b), indicating the presences of trace amount of these constituents. However, the iron oxy-hydroxide constituents (α-FeOOH and γ-FeOOH) were the major constituents in Peshawar WSS corrosion by-product (Fig. 2b). Also, the different XRD peaks among the WSS could be the variations in source water quality. Surface water sources in Chitral and Abbottabad WSS presented quite similar distribution patterns. These mineralogical variations in different geographical locations imply that highly variable water chemistry exists among these WSS even in well-maintained WSS.

Figure 3a–f shows the SEM images and inner view pictures of the corrosion deposits. Pipe corrosion has been divided in three categories based on the visual appearance and the structural features of corrosion scales. Yang and co-workers (2012) briefly described the categorical variations of corrosion scales among these categories. The corrosion scales in all the harvested pipes in this study possessed relatively thin inner layer (thickness varies from less than a millimeter to few millimeters) and considered to be in category II, where the corrosion scale had no tubercles (Fig. 3d, f) or very few tubercles irregularly distributed on the inner surface of pipe (Fig. 3e). However, all the three harvested pipes were completely covered with corrosion by-products. SEM analyses were also performed to identify the scales formed and presented in Fig. 3a–c. Under normal ambient conditions, iron oxy-hydroxides including α-FeOOH and γ-FeOOH, Fe3O4, and Fe2O3 are considered as the main corrosion by-products’ constituents (Gerke et al. 2008; Choi et al. 2015; Li et al. 2015). Thus, the progress of corrosion scale formation in developing country context (northern Pakistan) has been extensively studied in this study. Similarly, SEM images of the all the corrosion by-products demonstrated that α-FeOOH and γ-FeOOH and Fe3O4 were the main constituents (Fig. 3a–c). However, the composition varies from each other. For instance, filaments of α-FeOOH were more obvious in corrosion by-product harvested from Peshawar WSS (Fig. 3b). Stratified dense layer of Fe3O4 on γ-FeOOH composition was more prominent in Chitral and Abbottabad corrosion by-products, as shown in Fig. 3a, c. Generally, Fe3O4 can be formed from the transformation of α-FeOOH and γ-FeOOH (Li et al. 2015) and considered to be well-crystallized particle indicating the formation of dense oxide layer. Calcium carbonate in the corrosion by-products (Fig. 3a, c) seems to be strongly integrated with the corrosion layer and the EDS analysis also revealed of higher calcium content in both the samples (Table 1). In the internal corrosion, hematite formed the outer zone while the magnetite formed the inner zone of the corrosion by-products, which were reflected from the inner view pictures (radish-brown color) of corrosion by-products (Fig. 3d–f). In contrast, a different scenario can be seen in case of outer corrosion, as described earlier (Sancy et al. 2010).

A unique feature associated with this study was the FTIR spectra of the corrosion by-products, which was found missing from the studies reported earlier (Sancy et al. 2010; Sarin et al. 2001; Gerke et al. 2008; Li et al. 2015). Investigating the possible functional groups on corrosion by-products played an important role for the adsorption and releasing of toxic contaminants in DWDSs. Figure 4a–c presents the FTIR spectra of the three corrosion by-products harvested from Chitral, Peshawar, and Abbottabad. The peaks at 3424 and 2978 cm−1 were assigned to hydroxyl group and C–H stretching vibration (Jin et al. 2014). A wider characteristic peak that appeared at 1027 cm−1 was assigned to asymmetric stretching vibration of SiO2 (Tan et al. 2014), which was not present in Peshawar WSS corrosion by-product (Fig. 4b). Peaks that appeared at 521 and 1631 cm−1 could be attributed to the stretching vibration of Fe–O band (Tan et al. 2014; Liu et al. 2013).

Water quality characteristics

In the present study, some of the selected water quality parameters including pH, temperature, turbidity, TDS, EC, K, Na, Mg, Fe, PO4, NO3, Cl, and SO4 were measured from all the three WSS and summarized in Table 2. Temperature values ranged at 16.8–20.7, 22.2–26.8, and 20.4–22.9 °C, with the mean values of 18.8, 24.4, and 21.7 °C were recorded in WSS Chitral, Peshawar, and Abbottabad, respectively (Table 2). The highest pH was recorded at Chitral WSS (7.89), and lowest pH was measured at Peshawar WSS (7.43). TDS values of three WSS significantly varied from each other. The mean TDS values of Chitral, Peshawar, and Abbottabad were found to be about 354.33, 574.66, and 306.0 mg/L, respectively (Table 2), and the reason could be the variation of dissolved solids from surface and groundwater sources. Thus, the TDS values of WSS follow the order: Peshawar > Chitral > Abbottabad. Groundwater source (Peshawar WSS) contained a high amount of TDS as compared to the other two WSS. The mean values of K, Na, and Mg in all the three WSS were not significantly varied from each other, and all the parameters were equally contributed to K, Na, and Mg levels in all the WSS. The turbidity value of Chitral WSS was higher (3.7 NTU) as compared to the other samples (Table 2), and the reason could be the erosion or siltation in high mountain. Significantly, higher mean Fe amount of 0.28, 0.20, and 0.21 mg/L in Chitral, Peshawar, and Abbottabad, respectively, was recorded (Table 2), which found to be higher with the reported Fe value in the same geographical location (Shah et al. 2012). However, all the studied parameters were within the WHO permissible limits for drinking water (WHO 2006).

Table 3 presents the statistical comparison of various parameters at different sampling sites using one-way ANOVA procedure. The results demonstrated that the concentrations of pH, turbidity, TDS, K, and Mg varied from each other, and the variations were also found significant (P < 0.05) (Table 3). The concentrations of pH, turbidity, TDS, K, and Mg were significantly higher (P = 0.00) in the combined WSS water quality analysis (Table 3). Anions, like PO4, Cl, and SO4 variations, were also found significant; particularly, the concentration of SO4 was significantly higher (P = 0.01) in the combined WSS water quality analysis. The significant variations of parameters represented in bold letters demonstrated that the contributions of different samples were different within a sampling point (Table 3). However, no significant variation was found in EC, Na, Fe, and NO3 in water samples collected in all the three WSS (Table 3).

Discussion

Iron corrosion in DWDSs has been reported in many developed nations around the world and has become the subject of scientific research for over 150 years. This phenomenon puts a more serious threat to the water quality situation in developing nations, where the government’s priority is different and the researchers less likely explore such alarming conditions in DWDSs. It is a naturally occurring process, which could result from the reaction of pipes’ materials with its surrounding environment. As a result, corrosion can cause damages to water supply infrastructures and even to household appliances. In the present study, an attempt was made to explore the concurrent situation of iron corrosion scale formation and water quality in some selected WSS installed approximately 20–30 years ago in northern Pakistan (Fig. 1). Iron corrosion by-products are considered to be formed very rapidly at the beginning (Sontheimer et al. 1981), approximately after 3 years of installation (Gerke et al. 2008), and reported to be electrochemical corrosion at the initial stage (Sun et al. 2014). Rapid corrosion could cause uniform corrosion on the inner surface of entire pipes (Saber and Salem 1993). The DWDSs installed in the same year might have similar physico-chemical properties of iron corrosion scales, but this idea was not supported in the present study and the water quality condition was strongly influenced on corrosion formation. The compositions of corrosion by-products in Chitral and Abbottabad WSS were quite similar to each other as compared to Peshawar WSS (Table 1). It was interesting to note that spring water sources were supplying drinking water in both the WSS; however, groundwater was distributed to the community in Peshawar WSS. Significant variations in the quality of both surface water and groundwater were reported in northern Pakistan (Muhammad et al. 2011; Shah et al. 2012; Khan et al. 2013).

Major constituents of corrosion by-products in these WSS were generally comprised of Fe3O4, α-FeOOH, and γ-FeOOH with different proportions, which were also revealed in XRD pattern (Fig. 2) and EDS analysis (Table 1). However, the formation sequence of these compositions was different, depending on various conditions including water pH, Fe2+, and Fe3+ and oxidation rates at the inner surface of pipes (Gerke et al. 2008). Among the iron oxy-hydroxides constituents, lepidocrocite (γ-FeOOH) was appeared in the early stage of corrosion and the other compositions were not appeared in a short testing period (Liang et al. 2013). However, goethite formation is predominated over lepidocrocite in slower oxidation process (Benjamin et al. 1996). According to Cornell and Schwertmann (Cornell and Schwertmann 2001), the slow rate of oxidation and high water pH favored the formation of magnetite over lepidocrocite. The primary corrosion by-products in unlined cast iron pipe are FeCO3, α-FeOOH and γ-FeOOH, α-Fe2O3, and Fe3O4, but small amount of iron corrosion by-products is also found in polyvinyl chloride and aged lined ductile iron pipes (Tang et al. 2006). Sarin and co-workers (2001) widely studied the structural and composition variations of iron corrosion by-products before and after drying. Besides the primary corrosion by-products, many other materials were also identified in the corrosion by-products. For instance, XRD pattern (Fig. 2) revealed the presence of SiO2 as a major constituent in the corrosion by-product. The reason could be the presence of high amount of silicon (Table 1) due to siltation in water sources, especially in Chitral and Abbottabad WSS. Similarly, Tang et al. (2006) detected high amounts of zinc oxides (e.g., ZnO) in galvanized steel corrosion by-products. The predominant amount of lepidocrocite in water could indicate the presence of weak corroding layers and higher iron oxidation rate (Benjamin et al. 1996; Sarin et al. 2001; Gerke et al. 2008), while the presence of predominant amount of goethite revealed hard shell corrosion layer with thick and hard structure resulting from slower oxidation rate (Sarin et al. 2004; Liu et al. 2013). Thus, Liu et al. (2013) concluded the variability of water quality conditions including alkalinity; chloride and pH values significantly affect corrosion scale formation and iron release. However, due to the deposition of other matters (i.e., calcium deposits), the iron corrosion tended to be reduced and the calcium deposit acts as barrier for iron pipe corrosion and provides better protection layer (Umoru et al. 2012).

The presence of iron in the bulk water depends on several factors, including iron corrosion rate, intake water iron content, precipitation rate, and dissolution of corrosion by-product (Mutoti et al. 2007). The concentration of iron ranged at 0.37–0.22, 021–0.13, and 0.21–0.16 mg/L in Chitral, Peshawar, and Abbottabad WSS, respectively (Table 2), though other researchers (Shah et al. 2012) detected some amounts of Fe in the drinking water sources (both surface and sub-surface) in northern Pakistan. However, iron concentration level recorded in the present study was found to be much higher (Table 2), which could be the result of iron release from the corrosion by-product. However, the mean iron values in all the WSS were within the WHO permissible limits (WHO 2006). The availability of chloride in drinking water is an important parameter, which assumed to affect Fe–O–Fe linkages by iron oxide formation process and firmly promote lepidocrocite crystal and the presence of sulfate-favored goethite formation (Taylor 1984). The concentrations of chloride and sulfate were significantly higher (P = 0.02 and P = 0.01) in the combined WSS water quality analysis (Table 3).

Very rare or no research has been conducted on the concurrent conditions of corrosion scales and the associated corrosion management practices in developing countries, in general, and in Pakistan, in particular. In Pakistan, the provision of safe drinking water to the entire citizens comes under the state responsibility (GOP 2009; Mahmood et al. 2011; Baig et al. 2012). However, there is no clause in the national drinking water policy for corrosion management or years designated for WSS functionality and the replacements of decade-old pipes. Installation of WSS for a town or rural village is considered a one-time job, and the WSS has life time guaranteed. However, Pakistan is a disaster-prone country and mostly expends resources for the rehabilitation of existing WSS after the natural disasters, like earthquake (Mahmood et al. 2011) and floods (Baig et al. 2012), instead of developing a new WSS or replacing of decade-old cast iron pipes. The science of corrosion control is highly complex and associated several factors, which needs a professional to understand and properly device reliable preventive measures (Schmitt 2009). However, the developing countries lack corrosion preventive and management professionals and resources required. Only in the USA that the total direct cost of corrosion was about US$276 billion (Koch et al. 2009), which is considered very high for the developing countries to allocate in their annual development budgets. Thus, no significant research and investigation had been undertaken to know the concurrent situation of corrosion scales and water quality. However, the World Corrosion Organization (WCO) developed comprehensive information on raising an awareness about corrosion and its protection worldwide (Schmitt 2009). The information provided herewith would be useful for developing countries and provide an urgent need of international collaboration for identifying best corrosion prevention practices, providing relevant expertise and the establishment of global standards.

Intervention management plan for safe domestic water supply

The provision of clean portable water is essential for the protection of public health and the improvement of quality of life. The national guidelines emphasized the supply of 45 and 120 l per capita per day safe water in rural and urban settlements, respectively, for domestic uses including cooking, drinking, and domestic hygiene management (GoP 2009). In Pakistan, many government-line departments and foreign-funded non-government organizations involved for the provision and management of water and sanitation services in both urban and rural areas. Figure 5 presents a flow chart comprising a number of possible services for domestic water supply in the light of national water policy and concerned departments’ activities. It demonstrated that each line department is responsible for the provision of safe drinking water and environmental sanitation services in their jurisdiction areas. For instance, the Public Health Engineering Department and other utilities mainly focused on metropolitan cities and towns. However, Tehsil Municipal Administrations generally provide drinking water and environmental sanitation services in rural areas. They received funding from both the government and foreign donors (i.e., UNICEF) for WSS rehabilitation/installation and water quality monitoring. However, the corrosion management practices and decade-old iron pipe replacement in DWDSs have not been taken into consideration in their strategic plans so far. Also, no future plan exists for preventing corrosion scale formation or corrosion management practices in DWDSs even in mega cities across the country.

To reduce the health risks associated with the drinking of contaminated water from poorly managed DWDSs and to make the portable water acceptable for human consumption is very important. In such situation, the government needs to ensure its obligatory services to provide safe drinking water at domestic level, maintain WSS, monitor water quality, and promote research in water sector, as clearly mentioned in Fig. 5. Such efforts bring positive outputs in the overall situations in the management of drinking water quality at scheme as well as domestic levels. In addition, extensive researches on some of the appropriate treatment technologies have already been documented, which can be promoted for scale-up implementation in poor water quality areas (Mahmood et al. 2011; Baig et al. 2011, 2015). Further research needs to be conducted on iron pipes corrosion’s issue and the development of national protocols for best corrosion management practices outlined by WCO (Schmitt 2009). In addition, corrosion management plan needs to be designed to address iron pipe corrosion’s issue in DWDSs and possibly integrate, with each country, the national water policy for disseminating the following information to concerned stakeholders:

-

Better understanding of iron pipes’ corrosion issue and its impact on drinking water quality and public health.

-

Identifying the key corrosion risk areas in DWDSs and environmental resilient construction with the inclusion of Disaster Risk Reduction component.

-

Water quality monitoring and participatory evaluation of DWDSs.

-

Development of water safety and sustainability plan and further implementation.

-

Reforms in institutional setup of drinking water supplies which help to address corrosion issue on multiple perspectives (technical/scientific, socio-cultural, financial, institutional, and environmental).

Conclusions

Corrosion by-products formed in the DWDSs and the quality of drinking water in selected WSS in three different geographical districts (Chitral, Peshawar, and Abbottabad) in northern Pakistan were investigated by different characterization analyses (XRD, EDS, SEM, and FTIR) and water quality assessment for selected parameters. XRD data revealed the presence of primary crystalline structure of α-FeOOH and γ-FeOOH, Fe3O4, and SiO2 in all the samples with different proportions. Among the major constituent elements, Fe3O4 and SiO2 were highly available followed by other minor constituents including goethite, lepidcrocite, dolomite, and calcite. Water quality assessment results demonstrated that the mean values of K, Na, and Mg in all the three WSS were not significantly varied from each other, and all the parameters were equally contributed to K, Na, and Mg levels in all the WSS. However, pH, turbidity, TDS, K, Mg, PO4, Cl, and SO4 values showed significant variations, as revealed from the statistical analysis. Thus, proper corrosion preventive and management practices are highly desirable for the maintenance of decade-old DWDSs in developing countries, in general, and in Pakistan, in particular.

References

Ahmed, T., Pervez, A., Mehtab, M., & Sherwani, K. S. (2015). Assessment of drinking water quality and its potential health impacts in academic institutions of Abbottabad (Pakistan). Desalination and Water Treatment, 54, 1819–1828.

APHA. (1999). Standard methods for the examination of water and wastewater. PHA/AWWA/WPCF Washington, DC.

Baig, S. A., Mahmood, Q., Nawab, B., Shafqat, M. N., & Pervez, A. (2011). Improvement of drinking water quality by using plant biomass through household biosand filter—a decentralized approach. Ecological Engineering, 37, 1842–1848.

Baig, S. A., Xu, X., & Khan, R. (2012). Microbial water quality risks to public health: potable water assessment for a flood-affected town in northern Pakistan. Rural and Remote Health, 12(3).

Baig, S. A., Sheng, T., Hu, Y., Xu, J., & Xu, H. (2015). Arsenic removal from natural water using low cost granulated adsorbents: a review. Clean-Soil Air Water, 43(1), 13–26.

Benjamin, M. M., Sontheimer, H., & Leroy, P. (1996). Corrosion of iron and steel. Internal Corrosion of Water Distribution Systems, 90508.

Choi, J., Choi, B. G., & Hong, S. (2015). Effects of NF treated water on corrosion of pipe distribution system and its implications to blending with conventionally treated water. Desalination, 360, 138–145.

Cornell, R., & Schwertmann, U. (2001). The iron oxides. Structure, Properties.

Gerke, T. L., Maynard, J. B., Schock, M. R., & Lytle, D. L. (2008). Physiochemical characterization of five iron tubercles from a single drinking water distribution system: possible new insights on their formation and growth. Corrosion Science, 50(7), 2030–2039.

GoP. (2009). National drinking water policy draft, Government of Pakistan, Islamabad.

Jin, J., Wu, G., Zhang, Z., & Guan, Y. (2014). Effect of extracellular polymeric substances on corrosion of cast iron in the reclaimed wastewater. Bioresource Technology, 165, 162–165.

Khan, S. U., & Bangash, F. K. (2001). Drinking water quality forecast of Peshawar valley on the basis of sample data. Journal of Chemical Society of Pakistan, 23(4), 243–251.

Khan, K., Lu, Y., Khan, H., Zakir, S., Khan, S., Khan, A. A., et al. (2013). Health risks associated with heavy metals in the drinking water of Swat, northern Pakistan. Journal of Environmental Sciences, 25(10), 2003–2013.

Koch, G. H., Brongers, M. P. H., Thompson, N. G., Virmani, Y. P., & Payer, J. H. (2009). Corrosion costs and preventive strategies in the United States. Washington D.C.: FHWA, 2001.

Lee, E. J., & Schwab, K. J. (2005). Deficiencies in drinking water distribution systems in developing countries. Journal of Water and Health, 3(2), 109–127.

Li, X., Wang, H., Hu, C., Yang, M., Hu, H., & Niu, J. (2015). Characteristics of biofilms and iron corrosion scales with ground and surface waters in drinking water distribution systems. Corrosion Science, 90, 331–339.

Liang, J., Deng, A., Xie, R., Gomez, M., Hu, J., Zhang, J., et al. (2013). Impact of flow rate on corrosion of cast iron and quality of re-mineralized seawater reverse osmosis (SWRO) membrane product water. Desalination, 322, 76–83.

Liu, H., Schonberger, K. D., Peng, C.-Y., Ferguson, J. F., Desormeaux, E., Meyerhofer, P., et al. (2013). Effects of blending of desalinated and conventionally treated surface water on iron corrosion and its release from corroding surfaces and pre-existing scales. Water Research, 47(11), 3817–3826.

Mahmood, Q., Baig, S. A., Nawab, B., Shafqat, M. N., Pervez, A., & Zeb, B. S. (2011). Development of low cost household drinking water treatment system for the earthquake affected communities in Northern Pakistan. Desalination, 273(2–3), 316–320.

Muhammad, S., Shah, M. T., & Khan, S. (2011). Health risk assessment of heavy metals and their source apportionment in drinking water of Kohistan region, northern Pakistan. Microchemical Journal, 98(2), 334–343.

Mutoti, G., Dietz, J. D., Imran, S., Taylor, J., & Cooper, C. (2007). Development of a novel iron release flux model for distribution systems. Journal of American Water Works Association, 99(1), 102–111.

Peng, C.-Y., Hill, A. S., Friedman, M. J., Valentine, R. L., Larson, G. S., Romero, A. M., et al. (2012). Occurrence of trace inorganic contaminants in drinking water distribution systems. Journal of American Water Works Association, 104(3), 53.

Ray, R. I., Lee, J. S., Little, B. J., & Gerke, T. (2010). The anatomy of tubercles: a corrosion study in a fresh water estuary. Materials and Corrosion, 61(12), 993–999.

Saber, T., & Salem, A. (1993). Inhibition of the corrosion of steel pipes carrying potable water: II. Optimization of Ca2+ and HCO3− content in the presence of phosphate inhibitors. Desalination, 93(1), 461–471.

Sancy, M., Gourbeyre, Y., Sutter, E., & Tribollet, B. (2010). Mechanism of corrosion of cast iron covered by aged corrosion products: application of electrochemical impedance spectrometry. Corrosion Science, 52(4), 1222–1227.

Sarin, P., Snoeyink, V., Bebee, J., Kriven, W., & Clement, J. (2001). Physico-chemical characteristics of corrosion scales in old iron pipes. Water Research, 35(12), 2961–2969.

Sarin, P., Snoeyink, V., Lytle, D., & Kriven, W. (2004). Iron corrosion scales: model for scale growth, iron release, and colored water formation. Journal of Environmental Engineering, 130(4), 364–373.

Schmitt, G. (2009). Global needs for knowledge dissemination, research, and development in materials deterioration and corrosion control. World Corrosion Organization, 3–8.

Shah, M., Ara, J., Muhammad, S., Khan, S., & Tariq, S. (2012). Health risk assessment via surface water and sub-surface water consumption in the mafic and ultramafic terrain, Mohmand agency, northern Pakistan. Journal of Geochemical Exploration, 118, 60–67.

Sontheimer, H., Kolle, W., & Snoeyink, V. L. (1981). Siderite model of the formation of corrosion-resistant scales. Journal of the American Water Works Association, 73(11), 572–579.

Sun, H., Shi, B., Lytle, D. A., Bai, Y., & Wang, D. (2014). Formation and release behavior of iron corrosion products under the influence of bacterial communities in a simulated water distribution system. Environmental Science: Processes & Impacts, 16(3), 576–585.

Świetlik, J., Raczyk-Stanisławiak, U., Piszora, P., & Nawrocki, J. (2012). Corrosion in drinking water pipes: the importance of green rusts. Water Research, 46(1), 1–10.

Tan, L., Xu, J., Xue, X., Lou, Z., Zhu, J., Baig, S. A., et al. (2014). Multifunctional nanocomposite Fe3O4@ SiO2–mPD/SP for selective removal of Pb (ii) and Cr (vi) from aqueous solutions. RSC Advances, 4(86), 45920–45929.

Tang, Z., Hong, S., Xiao, W., & Taylor, J. (2006). Characteristics of iron corrosion scales established under blending of ground, surface, and saline waters and their impacts on iron release in the pipe distribution system. Corrosion Science, 48(2), 322–342.

Taylor, R. (1984). Influence of chloride on the formation of iron oxides from Fe (II) chloride. II. Effect of [Cl] on the formation of lepidocrocite and its crystallinity. Clays and Clay Minerals, 32(3), 175–180.

Umoru, L. E., Oladipo, A., & Ige, O. O. (2012). Carbonate coatings as protective barriers for pipe borne water transport material. Journal of Minerals and Materials Characterization and Engineering, 11(06), 609.

WHO. (2006). Guidelines for drinking-water quality [electronic resource]: incorporating first addendum. Vol. 1, Recommendations.

WHO. (2011). Guidelines for drinking water quality (4th ed.). Geneva: World Health Organization.

Yang, F., Shi, B., Gu, J., Wang, D., & Yang, M. (2012). Morphological and physicochemical characteristics of iron corrosion scales formed under different water source histories in a drinking water distribution system. Water Research, 46(16), 5423–5433.

Acknowledgements

This work is based upon the research supported by the Important National Science & Technology Specific Projects (2014ZX07101-012-04) and the National Natural Science Foundation of China (no. 21477108). S.A. Baig also acknowledged the Higher Education Commission (HEC) of Pakistan for the award of “start up research grant” (SRGP project no. 21-607/SRGP/R&D/HEC/2014). We gratefully acknowledge the Nasir Ullah Contraction Campany (Chitral), Engr. Khan Zeb, Engr. Nasir Ghafoor, Engr. Atta-ur-Rehman, and Ejaz of Water Supply and Sanitation Services Peshawar (WSSP) and Engr. Abbas of Abbott Associates (Abbottabad) who were willing to supply the pipe specimens from the selected WSS in the study areas.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baig, S.A., Lou, Z., Baig, M.A. et al. Assessment of tap water quality and corrosion scales from the selected distribution systems in northern Pakistan. Environ Monit Assess 189, 194 (2017). https://doi.org/10.1007/s10661-017-5907-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-017-5907-5