Abstract

Amendment of a carbon paste electrode consisting of graphite and Nujol®, with a variety of organic and inorganic materials, allows direct adsorption of silver nanoparticles (AgNPs) from aqueous solution in either open or close circuit modes. The adsorbed AgNPs are detected by stripping voltammetry. Detection limits of less than 1 ppb Ag are achievable with a rotating disk system. More than one silver peak was apparent in many of the stripping voltammograms. The appearance of multiple peaks could be due to different species of silver formed upon stripping or variation in the state of aggregation or size of nanoparticles. With most of these packing materials, dissolved Ag+ was also extracted from aqueous solution, but, with a packing material made with Fe(II,III) oxide nanoparticles, only AgNPs were extracted. Therefore, it is the best candidate for determination of metallic AgNPs in aqueous environmental samples without interference from Ag+.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Project on Emerging Nanotechnologies reported that there are “1600+ manufacturer-identified nanotechnology-based consumer products introduced to the market” (Vance et al. 2015). Many of these contain silver, zinc oxide, titanium dioxide, or gold nanoparticles (Nam et al. 2013). The US Environmental Protection Agency has identified nanomaterials as emerging contaminants and is reviewing their control under the Toxic Substances Control Act (USEPA 2014, USEPA 2015). One result is that the analysis of environmental media for nanoparticles has received much attention, and, a number of methods have been explored including single particle inductively coupled plasma mass spectrometry (Pace et al. 2012; Pergantis et al. 2012), stripping voltammetry (Jacobs 1963; Toh et al. 2013), and rotating metallic disks or disks whose surfaces were modified chemically to enhance the sorption of nanoparticles (Folsom and Hodge 1975; Hodge and Steinberg 2012).

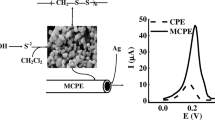

Prior research demonstrated that several chemically treated surfaces absorb silver nanoparticles (AgNPs). These include poly(4-vinylpyridine) (PVPy) (Zhou et al. 2011a; Kim et al. 2010), chitosan (Saifuddin et al. 2011), and 3-aminopropyl-functionalized glass, poly-l-lysine/glass, chitosan/glass, chitosan/stainless steel, and polyaniline/Ni (Hodge and Steinberg 2012). Electrochemical methods have previously been applied to the detection and characterization of nanoparticles. Zhou et al. (2011b) and Stuart et al. (2012, 2013) utilized an electrochemical approach based upon the oxidation of nanoparticles upon collision with an electrode held at a potential higher than the oxidation potential of silver metal, to determine the concentration and size distribution of nanoparticles. Cheng et al. (2013) demonstrated the collection of Ag nanoparticles on a disposable cysteine-modified gold electrode. Giovanni and Pumera (2012) demonstrated size-dependent electrochemical behavior of silver nanoparticles.

In the current study, it was decided to determine if carbon pastes containing chemical amendments, graphite, and Nujol®, when packed into the 2-mm well electrodes, would also enable voltammetric detection of AgNPs after deposition from aqueous solution. In the process of investigating the rotating disk electrode apparatus (RDEA) for collecting silver nanoparticles (AgNPs) from aqueous matrices, including environmental waters, both closed circuit and open circuit conditions were used. For all but one of the amended graphite electrodes explored, dissolved ionic silver (Ag+) was also extracted along with the AgNPs from aqueous matrices and reduced to metallic silver. Thus, upon anodic (oxidative) stripping of electrodes that had been exposed to aqueous samples, the resulting signal for most of the electrodes investigated was the sum of adsorbed silver nanoparticles collected and the ionic silver that was adsorbed and apparently reduced on both the open circuit and closed circuit electrodes. Therefore, dissolved silver in solution interferes with the measurement of AgNPs. However, using the RDEA, with an electrode-packing material made from Fe(II,III) oxide nanoparticles (nano-magnetite) and graphite, it was found that AgNPs were collected selectively without the reduction of Ag+ that was in the samples. Also, the RDEA used in these experiments was found to have an AgNP detection limit of 1 ppb. The electrode amendments included PVPy-graphite, 3-aminopropyl-functionalized silica gel–graphite (APS), goethite (FeOOH)–graphite, titanium–graphite, and Fe(II,III) oxide nano powder–graphite (magnetite).

Experimental

Chemicals

The following chemicals were purchased and used “as is”: synthetic graphite powder (7–11 μm) (Alfa Aesar, Salt Lake City, UT); chitosan (TCI America, Seekonk, MA); titanium metal powder (Chemical Corporation, Bedwas, Wales); 3-aminopropyl-functionalized silica gel (APS) (40–63 μm, 1 mM/g in amine group), PVPy with a molecular weight of ∼60 k, Fe(II,III) oxide (magnetite) nanoparticles, goethite, and Ni(II) oxide nanoparticles (Sigma-Aldrich, St. Louis, MO); Nujol® for IR spectroscopy (Alfa Aesar); potassium phosphate mono- and dibasic and nitric acid (EM Scientific, Darmstadt, Germany); sodium chloride (Ameresco, Solon, OH); and commercial AgNPs from nanoComposix (San Diego, CA). All aqueous solutions were prepared with nanopure water (18 MΩ/cm) from a Barnstead (Thermo Scientific, Detroit, MI) water system.

Electrodes

Three different carbon paste electrode holders were used in these studies. One electrode was a 3-mm-diameter well stationary electrode model MF2010 manufactured by BASi (West Lafayette, IN). This electrode was manufactured out of a solvent-resistant CTFE plastic body (7.5 cm length × 6 mm OD). A metal pin (0.75 cm) mounted in the plastic body of the electrode is used to connect these electrodes to an appropriate potentiostat and to make contact with the carbon paste. The second electrode was modified from an E3 series rotating disk electrode manufactured by Pine Instruments (Grove City, PA). This electrode is a 5-mm-diameter glassy carbon electrode with a Kel-F body that was modified by machining a 5-mm-diameter well of 2 mm depth into the stock electrode. The third carbon paste electrode holder was manufactured by Pine Instruments by modifying an E3 rotating platinum electrode by machining a 5-mm-diameter and 2-mm-deep well in the stock electrode. The electrode wells were filled with various carbon pastes that were prepared by physically mixing the graphite with an amendment such as PVPy. The amendment and graphite (usually 1:4) were weighed out into either the stainless steel vial of a Wig-L-bug grinder (ICL Laboratories, Garfield, NJ) containing a stainless steel pestle or into the grinding chamber of an IKA grinder (Wilmington, DE). The Wig-L-bug vial was shaken for 5 min. The IKA grinder was operated for ∼1 min in 10-s bursts. A packable paste was prepared by mixing 1.00 g of the amended graphite with 0.50 g of Nujol® binder, yielding a paste containing 33.3% of Nujol®, 53.3% graphite, and 13.3% amendment. The paste was packed into the electrode well using a stainless steel spatula. Care was taken to force the paste into the well to assure good electrical contact. The paste was further compressed by vigorously rubbing the electrode on glassine weighing paper and then gently polishing the electrode with filter paper. After packing, the electrode was immersed in buffer and conditioned by cycling the electrode between −600 and 800 mV. The electrode was cycled 25 times starting at −600 mV with a scan rate of 120 mV/s. An unmodified 5-mm-diameter rotating glassy carbon electrode was used for electrochemical detection of silver. This electrode was polished using a polishing kit purchased from Gamry Instruments. The electrode was conditioned by cyclic voltammetry using the same procedure described for the carbon paste electrode.

Between experiments, after anodic stripping, carbon paste electrode holders (BASi or rotating) were cleaned by ultrasonication in methanol for 30 min, flushing with nanopure water, and then ultrasonication in 0.1 M HNO3 for 30 min, followed by vigorous flushing with nanopure water. The electrode was then dried with a stream of nitrogen gas and packed with the amended graphite paste (also called carbon paste or just paste).

Potentiostats

Two different potentiostats were utilized during these studies. An eDAQ e-corder with potentiostat module (Colorado Springs, CO) was used for anodic stripping of carbon paste electrodes after open circuit adsorption of silver nanoparticles. For RDEA experiments, we utilized a CHI (Austin, TX) model 660A potentiostat. A Dr. Bob’s® Electrochemical Cell Kit from Gamry Instruments (Warminster, PA) was used with the eDAQ instrument for stripping experiments after open circuit exposure of the BASi carbon paste electrode. A Pine Instruments Modulated Speed Rotator was used for RDEA experiments with the CHI instrument. The rotation rate was controlled by the CHI software. Electrochemical studies were performed in ∼150 mL water-jacketed cell purchased from Pine Instruments. Constant temperatures were maintained using a VWR (Radnor, PA) circulating water bath. The Pine calomel reference electrode was inserted directly into the buffer solution. The platinum counter electrode was contained in a bridge tube.

Synthesis of silver nanoparticles

Photochemical reduction was used to produce many of the silver nanoparticles used in this study. The method was similar to a published method that utilized citrate or polyvinylpyrrolidone (PVP) as the capping reagent and as the reducing agent, along with UV irradiation (Huang and Yang 2004). A 1.0-mL aliquot of 0.5 M sodium citrate and a 0.100-mL aliquot of 0.1 N AgNO3 were placed in a quartz reaction vessel. The mixture was irradiated in a Rayonet (Southern New England Ultraviolet Company, Branford, CT) photochemical reactor for 2 h with ten 254-nm lamps. This resulted in AgNPs with a mean diameter of 87 nm. The diameter was determined by measuring the diffusion coefficient of the product with a NanoSight NS500 (Malvern, UK) instrument.

Procedure for AgNP analysis in aqueous media in open circuit mode

In a typical experiment using a BASi carbon paste well electrode containing an amendment, the electrolytic cell was filled to 50 mL with a sample solution. The solution was stirred at ∼1000 rpm for various lengths of time by rotating the electrode in the solution using an overhead laboratory stirrer (IKA RW 20). At the conclusion of the exposure period, the electrode was transferred to the potentiostat immersed in an appropriate buffer and stripped using the program in Table 1 and analyzed for dissolved Ag+ as described below.

For experiments using rotating carbon paste well electrodes, the electrode was attached to the rotator and immersed in buffer + sample. The electrode surface was inspected to make sure bubbles were not clinging to the surface, and the electrode was conditioned as also described in the previous section.

The electrode was rotated at 2000 rpm in the sample for 2 to 24 h at a potential of −200 mV and then stripped (scanned) from −200 to 800 mV using the differential pulse method with the program settings described in Table 1. Rotating disk voltammetry was conducted in a water-jacketed vessel that was maintained at 15 °C, unless otherwise indicated, with the headspace continuously sparged with nitrogen gas. The same sampling method was used for all of the rotating carbon paste electrodes.

Analysis of dissolved silver (Ag+) using a glassy carbon electrode

For some experiments, the buffer solution was replaced after the rotation (sorption) step. The electrode was then stripped into the fresh solution, and the recovered silver was then quantified in order to measure the recovery of silver nanoparticles. An unmodified Pine Instruments glassy carbon electrode (E3) was used to measure dissolved silver concentrations in stripping solutions in both the open and closed circuit modes. In the case of open circuit adsorption experiments, the adsorbed particles were stripped into pH 7 buffer. The stripping solution was transferred to a voltammetry cell equipped with a rotating glassy carbon electrode. This recovered silver in the stripping solution was measured by differential pulse anodic stripping voltammetry using the potentiostat setting that are shown in Table 1. The stripping solution volume was 50 mL of PHOSCL buffer if obtained from an open circuit experiment using the BASi electrode and 100 mL of PHOSCL if obtained from a closed circuit experiment using the modified rotating disk electrodes. The 50-mL samples were adjusted to 100 mL with additional buffer before the standard addition analysis. The electrode was cleaned before use using the Gamry Instruments fine polishing kit. The electrode was thoroughly rinsed with distilled water after polishing and then immersed in the pH 7 buffer solution. The cell was rinsed with copious quantities of distilled water then 100 mM nitric acid followed by distilled water. The cell was filled with buffer solution, and the electrode was initially conditioned by cycling from −600 to 800 mV at 120 mV/s for 50 complete cycles. After cycling the electrode, the sample solution was placed in the cell. During the course of this study, it was discovered that for reproducible analysis, the electrode must be subjected to several (4–6) deposition and stripping cycles to obtain consistent results. Deposition and stripping conditions were as follows. Silver deposition was carried out for 10 min at −600 mV with the electrode rotating at 2000 rpm. At the conclusion of the deposition period, the electrode rotation was stopped and the electrode was allowed to rest for 20 s at −600 mV before stripping was initiated. Stripping was performed using differential pulse voltammetry. The potentiostat program settings are shown in Table 1.

Using the repetitive run feature of the CHI potentiostat, the deposition and stripping experiment was run three to six times. For standard addition analysis, the deposition and stripping was continued until a consistent silver stripping peak was observed. At concentrations of 0–2 ppb, this generally required four or five runs. At higher concentrations, three runs generally sufficed. After a consistent silver signal was obtained, a 50-μL aliquot of a 10-ppm Ag+ standard was added to the sample using a micropipette. The analysis was repeated until a consistent signal was obtained.

Water samples

We obtained Lake Mead water samples from Boulder Beach, which was used without any modification. Experiments were also conducted with Perrier™ mineral water that was allowed to lose the added CO2 (go flat) over several days before experiments began. Several additional water samples included “raw” and processed wastewater obtained from the Clark County Water Reclamation District, Las Vegas, NV. The USEPA, NERL, ESD, Characterization, and Monitoring Branch collected unfiltered surface water samples from Silver Creek, Park City, Utah, on October 2 to October 4, 2012. All water samples were stored at 4 °C.

Results and discussion

The first Ag+ anodic stripping experiments that were conducted in a 0.1 M acetic acid/acetate pH 4.5 buffer demonstrated that the addition of NaCl chloride shifted the Ag stripping peak to a lower voltage and prevented the precipitation of AgCl(s) by complex ion formation. Because natural waters all contain chloride at low concentration, it was felt that one could minimize the formation of AgCl(s) by adding sufficient chloride so that Ag+ would exist predominately as AgCln 1-n species. Using Mineql 4.5+ (Environmental Research Software, Hallowell, ME) to calculate the speciation of silver, it showed that 0.5 M NaCl should be sufficient to control the speciation. A pH 7 phosphate buffer was also tested and utilized with several different amendment–graphite electrodes. Most experiments were performed in 0.1 M pH 7 phosphate buffer made with NaH2PO4 (37 mM) and Na2HPO4 (63 mM) containing 0.5 M NaCl (PHOSCl) and demonstrated that anodic stripping was very similar to that in the pH 4.5 buffer. We also prepared PHOSCL with double the concentration of phosphate and NaCl, called 2× PHOSCl. This was for mixing 1:1 with water samples before analysis with the various carbon paste electrodes. Buffers with pH values greater than 7 were not used to avoid the precipitation of silver oxide and possible precipitation of magnesium hydroxide in natural water samples, which would co-precipitate the AgNPs. Also, it was found that using a deposition potential of −200 mV tended to minimize the reduction of Ag+. The electrode was immersed in a 1:1 mixture of buffer (2× PHOSCl) and sample.

The results for sampling using the rotating disk method in open and closed circuit modes are presented in the following sections. The data have been organized by the amendment added to the graphite used for preparing the carbon paste. The amendment was mixed with the graphite in the ratio of 1:4 by weight, unless otherwise stated. Most of the experimental work was done using AgNP prepared in our laboratory by a photochemical method outlined previously.

PVPy-amended graphite electrodes

Open circuit mode

The results for the accumulation of AgNPs and Ag+ by a rotating (1000 rpm) BASi well electrode packed with a paste containing PVPy–graphite at 1:4 bound containing 33% Nujol are presented first. Stripping experiments for open circuit sorption experiments were performed with the eDAQ potentiostat. The best stripping results were achieved using a linear scan (−200 to +800 mV) with 50 mL of sample to which the AgNPs were added. These AgNP deposition experiments were carried out at 30 °C, which from preliminary experiments appeared to be optimal for the extraction. AgNP concentrations were generally in the range of 10–20 ppb (as total silver). Results are shown in Fig. 1 for the recovery of AgNPs from a 20-ppb citrate-capped AgNP solution in 50 mL of 2 mM NaHCO3, used to mimic natural groundwater. The electrode was then transferred to the Dr. Bob’s® cell and stripped. Two peaks that can be related to silver are apparent in the voltammogram. The signal at ∼0.5 V is apparent with all of the amendments used. The standard potential for the reduction of silver ion to silver metal is +0.8 V. Thus, the predicted reduction potential for Ag+ relative to the calomel electrode is about +0.55 V. The anodic stripping was repeated a number of times to determine if silver remains attached to the electrode. In some cases, it was apparent that much of the silver remains associated with the electrode and is reduced during the repeated scans. The second and subsequent scans show predominately the silver signal at ∼0 V in Fig. 2. As noted previously, in the presence of chloride, the silver reduction is shifted to a lower potential.

We do not have a clear explanation for this effect. We hypothesize that a significant fraction 50% or so of the AgNPs sorbed on contact with the experimental solution may diffuse into the carbon paste electrode, so that during stripping the liberated Ag+ may not be in contact with the solution chloride concentration. The influence of chloride on AgNP stripping has been noted by Stuart et al. 2013. Repetitive scans (four to eight) of the PVPy–graphite electrodes indicate that a large fraction of the silver remains associated with the electrode as Ag+ and is reduced when the potentiostat returns to the initial potential, −600 mV. On the other hand, Zhou et al. (2011b ) observed that the stripping potential of silver nanoparticles adsorbed on glassy carbon shifted with the quantity of adsorbed nanoparticles (exposure time). They suggested that this effect was a result of the degree of aggregation of the particles.

Splitting of the silver signal between several different peaks was also observed with some of the closed circuit rotating disk experiments as well. With the PVPy-amended graphite electrodes, the peak areas decrease with the stripping scan number. This gradual decrease is because of relatively tight binding of the silver to the electrode. With repetitive scanning, it was possible to remove most of the silver from the electrode. For the above experiment, the strip solution was transferred to the Pine Instruments system to determine silver “recovered” using the standard addition method. This assumes that all of the silver was stripped from the electrode before analysis with the glassy carbon electrode. The result showed that the open circuit method recovered about 21% of the silver (as AgNPs) from 50 mL of 2 mM NaHCO3 after ∼19 h. The sorption of Ag+ to the PVPy–graphite electrode was also investigated. Experiments were done with 20 ppb Ag+ in 2 mM NaHCO3 in deionized water for 23 h at 30 °C in the open circuit mode. The standard addition results indicate that ∼10% of the Ag+ is adsorbed and presumably reduced to silver metal on the electrode.

A similar experiment with Lake Mead water was done to gauge AgNP recovery. Citrate-capped AgNPs were added to 50 mL of Lake Mead water. The AgNP concentration was made ∼22 ppb. A BASi electrode was packed with the PVPy–graphite paste and suspended in Lake Mead water for ∼23 h at 30 °C, while rotating at 1040 rpm. The initial scan done on the eDAQ potentiostat showed a strong silver signal, predominantly at 0.5 V. Again, the silver signals in subsequent stripping scans were shifted predominately to ∼0 V. The stripping solution was transferred to the Pine Instruments rotating disk system for standard addition analysis with the glassy carbon electrode. The silver recovery was ∼10% from the lake waster versus ∼21% from 2 mM NaHCO3 buffer solution. This lower recovery was observed with other “real-world” water samples (natural and wastewater) and may reflect a change in the surface chemistry of the AgNPs in real-world samples that renders them less likely to adsorb to the surface of the electrode.

The silver signal for AgNPs in 2 mM NaHCO3, in Lake Mead water, and for Ag+ in 2 mM NaHCO3, is compared in Fig. 3 to facilitate the comparison of results. The results indicate that similar electrochemical signals are obtained in Lake Mead water and bicarbonate solution. The signal for Ag+ is significant and could complicate the interpretation of recovery experiments or nanoparticle analysis of water samples by adding to the silver signal from the AgNPs.

Comparison of Ag signals produced during repetitive anodic stripping scans in three different media. Nanoparticles were concentrated using an open circuit PVPy–graphite electrode. The electrode is left in the solution after each scan, and the potential is returned to the initial potential of −200 mV

We also examined the open circuit method for concentrating AgNPs from out-gassed (flat) Perrier mineral water as an example of a hard water sample. The PVPy electrode was exposed to ∼20 ppb Ag as AgNPs for ∼23 h at 30 °C at 1040 rpm. The electrode was subsequently stripped into the PHOSCL buffer. The initial stripping showed only the ∼0.5-V signal. Repetitive anodic stripping scans showed very little additional silver signal after the first scan suggesting that silver was not well retained by the electrode.

Visual inspection of the electrode showed that it was clearly coated with a white precipitate, which strongly effervesces when treated with dilute acid. The coating is most likely CaCO3. One possibility is that the coating prevents the reduction of adsorbed Ag+ when the electrode is returned to the initial potential of −200 mV. The stripping solution was analyzed by the standard addition method showing that ∼51% of the silver was recovered from the Perrier water. This is over twice the recovery from AgNPs in 2 mM NaHCO3 buffer solution. It is possible that AgNPs were co-deposited with the carbonate precipitate in addition to being sorbed by the PVPy paste.

The behavior of the closed circuit PVPy–graphite electrode was examined using 10 ppb Ag+ and 2 h of deposition times up to 16 h. The experiment was run at a constant voltage of −200 mV, in PHOSCL buffer, at 15 °C. After deposition, the differential pulse anodic scans were started from −300 mV. The results are shown in Fig. 4. The recoveries of Ag+ were low for the first few runs; however, there is a small silver peak that begins to be apparent after the third run.

Closed circuit mode

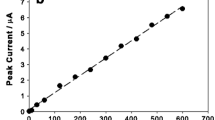

Experiments using the PVPy–graphite paste electrode were performed in the closed mode using ∼11 ppb of citrate-capped AgNPs (Fig. 5). The anodic stripping silver peak is at ∼0 V and is large compared to a small peak at 0.5 V. These analytical conditions discriminate against the dissolved silver, although simultaneous deposition occurs. In other closed circuit experiments, it was found that the reproducibility was enhanced if the electrode was preconditioned for 3 min at +900 mV (no rotation) in the matrix. Preconditioning was found to inhibit the deposition of Ag+. The effect of increased deposition time on the collection of AgNPs is shown in Fig. 6 where the voltammograms are superimposed. The deposition voltage was maintained at −200 mV, and preconditioning was utilized between runs. The peak areas have been plotted as a function of deposition time in Fig. 7. The curvature in the plot may be a result of electrode aging or depletion of the AgNPs with cumulative increased deposition time. It is clear that the silver signal does not increase linearly with deposition time. Similar experiments to those for the recovery of AgNPs from PHOSCL were conducted for the recovery of AgNPs from water from Lake Mead and for Perrier water. Both were diluted 1:1 with PHOSCL. The results for those recoveries are shown in Fig. 7.

Fe(II,III) oxide (magnetite)-amended graphite electrodes

A mixture of 1:4 Fe(II,III) magnetic oxide nanopowder (magnetite)–graphite with Nujol was performed in the open and closed circuit experiments to test the adsorption of AgNPs.

Open circuit mode

Recovery experiments were performed with the rotating disk (2000 rpm) packed with the graphite–magnetite mixture in 2 mM NaHCO3 and PHOSCL using citrate-capped AgNPs (11 ppb total silver) that were prepared by the photochemical synthesis. In 2 mM NaHCO3, the anodic stripping peak after 70 h of exposure was much higher than that at 21 h. The method of standard addition showed that 70% of the AgNPs were recovered by the electrode after 70 h. The first stripping scan of the 70-h electrode showed a large peak at ∼0.5 V and a small one at ∼0 V. The results for the sorption of the AgNPs by the graphite–magnetite from PHOSCL buffer is compared to graphite amended with either PVPy or APS. The results are presented in Fig. 8 which show that the recovery of AgNPs by the magnetite–graphite electrodes levels off after about 15 h.

We explored the deposition of 10 ppb free silver (Ag+) onto the magnetite–graphite electrode in PHOSCL buffer. No silver signal was found in the anodic stripping scans at deposition times up to 24 h at −200 and 2000 rpm. Thus, Ag+ was not collected under the same conditions where the collection of AgNPs was observed. Using the magnetite–graphite electrode in PHOSCL provides an AgNP-selective collection method.

Extracton of AgNPs from “flat” Perrier water, a 1:1 mixture with 2× PHOSCL, was monitored as a function of time. The water was spiked with ∼11 ppb total silver as citrate-capped AgNPs, and the results are shown in Fig. 9. There are at least three Ag stripping peaks in the voltammograms for Perrier water as seen in Fig. 9. At longer deposition times, the ∼0-V peak predominates. The silver signal in “Perrier” is graphed as a function of deposition time in Fig. 10. The signal was definitely attenuated from what was observed with buffer alone. This is most likely due to the observed deposition of carbonate minerals on the electrode as observed with the PVPy electrode.

The behavior of AgNPs on a rotating disk paste electrode with magnetite–graphite was examined in a 1:1 mixture of Lake Mead water and concentrated PHOSCL that was spiked with ∼11 ppb citrate-capped AgNPs. The anodic scans are plotted versus time in Fig. 11. As noted for the Perrier water, there are at least three silver peaks in the anodic stripping scans in the Lake Mead water. The majority of the silver signal is at ∼0 V for the Lake Mead water. The silver peak signals are at ∼0, ∼0.3, and ∼0.5 V, and the summed areas are graphed as a function of deposition time in Fig. 11.

The graphite–magnetite electrode, when exposed to aqueous samples in 1:1 PHOSCL buffer, collects AgNPs without collecting free silver, Ag+, and thus provides an electrochemical method for measuring AgNPs without interference from Ag+ in environmental samples.

Comparison of AgNPs in groundwater from Utah using PVPy and magnetite-amended electrodes

An AgNP-spiked sample from Silver Creek, Park City, Utah, was analyzed with both a nano-magnetite graphite and a PVPy–graphite electrode. The water sample contained visible suspended and settled particles. The sample was inverted several times and then filtered through a 1-μm glass fiber filter and then diluted to 1:1 with the PHOSCL buffer. The RDEA was run at −200 mV and 2000 rpm, for 24 h. The results are presented in Fig. 12. The magnetite–graphite electrode produced a much stronger silver signal when compared to the trace generated using a PVPy–graphite electrode in the RDEA.

Results for other amendments examined

Table 2 lists the observation for testing the following amendments: chitosan, APS, nickel oxide (NiO), goethite, and titanium (Ti). None of these amendments discriminated against the collection of Ag+, as did magnetite–graphite. However, 3-aminopropyl silica, goethite, and titanium show high recoveries for both AgNPs and Ag+.

Summary and conclusions

A variety of materials are apparently capable of adsorbing AgNPs from aqueous solution. These materials can function as adsorbents when mixed with graphite and Nujol®. The adsorbed AgNPs can be detected by stripping voltammetry. Adsorption was successful in an open circuit (electrode is not connected to the potentiostat) and closed circuit mode with the electrode held at −200 mV (relative to a calomel reference electrode) and rotating at 2000 rpm. Detection limits of less than 1 ppb Ag were achievable with the rotating disk system. More than one silver peak was apparent in the stripping voltammograms for most of the materials tested. The origin of the multiple peaks was not clear, although they may be related to the speciation of the “stripped” silver. Adsorbed AgNPs were quantified in open circuit experiments by a standard addition anodic stripping voltammetry procedure. The adsorbed silver could have also been quantified after anodic stripping using graphite furnace atomic adsorption or ICPMS. These latter methods could result in much lower detection limits and should be pursued in future studies.

With most of these materials, dissolved Ag+ was also extracted from aqueous solution and reduced to metallic silver. This reduction occurred both in open circuit and with the rotating disk extractions. The composite electrode made with Fe(II,III) oxide nanoparticles (nano-magnetite) obtained from Sigma-Aldrich did not appear to adsorb or reduce Ag+ but does collect AgNPs from aqueous samples. Therefore, it is the best candidate for determination of metallic AgNPs in aqueous environmental samples.

References

Cheng, F., Betts, J. W., Kelly, S. M., Schaller, J., & Heinze, T. (2013). Synthesis and antibacterial effects of aqueous colloidal solutions of silver nanoparticles using aminocellulose as a combined reducing and capping reagent. Green Chemistry, 15(4), 989–998.

Folsom, T. R., & Hodge, V. F. (1975). Experiments suggesting some first steps in the dispersal and disposal of plutonium and other alpha emitters in the ocean. Marine Sci. Comm., 13-4, 213–247.

Giovanni, M., & Pumera, M. (2012). Size dependant electrochemical behavior of silver nanoparticles with sizes of 10, 20, 40, 80 and 107 nm. Electroanalysis, 24(3), 615–617.

Huang, H., & Yang, X. (2004). Synthesis of polysaccharide-stabilized gold and silver nanoparticles: a green method. Carbohydrate Research, 339, 2627–2631.

Hodge, V.F., Steinberg, S.M. (2012) Final report: the separation and analysis of manufactured nanomaterials in environmental samples. EPA Report on contract # EP-11-D-01618.

Jacobs, E. S. (1963). Anodic stripping voltammetry of gold and silver with carbon paste electrodes. Analytical Chemistry, 35(13), 2112–2115.

Kim, H., Ryoo, H., & Shin, K.-S. (2010). Adsorption and aggregation characteristics of silver nanoparticles onto a poly (4-vinylpyridine) film: a comparison with gold nanoparticles. Langmuir, 13, 10827–10832.

Nam, S.-W., Kim, S.-W., & An, Y.-J. (2013). No evidence for the genotoxic potential of gold, silver, zinc oxide, and titanium dioxide nanoparticles in the SOS chromotest. J. Applied toxicology, 33, 1061–1069.

Pace, H. E., Rogers, N. J., Jarolimek, C., Coleman, V. A., Gray, E. P., Higgins, C. P., & Ranville, J. F. (2012). Single particle inductively coupled plasma-mass spectrometry: a performance evaluation and method comparison in the determination of nanoparticle size. Environmental Science and Technology, 46(22), 12272–12280.

Pergantis, S. A., Jones-Lepp, T. L., & Heithmar, E. M. (2012). Hydrodynamic chromatography online with single particle-inductively coupled plasma mass spectrometry for ultra trace detection of metal-containing nanoparticles. Analytical Chemistry, 84(15), 6454–6462.

Saifuddin, N., Nian, C. Y., Zhan, L. W., & Ning, K. X. (2011). Chitosan-silver nanoparticles composite as a point-of-use drinking water filtration system for household to remove pesticides in water. Asian Journal of Biochemistry, 6(2), 142–159.

Stuart, E. J. E., Zhou, Y.-G., Rees, N. V., & Compton, R. G. (2012). Determining unknown concentrations of nanoparticles: the particle-impact electrochemistry of nickel and silver. RSC Advances, 2012(2), 6879–6884.

Stuart, E. J. E., Tschulik, K., Omanovic, D., Cullen, J. T., Jurkschat, K., Crossley, A., & Compton, R. G. (2013). Electrochemical detection of commercial silver nanoparticles: identification, sizing and detection in environmental media. Nanotechnology, 24, 444002 (6pp).

Toh, H. S., Batchelor-McAuley, C., Tschulik, K., Uhlemann, M., Crossley, A., & Compton, R. C. (2013). The anodic stripping voltammetry of nanoparticles: electrochemical evidence for the surface agglomeration of silver nanoparticles. Nanoscale, 5(11), 4884–4893.

USEPA (2014). 505-F-14-002 technical fact sheet—nanomaterials.

USEPA (2015) Control of nanoscale materials under the toxic substances control act, https://www.epa.gov. Accessed 15 Aug 2016.

Vance, M., Kulken, T., Vejerano, E. P., McGinnis, S. P., Hochell Jr., M. R., Rejeski, D., & Hull, M. (2015). Nanotechnology in the real world: redeveloping the nanomaterial consumer products inventory. Beilstein Journal of Nanotechnology, 6, 1769–1780.

Zhou, Y.-G., Rees, N. V., & Compton, R. G. (2011a). The electrochemical detection and characterization of silver nanoparticles in aqueous solution. Angewandte Chemie, International Edition, 50, 4219–4221.

Zhou, Y.-G., Rees, N. V., & Compton, R. G. (2011b). Electrode–nanoparticle collisions: the measurement of the sticking coefficient of silver nanoparticles on a glassy carbon electrode. Chemical Physics Letters, 514, 291–293.

Acknowledgements

The US Environmental Protection Agency through its Office of Research and Development funded, managed, and collaborated in the research described here under contract EP-11-D-1618 to the University of Nevada, Las Vegas. It has been subjected to agency review and approved for publication. Mention of trade names or commercial products does not constitute endorsement or recommendation for use.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Steinberg, S., Hodge, V., Schumacher, B. et al. Sampling for silver nanoparticles in aqueous media using a rotating disk electrode: evidence for selective sampling of silver nanoparticles in the presence of ionic silver. Environ Monit Assess 189, 99 (2017). https://doi.org/10.1007/s10661-017-5809-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-017-5809-6