Abstract

A supervised field trial was conducted at four different agroclimatic locations in India to evaluate the dissipation pattern and risk assessment of carbendazim and mancozeb in mango fruits following foliar application of mixed formulation of carbendazim 12 % and mancozeb 63 % fungicide (SAAF-75WP) at recommended dose (90 + 472.5) and double the recommended dose (180 + 945 g a.i. ha−1). Average initial deposition of carbendazim was in the range of 1.12 to 2.7 and 1.95 to 4.09 mg kg−1 and for mancozeb in the range of 2.25 to 2.71 and 4.17 to 5.96 mg kg−1, given at respective doses. Residues of carbendazim and mancozeb were dissipated to the below detectable limit 7 days after spray at recommended dosage in all the locations. The fungicide degradation followed a first order kinetics with half-lives of 1–5 and 1–3 days, for carbendazim and mancozeb, respectively. The TMRC values, calculated from residue data generated from all four locations, were found to be below the MPI in mango fruit, and hence, the fungicide will not cause any adverse effect after consumption of mango fruits. This data could provide guidance for the proper and safe use of this fungicide mixture for managing disease incidence in mango in India.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mango (Mangifera indica L.) is an important tropical fruit crop, consumed both as fresh and processed. India is the largest producer of mango in the world accounting for 52.63 % of total mango production. India exports mango (59.22 thousand tons) to over 40 countries worldwide including US and Europe (Arauz 2000). The commercial cultivation of mango receives frequent application of a variety of contact and systemic pesticides right from panicle emergence to fruit harvest for controlling various insect-pests and diseases. Among the diseases, anthracnose is a major disease (Ploetz 1999) which affects both vegetative and reproductive stage of the crop leading to considerable reduction in fruit set and yield loss (Chowdhury et al. 2009).

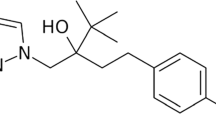

Carbendazim, chemically named as methyl benzamidazole-2-ylcarbamate, is a systemic fungicide with protective and curative action. It is commonly used to control postharvest diseases of mango like anthracnose and stem end rot through either preharvest spray (Prakash and Pandey 2000) or postharvest spray and dip in hot fungicidal solution (Sharma and Badiyala 1994; Bhattacherjee et al. 2009). Mancozeb (manganese ethylene bis (polymeric) complex with zinc salt) is a broad spectrum contact dithiocarbamate group of fungicide with protective action. Mancozeb in combination with metalaxyl is more effective in the control of downy mildew of cucumber than applied individually (Samoucha and Cohen 1984). Recently, a combination of carbendazim and mancozeb has been found to be very effective for the control of leaf blight on sunflower (Mathivanan and Prabhavathy 2007) and chili rots (Roy et al. 2010).

As mango contributes a major share in Indian foreign exchange, it is essential to assess the impact of the fungicide mixture from the residues point of view, food safety, and phytosanitary regulations of countries importing these products. There is little information available on its persistence and degradation pattern in mango fruit under Indian climatic conditions. Therefore, the present study was carried out to investigate the residual behavior and risk assessment of mixed formulation of carbendazim and mancozeb in mango fruits at different agroclimatic conditions in India.

Materials and methods

Chemicals and reagents

Analytical grade of carbendazim (purity 99 %), mancozeb (purity 98 %), and commercial formulation (SAAF- carbendazim 12 % + mancozeb 63 %) were obtained from United Phosphorus Ltd, Mumbai, India. All the solvents of HPLC grade and chemicals of analytical grade were purchased from Merck (Mumbai, India). Carbon disulphide (CS2), absolute ethanol, stannous chloride (SnCl2), lead acetate, and hydrochloric acid (HCl) were purchased from Merck; copper(II) acetate monohydrate and triethanolamine were purchased from Sigma-Aldrich, Germany.

Preparation of standard solutions

Stock solution (1000 mg L−1) of carbendazim was prepared in HPLC grade acetonitrile by dissolving accurately weighed 25 mg of pure analyte into a 25-mL volumetric flask and diluting to desired volume. Working standard solutions were used for sample spiking. All standard solutions were stored at −4 °C before use. A stock standard carbon disulphide (CS2) solution containing 5.04 mg ml−1 was prepared with 0.1 mL of CS2 in 25 mL of absolute ethanol, and working standard solutions were prepared by making suitable dilutions of stock solution in absolute ethanol. The HCl/SnCl2 mixture was prepared by dissolving 5 mL of a 40 % (mv−1) SnCl2.2H2O solution in 30 mL of HCl and diluting with water to 200 mL. Solution of color reagent was prepared by diluting 0.05 g cupric acetate in 25-mL distilled water, 800 mL of absolute ethanol, 1 mL of diethyl ether, and 20 mL of triethanol amine were added and made up to 1000 mL with absolute ethanol.

Field trials and sampling

Field trials were conducted at four different locations of India viz., Tamil Nadu Agricultural University, Tamil Nadu (Location-I), Dr. Yashwant Singh Parmar University of Horticulture and Forestry, Himachal Pradesh, Solan (Location-II), Bidhan Chandra Krishi Vishwavidyalaya, West Bengal (Location-III) and Regional Fruit Research Station, Dr. Balasaheb Sawant Krishi Vidyapeeth, Vengurla, Maharastra (Location-IV). A combination formulation consisting of carbendazim 12 % + mancozeb 63 % (SAAF-75 WP) was applied at the rate of 90 + 472.5 and 180 + 945 g a.i. ha−1 as recommended and double the recommended dose, respectively. Each application dosage was sprayed three times at an interval of 15 days at fruiting stage by using a high volume foot sprayer with 750 L of spray fluid per hectare. A plot with the same size but without fungicide application was compared simultaneously. It was ensured that the fungicides under investigation were not used earlier on the experimental plots. The average minimum and maximum temperatures were 23.3, 20.9, 26.7, 23.4, and 31.3, 30.0, 34.3, and 34.4 °C at location I, II, III, and IV, respectively. The average relative humidity ranged between 58.5–80.5 % and the rainfall ranged from 1.27–68.22 mm.

About 500 g of mango fruit samples were collected randomly from each treatment separately at 0 (2 h after application), 1, 3, 7, and 15 days after application of the fungicide mixture. The soil samples and fruit samples ripened at 90, 105, 100, and 95 days at location I, II, III, and IV, respectively, were collected at harvest. These variations might be due to different agroclimatic conditions. All the samples were transported to the laboratory and processed immediately.

Carbendazim extraction and cleanup

Mango fruits were chopped and homogenized separately and a representative 20 g of mango sample macerated using warring blender with 200 mL of ethyl acetate. The extracts were filtered through a Buchner funnel under vacuum, and the process was repeated twice with 100 mL of ethyl acetate. The combined extracts were evaporated to near dryness in rotary vacuum evaporator at 40 °C. The residue was dissolved in 50 ml of 0.5 N H2SO4 and washed thrice with 75 mL of chloroform at each time after passing through glass wool into a separating funnel. The chloroform layer was discarded after phase separation. The pH of the acidic aqueous layer was then adjusted to 8.5–9.0 with 60 % NaOH solution and extracted with 50 mL dichloromethane twice. The dichloromethane extracts were combined, dried over anhydrous sodium sulfate, and completely evaporated in rotary vacuum evaporator at 40 °C. The final volume reconstituted to about 2-mL using mobile phase of acetonitrile: water (45:55, v/v) and analyzed by HPLC.

Mancozeb extraction and cleanup

The residues of mancozeb were analyzed colorimetrically using carbon disulphide (CS2) evolution method (Keppel 1971). A 25-g homogenized sample (mango fruit and soil sample) was taken separately (replication and treatment wise) in a three-necked round-bottom flask. The flask was refluxed on a heating mantle for 30 min at 85–95 °C with 1.5 % SnCl2 solution in 5 N HCl and maintaining positive pressure inside the flask. The liberated carbon disulphide was adsorbed in 25 mL of color reagent after passing through 30 % lead acetate solution to remove hydrogen sulfide. The carbon disulphide was diluted suitably in the color reagent and absorbance measured at 435 nm against blank.

Recovery study

In the present investigation, recovery experiments were carried out at different levels to establish the reliability and validity of the analytical method and to know the efficiency of extraction and cleanup procedures. Untreated mango fruit and soil samples were spiked with carbendazim and mancozeb at 0.5, 1, and 2 mg kg−1 and replicated thrice along with a control. The spiked samples were equilibrated and processed by adopting the standard procedure.

Determination by HPLC and spectrophotometer

The carbendazim residue was determined on Shimadzu HPLC (LC-2010 HT) equipped with photodiode array detector. The HPLC separation was carried out using reverse phase C18 column Luna Phenomenex (250 × 4.6 mm id., 5 μm). The mobile phase composed of acetonitrile: water (45:55, v/v) at a constant flow rate of 1.0 mL/min. The injection volume was 20 μL, and the residues of carbendazim were detected at 286 nm. Under these operating conditions, the carbendazim was eluted at retention time of 5.45 min. The quantitative analysis of mancozeb as CS2 was performed spectrophotometrically using a UV–VIS spectrophotometer (ELICO SL 159) at wavelength of 435 nm.

Results and discussion

Efficiency of the method

The average recovery of carbendazim was found to be 92.67 to 99.74 % in mango fruits, and the relative standard deviation (RSD) for repeatability ranged from 0.15 to 3.38 % at three different levels of spiking. Similarly, the recovery percentage of mancozeb in mango fruit ranged from 94.6 to 96.40 % at 0.5, 1.0, and 2 mg of CS2 kg−1 levels. The RSD ranged from 0.45 to 1.56 % at three different levels of spiking. As the recovery percentage is more than 85 % for the substrates, hence, this method can be adopted for residue and dissipation study for both carbendazim and mancozeb in mango fruit samples. The limit of quantification (LOQ) of this method was found to be 0.5 mg kg−1 while limit of detection (LOD) being 0.15 mg kg−1 for both the compounds. The quantification limits obtained are much lower than European Union maximum residue level (EU MRL) and Food Safety and Standard Authority of India (FSSAI) value (2 mg kg−1) for mancozeb and carbendazim, respectively.

Persistence and dissipation of carbendazim on mango fruit

The results of persistence and dissipation of carbendazim in mango fruits are presented in Table 1. The initial (2 h after application) residue deposits of carbendazim were found to be 1.21, 2.74, 1.12, and 1.12 mg kg−1 for location I, II, III, and IV, respectively, at the recommended dose with the corresponding levels of 1.95, 4.09, 1.90 and 2.50 mg kg−1 at double the recommended dose. More than 40 % of the initial deposits of this fungicide dissipated 7 days after field applications at both recommended and double the recommended doses. The dissipation of carbendazim residues in mango fruits was more than 63 % after 7 days of last spraying of fungicide in all the locations at double the recommended dose. The residues found at this stage were much lower than the MRL (2 mg kg−1) prescribed by Food Safety and Standard Authority of India (FSSAI) (Sharma 2007). Fungicide residues were not detected in mango fruit at maturity (65 days after last spraying) at all the four locations. The rapid degradation/dissipation of fungicide in subsequent sampling after spraying might be due to the favorable climatic conditions, i.e., temperature, rainfall, and relative humidity prevailing at the time of application. Similar dissipation pattern was also observed in Dashehari mango for carbendazim residues (Bhattacherjee et al. 2009). The residues of carbendazim on mango fruits decreased progressively with time from all the treatments and reached below the detectable level on 15 days after last application in all the four locations.

Persistence and dissipation of mancozeb in mango fruit

The initial deposits of mancozeb residues in mango fruit were ranged from 2.25 to 2.71 and 4.17 to 5.96 mg kg−1, when applied at 472.5 and 945 g a.i. ha−1, at all locations (Table 2). These deposits dissipated to 50.48 to 77 % after 3 days of their application from both the treatments. The residues of mancozeb on mango fruits declined progressively with time in all the treatments and reached to non-detectable level on the 7th day of application in all the four locations at both recommended dose and double the recommended dose. The results are in agreement with those of Paramasivam and Chandrasekaran (2013), who reported that mancozeb residues were non-detectable in gherkin within 5 and 7 days at application of 750 and 1500 g a.i. ha−1, respectively. The results showed that mancozeb dissipated rapidly after application. The mancozeb residue reached its EU MRL of 2 mg kg−1 after 1 day in recommended dose, whereas in double the recommended dose, it took 3 days after at all locations. Residues were not detected in fruit at maturity (65 days after spraying) at all the four locations. Soil samples were collected 90 days after the last spray at recommended, and double the recommended dosages did not show the presence of carbendazim and mancozeb at their quantification limit of 0.5 mg kg−1.

Half-life and pre-harvest intervals of carbendazim and mancozeb

The dissipation kinetics of carbendazim and mancozeb in mango fruit fitted into first order dissipation C = C o e -kt and t1/2 = ln 2/k, where C = (mg kg−1) is the pesticide concentration at time t, C o = apparent initial concentration (mg kg−1), k = rate constant, and t1/2 is the pesticide half-life in mango. The kinetic equation, half-lives, and coefficient (R 2) of the carbendazim and mancozeb residue dissipation were calculated from the experimental data and summarized in Table 3. The rate of dissipation followed the first-order kinetic with half-life time of 1–5 and 1–3 days, for carbendazim and mancozeb, respectively (Table 3). Similar results were reported by Bhattacherjee et al. 2009, who evaluated the residues of carbendazim in whole mango fruit. The faster dissipation of mancozeb in the present study may be due to the effect of environmental conditions. The results showed that the dissipation of mancozeb was much faster than the carbendazim. As per the MRL value (2 mg kg−1) of carbendazim and mancozeb in mango fixed by Food Safety and Standard Authority of India (FSSAI) and European Union maximum residue level (EU MRL), respectively, a pre-harvest interval of 3 days was suggested.

Risk assessment of carbendazim and mancozeb on mango fruits

The presence of harmful pesticide residues in food has caused a great concern among the consumers. Residue implication of foliar application of carbendazim and mancozeb on mango crop has been evaluated by comparing theoretical maximum residue contribution (TMRC) of the pesticide with its maximum permissible intake (MPI). The prescribed acceptable daily intake (ADI) of carbendazim and mancozeb is 0.03 mg kg body weight−1 day−1 (Sharma 2007). Multiplying the ADI with the average body weight of an adult taken as 55 kg (Mukherjee and Gopal 2000), the MPI was found to be 1.65 mg person−1 day−1. The TMRC has been calculated by multiplying the maximum residue levels with average per capita daily consumption of 50 g of mango fruits in Indian context. The TMRC values calculated for residues corresponding to each sampling date in mango fruit were less than the MPI at both the doses of application ensuring safety of the fruits with incurred residues from the consumers’ point of view. Therefore, the application of carbendazim and mancozeb, on mango at recommended doses seems to be safe from crop protection and consumer point of view.

Conclusions

In this study, dissipation kinetics and risk assessment of mixed formulation of carbendazim and mancozeb in mango fruit was investigated. The results showed that dissipation of mancozeb was comparatively faster than carbendazim, and the half lives were in the range of 1–3 and 1–5 days, respectively. TMRC values calculated from residue data generated from all four locations were found to be below the MPI on mango fruit. The PHI could be 3 days between the last application of the formulation and the harvest of mango fruits. Therefore, application of mixed formulation of carbendazim and mancozeb at the recommended dose on mango is safe for consumption of mango fruits.

References

Arauz, L. F. (2000). Mango anthracnose: economic impact and current options for integrated management. Plant Disease, 84, 600–611.

Bhattacherjee, A. K., Pandey, B. K., & Prakash, O. (2009). Persistence and dissipation of carbendazim residues in mango fruits after pre- and post-harvest application. Journal of Food Science and Technology, 46, 347–347.

Chowdhury, M. N. A., Rahim, M. A., Khalequzzaman, A. M. J., & Humauan, M. R. (2009). Effect of horticultural practices on incidence of anthracnose on yield and quality of mango. International Journal of Sustainable Crop Production, 3, 1–9.

Keppel, G. E. (1971). Collaborative study of the determination of dithiocarbamate residues by modified carbon disulphide evaluation method. Journal of AOAC International, 73, 509–512.

Mathivanan, A., & Prabhavathy, V. R. (2007). Effect of carbendazim and mancozeb combination on alternaria leaf blight and seed yield in sunflower. Archives of Phytopathology and Plant Protection, 40, 90–96.

Mukherjee, I., & Gopal, M. (2000). Environmental behavior and translocation of imidacloprid in eggplant, cabbage and mustard. Pest Management Science, 56, 932–936.

Paramasivam, M., & Chandrasekaran, S. (2013). Dynamics and residues of mixed formulation of fenamidone and mancozeb in gherkin field ecosystem. Ecotoxicology and Environmental Safety, 98, 292–296.

Ploetz, R. (1999). Anthracnose: the most important disease in much of the mango producing world. The News Letter of the Plant Pathology, 3, 1–6.

Prakash, O. M., & Pandey, B. K. (2000). Control of mango anthracnose by hot water and fungicidal treatment. Indian Phytopathology, 53, 92–94.

Roy, S., Banerjee, A., Tarafdar, J., & Samanta, S. K. (2010). Superior bio-efficacy of a combined formulation of carbendazim and mancozeb in inducing defense responses in chilli seedlings against Sclerotium rolfsii Sacc. in comparison with methyl jasmonate. Crop Protection, 29, 163–167.

Samoucha, Y., & Cohen, Y. (1984). Synergy between metalaxyl and mancozeb in controlling downy mildew in cucumbers. Disease Control and Pest Management, 74, 1433–1437.

Sharma, K. K. (2007). Pesticide residue analysis manual. Directorate of Information and Publications of Agriculture. New Delhi: Indian Council of Agricultural Research.

Sharma, I. M., & Badiyala, S. D. (1994). Effect of post-harvest fungicidal sprays against stem end rot of mango fruit in storage caused by Botrayodiplodia theobromai pest in Himachal Pradesh. Journal of Mycology and Plant Pathology, 24, 141–142.

Acknowledgments

Authors are thankful to M/s United Phosphorus Limited, Mumbai for the financial assistance and providing the analytical standards and formulations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Devi, P.A., Paramasivam, M. & Prakasam, V. Degradation pattern and risk assessment of carbendazim and mancozeb in mango fruits. Environ Monit Assess 187, 4142 (2015). https://doi.org/10.1007/s10661-014-4142-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-014-4142-6