Abstract

In this work, particulate matter was collected using an active sampling system consisting of a PM10 (<10 μm) inlet coupled to a multifold device containing six channels, connected to a vacuum pump. Each channel was equipped with a filter holder fitted with adequately chosen filters. The system was fixed on a metallic structure, which was placed on the roof of the laboratory building, at the Faculty of Sciences, in Lisbon. Sampling took place under flow-controlled conditions. Aerosols were extracted from the filters with water, in defined conditions, and the water-soluble fraction was quantified by ion chromatography (IC) for the determination of inorganic anions (Cl−, NO3 − and SO4 2−). Equivalent sampling through the various channels was validated. Validation was based on the metrological compatibility of the content results for the various filters. Ion masses are metrologically equivalent when their absolute difference is smaller than the respective expanded uncertainty. When this condition is verified, the studied multifold device produces equivalent samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Atmospheric aerosols consist of relatively stable suspensions of solid or liquid particles in air either directly emitted into the atmosphere (primary) or formed by chemical reactions (secondary) (Seinfeld and Pandis 1998).

Particulate matter (PM) in air is a matter of great concern and the European legislation imposes limits on its emissions (EC 2008). The knowledge of both the mass of PM and its chemical composition is of relevance for making decisions concerning air quality control in urban areas.

Primary particles are usually produced by mechanical processes such as grinding or erosion and have their origin mainly in natural processes such as wind action on soil, rocks and sea surfaces. Secondary ones are a consequence of condensation and nucleation reactions, their major constituents belonging to three main groups, sulphates, nitrates and organic compounds and, in general, having their origin in anthropogenic sources, namely car traffic and industrial processes (John 2011). Hence, chemical composition reflects their source and origin.

Atmospheric aerosol sampling creates specific problems, since air is in motion and the particles have a great variability of sizes and chemical properties (WMO/GAW 2003). This diversity often points to the need to use different types of filters, conveniently selected according to the respective target measurand, the analytical methodology and the flow rate used for active sampling (McMurry 2000; EMEP 2001; Vicent 2007; Raynor 2011).

Atmospheric samples are single events and there is evidence of large uncertainties being introduced by independent parallel sampling (Arias et al. 2013), thus giving rise to undesirably high uncertainty. This variability is tentatively overcome by using a common air collector which distributes equivalent fractions of the aerosols through its various channels followed by deposition onto the filters placed at the filter holders. There is awareness of the possible effect that fluid dynamics may have upon sampling reflecting on the degree of equivalence of samples from the various channels.

Despite the ample variety of literature references on sampling issues, both indoor and outdoor, and on the validation of the associated data, by both individuals and organizations, denoting the relevance of the problem (Harrison and Pio 1981; Brockmann 2001; Raynor et al. 2011; Watson and Chow 2011; Anthony et al. 2014), the developed instrumental and metrological approaches are, to the authors’ understanding, original, simple and fit for the purpose.

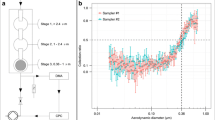

This work presents a strategy for the validation of a specific multichannel sampling system and the application of the presented approach to assess its performance. The multifold consists of two main stainless steel tubes, connected by six channels, each with a filter holder. It is adapted to a common PM10 (particulate matter with aerodynamic diameter <10 μm) inlet (Nunes 2002) and to a vacuum pump (Fig. 1a, b). The performance was assessed through the data obtained from ion chromatography (IC) of Cl−, NO3 − and SO4 2− in the water-soluble fraction of the aerosols (Lopez-Ruiz 2000; Mouli et al. 2003) collected on the differently positioned filters.

The equivalence of various sets of combinations of channels and filters was verified by means of the metrological compatibility of corresponding ion masses (JCGM 2012).

The studied multifold system can be eventually used for the quantification of other inorganic or organic species of aerosols, once the validity of replicate collection, hence equivalent sampling, is observed for the chemical species under concern and at the appropriate sampling flow conditions.

Material and methods

Sampling setup

Aerosol samples were collected onto Whatman® 41 filters of 47 mm in diameter, between April and May 2012. The sampling system (Fig. 1a) was equipped with a PM10 inlet, connected by a stainless steel tube to a multifold of six channels. Each channel is coupled to a filter holder (Fig. 1b); sets of measurements can be conducted with all six channels or with only some of them. The system was connected to a vacuum pump BOC Edwards XDS 10c, operating 24 h, at a flow rate of 12 L min-1 controlled by a flow meter, Aalborg. Filters were manually replaced daily.

Three sets of samples, each set on a different day, were collected with filter holders placed in different positions (set A—1, 2, 3, 4, 5, 6; set B—4, 5, 6 and set C—2, 3), aiming at comparing results within each set. The sampling system was placed on the 4th floor roof terrace of building C8 of the Faculty of Sciences of the University of Lisbon, Portugal.

Analytical assay

All chemicals used for the preparation of both calibration standard solutions and eluent were of analytical reagent grade, and the water used in all steps was obtained from a Milli-Q Academic system from Millipore® (18.2 MΩ cm). In order to avoid sample contamination, filters were handled with plastic gloves and tweezers, in a clean air bench (Faster Two 30).

Mixed (Cl−, NO3 −, SO4 2−) calibration standards were prepared from each anion stock standard solution according to the procedure shown in Fig. 2. Each filter with the collected aerosol was inserted in a PTFE 15-mL bottle to which 10 mL, V 1, of water was added. The capped bottles were sonicated in an ultrasonic bath (Branson 3200, Sotel) at (45 ± 1) °C for (45 ± 2) min, and the extracted solutions were filtered through a pre-washed Whatman 41® filter. If necessary, a portion V 2 of the sample extract was diluted by adding water, V 3 [dilution factor, F dil = (V 2 + V 3)/V 2], before being analysed by ion chromatography (IC). IC measurements were performed in a Dionex® DX500 system with conductivity detection (CD20), equipped with Peaknet ® software. The chromatograph was equipped with an isocratic pump IP20, an anion pre-column IonPack AG14 4 × 50 mm, an analytical column IonPack AS14 4 × 250 mm and an anion suppressor ASRSR–Ultra 4 mm. The eluent was a carbonate-bicarbonate buffer solution (3.5 mmol dm−3 Na2CO3 + 1 mmol dm-3 NaHCO3).

Schematic representation of the dilution of the stock solutions for the preparation of the calibration standards for IC determinations (Silva et al. 2012). γ is the mass concentration of the specified anion in solution

Daily calibration with four equidistant mass concentration calibration standards (concentrations shown in Fig. 2) fit for the application of the linear unweighted regression model (Miller and Miller 2005; Silva and Camões 2010) was performed using duplicate measurements.

Evaluation of the measurement uncertainty

The evaluation of the measurement uncertainty involves different steps, namely definition of the measurand, identification of the sources of uncertainty, quantification of the uncertainty components, combination of the uncertainty components and expansion of the combined standard uncertainty (JCGM 2008; Silva et al. 2012). In this study, the measurand is the mass of a specific anion (chloride, nitrate or sulphate) in the aerosol water-soluble fraction, obtained as described above. The mass, m, of an ion was estimated from Eq. (1):

where γ is the mass concentration of the ion in the diluted sample extract, V 1 is the volume of aerosol extract and F dil is the dilution factor.

The cause and effect diagram in Fig. 3 schematically presents the identified sources of uncertainty to be considered (Silva and Camões 2010; Silva et al. 2012). The input quantities presented in Fig. 3 are the variables of Eq. (1) and an additional multiplying unitary factor, f Ext, representing the precision of the extraction of ionic compounds from the aerosols in the defined conditions. Although this factor (f Ext = 1) does not affect the estimation of the measured quantity value m, it is required to define the way in which extraction precision affects the uncertainty of m. All input quantities presented in Fig. 3 are independent.

Cause and effect diagram representing the identified sources of uncertainty; Rep. repeatability, Tol. tolerance of the nominal value of the pipette, Temp. temperature effect (Silva et al. 2012)

The quantification of the uncertainty associated with the input quantities is described in detail in the following paragraphs; an explanation is given on how variables are divided in the independent components represented in the respective vector (Fig. 3).

All volumetric operations are affected by the repeatability of the volumetric material manipulation (Rep.) and by the tolerance of its nominal value (Tol.). The volumetric measurement V 1 is also affected by temperature (Temp.). The concentration estimate of the diluted extract (γ) is affected by the statistical interpolation of the sample signal in the calibration curve (Interpolation) and by the uncertainty associated with the concentration of the calibration standards (f std).

The quantification of the uncertainty components is based on the following equations:

-

The uncertainty associated with the dilution factor F dil = (V 2 + V 3)/V 2 was estimated using Eq. (2):

$$ {u}_{F_{\mathrm{dil}}}=\sqrt{{\left(-\frac{V_3}{{\left({V}_2\right)}^2}\right)}^2u{\left({V}_2\right)}^2+{\left(-\frac{1}{V_2}\right)}^2u{\left({V}_3\right)}^2} $$(2)where u(x) is the standard uncertainty of variable x. Equation (2) results from the application of the uncertainty propagation laws (UPL) to the F dil equation (Silva et al. 2012).

The uncertainty associated with measured volumes, V 1, V 2 and V 3, is quantified as proposed in the Eurachem/CITAC Guide (Eurachem 2012).

-

Statistical interpolation uncertainty u Int was estimated using Eq. (2) deduced from the linear unweighted regression model (Silva et al. 2012):

$$ {u}_{\mathrm{Int}}\cong \frac{s_{y/x}}{b}\sqrt{\frac{1}{p}+\frac{1}{q}+\frac{{\left(\overline{y_0}-\overline{y}\right)}^2}{b^2{\displaystyle {\sum}_j{\left({x}_j-\overline{x}\right)}^2}}} $$(3)where p is the number of signals of standards used for the calibration of the IC, q is the number of sample signals, x j is the mass concentration of the calibration standard of signal j (j = 1 to p), \( \overline{x\;} \) is the average of p x j values, \( \overline{y} \) is the average of p y j values and \( {\overline{y}}_0 \) is the average of the q sample signals. The relative standard uncertainty of statistical interpolation u′Int was estimated by dividing the standard uncertainty of statistical interpolation u Int by the mass concentration of the ion estimated by interpolating \( {\overline{y}}_0 \) in the regression line.

The relative standard uncertainty, u′std, associated with the preparation of the standard solutions (i.e. associated with f std) is equivalent to the relative standard uncertainty of the concentration of the diluted stock solution from which standard solutions are prepared (Eq. 3). This simplification is possible if standard solutions are prepared from the diluted stock solution through dilutions with negligible uncertainty considering instrumental signal precision (Silva and Camões 2010; Silva et al. 2012).

$$ u{\prime}_{\mathrm{std}}=\sqrt{{\left(u{\prime}_{\mathrm{stk}}\right)}^2+{\left(u{\prime}_{\mathrm{VA}}\right)}^2+{\left(u{\prime}_{\mathrm{VB}}\right)}^2} $$(4)where

-

u ′ stk is the relative standard uncertainty of the stock solution concentration.

-

u ′ VA is the relative standard uncertainty of the initial volume of the dilution of the stock solution.

-

u ′ VB is the relative standard uncertainty of the final volume of the dilution of the stock solution.

-

-

The combined relative standard uncertainty, \( {u}_{\mathrm{c}}^{\prime } \), was estimated through the application of UPL, Eq. (4):

$$ u{\prime}_{\mathrm{c}}=\sqrt{{\left(u{\prime}_{\mathrm{Int}}\right)}^2+{\left(u{\prime}_{\mathrm{std}}\right)}^2+{\left(u{\prime}_{v_1}\right)}^2+{\left(u{\prime}_{F_{\mathrm{dil}}}\right)}^2+{\left(u{\prime}_{\mathrm{Ext}}\right)}^2} $$(5)where the terms under square root are the squares of the relative standard uncertainties of the statistical interpolation, u ′ Int, standards concentration, u ′ std, sample extract volume, \( u{\prime}_{v_1} \), dilution factor, \( u{\prime}_{F_{\mathrm{dil}}} \) and extraction efficiency, u ′ Ext, respectively.

The relative standard uncertainty of the extraction, u ′ Ext (i.e. associated with f Ext) has been estimated previously (Silva et al. 2012) as being 11.05 % for chloride, 13.07 % for nitrate and 8.24 % for sulphate.

-

Once the relative uncertainty, u ′ c, has been converted into the absolute uncertainty, u c, the expanded uncertainty was estimated by multiplying the combined standard uncertainty, u c, by a coverage factor of 2 to obtain an expanded measurement uncertainty, U c, for the confidence level of approximately 95 %. Table 1 presents the estimated m values with expanded uncertainty.

Table 1 Estimated mass, m (ng), of chloride, Cl−, nitrate, NO3 − and sulphate, SO4 2− ions, in filters placed in each of the various selected filter holder positions, reported with expanded (k = 2), uncertainty, U

Compatibility of measurements of filters

According to the VIM, the compatibility of measurement results is “the property of a set of measurement results for a specified measurand, such that the absolute value of the difference of any pair of measured quantity values from two different measurement results is smaller than some chosen multiple of the standard measurement uncertainty of that difference” (JCGM 2012). In order to carry out the compatibility test of pairs of measurement results from different positions of filter holders in the chosen sets, for a confidence level of approximately 95 %, Eq. (5) was used:

where |m i − m j | or |d| is the absolute difference of the masses of the ion under concern in filters i and j, and u i and u j are the respective standard uncertainties. The second term of Eq. (5) (\( 2\sqrt{\left({u}_i^2+{u}_j^2\right)}={U}_d \)) is the expanded uncertainty of the difference, d. Results are declared compatible and positions are metrologically equivalent, “Eq” (Table 3), upon verification of this condition. Otherwise, the positions are not equivalent, i.e. different “Dif”. The evaluation of the compatibility of measurement results taken from filters of the various sets of positions in the multifold (described in the section “Sampling setup”) was used to validate the sampling equipment and procedure.

Results and discussion

Table 1 presents the estimated masses of chloride, nitrate and sulphate ions of the aerosols’ water-soluble fraction. Mass values, m, are reported with expanded uncertainty, U.

The actual values of anion masses in the sampled aerosols (Table 1) are not particularly relevant for this study whose objective is limited to verifying the validity of the sampling step, and this is decided from mass differences (Eq. 5).

The assessment of the compatibility of measurement results of chloride ion in pairs from filter positions 4, 5 and 6, set B, is presented below, as an example:

The results for all assessed ions in sets A, B and C are presented in Table 2.

The observation of the stated condition (Eq. 5) determines the compatibility of measurement results and consequently the equivalence of the sampling positions.

Results in Table 2 led to the conclusion that the masses estimated for ions in pairs of filters are compatible for a confidence level of 95 % with the exception of filters 2 and 3 of set A (Table 3). The lack of compatibility of this pair of measurements is explained by the confidence level, 95 %, of the initial comparison. In the case of 99 % confidence level, coverage factor of 3 instead of 2, all values are compatible. In 95 % confidence level statistical assessments, 1 in 20 evaluations (5 %) is left out of the interval, seeming different when, in fact, populations are equivalent. Therefore, the observation of one divergence in a total of 57 performed comparisons is normal and does not affect the general conclusion about the adequacy of the multifold for the performed measurements.

The sampling equipment and procedure are also adequate for equally uncertain determinations of other composition parameters of eventual interest. However, if less uncertain determinations are conducted, the relevance of the variability of the data should be tested in those more strict conditions.

Conclusions

The strategy developed for validating a six-channel multifold with a common inlet capable of replicating aerosol samples at different filter positions was successfully applied.

The estimated masses of chloride, nitrate and sulphate collected in various pairs of filters are metrologically compatible, for 95 % confidence level.

The results support the conclusion that the variability of the replicate collection of aerosols in different filter positions of the multifold is negligible, taking into account the uncertainty of the measurements of studied components.

The validity of the used sampling procedure can be extrapolated to the determination of other not significantly less uncertain parameters. If less uncertain analytical quantifications are conducted, the performance of the multifold must be verified for those more strict criteria.

References

Anthony, T.R., Sleeth, D.K., Volckens, J., (2014). Design, evaluation and validation of a next-generation inhalable aerosol sampler. R01OH 2012–2016 Project, National Institute of Health, U.S.A.

Arias, A., Silva, R. J. N. B., Camões, M. F. G. F. C., & Oliveira, C. M. R. R. (2013). Evaluation of the performance of the determination of anions in the water soluble fraction of atmospheric aerosols. Talanta, 104, 10–16.

Brockmann, J. E. (2001). Sampling and transport of aerosols. In P. Baron & K. Willeke (Eds.), Aerosol measurement: principles, techniques and applications (2nd ed., pp. 143–195). New York: John Wiley & Sons.

EC (2008). Directive 2008/50/EC of the European Parliament and of the Council of 21 of May 2008 on ambient air quality and cleaner air for Europe. Official Journal of the European Union, 11/6/2008.

EMEP (2001). Manual for sampling and chemical analysis, NILU. revision 2001.

Eurachem CITAC (2012). Quantifying uncertainty in analytical measurement, 3rd ed., Eurachem. (http://www.eurachem.org/index.php/publications/guides/quam).

Harrison, R. M., & Pio, C. A. (1981). Apparatus for simultaneous size-differentiated sampling of optical and aerosols. Journal of the Air Pollution Control Association, 31(7), 784–787.

JCGM (2008). Evaluation of measurement data—guide to the expression of uncertainty in measurement (GUM). JCGM 100, Joint Committee for Guides in Metrology, BIPM (http://www.bipm.org/utils/common/documents/jcgm/JCGM_100_2008_E.pdf).

JCGM (2012). International vocabulary of metrology—basic and general concepts and associated terms (VIM). JCGM 200, Joint Committee for Guides in Metrology, BIPM. (http://www.bipm.org/utils/common/documents/jcgm/JCGM_200_2012.pdf).

John, W. (2011). Size distribution characteristics of aerosols. In P. Kulkarni, P. A. Baron, & K. Willeke (Eds.), Aerosol measurement: principles, techniques and applications (3rd ed.). USA: Wiley.

Lopez-Ruiz, B. (2000). Advances in the determination of inorganic anions by ion chromatography. Journal of Chromatography A, 881, 607–627.

McMurry, P. H. (2000). A review of atmospheric aerosol measurements. Atmospheric Environment, 34, 1959–1999.

Miller, J. C., & Miller, J. N. (2005). Statistics and chemometrics for analytical chemistry (5th ed.). UK: Pearson Education Limited.

Mouli, P. C., Mohan, S. V., & Reddy, S. J. (2003). The study on major inorganic ion composition of atmospheric aerosols at Tirupati. Journal of Hazardous Materials B, 96, 217–228.

Nunes, M.J.M. (2002). Establishment of chemical properties of the aerosol in the north east Atlantic Ocean. PhD Thesis, University of Lisbon.

Raynor, P. C. (2011). Controlling nanoparticle exposures. In G. Ramachandran (Ed.), Assessing nanoparticle risks to human health. USA: William Andrew. Chap. 7.

Raynor, P. C., Leith, D., Lee, K. W., & Mukund, R. (2011). Sampling and analysis using filters. In P. Kulkarni, P. A. Baron, & K. Willeke (Eds.), Aerosol measurement: principles, techniques and applications (3rd ed., pp. 107–128). Hoboken: John Wiley & Sons, Inc.

Seinfeld, J. H., & Pandis, N. S. (1998). Atmospheric chemistry and physics—from air pollution to climate change. USA: Wiley-Interscience Publication.

Silva, R. J. N., & Camões, M. F. (2010). The quality of standards in least squares calibrations. Analytical Letters, 43, 1257–1266.

Silva, R. J. N. B., Arias, A., Oliveira, C. M. R. R., & Camões, M. F. G. F. C. (2012). Assessment of the determination of water-soluble ionic composition of atmospheric aerosols from the analysis of crossed halves of filters. Accreditation and Quality Assurance, 17, 147–157.

Vincent, J. H. (2007). Aerosol sampling, science, standards, instrumentation and applications. USA: John Wiley & Sons.

Watson, J. G., & Chow, J. C. (2011). Ambient aerosol sampling. In P. Kulkarni, P. A. Baron, & K. Willeke (Eds.), Aerosol measurement: principles, techniques and applications (3rd ed., pp. 591–614). Hoboken: John Wiley & Sons, Inc.

WMO/GAW (2003). Aerosol measurement procedures guidelines and recommendations, N° 153, World Meteorological Organisation Global Atmosphere Watch, September.

Acknowledgments

The authors acknowledge Fundação para a Ciência e a Tecnologia (FCT) for financial support through project UID/QUI/00100/2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oliveira, C.M., Camões, M.F., Bigus, P. et al. Validation of atmospheric aerosols parallel sampling in a multifold device. Environ Monit Assess 187, 380 (2015). https://doi.org/10.1007/s10661-015-4615-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-015-4615-2